Investigation of InGaN-Based Green Micro-Photonic-Crystal- Light-Emitting-Diodes with Bottom, Nanoporous, Distributed Bragg Reflectors

Abstract

1. Introduction

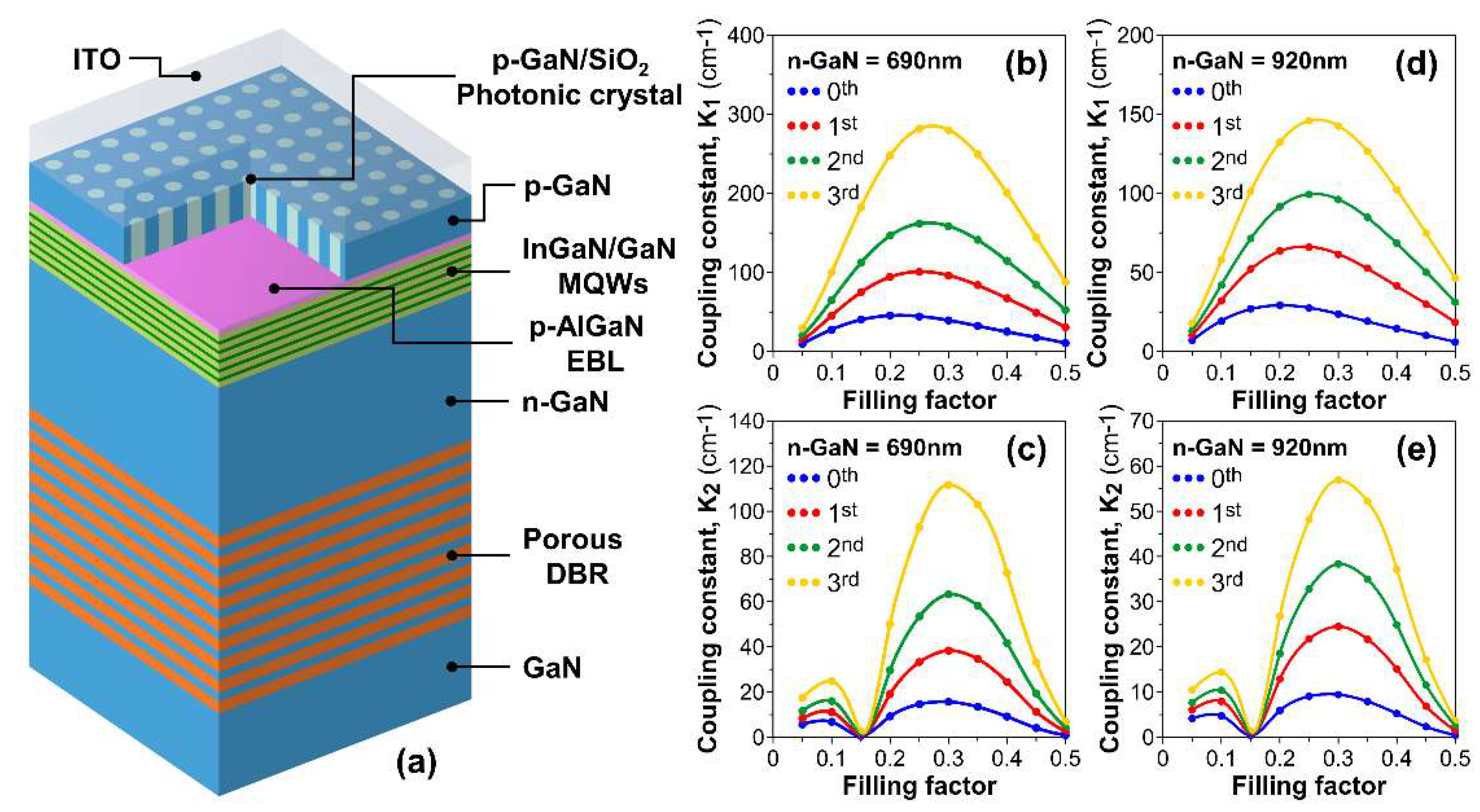

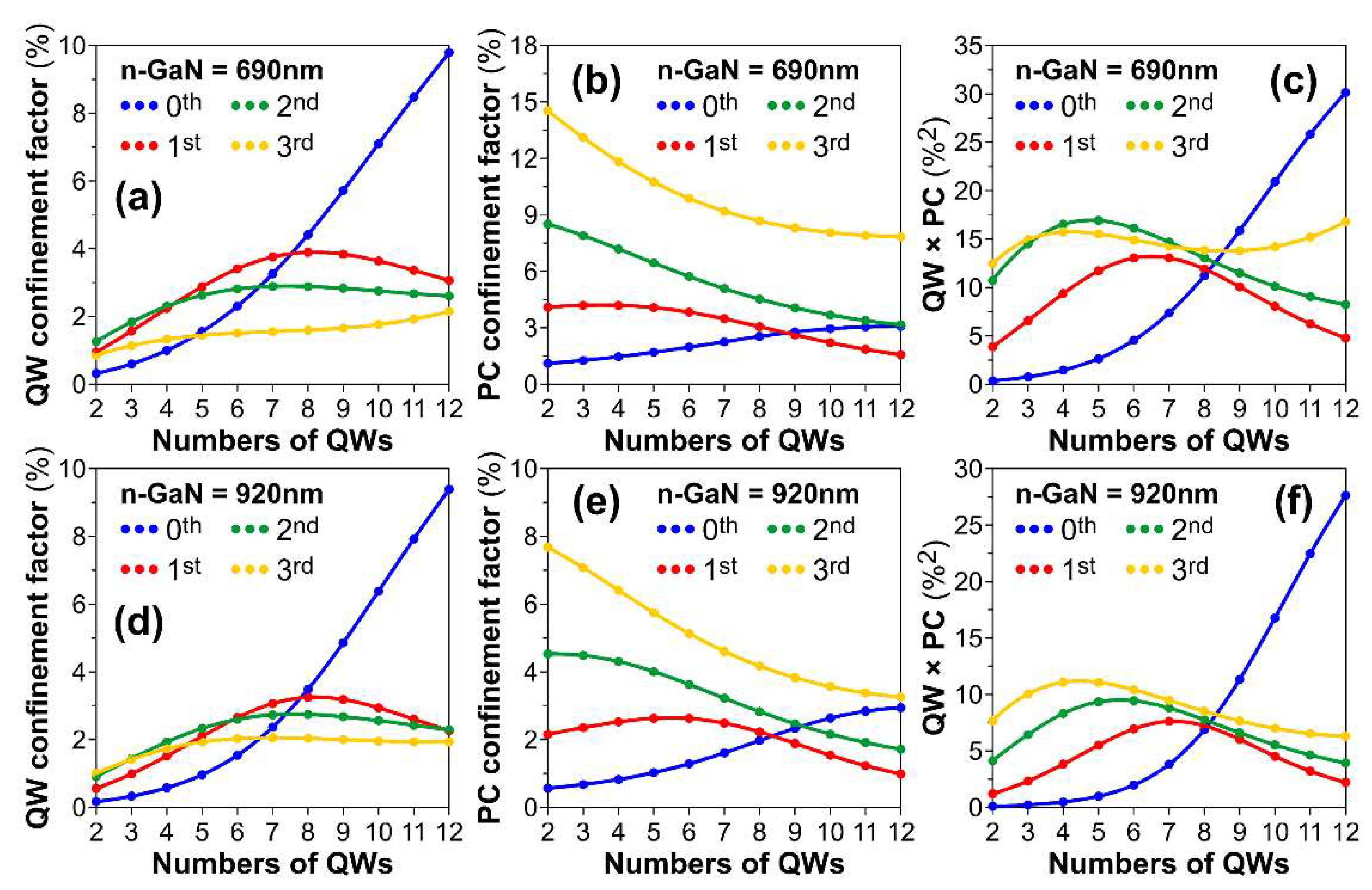

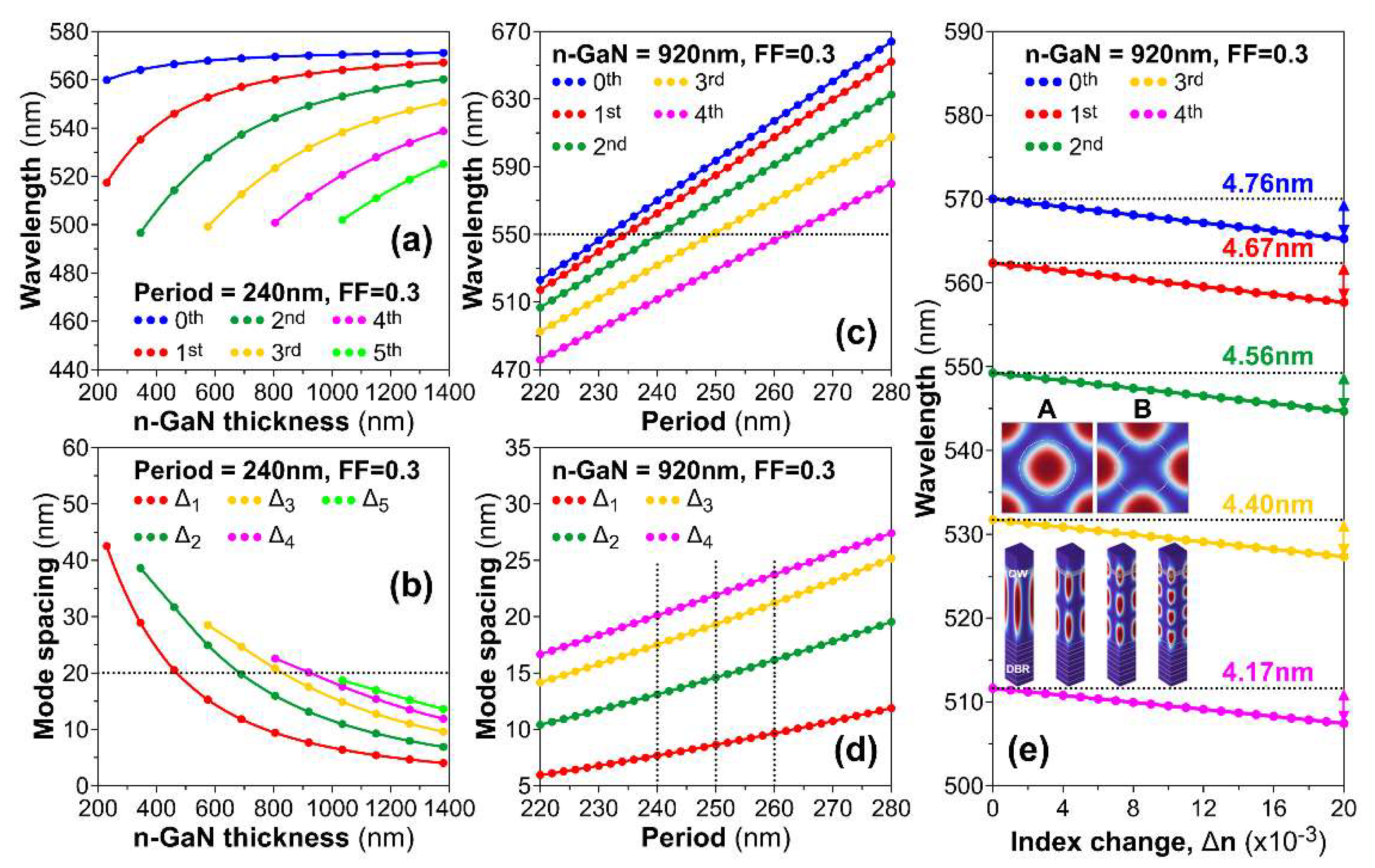

2. Design and Simulation

3. Growth and Fabrication

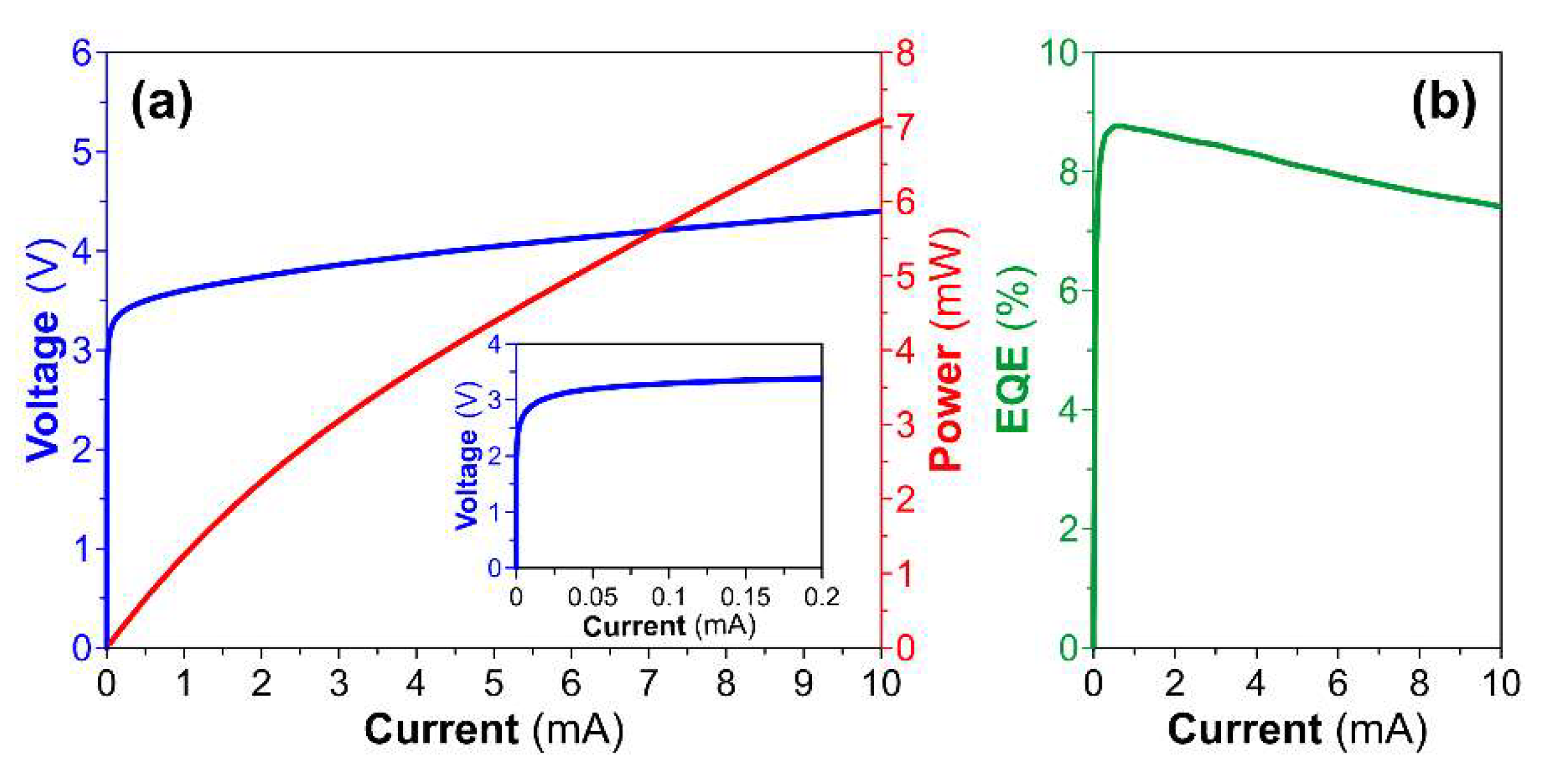

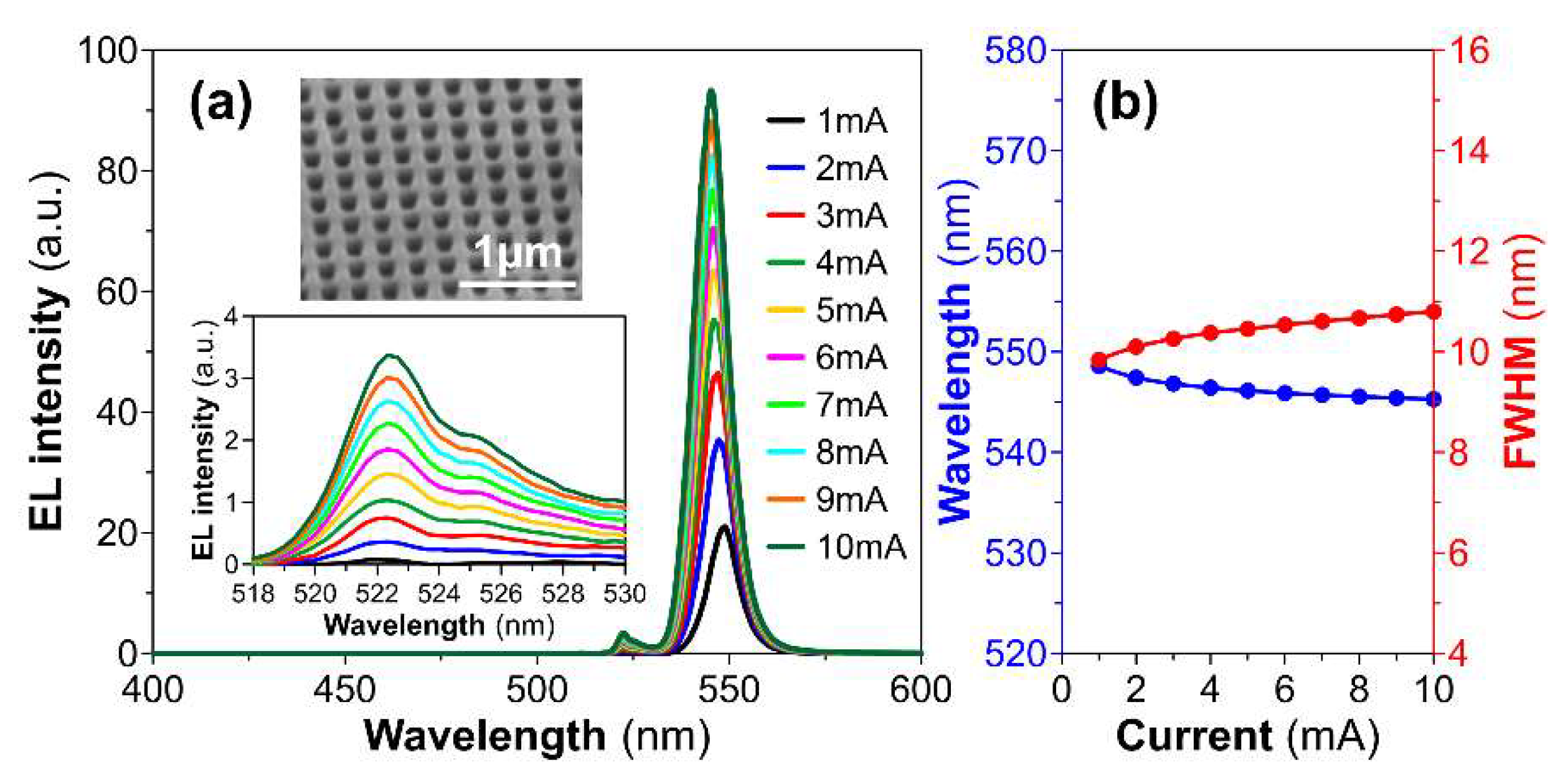

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Park, S.I.; Xiong, Y.; Kim, R.H.; Elvikis, P.; Meitl, M.; Kim, D.H.; Wu, J.; Yoon, J.; Yu, C.J.; Liu, Z.; et al. Printed assemblies of inorganic light-emitting diodes for deformable and semitransparent display. Science 2009, 325, 977–981. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Li, Y.; Li, Y.; Deng, Z.; Lu, T.; Ma, Z.; Zuo, P.; Dai, L.; Wang, L.; Jia, H.; et al. Realization of high-luminous-efficiency InGaN light-emitting diodes in the “green gap” range. Sci. Rep. 2015, 5, 10883. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Lin, R.; Chen, H.; Zhang, S.; Qian, Z.; Zhou, G.; Chen, X.; Zhou, X.; Zheng, L.; Liu, R.; et al. High-bandwidth InGaN self-powered detector arrays toward MIMO visible light communication based on micro-LED arrays. ACS Photonics 2019, 6, 3186–3195. [Google Scholar] [CrossRef]

- Haas, H. LiFi is a paradigm-shifting 5G technology. Rev. Phys. 2018, 3, 26–31. [Google Scholar] [CrossRef]

- Bergh, A.A. Blue laser diode (LD) and light emitting diode (LED) applications. Phys. Stat. Sol. 2004, 201, 2740–2754. [Google Scholar]

- Taniyasu, Y.; Kasu, M.; Makimoto, T. An aluminium nitride light-emitting diode with a wavelength of 210 nanometres. Nature 2006, 441, 325–328. [Google Scholar] [CrossRef]

- Zhan, T.; Yin, K.; Xiong, J.; He, Z.; Wu, S.T. Augmented reality and virtual reality displays: Perspectives and challenges. iScience 2020, 23, 101397. [Google Scholar] [CrossRef]

- Huang, Y.; Hsiang, E.L.; Deng, M.Y.; Wu, S.T. Mini-LED, micro-LED and OLED displays: Present status and future perspectives. Light Sci. Appl. 2020, 9, 105. [Google Scholar] [CrossRef]

- Xiong, J.; Hsiang, E.L.; He, Z.; Zhan, T.; Wu, S.T. Augmented reality and virtual reality displays: Emerging technologies and future perspectives. Light Sci. Appl. 2021, 10, 216. [Google Scholar] [CrossRef]

- Liu, Z.; Lin, C.-H.; Hyun, B.-R.; Sher, C.-W.; Lv, Z.; Luo, B.; Jiang, F.; Wu, T.; Ho, C.-H.; Kuo, H.-C.; et al. Micro-light-emitting diodes with quantum dots in display technology. Light Sci. Appl. 2020, 9, 83. [Google Scholar] [CrossRef]

- Hsiang, E.-L.; He, Z.; Huang, Y.; Gou, F.; Lan, Y.-F.; Wu, S.-T. Improving the Power Efficiency of Micro-LED Displays with Optimized LED Chip Sizes. Crystals 2020, 10, 494. [Google Scholar] [CrossRef]

- Huang, H.-W.; Chu, J.T.; Kao, C.C.; Hseuh, T.H.; Lu, T.C.; Kuo, H.C.; Wang, S.C.; Yu, C.C. Enhanced light output of an InGaN/GaN light emitting diode with a nano-roughened p-GaN surface. Nanotechnology 2005, 16, 1844. [Google Scholar] [CrossRef]

- Ee, Y.-K.; Kumnorkaew, P.; Arif, R.A.; Tong, H.; Gilchrist, J.F.; Tansu, N. Light extraction efficiency enhancement of InGaN quantum wells light-emitting diodes with polydimethylsiloxane concave microstructures. Opt. Express 2009, 17, 13747–13757. [Google Scholar] [CrossRef]

- Denbaars, S.P.; Feezell, D.; Kelchner, K.; Pimputkar, S.; Pan, C.C.; Yen, C.C.; Tanaka, S.; Zhao, Y.; Pfaff, N.; Farrell, R.; et al. Development of gallium-nitride-based light-emitting diodes (LEDs) and laser diodes for energy-efficient lighting and displays. Acta Mater. 2013, 61, 945–951. [Google Scholar] [CrossRef]

- David, A. Surface-Roughened Light-Emitting Diodes: An Accurate Model. J. Display Technol. 2013, 9, 301–316. [Google Scholar] [CrossRef]

- Kim, J.Y.; Kwon, M.K.; Lee, K.S.; Park, S.J. Enhanced light extraction from GaN-based green light-emitting diode with photonic crystal. Appl. Phys. Lett. 2007, 91, 181109. [Google Scholar] [CrossRef]

- Xu, Z.; Cao, L.; Tan, Q.; He, Q.; Jin, G. Enhancement of the light output of light-emitting diode with double photonic crystals. Opt. Commun. 2007, 278, 211–214. [Google Scholar] [CrossRef]

- Cheng, B.S.; Chiu, C.H.; Huang, K.J.; Lai, C.F.; Kuo, H.C.; Lin, C.H.; Lu, T.C.; Wang, S.C.; Yu, C.C. Enhanced light extraction of InGaN-based green LEDs by nano-imprinted 2D photonic crystal pattern. Semicond. Sci. Technol. 2008, 23, 055002. [Google Scholar] [CrossRef][Green Version]

- Lai, C.F.; Chao, C.H.; Kuo, H.C.; Yen, H.H.; Lee, C.E.; Yeh, W.Y. Directional light extraction enhancement from GaN-based film-transferred photonic crystal light-emitting diodes. Appl. Phys. Lett. 2009, 94, 123106. [Google Scholar] [CrossRef]

- Wierer, J.; David, A.; Megens, M. III-nitride photonic-crystal light-emitting diodes with high extraction efficiency. Nature Photon. 2009, 3, 163–169. [Google Scholar] [CrossRef]

- Kim, J.Y.; Kwon, M.K.; Park, S.J.; Kim, S.H.; Lee, K.D. Enhancement of light extraction from GaN-based green light-emitting diodes using selective area photonic crystal. Appl. Phys. Lett. 2010, 96, 251103. [Google Scholar] [CrossRef]

- Chang, Y.C.; Liou, J.K.; Liu, W.C. Improved light extraction efficiency of a high-power GaN-based light-emitting diode with a three-dimensional-photonic crystal (3-D-PhC) backside reflector. IEEE Electron Device Lett. 2013, 34, 777–779. [Google Scholar] [CrossRef]

- Yin, Y.F.; Lan, W.Y.; Lin, T.C.; Wang, C.; Feng, M.; Huang, J.J. High-speed visible light communication using GaN-based light-emitting diodes with photonic crystals. J. Light. Technol. 2017, 35, 258–264. [Google Scholar] [CrossRef]

- Schubert, E.F.; Wang, Y.H.; Cho, A.Y.; Tu, L.W.; Zydzik, G.J. Resonant cavity light-emitting diode. Appl. Phys. Lett. 1992, 60, 921. [Google Scholar] [CrossRef]

- Pessa, M.; Guina, M.; Dumitrescu, M.; Hirvonen, I.; Saarinen, M.; Toikkanen, L.; Xiang, N. Resonant cavity light emitting diode for a polymer optical fibre system. Semicond. Sci. Technol. 2002, 17, R1. [Google Scholar] [CrossRef]

- Delbeke, D.; Bockstaele, R.; Bienstman, P.; Baets, R.; Benisty, H. High-Efficiency Semiconductor Resonant-Cavity Light-Emitting Diodes: A Review. IEEE J. Sel. Top. Quantum Electron. 2002, 8, 189–206. [Google Scholar] [CrossRef]

- Byrne, D.; Natali, F.; Damilano, B.; Dussaigne, A.; Grandjean, N.; Massies, J. Blue resonant cavity light emitting diodes with a high-Al-content GaN/AlGaN distributed Bragg reflector. Jpn. J. Appl. Phys. 2003, 42, L1509. [Google Scholar] [CrossRef]

- Shiu, G.Y.; Chen, K.T.; Fan, F.H.; Huang, K.P.; Hsu, W.J.; Dai, J.J.; Lai, C.F.; Lin, C.F. InGaN Light-Emitting Diodes with an Embedded Nanoporous GaN Distributed Bragg Reflectors. Sci. Rep. 2016, 6, 29138. [Google Scholar] [CrossRef]

- Ryu, H.-Y.; Hwang, J.-K.; Lee, Y.-J.; Lee, Y.-H. Enhancement of light extraction from two-dimensional photonic crystal slab structures. J. Sel. Top. Quantum Electron. 2002, 8, 231–237. [Google Scholar]

- Shin, Y.C.; Kim, D.H.; Kim, E.H.; Park, J.M.; Ho, K.M.; Constant, K.; Choe, J.H.; Park, Q.H.; Ryu, H.Y.; Baek, J.H.; et al. High efficiency GaN light-emitting diodes with two dimensional photonic crystal Structures of deep-hole square lattices. IEEE J. Quantum Electron. 2010, 46, 116–120. [Google Scholar] [CrossRef]

- Yamamoto, S.; Zhao, Y.; Pan, C.C.; Chung, R.B.; Fujito, K.; Sonoda, J.; DenBaars, S.P.; Nakamura, S. High-efficiency single-quantum-well green and yellow-green light-emitting diodes on semipolar (2021) GaN substrates. Appl. Phys. Express 2010, 3, 122102. [Google Scholar] [CrossRef]

- Iida, D.; Niwa, K.; Kamiyama, S.; Ohkawa, K. Demonstration of InGaN-based orange LEDs with hybrid multiple-quantum-wells structure. Appl. Phys. Express 2016, 9, 111003. [Google Scholar] [CrossRef]

- Iida, D.; Lu, S.; Hirahara, S.; Niwa, K.; Kamiyama, S.; Ohkawa, K. Enhanced light output power of InGaN-based amber LEDs by strain-compensating AlN/AlGaN barriers. J. Cryst. Growth 2016, 448, 105–108. [Google Scholar] [CrossRef]

- Hu, H.; Zhou, S.; Wan, H.; Liu, X.; Li, N.; Xu, H. Effect of strain relaxation on performance of InGaN/GaN green LEDs grown on 4-inch sapphire substrate with sputtered AlN nucleation layer. Sci. Rep. 2019, 9, 3447. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, Z.; Iida, D.; Velazquez-Rizo, M.; Ohkawa, K. 606-nm InGaN amber micro-light-emitting diodes with an on-wafer external quantum efficiency of 0.56%. IEEE Electron Device Lett. 2021, 42, 1029–1032. [Google Scholar] [CrossRef]

- Zhuang, Z.; Iida, D.; Ohkawa, K. Investigation of InGaN-based red/green micro-light-emitting diodes. Opt. Lett. 2021, 46, 1912–1915. [Google Scholar] [CrossRef]

- Huang, W.T.; Peng, C.Y.; Chiang, H.; Huang, Y.M.; Singh, K.J.; Lee, W.B.; Chow, C.W.; Chen, S.C.; Kuo, H.C. Toward high-bandwidth yellow-green micro-LEDs utilizing nanoporous distributed Bragg reflectors for visible light communication. Photon. Res. 2022, 10, 1810–1818. [Google Scholar] [CrossRef]

- Gonga, Z.; Jin, S.; Chen, Y.; McKendry, J.; Massoubre, D.; Watson, I.M.; Gu, E.; Dawson, M.D. Size-dependent light output, spectral shift, and self-heating of 400 nm InGaN light-emitting diodes. J. Appl. Phys. 2010, 107, 013103. [Google Scholar] [CrossRef]

- Guo, Q.; Li, D.; Hua, Q.; Ji, K.; Sun, W.; Hu, W.; Wang, Z.L. Enhanced Heat Dissipation in Gallium Nitride-Based Light-Emitting Diodes by Piezo-phototronic Effect. Nano Lett. 2021, 21, 4062–4070. [Google Scholar] [CrossRef]

- Alaei, S.; Seifouri, M.; Babaabbasi, G.; Olyaee, S. Numerical investigation on self-heating effect in 1.3 µm quantum dot photonic crystal microstructure VCSELs. Eur. Phys. J. Plus 2022, 137, 515. [Google Scholar] [CrossRef]

- Rashidi, A.; Monavarian, M.; Aragon, A.; Feezell, D. Thermal and efficiency droop in InGaN/GaN light-emitting diodes: Decoupling Multiphysics effects using temperature-dependent RF measurements. Sci. Rep. 2019, 9, 19921. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Lu, S.; Qiu, Y.; Wu, J.; Zhang, M.; Luo, D. Experimental and Modeling Investigations of Miniaturization in InGaN/GaN Light-Emitting Diodes and Performance Enhancement by Micro-Wall Architecture. Front. Chem. 2021, 8, 2296–2646. [Google Scholar] [CrossRef] [PubMed]

- Streifer, W.; Scifres, D.; Burnham, R. Coupled wave analysis of DFB and DBR lasers. IEEE J. Quantum Electron. 1977, 13, 134–141. [Google Scholar] [CrossRef]

- Wiesmann, D.; Germann, R.; Bona, G.L. Add–drop filter based on apodized surface-corrugated gratings. J. Opt. Soc. Am. B 2003, 20, 417–423. [Google Scholar] [CrossRef]

- Jiang, H.X.; Lin, J.Y. Mode spacing ‘‘anomaly’’ in InGaN blue lasers. Appl. Phys. Lett. 1999, 74, 1066–1068. [Google Scholar] [CrossRef]

- de Arriba, G.M.; Feng, P.; Xu, C.; Zhu, C.; Bai, J.; Wang, T. Simple approach to mitigate the emission wavelength instability of III-Nitride μLED Arrays. ACS Photonics 2022, 9, 2073–2078. [Google Scholar] [CrossRef]

- Lai, C.F.; Kuo, H.C.; Chao, C.H.; Yu, P.; Yeh, W.Y. Structural effects on highly directional far-field emission patterns of GaN-based micro-cavity light-emitting diodes with photonic crystals. J. Light. Technol. 2010, 28, 2881–2889. [Google Scholar] [CrossRef]

- Lai, C.F.; Kuo, H.C.; Yu, P.; Lu, T.C.; Chao, C.H.; Yen, H.H.; Yeh, W.Y. Highly-directional emission patterns based on near single guided mode extraction from GaN-based ultrathin microcavity light-emitting diodes with photonic crystals. Appl. Phys. Lett. 2010, 97, 013108. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, B.; Xu, F.; Sang, Y.; Tao, T.; Xie, Z.; Wang, K.; Xiu, X.; Chen, P.; Chen, D.; et al. High-efficiency green micro-LEDs with GaN tunnel junctions grown hybrid by PA-MBE and MOCVD. Photon. Res. 2021, 9, 1683–1688. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, S.; Shan, X.; Yuan, Z.; Qian, Z.; Lu, X.; Fu, Y.; Tu, K.; Guan, H.; Cui, X.; et al. Red, green and blue InGaN micro-LEDs for display application: Temperature and current density effects. Opt. Express 2022, 30, 36403–36413. [Google Scholar] [CrossRef]

- Yu, L.; Lu, B.; Yu, P.; Wang, Y.; Ding, G.; Feng, Q.; Jiang, Y.; Chen, H.; Huang, K.; Hao, Z.; et al. Ultra-small size (1–20 μm) blue and green micro-LEDs fabricated by laser direct writing lithography. Appl. Phys. Lett. 2022, 121, 042106. [Google Scholar] [CrossRef]

- Li, H.; Wong, M.S.; Khoury, M.; Bonef, B.; Zhang, H.; Chow, Y.; Li, P.; Kearns, J.; Taylor, A.A.; Mierry, P.D.; et al. Study of efficient semipolar (11-22) InGaN green micro-light-emitting diodes on highquality (11–22) GaN/sapphire template. Opt. Express 2019, 27, 24154–24160. [Google Scholar] [CrossRef] [PubMed]

- Wei, T.; Huo, Z.; Zhang, Y.; Zheng, H.; Chen, Y.; Yang, J.; Hu, Q.; Duan, R.; Wang, J.; Zeng, Y.; et al. Efficiency enhancement of homoepitaxial InGaN/GaN light-emitting diodes on freestanding GaN substrate with double embedded SiO2 photonic crystals. Opt. Express 2014, 22, A1093–A1100. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Feng, Y.; Chen, Z.; Zhang, L.; Jiang, X.; Jiao, Q.; Li, J.; Chen, Y.; Li, D.; Liu, L.; et al. Study on light extraction from GaN-based green light-emitting diodes using anodic aluminum oxide pattern and nanoimprint lithography. Sci. Rep. 2016, 6, 21573. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, K.-B.; Huang, W.-T.; Hsu, W.-C.; Tu, C.-C.; Kuo, H.-C. Investigation of InGaN-Based Green Micro-Photonic-Crystal- Light-Emitting-Diodes with Bottom, Nanoporous, Distributed Bragg Reflectors. Photonics 2022, 9, 939. https://doi.org/10.3390/photonics9120939

Hong K-B, Huang W-T, Hsu W-C, Tu C-C, Kuo H-C. Investigation of InGaN-Based Green Micro-Photonic-Crystal- Light-Emitting-Diodes with Bottom, Nanoporous, Distributed Bragg Reflectors. Photonics. 2022; 9(12):939. https://doi.org/10.3390/photonics9120939

Chicago/Turabian StyleHong, Kuo-Bin, Wei-Ta Huang, Wen-Cheng Hsu, Chang-Ching Tu, and Hao-Chung Kuo. 2022. "Investigation of InGaN-Based Green Micro-Photonic-Crystal- Light-Emitting-Diodes with Bottom, Nanoporous, Distributed Bragg Reflectors" Photonics 9, no. 12: 939. https://doi.org/10.3390/photonics9120939

APA StyleHong, K.-B., Huang, W.-T., Hsu, W.-C., Tu, C.-C., & Kuo, H.-C. (2022). Investigation of InGaN-Based Green Micro-Photonic-Crystal- Light-Emitting-Diodes with Bottom, Nanoporous, Distributed Bragg Reflectors. Photonics, 9(12), 939. https://doi.org/10.3390/photonics9120939