Towards a Better Understanding of Texturization during High-Moisture Extrusion (HME)—Part II: Characterization of Thermophysical Properties of High-Moisture Meat Analogues

Abstract

:1. Introduction

2. Material and Methods

2.1. Raw Materials

2.2. High-Moisture Extrusion (HME)

2.3. Determination of Apparent Density

2.4. Determination of Specific Heat Capacity by µDSC

2.5. Model Prediction for Thermal Diffusivity

2.6. Model Prediction for Thermal Conductivity

2.7. Statistical Analysis

3. Results and Discussion

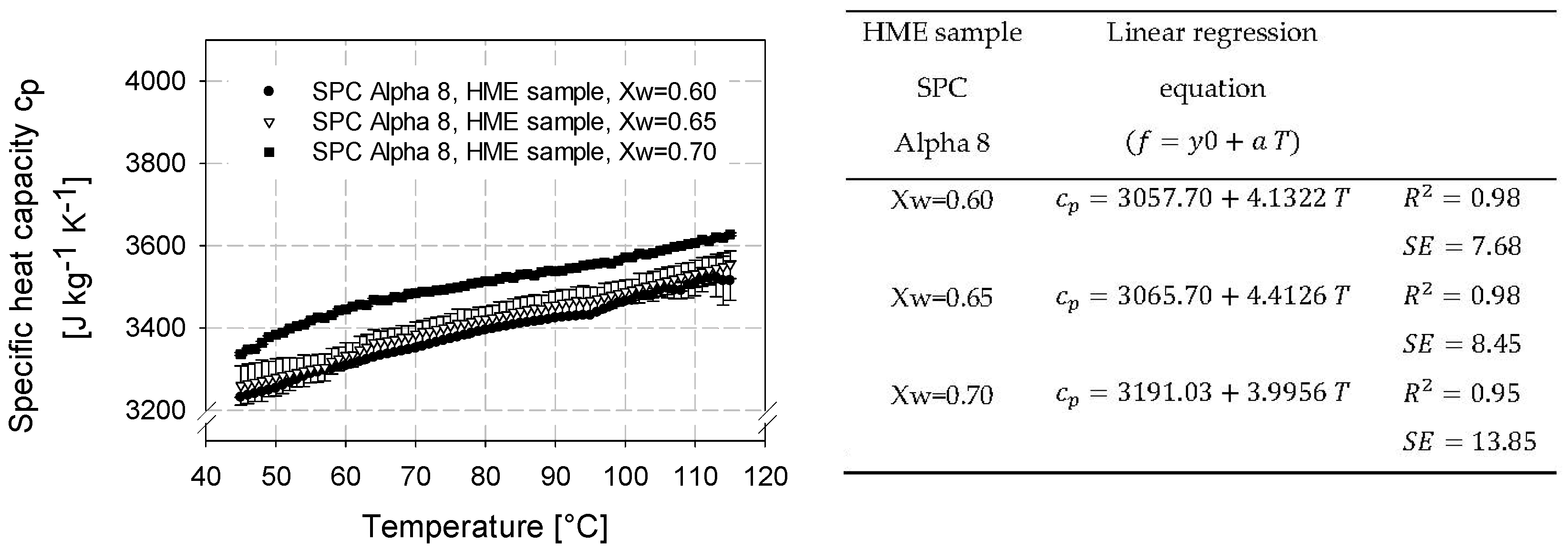

3.1. Characterization of Specific Heat Capacity of High-Moisture Extruded Samples

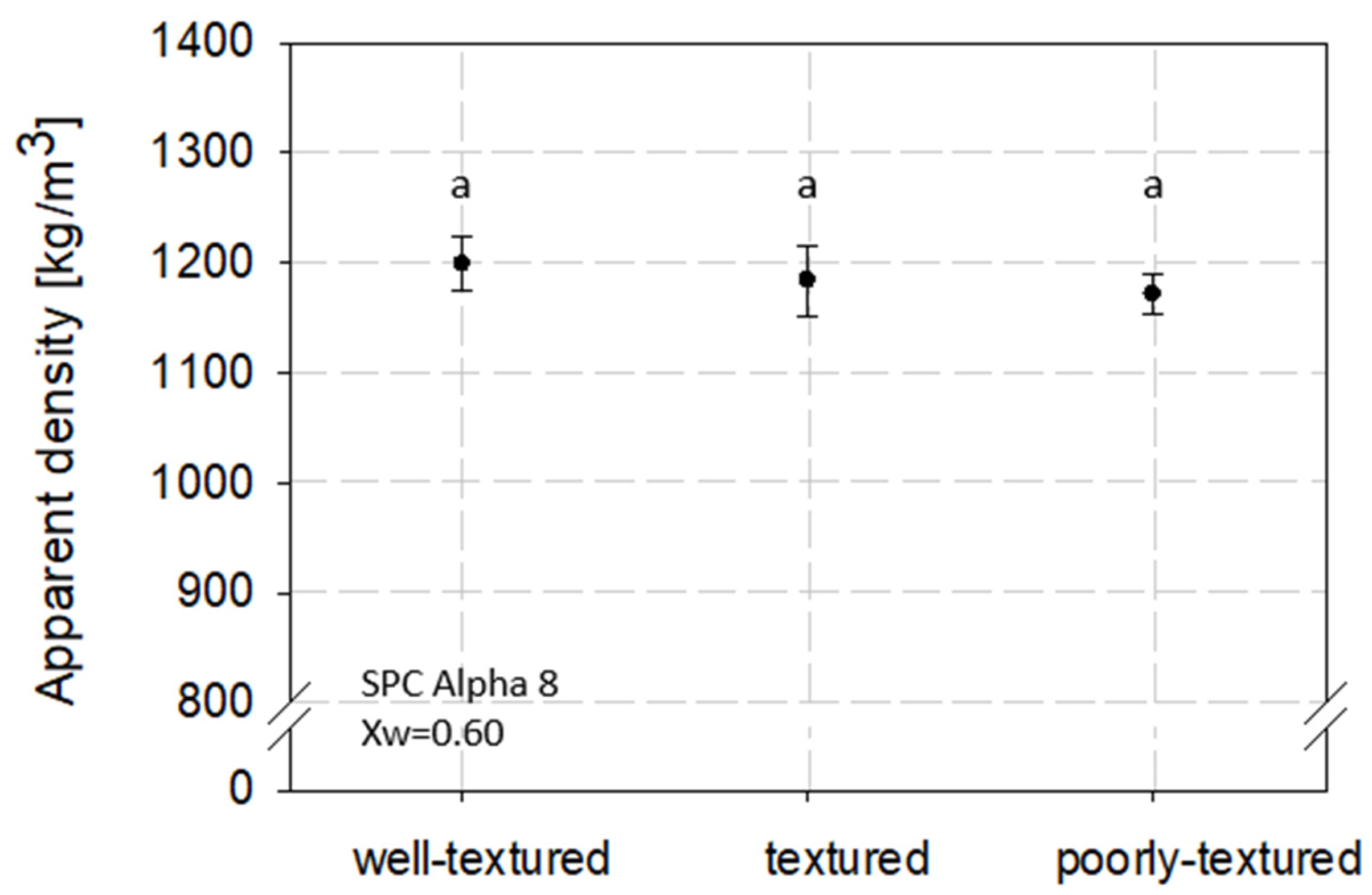

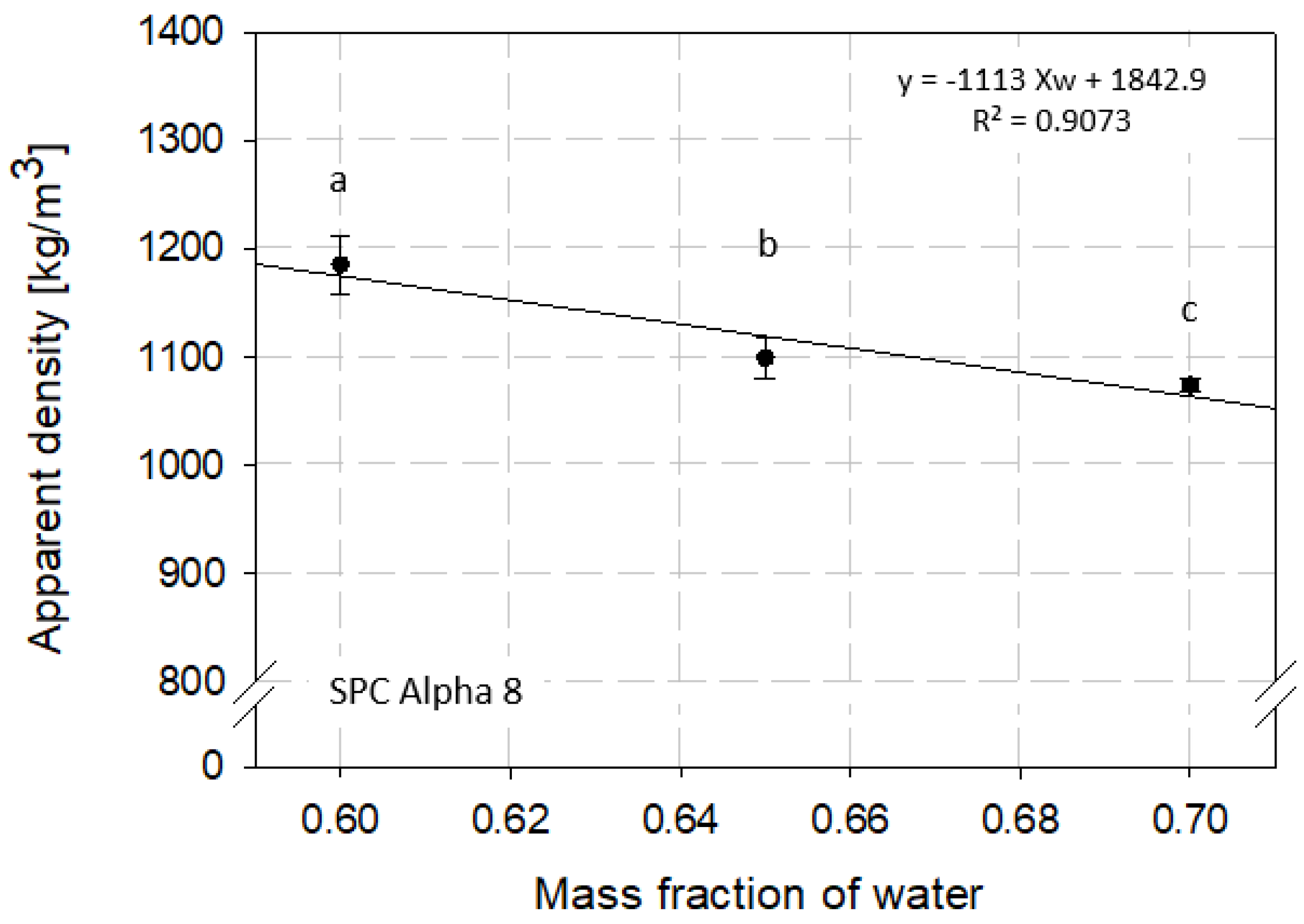

3.2. Determination of Apparent Density

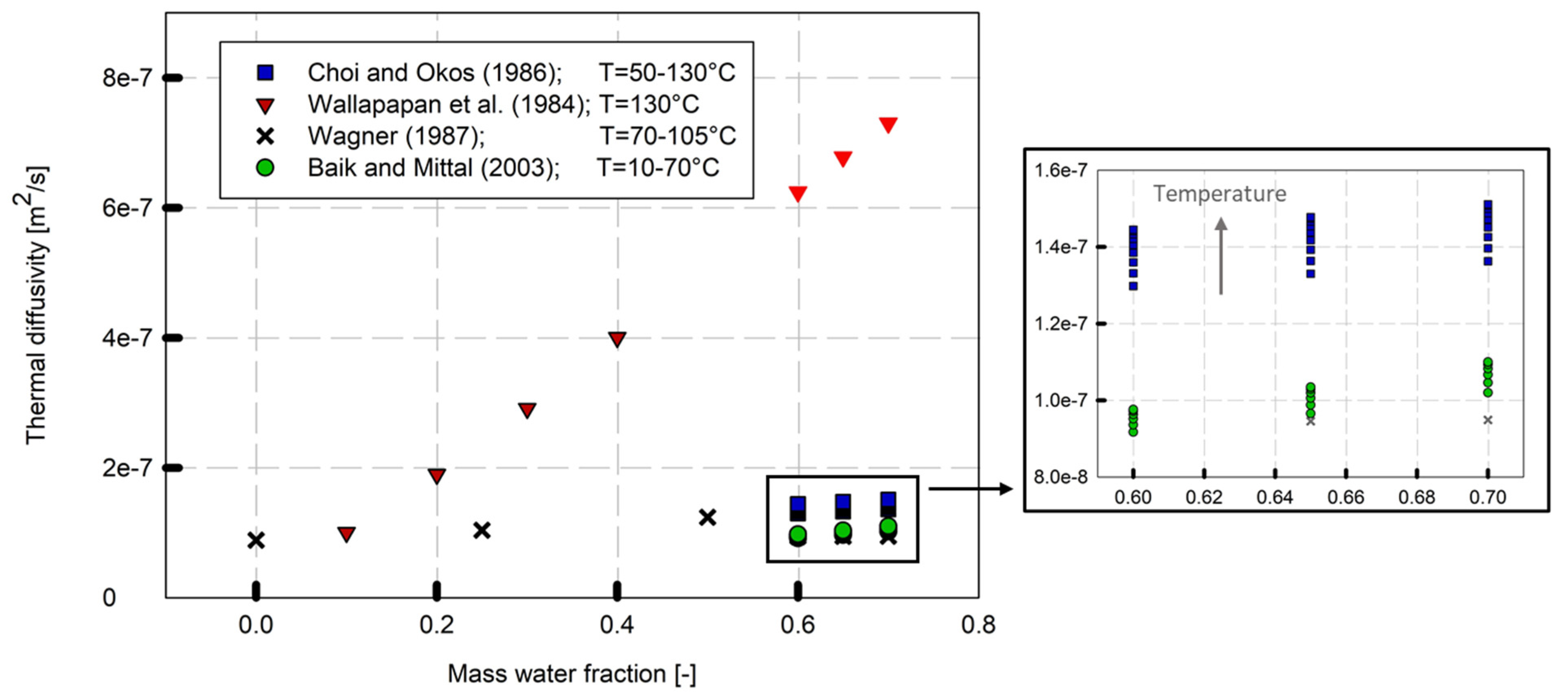

3.3. Prediction of Thermal Diffusivity

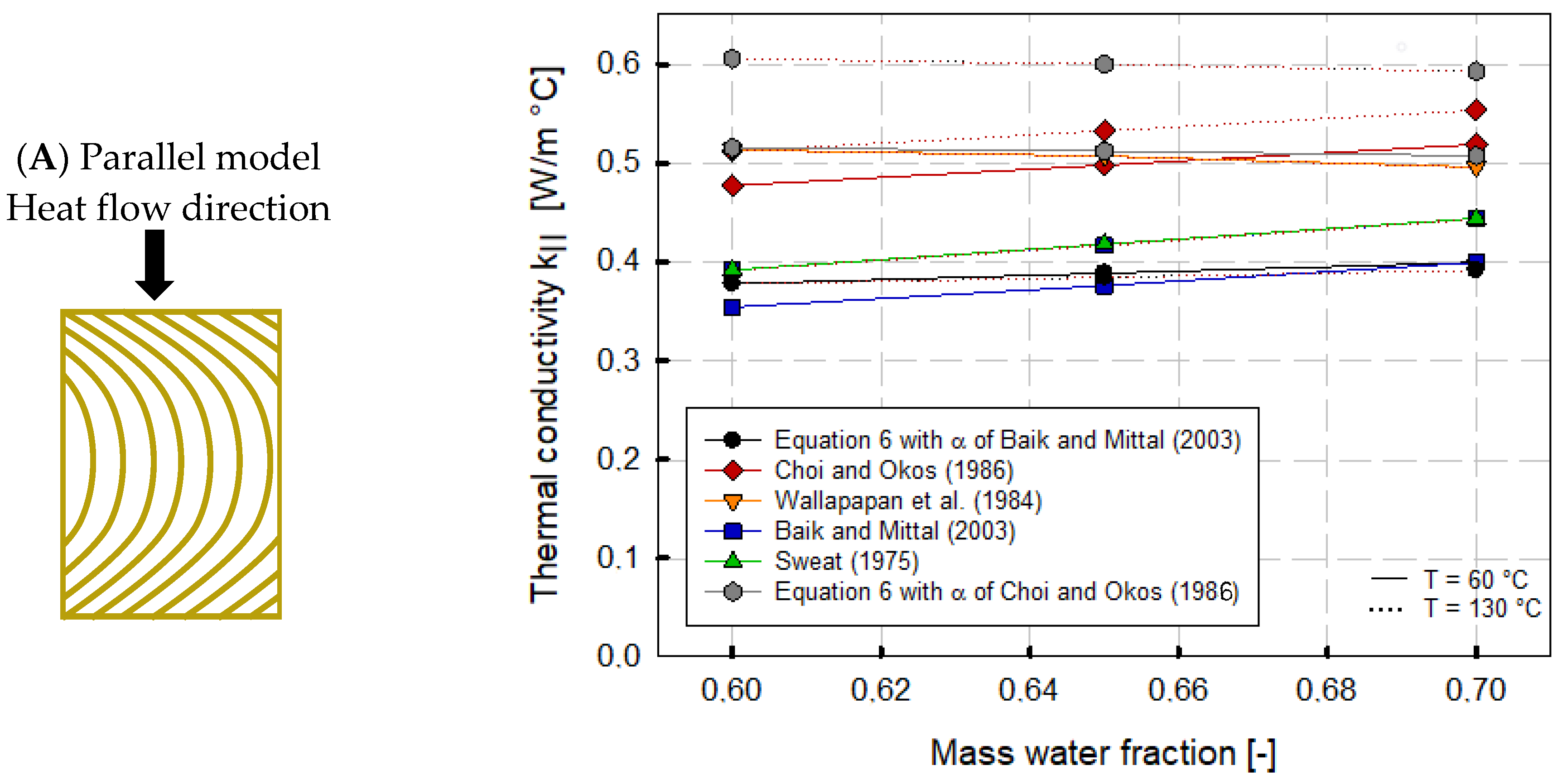

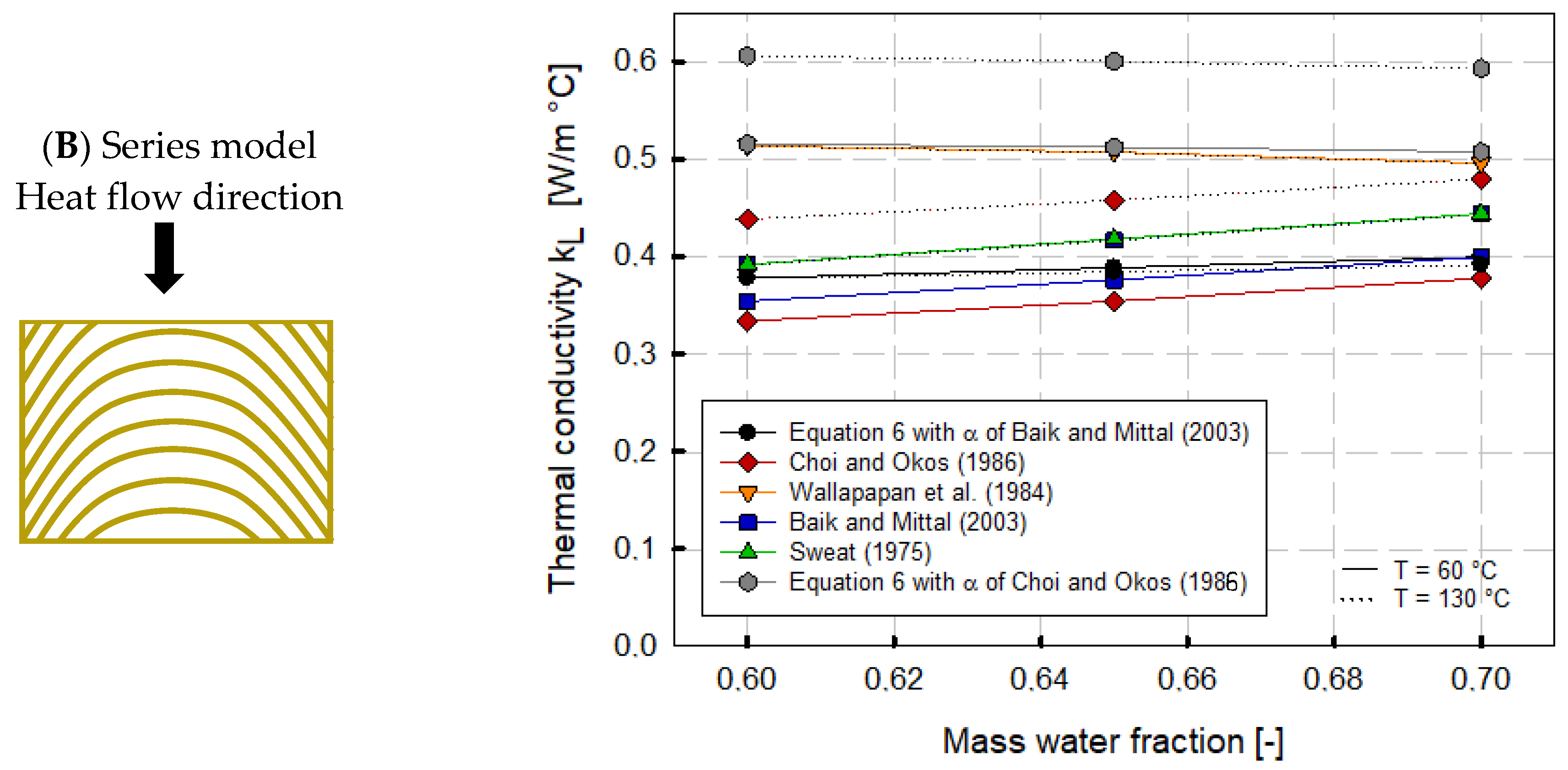

3.4. Prediction of Thermal Conductivity

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Frede, W. Taschenbuch für Lebensmittelchemiker. In Lebensmittel–Bedarfsgegenstände–Kosmetika–Futtermittel; German Edition; Springer: Dordrecht, The Netherlands, 2006. [Google Scholar]

- Figura, L.O.; Teixeira, A.A. Food Physics. Physical Properties—Measurement and Applications; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Loeb, A. Thermal Conductivity: VIII, A Theory of Thermal Conductivity of Porous Materials. J. Am. Ceram. Soc. 1954, 37, 96–99. [Google Scholar] [CrossRef]

- Choi, Y.; Okos, M.R. Effects of temperature and composition on the thermal conductivity and thermal diffusivity of some food components. Korean J. Food Sci. Technol. 1986, 18, 357–363. [Google Scholar]

- Dane, J.H.; Topp, C.G.; Bristow, K.L. 5.3 Thermal Conductivity. In Methods of Soil Analysis; Number 5 in the Soil Science Society of America Book Series; Dane, J.H., Topp, G.C., Campbell, G.S., Eds.; Soil Science Society of America: Madison, WI, USA, 2002. [Google Scholar]

- Boukouvalas, C.J.; Krokida, M.K.; Maroulis, Z.B.; Marinos-Kouris, D. Effect of Material Moisture Content and Temperature on the True Density of Foods. Int. J. Food Prop. 2006, 9, 109–125. [Google Scholar] [CrossRef] [Green Version]

- Souza, E.C.; Fontan, R.C.I.; Veríssimo, L.A.A.; Sampaio, V.S.; Silva, W.S.; Bonomo, R.C.F.; Veloso, C.M. Thermal Diffusivity and Specific Heat of Bovine Milk Affected by Temperature and Composition. Int. J. Food Eng. 2012, 8, 2307. [Google Scholar] [CrossRef] [Green Version]

- Rao, M.A.; Rizvi, S.S.; Datta, A.K.; Ahmed, J. Engineering Properties of Foods, 4th ed.; Taylor and Francis: Hoboken, NJ, USA, 2014. [Google Scholar]

- Dehghan-Nayeri, N.; Rezaei-Tavirani, M. The Interpretation of Protein Structure Through Relationship Ofmelting Point (Tm) and Enthalpy of Unfolding (ΔHu). Int. J. Anakytical Pharm. Biomed. Sci. 2015, 4, 47–50. [Google Scholar]

- Berk, Z. Physical properties of food materials. In Food Process Engineering and Technology; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1–29. [Google Scholar]

- Heldman, D.R.; Singh, R.P. Food Process Engineering; Springer: Dordrecht, The Netherlands, 1981. [Google Scholar]

- Sweat, V.E. Modeling the Thermal Conductivity of Meats. Trans. ASAE 1975, 18, 564–568. [Google Scholar] [CrossRef]

- Wallapapan, K.; Sweat, V.E.; Arce, J.A.; Dahm, P.F. Thermal Diffusivity and Conductivity of Defatted Soy Flour. Trans. ASAE 1984, 27, 1610–1613. [Google Scholar] [CrossRef]

- Fricke, B.; Becker, B. Evaluation of Thermophysical Property Models for Foods. HVACR Res. 2001, 7, 311–330. [Google Scholar] [CrossRef]

- Irudayaraj, J. Food Processing Operations Modeling. Design and Analysis. Food Science and Technology; Marcel Dekker: New York, NY, USA, 2001; Volume 107. [Google Scholar]

- Becker, B.R.; Fricke, B.A. Freezing Principles. In Encyclopedia of Food Sciences and Nutrition; Elsevier: Amsterdam, The Netherlands, 2003; pp. 2706–2711. [Google Scholar]

- Sahin, S.; Sumnu, S.G. Thermal Properties of Foods. In Physical Properties of Foods; Food Science Text Series; Springer: New York, NY, USA, 2006; pp. 107–155. [Google Scholar]

- Marcotte, M.; Taherian, A.R.; Karimi, Y. Thermophysical properties of processed meat and poultry products. J. Food Eng. 2008, 88, 315–322. [Google Scholar] [CrossRef]

- Phinney, D.M.; Frelka, J.C.; Heldman, D.R. Composition-Based Prediction of Temperature-Dependent Thermophysical Food Properties: Reevaluating Component Groups and Prediction Models. J. Food Sci. 2017, 82, 6–15. [Google Scholar] [CrossRef]

- Choi, Y.; Okos, M.R. Effects of temperature and composition on thermal properties of foods. Food Eng. Process Appl. 1986, 1, 93–101. [Google Scholar]

- Cengel, Y.; Boles, M.; Kanoglu, M. Thermodynamics: An Engineering Approach, 9th ed.; McGraw-Hill: New York, NY, USA, 2018. [Google Scholar]

- Sopade, P.A.; LeGrys, G.A. Specific heat capacity of starch-sucrose systems. Food Control 1991, 2, 50–52. [Google Scholar] [CrossRef]

- Murakami, E.G.; Okos, M.R. Measurement and Prediction of Thermal Properties of Foods. In Food Properties and Computer-Aided Engineering of Food Processing Systems; Singh, R.P., Medina, A.G., Eds.; Springer: Dordrecht, The Netherlands, 1989; pp. 3–48. [Google Scholar]

- Wild, F. Manufacture of Meat Analogues through High Moisture Extrusion. In Reference Module in Food Science; Smithers, G.W., Ed.; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Ganjyal, G.M. Extrusion Cooking. Cereal Grains Processing; Woodhead Publishing: Duxford, UK, 2020. [Google Scholar]

- Guyony, V.; Fayolle, F.; Jury, V. High moisture extrusion of vegetable proteins for making fibrous meat analogs: A review. Food Rev. Int. 2022, 18, 1–26. [Google Scholar] [CrossRef]

- Wagner, L.L. Numerical Modeling of the Cooking Extrusion of a Biopolymer. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 1987. [Google Scholar]

- Baik, O.-D.; Mittal, G.S. Determination and Modeling of Thermal Properties of Tofu. Int. J. Food Prop. 2003, 6, 9–24. [Google Scholar] [CrossRef] [Green Version]

- Meuser, F.; van Lengerich, B.H. Systems analytical model for the extrusion of starches. Therm. Process. Qual. Foods 1984, 10, 175–179. [Google Scholar]

- Högg, E.; Rauh, C. Towards a better understanding of texturization during high-moisture extrusion (HME)–Part I: Modeling the texturability of plant-based proteins. Foods 2023, 12, 1955. [Google Scholar] [CrossRef]

- Skierkowsiki, K.; Gujska, E.; Khan, K. Instrumental and Sensory Evaluation of Textural Properties of Extrudates from Blends of High Starch/High Protein Fractions of Dry Beans. J. Food Sci. 1990, 55, 1081–1083. [Google Scholar] [CrossRef]

- Ali, Y.; Hanna, M.A.; Chinnaswamy, R. Expansion Characteristics of Extruded Corn Grits. LWT–Food Sci. Technol. 1996, 29, 702–707. [Google Scholar] [CrossRef]

- Ilo, S.; Liu, Y.; Berghofer, E. Extrusion Cooking of Rice Flour and Amaranth Blends. LWT–Food Sci. Technol. 1999, 32, 79–88. [Google Scholar] [CrossRef]

- Rahman, S. Food Properties Handbook, Contemporary Food Science, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Högg, E.; Boguslawski, S.; Dauwe, C.; Rauh, C. The influence of thermomechanical treatment on proteins during High Moisture Extrusion Cooking (HMEC): A new chromatographic approach to analyse structural changes. In Proceedings of the 33rd EFFoST International Conference 2019, Rotterdam, The Netherlands, 12 November 2019. [Google Scholar]

- Rahman, M.S.; Driscoll, R.H. Density of fresh and frozen seafood. J. Food Process Eng. 1994, 17, 121–140. [Google Scholar] [CrossRef]

- Yu, L.; Christie, G. Measurement of starch thermal transitions using differential scanning calorimetry. Carbohydr. Polym. 2001, 46, 179–184. [Google Scholar] [CrossRef]

- Zhang, J.; Farkas, B.E.; Hale, S.A. Thermal properties of skipjack tuna. Int. J. Food Prop. 2001, 4, 81–90. [Google Scholar] [CrossRef]

- Lazou, A.; Krokida, M. Thermal characterisation of corn-lentil extruded snacks. Food Chem. 2011, 127, 1625–1633. [Google Scholar] [CrossRef]

- Baird, D.G.; Reed, C.M. Transport Properties of Food Doughs. In Extrusion Cooking; Mercier, C., Linko, P., Harper, J.M., Eds.; American Association of Cereal Chemists: Saint Paul, MN, USA, 1989; pp. 205–234. [Google Scholar]

- Paternoster, R.; Brame, R.; Mazerolle, P.; Piquero, A. Using the correct statistical test for the equality of regression coefficients. Criminology 1998, 36, 859–866. [Google Scholar] [CrossRef]

- Ioannidi, E.; Risbo, J.; Aarøe, E.; van den Berg, F.W.J. Thermal Analysis of Dark Chocolate with Differential Scanning Calorimetry—Limitations in the Quantitative Evaluation of the Crystalline State. Food Anal. Methods 2021, 14, 2556–2568. [Google Scholar] [CrossRef]

- Höhne, G.W.H.; Hemminger, W.F.; Flammersheim, H.-J. Differential Scanning Calorimetry; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- Darros-Barbosa, R.; Balaban, M.O.; Teixeira, A.A. Temperature and Concentration Dependence of Density of Model Liquid Foods. Int. J. Food Prop. 2003, 6, 195–214. [Google Scholar] [CrossRef]

- Hanson, J.L.; Edil, T.B.; Yesiller, N. Thermal Properties of High Water Content Materials. In Geotechnics of High Water Content Materials; Edil, T.B., Fox, P.J., Eds.; ASTM International: West Conshohocken, PA, USA, 2000. [Google Scholar]

- Becker, B.R.; Fricke, B.A. Food thermophysical property models. Int. Commun. Heat Mass Transf. 1999, 26, 627–636. [Google Scholar] [CrossRef]

- Hatakeyama, T. Thermal Properties of Cellulose and its Derivatives. In Thermal Properties of Green Polymers and Biocomposites, Topics in Thermal Analysis and Calorimetry; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2005; Volume 4, pp. 39–130. [Google Scholar]

- Rodríguez, R.; Rodrigo, M.E.; Kelly, P. A calorimetric method to determine specific heats of prepared foods. J. Food Eng. 1995, 26, 81–96. [Google Scholar] [CrossRef]

- Heertje, I. Structure and function of food products: A review. Food Struct. 2014, 1, 3–23. [Google Scholar] [CrossRef] [Green Version]

- Wittek, P.; Zeiler, N.; Karbstein, H.P.; Emins, M.A. High Moisture Extrusion of Soy Protein: Investigations on the Formation of Anisotropic Product Structure. Foods 2021, 10, 102. [Google Scholar] [CrossRef]

- Kristiawan, M.; Micard, V.; Maladira, P.; Alchamieh, C.; Maigret, J.-E.; Réguerre, A.-L.; Emin, M.A.; Della Valle, G. Multi-scale structural changes of starch and proteins during pea flour extrusion. Food Res. Int. 2018, 108, 203–215. [Google Scholar] [CrossRef] [PubMed]

- Omohimi, C.I.; Sobukola, O.P.; Sarafadeen, K.O.; Sanni, L.O. Effect of Thermo-extrusion Process Parameters on Selected Quality Attributes of Meat Analogue from Mucuna Bean Seed Flour. Niger. Food J. 2014, 32, 21–30. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.X. Development of a New Meat Analog through Twin-Screw Extrusion of Defatted Soy Flour-lean Pork Blend. Food Sci. Technol. Int. 2005, 11, 463–470. [Google Scholar] [CrossRef]

- Kasaai, M.R. Use of Water Properties in Food Technology: A Global View. Int. J. Food Prop. 2014, 17, 1034–1054. [Google Scholar] [CrossRef] [Green Version]

- Martynenko, A. The System of Correlations between Moisture, Shrinkage, Density, and Porosity. Dry. Technol. 2008, 26, 1497–1500. [Google Scholar] [CrossRef]

- Tavman, I.H.; Tavman, S. Measurement of thermal conductivity of dairy products. J. Food Eng. 1999, 41, 109–114. [Google Scholar] [CrossRef]

| Unit/Legend | SPC Alpha 8 | |

|---|---|---|

| Composition | ||

| Dry matter (TS) | g/100 g raw material | 95.4 |

| Protein | 66.5 | |

| Fat | 1.6 | |

| Ash | 6.8 | |

| Carbohydrates (incl. 18 g/100 g dietary fibers) | 20.5 |

| Experimental Plan | Responses | |||||||

|---|---|---|---|---|---|---|---|---|

| Process Variables | Process Response | Product Response | ||||||

| No. | Moisture content [%] | Screw speed [rpm] | Mass flow rate [kg/h] | Barrel temperature [°C] | Material temperature [°C] | Extruder pressure [bar] | SME [Wh/kg] | Texture |

| 1 | 60 | 400 | 13 | 160 | 133.10 | 21.06 | 30.68 | well-textured |

| 2 | 60 | 400 | 13 | 120 | 104.85 | 16.73 | 26.20 | poorly textured |

| 3 | 60 | 400 | 13 | 140 | 116.4 | 15.07 | 20.81 | textured |

| 4 | 65 | 310 | 9.5 | 170 | 137.76 | 9.69 | 9.71 | textured |

| 5 | 70 | 400 | 13 | 160 | 120.11 | 6.63 | 6.09 | textured |

| Cluster | Description and Example of Texture |

|---|---|

| Poorly textured | Soft, mushy, and brittle HME samples displaying no multilayered, fibrous structure, with a structure like shortcrust pastry. |

| |

| Textured | HME samples displaying a slightly fiber-like structure, a weak parabolic pattern, when manually torn apart, as well as the trend of a V-shape pattern, if cut longitudinally to the flow direction. |

| |

| Well-textured (=HMMA) | HME samples displaying firm and defined multilayered, fibrous structures, a pronounced parabolic pattern, and a well-defined V-shape pattern. |

|

| Food Product | Temperature | Prediction Model * | Reference | |

|---|---|---|---|---|

| Various high-moisture food products | with | [20] | ||

| Water | ||||

| Protein | ||||

| Fat | ||||

| Carbohydrate | ||||

| Fiber | ||||

| Ash | ||||

| Defatted soy flour with Xw = 0.09–0.39 | [13] | |||

| Soy dough with Xw = 0–0.50 | Xw = 0: Xw = 0.25: Xw = 0.5: | [27] | ||

| Tofu with Xw = 0.34–0.76 (w.b.) | [28] | |||

| Food Product | Temperature | Prediction Model | Reference | |

|---|---|---|---|---|

| Various high-moisture food products | [20] | |||

| Water | ||||

| Protein | ||||

| Fat | ||||

| Carbohydrate | ||||

| Fiber | ||||

| Ash | ||||

| Defatted soy flour with Xw = 0.09–0.39 | [13] | |||

| Tofu with Xw = 0.34–0.72 (w.b.) | [28] | |||

| Meat and fish products with Xw = 0.60–0.80 (w.b.) | [12] | |||

| HME sample with Xw = 0.60–0.70 (d.b.) | Specific heat and density ρ were calculated with models developed in this study, α was taken from [28] (2003) and [9] (1986), respectively | Mathematical calculation | ||

| Food Product | Temperature | Prediction Model | Percentage Deviation (at T = 90 °C and Xw = 0.60) † | Reference | |

|---|---|---|---|---|---|

| Broad range of food products Average for all types of carbohydrates (), protein (), fat (), and ash () | HME sample: 0.84% | [4] | |||

| Water | |||||

| Protein | |||||

| Fat | |||||

| Carbohydrate | |||||

| Fiber | |||||

| Ash | |||||

| Defatted soy flour at MC of 9.2 to 39% | (DSC method) | (cp in J/kg °C) | HME sample: 5.54% at T = 130 °C and Xw = 0.60 | [13] | |

| Defatted soy dough at MC of 0 to 70% | (DSC method) | 50 % MC and T = 90 °C: | HME sample: −7.23% at T = 90 °C and Xw = 0.50 | [27] | |

| Soy dough | (cp in J/kg °C) | HME sample: −1.10% at T = 20°C and Xw = 0.60 | [40] | ||

| Tofu Xw = 0.3–0.7 (w.b.) | (modulated DSC method) | () (cp in J/kg °C, T in °C) | HME sample: −1.46% | [28] | |

| Turkey Xw = 74.88 % | (modulated DSC method) | () (cp in J/kg °C, T in °C) | HME sample: −5.19% at T = 80 °C and Xw = 0.7488 | [18] | |

| Regression model Xw = 0.6–0.7 (d.b.) | (DSC method) | ) | HME sample: −0.29% ‡ | Developed in this study | |

| Food Product | Temperature | Prediction Model | Percentage Deviation (at T = 20 °C) † | Reference | |

|---|---|---|---|---|---|

| Fresh seafood Xw = 0.73–0.86 (w.b.) | HME sample, Xw = 0.60: −11.24% HME sample, Xw = 0.65: −4.83% HME sample, Xw = 0.70: −3.20% | [36] based on [4] | |||

| Water | |||||

| Protein | |||||

| Fat | |||||

| Carbohydrate | |||||

| Fiber | |||||

| Ash | |||||

| Excess volume | |||||

| Tofu Xw = 0.34–0.73 (w.b.) | () | HME sample, Xw = 0.60: −5.88% HME sample, Xw = 0.65: −0.63% HME sample, Xw = 0.70: −0.54% | [28] | ||

| HME sample Xw based on HME process | Based on HME process | HME sample, Xw = 0.60: −2.34% HME sample, Xw = 0.65: −3.32% HME sample, Xw = 0.70: −2.71% | HME process (based on process conditions) | ||

| HME sample Xw = 0.60–0.70 (d.b.) | () | HME sample, Xw = 0.60: −0.86% HME sample, Xw = 0.65: 1.87% HME sample, Xw = 0.70: −0.95% | Regression equation (experimental data) | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Högg, E.; Rauh, C. Towards a Better Understanding of Texturization during High-Moisture Extrusion (HME)—Part II: Characterization of Thermophysical Properties of High-Moisture Meat Analogues. Foods 2023, 12, 2283. https://doi.org/10.3390/foods12122283

Högg E, Rauh C. Towards a Better Understanding of Texturization during High-Moisture Extrusion (HME)—Part II: Characterization of Thermophysical Properties of High-Moisture Meat Analogues. Foods. 2023; 12(12):2283. https://doi.org/10.3390/foods12122283

Chicago/Turabian StyleHögg, Elisabeth, and Cornelia Rauh. 2023. "Towards a Better Understanding of Texturization during High-Moisture Extrusion (HME)—Part II: Characterization of Thermophysical Properties of High-Moisture Meat Analogues" Foods 12, no. 12: 2283. https://doi.org/10.3390/foods12122283

APA StyleHögg, E., & Rauh, C. (2023). Towards a Better Understanding of Texturization during High-Moisture Extrusion (HME)—Part II: Characterization of Thermophysical Properties of High-Moisture Meat Analogues. Foods, 12(12), 2283. https://doi.org/10.3390/foods12122283