Determination of Material Requirements for 3D Gel Food Printing Using a Fused Deposition Modeling 3D Printer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. 3D Printing

2.4. Determination of the Gel Food Formulation

2.5. Determination of Printing Material Requirements

2.6. Determination of the Rheological and Mechanical Parameters

3. Results and Discussion

3.1. Determination of the Gel Food Formulation

3.2. Determination of Printing Material Requirements

3.2.1. Fidelity

3.2.2. Shape Retention

3.2.3. Extrudability

3.3. Effects of the Use of Pectin and the Gum Mixture on the Printing Material Requirements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D printing of polymers containing natural fillers: A review of their mechanical properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Z.; Wang, Y.; Wu, B.; Cui, C.; Guo, Y.; Yan, C. A critical review of fused deposition modeling 3D printing technology in manufacturing polylactic acid parts. Int. J. Adv. Manuf. Technol. 2019, 102, 2877–2889. [Google Scholar] [CrossRef]

- Pereira, T.; Barroso, S.; Gil, M.M. Food texture design by 3D Printing: A review. Foods 2021, 10, 320. [Google Scholar] [CrossRef] [PubMed]

- Park, H.J.; Kim, H.W. Global 3D food printing technology and industry trends and future prospect. World Agric. 2017, 202, 147–168. [Google Scholar]

- Liu, Y.; Liang, X.; Saeed, A.; Lan, W.; Qin, W. Properties of 3D printed dough and optimization of printing parameters. Innov. Food Sci. Emerg. Technol. 2019, 54, 9–18. [Google Scholar] [CrossRef]

- Chen, H.H.; Wang, Y.S.; Leng, Y.; Zhao, Y.; Zhao, X. Effect of NaCl and sugar on physicochemical properties of flaxseed polysaccharide-potato starch complexes. Sci. Asia. 2014, 40, 60–68. [Google Scholar] [CrossRef] [Green Version]

- Yoo, B.; Yoo, D.; Kim, Y.R.; Lim, S.T. Effect of sugar type on rheological properties of high-methoxly pectin gels. Food Sci. Biotechnol. 2003, 12, 316–319. [Google Scholar]

- Thakre, G.; Barse, A. Development of herbal jelly (with Hibiscus Rosa sinensis and Rose petals). J. Med. Plants Stud. 2018, 6, 30–32. [Google Scholar]

- Lille, M.; Nurmela, A.; Nordlund, E.; Metsä-Kortelainen, S.; Sozer, N. Applicability of protein and fiber-rich food materials in extrusion-based 3D printing. J. Food Eng. 2018, 220, 20–27. [Google Scholar] [CrossRef]

- Azam, R.S.M.; Zhang, M.; Bhandari, B.; Yang, C. Effect of different gums on features of 3D printed object based on vitamin-D enriched orange concentrate. Food Biophys. 2018, 13, 250–262. [Google Scholar] [CrossRef]

- Gholamipour-Shirazi, A.; Norton, I.T.; Mills, T. Designing hydrocolloid based food-ink formulations for extrusion 3D printing. Food Hydrocoll. 2019, 95, 161–167. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Bhandari, B. Effect of gums on the rheological, microstructural and extrusion printing characteristics of mashed potatoes. Int. J. Biol. Macromol. 2018, 117, 1179–1187. [Google Scholar] [CrossRef]

- Yang, F.; Guo, C.; Zhang, M.; Bhandari, B.; Liu, Y. Improving 3D printing process of lemon juice gel based on fluid flow numerical simulation. LWT Food Sci. Technol. 2019, 102, 89–99. [Google Scholar] [CrossRef] [Green Version]

- Zhu, S.; Stieger, M.A.; van der Goot, A.J.; Schutyser, M.A.I. Extrusion-based 3D printing of food pastes: Correlating rheological properties with printing behaviour. Innov. Food Sci. Emerg. Technol. 2019, 58, 102214. [Google Scholar] [CrossRef]

- Ren, X.; Shao, H.; Lin, T.; Zheng, H. 3D gel-printing—An additive manufacturing method for producing complex shape parts. Mater. Design. 2016, 101, 80–87. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, M.; Bhandari, B.; Yang, C. Investigation on fish surimi gel as promising food material for 3D printing. J. Food Eng. 2018, 220, 101–108. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Yang, C.H. Dual extrusion 3D printing of mashed potatoes/strawberry juice gel. LWT Food Sci. Technol. 2018, 96, 589–596. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Bhandari, B.; Yang, C. Impact of rheological properties of mashed potatoes on 3D printing. J. Food Eng. 2018, 220, 76–82. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.W.; Bae, H.; Park, H.J. Classification of the printability of selected food for 3D printing: Development of an assessment method using hydrocolloids as reference material. J. Food Eng. 2017, 215, 23–32. [Google Scholar] [CrossRef]

- Kim, H.; Kim, B.Y.; Gunasekaran, S.; Park, J.W.; Yoon, W.B. Comparison of concentration dependence of mechanical modulus in two biopolymer gel systems using scaling analysis. Food Sci. Biotechnol. 2013, 22, 1601–1606. [Google Scholar] [CrossRef]

- Nijdam, J.J.; LeCorre-Bordes, D.; Delvart, A.; Schon, B.S. A rheological test to assess the ability of food inks to form dimensionally stable 3D food structures. J. Food Eng. 2021, 291, 110235. [Google Scholar] [CrossRef]

- Barnes, H.A. The yield stress—A review or ‘παντα ρει’—Everything flows? J. Nonnewton Fluid Mech. 1999, 81, 133–178. [Google Scholar] [CrossRef]

- Kim, B.H.; Park, J.W.; Woo, M.J. Studies on the mass-production system for making biodegradable film based on chitosan/gelatin blend. Korean J. Packag. Sci. Technol. 2006, 12, 117–123. [Google Scholar]

- Garrido, J.I.; Lozano, J.E.; Genovese, D.B. Effect of formulation variables on rheology, texture, colour, and acceptability of apple jelly: Modelling and optimization. LWT Food Sci. Technol. 2015, 62, 325–332. [Google Scholar] [CrossRef]

- Park, G.Y.; Ra, H.N.; Cho, Y.S.; Kim, H.Y.; Kim, K.M. Effects of addition of mixed gelling agent on quality of peach (Prunus persica L. Batsch) jelly. J. Korean Soc. Food Cult. 2018, 33, 458–463. [Google Scholar] [CrossRef]

- Eidam, D.; Kulicke, W.M.; Kuhn, K.; Stute, R. Formation of maize starch gels selectively regulated by the addition of hydrocolloids. Starch-Stärke 1995, 47, 378–384. [Google Scholar] [CrossRef]

- Lee, S.Y.; Kim, Y.N. Food Rheology, 1st ed.; Soohaksa Press: Seoul, Korea, 2017; pp. 113–144. [Google Scholar]

- Kim, J.H.; Min, S.C. Development and shelf-life determination of senior-friendly strawberry jelly. Korean J. Food Sci. Technol. 2017, 49, 181–185. [Google Scholar] [CrossRef] [Green Version]

- Copetti, G.; Grassi, M.; Lapasin, R.; Pricl, S. Synergistic gelation of xanthan gum with locust bean gum: A rheological investigation. Glycoconj. J. 1997, 14, 951–961. [Google Scholar] [CrossRef]

| Sample | Gelatin (g) | Pectin (g) | Gum Mixture (g) | Water (g) | Sugar (g) | Citric Acid (g) |

|---|---|---|---|---|---|---|

| A1 | 14 | 0 | 0 | 55 | 30 | 1 |

| A2 | 14 | 0 | 0 | 45 | 40 | 1 |

| A3 | 16 | 0 | 0 | 53 | 30 | 1 |

| A4 | 16 | 0 | 0 | 43 | 40 | 1 |

| A5 | 18 | 0 | 0 | 51 | 30 | 1 |

| A6 | 18 | 0 | 0 | 41 | 40 | 1 |

| B1 | 8 | 7 | 0 | 54 | 30 | 1 |

| B2 | 8 | 8 | 0 | 53 | 30 | 1 |

| B3 | 8 | 9 | 0 | 52 | 30 | 1 |

| B4 | 10 | 7 | 0 | 52 | 30 | 1 |

| B5 | 10 | 8 | 0 | 51 | 30 | 1 |

| B6 | 10 | 9 | 0 | 50 | 30 | 1 |

| C1 | 0 | 0 | 8 | 61 | 30 | 1 |

| C2 | 0 | 0 | 8 | 51 | 40 | 1 |

| C3 | 0 | 0 | 10 | 59 | 30 | 1 |

| C4 | 0 | 0 | 10 | 49 | 40 | 1 |

| C5 | 0 | 0 | 12 | 57 | 30 | 1 |

| C6 | 0 | 0 | 12 | 47 | 40 | 1 |

| Processing Parameter | Value |

|---|---|

| Heating barrel temperature | 24 °C |

| Nozzle temperature | 24 °C |

| Print platform temperature | 24 °C |

| Nozzle diameter | 0.60 mm (0.84 mm for printing gum-mixture-based formulations) |

| Layer height | 0.2 mm |

| Coasting distance | 4 mm |

| Extruder moving speed | 6 mm/s |

| Sample | Printed Products | Printing Height (mm) | Printing Height after 1 h (mm) | Printability (%) | Dimensional Stability (%) | Observations |

|---|---|---|---|---|---|---|

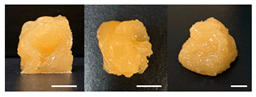

| A1 |  | 8.25 ± 0.2 | 7.10 ± 0.2 | 82.54 | 86.06 | Uneven layer on the top of the printed object |

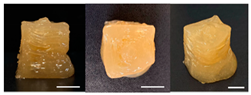

| A2 |  | 9.00 ± 0.0 | 8.49 ± 0.1 | 90.09 | 94.32 | Good molding |

| A3 |  | 8.40 ± 0.1 | 7.35 ± 0.2 | 83.99 | 87.55 | Uneven layer on the top of the printed object |

| A4 |  | 9.65 ± 0.1 | 9.36 ± 0.2 | 96.49 | 96.96 | Good molding |

| A5 |  | 8.40 ± 0.1 | 7.45 ± 0.1 | 83.90 | 88.78 | Uneven layer surface and unstable internal filling |

| A6 |  | 8.90 ± 0.2 | 8.78 ± 0.1 | 89.03 | 98.60 | Good molding but there are broken threads |

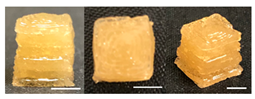

| B1 |  | 7.84 ± 0.2 | 5.55 ± 0.1 | 78.41 | 85.01 | No basic form and spreads after printing |

| B2 |  | 8.05 ± 0.1 | 6.67 ± 0.1 | 80.45 | 75.23 | No basic form and spreads after printing |

| B3 |  | 9.01 ± 0.2 | 6.38 ± 0.1 | 90.12 | 70.84 | Good adhesion between layers but not enough hardening |

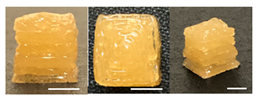

| B4 |  | 9.77 ± 0.1 | 9.21 ± 0.1 | 97.68 | 94.32 | Good molding |

| B5 |  | 9.71 ± 0.2 | 9.27 ± 0.1 | 97.05 | 95.48 | Good molding |

| B6 |  | 9.68 ± 0.1 | 9.38 ± 0.1 | 96.79 | 96.96 | Good molding |

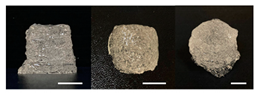

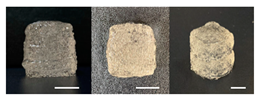

| C1 |  | 8.88 ± 0.2 | 8.40 ± 0.2 | 88.76 | 94.66 | Weak gel formulation, poor shape retention |

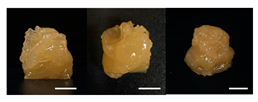

| C2 |  | 9.53 ± 0.1 | 9.29 ± 0.3 | 95.32 | 97.45 | Good molding |

| C3 |  | 9.00 ± 0.1 | 8.47 ± 0.2 | 89.99 | 94.11 | Cluttered line and uneven layer |

| C4 |  | 9.51 ± 01 | 9.32 ± 0.2 | 95.06 | 98.06 | Good molding |

| C5 |  | 9.08 ± 0.1 | 8.65 ± 0.1 | 90.78 | 95.34 | Cluttered line and uneven layer |

| C6 |  | 9.49 ± 0.1 | 9.68 ± 0.1 | 94.89 | 98.86 | Good molding |

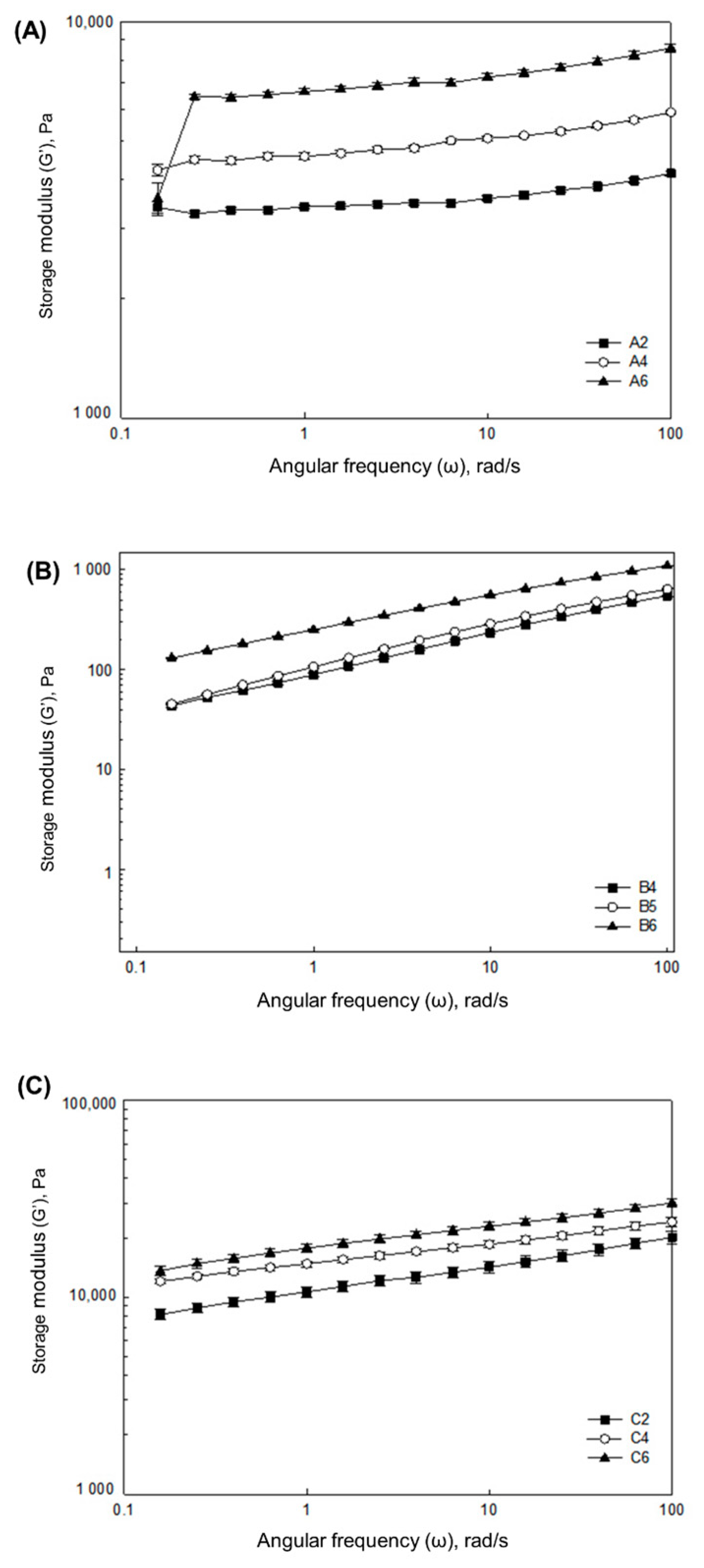

| Sample | G’ (Pa) | τ0 (Pa) | δ (°) |

|---|---|---|---|

| A2 | 3539.70 ± 18.80 | 258.30 | 5.88 ± 3.56 |

| A4 | 5410.13 ± 88.41 | 267.28 | 5.04 ± 0.21 |

| A6 | 7597.08 ± 170.43 | 283.09 | 4.78 ± 1.80 |

| B4 | 208.74 ± 7.78 | 207.06 | 33.96 ± 0.77 |

| B5 | 247.95 ± 12.34 | 224.41 | 33.64 ± 0.97 |

| B6 | 470.48 ± 26.22 | 281.45 | 28.79 ± 0.99 |

| C2 | 6577.77 ± 115.53 | 204.21 | 12.86 ± 0.13 |

| C4 | 8754.99 ± 50.71 | 280.32 | 9.81 ± 0.07 |

| C6 | 14,287.78 ± 91.24 | 295.15 | 7.55 ± 0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

In, J.; Jeong, H.; Song, S.; Min, S.C. Determination of Material Requirements for 3D Gel Food Printing Using a Fused Deposition Modeling 3D Printer. Foods 2021, 10, 2272. https://doi.org/10.3390/foods10102272

In J, Jeong H, Song S, Min SC. Determination of Material Requirements for 3D Gel Food Printing Using a Fused Deposition Modeling 3D Printer. Foods. 2021; 10(10):2272. https://doi.org/10.3390/foods10102272

Chicago/Turabian StyleIn, Jiwon, Haeun Jeong, Sanghoon Song, and Sea C. Min. 2021. "Determination of Material Requirements for 3D Gel Food Printing Using a Fused Deposition Modeling 3D Printer" Foods 10, no. 10: 2272. https://doi.org/10.3390/foods10102272