Mineral Composition in Delactosed Dairy Products: Quality and Safety Status

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Collection

2.2. Sample Preparation

2.3. Instrumentation

2.4. Multielement Analysis by ICP-MS

3. Results

3.1. Method Validation

3.2. Element Contents in Commercial Delactosed Dairy Products from Different Varieties

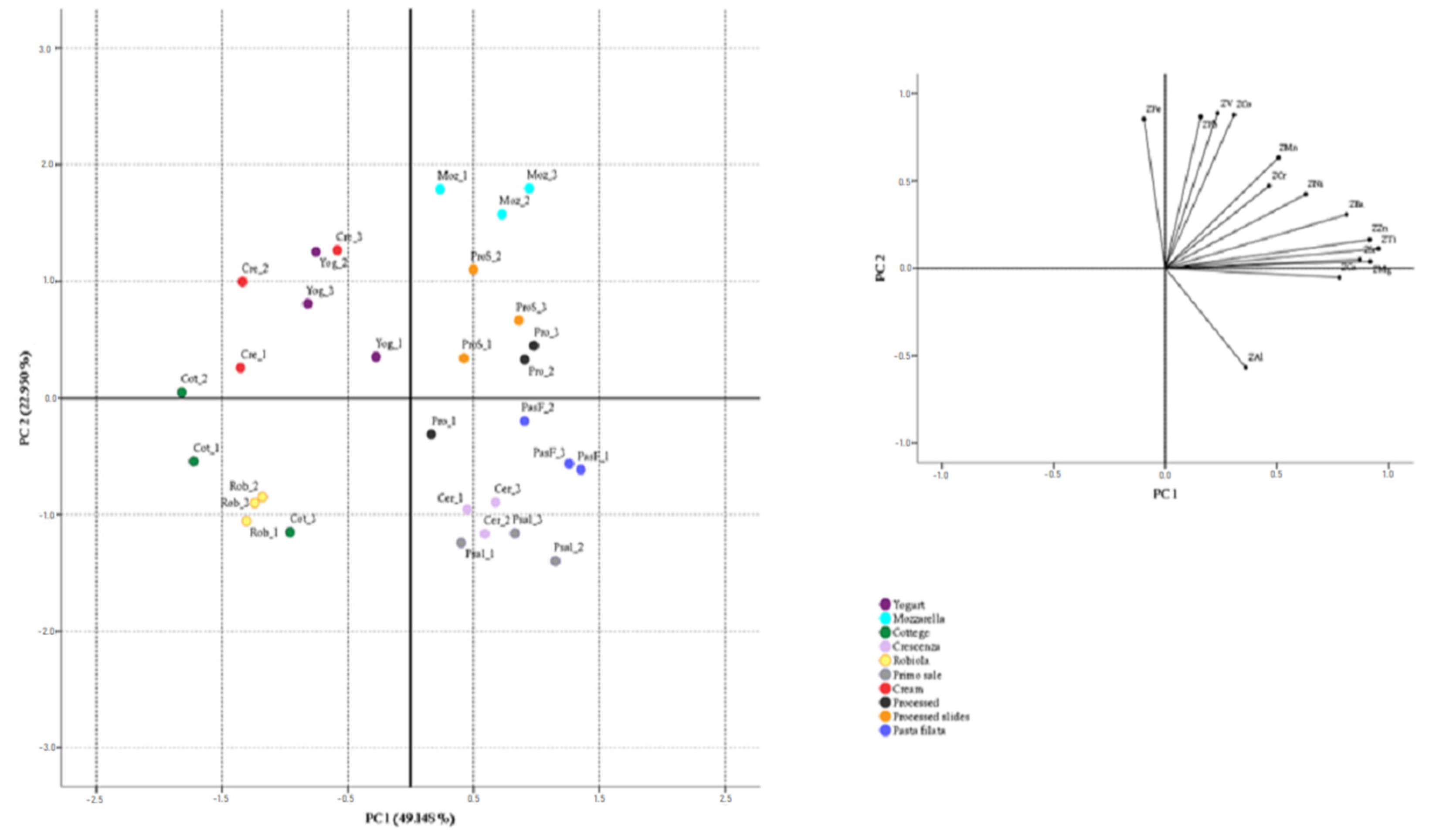

3.3. Principal Component Analysis

3.4. Elements Uptake by Delactosed Dairy Products

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rizzoli, R. Dairy products, yogurts, and bone health. Am. J. Clin. Nutr. 2014, 99, 1256S–1262S. [Google Scholar] [CrossRef] [Green Version]

- Bonjour, J.-P. Dietary protein: An essential nutrient for bone health. J. Am. Coll. Nutr. 2005, 24, 526S–536S. [Google Scholar] [CrossRef] [PubMed]

- Zhu, K.; Prince, R.L. Calcium and bone. Clin. Biochem. 2012, 45, 936–942. [Google Scholar] [CrossRef]

- Promislow, J.H.; Hertz-Picciotto, I.; Schramm, M.; Watt-Morse, M.; Anderson, J.J. Bed rest and other determinants of bone loss during pregnancy. Am. J. Obstet. Gynecol. 2004, 191, 1077–1083. [Google Scholar] [CrossRef]

- Zamberlin, Š.; Antunac, N.; Havranek, J.; Samaržija, D. Mineral elements in milk and dairy products. Mljekarstvo Časopis Unaprjeđenje Proizv. I Prerade Mlijeka 2012, 62, 111–125. [Google Scholar]

- Licata, P.; Di Bella, G.; Potortì, A.; Lo Turco, V.; Salvo, A.; Dugo, G.M. Determination of trace elements in goat and ovine milk from Calabria (Italy) by ICP-AES. Food Addit. Contam. Part B 2012, 5, 268–271. [Google Scholar] [CrossRef] [PubMed]

- Tomar, B.S. Lactose intolerance and other disaccharidase deficiency. Indian J. Pediatr. 2014, 81, 876–880. [Google Scholar] [CrossRef] [PubMed]

- Silanikove, N.; Leitner, G.; Merin, U. The interrelationships between lactose intolerance and the modern dairy industry: Global perspectives in evolutional and historical backgrounds. Nutrients 2015, 7, 7312–7331. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Adegboye, A.R.; Christensen, L.B.; Holm-Pedersen, P.; Avlund, K.; Boucher, B.J.; Heitmann, B.L. Intake of dairy products in relation to periodontitis in older Danish adults. Nutrients 2012, 4, 1219–1229. [Google Scholar] [CrossRef] [Green Version]

- Di Bella, G.; Naccari, C.; Bua, G.D.; Rastrelli, L.; Lo Turco, V.; Potortì, A.G.; Dugo, G. Mineral composition of some varieties of beans from Mediterranean and Tropical areas. Int. J. Food Sci. Nutr. 2016, 67, 239–248. [Google Scholar] [CrossRef]

- Di Bella, G.; Potortì, A.G.; Beltifa, A.; Ben Mansour, H.; Nava, V.; Lo Turco, V. Discrimination of Tunisian honey by mineral and trace element chemometrics profiling. Foods 2021, 10, 724. [Google Scholar] [CrossRef] [PubMed]

- Lo Turco, V.; Potortì, A.G.; Tropea, A.; Dugo, G.; Di Bella, G. Element analysis of dried figs (Ficus carica L.) from the Mediterranean areas. J. Food Compos. Anal. 2020, 90, 103503. [Google Scholar] [CrossRef]

- Potortί, A.G.; Bua, G.D.; Lo Turco, V.; Ben Tekaya, A.; Belfita, A.; Ben Mansour, H.; Dugo, G.; Di Bella, G. Major, minor and trace element concentrations in spices and aromatic herbs from Sicily (Italy) and Mahdia (Tunisia) by ICP-MS and multivariate analysis. Food Chem. 2020, 313, 126094. [Google Scholar] [CrossRef]

- EURACHEM. Guide, 2nd ed.; Ellison, S.L.R., Rosslein, M., Williams, A., Eds.; 2000; Available online: https://aqs.iswa.uni-stuttgart.de/pdf/quam2000-p1.pdf (accessed on 28 November 2021).

- Barone, G.; Dambrosio, A.; Storelli, A.; Busco, A.; Ioanna, F.; Quaglia, N.C.; Giacominelli-Stuffler, R.; Storelli, M.M. Traditional Italian cheeses: Trace element levels and estimation of dietary intake. J. Food Compos. Anal. 2018, 66, 205–211. [Google Scholar] [CrossRef]

- Khan, N.; Choi, J.Y.; Nho, E.Y.; Hwang, I.M.; Habte, G.; Khan, M.A.; Park, K.S.; Kim, K.S. Determination of mineral elements in milk products by inductively coupled plasma-optical emission spectrometry. Anal. Lett. 2014, 47, 1606–1613. [Google Scholar] [CrossRef]

- Cashman, K. Trace elements, Nutritional Significance. In Encyclopedia of Dairy Sciences, No 3; Roginski, H., Fuquay, J.W., Fox, P.F., Eds.; Academic Press: London, UK, 2002. [Google Scholar]

- Commission Regulation (EC) No 1881/2006 of 19 December 2006 setting maximum levels for certain contaminants in foodstuffs. Off. J. Eur. 2006, L364, 5–24. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2006:364:0005:0024:EN:PDF (accessed on 28 November 2021).

- EFSA (European Food Safety Authority). Opinion of the scientific panel on dietetic products, nutrition and allergies on a request from the commission related to the tolerable upper intake level of sodium. EFSA J. 2005, 209, 1–26. [Google Scholar]

- European Communities Commission. Commission Directive 2008/100/EC of 28 October 2008 Amending Council Directive 90/496. In EEC on Nutrition Labelling for Foodstuffs as Regards Recommended Daily Allowances, Energy Conversion Factors and Definitions; 2008. Available online: https://efsa.onlinelibrary.wiley.com/doi/pdf/10.2903/j.efsa.2008.754 (accessed on 28 November 2021).

- EFSA. Safety of aluminium from dietary intake. Scientific Opinion of the Panel on Food Additives, Flavourings, Processing Aids and Food Contact Materials on a request from the European Commission on safety of aluminium from dietary intake. EFSA J. 2008, 754, 1–34. [Google Scholar]

- EFSA (European Food Safety Authority). Scientific opinion on arsenic in food. EFSA J. 2009, 7, 1–199. [Google Scholar]

- EFSA (European Food Safety Authority). Scientific opinion on lead in food. EFSA J. 2010, 8, 1–151. [Google Scholar]

- EFSA (European Food Safety Authority). Cadmium dietary exposure in the European population. EFSA J. 2012, 10, 1–37. [Google Scholar]

- EFSA (European Food Safety Authority). Scientific Opinion on the risk for public health related to the presence of mercury and methylmercury in food. EFSA J. 2012, 10, 2985. [Google Scholar]

- WHO (World Health Organization). Nickel in Drinking-Water. Background Document for Development of WHO Guidelines for Drinking-Water Quality. 2005. Available online: http://www.who.int/water_sanitation_health/gdwqrevision/nickel2005.pdf (accessed on 28 November 2021).

| Step | Time | Temperature | Microwave Power |

|---|---|---|---|

| 1 | 15 min | 0–180 °C | 1100 W |

| 2 | 15 min | 180 °C | 1100 W |

| 3 | 20 min | Cooling |

| Spectrometer | iCAP Q Thermo Scientific with Qcell Reaction System |

|---|---|

| Nebulizer | Concentric PFA |

| RF generator | 1550 W |

| Sample depth | 5 mm |

| Interface | Sample and skimmer cones in Ni |

| Interface pressure | 1.89 × 10+00 Pa |

| Argon flow (plasma/ausiliario/carrier) | 14/0.8/1.1 L/min |

| Sample introduction Flow | 0.93 mL/min |

| Scanning condition | Number of replicates: 3, dwell time: 1 s |

| CCT gas flow (He) | 4.7 mL/min |

| Vacuum | <7, 5 × 10−7 Pa |

| Extract Lens 1 Voltage | 1.5 V |

| Spray chamber temperature | 2.7 °C |

| SKIMMED MILK POWDER ERM-BD150 (mg/kg) | ||||||

|---|---|---|---|---|---|---|

| Element | LOD (μg/kg) | LOQ (μg/kg) | R2 | Experimental Value | Expected Value | Recovery (%) |

| Li | 0.003 | 0.010 | 0.9998 | 1.90 * | 2.00 * | 95.00 |

| Be | 0.005 | 0.017 | 0.9997 | 1.92 * | 2.00 * | 96.00 |

| B | 0.003 | 0.010 | 0.9997 | 1.89 * | 2.00 * | 94.50 |

| Na | 1.323 | 4.366 | 0.9975 | 3565 | 4180 | 85.29 |

| Mg | 0.037 | 0.122 | 0.9991 | 1197 | 1260 | 95.00 |

| Al | 0.081 | 0.267 | 0.9995 | 1.91 * | 2.00 * | 95.50 |

| K | 0.221 | 0.729 | 0.9972 | 15,106 | 17,000 | 88.86 |

| Ti | 0.001 | 0.003 | 0.9997 | 2.02 * | 2.00 * | 101.00 |

| V | 0.001 | 0.003 | 0.9998 | 2.01 * | 2.00 * | 100.50 |

| Cr | 0.001 | 0.003 | 0.9997 | 1.97 * | 2.00 * | 98.50 |

| Mn | 0.001 | 0.003 | 0.9998 | 0.285 | 0.289 | 98.62 |

| Fe | 0.014 | 0.046 | 0.9997 | 4.35 | 4.60 | 94.57 |

| Co | 0.001 | 0.003 | 0.9998 | 2.02 * | 2.00 * | 101.00 |

| Ni | 0.018 | 0.054 | 0.9998 | 1.96 * | 2.00 * | 98.00 |

| Cu | 0.015 | 0.050 | 0.9973 | 1.03 | 1.08 | 95.37 |

| Zn | 0.057 | 0.188 | 0.9982 | 43.95 | 44.80 | 98.10 |

| As | 0.001 | 0.003 | 0.9997 | 2.00 * | 2.00 * | 100.00 |

| Se | 0.062 | 0.205 | 0.9980 | 0.179 | 0.188 | 95.21 |

| Sr | 0.004 | 0.013 | 0.9998 | 1.98 * | 2.00 * | 99.00 |

| Mo | 0.002 | 0.007 | 0.9997 | 2.01 * | 2.00 * | 100.50 |

| Ag | 0.001 | 0.003 | 0.9997 | 1.98 * | 2.00 * | 99.00 |

| Cd | 0.001 | 0.003 | 0.9997 | 0.0108 | 0.0114 | 94.74 |

| Sb | 0.001 | 0.003 | 0.9998 | 1.92 * | 2.00 * | 96.00 |

| Ba | 0.002 | 0.007 | 0.9997 | 1.95 * | 2.00 * | 97.50 |

| Tl | 0.001 | 0.003 | 0.9997 | 1.92 * | 2.00 * | 96.00 |

| Pb | 0.001 | 0.003 | 0.9998 | 0.018 | 0.019 | 94.74 |

| Bi | 0.001 | 0.003 | 0.9997 | 1.97 * | 2.00 * | 98.50 |

| Hg * | 0.001 | 0.003 | 0.9997 | 0.061 | 0.060 | 101.67 |

| Yogurt (n = 3) | Cottage (n = 3) | Crescenza (n = 3) | Robiola (n = 3) | Primo Sale (n = 3) | Cream (n = 3) | Processed (n = 3) | Processed Slices (n = 3) | Pasta Filata (n = 3) | Mozzarella (n = 3) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | S.D. | Mean | S.D. | Mean | S.D. | Mean | S.D. | Mean | S.D. | Mean | S.D. | Mean | S.D. | Mean | S.D. | Mean | S.D. | Mean | S.D. | |

| Ca | 1223 | 25.2 | 2843 | 121.0 | 3567 | 58.6 | 807 | 51.6 | 4250 | 90.0 | 1114 | 132.6 | 3799 | 235.3 | 6011 | 116.8 | 6145 | 126.8 | 3700 | 180.3 |

| Na | 657 | 144.8 | 3217 | 231.8 | 3067 | 61.5 | 3144 | 368.8 | 4117 | 1732.6 | 3344 | 417.6 | 9461 | 851.1 | 10,473 | 802.6 | 4722 | 818.4 | 2495 | 447.2 |

| K | 213 | 6.6 | 95 | 18.6 | 170 | 18.3 | 197 | 28.2 | 252 | 13.6 | 193 | 17.0 | 221 | 36.0 | 98 | 5.9 | 194 | 21.3 | 65 | 14.4 |

| Mg | 31.42 | 13.94 | 11.05 | 3.87 | 36.66 | 6.89 | 13.17 | 2.50 | 46.74 | 10.37 | 20.09 | 10.22 | 33.72 | 8.39 | 45.49 | 8.80 | 93.84 | 10.24 | 40.74 | 18.62 |

| Fe | 2.58 | 1.12 | 0.38 | 0.28 | 0.36 | 0.12 | 0.52 | 0.24 | 0.04 | 0.02 | 1.12 | 0.26 | 0.24 | 0.12 | 2.29 | 1.04 | 0.61 | 0.25 | 6.94 | 1.45 |

| Al | 0.43 | 0.24 | 0.25 | 0.18 | 0.57 | 0.08 | 0.55 | 0.13 | 0.34 | 0.12 | 0.16 | 0.09 | 0.48 | 0.22 | 0.43 | 0.27 | 0.86 | 0.09 | 0.13 | 0.01 |

| Zn | 0.33 | 0.10 | 0.40 | 0.26 | 1.31 | 0.04 | 0.26 | 0.15 | 1.64 | 0.63 | 0.46 | 0.27 | 2.42 | 1.36 | 1.47 | 0.19 | 2.07 | 0.33 | 3.61 | 0.92 |

| Ti | 0.75 | 0.17 | 0.26 | 0.06 | 1.61 | 0.38 | 0.31 | 0.06 | 2.15 | 0.84 | 0.47 | 0.19 | 1.12 | 0.13 | 2.08 | 0.49 | 2.33 | 0.47 | 1.89 | 0.52 |

| Sr | 0.14 | 0.06 | 0.03 | 0.02 | 0.63 | 0.20 | 0.12 | 0.02 | 0.30 | 0.06 | 0.13 | 0.05 | 0.41 | 0.18 | 0.30 | 0.03 | 0.46 | 0.06 | 0.49 | 0.31 |

| Mn | 0.043 | 0.015 | 0.027 | 0.015 | 0.047 | 0.009 | 0.022 | 0.013 | 0.039 | 0.008 | 0.037 | 0.023 | 0.061 | 0.035 | 0.343 | 0.422 | 0.049 | 0.025 | 0.191 | 0.069 |

| Ba | 0.027 | 0.012 | 0.005 | 0.003 | 0.040 | 0.010 | 0.011 | 0.004 | 0.036 | 0.018 | 0.014 | 0.012 | 0.037 | 0.003 | 0.108 | 0.014 | 0.083 | 0.029 | 0.206 | 0.130 |

| Ni | 0.016 | 0.003 | 0.008 | 0.004 | 0.009 | 0.001 | 0.012 | 0.002 | 0.026 | 0.009 | 0.014 | 0.006 | 0.042 | 0.011 | 0.018 | 0.008 | 0.023 | 0.006 | 0.051 | 0.025 |

| Cd | 0.018 | 0.008 | 0.028 | 0.024 | 0.018 | 0.003 | 0.025 | 0.005 | 0.029 | 0.013 | 0.016 | 0.006 | 0.020 | 0.003 | 0.010 | 0.001 | 0.010 | 0.000 | 0.023 | 0.003 |

| V | 0.009 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.000 | 0.001 | 0.001 | 0.005 | 0.003 | 0.004 | 0.003 | 0.011 | 0.001 | 0.004 | 0.004 | 0.016 | 0.005 |

| Cr | 0.010 | 0.002 | 0.007 | 0.003 | 0.018 | 0.002 | n.d. | - | 0.003 | 0.001 | 0.014 | 0.008 | 0.043 | 0.030 | 0.012 | 0.008 | 0.017 | 0.006 | 0.021 | 0.009 |

| Co | 0.002 | 0.001 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 0.001 | 0.001 | 0.001 | 0.001 | 0.003 | 0.001 | 0.001 | 0.000 | 0.004 | 0.001 |

| Pb | 0.002 | 0.001 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 0.005 | 0.002 | 0.004 | 0.003 | 0.003 | 0.001 | n.d. | - | 0.009 | 0.005 |

| As | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 0.001 | 0.000 | 0.001 | 0.001 | 0.002 | 0.001 | n.d. | - | 0.002 | 0.001 |

| Hg | n.d. | - | 0.010 | 0.002 | 0.012 | 0.003 | 0.005 | 0.001 | 0.003 | 0.001 | 0.007 | 0.003 | 0.016 | 0.004 | 0.006 | 0.004 | 0.031 | 0.009 | 0.010 | 0.002 |

| Se | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 0.036 | * | 0.018 | 0.008 | n.d | - | n.d. | - | 0.069 | 0.027 |

| Cu | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 0.109 | * | 0.051 | 0.019 | n.d. | - | n.d. | - | 0.241 | 0.086 |

| Yogurt | Cottage | Crescenza | Robiola | Primo Sale | Cream | Processed | Processed | Pasta Filata | Mozzarella | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B | |

| Ca | 19% | 27% | 36% | 8% | 43% | 6% | 10% | 21% | 35% | 58% | ||||||||||

| Na | 5.5% | 16.1% | 16.4% | 16.8% | 22.0% | 8.9% | 12.9% | 20.0% | 14.2% | 20.8% | ||||||||||

| K | 1.3% | 0.4% | 0.7% | 0.8% | 1.0% | 0.4% | 0.2% | 0.1% | 0.4% | 0.4% | ||||||||||

| Mg | 1.0% | 0.2% | 0.8% | 0.3% | 1.0% | 0.2% | 0.2% | 0.3% | 1.1% | 1.4% | ||||||||||

| Fe | 2.31% | 0.20% | 0.20% | 0.30% | 0.02% | 0.32% | 0.03% | 0.47% | 0.20% | 6.19% | ||||||||||

| Zn | 0.4% | 0.3% | 1.0% | 0.2% | 1.3% | 0.2% | 0.5% | 0.4% | 0.9% | 4.5% | ||||||||||

| Mn | 0.3% | 0.1% | 0.2% | 0.1% | 0.2% | 0.1% | 0.1% | 0.5% | 0.1% | 1.2% | ||||||||||

| Cr | 3.2% | 1.3% | 3.6% | n.a. | 0.5% | 1.4% | 2.2% | 0.9% | 1.9% | 6.7% | ||||||||||

| Se | n.a. | n.a. | n.a. | n.a. | 2.6% | 0.7% | n.a. | n.a. | 15.8% | |||||||||||

| Cu | n.a. | n.a. | n.a. | n.a. | 0.4% | 0.1% | n.a. | n.a. | 3.0% | |||||||||||

| Al | 88.61% | |||||||||||||||||||

| Ni | 0.15% | 0.04% | 0.05% | 0.07% | 0.16% | 0.04% | 0.07% | 0.04% | 0.08% | 0.48% | ||||||||||

| Cd | 1.5% | 1.4% | 0.9% | 1.3% | 1.5% | 0.4% | 0.3% | 0.2% | 0.3% | 1.9% | ||||||||||

| Pb | 0.7% | n.a. | n.a. | n.a. | n.a. | 0.6% | 0.3% | 0.3% | n.a. | 3.6% | ||||||||||

| As | n.a. | n.a. | n.a. | n.a. | n.a. | 0.2% | 0.2% | 0.3% | n.a. | 1.2% | ||||||||||

| Hg | n.a. | 0.3% | 0.4% | 0.2% | 0.1% | 0.1% | 0.1% | 0.1% | 0.6% | 0.5% | ||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Crupi, R.; Lo Turco, V.; Gugliandolo, E.; Nava, V.; Potortì, A.G.; Cuzzocrea, S.; Di Bella, G.; Licata, P. Mineral Composition in Delactosed Dairy Products: Quality and Safety Status. Foods 2022, 11, 139. https://doi.org/10.3390/foods11020139

Crupi R, Lo Turco V, Gugliandolo E, Nava V, Potortì AG, Cuzzocrea S, Di Bella G, Licata P. Mineral Composition in Delactosed Dairy Products: Quality and Safety Status. Foods. 2022; 11(2):139. https://doi.org/10.3390/foods11020139

Chicago/Turabian StyleCrupi, Rosalia, Vincenzo Lo Turco, Enrico Gugliandolo, Vincenzo Nava, Angela Giorgia Potortì, Salvatore Cuzzocrea, Giuseppa Di Bella, and Patrizia Licata. 2022. "Mineral Composition in Delactosed Dairy Products: Quality and Safety Status" Foods 11, no. 2: 139. https://doi.org/10.3390/foods11020139

APA StyleCrupi, R., Lo Turco, V., Gugliandolo, E., Nava, V., Potortì, A. G., Cuzzocrea, S., Di Bella, G., & Licata, P. (2022). Mineral Composition in Delactosed Dairy Products: Quality and Safety Status. Foods, 11(2), 139. https://doi.org/10.3390/foods11020139