Influences of Smoking in Traditional and Industrial Conditions on Flavour Profile of Harbin Red Sausages by Comprehensive Two-Dimensional Gas Chromatography Mass Spectrometry

Abstract

1. Introduction

2. Materials and Methods

2.1. Sausage Preparation

2.2. Moisture Content

2.3. Colour

2.4. Texture Profile Analysis

2.5. Sensory Analysis

2.6. Volatile Compound Analysis

2.7. Statistical Analysis

3. Results

3.1. Moisture Content

3.2. Colour Measurement

3.3. Texture Profile Analysis (TPA)

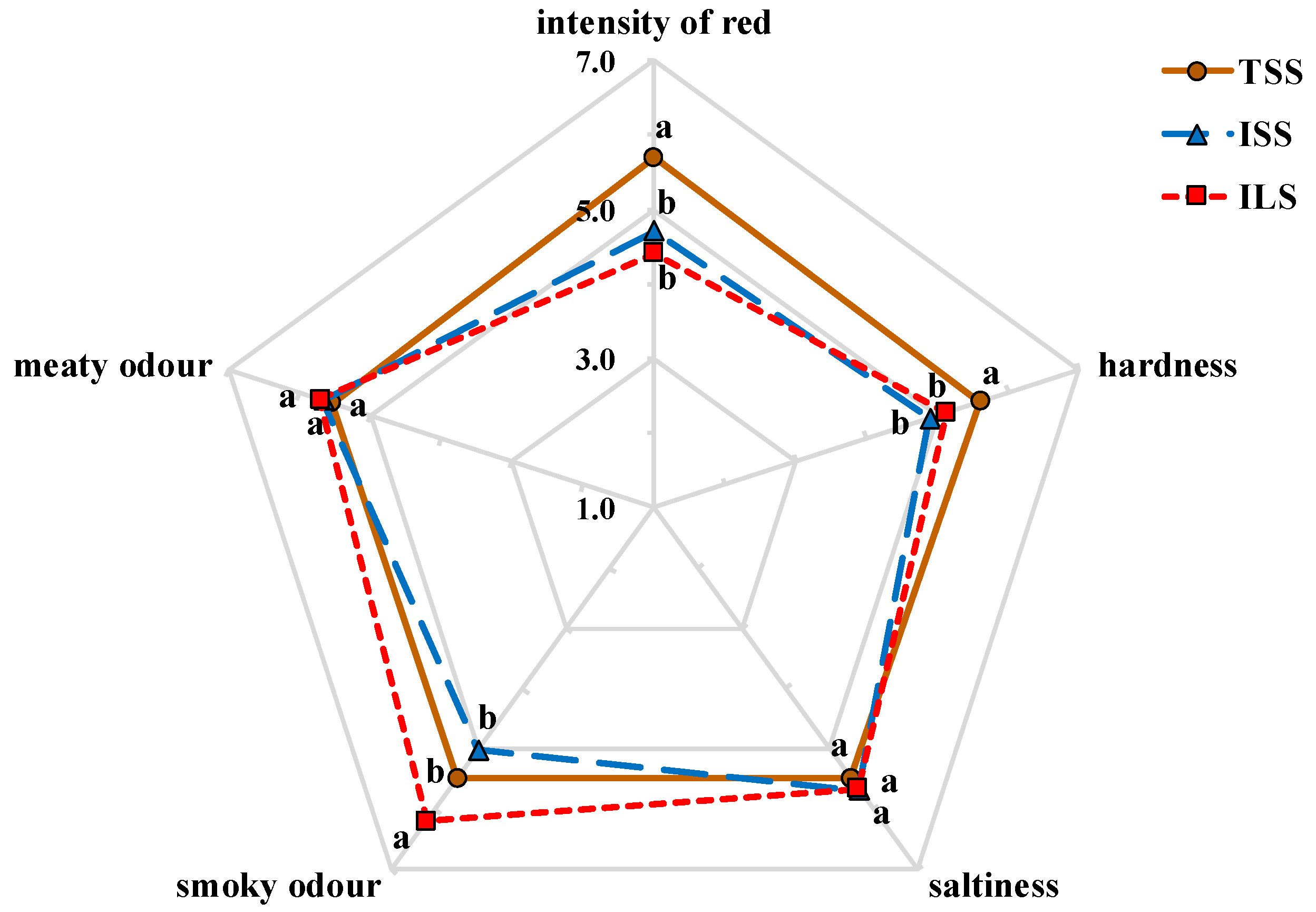

3.4. Sensory Evaluation

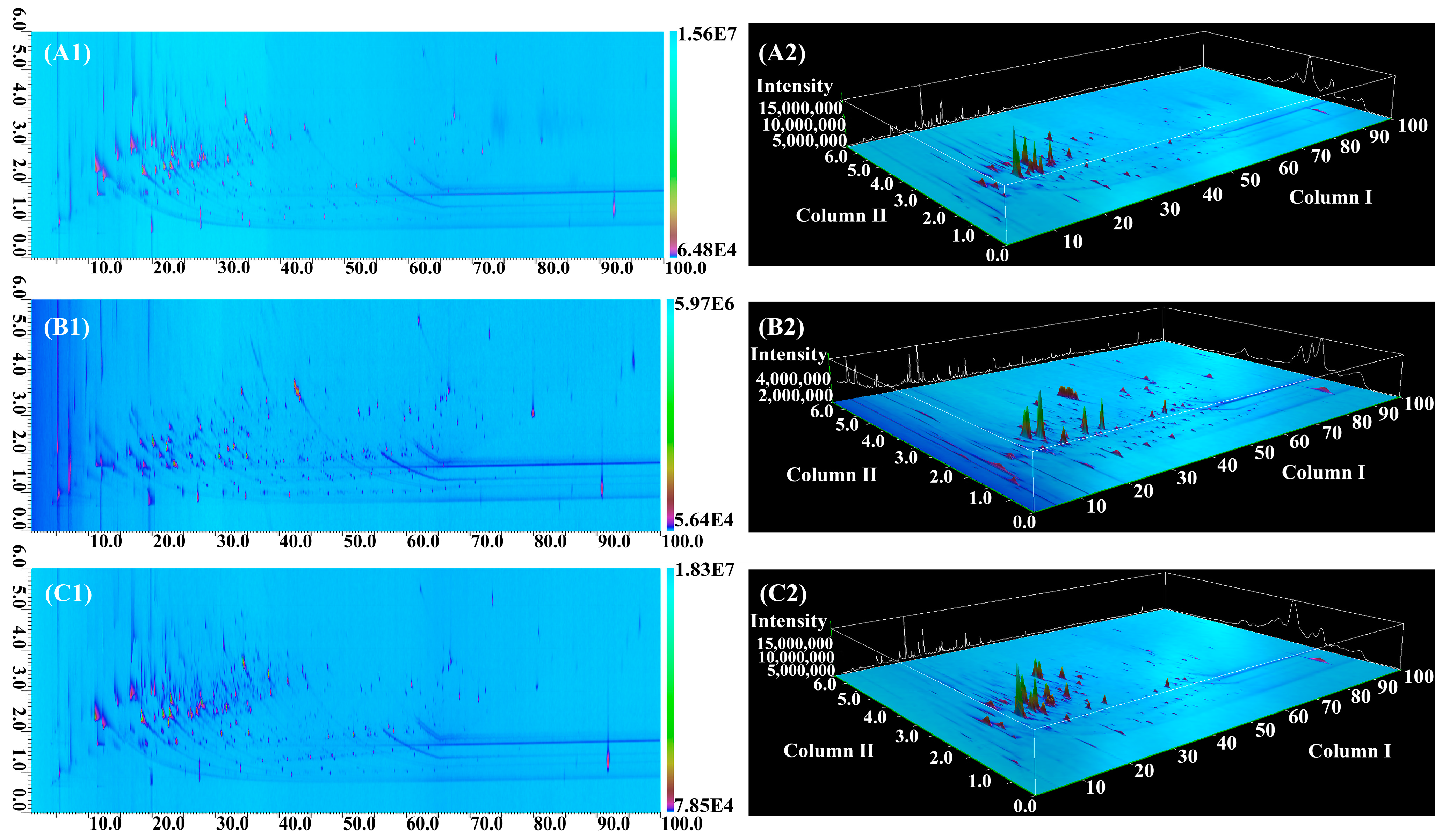

3.5. Volatile Compounds in the Harbin Red Sausages

3.5.1. Alcohols

3.5.2. Aldehydes

3.5.3. Ketones

3.5.4. Acids

3.5.5. Esters

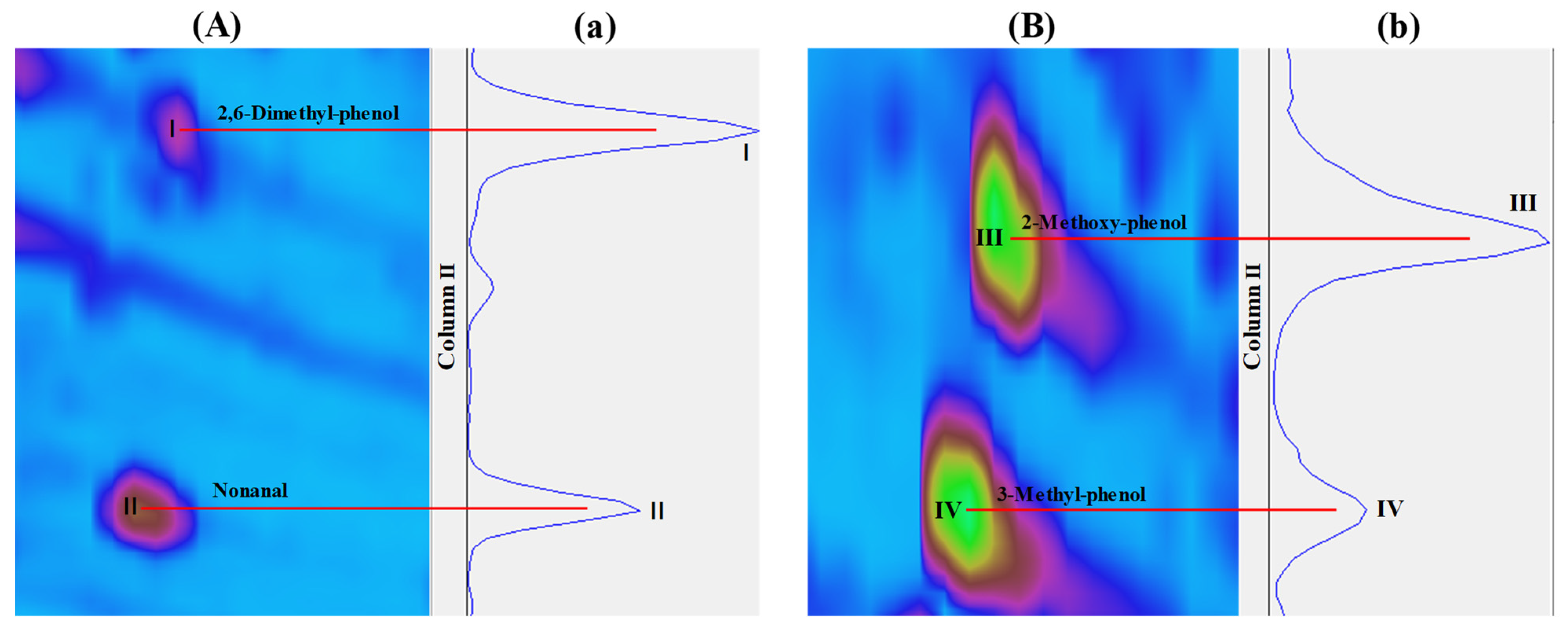

3.5.6. Phenols

3.5.7. Hydrocarbons

3.5.8. Others

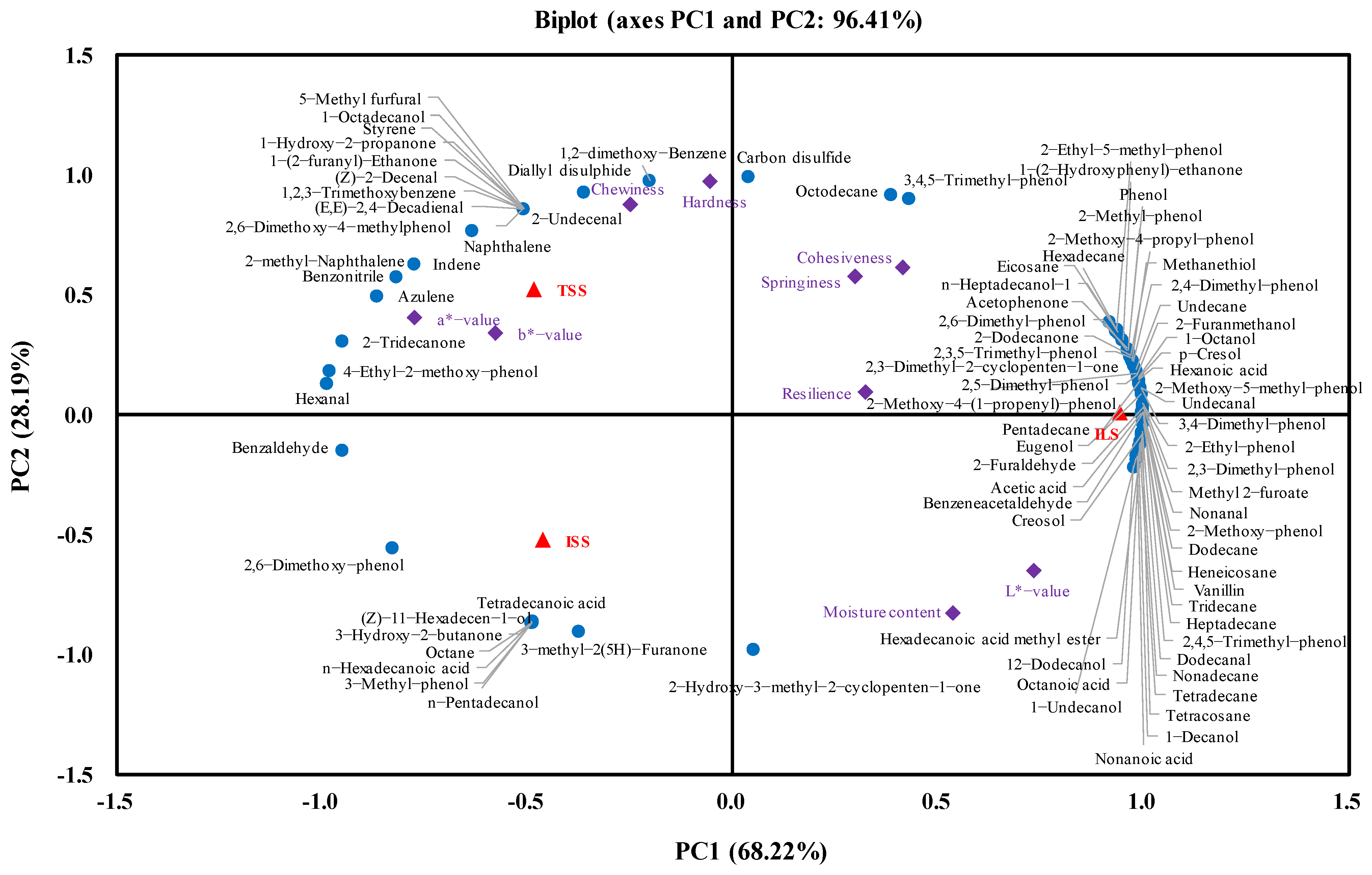

3.6. Principal Component Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ogbadu, L.J. PRESERVATIVES|Traditional Preservatives—Wood Smoke. In Encyclopedia of Food Microbiology; Academic Press: Cambridge, MA, USA, 2014; pp. 141–148. [Google Scholar] [CrossRef]

- Sikorski, Z.E.; Sinkiewicz, I. SMOKING|Traditional. In Encyclopedia of Meat Sciences; Academic Press: Cambridge, MA, USA, 2014; pp. 321–327. [Google Scholar] [CrossRef]

- Ledesma, E.; Rendueles, M.; Díaz, M. Smoked food. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2017; pp. 201–243. [Google Scholar] [CrossRef]

- Fellows, P.J. Smoking. In Food Processing Technology. Principles and Practice, 4th ed.; Fellows, P.J., Ed.; Woodhead Publishing Inc.: Kidlington, UK, 2017; pp. 717–732. [Google Scholar]

- Rozum, J. SMOKING|Liquid Smoke (Smoke Condensate) Application. In Encyclopedia of Meat Sciences; Academic Press: Cambridge, MA, USA, 2014; pp. 315–320. [Google Scholar] [CrossRef]

- Lv, Y.; Yin, X.; Wang, Y.; Chen, Q.; Kong, B. The prediction of specific spoilage organisms in Harbin red sausage stored at room temperature by multivariate statistical analysis. Food Control 2020, 123, 107701. [Google Scholar] [CrossRef]

- Kanokruangrong, S.; Birch, J.; Bekhit, A.E.A. Processing effects on meat flavor. In Encyclopedia of Food Chemistry; Elsevier: Amsterdam, The Netherlands, 2019; pp. 302–308. [Google Scholar] [CrossRef]

- Huang, X.H.; Zheng, X.; Chen, Z.H.; Zhang, Y.Y.; Du, M.; Dong, X.P.; Qin, L.; Zhu, B.W. Fresh and grilled eel volatile fingerprinting by e-Nose, GC-O, GC–MS and GC × GC-QTOF combined with purge and trap and solvent-assisted flavor evaporation. Food Res. Int. 2019, 115, 32–43. [Google Scholar] [CrossRef] [PubMed]

- Chambers, E.; Koppel, K. Associations of volatile compounds with sensory aroma and flavor: The complex nature of flavor. Molecules 2013, 18, 4887–4905. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Feng, X.; Zhang, D.; Li, B.; Sun, B.; Tian, H.; Liu, Y. Analysis of volatile compounds in Chinese dry-cured hams by comprehensive two-dimensional gas chromatography with high-resolution time-of-flight mass spectrometry. Meat Sci. 2018, 140, 14–25. [Google Scholar] [CrossRef] [PubMed]

- Duan, Y.; Zheng, F.; Chen, H.; Huang, M.; Xie, J.; Chen, F.; Sun, B. Analysis of volatiles in Dezhou Braised Chicken by comprehensive two-dimensional gas chromatography/high resolution-time of flight mass spectrometry. LWT Food Sci. Technol. 2015, 60, 1235–1242. [Google Scholar] [CrossRef]

- AOAC. Association of Official Methods of Analysis Methods 925.04, 16th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 1995. [Google Scholar]

- Han, G.; Zhang, L.; Li, Q.; Wang, Y.; Chen, Q.; Kong, B.H. Impacts of different altitudes and natural drying times on lipolysis, lipid oxidation and flavour profile of traditional Tibetan yak jerky. Meat Sci. 2020, 162, 108030. [Google Scholar] [CrossRef] [PubMed]

- AMSA. Research Guidelines for Cookery, Sensory Evaluation and Instrumental Measurements of Fresh Meat, 2nd ed.; American Meat Science Association and National Livestock and Meat Board: Champaign, IL, USA, 2015. [Google Scholar]

- Mastanjević, M.; Kartalović, B.; Petrović, J.; Novakov, N.; Puljić, L.; Kovačević, D.; Jukić, M.; Lukinac, J.; Mastanjević, K. Polycyclic aromatic hydrocarbons in the traditional smoked sausage Slavonska kobasica. J. Food Compos. Anal. 2019, 83, 103282. [Google Scholar] [CrossRef]

- Petričević, S.; Marušić Radovčić, N.; Lukić, K.; Listeš, E.; Medić, H. Differentiation of dry-cured hams from different processing methods by means of volatile compounds, physico-chemical and sensory analysis. Meat Sci. 2018, 137, 217–227. [Google Scholar] [CrossRef]

- Swaney-Stueve, M.; Talavera, M.; Jepsen, T.; Severns, B.; Wise, R.; Deubler, G. Sensory and consumer evaluation of smoked pulled pork prepared using different smokers and different types of wood. J. Food Sci. 2019, 84, 640–649. [Google Scholar] [CrossRef]

- Blonder, G. Summary Nitrogen Oxide Smoke Ring. 2014. Available online: https://genuineideas.com/ArticlesIndex/sranoxring.html (accessed on 22 May 2014).

- Lorenzo, J.M.; Franco, D. Fat effect on physico-chemical, microbial and textural changes through the manufactured of dry-cured foal sausage Lipolysis, proteolysis and sensory properties. Meat Sci. 2012, 92, 704–714. [Google Scholar] [CrossRef]

- Swastawati, F.; Ambaryanto Cahyono, B.; Wijayanti, I.; Chilmawati, D. Characterizations of milkfish (Chanos chanos) meatballs as effect of nanoencapsulation liquid smoke addition. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; Volume 116, p. 012027. [Google Scholar] [CrossRef]

- Ktari, N.; Smaoui, S.; Trabelsi, I.; Nasri, M.; Ben Salah, R. Chemical composition, techno-functional and sensory properties and effects of three dietary fibers on the quality characteristics of Tunisian beef sausage. Meat Sci. 2014, 96, 521–525. [Google Scholar] [CrossRef] [PubMed]

- Toldrá, F. Lawrie’s Meat Science, 8th ed.; Woodhead Publishing Inc.: Cambridge, UK, 2017. [Google Scholar]

- Van Gemert, L.J. Compilations of Odour Threshold Values in Air, Water and Other Media; Oliemans Punter & Partners BV: Zeist, The Netherlands, 2011. [Google Scholar]

- Yu, A.; Sun, B.; Tian, D.; Qu, W. Analysis of volatile compounds in traditional smoke-cured bacon (CSCB) with different fiber coatings using SPME. Food Chem. 2008, 110, 233–238. [Google Scholar] [CrossRef]

- Chen, Q.; Kong, B.H.; Han, Q.; Xia, X.F.; Xu, L. The role of bacterial fermentation in lipolysis and lipid oxidation in Harbin dry sausages and its flavour development. LWT Food Sci. Technol. 2017, 77, 389–396. [Google Scholar] [CrossRef]

- Hu, Y.Y.; Zhang, L.; Zhang, H.; Wang, Y.; Chen, Q.; Kong, B.H. Physicochemical properties and flavour profile of fermented dry sausages with a reduction of sodium chloride. LWT Food Sci. Technol. 2020, 109061. [Google Scholar] [CrossRef]

- Mottram, D. Volatile compounds in food—Qualitative and quantitative data by H. Maarse and C. A. Food Chem. 1991, 39, 120–122. [Google Scholar] [CrossRef]

- Saldaña, E.; Saldarriaga, L.; Cabrera, J.; Siche, R.; Behrens, J.; Selani, M.; de Almeida, M.; Silva, L.; Pinto, J.; Contreras-Castillo, C. Relationship between volatile compounds and consumer-based sensory characteristics of bacon smoked with different Brazilian woods. Food Res. Int. 2019, 119, 839–849. [Google Scholar] [CrossRef] [PubMed]

- Lorenzo, J.M.; Domínguez, R. Cooking losses, lipid oxidation and formation of volatile compounds in foal meat as affected by cooking procedure. Flavour Frag. J. 2014, 29, 240–248. [Google Scholar] [CrossRef]

- Mottram, D.S.; Nobrega, I.C.C. Formation of sulfur aroma compounds in reaction mixtures containing cysteine and three different forms of ribose. J. Agric. Food Chem. 2002, 50, 4080–4086. [Google Scholar] [CrossRef]

- Maga, J.A. The flavor chemistry of wood smoke. Food Rev. Int. 1987, 3, 139–183. [Google Scholar] [CrossRef]

- Lustre, A.O.; Issenberg, P. Phenolic components of smoked meat products. J. Agric. Food Chem. 1970, 18, 1056–1060. [Google Scholar] [CrossRef]

- Ramírez, R.; Cava, R. Volatile profiles of dry-cured meat products from three different Iberian × Duroc genotypes. J. Agric. Food Chem. 2007, 55, 1923–1931. [Google Scholar] [CrossRef] [PubMed]

- Meng, Q.; Kitagawa, R.; Imamura, M.; Katayama, H.; Obata, A.; Sugawara, E. Contribution of 2-methyl-3-furanthiol to the cooked meat-like aroma of fermented soy sauce. Biosci. Biotechnol. Biochem. 2017, 81, 168–172. [Google Scholar] [CrossRef] [PubMed]

- Domínguez, R.; Gómez, M.; Fonseca, S.; Lorenzo, J.M. Effect of different cooking methods on lipid oxidation and formation of volatile compounds in foal meat. Meat Sci. 2014, 97, 223–230. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Chambers, I.V.E. Sensory characteristics of various concentrations of phenolic compounds potentially associated with smoked aroma in foods. Molecules 2018, 23, 780. [Google Scholar] [CrossRef] [PubMed]

- Gomes, A.; Santos, C.; Almeida, J.; Elias, M.; Roseiro, L.C. Effect of fat content, casing type and smoking procedures on PAHs contents of Portuguese traditional dry fermented sausages. Food Chem. Toxicol. 2013, 58, 369–374. [Google Scholar] [CrossRef]

- Fleming-Jones, M.E.; Smith, R.E. Volatile organic compounds in foods: A five-year study. J. Agric. Food Chem. 2003, 51, 8120–8127. [Google Scholar] [CrossRef]

- Zhang, Y.; Silcock, P.; Jones, J.; Eyres, G. Changes in wood smoke volatile composition by manipulating the smoke generation conditions. J. Anal. Appl. Pyrolysis 2020, 148, 104769. [Google Scholar] [CrossRef]

| TSS | ISS | ILS | |

|---|---|---|---|

| Moisture content (g/100 g) | 55.74 ± 0.06 b | 61.50 ± 0.17 a | 61.72 ± 0.27 a |

| L*-value | 53.85 ± 0.16 c | 56.49 ± 0.06 b | 57.61 ± 0.25 a |

| a*-value | 13.15 ± 0.22 a | 12.65 ± 0.23 b | 11.97 ± 0.17 c |

| b*-value | 12.92 ± 0.25 a | 12.61 ± 0.29 ab | 12.19 ± 0.20 b |

| Hardness (N) | 29.17 ± 0.56 a | 24.25 ± 0.49 c | 26.49 ± 0.47 b |

| Springiness | 0.89 ± 0.02 a | 0.84 ± 0.03 a | 0.89 ± 0.02 a |

| Cohesiveness | 0.78 ± 0.01 a | 0.71 ± 0.04 a | 0.79 ± 0.02 a |

| Chewiness (N) | 17.32 ± 0.58 a | 13.42 ± 0.70 b | 14.36 ± 0.71 b |

| Resilience | 0.44 ± 0.03 a | 0.44 ± 0.01 a | 0.46 ± 0.02 a |

| Compound Name | CAS | Peak I (min) | Peak II (s) | Library Probability | TSS | ISS | ILS | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Library Match Factor | Library Reverse Match Factor | Content | Library Match Factor | Library Reverse Match Factor | Content | Library Match Factor | Library Reverse Match Factor | Content | |||||

| Alcohols | |||||||||||||

| 2-Furanmethanol | 98-00-0 | 12.30 | 2.10 | 55.19 | 832 | 842 | 770.94 ± 15.66 b | 825 | 870 | 424.88 ± 11.44 c | 840 | 848 | 2524.80 ± 26.52 a |

| 1-Octanol | 111-87-5 | 22.70 | 1.72 | 62.71 | 750 | 905 | 100.23 ± 1.90 b | 815 | 895 | 53.84 ± 1.86 c | 674 | 870 | 351.41 ± 8.90 a |

| 1-Decanol | 112-30-1 | 26.00 | 2.94 | 9.81 | ND | ND | ND | 742 | 839 | 49.32 ± 0.14 b | 687 | 838 | 267.53 ± 6.60 a |

| 1-Undecanol | 112-42-5 | 30.50 | 2.94 | 12.37 | ND | ND | ND | 725 | 813 | 170.18 ± 2.96 b | 724 | 815 | 822.41 ± 20.48 a |

| 12-Dodecanol | 112-53-8 | 39.60 | 2.78 | 8.16 | ND | ND | ND | 679 | 850 | 31.14 ± 1.08 b | 579 | 824 | 129.73 ± 2.49 a |

| n-Pentadecanol | 629-76-5 | 53.70 | 2.92 | 13.77 | ND | ND | ND | 673 | 852 | 9.30 ± 0.16 | ND | ND | ND |

| (Z)-11-Hexadecen-1-ol | 56683-54-6 | 54.30 | 3.02 | 37.53 | ND | ND | ND | 600 | 816 | 6.21 ± 0.38 | ND | ND | ND |

| n-Heptadecanol-1 | 1454-85-9 | 59.80 | 2.98 | 28.89 | 657 | 848 | 58.40 ± 2.65 b | 718 | 846 | 24.62 ± 0.14 c | 708 | 837 | 125.91 ± 3.27 a |

| 1-Octadecanol | 112-92-5 | 71.60 | 2.82 | 26.31 | 518 | 806 | 118.62 ± 3.37 | ND | ND | ND | ND | ND | ND |

| Total | 1048.20 ± 23.57 b | 769.51 ± 18.15 c | 4221.80 ± 68.26 a | ||||||||||

| Aldehydes | |||||||||||||

| Hexanal | 66-25-1 | 9.80 | 2.48 | 67.68 | 631 | 814 | 80.14 ± 2.23 a | 584 | 823 | 71.06 ± 1.74 b | 533 | 801 | 16.67 ± 0.81 c |

| 2-Furaldehyde | 98-01-1 | 11.10 | 2.36 | 77.48 | 884 | 892 | 984.82 ± 17.65 b | 419 | 893 | 937.51 ± 28.27 b | 903 | 916 | 3158.30 ± 38.57 a |

| Benzaldehyde | 100-52-7 | 16.50 | 3.90 | 43.12 | 614 | 811 | 52.98 ± 3.02 a | 558 | 858 | 58.62 ± 2.01 a | 645 | 812 | 26.96 ± 2.10 b |

| 5-Methyl furfural | 620-02-0 | 16.70 | 2.94 | 75.79 | 851 | 879 | 267.74 ± 15.26 | ND | ND | ND | ND | ND | ND |

| Nonanal | 124-19-6 | 23.80 | 1.74 | 93.74 | 863 | 896 | 159.76 ± 2.63 b | 900 | 901 | 162.31 ± 3.18 b | 885 | 886 | 639.52 ± 33.46 a |

| (Z)-2-Decenal | 2497-25-8 | 31.00 | 1.92 | 39.03 | 903 | 924 | 115.97 ± 2.74 | ND | ND | ND | ND | ND | ND |

| Undecanal | 112-44-7 | 32.60 | 2.76 | 90.62 | 749 | 939 | 34.27 ± 0.11 b | 902 | 955 | 21.12 ± 0.46 c | 844 | 965 | 138.69 ± 2.22 a |

| (E,E)-2,4-Decadienal | 25152-84-5 | 33.30 | 2.22 | 33.28 | 878 | 898 | 95.84 ± 1.79 | ND | ND | ND | ND | ND | ND |

| Benzeneacetaldehyde | 122-78-1 | 34.10 | 4.86 | 76.21 | ND | ND | ND | ND | ND | ND | 677 | 823 | 187.15 ± 0.74 |

| 2-Undecenal | 2463-77-6 | 35.30 | 1.96 | 60.03 | 913 | 919 | 111.73 ± 2.05 | ND | ND | ND | ND | ND | ND |

| Vanillin | 121-33-5 | 36.40 | 3.98 | 44.37 | ND | ND | ND | ND | ND | ND | 638 | 829 | 141.25 ± 1.25 |

| Dodecanal | 112-54-9 | 51.40 | 2.90 | 84.22 | 697 | 905 | 40.13 ± 1.48 c | 836 | 889 | 85.12 ± 1.27 b | 842 | 888 | 516.09 ± 14.16 a |

| Total | 1943.40 ± 48.95 b | 1335.7 ± 36.93 c | 4824.60 ± 93.30 a | ||||||||||

| Ketones | |||||||||||||

| 1-Hydroxy-2-propanone | 116-09-6 | 5.20 | 2.16 | 49.94 | 608 | 827 | 187.37 ± 3.17 | ND | ND | ND | ND | ND | ND |

| 3-Hydroxy-2-butanone | 513-86-0 | 7.10 | 2.44 | 38.71 | ND | ND | ND | 730 | 846 | 314.70 ± 8.70 | ND | ND | ND |

| 2-Hydroxy-3-methyl-2-cyclopenten-1-one | 765-70-8 | 19.80 | 2.96 | 54.58 | 828 | 861 | 280.86 ± 6.31 c | 802 | 804 | 536.36 ± 11.11 a | 598 | 812 | 416.54 ± 9.94 b |

| 2,3-Dimethyl-2-cyclopenten-1-one | 80-71-7 | 20.40 | 2.96 | 53.74 | 802 | 854 | 413.96 ± 12.60 b | 647 | 802 | 273.56 ± 7.98 c | 854 | 867 | 959.85 ± 25.64 a |

| Acetophenone | 98-86-2 | 21.80 | 3.06 | 72.40 | 838 | 904 | 91.14 ± 1.89 b | ND | ND | ND | 794 | 889 | 332.92 ± 9.02 a |

| 1-(2-Hydroxyphenyl)-ethanone | 118-93-4 | 26.30 | 3.00 | 47.90 | 675 | 821 | 46.23 ± 1.43 b | ND | ND | ND | 558 | 816 | 150.29 ± 2.26 a |

| 3-methyl-2(5H)-furanone | 22122-36-7 | 34.30 | 4.16 | 63.67 | 543 | 819 | 22.37 ± 1.79 b | 622 | 822 | 77.66 ± 2.06 a | 589 | 807 | 29.57 ± 2.22 b |

| 1-(2-furanyl)-ethanone | 1192-62-7 | 14.50 | 2.66 | 44.65 | 847 | 893 | 248.87 ± 7.60 | ND | ND | ND | ND | ND | ND |

| 2-Dodecanone | 6175-49-1 | 47.50 | 2.88 | 43.52 | 871 | 919 | 66.92 ± 2.86 b | 779 | 828 | 34.57 ± 0.20 c | 784 | 843 | 167.79 ± 2.56 a |

| 2-Tridecanone | 593-08-8 | 48.00 | 1.88 | 52.70 | 702 | 830 | 18.37 ± 0.29 a | 736 | 821 | 12.47 ± 0.08 b | ND | ND | ND |

| Total | 1376.10 ± 37.95 b | 1249.30 ± 30.11 b | 2056.90 ± 51.64 a | ||||||||||

| Acids | |||||||||||||

| Acetic acid | 64-19-7 | 5.40 | 0.94 | 14.10 | 876 | 943 | 70.47 ± 1.29 b | 864 | 883 | 72.18 ± 1.23 b | 931 | 934 | 163.56 ± 7.15 a |

| Hexanoic acid | 142-62-1 | 18.50 | 1.72 | 67.67 | 636 | 813 | 54.77 ± 2.04 b | 752 | 884 | 32.57 ± 1.37 c | 631 | 843 | 189.34 ± 3.35 a |

| Octanoic acid | 124-07-2 | 27.20 | 2.70 | 63.77 | ND | ND | ND | 657 | 800 | 32.13 ± 1.74 b | 625 | 823 | 222.41 ± 5.94 a |

| Nonanoic acid | 112-05-0 | 31.40 | 2.74 | 77.26 | ND | ND | ND | 759 | 820 | 32.49 ± 1.43 b | 645 | 805 | 166.22 ± 3.12 a |

| Tetradecanoic acid | 544-63-8 | 49.80 | 2.94 | 56.62 | ND | ND | ND | 777 | 838 | 31.71 ± 0.30 | ND | ND | ND |

| n-Hexadecanoic acid | 57-10-3 | 56.20 | 3.00 | 65.36 | ND | ND | ND | 697 | 862 | 41.22 ± 0.25 | ND | ND | ND |

| Total | 125.24 ± 3.33 c | 242.31 ± 6.31 b | 741.54 ± 19.56 a | ||||||||||

| Esters | |||||||||||||

| Methyl 2-furoate | 611-13-2 | 17.40 | 2.80 | 48.82 | 784 | 801 | 65.27 ± 1.08 b | 746 | 812 | 56.83 ± 1.61 b | 553 | 855 | 665.62 ± 22.98 a |

| Hexadecanoic acid methyl ester | 112-39-0 | 54.90 | 2.88 | 65.55 | ND | ND | ND | 699 | 811 | 19.27 ± 0.06 b | 748 | 843 | 190.94 ± 1.95 a |

| Total | 66.27 ± 1.08 b | 76.10 ± 1.67 b | 856.56 ± 24.93 a | ||||||||||

| Phenols | |||||||||||||

| Phenol | 108-95-2 | 18.20 | 3.32 | 56.09 | 868 | 898 | 1684.30 ± 29.68 b | 800 | 869 | 450.70 ± 11.64 c | 865 | 903 | 5004.40 ± 69.08 a |

| 2-Methyl-phenol | 95-48-7 | 21.70 | 2.42 | 50.68 | 891 | 892 | 424.99 ± 9.61 b | 707 | 853 | 46.31 ± 0.21 c | 890 | 890 | 1484.10 ± 39.42 a |

| 3-Methyl-phenol | 108-39-4 | 22.60 | 3.38 | 33.06 | ND | ND | ND | 837 | 884 | 29.04 ± 0.35 | ND | ND | ND |

| p-Cresol | 106-44-5 | 22.80 | 2.44 | 20.26 | 897 | 905 | 654.25 ± 21.39 b | 818 | 909 | 233.56 ± 6.20 c | 895 | 903 | 3099.30 ± 64.05 a |

| 2-Methoxy-phenol | 95-05-1 | 23.00 | 2.80 | 69.93 | 874 | 907 | 883.71 ± 15.64 b | 817 | 895 | 912.57 ± 19.33 b | 880 | 912 | 2726.40 ± 42.08 a |

| 2,6-Dimethyl-phenol | 576-26-1 | 24.00 | 2.54 | 17.65 | 802 | 832 | 104.93 ± 2.14 b | 714 | 821 | 20.05 ± 0.54 c | 790 | 837 | 339.89 ± 17.60 a |

| 2-Ethyl-phenol | 90-00-6 | 25.70 | 2.46 | 10.06 | 699 | 826 | 84.41 ± 3.18 b | 726 | 821 | 72.44 ± 3.22 b | 791 | 827 | 398.59 ± 8.82 a |

| 2,4-Dimethyl-phenol | 105-67-9 | 25.90 | 3.42 | 17.31 | 866 | 871 | 247.31 ± 4.99 b | 660 | 814 | 40.94 ± 1.08 c | 863 | 866 | 982.11 ± 17.80 a |

| 2,5-Dimethyl-phenol | 526-75-0 | 26.90 | 3.44 | 15.58 | 860 | 860 | 193.61 ± 2.45 b | 649 | 822 | 30.70 ± 0.51 c | 859 | 859 | 1028.60 ± 30.72 a |

| 2-Methoxy-5-methyl-phenol | 1195-09-1 | 27.30 | 2.68 | 50.61 | 837 | 865 | 36.60 ± 0.77 b | 811 | 837 | 27.04 ± 2.07 c | 841 | 879 | 102.27 ± 2.23 a |

| 2,3-Dimethyl-phenol | 526-75-0 | 27.50 | 2.62 | 30.55 | 838 | 869 | 37.82 ± 0.70 b | 715 | 828 | 31.87 ± 0.17 b | 836 | 866 | 203.00 ± 4.03 a |

| Creosol | 93-51-6 | 27.60 | 3.68 | 67.40 | 882 | 882 | 357.18 ± 7.71 c | 807 | 851 | 468.44 ± 9.39 b | 890 | 890 | 1416.60 ± 33.20 a |

| 3,4-Dimethyl-phenol | 95-65-8 | 28.20 | 2.60 | 27.91 | 751 | 813 | 64.55 ± 1.51 b | ND | ND | 31.43 ± 0.77 c | 815 | 839 | 328.21 ± 8.31 a |

| 2,4,5-Trimethyl-phenol | 496-78-6 | 28.50 | 2.50 | 23.22 | ND | ND | ND | ND | ND | ND | 780 | 805 | 194.15 ± 2.93 |

| 2-Ethyl-5-methyl-phenol | 1687-61-2 | 29.70 | 2.46 | 36.38 | 808 | 853 | 84.48 ± 1.99 b | ND | ND | ND | 743 | 876 | 242.42 ± 4.78 a |

| 2,3,5-Trimethyl-phenol | 697-82-5 | 29.70 | 2.68 | 12.22 | 659 | 850 | 38.39 ± 1.09 b | ND | ND | ND | 764 | 825 | 163.38 ± 2.20 a |

| 3,4,5-Trimethyl-phenol | 527-54-8 | 31.40 | 2.58 | 11.80 | 798 | 863 | 56.55 ± 1.88 a | ND | ND | ND | 784 | 843 | 52.35 ± 1.30 a |

| 4-Ethyl-2-methoxy-phenol | 2785-87-7 | 31.40 | 3.58 | 16.92 | 860 | 899 | 209.60 ± 5.18 a | 678 | 826 | 167.74 ± 4.12 b | ND | ND | ND |

| 2,6-Dimethoxy-phenol | 91-10-1 | 34.50 | 3.66 | 63.67 | 857 | 860 | 355.90 ± 7.80 b | 629 | 813 | 790.47 ± 11.55 a | ND | ND | ND |

| Eugenol | 97-53-0 | 35.00 | 2.66 | 26.39 | 797 | 897 | 64.32 ± 1.11 b | 804 | 870 | 40.70 ± 0.66 b | 861 | 908 | 338.51 ± 15.17 a |

| 2-Methoxy-4-propyl-phenol | 2785-87-7 | 35.60 | 2.54 | 95.61 | 761 | 848 | 87.28 ± 1.91 b | ND | ND | ND | 812 | 856 | 361.57 ± 15.20 a |

| 2-Methoxy-4-(1-propenyl)-phenol | 97-54-1 | 38.80 | 2.94 | 69.62 | 876 | 926 | 135.56 ± 3.31 b | 805 | 917 | 28.83 ± 0.12 c | 894 | 934 | 658.62 ± 15.22 a |

| 2,6-Dimethoxy-4-methylphenol | 6638-05-7 | 38.40 | 3.38 | 50.40 | 811 | 859 | 199.14 ± 3.11 | ND | ND | ND | ND | ND | ND |

| Total | 6004.90 ± 127.07 b | 3422.80 ± 71.91 c | 19124.00 ± 394.15 a | ||||||||||

| Hydrocarbons | |||||||||||||

| Octane | 111-65-9 | 10.20 | 3.46 | 54.21 | ND | ND | ND | 553 | 890 | 64.57 ± 0.28 | ND | ND | ND |

| Undecane | 1120-21-4 | 24.10 | 2.12 | 41.88 | 500 | 829 | 50.69 ± 0.99 b | 696 | 898 | 21.69 ± 0.36 c | 476 | 835 | 176.72 ± 3.02 a |

| Dodecane | 112-40-3 | 28.70 | 2.18 | 51.94 | 761 | 887 | 16.13 ± 0.30 b | 807 | 900 | 17.12 ± 0.49 b | 635 | 885 | 105.28 ± 3.47 a |

| Tridecane | 629-50-5 | 33.00 | 2.24 | 24.24 | 702 | 873 | 13.58 ± 0.20 b | 785 | 881 | 24.94 ± 0.92 b | 641 | 856 | 218.36 ± 4.57 a |

| Tetradecane | 629-59-4 | 37.10 | 2.26 | 33.93 | ND | ND | ND | 789 | 869 | 18.99 ± 0.19 b | 866 | 902 | 120.69 ± 2.73 a |

| Pentadecane | 629-62-9 | 40.90 | 2.32 | 40.39 | 741 | 876 | 36.87 ± 1.24 b | 820 | 899 | 19.19 ± 0.45 c | 812 | 918 | 149.45 ± 3.76 a |

| Hexadecane | 544-76-3 | 44.60 | 2.36 | 43.46 | 825 | 902 | 57.28 ± 2.10 b | 800 | 879 | 36.13 ± 1.74 c | 891 | 896 | 98.12 ± 2.75 a |

| Heptadecane | 629-78-7 | 48.10 | 2.40 | 26.66 | 656 | 828 | 13.69 ± 0.21 b | 837 | 880 | 25.22 ± 0.09 b | 841 | 869 | 422.99 ± 11.60 a |

| Octodecane | 593-45-3 | 51.90 | 1.90 | 3.85 | 847 | 903 | 118.93 ± 3.00 a | 706 | 811 | 13.22 ± 0.21 c | 728 | 867 | 105.75 ± 3.47 b |

| Nonadecane | 629-92-5 | 54.80 | 1.48 | 18.46 | ND | ND | ND | 719 | 846 | 25.04 ± 0.27 b | 803 | 884 | 185.11 ± 3.27 a |

| Eicosane | 112-95-8 | 58.00 | 1.54 | 38.71 | 818 | 873 | 27.36 ± 1.24 b | 764 | 866 | 14.21 ± 0.23 c | 731 | 866 | 49.03 ± 2.08 a |

| Heneicosane | 629-94-7 | 60.90 | 1.56 | 20.40 | 802 | 877 | 28.11 ± 1.59 b | 719 | 851 | 35.14 ± 1.32 b | 741 | 850 | 410.08 ± 15.08 a |

| Tetracosane | 646-31-1 | 63.20 | 2.60 | 12.71 | ND | ND | ND | 843 | 878 | 13.97 ± 0.36 b | 606 | 801 | 136.13 ± 3.27 a |

| Total | 362.52 ± 10.87 b | 329.43 ± 6.90 b | 2177.70 ± 59.06 a | ||||||||||

| Others | |||||||||||||

| Methanethiol | 74-93-1 | 4.10 | 2.70 | 93.20 | 689 | 890 | 33.35 ± 1.98 b | 471 | 895 | 12.88 ± 0.08 c | 475 | 893 | 104.15 ± 1.42 a |

| Diallyl disulphide | 2179-57-9 | 22.60 | 2.22 | 89.79 | 804 | 806 | 33.31 ± 0.77 a | 796 | 800 | 13.56 ± 0.58 b | 789 | 806 | 16.56 ± 0.71 b |

| 2-methyl-naphthalene | 91-57-6 | 32.50 | 2.86 | 49-13 | 756 | 868 | 43.11 ± 0.77 a | 805 | 859 | 15.17 ± 0.80 b | ND | ND | ND |

| Styrene | 100-42-5 | 13.80 | 1.80 | 45.79 | 589 | 876 | 52.28 ± 0.94 | ND | ND | ND | ND | ND | ND |

| Carbon disulfide | 75-15-0 | 4.70 | 1.98 | 81.00 | 636 | 897 | 100.14 ± 1.16 a | ND | ND | ND | 710 | 894 | 54.52 ± 0.92 b |

| Benzonitrile | 100-47-0 | 17.60 | 3.10 | 70.51 | 820 | 888 | 31.90 ± 0.76 a | 810 | 903 | 13.22 ± 0.30 b | ND | ND | ND |

| 1,2-dimethoxy-benzene | 91-16-7 | 25.50 | 3.02 | 46.54 | 611 | 816 | 122.57 ± 2.57 a | ND | ND | ND | 622 | 834 | 40.62 ± 0.81 b |

| 1,2,3-Trimethoxybenzene | 634-34-6 | 32.80 | 3.24 | 86.87 | 681 | 859 | 74.49 ± 1.50 | ND | ND | ND | ND | ND | ND |

| Indene | 95-13-6 | 21.00 | 2.44 | 36.95 | 771 | 835 | 147.65 ± 2.90 a | 666 | 862 | 52.08 ± 1.52 b | ND | ND | ND |

| Azulene | 275-51-4 | 27.20 | 3.92 | 63.64 | 894 | 911 | 39.83 ± 1.86 a | 740 | 866 | 19.79 ± 0.66 b | ND | ND | ND |

| Naphthalene | 275-51-4 | 27.30 | 3.88 | 50.17 | 898 | 936 | 115.41 ± 2.41 a | 759 | 902 | 19.01 ± 0.24 b | ND | ND | ND |

| Total | 792.05 ± 17.62 a | 145.71 ± 4.17 c | 215.86 ± 3.86 b | ||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, X.; Chen, Q.; Liu, Q.; Wang, Y.; Kong, B. Influences of Smoking in Traditional and Industrial Conditions on Flavour Profile of Harbin Red Sausages by Comprehensive Two-Dimensional Gas Chromatography Mass Spectrometry. Foods 2021, 10, 1180. https://doi.org/10.3390/foods10061180

Yin X, Chen Q, Liu Q, Wang Y, Kong B. Influences of Smoking in Traditional and Industrial Conditions on Flavour Profile of Harbin Red Sausages by Comprehensive Two-Dimensional Gas Chromatography Mass Spectrometry. Foods. 2021; 10(6):1180. https://doi.org/10.3390/foods10061180

Chicago/Turabian StyleYin, Xiaoyu, Qian Chen, Qian Liu, Yan Wang, and Baohua Kong. 2021. "Influences of Smoking in Traditional and Industrial Conditions on Flavour Profile of Harbin Red Sausages by Comprehensive Two-Dimensional Gas Chromatography Mass Spectrometry" Foods 10, no. 6: 1180. https://doi.org/10.3390/foods10061180

APA StyleYin, X., Chen, Q., Liu, Q., Wang, Y., & Kong, B. (2021). Influences of Smoking in Traditional and Industrial Conditions on Flavour Profile of Harbin Red Sausages by Comprehensive Two-Dimensional Gas Chromatography Mass Spectrometry. Foods, 10(6), 1180. https://doi.org/10.3390/foods10061180