Physicochemical, Functional, Fatty Acids Profile, Health Lipid Indices, Microstructure and Sensory Characteristics of Walnut-Processed Cheeses

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Formulation and Processing of Walnuts Processed Cheese

2.2.2. Physicochemical and Functional Analysis

2.2.3. Fatty Acids Profile

2.2.4. Health Lipid Indices

2.2.5. Cheese Microstructure

2.2.6. Sensory Evaluation

2.2.7. Statistical Analysis

3. Results and Discussion

3.1. Physicochemical and Functional Characteristics

3.2. Meltability and Oil Separation

3.3. Fatty Acids Profile of Walnuts Processed Cheeses

3.4. Health-Related Lipids Indices

3.5. Microstructure of Processed Cheese

3.6. Sensory Evaluation

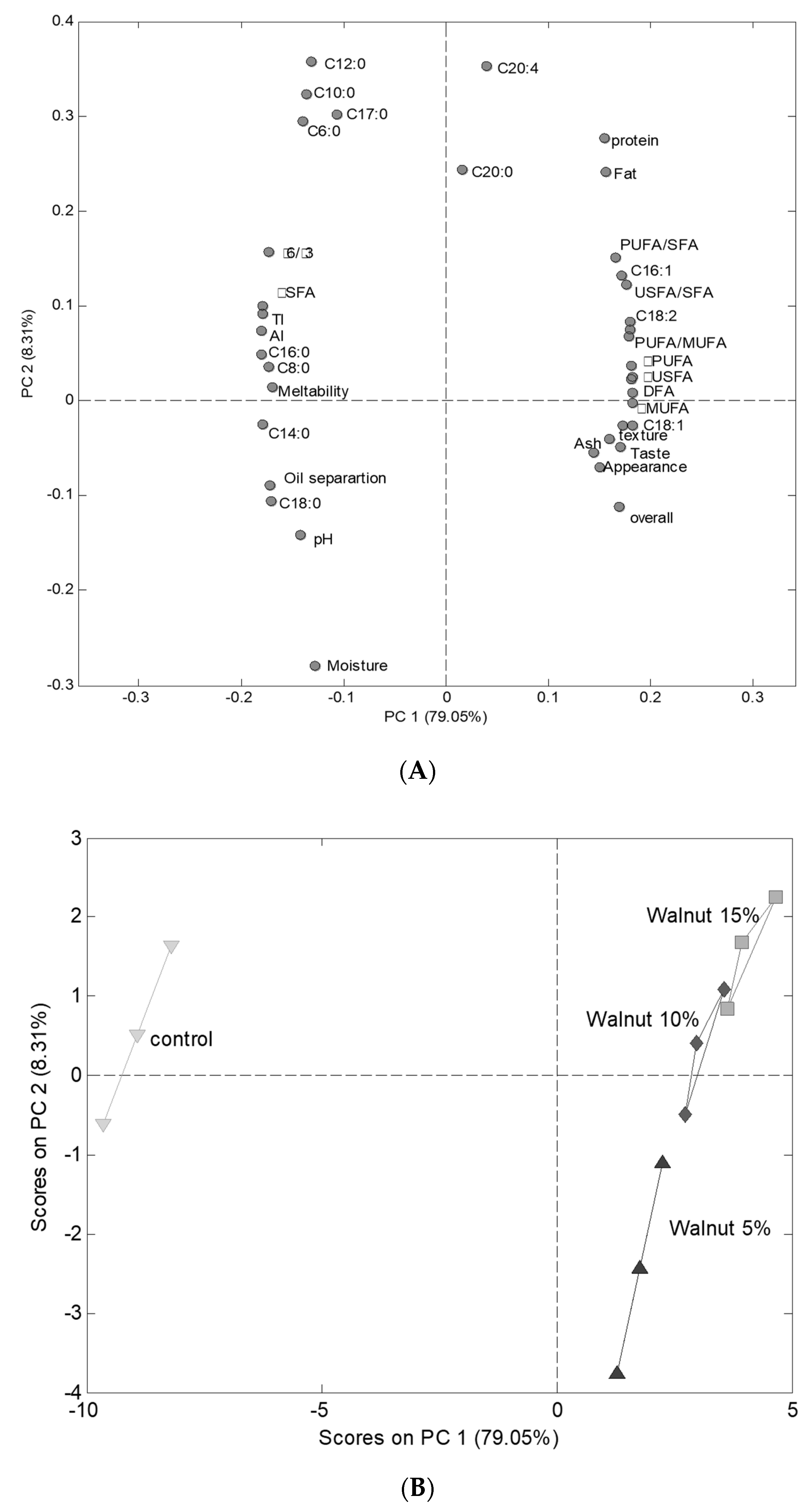

3.7. Principal Components Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jiménez-Colmenero, F.; Sánchez-Muniz, F.J.; Olmedilla-Alonso, B. Design and development of meat-based functional foods with walnut: Technological, nutritional and health impact. Food Chem. 2010, 123, 959–967. [Google Scholar] [CrossRef] [Green Version]

- Pereira, J.A.; Oliveira, I.; Sousa, A.; Ferreira, I.C.; Bento, A.; Estevinho, L. Bioactive properties and chemical composition of six walnut (Juglans regia L.) cultivars. Food Chem. Toxicol. 2008, 46, 2103–2111. [Google Scholar] [CrossRef]

- Ros, E. Health benefits of nut consumption. Nutrients 2010, 2, 652–682. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moigradean, D.; Poiana, M.-A.; Alda, L.-M.; Gogoasa, I. Quantitative identification of fatty acids from walnut and coconut oils using GC-MS method. Journal of Agroalimentary. Process. Technol. 2013, 19, 459–463. [Google Scholar]

- Grosso, G.; Estruch, R. Nut consumption and age-related disease. Maturitas 2016, 84, 11–16. [Google Scholar] [CrossRef] [PubMed]

- Petrović-Oggiano, G.; Debeljak-Martačić, J.; Ranković, S.; Pokimica, B.; Mirić, A.; Glibetić, M.; Popović, T. The effect of walnut consumption on n-3 fatty acid profile of healthy people living in a non-Mediterranean West Balkan country, a small-scale randomized study. Nutrients 2020, 12, 192. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Serrano, A.; Librelotto, J.; Cofrades, S.; Sánchez-Muniz, F.J.; Jiménez-Colmenero, F. Composition and physicochemical characteristics of restructured beef steaks containing walnuts as affected by cooking method. Meat Sci. 2007, 77, 304–313. [Google Scholar] [CrossRef]

- Guinee, T. Effects of natural cheese characteristics and processing conditions on rheology and texture: The functionality of cheese components in the manufacture of processed cheese. Process. Cheese Analog. 2011, 81–109. [Google Scholar] [CrossRef]

- Solhi, P.; Azadmard-Damirchi, S.; Hesari, J.; Hamishehkar, H. Production of the processed cheese containing tomato powder and evaluation of its rheological, chemical and sensory characteristics. J. Food Sci. Technol. 2020, 57, 2198–2205. [Google Scholar] [CrossRef]

- Solhi, P.; Azadmard-Damirchi, S.; Hesari, J.; Hamishehkar, H. Effect of fortification with asparagus powder on the qualitative properties of processed cheese. Int. J. Dairy Technol. 2020, 73, 226–233. [Google Scholar] [CrossRef]

- Rafiq, S.; Ghosh, B. Effect of Peanut Addition on the Fatty Acid Profile and Rheological Properties of Processed Cheese. Food Process. Technol. 2017, 8, 2. [Google Scholar]

- Mohamed, A.; Abo-El-Khair, B.; Shalaby, S.M. Quality of novel healthy processed cheese analogue enhanced with marine microalgae Chlorella vulgaris biomass. World Appl. Sci. J. 2013, 23, 914–925. [Google Scholar]

- Krumov, K.; Ivanov, G.; Slavchev, A.; Nenov, N. Improving the processed cheese quality by the addition of natural spice extracts. Adv. J. Food Sci. Technol. 2010, 2, 335–339. [Google Scholar]

- Giri, A.; Kanawjia, S.K.; Singh, M.P. Effect of inulin on physico-chemical, sensory, fatty acid profile and microstructure of processed cheese spread. J. Food Sci. Technol. 2017, 54, 2443–2451. [Google Scholar] [CrossRef]

- El-Sayed, S.M.; Salama, H.H.; El-Sayed, M.M. Function processed cheese sauce fortified with peanut butter. J. Food Process. Preserv. 2020, 44, e14656. [Google Scholar] [CrossRef]

- Ye, A.; Cui, J.; Taneja, A.; Zhu, X.; Singh, H. Evaluation of processed cheese fortified with fish oil emulsion. Food Res. Int. 2009, 42, 1093–1098. [Google Scholar] [CrossRef]

- AOAC. Association of Official Analytical Chemists, 19th ed.; AOAC: Washington, DC, USA, 2010. [Google Scholar]

- Wang, F.; Zhang, X.; Luo, J.; Guo, H.; Zeng, S.S.; Ren, F. Effect of Proteolysis and Calcium Equilibrium on Functional Properties of Natural Cheddar Cheese during Ripening and the Resultant Processed Cheese. J. Food Sci. 2011, 76, E248–E253. [Google Scholar] [CrossRef]

- Thomas, M. The use of a hard milkfat fraction in processed cheese. Aust. J. Dairy Technol. 1973, 28, 77. [Google Scholar]

- Maguire, L.; O’sullivan, S.; Galvin, K.; O’connor, T.; O’brien, N. Fatty acid profile, tocopherol, squalene and phytosterol content of walnuts, almonds, peanuts, hazelnuts and the macadamia nut. Int. J. Food Sci. Nutr. 2004, 55, 171–178. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, N.; Manzoor, M.F.; Shabbir, U.; Ahmed, S.; Ismail, T.; Saeed, F.; Nisa, M.; Anjum, F.M.; Hussain, S. Health lipid indices and physicochemical properties of dual fortified yogurt with extruded flaxseed omega fatty acids and fibers for hypercholesterolemic subjects. Food Sci. Nutr. 2020, 8, 273–280. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cunha, C.R.; Dias, A.I.; Viotto, W.H. Microstructure, texture, colour and sensory evaluation of a spreadable processed cheese analogue made with vegetable fat. Food Res. Int. 2010, 43, 723–729. [Google Scholar] [CrossRef]

- Amini, R.K.; Islam, M.Z.; Kitamura, Y.; Kokawa, M. Utilization of fermented rice milk as a novel coagulant for development of paneer (soft cheese). Foods 2019, 8, 339. [Google Scholar] [CrossRef] [Green Version]

- Patraş, A.; Dorobanţu, P. Physical and chemical composition of some walnut (Juglans regia L) biotypes from Moldavia. Lucrări Ştiinţifice 2010, 53, 57. [Google Scholar]

- Ozturkoglu-Budak, S.; Akal, C.; Yetisemiyen, A. Effect of dried nut fortification on functional, physicochemical, textural, and microbiological properties of yogurt. J. Dairy Sci. 2016, 99, 8511–8523. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lamichhane, P.; Kelly, A.L.; Sheehan, J.J. Symposium review: Structure-function relationships in cheese. J. Dairy Sci. 2018, 101, 2692–2709. [Google Scholar] [CrossRef]

- Awad, R.; Abdel-Hamid, L.; El-Shabrawy, S.; Singh, R. Physical and sensory properties of block processed cheese with formulated emulsifying salt mixtures. Int. J. Food Prop. 2004, 7, 429–448. [Google Scholar] [CrossRef]

- Monteiro, R.; Tavares, D.; Kindstedt, P.; Gigante, M. Effect of pH on microstructure and characteristics of cream cheese. J. Food Sci. 2009, 74, C112–C117. [Google Scholar] [CrossRef]

- Goh, K.K.T.; Ye, A.; Dale, N. Characterisation of ice cream containing flaxseed oil. Int. J. Food Sci. Technol. 2006, 41, 946–953. [Google Scholar] [CrossRef]

- Krauss, R.M.; Eckel, R.H.; Howard, B.; Appel, L.J.; Daniels, S.R.; Deckelbaum, R.J.; Erdman, J.W., Jr.; Kris-Etherton, P.; Goldberg, I.J.; Kotchen, T.A. AHA Dietary Guidelines: Revision 2000: A statement for healthcare professionals from the Nutrition Committee of the American Heart Association. Circulation 2000, 102, 2284–2299. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wood, J.D.; Richardson, R.I.; Nute, G.R.; Fisher, A.V.; Campo, M.M.; Kasapidou, E.; Sheard, P.R.; Enser, M. Effects of fatty acids on meat quality: A review. Meat Sci. 2004, 66, 21–32. [Google Scholar] [CrossRef]

- Jiménez Colmenero, F.; Serrano, A.; Ayo, J.; Solas, M.T.; Cofrades, S.; Carballo, J. Physicochemical and sensory characteristics of restructured beef steak with added walnuts. Meat Sci. 2003, 65, 1391–1397. [Google Scholar] [CrossRef]

| Attributes | Samples | |||

|---|---|---|---|---|

| Control | 5% Walnuts | 10% Walnuts | 15% Walnuts | |

| pH | 5.20 ± 0.00 a | 5.13 ± 0.06 ab | 5.07 ± 0.06 bc | 5.00 ± 0.00 c |

| Acidity (%) | 1.32 ± 0.08 c | 1.87 ± 0.13 b | 1.95 ± 0.05 b | 2.10 ± 0.02 a |

| Moisture (%) | 40.76 ± 0.06 a | 40.63 ± 0.31 a | 38.41 ± 0.27 b | 38.34 ± 0.07 b |

| Fat (%) | 28.33 ± 0.29 d | 29.50 ± 0.00 c | 31.67 ± 0.29 b | 32.17 ± 0.29 a |

| Protein (%) | 23.03 ± 0.45 b | 23.53 ± 0.30 b | 24.24 ± 0.06 a | 24.45 ± 0.13 a |

| Ash (%) | 4.78 ± 0.07 c | 5.02 ± 0.06 b | 5.41 ± 0.02 a | 5.50 ± 0.10 a |

| Meltability (%) | 38.33 ± 1.44 a | 21.67 ± 3.82 b | 20.83 ± 2.89 c | 14.17 ±1.44 d |

| Oil separation index (%) | 32.47 ± 0.23 a | 28.04 ± 0.11 b | 26.92 ± 0.35 c | 24.66 ± 0.02 d |

| Fatty Acids | Samples | |||

|---|---|---|---|---|

| Control | 5% Walnuts | 10% Walnuts | 15% Walnuts | |

| Saturated fatty acids (SFA %) | ||||

| Caproic acid (C6:0) | 3.21 ± 0.27 a | 2.41 ± 0.01 c | 2.45 ± 0.01 c | 2.76 ± 0.02 b |

| Caprylic acid (C8:0) | 4.27 ± 0.30 a | 2.87 ± 0.04 b | 2.27 ± 0.05 d | 2.56 ± 0.03 c |

| Capric acid (C10:0) | 5.91 ± 0.40 a | 3.17 ± 0.03 d | 3.44 ± 0.06 c | 4.70 ± 0.02 b |

| Lauric acid (C12:0) | 6.33 ± 0.37 a | 0.95 ± 0.05 c | 3.62 ± 0.01 b | 3.63 ± 0.01 b |

| Myristic acid (C14:0) | 11.74 ± 0.26 a | 6.89 ± 0.02 b | 5.75 ± 002 c | 4.74 ± 0.04 d |

| Palmitic acid (C16:0) | 16.78 ± 0.25 a | 10.04 ± 0.07 b | 8.69 ± 0.08 d | 9.02 ± 0.05 c |

| Margaric acid (C17:0) | 1.62 ± 0.28 a | 0.57 ± 0.09 d | 1.37 ± 0.05 b | 0.77 ± 0.09 c |

| Stearic acid (C18:0) | 7.82 ± 0.29 a | 6.25 ± 0.01 b | 5.24 ± 0.06 c | 4.82 ± 0.06 d |

| Arachidic acid (C20:0) | 0.10 ± 0.01 a | 0.09 ± 0.01 a | 0.11 ± 0.01 a | 0.12 ± 0.02 a |

| Unsaturated fatty acids (USFA %) | ||||

| Palmitoleic acid (C16:1) | 4.17 ± 0.12 c | 5.49 ± 0.49 b | 5.57 ± 0.45 b | 6.32 ± 0.12 a |

| Oleic acid (C18:1) | 3.59 ± 0.18 d | 8.49 ± 0.35 c | 8.64 ± 0.40 b | 9.24 ± 0.35 a |

| Linoleic acid (C18:2) ω6 | 1.69 ± 0.45 d | 6.51 ± 0.66 c | 8.60 ± 0.45 b | 9.02 ± 0.66 a |

| Linolenic acid (C18:3) ω3 | 0.82 ± 0.25 d | 11.38 ± 0.44 c | 13.85 ± 0.45 b | 14.61 ± 0.33 a |

| Arachidonic acid (C20:4) | 0.10 ± 0.45 c | 0.09 ± 0.22 b | 0.08 ± 0.19 b | 0.30 ± 0.15 a |

| Indices | Samples | |||

|---|---|---|---|---|

| Control | 5% Walnuts | 10% Walnuts | 15% Walnuts | |

| Σ SFA (%) | 57.88 ± 0.24 a | 33.24 ± 0.25 b | 32.76 ± 0.26 c | 33.12 ± 0.28 b |

| Σ USFA (%) | 10.37 ± 0.26 d | 31.96 ± 0.23 c | 36.74 ± 0.14 b | 39.49 ± 0.15 a |

| Σ MUFA (%) | 7.76 ± 0.24 d | 13.98 ± 0.13 c | 14.21 ± 0.16 b | 15.56 ± 0.18 a |

| Σ PUFA (%) | 2.61 ± 0.22 d | 17.98 ± 0.21 c | 22.53 ± 0.12 b | 23.93 ± 0.27 a |

| USFA/SFA ratio | 0.18 ± 0.21 d | 0.96 ± 0.16 c | 1.12 ± 0.11 b | 1.31 ± 0.09 a |

| PUFA/MUFA ratio | 0.33 ± 0.09 c | 1.28 ± 0.16 b | 1.58 ± 0.13 a | 1.54 ± 0.13 a |

| PUFA/SFA ratio | 0.04 ± 0.18 c | 0.54 ± 0.13 b | 0.68 ± 0.15 a | 0.72 ± 0.16 a |

| ω6/ω3 ratio | 2.06 ± 0.12 a | 0.57 ± 0.15 b | 0.62 ± 0.09 b | 0.61 ± 0.11 b |

| Desirable fatty acids (DFA) (%) | 18.19 ± 0.21 d | 38.21 ± 0.22 c | 41.98 ± 0.19 b | 44.29 ± 0.13 a |

| Atherogenic index (AI) (%) | 6.85 ± 0.01 a | 1.21 ± 0.02 b | 0.96 ± 0.00 c | 0.80 ± 0.01 d |

| Thrombogenic index (TI) (%) | 4.74 ± 0.09 a | 0.50 ± 0.08 b | 0.36 ± 0.01 c | 0.32 ± 0.01 c |

| Attribute | Samples | |||

|---|---|---|---|---|

| Control | 5% Walnuts | 10% Walnuts | 15% Walnuts | |

| Appearance | 7.00 ± 0.47 c | 8.60 ± 0.52 a | 8.20 ± 0.63 ab | 7.90 ± 0.57 b |

| Texture | 7.20 ± 0.42 c | 8.80 ± 0.42 a | 8.70 ± 0.48 a | 7.90 ± 0.57 b |

| Taste | 6.90 ± 0.32 c | 8.80 ± 0.42 a | 8.60 ± 0.52 a | 8.40 ± 0.52 b |

| Smell | 6.70 ± 0.67 c | 8.90 ± 0.32 a | 8.80 ± 0.42 a | 8.60 ± 0.52 b |

| Overall acceptability | 27.80 ± 0.92 c | 35.10 ± 1.20 a | 34.30 ± 1.25 a | 33.10 ± 1.20 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbas, K.A.; Abdelmontaleb, H.S.; Hamdy, S.M.; Aït-Kaddour, A. Physicochemical, Functional, Fatty Acids Profile, Health Lipid Indices, Microstructure and Sensory Characteristics of Walnut-Processed Cheeses. Foods 2021, 10, 2274. https://doi.org/10.3390/foods10102274

Abbas KA, Abdelmontaleb HS, Hamdy SM, Aït-Kaddour A. Physicochemical, Functional, Fatty Acids Profile, Health Lipid Indices, Microstructure and Sensory Characteristics of Walnut-Processed Cheeses. Foods. 2021; 10(10):2274. https://doi.org/10.3390/foods10102274

Chicago/Turabian StyleAbbas, Khaled A., Hani S. Abdelmontaleb, Shaimaa M. Hamdy, and Abderrahmane Aït-Kaddour. 2021. "Physicochemical, Functional, Fatty Acids Profile, Health Lipid Indices, Microstructure and Sensory Characteristics of Walnut-Processed Cheeses" Foods 10, no. 10: 2274. https://doi.org/10.3390/foods10102274

APA StyleAbbas, K. A., Abdelmontaleb, H. S., Hamdy, S. M., & Aït-Kaddour, A. (2021). Physicochemical, Functional, Fatty Acids Profile, Health Lipid Indices, Microstructure and Sensory Characteristics of Walnut-Processed Cheeses. Foods, 10(10), 2274. https://doi.org/10.3390/foods10102274