Freeze-Dried Banana Slices Carrying Probiotic Bacteria

Abstract

:1. Introduction

2. Materials and Methods

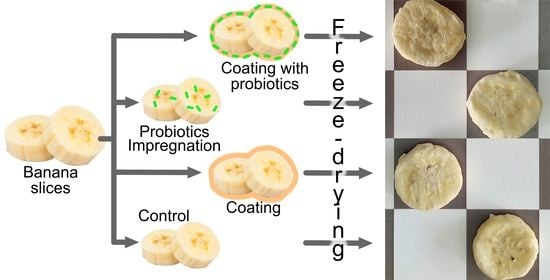

2.1. Processing of Probiotic Banana Slices

2.2. Characterization of Probiotic Banana Slices

2.2.1. Viable Cell Counts

2.2.2. Shear Force

2.2.3. Surface Color

2.2.4. Scanning Electron Microscopy (SEM)

2.2.5. Sensory Evaluation

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shahbandeh, M. World Production of Bananas in 2021, by Region. Available online: https://www.statista.com/statistics/264003/production-of-bananas-worldwide-by-region/ (accessed on 2 April 2023).

- Azeredo, H.M.C.; Matos, M.C.; Niro, C.M. Something to Chew on: Technological Aspects for Novel Snacks. J. Sci. Food Agric. 2021, 102, 2191–2198. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, M.V.; Bambace, M.F.; Quintana, G.; Gomez-Zavaglia, A.; del Rosario Moreira, M. Prebiotic-Alginate Edible Coating on Fresh-Cut Apple as a New Carrier for Probiotic Lactobacilli and Bifidobacteria. LWT 2021, 137, 110483. [Google Scholar] [CrossRef]

- Galvão, A.M.M.T.; Rodrigues, S.; Fernandes, F.A.N. Probiotic Dried Apple Snacks: Development of Probiotic Coating and Shelf-Life Studies. J. Food Process. Preserv. 2020, 44, e14974. [Google Scholar] [CrossRef]

- Oliveira, A.S.; Niro, C.M.; Bresolin, J.D.; Soares, V.F.; Ferreira, M.D.; Sivieri, K.; Azeredo, H.M.C. Dehydrated Strawberries for Probiotic Delivery: Influence of Dehydration and Probiotic Incorporation Methods. LWT 2021, 144, 111105. [Google Scholar] [CrossRef]

- Monteiro, S.S.; da Silva, W.P.; Monteiro, S.S.; Gomes, J.P.; Pereira, E.M.; de Lima Ferreira, J.P. Probiotic Coating Applied to Papaya Slices for High Quality Snack Production by Convective Drying. J. Food Process. Preserv. 2022, 46, e16183. [Google Scholar] [CrossRef]

- Niro, C.M.; de Medeiros, J.A.; Bresolin, J.D.; Dionísio, A.P.; Salgaço, M.K.; Sivieri, K.; Azeredo, H.M.C. Banana Leathers as Influenced by Polysaccharide Matrix and Probiotic Bacteria. Food Hydrocoll. Health 2022, 2, 100081. [Google Scholar] [CrossRef]

- Neffe-Skocińska, K.; Rzepkowska, A.; Szydłowska, A.; Kołozyn-Krajewska, D. Trends and Possibilities of the Use of Probiotics in Food Production. Altern. Replace. Foods 2018, 17, 65–94. [Google Scholar] [CrossRef]

- Kiepś, J.; Dembczyński, R. Current Trends in the Production of Probiotic Formulations. Foods 2022, 11, 2330. [Google Scholar] [CrossRef] [PubMed]

- Elshaghabee, F.M.F.; Rokana, N.; Gulhane, R.D.; Sharma, C.; Panwar, H. Bacillus as Potential Probiotics: Status, Concerns, and Future Perspectives. Front. Microbiol. 2017, 8, 1490. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Soares, M.B.; Martinez, R.C.R.; Pereira, E.P.R.; Balthazar, C.F.; Cruz, A.G.; Ranadheera, C.S.; Sant’Ana, A.S. The Resistance of Bacillus, Bifidobacterium, and Lactobacillus Strains with Claimed Probiotic Properties in Different Food Matrices Exposed to Simulated Gastrointestinal Tract Conditions. Food Res. Int. 2019, 125, 108542. [Google Scholar] [CrossRef] [PubMed]

- Cao, J.; Yu, Z.; Liu, W.; Zhao, J.; Zhang, H.; Zhai, Q.; Chen, W. Probiotic Characteristics of Bacillus coagulans and Associated Implications for Human Health and Diseases. J. Funct. Foods 2020, 64, 103643. [Google Scholar] [CrossRef]

- Akman, P.K.; Uysal, E.; Ozkaya, G.U.; Tornuk, F.; Durak, M.Z. Development of Probiotic Carrier Dried Apples for Consumption as Snack Food with the Impregnation of Lactobacillus paracasei. LWT 2019, 103, 60–68. [Google Scholar] [CrossRef]

- Zura-Bravo, L.; Rodriguez, A.; Stucken, K.; Vega-Gálvez, A. Drying Kinetics of Probiotic-Impregnated Murta (Ugni molinae T.) Berries. J. Food Sci. Technol. 2019, 56, 103–113. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Guillén, M.C.; Montero, M.P. Enhancement of Oral Bioavailability of Natural Compounds and Probiotics by Mucoadhesive Tailored Biopolymer-Based Nanoparticles: A Review. Food Hydrocoll. 2021, 118, 106772. [Google Scholar] [CrossRef]

- Alfaro-Galarza, O.; López-Villegas, E.O.; Rivero-Perez, N.; Tapia-Maruri, D.; Jiménez-Aparicio, A.R.; Palma-Rodríguez, H.M.; Vargas-Torres, A. Protective Effects of the Use of Taro and Rice Starch as Wall Material on the Viability of Encapsulated Lactobacillus paracasei subsp. Paracasei. LWT 2020, 117, 108686. [Google Scholar] [CrossRef]

- Pech-Canul, A.d.l.C.; Ortega, D.; García-Triana, A.; González-Silva, N.; Solis-Oviedo, R.L. A Brief Review of Edible Coating Materials for the Microencapsulation of Probiotics. Coatings 2020, 10, 197. [Google Scholar] [CrossRef] [Green Version]

- Silva, O.A.; Pellá, M.G.; Pellá, M.G.; Caetano, J.; Simões, M.R.; Bittencourt, P.R.S.; Dragunski, D.C. Synthesis and Characterization of a Low Solubility Edible Film Based on Native Cassava Starch. Int. J. Biol. Macromol. 2019, 128, 290–296. [Google Scholar] [CrossRef] [PubMed]

- Milani, A.; Jouki, M.; Rabbani, M. Production and Characterization of Freeze-Dried Banana Slices Pretreated with Ascorbic Acid and Quince Seed Mucilage: Physical and Functional Properties. Food Sci. Nutr. 2020, 8, 3768–3776. [Google Scholar] [CrossRef] [PubMed]

| Treatment | Viable Cell Counts (log cfu g−1) | |

|---|---|---|

| Before Freeze Drying | After Freeze Drying | |

| C | n.d. | n.d. |

| COAT | n.d. | n.d. |

| IMP-Pro | 7.92 ± 0.04 (*) | 7.44 ± 0.14 (*) |

| COAT-Pro | 7.95 ± 0.25 | 7.75 ± 0.17 |

| Treatment | Chromaticity | Hue (°) | Shear Force (N) |

|---|---|---|---|

| C | 22.04 ± 4.26 | −86.78 ± 1.08 | 73.89 ± 10.12 (b) |

| COAT | 19.91 ± 1.76 | −85.98 ± 1.17 | 113.60 ± 28.10 (a) |

| IMP-Pro | 20.35 ± 1.64 | −86.28 ± 0.92 | 71.28 ± 16.18 (b) |

| COAT-Pro | 22.15 ± 2.37 | −86.18 ± 0.68 | 115.12 ± 13.77 (a) |

| Treatment | Overall Acceptance | Crispiness |

|---|---|---|

| C | 6.19 ± 1.74 (b) | −0.53 ± 0.96 |

| IMP-Pro | 6.58 ± 1.73 (ab) | −0.44 ± 0.72 |

| COAT-Pro | 6.88 ± 1.72 (a) | −0.28 ± 0.78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niro, C.M.; Mendonça, G.M.N.; Paulino, L.R.; Soares, V.F.; Azeredo, H.M.C. Freeze-Dried Banana Slices Carrying Probiotic Bacteria. Foods 2023, 12, 2282. https://doi.org/10.3390/foods12122282

Niro CM, Mendonça GMN, Paulino LR, Soares VF, Azeredo HMC. Freeze-Dried Banana Slices Carrying Probiotic Bacteria. Foods. 2023; 12(12):2282. https://doi.org/10.3390/foods12122282

Chicago/Turabian StyleNiro, Carolina M., Giovana M. N. Mendonça, Lucca R. Paulino, Viviane F. Soares, and Henriette M. C. Azeredo. 2023. "Freeze-Dried Banana Slices Carrying Probiotic Bacteria" Foods 12, no. 12: 2282. https://doi.org/10.3390/foods12122282

APA StyleNiro, C. M., Mendonça, G. M. N., Paulino, L. R., Soares, V. F., & Azeredo, H. M. C. (2023). Freeze-Dried Banana Slices Carrying Probiotic Bacteria. Foods, 12(12), 2282. https://doi.org/10.3390/foods12122282