Pretreated Green Pea Flour as Wheat Flour Substitutes in Composite Bread Making

Abstract

:1. Introduction

- investigation of pasting properties of individual untreated and pretreated green pea flour in addition to dough mixing properties of selected composite flour in comparison with wheat flour;

- effect of pretreated green pea flour on fresh bread technological quality and during storage. In this section, a full factorial design was considered in association with multivariate analysis for a better understanding of the impact of each studied factor (level of the addition, type of pretreatment, storage period, and their interaction);

- effect on nutritional quality with a focus on starch digestibility in the product with industrial relevance.

2. Materials and Methods

2.1. Wheat and Green Pea Flour

2.2. Dough Rheological Properties

2.3. Bread Formulation, Production, and Storage

2.4. Technological Properties of Fresh and Stored Bread

2.5. Bread Nutritional Quality

2.6. Statistical Analysis

3. Results and Discussion

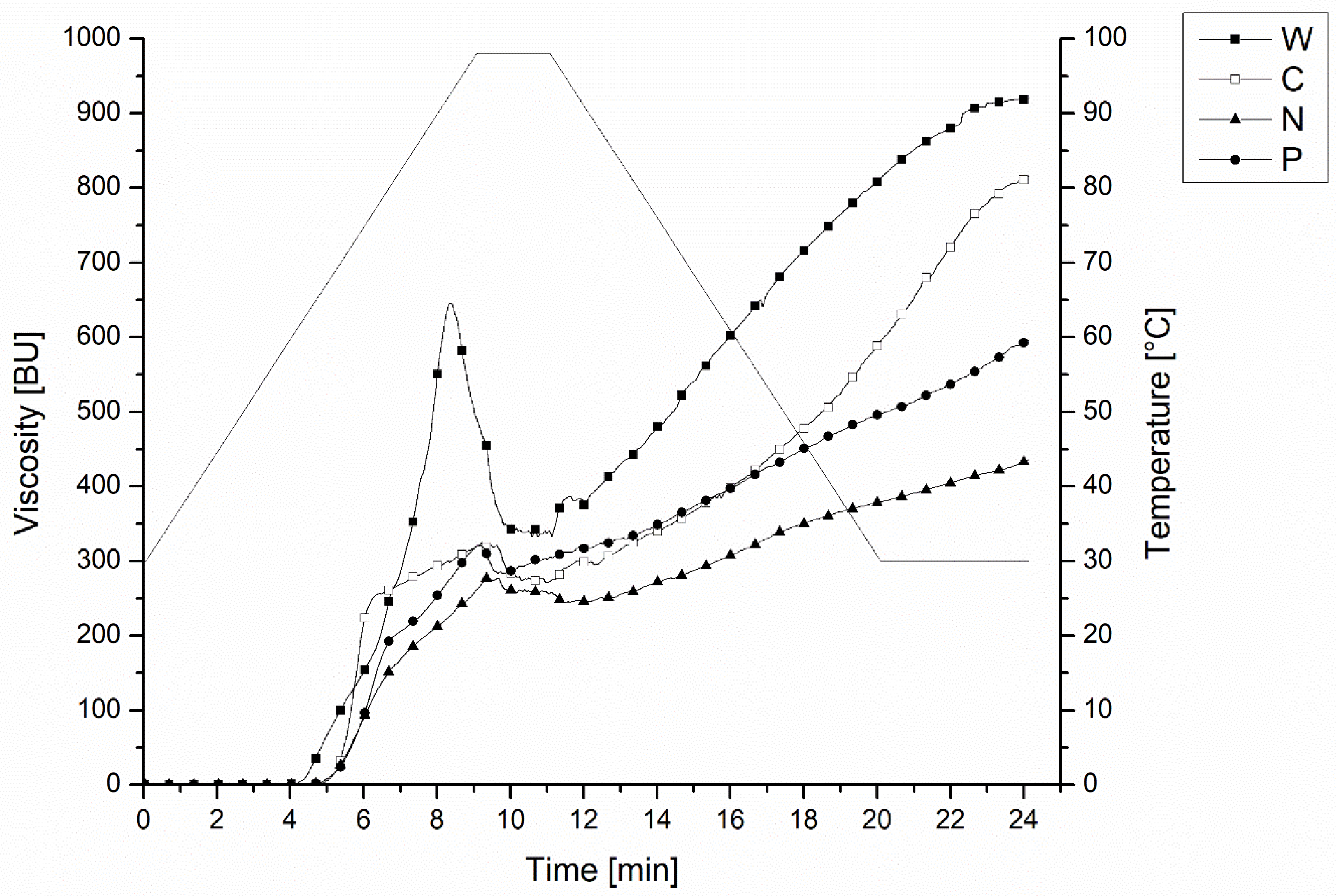

3.1. Rheological Properties

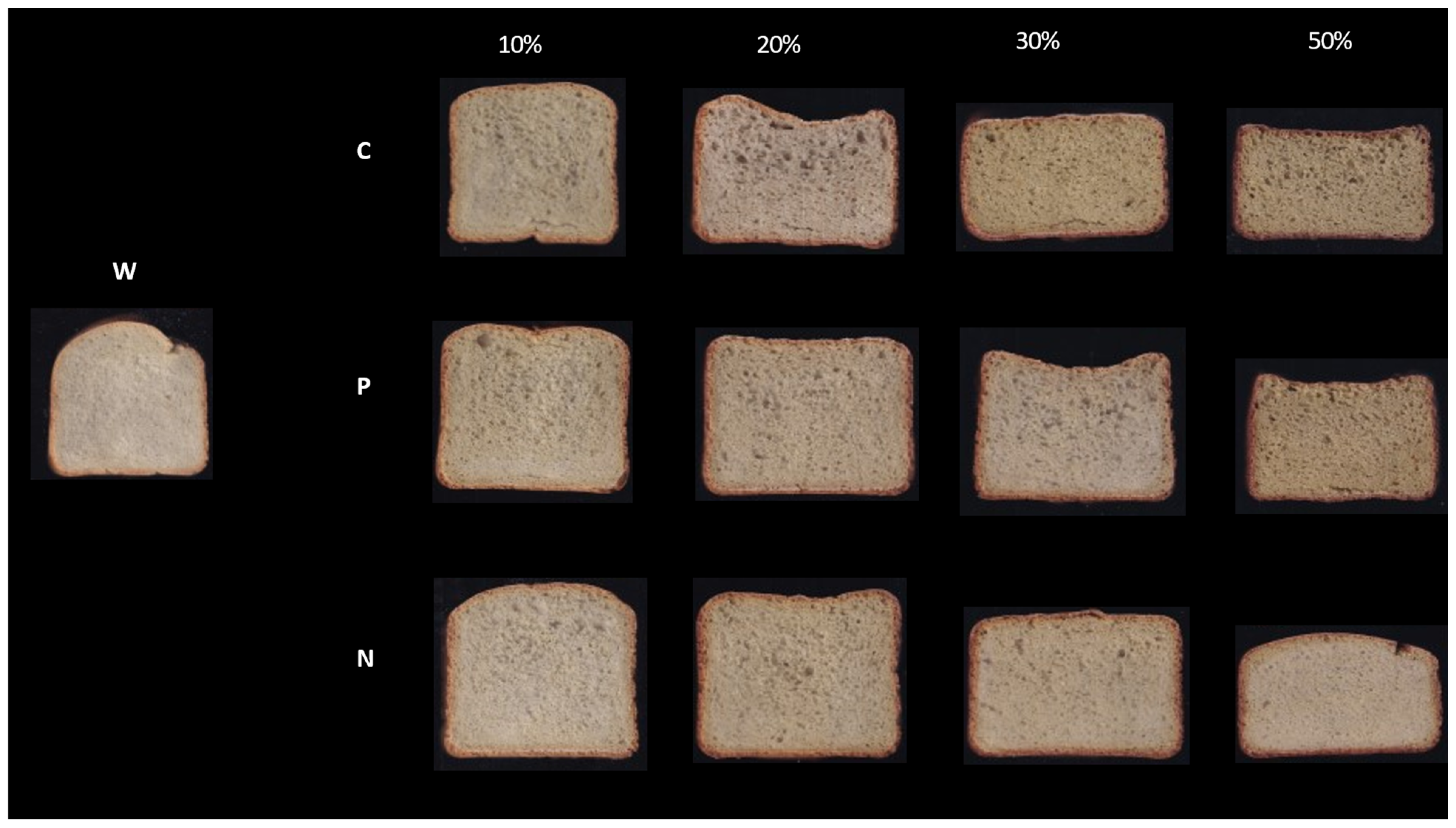

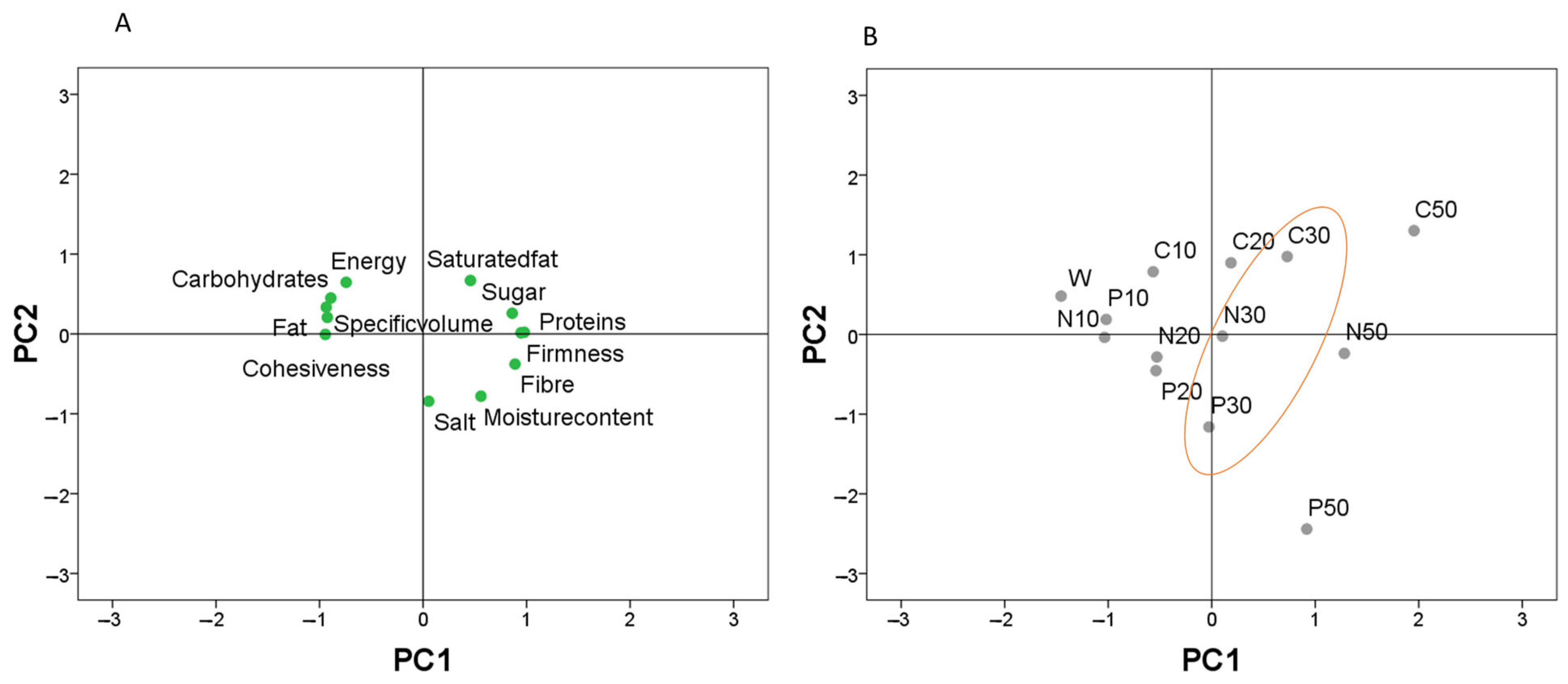

3.2. Fresh Composite Bread Quality

3.3. Changes in Composite Bread Quality during Storage

3.4. Nutritional Features of Composite Bread

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Boukid, F.; Zannini, E.; Carini, E.; Vittadini, E. Pulses for Bread Fortification: A Necessity or a Choice? Trends Food Sci. Technol. 2019, 88, 416–428. [Google Scholar] [CrossRef]

- Mefleh, M.; Pasqualone, A.; Caponio, F.; Faccia, M. Legumes as Basic Ingredients in the Production of Dairy-Free Cheese Alternatives: A Review. J. Sci. Food Agric. 2022, 102, 8–18. [Google Scholar] [CrossRef] [PubMed]

- Suo, X.; Dall’Asta, M.; Giuberti, G.; Minucciani, M.; Wang, Z.; Vittadini, E. The Effect of Chickpea Flour and Its Addition Levels on Quality and in Vitro Starch Digestibility of Corn–Rice-Based Gluten-Free Pasta. Int. J. Food Sci. Nutr. 2022, 73, 600–609. [Google Scholar] [CrossRef] [PubMed]

- Boukid, F.; Vittadini, E.; Lusuardi, F.; Ganino, T.; Carini, E.; Morreale, F.; Pellegrini, N. Does Cell Wall Integrity in Legumes Flours Modulate Physiochemical Quality and in Vitro Starch Hydrolysis of Gluten-Free Bread? J. Funct. Foods 2019, 59, 110–118. [Google Scholar] [CrossRef]

- Boukid, F.; Rosell, C.M.; Rosene, S.; Bover-Cid, S.; Castellari, M. Non-Animal Proteins as Cutting-Edge Ingredients to Reformulate Animal-Free Foodstuffs: Present Status and Future Perspectives. Crit. Rev. Food Sci. Nutr. 2022, 62, 6390–6420. [Google Scholar] [CrossRef]

- Wang, Y.; Jian, C. Sustainable Plant-Based Ingredients as Wheat Flour Substitutes in Bread Making. Npj Sci. Food 2022, 6, 49. [Google Scholar] [CrossRef]

- Yu, S.; Wu, Y.; Li, Z.; Wang, C.; Zhang, D.; Wang, L. Effect of Different Milling Methods on Physicochemical and Functional Properties of Mung Bean Flour. Front. Nutr. 2023, 10, 237. [Google Scholar] [CrossRef]

- Marchini, M.; Carini, E.; Cataldi, N.; Boukid, F.; Blandino, M.; Ganino, T.; Vittadini, E.; Pellegrini, N. The Use of Red Lentil Flour in Bakery Products: How Do Particle Size and Substitution Level Affect Rheological Properties of Wheat Bread Dough? LWT 2021, 136, 110299. [Google Scholar] [CrossRef]

- Samtiya, M.; Aluko, R.E.; Dhewa, T. Plant Food Anti-Nutritional Factors and Their Reduction Strategies: An Overview. Food Prod. Process. Nutr. 2020, 2, 6. [Google Scholar] [CrossRef] [Green Version]

- Millar, K.A.; Barry-Ryan, C.; Burke, R.; McCarthy, S.; Gallagher, E. Dough Properties and Baking Characteristics of White Bread, as Affected by Addition of Raw, Germinated and Toasted Pea Flour. Innov. Food Sci. Emerg. Technol. 2019, 56, 102189. [Google Scholar] [CrossRef]

- Mefleh, M.; Faccia, M.; Natrella, G.; De Angelis, D.; Pasqualone, A.; Caponio, F.; Summo, C. Development and Chemical-Sensory Characterization of Chickpeas-Based Beverages Fermented with Selected Starters. Foods 2022, 11, 3578. [Google Scholar] [CrossRef] [PubMed]

- Kowalczewski, L.; Boukid, F.; Hassoun, A.; Zouari, A.; Tülbek, M.Ç.; Mefleh, M.; Aït-Kaddour, A.; Castellari, M. Fermentation for Designing Innovative Plant-Based Meat and Dairy Alternatives. Foods 2023, 12, 1005. [Google Scholar] [CrossRef]

- Coda, R.; Varis, J.; Verni, M.; Rizzello, C.G.; Katina, K. Improvement of the Protein Quality of Wheat Bread through Faba Bean Sourdough Addition. LWT-Food Sci. Technol. 2017, 82, 296–302. [Google Scholar] [CrossRef] [Green Version]

- Kotsiou, K.; Sacharidis, D.D.; Matsakidou, A.; Biliaderis, C.G.; Lazaridou, A. Impact of Roasted Yellow Split Pea Flour on Dough Rheology and Quality of Fortified Wheat Breads. Foods 2021, 10, 1832. [Google Scholar] [CrossRef] [PubMed]

- Drulyte, D.; Orlien, V. The Effect of Processing on Digestion of Legume Proteins. Foods 2019, 8, 224. [Google Scholar] [CrossRef] [Green Version]

- Boukid, F.; Castellari, M. How Can Processing Technologies Boost the Application of Faba Bean (Vicia faba L.) Proteins in Food Production? eFood 2022, 3, e18. [Google Scholar] [CrossRef]

- Luo, S.; Koksel, F. Physical and Technofunctional Properties of Yellow Pea Flour and Bread Crumb Mixtures Processed with Low Moisture Extrusion Cooking. J. Food Sci. 2020, 85, 2688–2698. [Google Scholar] [CrossRef]

- Meng, Y.; Guan, X.; Liu, X.; Zhang, H. The Rheology and Microstructure of Composite Wheat Dough Enriched with Extruded Mung Bean Flour. LWT 2019, 109, 378–386. [Google Scholar] [CrossRef]

- Sinaki, N.Y.; Paliwal, J.; Koksel, F. Enhancing the Techno-Functionality of Pea Flour by Air Injection-Assisted Extrusion at Different Temperatures and Flour Particle Sizes. Foods 2023, 12, 889. [Google Scholar] [CrossRef]

- Collar, C.; Angioloni, A. High-Legume Wheat-Based Matrices: Impact of High Pressure on Starch Hydrolysis and Firming Kinetics of Composite Breads. Food Bioprocess Technol. 2017, 10, 1103–1112. [Google Scholar] [CrossRef] [Green Version]

- Yaver, E.; Bilgiçli, N. Ultrasound-Treated Lupin (Lupinus albus L.) Flour: Protein- and Fiber-Rich Ingredient to Improve Physical and Textural Quality of Bread with a Reduced Glycemic Index. LWT 2021, 148, 111767. [Google Scholar] [CrossRef]

- AACC. Approved Methods of the American Association of Cereal Chemists, 10th ed.; The Association: Saint Paul, MN, USA, 2000. [Google Scholar]

- European Parliament and of the Council Regulation (EU) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the Provision of Food Information to Consumers. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32011R1169 (accessed on 21 August 2020).

- Englyst, K.N.; Englyst, H.N.; Hudson, G.J.; Cole, T.J.; Cummings, J.H. Rapidly Available Glucose in Foods: An in Vitro Measurement That Reflects the Glycemic Response. Am. J. Clin. Nutr. 1999, 69, 448–454. [Google Scholar] [CrossRef] [Green Version]

- McCleary, B.V.; Monaghan, D.A. Measurement of Resistant Starch. J. AOAC Int. 2002, 85, 665–675. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pasqualone, A.; Costantini, M.; Faccia, M.; Difonzo, G.; Caponio, F.; Summo, C. The Effectiveness of Extruded-Cooked Lentil Flour in Preparing a Gluten-Free Pizza with Improved Nutritional Features and a Good Sensory Quality. Foods 2022, 11, 482. [Google Scholar] [CrossRef]

- Curti, E.; Carini, E.; Tribuzio, G.; Vittadini, E. Effect of Bran on Bread Staling: Physico-Chemical Characterization and Molecular Mobility. J. Cereal Sci. 2015, 65, 25–30. [Google Scholar] [CrossRef]

- Boukid, F.; Carini, E.; Curti, E.; Pizzigalli, E.; Vittadini, E. Bread Staling: Understanding the Effects of Transglutaminase and Vital Gluten Supplementation on Crumb Moisture and Texture Using Multivariate Analysis. Eur. Food Res. Technol. 2019, 245, 1337–1345. [Google Scholar] [CrossRef]

- Turfani, V.; Narducci, V.; Durazzo, A.; Galli, V.; Carcea, M. Technological, Nutritional and Functional Properties of Wheat Bread Enriched with Lentil or Carob Flours. LWT-Food Sci. Technol. 2017, 78, 361–366. [Google Scholar] [CrossRef]

- Keskin, S.O.; Ali, T.M.; Ahmed, J.; Shaikh, M.; Siddiq, M.; Uebersax, M.A. Physico-Chemical and Functional Properties of Legume Protein, Starch, and Dietary Fiber—A Review. Legum. Sci. 2022, 4, e117. [Google Scholar] [CrossRef]

- Bento, J.A.C.; Morais, D.K.; de Berse, R.S.; Bassinello, P.Z.; Caliari, M.; Soares Júnior, M.S. Functional, Thermal, and Pasting Properties of Cooked Carioca Bean (Phaseolus vulgaris L.) Flours. Appl. Food Res. 2022, 2, 100027. [Google Scholar] [CrossRef]

- Ali, S.A.; Saeed, S.M.G.; Ejaz, U.; Baloch, M.N.; Sohail, M. A Novel Approach to Improve the Nutritional Value of Black Gram (Vigna mungo L.) by the Combined Effect of Pre-Gelatinization and Fermentation by Lactobacillus sp. E14 and Saccharomyces Cerevisiae MK-157: Impact on Morphological, Thermal, and Chemical Structural Properties. LWT 2022, 172, 114216. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, R.; Tilley, M.; Siliveru, K.; Li, Y. Effect of Pulse Type and Substitution Level on Dough Rheology and Bread Quality of Whole Wheat-Based Composite Flours. Processes 2021, 9, 1687. [Google Scholar] [CrossRef]

- Fetouhi, A.; Benatallah, L.; Nawrocka, A.; Szymańska-Chargot, M.; Bouasla, A.; Tomczyńska-Mleko, M.; Zidoune, M.N.; Sujak, A. Investigation of Viscoelastic Behaviour of Rice-Field Bean Gluten-Free Dough Using the Biophysical Characterization of Proteins and Starch: A FT-IR Study. J. Food Sci. Technol. 2019, 56, 1316–1327. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sopiwnyk, E.; Bourré, L.; Young, G.; Borsuk, Y.; Lagassé, S.; Boyd, L.; Sarkar, A.; Jones, S.; Dyck, A.; Malcolmson, L. Flour and Bread Making Properties of Whole and Split Yellow Peas Treated with Dry and Steam Heat Used as Premilling Treatment. Cereal Chem. 2020, 97, 1290–1302. [Google Scholar] [CrossRef]

- Ungureanu-Iuga, M.; Atudorei, D.; Codină, G.G.; Mironeasa, S. Rheological Approaches of Wheat Flour Dough Enriched with Germinated Soybean and Lentil. Appl. Sci. 2021, 11, 11706. [Google Scholar] [CrossRef]

- Kohajdová, Z.; Karovičová, J.; Magala, M. Effect of Lentil and Bean Flours on Rheological and Baking Properties of Wheat Dough. Chem. Pap. 2013, 67, 398–407. [Google Scholar] [CrossRef]

- Mashayekh, M.; Mahmoodi, M.R.; Entezari, M.H. Effect of Fortification of Defatted Soy Flour on Sensory and Rheological Properties of Wheat Bread. Int. J. Food Sci. Technol. 2008, 43, 1693–1698. [Google Scholar] [CrossRef]

- Bojňanská, T.; Musilová, J.; Vollmannová, A. Effects of Adding Legume Flours on the Rheological and Breadmaking Properties of Dough. Foods 2021, 10, 1087. [Google Scholar] [CrossRef]

- Atudorei, D.; Atudorei, O.; Codină, G.G. The Impact of Germinated Chickpea Flour Addition on Dough Rheology and Bread Quality. Plants 2022, 11, 1225. [Google Scholar] [CrossRef]

- Boukid, F.; Rosell, C.M.; Castellari, M. Pea Protein Ingredients: A Mainstream Ingredient to (Re)Formulate Innovative Foods and Beverages. Trends Food Sci. Technol. 2021, 110, 729–742. [Google Scholar] [CrossRef]

- Mohammed, I.; Ahmed, A.R.; Senge, B. Effects of Chickpea Flour on Wheat Pasting Properties and Bread Making Quality. J. Food Sci. Technol. 2014, 51, 1902–1910. [Google Scholar] [CrossRef] [Green Version]

- Sanfilippo, R.; Canale, M.; Dugo, G.; Oliveri, C.; Scarangella, M.; Strano, M.C.; Amenta, M.; Crupi, A.; Spina, A. Effects of Partial Replacement of Durum Wheat Re-Milled Semolina with Bean Flour on Physico-Chemical and Technological Features of Doughs and Breads during Storage. Plants 2023, 12, 1125. [Google Scholar] [CrossRef]

- Patrascu, L.; Vasilean, I.; Turtoi, M.; Garnai, M.; Aprodu, I. Pulse Germination as Tool for Modulating Their Functionality in Wheat Flour Sourdoughs. Qual. Assur. Saf. Crop. Foods 2019, 11, 269–282. [Google Scholar] [CrossRef]

- Monnet, A.F.; Laleg, K.; Michon, C.; Micard, V. Legume Enriched Cereal Products: A Generic Approach Derived from Material Science to Predict Their Structuring by the Process and Their Final Properties. Trends Food Sci. Technol. 2019, 86, 131–143. [Google Scholar] [CrossRef]

- Gasparre, N.; Mefleh, M.; Boukid, F. Nutritional Facts and Health/Nutrition Claims of Commercial Plant-Based Infant Foods: Where Do We Stand? Plants 2022, 11, 2531. [Google Scholar] [CrossRef] [PubMed]

- Dhital, S.; Bhattarai, R.R.; Gorham, J.; Gidley, M.J. Intactness of Cell Wall Structure Controls the in Vitro Digestion of Starch in Legumes. Food Funct. 2016, 7, 1367–1379. [Google Scholar] [CrossRef]

- Rovalino-Córdova, A.M.; Fogliano, V.; Capuano, E. A Closer Look to Cell Structural Barriers Affecting Starch Digestibility in Beans. Carbohydr. Polym. 2018, 181, 994–1002. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Liu, H.; Ma, Y.; Mai, S.; Li, C. Effects of Extrusion on Starch Molecular Degradation, Order-Disorder Structural Transition and Digestibility—A Review. Foods 2022, 11, 2538. [Google Scholar] [CrossRef]

| Ingredients (%) | W | C10 | C20 | C30 | C50 | P10 | P20 | P30 | P50 | N10 | N20 | N30 | N50 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flour | 100 | ||||||||||||

| W | 100 | 90 | 80 | 70 | 50 | 90 | 80 | 70 | 50 | 90 | 80 | 70 | 50 |

| C | - | 10 | 20 | 30 | 50 | - | - | - | - | - | - | - | - |

| P | - | - | - | - | - | 10 | 20 | 30 | 50 | - | - | - | - |

| N | - | - | - | - | - | - | - | - | - | 10 | 20 | 30 | 50 |

| Water * | 55 | 57 | 59 | 61 | 64 | 60 | 65 | 69 | 78 | 58 | 61 | 64 | 69 |

| Sugar | 1.3 | ||||||||||||

| Salt | 2 | ||||||||||||

| Yeast | 2 | ||||||||||||

| Olive oil | 3.3 | ||||||||||||

| Initial Viscosity (BU) | Begining of Gelatinization Temperature (°C) | Peak Viscosity (BU) | Peak Viscosity Temperature (°C) | Cooling Maximum Viscosity (BU) | Breakdown (BU) | Setback (BU) | |

|---|---|---|---|---|---|---|---|

| W | 12.5 ± 0.5 ab | 61.2 ± 0.5 b | 648.3 ± 158.0 a | 90.5 ± 0.5 b | 911.0 ± 45.0 a | 365.5 ± 59.0 a | 535.0 ± 49.0 a |

| C | 12.7 ± 0.6 a | 69.8 ± 0.9 a | 327.0 ± 23.1 b | 95.2 ± 0.6 a | 588.7 ± 52.0 b | 47.3 ± 27.9 b | 309.0 ± 57.7 b |

| P | 11.0 ± 0.0 c | 69.5 ± 0.2 a | 281.0 ± 4.0 b | 96.3 ± 1.4 a | 518.0 ± 21.8 b | 16.3 ± 11.0 b | 217.0 ± 28.0 c |

| N | 11.7 ± 0.6 bc | 69.1 ± 0.4 a | 317.3 ± 13.1 b | 96.3 ± 0.9 a | 397.0 ± 16.4 c | 22.7 ± 3.1 b | 136.3 ± 15.0 c |

| Doughs | Water Absorption (%) | Development Time (min) | Stability Time (min) |

|---|---|---|---|

| W | 60.75 ± 0.35 d | 1.50 ± 0.14 c | 16.65 ± 0.07 a |

| C50 | 64.00 ± 0.70 c | 8.80 ± 0.14 a | 1.90 ± 0.28 d |

| P50 | 78.30 ± 0.21 a | 6.85 ± 0.07 b | 2.45 ± 0.07 c |

| N50 | 70.40 ± 0.07 b | 1.70 ± 0.14 c | 7.25 ± 0.07 b |

| PT | LA | PT × LA | ||||

|---|---|---|---|---|---|---|

| SS% | Sig. | SS% | Sig. | SS% | Sig. | |

| Specific volume | 1.19 | ** | 94.49 | *** | 4.32 | *** |

| Moisture content | 13.45 | *** | 46.02 | *** | 40.53 | *** |

| Firmness | 6.94 | *** | 86.74 | * | 6.32 | *** |

| Cohesiveness | 25.82 | *** | 68.55 | *** | 5.64 | ns |

| Bread | Specific Volume (cm3 g−1) | Moisture Content (g/100 g) | Firmness (N) | Cohesiveness (Dimensionless) |

|---|---|---|---|---|

| W | 3.78 ± 0.03 a | 40.96 ± 0.33 d | 3.08 ± 0.94 h | 0.67 ± 0.04 a |

| C10 | 3.85 ± 0.08 a | 42.57 ± 0.06 c | 3.09 ± 1.37 h | 0.53 ± 0.72 abcd |

| C20 | 2.90 ± 0.11 c | 42.73 ± 0.40 c | 8.24 ± 1.06 e | 0.48 ± 0.04 bcd |

| C30 | 2.59 ± 0.03 d | 42.93 ± 0.24 c | 13.62 ± 1.58 c | 0.50 ± 0.02 bcd |

| C50 | 2.36 ± 0.10 e | 43.19 ± 0.09 c | 24.56 ± 2.68 a | 0.39 ± 0.02 d |

| P10 | 3.75 ± 0.08 a | 41.50 ± 0.23 d | 3.08 ± 0.93 h | 0.61 ± 0.07 ab |

| P20 | 3.33 ± 0.11 b | 42.96 ± 0.13 c | 5.89 ± 1.76 f | 0.60 ± 0.04 abc |

| P30 | 2.79 ± 0.12 c | 44.37 ± 0.82 b | 7.24 ± 1.39 e | 0.54 ± 0.04 abcd |

| P50 | 2.40 ± 0.05 e | 47.90 ± 0.04 a | 15.22 ± 1.95 b | 0.44 ± 0.02 cd |

| N10 | 3.69 ± 0.10 a | 43.00 ± 1.35 c | 4.64 ± 1.12 fg | 0.67 ± 0.03 a |

| N20 | 3.33 ± 0.12 b | 43.47 ± 0.27 c | 5.62 ± 1.46 f | 0.61 ± 0.03 ab |

| N30 | 2.75 ± 0.13 c | 43.20 ± 0.11 b | 9.92 ± 1.23 e | 0.55 ± 0.03 abcd |

| N50 | 2.05 ± 0.10 f | 44.57 ± 0.14 b | 24.12 ± 2.58 a | 0.45 ± 0.02 cd |

| Factor | Moisture Content | Firmness | Cohesiveness | |

|---|---|---|---|---|

| PT | SS% | 31.01 | 2.55 | 1.75 |

| sig. | *** | *** | * | |

| LA | SS% | 44.64 | 72.30 | 12.68 |

| sig. | *** | *** | *** | |

| S | SS% | 2.42 | 14.91 | 74.35 |

| sig. | *** | *** | *** | |

| PT × LA | SS% | 14.00 | 1.19 | 0.38 |

| sig. | *** | ** | ns | |

| PT × S | SS% | 5.03 | 1.51 | 3.68 |

| sig. | *** | *** | *** | |

| LA × S | SS% | 0.97 | 5.66 | 5.10 |

| sig. | ns | *** | *** | |

| PT × LA × S | SS% | 1.93 | 1.86 | 2.10 |

| sig. | ns | *** | ns |

| Sample | W | C10 | C20 | C30 | C50 | P10 | P20 | P30 | P50 | N10 | N20 | N30 | N50 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Energy (Kcal) | 218.36 | 210.68 | 208.35 | 205.88 | 201.49 | 214.87 | 208.02 | 199.72 | 185.99 | 212.46 | 206.68 | 206.48 | 198.95 |

| Fat (g) | 3.49 | 3.31 | 3.21 | 3.11 | 2.92 | 3.41 | 3.27 | 3.12 | 2.86 | 3.35 | 3.21 | 3.16 | 2.96 |

| Saturated fat (g) | 0.38 | 0.66 | 0.66 | 0.67 | 0.69 | 0.39 | 0.4 | 0.4 | 0.4 | 0.38 | 0.38 | 0.4 | 0.4 |

| Carbohydrates (g) | 42.59 | 40.06 | 38.57 | 37.06 | 34.16 | 40.93 | 38.65 | 36.17 | 31.88 | 40.42 | 38.32 | 37.26 | 33.91 |

| Sugar (g) | 1.63 | 1.65 | 1.71 | 1.77 | 1.89 | 1.68 | 1.7 | 1.7 | 1.72 | 1.64 | 1.64 | 1.69 | 1.72 |

| Fibre (g) | 1.01 | 1.31 | 1.62 | 1.94 | 2.57 | 1.41 | 1.76 | 2.09 | 2.69 | 1.4 | 1.77 | 2.18 | 2.91 |

| Proteins (g) | 5.52 | 6.18 | 6.96 | 7.74 | 9.29 | 6.11 | 6.59 | 6.97 | 7.73 | 6.15 | 6.74 | 7.5 | 8.72 |

| Protein contribution to the energy value * | 10.11 | 11.73 | 13.36 * | 15.04 * | 18.44 * | 11.37 | 12.67 * | 13.96 * | 16.62 * | 11.58 | 13.04 * | 14.53 * | 17.53 * |

| Salt (g) | 1.09 | 1.06 | 1.06 | 1.05 | 1.05 | 1.27 | 1.43 | 1.57 | 1.83 | 1.06 | 1.04 | 1.05 | 1.02 |

| Bread | TS g/100 g Dry Matter | RS g/100 g Dry Matter | RDS g/100 g dry Matter | SDS g/100 g Dry Matter | SDI (%) |

|---|---|---|---|---|---|

| W | 71.39 ± 1.07 a | 13.27 ± 0.27 a | 54.34 ± 0.46 a | 3.77 ± 0.40 b | 76.11 ± 0.51 a |

| C30 | 55.03 ± 0.77 b | 14.12 ± 0.64 a | 39.10 ± 0.37 c | 1.81 ± 0.29 c | 71.05 ± 0.67 c |

| P30 | 55.55 ± 0.83 b | 9.20 ± 0.71 c | 41.04 ± 0.40 b | 5.31 ± 0.58 a | 73.87 ± 0.97 b |

| N30 | 54.80 ± 0.56 b | 12.04 ± 0.78 b | 40.95 ± 0.49 b | 1.81 ± 0.15 c | 74.72 ± 1.25 ab |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moreno-Araiza, O.; Boukid, F.; Suo, X.; Wang, S.; Vittadini, E. Pretreated Green Pea Flour as Wheat Flour Substitutes in Composite Bread Making. Foods 2023, 12, 2284. https://doi.org/10.3390/foods12122284

Moreno-Araiza O, Boukid F, Suo X, Wang S, Vittadini E. Pretreated Green Pea Flour as Wheat Flour Substitutes in Composite Bread Making. Foods. 2023; 12(12):2284. https://doi.org/10.3390/foods12122284

Chicago/Turabian StyleMoreno-Araiza, Oscar, Fatma Boukid, Xinying Suo, Shihao Wang, and Elena Vittadini. 2023. "Pretreated Green Pea Flour as Wheat Flour Substitutes in Composite Bread Making" Foods 12, no. 12: 2284. https://doi.org/10.3390/foods12122284

APA StyleMoreno-Araiza, O., Boukid, F., Suo, X., Wang, S., & Vittadini, E. (2023). Pretreated Green Pea Flour as Wheat Flour Substitutes in Composite Bread Making. Foods, 12(12), 2284. https://doi.org/10.3390/foods12122284