Recent Advances in Aluminum Nitride (AlN) Growth by Magnetron Sputtering Techniques and Its Applications

Abstract

1. Introduction

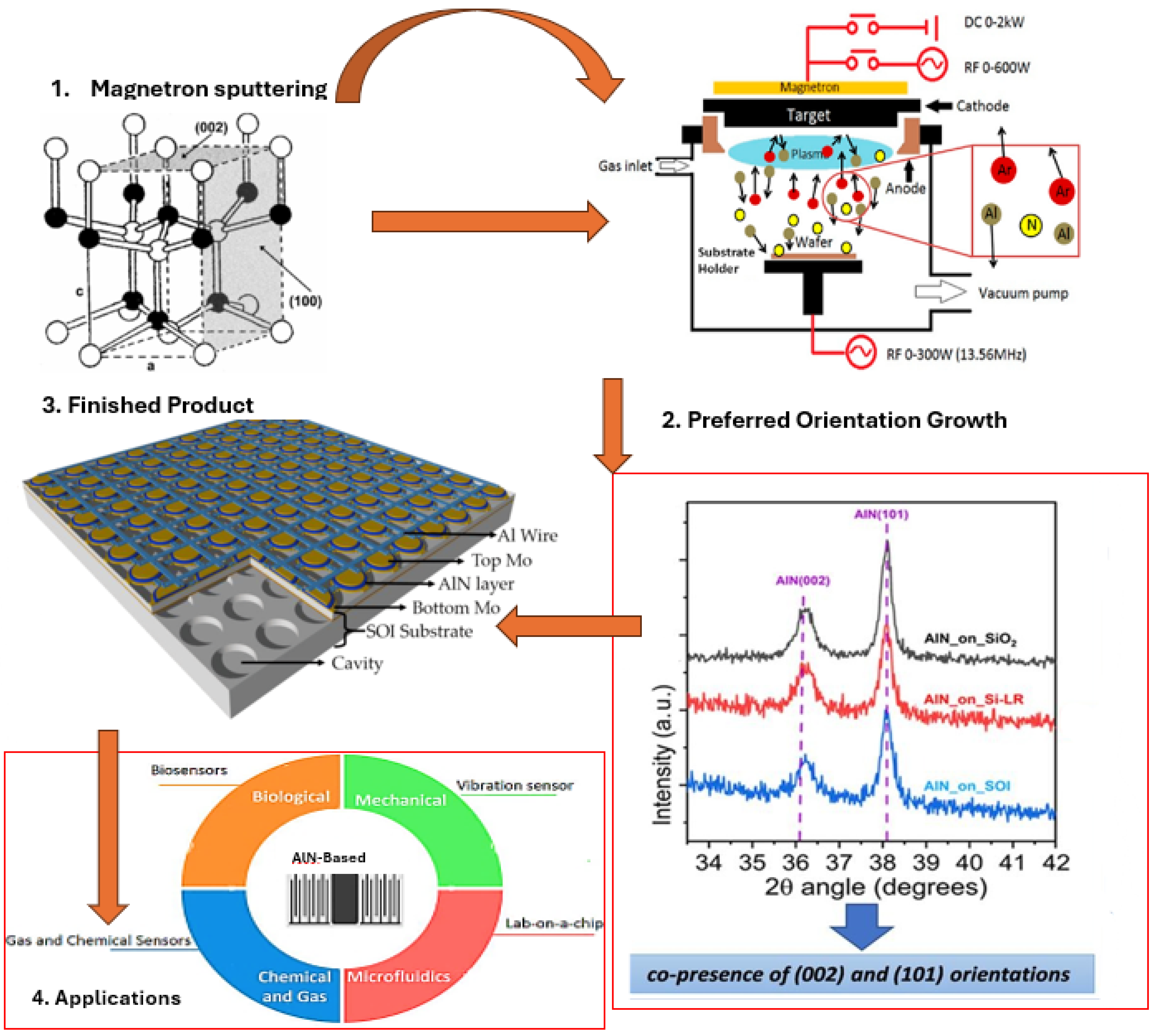

2. AlN Growth and Mechanism

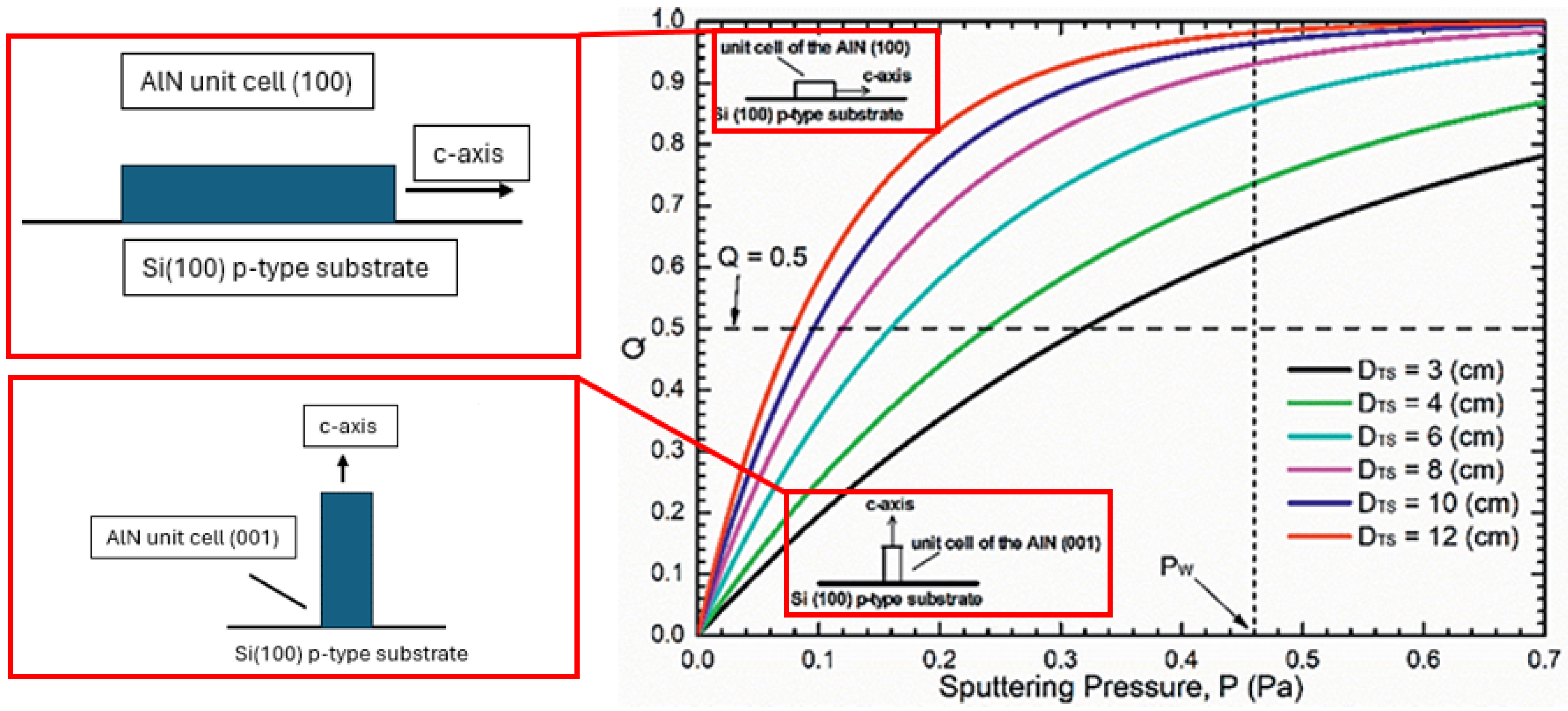

2.1. AlN Crystal Structure and Growth Mechanism

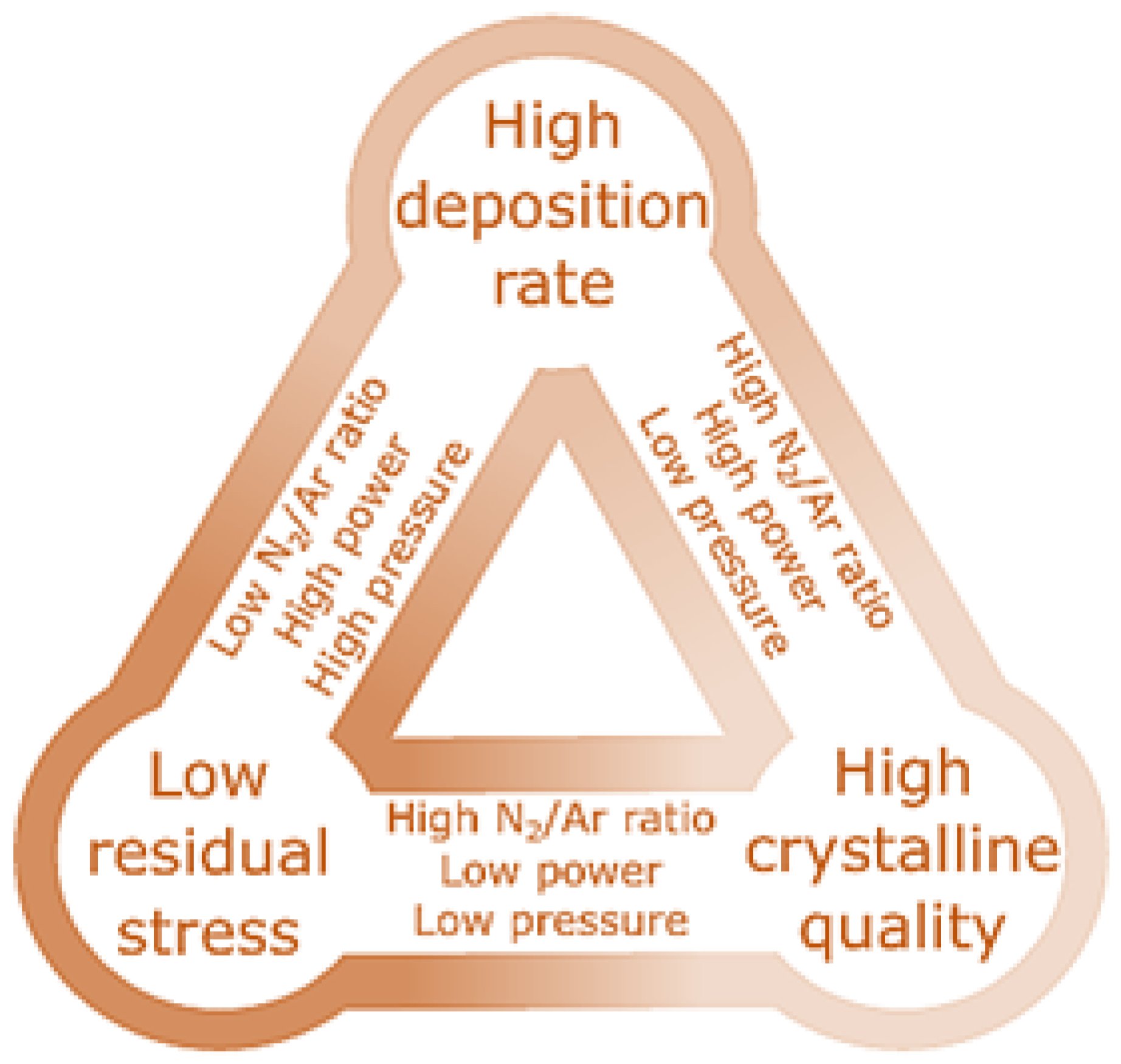

2.2. Effect of Operational Parameters and Development Techniques on Grown AlN Film Properties

3. Fabrication

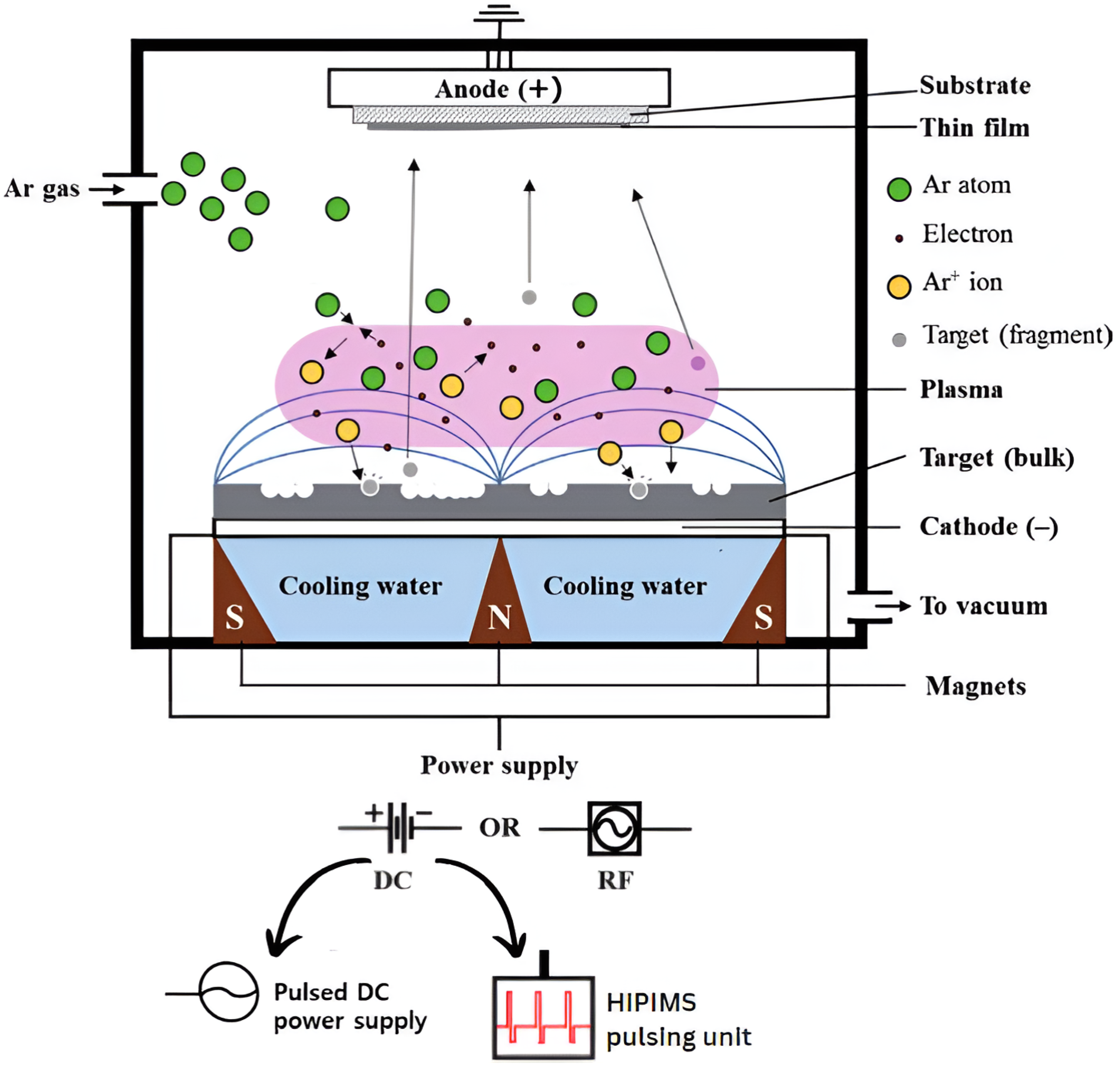

3.1. Magnetron Sputtering General Mechanism

3.1.1. Types of Magnet Configurations and Arrangements

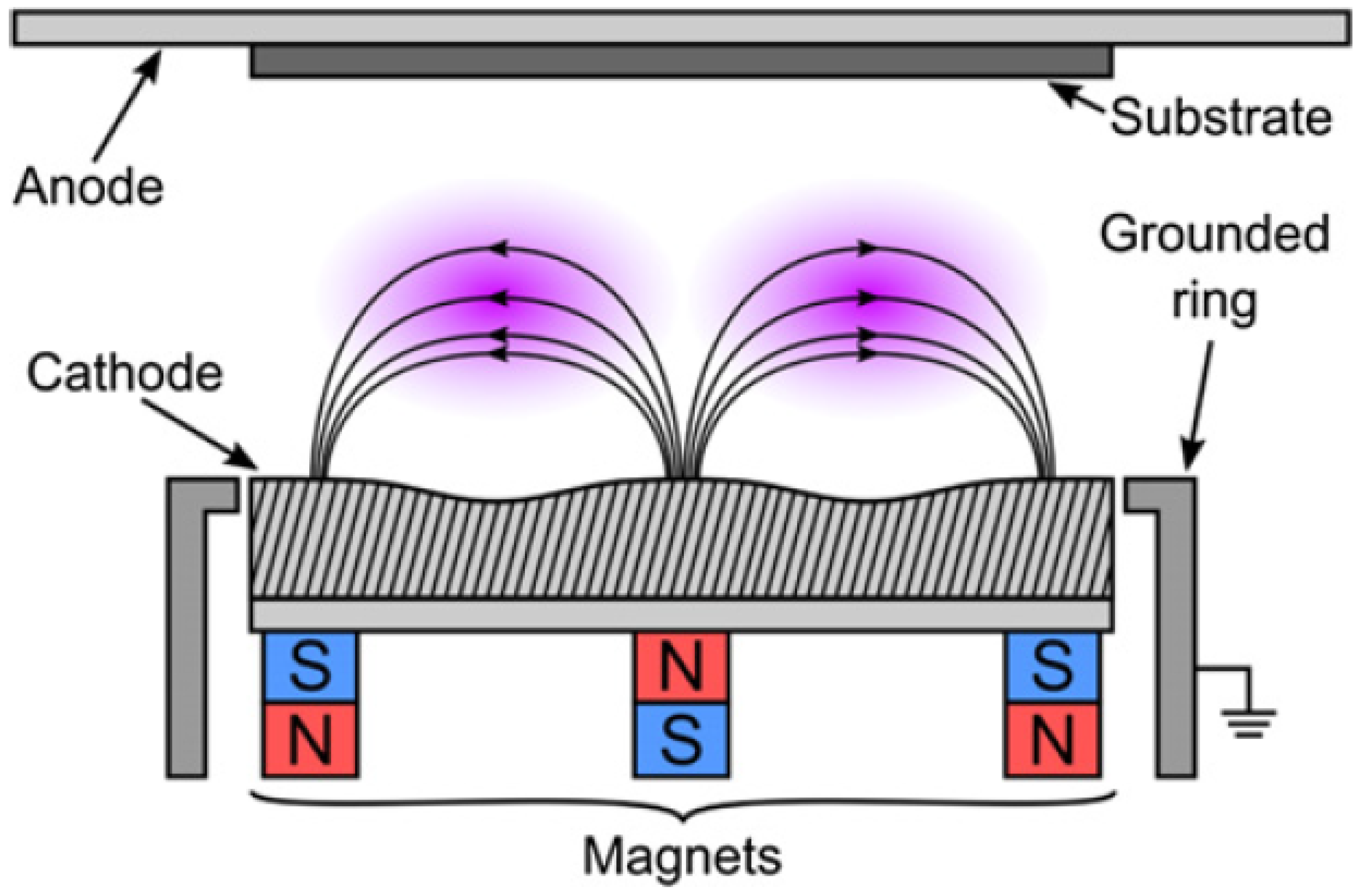

- Planar Magnetron Sputtering: In this configuration, magnets are arranged behind a flat target. The magnetic field lines run parallel to the target surface, creating a closed loop that traps electrons near the target. This is the most common configuration and is widely used for a variety of applications [50,54], depicted in Figure 4.

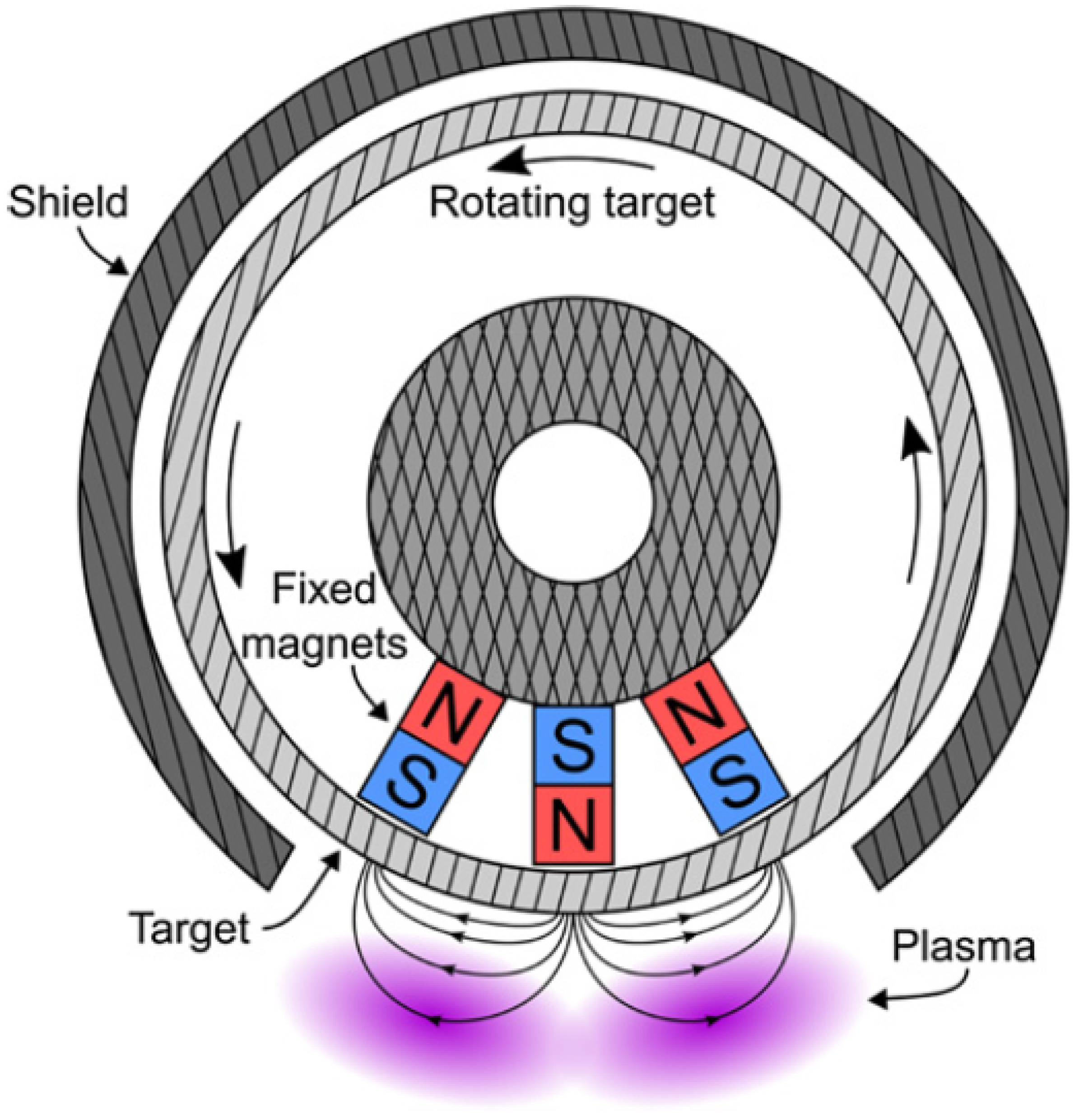

- Rotatable Cylindrical Magnetron: In this advanced configuration, the target is a cylindrical tube that rotates around a stationary magnet assembly, as shown in Figure 5. This setup maximizes target utilization and is used for large-area coatings, such as architectural glass and display panels [50,54].

- Balanced and Unbalanced Magnetrons: Balanced magnetrons have equal magnetic flux from the central and outer magnets, which is the case in Figure 4, in a planner configuration. On the other hand, unbalanced magnetrons have stronger outer magnets, allowing magnetic field lines to extend towards the substrate [50,54].

3.1.2. Magnetron Sputtering Categorization

3.2. Pre-Experimental Steps for AlN Deposition in Magnetron Sputtering Methods

3.2.1. Substrate Cleaning

3.2.2. Target Preparation and Positioning

3.3. Sputtering Conditions and Deposition Parameters for Magnetron Sputtering of AlN Films

3.3.1. RF Magnetron Sputtering Conditions and Related Work

3.3.2. Reactive Magnetron Sputtering Conditions and Related Work

3.3.3. DC Magnetron Sputtering Conditions and Related Work

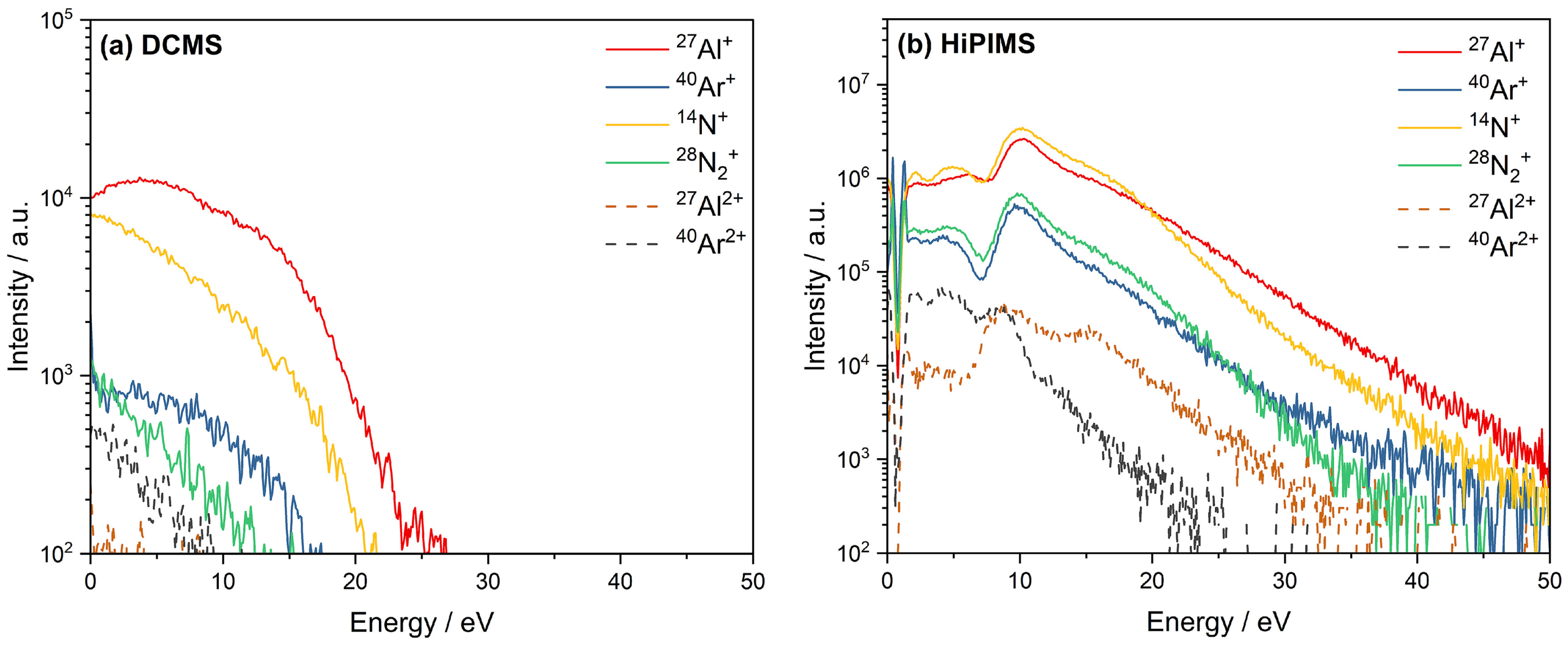

3.3.4. High-Impluse DC Magnetron Sputtering Conditions and Related Work

3.4. Comparative Study of Synthesis of AlN with Various Deposition Techniques

3.4.1. Dual Ion Beam Sputtering

3.4.2. Molecular Beam Epitaxy (MBE)

3.4.3. Chemical Vapor Deposition (CVD)

3.4.4. Pulsed Laser Deposition (PLD)

3.5. Doping and Coating Al Target with Other Materials

3.5.1. Scandium Doping

3.5.2. Chromium Doping

3.5.3. Chromium Coating

4. Applications of AlN

4.1. Application in Wave Resonators

4.2. AlN-Based Energy Harvesting Application

4.3. AlN Applications in Thermal Management

5. Summary and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Cunha, C.L.A.; Pimenta, T.C.; Fraga, M.A. Development and Applications of Aluminum Nitride Thin Film Technology. In Thin Films; Yang, D., Ed.; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Yen, T.T.; Hirasawa, T.; Wright, P.K.; Pisano, A.P.; Lin, L. Corrugated aluminum nitride energy harvesters for high energy conversion effectiveness. J. Micromechanics Microengineering 2011, 21, 085037. [Google Scholar] [CrossRef]

- Elfrink, R.; Kamel, T.M.; Goedbloed, M.; Matova, S.; Hohlfeld, D.; van Andel, Y.; van Schaijk, R. Vibration energy harvesting with aluminum nitride-based piezoelectric devices. J. Micromechanics Microengineering 2009, 19, 094005. [Google Scholar] [CrossRef]

- Elfrink, R.; Renaud, M.; Kamel, T.M.; de Nooijer, C.; Jambunathan, M.; Goedbloed, M.; Hohlfeld, D.; van Andel, Y.; van Schaijk, R. Vacuum-packaged piezoelectric vibration energy harvesters: Damping contributions and autonomy for a wireless sensor system. J. Micromechanics Microengineering 2010, 20, 104001. [Google Scholar] [CrossRef]

- Bu, G.; Ciplys, D.; Shur, M.; Schowalter, L.J.; Schujman, S.; Gaska, R. Surface acoustic wave velocity in single-crystal AlN substrates. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2006, 53, 251–254. [Google Scholar] [CrossRef] [PubMed]

- Shelton, S.; Chan, M.L.; Park, H.; Horsley, D.; Boser, B.; Izyumin, I.; Przybyla, R.; Frey, T.; Judy, M.; Nunan, K.; et al. CMOS-compatible AlN piezo electric micromachined ultrasonic transducers. In Proceedings of the 2009 IEEE International Ultrasonics Symposium, Rome, Italy, 20–23 September 2009; pp. 402–405. [Google Scholar]

- Horsley, D. Aluminum nitride pMUT based on a flexurally-suspended membrane. In Proceedings of the 2011 Solid State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011. [Google Scholar]

- Yokoyama, T.; Iwazaki, Y.; Nishihara, T.; Ueda, M. Analysis on electromechanical coupling coefficients in AlN-based bulk acoustic wave resonators based on first-principle calculations. In Proceedings of the 2012 IEEE International Ultrasonics Symposium, Dresden, Germany, 7–10 October 2012; pp. 551–554. [Google Scholar] [CrossRef]

- Hartnett, T.M.; Bernstein, S.D.; Maguire, E.A.; Tustison, R.W. Optical properties of ALON (aluminum oxynitride). In Proceedings of the Window and Dome Technologies and Materials V, Orlando, FL, USA, 27 June 1997. [Google Scholar]

- Fan, Z.; Qin, Z.; Sun, Z.; Wu, H. Broad Spectrum Detector Based on AlN Crystal. J. Phys. Conf. Ser. 2022, 2350, 012013. [Google Scholar] [CrossRef]

- Bickermann, M.; Epelbaum, B.M.; Filip, O.; Heimann, P.J.; Nagata, S.; Winnacker, A. UV transparent single-crystalline bulk AlN substrates. Phys. Status Solidi 2010, 7, 21–24. [Google Scholar] [CrossRef]

- Xu, X.; Huang, X.; Wang, X.; Kang, J.; Zheng, Y.; Chen, X. Aluminum Nitride Film and Preparation Method and Application Thereof. CN111690907A. 22 September 2020. Available online: https://www.iprdb.com/patent/CN111690907A.html#/basic (accessed on 2 September 2023).

- Park, J.H.; Steckl, A.J. Laser action in Eu-doped GaN thin-film cavity at room temperature. Appl. Phys. Lett. 2004, 85, 4588–4590. [Google Scholar] [CrossRef]

- Pearton, S.J.; Zolper, J.C.; Shul, R.J.; Ren, F. GaN: Processing, defects, and devices. J. Appl. Phys. 1999, 86, 1–78. [Google Scholar] [CrossRef]

- Furqan, C.M.; Ho, J.Y.L.; Kwok, H.S. GaN thin film: Growth and Characterizations by Magnetron Sputtering. Surfaces Interfaces 2021, 26, 101364. [Google Scholar] [CrossRef]

- Anjum, F.; Ahmad, R.; Afzal, N.; Murtaza, G. Characterization of InN films prepared using magnetron sputtering at variable power. Mater. Lett. 2018, 219, 23–28. [Google Scholar] [CrossRef]

- Ishibe, T.; Tomeda, A.; Watanabe, K.; Kamakura, Y.; Mori, N.; Naruse, N.; Mera, Y.; Yamashita, Y.; Nakamura, Y. Methodology of Thermoelectric Power Factor Enhancement by Controlling Nanowire Interface. ACS Appl. Mater. Interfaces 2018, 10, 37709–37716. [Google Scholar] [CrossRef] [PubMed]

- Polewczyk, V.; Magrin Maffei, R.; Vinai, G.; Lo Cicero, M.; Prato, S.; Capaldo, P.; Dal Zilio, S.; di Bona, A.; Paolicelli, G.; Mescola, A.; et al. ZnO Thin Films Growth Optimization for Piezoelectric Application. Sensors 2021, 21, 6114. [Google Scholar] [CrossRef] [PubMed]

- van Deurzen, L.; Singhal, J.; Encomendero, J.; Pieczulewski, N.; Chang, C.S.; Cho, Y.; Muller, D.A.; Xing, H.G.; Jena, D.; Brandt, O.; et al. Excitonic and deep-level emission from N- and Al-polar homoepitaxial AlN grown by molecular beam epitaxy. APL Mater. 2023, 11, 081109. [Google Scholar] [CrossRef]

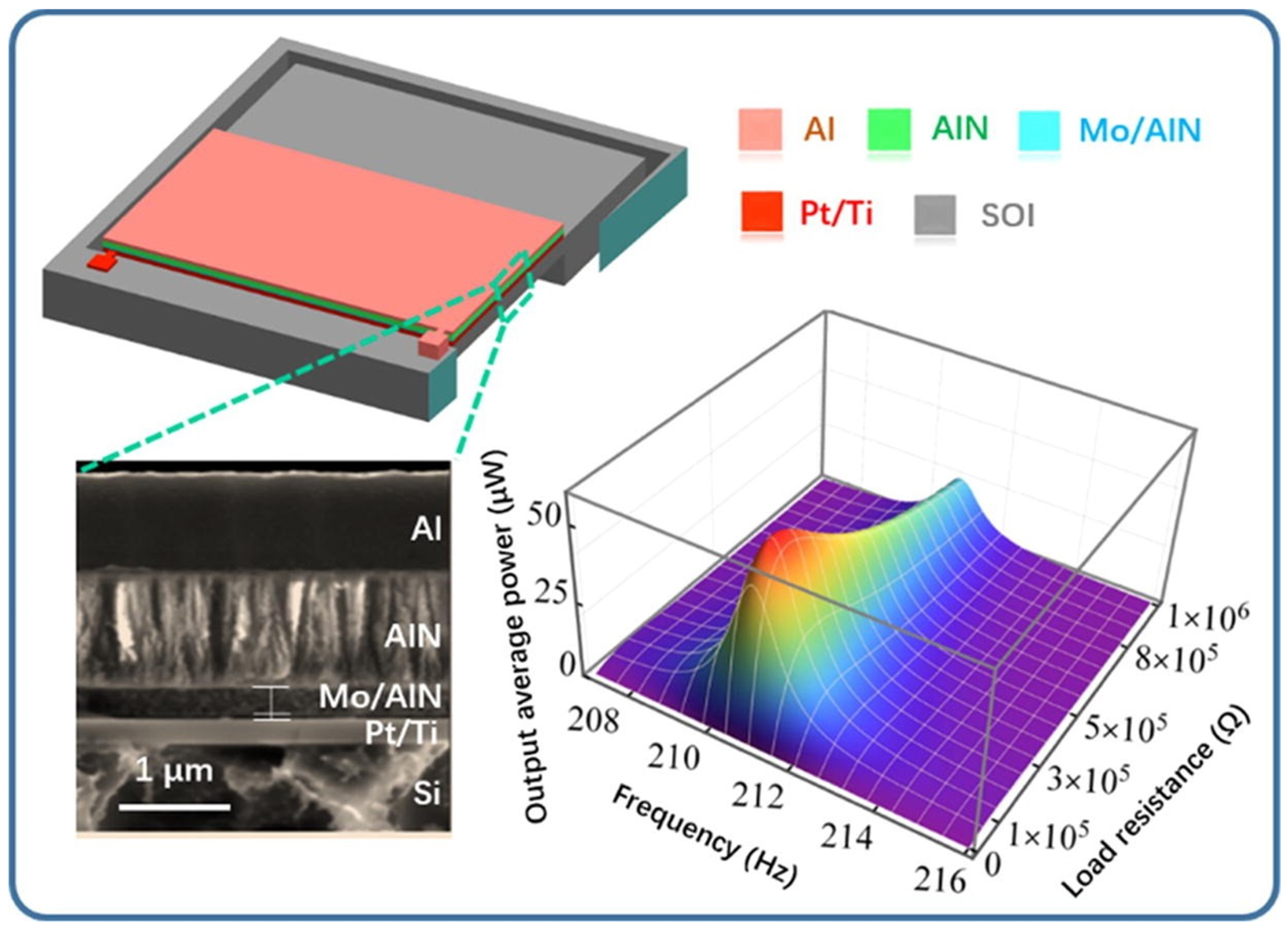

- Popov, V.; Chirumamilla, M.; Krekeler, T.; Ritter, M.; Pedersen, K. Magnetron Sputter Grown AlN Nanostructures with Giant Piezoelectric Response toward Energy Generation. ACS Appl. Nano Mater. 2023, 6, 8849–8856. [Google Scholar] [CrossRef]

- Hasegawa, F.; Takahashi, T.; Kubo, K.; Nannichi, Y. Plasma CVD of amorphous AlN from metalorganic Al source and properties of the deposited films. Jpn. J. Appl. Phys. 1987, 26, 1555. [Google Scholar] [CrossRef]

- Hisyam, M.I.; Shuhaimi, A.; Norhaniza, R.; Mansor, M.; Williams, A.; Hussin, M.R.M. Study of AlN Epitaxial Growth on Si (111) Substrate Using Pulsed Metal–Organic Chemical Vapour Deposition. Crystals 2024, 14, 371. [Google Scholar] [CrossRef]

- Sanz-Hervás, A.; Vergara, L.; Olivares, J.; Iborra, E.; Morilla, Y.; García-López, J.; Clement, M.; Sangrador, J.; Respaldiza, M.A. Comparative study of c-axis AlN films sputtered on metallic surfaces. Diam. Relat. Mater. 2005, 14, 1198–1202. [Google Scholar] [CrossRef]

- Barth, S.; Bartzsch, H.; Glöß, D.; Frach, P.; Modes, T.; Zywitzki, O.; Suchaneck, G.; Gerlach, G. Magnetron sputtering of piezoelectric AlN and AlScN thin films and their use in energy harvesting applications. Microsyst. Technol. 2016, 22, 1613–1617. [Google Scholar] [CrossRef]

- Fu, Y.Q.; Luo, J.K.; Nguyen, N.T.; Walton, A.J.; Flewitt, A.J.; Zu, X.T.; McHale, G.; Matthews, A.; Iborra, E.; Rowland, D.J.; et al. Advances in piezoelectric thin films for acoustic biosensors, acoustofluidics and lab-on-chip applications. Prog. Mater. Sci. 2017, 89, 31–91. [Google Scholar] [CrossRef]

- Badis, R.; Camus, J.; Ayad, A.; Rammal, M.; Zernadji, R.; Rouag, N.; Abdou, M.; Hetero, D. Epitaxial Growth of AlN Deposited by DC Magnetron Sputtering on Si(111) Using a AlN Buffer Layer. Coatings 2021, 11, 1063. [Google Scholar] [CrossRef]

- Jiang, J.; Fu, Y.; Zhang, J.; Wei, Y.; Zhang, G.; Cui, J. Growth of c-axis oriented AlN thin films on titanium alloy substrate by middle frequency magnetron sputtering. J. Vac. Sci. Technol. 2015, 33, 041509. [Google Scholar] [CrossRef]

- Uchiyama, S.; Nishi, N.; Makishima, A.; Miyamoto, S.; Ohmori, A.; Araki, Y. Growth of AlN films by magnetron sputtering. J. Cryst. Growth 1998, 189, 448–451. [Google Scholar] [CrossRef]

- Ke, G.; Lu, P.; Jiang, L.; Zhao, W.; Li, Q.; Yu, Z.; Liu, Y. Highly c-axis oriented AlN film grown by unbalanced magnetron reactive sputtering and its electrical properties. J. Alloy. Compd. 2015, 646, 446–453. [Google Scholar] [CrossRef]

- Mishin, S.; Oshmyansky, Y. Magnetron Deposition of AlN and ScAlN for Massproduction for BAW Devices and MEMS. In Proceedings of the 2019 IEEE International Ultrasonics Symposium, Glasgow, UK, 6–9 October 2019. [Google Scholar] [CrossRef]

- Behera, L.; Pandey, N.; Gupta, M. Synthesis and characterization of AlN thin films deposited using DC and RF magnetron sputtering. J. Appl. Phys. 2020. [Google Scholar] [CrossRef]

- Foroughi-Abari, A.; Cadien, K.C. Growth, structure and properties of sputtered niobium oxide thin films. Thin Solid Film. 2011, 519, 3068–3073. [Google Scholar] [CrossRef]

- Mwema, F.M.; Akinlabi, E.T.; Oladijo, O.P. A systematic review of magnetron sputtering of AlN thin films for extreme condition sensing. Mater. Today Proc. 2020, 26, 1546–1550. [Google Scholar] [CrossRef]

- Iqbal, A.; Mohd-Yasin, F. Reactive Sputtering of Aluminum Nitride (002) Thin Films for Piezoelectric Applications: A Review. Sensors 2018, 18, 1797. [Google Scholar] [CrossRef]

- Liu, W.; He, L.; Wang, X.; Zhou, J.; Xu, W.; Smagin, N.; Toubal, M.; Yu, H.; Gu, Y.; Xu, J.; et al. 3D FEM Analysis of High-Frequency AlN-Based PMUT Arrays on Cavity SOI. Sensors 2019, 19, 4450. [Google Scholar] [CrossRef]

- Signore, M.A.; Velardi, L.; De Pascali, C.; Kuznetsova, I.; Blasi, L.; Biscaglia, F.; Quaranta, F.; Siciliano, P.; Francioso, L. Effect of silicon-based substrates and deposition type on sputtered AlN thin films. Appl. Surf. Sci. 2022, 599, 154017. [Google Scholar] [CrossRef]

- Bairagi, S.; Järrendahl, K.; Eriksson, F.; Hultman, L.; Birch, J.; Hsiao, C.L. Glancing Angle Deposition and Growth Mechanism of Inclined AlN Nanostructures Using Reactive Magnetron Sputtering. Coatings 2020, 10, 768. [Google Scholar] [CrossRef]

- Cunha, C.L.A.; Pimenta, T.C.; Fraga, M.A. Growth and properties of sputtered highly (100)-oriented oxygenated AlN thin films for SAW sensing applications. Microsyst. Technol. 2021, 27, 3773–3782. [Google Scholar] [CrossRef]

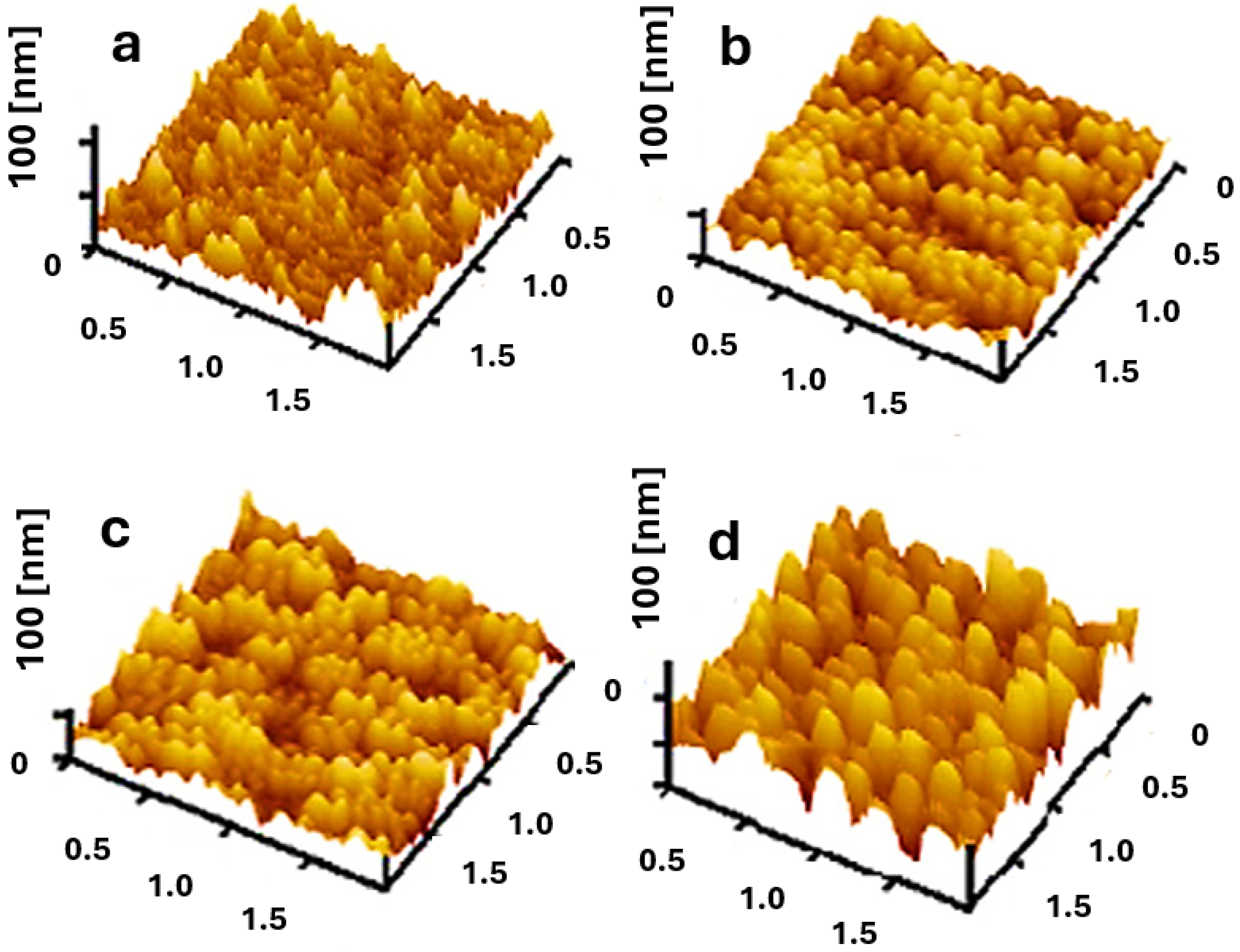

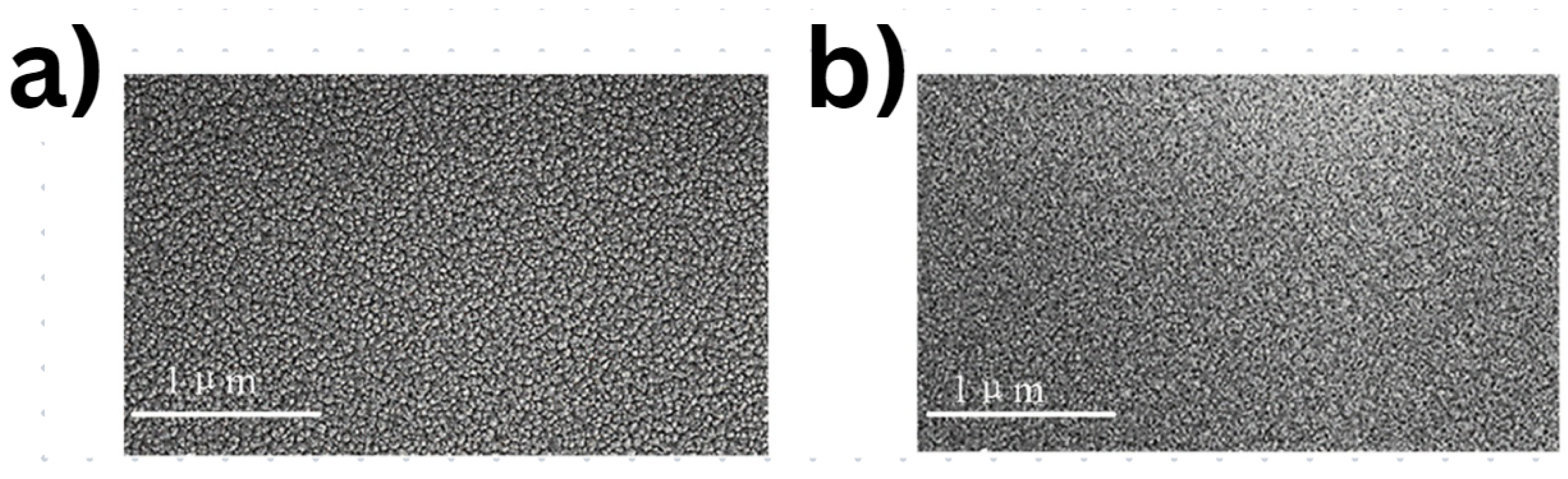

- Chirumamilla, M.; Krekeler, T.; Wang, D.; Kristensen, P.K.; Ritter, M.; Popok, V.N.; Pedersen, K. Magnetron Sputter Deposition of Nanostructured AlN Thin Films. Appl. Nano 2023, 4, 280–292. [Google Scholar] [CrossRef]

- Ababneh, A.; Dagamseh, A.M.K.; Albataineh, Z.; Tantawi, M.; Al-Bataineh, Q.M.; Telfah, M.; Zengerle, T.; Seidel, H. Optical and structural properties of aluminium nitride thin-films synthesized by DC-magnetron sputtering technique at different sputtering pressures. Microsyst. Technol. 2021, 27, 3149–3159. [Google Scholar] [CrossRef]

- Sandager, M.K.; Kjelde, C.; Popok, V. Growth of Thin AlN Films on Si Wafers by Reactive Magnetron Sputtering: Role of Processing Pressure, Magnetron Power and Nitrogen/Argon Gas Flow Ratio. Crystals 2022, 12, 1379. [Google Scholar] [CrossRef]

- Alyousef, H.A.; Hassan, A.M.; Zakaly, H.M.H. Reactive magnetron sputtered AlN thin films: Structural, linear and nonlinear optical characteristics. J. Mater. Sci. Mater. Electron. 2023, 34, 1088. [Google Scholar] [CrossRef]

- Yin, J.; Zhou, B.; Li, L.; Liu, Y.; Guo, W.; Talwar, D.N.; He, K.; Ferguson, I.T.; Wan, L.; Feng, Z.C. Optical and structural properties of AlN thin films deposited on different faces of sapphire substrates. Semicond. Sci. Technol. 2021, 36, 045012. [Google Scholar] [CrossRef]

- Chen, G.; Li, H.; Xie, X.; Xie, L.; Wang, E.; Liu, G.; Zhang, H.; Lu, B.; Li, C.; Pei, H. Influence of nitrogen flow ratio on properties of c-axis oriented AlN films grown by RF magnetron sputtering. Appl. Phys. A 2021, 127, 819. [Google Scholar] [CrossRef]

- Desideri, D.; Bernardo, E.; Corso, A.J.; Moro, F.; Pelizzo, M.G. Electrical Properties of Aluminum Nitride Thick Films Magnetron Sputtered on Aluminum Substrates. Materials 2022, 15, 2090. [Google Scholar] [CrossRef]

- Uesugi, K.; Shojiki, K.; Xiao, S.; Kuboya, S.; Miyake, H. Effect of the Sputtering Deposition Conditions on the Crystallinity of High-Temperature Annealed AlN Films. Coatings 2021, 11, 956. [Google Scholar] [CrossRef]

- Liu, S.; Li, Y.; Tao, J.; Tang, R.; Zheng, X. Structural, Surface, and Optical Properties of AlN Thin Films Grown on Different Substrates by PEALD. Crystals 2023, 13, 910. [Google Scholar] [CrossRef]

- Sanjeeva, S.; Rudresh, J.; Vinayakumar, K.B.; Nagaraja, K.K. A strong dependence of sputtering power on c-axis oriented aluminium nitride on Si (111): A structural and electrical study. IET Nanodielectrics 2024, 7, 7–17. [Google Scholar] [CrossRef]

- Wang, F.; Wu, J. Chapter 3—Fundamentals of Plasma Physics. In Modern Ion Plating Technology; Elsevier: Amsterdam, The Netherlands, 2023; pp. 29–89. [Google Scholar] [CrossRef]

- Gudmundsson, J.T.; Lundin, D. Introduction to magnetron sputtering. In High Power Impulse Magnetron Sputtering; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–48. [Google Scholar] [CrossRef]

- Hishimone, P.; Nagai, H.; Sato, M. Methods of Fabricating Thin Films for Energy Materials and Devices. In Lithium-Ion Batteries—Thin Film for Energy Materials and Devices; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef]

- Forge Project. High-Throughput Experiments in PVD Coating Technology. 2021. Available online: https://www.forge-project.eu/news/2021/high-throughput-experiments-pvd-coating-technology (accessed on 28 May 2024).

- Aijaz, A.; Sarakinos, K.; Lundin, D.; Brenning, N.; Helmersson, U. HiPIMS-Based Novel Deposition Processes for Thin Films. Linköping Studies in Science and Technology. Ph.D. Thesis, Linköping University Electronic Press, Linköping, Sweden, 2012. [Google Scholar]

- Gudmundsson, J.T. Physics and technology of magnetron sputtering discharges. Plasma Sources Sci. Technol. 2020, 29, 113001. [Google Scholar] [CrossRef]

- Lee, C.; Placido, F.; Kirk, K.F. RF Magnetron Sputtered AlN Films on Glass Substrate without Substrate Heating. 2008. Available online: https://www.researchgate.net/publication/272091562_RF_magnetron_sputtered_AlN_films_on_glass_substrate_without_substrate_heating (accessed on 2 September 2023).

- Ma, D.; Liu, H.; Deng, Q.; Yang, W.; Silins, K.; Huang, N.; Leng, Y. Optimal target sputtering mode for aluminum nitride thin film deposition by high power pulsed magnetron sputtering. Vacuum 2019, 160, 410–417. [Google Scholar] [CrossRef]

- Bakri, A.S.; Nafaziazi, A.S.; Abu Bakar, M.M.I.; Megat Hasan, N.A.; Raship, W.I.; Wan Omar, Z.; Azman, R.A.; Mohamed Ali, W.H.; Abd Majid, M.K.A. Electrical and Structural Comparison of (100) and (002) Oriented AlN Thin Films Deposited by RF Magnetron Sputtering. J. Mater. Sci. Mater. Electron. 2022, 33, 12271–12280. [Google Scholar] [CrossRef]

- Witit-Anun, N.; Buranawong, A. Effect of Substrate-Target Distance on the Structure of TiCrN Films Deposited from Mosaic Target by Reactive DC Magnetron Sputtering. Key Eng. Mater. 2019, 798, 163–168. [Google Scholar] [CrossRef]

- Ko, D.W.; Jang, S.H.; Kim, J.H.; Lee, K.Y.; Kim, Y.J. Improvement on Plasma Intensity Uniformity in Rectangular DC Magnetron Sputter by Optimizing Structures of Substrate Electrode. J. Korean Soc. Manuf. Technol. Eng. 2023, 32, 57–62. [Google Scholar] [CrossRef]

- Suresh Babu, S.; Fischer, J.; Barynova, K.; Rudolph, M.; Lundin, D.; Gudmundsson, J.T. High power impulse magnetron sputtering of a zirconium target. J. Vac. Sci. Technol. A 2024, 42, 043007. [Google Scholar] [CrossRef]

- Wei, Z.; Shen, L.; Kuang, Y.; Wang, J.; Yang, G.; Lei, W. The evolution of preferred orientation and morphology of AlN films under various sputtering parameters. J. Cryst. Growth 2024, 625, 127439. [Google Scholar] [CrossRef]

- Dubois, M.; Muralt, P. Stress and piezoelectric properties of aluminum nitride thin films deposited onto metal electrodes by pulsed direct current reactive sputtering. J. Appl. Phys. 2001, 89, 6389–6395. [Google Scholar] [CrossRef]

- Ababneh, A.; Roma, P.I.; Georgarakis, A.; Tichelaar, F.D.; Arnoldbik, W.M.; van den Berg, A.; van der Zaag, P.J. The influence of sputter deposition parameters on piezoelectric and mechanical properties of AlN thin films. Mater. Sci. Eng. B 2010, 172, 253–258. [Google Scholar] [CrossRef]

- Bian, Y.; Liu, M.; Ke, G.; Chen, Y.; DiBattista, J.; Chan, E.; Yang, Y. Aluminum nitride thin film growth and applications for heat dissipation. Surf. Coatings Technol. 2015, 267, 65–69. [Google Scholar] [CrossRef]

- Wu, S.; Xu, R.; Guo, B.; Ma, Y.; Yu, D. Influence of Growth Parameters and Systematical Analysis on 8-Inch Piezoelectric AlN Thin Films by Magnetron Sputtering. Mater. Sci. Semicond. Process. 2024, 169, 107895. [Google Scholar] [CrossRef]

- Patidar, J.; Sharma, A.; Zhuk, S.; Lorenzin, G.; Cancellieri, C.; Sarott, M.F.; Trassin, M.; Thorwarth, K.; Michler, J.; Siol, S. Improving the Crystallinity and Texture of Oblique-Angle-Deposited AlN Thin Films Using Reactive Synchronized HiPIMS. Surf. Coat. Technol. 2023, 468, 129719. [Google Scholar] [CrossRef]

- Han, S.; Chen, H.Y.; Cheng, C.H.; Lin, J.H.; Shih, H. Aluminum nitride films synthesized by dual ion beam sputtering. J. Mater. Res. 2004, 19, 3521–3525. [Google Scholar] [CrossRef]

- Davis, C.; Novikov, S.; Cheng, T.; Campion, R.; Foxon, C. Surface reconstruction patterns of AlN grown by molecular beam epitaxy on sapphire. J. Cryst. Growth 2001, 226, 203–208. [Google Scholar] [CrossRef]

- Guerrero, R.; Vargas-Garcia, J.R. Growth of AlN Films by Chemical Vapor Deposition. Superf. Vacío 1999, 9, 82–84. [Google Scholar]

- Vispute, F.; Narayan, J.; Wu, H.; Jagannadham, K. Epitaxial growth of AlN thin films on silicon (111) substrates by pulsed laser deposition. J. Appl. Phys. 1995, 77, 4724–4727. [Google Scholar] [CrossRef]

- Wang, M.; Bo, H.; Wang, A.; Cheng, Z.; Li, S.; Zou, W.; He, J.; Ma, X. High-quality c-axis oriented Al(Sc)N thin films prepared by magnetron sputtering. Thin Solid Film. 2023, 781, 140000. [Google Scholar] [CrossRef]

- Felmetsger, V.V.; Mikhov, M.K. Reactive Magnetron Sputtering of Piezoelectric Cr-doped AlN Thin Films. In Proceedings of the 2011 IEEE International Ultrasonics Symposium, Orlando, FL, USA, 18–21 October 2011; pp. 835–839. [Google Scholar] [CrossRef]

- Su, Y.; Kao, W.; Horng, J.; Hsueh, H.; Cian, Y.; Hsieh, T. Corrosion resistance and conductivity behavior of Cr-Al-N MAX phase coatings prepared by magnetron sputtering technology. Thin Solid Film. 2024, 793, 140274. [Google Scholar] [CrossRef]

- Nian, L.; Qu, Y.; Gu, X.; Luo, T.; Xie, Y.; Wei, M.; Cai, Y.; Liu, Y.; Sun, C. Preparation, Characterization, and Application of AlN/ScAlN Composite Thin Films. Micromachines 2023, 14, 557. [Google Scholar] [CrossRef]

- Chiu, K.H.; Chen, J.H.; Chen, H.R.; Huang, R.S. Deposition and characterization of reactive magnetron sputtered aluminum nitride thin films for film bulk acoustic wave resonator. Thin Solid Film. 2007, 515, 4819–4825. [Google Scholar] [CrossRef]

- Zhang, J.; Cao, Z.; Kuwano, H. Fabrication of Low-Residual-Stress AlN Thin Films and Their Application to Microgenerators for Vibration Energy Harvesting. Jpn. J. Appl. Phys. 2011, 50, 09ND18. [Google Scholar] [CrossRef]

- Chung, G.S.; Lee, B.C. Fabrication and characterization of vibration-driven AlN piezoelectric micropower generator compatible with complementary metal-oxide semiconductor process. J. Intell. Mater. Syst. Struct. 2015, 26, 1971–1979. [Google Scholar] [CrossRef]

- Xu, R.; Kim, S.G. Figures of merits of piezoelectric materials in energy harvesters. In Proceedings of the PowerMEMS, Atlanta, GA, USA, 2–5 December 2012; Volume 12. [Google Scholar]

- He, X.; Wen, Q.; Lu, Z.; Shang, Z.; Wen, Z. A micro-electromechanical systems based vibration energy harvester with aluminum nitride piezoelectric thin film deposited by pulsed direct-current magnetron sputtering. Appl. Energy 2018, 228, 881–890. [Google Scholar] [CrossRef]

- Pandey, A.; Dutta, S.; Kaushik, J.; Gupta, N.; Gupta, G.; Raman, R.; Kaur, D. Growth, structural and electrical properties of AlN/Si (111) for futuristic MEMS applications. Mater. Sci. Semicond. Process. 2021, 123, 105567. [Google Scholar] [CrossRef]

- Duquenne, C.; Besland, M.P.; Tessier, P.Y.; Gautron, E.; Scudeller, Y.; Averty, D. Thermal conductivity of aluminium nitride thin films prepared by reactive magnetron sputtering. J. Phys. D Appl. Phys. 2011, 45, 015301. [Google Scholar] [CrossRef]

- Duquenne, C.; Popescu, B.; Tessier, P.Y.; Besland, M.P.; Scudeller, Y.; Brylinski, C.; Delage, S.; Djouadi, M.A. Magnetron Sputtering of Aluminium Nitride Thin Films for Thermal Management. Plasma Process. Polym. 2007, 4, S1–S5. [Google Scholar] [CrossRef]

- Hamza El-Ladan, A.; Subramani, S. Development of AlNB alloy in (Al/AlN/B) stacking sequence using RF reactive sputtering towards thermal management application. J. Mater. Sci. Mater. Electron. 2021, 32, 1–13. [Google Scholar] [CrossRef]

- Perez, C.; McLeod, A.J.; Chen, M.E.; Yi, S.i.; Vaziri, S.; Hood, R.; Ueda, S.T.; Bao, X.; Asheghi, M.; Park, W.; et al. High Thermal Conductivity of Submicrometer Aluminum Nitride Thin Films Sputter-Deposited at Low Temperature. ACS Nano 2023, 17, 21240–21250. [Google Scholar] [CrossRef] [PubMed]

- Cassella, C.; Piazza, G. AlN Two-Dimensional-Mode Resonators for Ultra-High Frequency Applications. IEEE Electron Device Lett. 2015, 36, 1192–1194. [Google Scholar] [CrossRef]

| Key Points/Parameters | Description |

|---|---|

| Crystal Orientations | AlN film growth primarily along the AlN(100) and AlN(001) planes determined by vibrational phonon modes. |

| Operational Parameters | RF power, pressure, temperature, and target distance influence crystal orientation. |

| Deposition Process | Adsorption, diffusion, nucleation, and coalescence form thin-film layers. |

| Processing Parameters | Key for high-quality films, optimized via magnetron sputtering. |

| Nanostructure Growth | Reactive magnetron sputtering enables tailored nanostructure growth. |

| Substrate Influence | Substrate material and morphology impact film properties. |

| Deposition Technique | Substrate Temperature (°C) | Growth Rate (Å/min) | Film Quality | Equipment Complexity | Application Suitability |

|---|---|---|---|---|---|

| Reactive RF Magnetron Sputtering | 500–700 | 10–20 | High | Moderate | Large area, uniform films |

| DC Magnetron Sputtering | 500–700 | 10–20 | Moderate | Low | Conductive targets, large area |

| Dual Ion Beam Sputtering | 300–600 | 5–15 | Very High | High | High-quality films, advanced electronics |

| Molecular Beam Epitaxy (MBE) | 650–850 | 0.1–1 | Very High | Very High | High-purity single-crystal films |

| Chemical Vapor Deposition (CVD) | 600–900 | 5–10 | High | High | Large area, uniform films, electronic packaging |

| Pulsed Laser Deposition (PLD) | 500–750 | 2-5 | High | Moderate | Complex material deposition, research applications |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jadoon, N.A.K.; Puvanenthiram, V.; Mosa, M.A.H.; Sharma, A.; Wang, K. Recent Advances in Aluminum Nitride (AlN) Growth by Magnetron Sputtering Techniques and Its Applications. Inorganics 2024, 12, 264. https://doi.org/10.3390/inorganics12100264

Jadoon NAK, Puvanenthiram V, Mosa MAH, Sharma A, Wang K. Recent Advances in Aluminum Nitride (AlN) Growth by Magnetron Sputtering Techniques and Its Applications. Inorganics. 2024; 12(10):264. https://doi.org/10.3390/inorganics12100264

Chicago/Turabian StyleJadoon, Nabeel Ahmad Khan, Vaigunthan Puvanenthiram, Mayada Ahmed Hassan Mosa, Ashutosh Sharma, and Kaiying Wang. 2024. "Recent Advances in Aluminum Nitride (AlN) Growth by Magnetron Sputtering Techniques and Its Applications" Inorganics 12, no. 10: 264. https://doi.org/10.3390/inorganics12100264

APA StyleJadoon, N. A. K., Puvanenthiram, V., Mosa, M. A. H., Sharma, A., & Wang, K. (2024). Recent Advances in Aluminum Nitride (AlN) Growth by Magnetron Sputtering Techniques and Its Applications. Inorganics, 12(10), 264. https://doi.org/10.3390/inorganics12100264