Effect of Durum Wheat Oil on the Physico-Chemical and Sensory Features of Biscuits

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

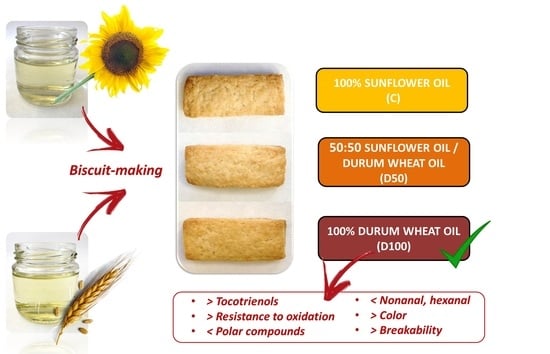

2.2. Biscuit Preparation

2.3. Determination of the Resistance to Oxidation

2.4. Determination of Tocopherols and Tocotrienols

2.5. Determination of Polar Compounds of the Lipid Fraction

2.6. Determination of Volatile Compounds

2.7. Texture Profile Analysis

2.8. Color Measurement

2.9. Determination of Dimensional Parameters

2.10. Determination of Sensory Properties

2.11. Statistical Analysis

3. Results and Discussion

3.1. Tocopherols and Tocotrienols Content, Resistance to the Oxidation, and Polar Compounds

3.2. Volatile Compounds

3.3. Physical Characteristics

3.4. Sensory Features

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tarancón, P.; Sanz, T.; Fiszman, S.; Tárrega, A. Consumers’ hedonic expectations and perception of the healthiness of biscuits made with olive oil or sunflower oil. Food Res. Int. 2014, 55, 197–206. [Google Scholar] [CrossRef]

- Janssen, M.; Chang, B.P.; Hristov, H.; Pravst, I.; Profeta, A.; Millard, J. Changes in food consumption during the COVID-19 pandemic: Analysis of consumer survey data from the first lockdown period in Denmark, Germany, and Slovenia. Front. Nutr. 2021, 8, 635859. [Google Scholar] [CrossRef] [PubMed]

- Cookie Report—TOP Agency. Available online: https://topagency.com/report/cookie-report/ (accessed on 20 December 2021).

- Canali, G.; Balestra, F.; Glicerina, V.; Pasini, F.; Caboni, M.F.; Romani, S. Influence of different baking powders on physico-chemical, sensory and volatile compounds in biscuits and their impact on textural modifications during soaking. J. Food Sci. Technol. 2020, 57, 3864–3873. [Google Scholar] [CrossRef] [PubMed]

- Romani, S.; Rodriguez-Estrada, M.T. Bakery products and electronic nose. In Electronic Noses and Tongues in Food Science; Academic Press: Oxford, UK, 2016; pp. 39–47. [Google Scholar]

- Drakos, A.; Andrioti-Petropoulou, L.; Evageliou, V.; Mandala, I. Physical and textural properties of biscuits containing jet milled rye and barley flour. J. Food Sci. Technol. 2019, 56, 367–375. [Google Scholar] [CrossRef] [PubMed]

- Konstantas, A.; Stamford, L.; Azapagic, A. Evaluation of environmental sustainability of biscuits at the product and sectoral levels. J. Clean. Prod. 2019, 230, 1217–1228. [Google Scholar] [CrossRef]

- Arepally, D.; Reddy, R.S.; Goswami, T.K.; Datta, A.K. Biscuit baking: A review. LWT Food Sci. Technol. 2020, 131, 109726. [Google Scholar] [CrossRef]

- Caponio, F.; Summo, C.; Delcuratolo, D.; Pasqualone, A. Quality of the lipid fraction of Italian biscuits. J. Sci. Food Agric. 2006, 86, 356–361. [Google Scholar] [CrossRef]

- Cervenka, L.; Brožková, I.; Vytrasová, J. Effects of the principal ingredients of biscuits upon water activity. J. Food Nutr. Res. 2006, 45, 39–43. [Google Scholar]

- Devi, A.; Khatkar, B.S. Physicochemical, rheological and functional properties of fats and oils in relation to cookie quality: A review. J. Food Sci. Technol. 2016, 53, 3633–3641. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Zhang, Y.; Wang, W.; Li, Y. Advanced properties of gluten-free cookies, cakes, and crackers: A review. Trends Food Sci. Technol. 2020, 103, 200–203. [Google Scholar] [CrossRef]

- Pasqualone, A.; Haider, N.N.; Summo, C.; Coldea, T.E.; George, S.S.; Altemimi, A.B. Biscuit Contaminants, Their Sources and Mitigation Strategies: A Review. Foods 2021, 10, 2751. [Google Scholar] [CrossRef] [PubMed]

- Billek, G. Health aspects of thermoxidized oils and fats. Eur. J. Lipid Sci. Technol. 2000, 102, 587–593. [Google Scholar] [CrossRef]

- Balestra, F.; Verardo, V.; Tappi, S.; Caboni, M.F.; Dalla Rosa, M.; Romani, S. Chemical and physical changes during storage of differently packed biscuits formulated with sunflower oil. J. Food Sci. Technol. 2019, 56, 4714–4721. [Google Scholar] [CrossRef] [PubMed]

- Goswami, M.; Sharma, B.D.; Mendiratta, S.K.; Pathak, V. Quality evaluation of functional carabeef cookies incorporated with guar gum (Cyamopsis tetragonoloba) as fat replacer. NFS 2019, 49, 432–440. [Google Scholar] [CrossRef]

- Santiago-García, P.A.; Mellado-Mojica, E.; León-Martínez, F.M.; López, M.G. Evaluation of Agave angustifolia fructans as fat replacer in the cookies manufacture. LWT Food Sci. 2017, 77, 100–109. [Google Scholar] [CrossRef]

- Giarnetti, M.; Paradiso, V.M.; Caponio, F.; Summo, C.; Pasqualone, A. Fat replacement in shortbread cookies using an emulsion filled gel based on inulin and extra virgin olive oil. LWT Food Sci. 2015, 63, 339–345. [Google Scholar] [CrossRef]

- Yashini, M.; Sahana, S.; Hemanth, S.D.; Sunil, C.K. Partially defatted tomato seed flour as a fat replacer: Effect on physicochemical and sensory characteristics of millet-based cookies. J. Food Sci. Technol. 2021, 58, 4530–4541. [Google Scholar] [CrossRef]

- Yalcin, S. Determination of quality characteristic of biscuits including ground yellow poppy seed as fat replacer. Int. J. Second Metab. 2017, 4, 406–411. [Google Scholar] [CrossRef]

- Seker, I.T.; Ozboy-Ozbas, O.; Gokbulut, I.; Ozturk, S.; Koksel, H. Utilization of apricot kernel flour as fat replacer in cookies. J. Food Process. Preserv. 2010, 34, 15–26. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO). Data of Crops Production. 2020. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 21 March 2022).

- Food and Agriculture Organization of the United Nations (FAO). Available online: https://www.fao.org/worldfoodsituation/csdb/en/ (accessed on 21 March 2022).

- Elias, E.M. Durum wheat products. Options Mediterr. 1995, 40, 23–31. [Google Scholar]

- Pasqualone, A. Italian durum wheat breads. In Bread Consumption and Health; Pedrosa Silva Clerici, M.T., Ed.; Nova Science Publisher Inc.: Hauppauge, NY, USA, 2012; pp. 57–79. [Google Scholar]

- Pasqualone, A. Traditional flat breads spread from the Fertile Crescent: Production process and history of baking systems. J. Ethn. Foods 2018, 5, 10–19. [Google Scholar] [CrossRef]

- Consiglio per la Ricerca in Agricoltura e L’analisi Dell’economia Agraria. Available online: https://www.fidaf.it/wp-content/uploads/2020/05/CREA-Considerazioni-grano-duro-CREA-01.08.2016-AGGIORNAMENTO.pdf (accessed on 21 March 2022).

- ISTAT. Available online: http://dati.istat.it/Index.aspx?DataSetCode=DCSP_COLTIVAZIONI (accessed on 21 March 2022).

- ISTAT. Available online: https://www.istat.it/it/files//2021/04/Previsioni-coltivazioni-agricole.pdf (accessed on 20 December 2021).

- Prueckler, M.; Siebenhandl-Ehn, S.; Apprich, S.; Hoeltinger, S.; Haas, C.; Schmid, E.; Kneifel, W. Wheat bran-based biorefinery 1: Composition of wheat bran and strategies of functionalization. LWT Food Sci. Technol. 2014, 56, 211–221. [Google Scholar] [CrossRef]

- Lafiandra, D.; Masci, S.; Sissons, M.; Dornez, E.; Delcour, J.A.; Courtin, C.M.; Caboni, M.F. Kernel components of technological value. In Durum Wheat Chemistry and Technology, 2nd ed.; Sissons, M., Marchylo, B., Abecassis, J., Eds.; AACC International Inc.: St. Paul, MN, USA, 2012; pp. 85–124. [Google Scholar]

- Osorio, L.L.D.R.; Flórez-López, E.; Grande-Tovar, C.D. The Potential of Selected Agri-Food Loss and Waste to Contribute to a Circular Economy: Applications in the Food, Cosmetic and Pharmaceutical Industries. Molecules 2021, 26, 515. [Google Scholar] [CrossRef] [PubMed]

- Squeo, G.; Silletti, R.; Napoletano, G.; Greco Miani, M.; Difonzo, G.; Pasqualone, A.; Caponio, F. Characterization and Effect of Refining on the Oil Extracted from Durum Wheat By-Products. Foods 2022, 11, 683. [Google Scholar] [CrossRef]

- Caponio, F.; Gomes, T.; Pasqualone, A.; Summo, C. Use of the high performance size exclusion chromatography analysis for the measurement of the degree of hydrolytic and oxidative degradation of the lipid fraction of biscuits. Food Chem. 2007, 102, 232–236. [Google Scholar] [CrossRef]

- Pasqualone, A.; Makhlouf, F.Z.; Barkat, M.; Difonzo, G.; Summo, C.; Squeo, G.; Caponio, F. Effect of acorn flour on the physico-chemical and sensory properties of biscuits. Heliyon 2019, 5, e02242. [Google Scholar] [CrossRef] [Green Version]

- Brochard, M.; Correia, P.; Barroca, M.J.; Guiné, R.P. Development of a New Pasta Product by the Incorporation of Chestnut Flour and Bee Pollen. Appl. Sci. 2021, 11, 6617. [Google Scholar] [CrossRef]

- ISO 13299; Sensory Analysis. Methodology. General Guidance for Establishing a Sensory Profile. ISO: Geneva, Switzerland, 2016.

- ISO 11132; Sensory Analysis. Methodology. Guidelines for the Measurement of the Performance of a Quantitative Descriptive Sensory Panel. ISO: Geneva, Switzerland, 2021.

- ISO 8589; Sensory Analysis. General Guidance for the Design of Test Rooms. ISO: Geneva, Switzerland, 2007.

- Szewczyk, K.; Chojnacka, A.; Górnicka, M. Tocopherols and Tocotrienols—Bioactive Dietary Compounds; What Is Certain, What Is Doubt? Int. J. Mol. Sci. 2021, 22, 6222. [Google Scholar] [CrossRef]

- Ghafoor, K.; Özcan, M.M.; AL-Juhaımı, F.; Babıker, E.E.; Sarker, Z.I.; Ahmed, I.A.M.; Ahmed, M.A. Nutritional composition, extraction, and utilization of wheat germ oil: A review. Eur. J. Lipid Sci. Technol. 2017, 119, 1600160. [Google Scholar] [CrossRef]

- Mishra, S.K.; Belur, P.D.; Iyyaswami, R. Use of antioxidants for enhancing oxidative stability of bulk edible oils: A review. Int. J. Food Sci. Technol. 2021, 56, 1–12. [Google Scholar] [CrossRef]

- Buddrick, O.; Jones, O.A.; Morrison, P.D.; Small, D.M. Effect of fermentation and oil incorporation on the retention of E vitamers during breadmaking. Cereal Chem. 2015, 92, 327–331. [Google Scholar] [CrossRef]

- Kamal-Eldin, A. Effect of fatty acids and tocopherols on the oxidative stability of vegetable oils. Eur. J. Lipid Sci. Technol. 2006, 108, 1051–1061. [Google Scholar] [CrossRef]

- Nesaretnam, K.; Yew, W.W.; Wahid, M.B. Tocotrienols and cancer: Beyond antioxidant activity. Eur. J. Lipid Sci. Technol. 2007, 109, 445–452. [Google Scholar] [CrossRef]

- Brigelius-Flohé, R. Bioactivity of vitamin E. Nutr. Res. Rev. 2006, 19, 174–186. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saldeen, K.; Saldeen, T. Importance of tocopherols beyond a tocopherol: Evidence from animal and human studies. Nutr. Res. 2005, 25, 877–889. [Google Scholar] [CrossRef]

- Engelsen, M.M.L.; Hansen, Å. Tocopherol and tocotrienol content in commercial wheat mill streams. Cereal Chem. 2009, 86, 499–502. [Google Scholar] [CrossRef]

- Labuschagne, M.T.; Mkhatywa, N.; Wentzel, B.; Johansson, E.; Van Biljon, A. Tocochromanol concentration, protein composition and baking quality of white flour of South African wheat cultivars. J. Food Comp. Anal. 2014, 33, 127–131. [Google Scholar] [CrossRef]

- Imeneo, V.; Romeo, R.; Gattuso, A.; De Bruno, A.; Piscopo, A. Functionalized Biscuits with Bioactive Ingredients Obtained by Citrus Lemon Pomace. Foods 2021, 10, 2460. [Google Scholar] [CrossRef]

- Sharif, M.K.; Butt, M.S.; Anjum, F.M.; Nasir, M.; Minhas, R.; Qayyum, M.N. Extension of cookies shelf life by using rice bran oil. Int. J. Agric. Biol. 2003, 5, 455. [Google Scholar]

- Caponio, F.; Pasqualone, A.; Gomes, T. Effects of conventional and microwave heating on the degradation of olive oil. Eur. Food Res. Technol. 2002, 215, 114–117. [Google Scholar] [CrossRef]

- Zhao, Z.; Huang, J.; Jin, Q.; Wang, X. Influence of oryzanol and tocopherols on thermal oxidation of rice bran oil during the heating process at Chinese cooking temperatures. LWT Food Sci. 2021, 142, 111022. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, L.; Li, Y.; Zhang, N.; Gao, Y.; Yu, X. The formation, determination and health implications of polar compounds in edible oils: Current status, challenges and perspectives. Food Chem. 2021, 364, 130451. [Google Scholar] [CrossRef]

- Caponio, F.; Giarnetti, M.; Summo, C.; Gomes, T. Influence of the different oils used in dough formulation on the lipid fraction of taralli. J. Food Sci. 2011, 76, 549–554. [Google Scholar] [CrossRef] [PubMed]

- Pasqualone, A.; Bianco, A.M.; Paradiso, V.M.; Summo, C.; Gambacorta, G.; Caponio, F.; Blanco, A. Production and characterization of functional biscuits obtained from purple wheat. Food Chem. 2015, 180, 64–70. [Google Scholar] [CrossRef] [PubMed]

- Kishimoto, N. Evaluation of Photooxidation of Olive Oil by Determining the Concentration of Hexanal as an Oxidative Marker Using an Electronic Nose. Chem. Eng. Trans. 2021, 85, 181–186. [Google Scholar]

- Pripis-Nicolau, L.; De Revel, G.; Bertrand, A.; Maujean, A. Formation of flavor components by the reaction of amino acid and carbonyl compounds in mild conditions. J. Agric. Food Chem. 2000, 48, 3761–3766. [Google Scholar] [CrossRef]

- Kyacier, A.; Singh, R.K. Effect of mono-and diglyceride addition on baked tortilla chips and their storage properties. J. Food Proc. Pres. 2003, 2, 1–8. [Google Scholar] [CrossRef]

- Kara, H.H.; Yasemin, B.O.R. A review on: Production, usage, health effect and analysis of mono-and di-glyceride of fatty acids. J. Halal Ethical Res. 2019, 1, 40–47. [Google Scholar]

- Li, S.; Wu, G.; Jin, Q.; Wang, X.; Zhang, H. Relationship between the microstructure and physical properties of emulsifier based oleogels and cookies quality. Food Chem. 2022, 377, 131966. [Google Scholar] [CrossRef]

- Guiné, R.P.; Souta, A.; Gürbüz, B.; Almeida, E.; Lourenço, J.; Marques, L.; Pereira, R.; Gomes, R. Textural properties of newly developed cookies incorporating whey residue. J. Culin. Sci. Technol. 2020, 18, 317–332. [Google Scholar] [CrossRef]

- Li, S.; Wu, G.; Li, X.; Jin, Q.; Wang, X.; Zhang, H. Roles of gelator type and gelation technology on texture and sensory properties of cookies prepared with oleogels. Food Chem. 2021, 356, 129667. [Google Scholar] [CrossRef] [PubMed]

- Pasqualone, A.; Laddomada, B.; Boukid, F.; Angelis, D.D.; Summo, C. Use of Almond Skins to Improve Nutritional and Functional Properties of Biscuits: An Example of Upcycling. Foods 2020, 9, 1705. [Google Scholar] [CrossRef] [PubMed]

- Boukid, F.; Folloni, S.; Ranieri, R.; Vittadini, E. A compendium of wheat germ: Separation, stabilization and food applications. Trends Food Sci. Technol. 2018, 78, 120–133. [Google Scholar] [CrossRef]

| Ingredients | C (g) | D50 (g) | D100 (g) |

|---|---|---|---|

| Wheat flour | 400 | 400 | 400 |

| Sunflower oil | 112 | 56 | − |

| Durum wheat oil | − | 56 | 112 |

| Sugar | 112 | 112 | 112 |

| Partially skimmed milk | 128 | 128 | 128 |

| Baking powder | 4.8 | 4.8 | 4.8 |

| Descriptor | Definition | Scale Anchors | |

|---|---|---|---|

| Min = 0 (c.u.) * | Max = 10 (c.u.) | ||

| Visual–tactile characteristics | |||

| Porosity | Presence of pores | Absent | Very intense |

| The way the biscuit fractures when broken by fingers | Breaks with difficulty | Crumbly, breaks easily | |

| Breakability | The way the biscuit fractures when broken by fingers | Breaks with difficulty | Crumbly, breaks easily |

| Odor notes | |||

| Caramel | Typical odor associated with caramel | Absent | Very intense |

| Oxidized oil | Typical odor associated with oxidized oil | Absent | Very intense |

| Shortbread | Typical odor associated with biscuits | Absent | Very intense |

| Sample | Tocopherols (mg/kg) | Tocotrienols (mg/kg) |

|---|---|---|

| Oils | ||

| Sunflower oil | 677.9 ± 7.1 a | 7.4 ± 1.4 b |

| Durum wheat oil | 305.6 ± 7.6 b ** | 1119.6 ± 19.5 a ** |

| Biscuits | ||

| C | 601.8 ± 10.1 a | 64.1 ± 11.8 c |

| D50 | 418.9 ± 11.1 b | 635.2 ± 38.7 b |

| D100 | 280.6 ± 8.3 c | 982.9 ± 11.2 a |

| Sample | IT * (h) |

|---|---|

| Oils | |

| Sunflower oil | 31.50 ± 0.42 b |

| Durum wheat oil | 39.80 ± 0.09 a |

| Biscuits | |

| C | 53.61 ± 1.87 c |

| D50 | 70.87 ± 2.94 b |

| D100 | 79.92 ± 2.21 a |

| Compound (g/kg) | Sample Type | ||

|---|---|---|---|

| C | D50 | D100 | |

| TAGP | 0.43 ± 0.03 a | 0.31 ± 0.02 b | 0.17 ± 0.02 c |

| ox-TAG | 3.52 ± 0.13 a | 2.63 ± 0.43 b | 1.81 ± 0.19 b |

| DG | 1.30 ± 0.02 c | 3.03 ± 0.05 b | 4.93 ± 0.17 a |

| Volatile Compounds (µg/g) | Sample Type | ||

|---|---|---|---|

| C | D50 | D100 | |

| Aldehydes | |||

| Hexanal | 40.88 ± 0.49 a | 33.53 ± 0.26 b | 25.97 ± 1.06 c |

| Hexenal | 5.38 ± 0.35 a | 2.20 ± 0.11 b | 2.52 ± 0.31 b |

| 2-Heptenal | 4.69 ± 0.17 a | 2.83 ± 0.03 b | 0.42 ± 0.16 c |

| Nonanal | 11.83 ± 0.61 a | 6.36 ± 0.36 b | 6.38 ± 0.22 b |

| 2-Methylbutanal | 10.26 ± 0.23 b | 13.92 ± 1.42 a | 16.88 ± 0.41 a |

| 3-Methylbutanal | 17.71 ± 0.86 b | 25.41 ± 0.77 a | 27.03 ± 0.89 a |

| Benzaldehyde | 4.85 ± 0.38 b | 7.12 ± 0.92 a | 7.24 ± 0.15 a |

| Furan compounds | |||

| 2-Furanmethanol | 4.60 ± 0.51 b | 8.78 ± 0.74 a | 9.95 ± 0.68 a |

| 2-Furancarboxaldehyde (furfural) | 3.67 ± 0.25 b | 5.41 ± 1.99 ab | 8.60 ± 0.44 a |

| Pyrazines | |||

| Pyrazine | 8.27 ± 1.19 b | 13.10 ± 0.13 a | 13.15 ± 0.20 a |

| Methyl-pyrazine | 30.79 ± 1.31 b | 30.90 ± 1.82 b | 44.19 ± 1.71 a |

| Ethyl-pyrazine | 7.08 ± 1.21 b | 6.15 ± 0.48 b | 10.53 ± 0.17 a |

| Parameter | Sample Type | ||

|---|---|---|---|

| C | D50 | D100 | |

| Color | |||

| a* | 6.20 ± 0.32 a | 7.04 ± 0.68 a | 7.04 ± 0.52 a |

| b* | 33.33 ± 1.51 a | 32.47 ± 0.30 a | 34.56 ± 1.40 a |

| L* | 74.16 ± 1.63 a | 73.96 ± 0.52 a | 73.37 ± 1.43 a |

| ∆E | - | 1.23 | 1.46 |

| Texture | |||

| Hardness (N) | 19.10 ± 0.45 a | 18.70 ± 0.51 a | 16.62 ± 0.53 b |

| Dimensional variations during baking | |||

| Thickness increase (mm) | 7.5 ± 0.5 a | 7.0 ± 0.5 a | 7.2 ± 0.6 a |

| Length increase (mm) | 1.5 ± 0.1 a | 1.2 ± 0.3 a | 1.5 ± 0.1 a |

| Width increase (mm) | 2.0 ± 0.1 a | 1.5 ± 0.5 a | 1.7 ± 0.6 a |

| Sensory Descriptor (c.u.) * | Sample Type | ||

|---|---|---|---|

| C | D50 | D100 | |

| Visual–tactile characteristics | |||

| Porosity | 4.2 ± 0.4 a | 4.4 ± 0.2 a | 5.2 ± 0.5 a |

| Breakability | 3.5 ± 0.2 b | 4.3 ± 0.4 a | 5.1 ± 0.3 a |

| Odor notes | |||

| Caramel | 0.6 ± 0.2 a | 0.7 ± 0.2 a | 0.7 ± 0.1 a |

| Oxidized oil | 0.1 ± 0.1 a | 0.0 ± 0.0 a | 0.0 ± 0.0 a |

| Shortbread | 7.6 ± 0.5 a | 7.3 ± 0.5 a | 6.6 ± 0.7 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vurro, F.; Greco Miani, M.; Summo, C.; Caponio, F.; Pasqualone, A. Effect of Durum Wheat Oil on the Physico-Chemical and Sensory Features of Biscuits. Foods 2022, 11, 1282. https://doi.org/10.3390/foods11091282

Vurro F, Greco Miani M, Summo C, Caponio F, Pasqualone A. Effect of Durum Wheat Oil on the Physico-Chemical and Sensory Features of Biscuits. Foods. 2022; 11(9):1282. https://doi.org/10.3390/foods11091282

Chicago/Turabian StyleVurro, Francesca, Marcello Greco Miani, Carmine Summo, Francesco Caponio, and Antonella Pasqualone. 2022. "Effect of Durum Wheat Oil on the Physico-Chemical and Sensory Features of Biscuits" Foods 11, no. 9: 1282. https://doi.org/10.3390/foods11091282

APA StyleVurro, F., Greco Miani, M., Summo, C., Caponio, F., & Pasqualone, A. (2022). Effect of Durum Wheat Oil on the Physico-Chemical and Sensory Features of Biscuits. Foods, 11(9), 1282. https://doi.org/10.3390/foods11091282