Assessing the Conformity of Plasticizer-Free Polymers for Foodstuff Packaging Using Solid Phase Microextraction Coupled to Gas Chromatography/Mass Spectrometry

Abstract

1. Introduction

2. Materials and Methods

2.1. SA Films

2.1.1. Reagents

2.1.2. GPE from Grape Pomace By-Products

2.1.3. Preparation

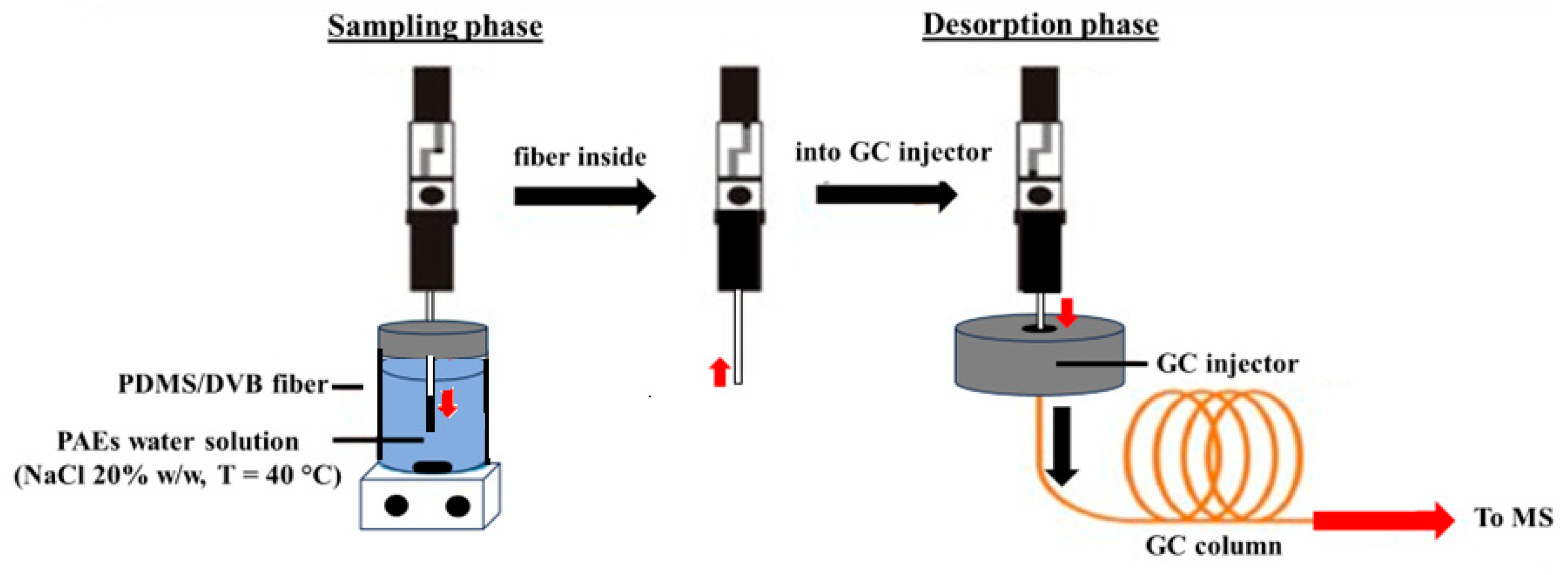

2.2. Determination of the PAE Release

2.2.1. Chemicals

2.2.2. Experimental Design of Food PAE Release Simulation

2.2.3. SPME–GC/MS Experimental Conditions

2.2.4. Method Validation

3. Results

4. Discussion

5. Limitations of the Study and Future Recommendations

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the reduction of the impact of certain plastic products on the environment. Off. J. Eur. Union 2019, 155, 1–19.

- Thompson, R.C.; Moore, C.J.; Vom Saal, F.S.; Swan, S.H. Plastics, the environment and human health: Current consensus and future trends. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2153–2166. [Google Scholar] [CrossRef]

- Fobil, J.; Hogarh, J. The dilemmas of plastic wastes in a developing economy: Proposals for a sustainable management approach for Ghana. West Afr. J. Appl. Ecol. 2006, 10. [Google Scholar] [CrossRef]

- Vimal, K.E.K.; Mathiyazhagan, K.; Agarwal, V.; Luthra, S.; Sivakumar, K. Analysis of barriers that impede the elimination of single-use plastic in developing economy context. J. Clean. Prod. 2020, 272, 122629. [Google Scholar] [CrossRef]

- Golwalaa, H.; Zhanga, X.; Iskandera, S.M.; Smith, A.L. Solid waste: An overlooked source of microplastics to the environment. Sci. Total Environ. 2021, 769, 144581. [Google Scholar] [CrossRef]

- Commission Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food. Off. J. Eur. Comm. 2011, 12, 42–130.

- Li, P.; Wang, X.; Su, M.; Zou, X.; Duan, L.; Zhang, H. Characteristics of plastic pollution in the environment: A review. Bull. Environ. Contamin. Toxicol. 2021, 107, 577–584. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, G.; Zheng, H.; Liu, N.; Shi, M.; Luo, X.; Chen, L.; Li, F.; Hu, S. Fate of four phthalate esters with presence of Karenia brevis: Uptake and biodegradation. Aquat Toxicol. 2019, 206, 81–90. [Google Scholar] [CrossRef]

- Lahimer, M.C.; Ayed, N.; Horriche, J.; Belgaied, S. Characterization of plastic packaging additives: Food contact, stability and toxicity. Arab. J. Chem. 2017, 10, S1938–S1954. [Google Scholar] [CrossRef]

- Wang, Y.; Qian, H. Phthalates and Their Impacts on Human Health. Healthcare 2021, 9, 603. [Google Scholar] [CrossRef]

- European Commission. Regulation (EC) No 1907/2006 of the European Parliament and of the Council of 18 December 2006 Concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH), Establishing a European Chemicals Agency, Amending Directive 1999/45/EC and Repealing Council. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02006R1907-20140410 (accessed on 1 January 2023).

- Etxabide, A.; Young, B.; Bremer, P.J.; Kilmartin, P.A. Non-permanent primary food packaging materials assessment: Identification, migration, toxicity, and consumption of substances. Compr. Rev. Food Sci. Food Saf. 2022, 21, 4130–4145. [Google Scholar] [CrossRef] [PubMed]

- Avila, L.B.; Schnorr, C.; Silva, L.F.O.; Morais, M.M.; Moraes, C.C.; da Rosa, G.S.; Dotto, G.L.; Lima, É.C.; Naushad, M. Trends in bioactive multilayer films: Perspectives in the use of polysaccharides, proteins, and carbohydrates with natural additives for application in food packaging. Foods 2023, 12, 1692. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.Y.; Mooney, D.J. Alginate: Properties and biomedical applications. Prog. Polym. Sci. 2012, 37, 106–126. [Google Scholar] [CrossRef] [PubMed]

- Regulation (EEC) No 793/93 and Commission Regulation (EC) No 1488/94 as well as Council Directive 76/769/EEC and Commission Directives 91/155/EEC, 93/67/ EEC, 93/105/EC and 2000/21/EC. Off. J. Eur. Comm. 2006, 1–516.

- Tumu, K.; Vorst, K.; Curtzwiler, G. Endocrine modulating chemicals in food packaging: A review of phthalates and bisphenols. Compr. Rev. Food Sci. Food. Saf. 2023, 2, 1337–1359. [Google Scholar] [CrossRef] [PubMed]

- Martín-Pozo, L.; Gómez-Regalado, M.; Moscoso-Ruiz, I.; Zafra-Gómez, A. Analytical methods for the determination of endocrine disrupting chemicals in cosmetics and personal care products: A review. Talanta 2021, 234, 122642. [Google Scholar] [CrossRef] [PubMed]

- Celeiro, M.; Lamas, P.J.; Garcia-Jares, C.; Llompart, M. Pressurized liquid extraction-gas chromatography-mass spectrometry analysis of fragrance allergens, musks, phthalates and preservatives in baby wipes. J. Chrom. A 2015, 1384, 9–21. [Google Scholar] [CrossRef]

- European Commission Recomandation (EU) 2019/794: “On a coordinated control plan with a view to establishing the prevalence of certain substances migrating from materials and articles intended to come into contact with food”. Off. J. Eur. Union 2019, 129, 37–42.

- Rascon, A.J.; Rocío-Bautista, P.; Moreno-Gonzalez, D.; García-Reyes, J.F.; Ballesteros, E. Fiber coating based on a green metal-organic framework to determine phthalates in bottled waters by direct-immersion microsolid-phase extraction. Microchem. J. 2023, 191, 108767–108777. [Google Scholar] [CrossRef]

- Environment Protection Agency. Official EPA METHOD 8061 Phthalate Esters by Gas Chromatography with Electron Capture Detection (GC/ECD); EPA Meths. Rev 1; Environment Protection Agency: Washington, DC, USA, 1996.

- Liu, W.; Lun, Y. Determination of Sub-Ppb Level of Phthalates in Water by Auto-SPME and GC–MS; Application 5989-7726EN; Agilent Technologies: Santa Clara, CA, USA, 2008. [Google Scholar]

- Herrington, J.S.; Gómez-Ríos, G.A.; Myers, C.; Stidsen, G.; Bell, D.S. Hunting Molecules in Complex Matrices with SPME Arrows: A Review. Separations 2020, 7, 12–31. [Google Scholar] [CrossRef]

- Bojko, B.; Cudjoe, E.; German, A.; Ríos, G.; Gorynski, K.; Jiang, R.; Reyes-Garcés, N.; Risticevic, S.; Silva, É.A.S.; Togunde, O.; et al. SPME—Quo vadis? Anal. Chim. Acta 2012, 75, 132–151. [Google Scholar] [CrossRef] [PubMed]

- Gubitosa, J.; Rizzi, V.; Marasciulo, C.; Maggi, F.; Caprioli, G.; Mustafa, A.M.; Fini, P.; De Vietro, N.; Aresta, A.M.; Cosma, P. Realizing eco-friendly water-resistant sodium-alginate-based films blended with a polyphenolic aqueous extract from grape pomace waste for potential food packaging applications. Int. J. Mol. Sci. 2023, 24, 11462–11480. [Google Scholar] [CrossRef] [PubMed]

- Dirpan, A.; Hidayat, S.H.; Djalal, M.; Ainani, A.F.; Kasmira, D.S.Y.; Khosuma, M.; Solon, G.T.; Ismayanti, N. Trends over the last 25 years and future research into smart packaging for food: A review. Future Foods 2023, 8, 100252–100268. [Google Scholar] [CrossRef]

- Farag, R.S.; Hewedi, F.M.; Abu-Raiia, S.H.; El-Baroty, G.S. Comparative study on the deterioration of oils by microwave and conventional heating. J. Food Prot. 1992, 55, 722–727. [Google Scholar] [CrossRef] [PubMed]

- Wei, H.; Sun, H.; Tai, Z.; Gao, S.; Xu, W.; Chen, W. A Simple and Sensitive HPLC Method for the Simultaneous Determination of Eight Bioactive Components and Fingerprint Analysis of Schisandra sphenanthera. Anal. Chim. Acta 2010, 662, 97–104. [Google Scholar] [CrossRef]

- Batlle, R.; Sánchez, C.; Nerín, C. A systematic approach to optimize solid-phase microextraction. Determination of pesticides in ethanol/water mixtures used as food simulants. Anal. Chem. 1999, 71, 2417–2422. [Google Scholar] [CrossRef]

- Gionfriddo, A.; Gruszecka, D.; Li, X.; Pawliszyn, J. Direct-immersion SPME in soy milk for pesticide analysis at trace levels by means of a matrix-compatible coating. Talanta 2020, 211, 120746–120752. [Google Scholar] [CrossRef]

- Merkle, S.; Kleeberg, K.K.; Fritsche, J. Recent developments and applications of solid phase microextraction (SPME) in food and environmental analysis—A review. Chromatography 2015, 2, 293–381. [Google Scholar] [CrossRef]

- Liu, J.M.; Li, C.Y.; Yang, F.; Zhao, N.; Lv, S.-W.; Liu, J.C.; Chen, L.J.; He, Z.; Zhang, Y.; Wang, S. Assessment of migration regularity of phthalates from food packaging materials. Food Addit. Contam. 2020, 31, 546–555. [Google Scholar] [CrossRef]

- Van Den Houwe, K.; Van Loco, J.; Lynen, F.; Van Hoeck, E. The Use of Tenax® as a Simulant for the Migration of Contaminants in Dry Foodstuffs: A Review. Packag. Technol. Sci. 2018, 31, 781–790. [Google Scholar] [CrossRef]

- Agyekum, A.A.; Derick, C.; Dontoh, D. Assessment of phthalate migration in polyethylene food contact materials sold on the Ghanaian market. Cogent Environ. Sci. 2020, 6, 1794242. [Google Scholar]

- Doan, K.; Bronaugh, R.L.; Yourick, J.J. In vivo and in vitro skin absorption of lipophilic compounds, dibutyl phthalate, farnesol and geraniol in the hairless guinea pig. Food Chem. Toxicol. 2010, 48, 18–23. [Google Scholar] [CrossRef] [PubMed]

| FS | Composition | Foodstuffs |

|---|---|---|

| A | Ethanol 10% (v/v) | Hydrophilic, with pH > 4.5 |

| B | Ethanol 20% (v/v) | Alcoholic, with alcohol < 20%; lipophilic |

| C | Ethanol 50% (v/v) | Alcoholic, with alcohol > 20%; lipophilic |

| D | Acetic acid 3% (v/v) | Hydrophilic, with pH < 4.5 |

| E | Vegetable oil | With fat on the surface |

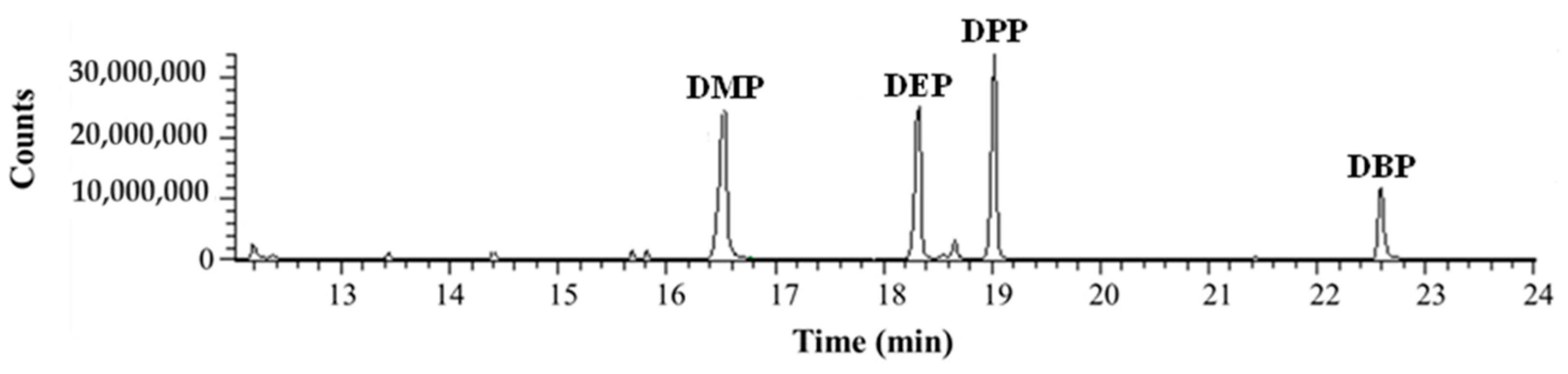

| PAEs | RT (Min) | Ion (m/z) | Concentration (%, w/w) | Extracted Area (%) |

|---|---|---|---|---|

| DMP | 16.53 ± 0.05 | 135, 163, 194 | 20.5 | 31 ± 5 |

| DEP | 18.33 ± 0.06 | 105, 149, 177 | 23.5 | 27 ± 4 |

| DPP | 19.02 ± 0.06 | 104, 149, 167 | 26.5 | 28 ± 5 |

| DBP | 22.59 ± 0.07 | 149, 205, 223 | 29.5 | 14 ± 2 |

| PAEs | Slope | Correlation Coefficient | LOD (µg/mL) | LOQ (µg/mL) | Within-Day | Between-Day | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Concentration Levels (µg/mL) | ||||||||||

| 0.5 | 2.5 | 5.0 | 0.5 | 2.5 | 5.0 | |||||

| DMP | 6 × 107 | 0.9966 | 0.037 | 0.122 | 12.9% | 12.7% | 12.3% | 26.0% | 27.2% | 26.9% |

| DEP | 6 × 107 | 0.9867 | 0.073 | 0.243 | 15.2% | 14.2% | 14.8% | 25.5% | 25.3% | 25.9% |

| DPP | 6 × 107 | 0.9928 | 0.054 | 0.179 | 14.3% | 13.6% | 14.1% | 22.6% | 22.3% | 21.9% |

| DBP | 3 × 106 | 0.9965 | 0.029 | 0.970 | 25.7% | 24.4% | 25.5% | 35.7% | 35.8% | 35.3% |

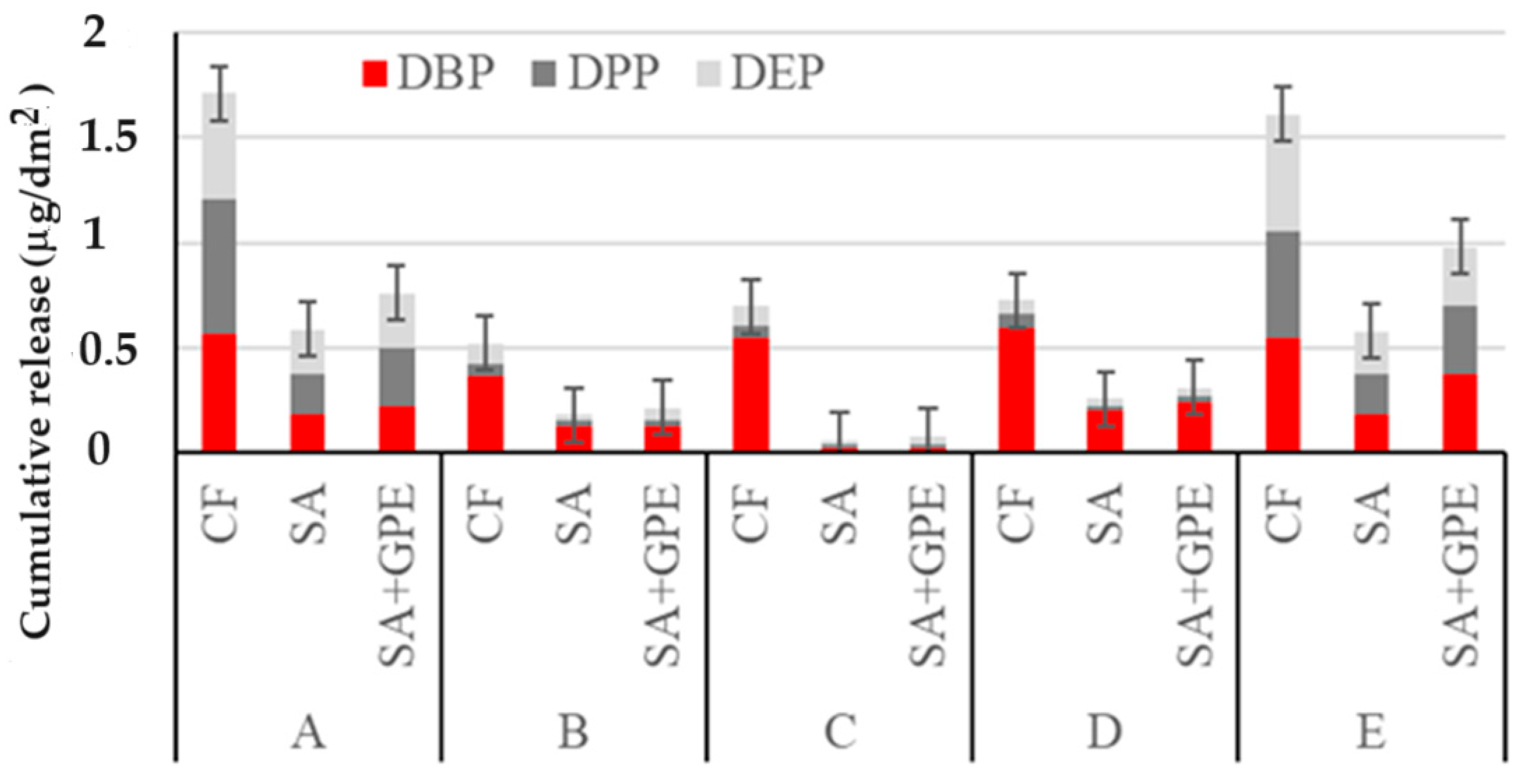

| FS | 1 h | 1 Day | 7 Days | 14 Days | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CF | SA | SA + GPE | CF | SA | SA + GPE | CF | SA | SA + GPE | CF | SA | SA + GPE | |

| mg/dm2 ± SD | mg/dm2 ± SD | mg/dm2 ± SD | mg/dm2 ± SD | |||||||||

| A | 0.36 ± 0.02 | / | / | 0.72 ± 0.04 | / | / | 1.19 ± 0.06 | 0.18 ± 0.01 | 0.17 ± 0.01 | 1.64 ± 0.08 | 0.22 ± 0.01 | 0.17 ± 0.01 |

| B | 0.02 ± 0.01 | / | / | 0.58 ± 0.03 | 0.01 ± 0.01 | / | 0.86 ± 0.04 | 0.18 ± 0.01 | 0.18 ± 0.01 | 1.20 ± 0.06 | 0.24 ± 0.01 | 0.24 ± 0.01 |

| C | 0.02 ± 0.01 | / | / | 0.42 ± 0.03 | / | / | 0.53 ± 0.03 | 0.15 ± 0.01 | 0.03 ± 0.01 | 1.09 ± 0.05 | 0.20 ± 0.01 | 0.03 ± 0.01 |

| D | 0.03 ± 0.01 | / | / | 0.13 ± 0.01 | / | / | 0.49 ± 0.03 | 0.14 ± 0.01 | / | 1.31 ± 0.06 | 0.15 ± 0.01 | / |

| E | 0.20 ± 0.01 | 0.06 ± 0.01 | 0.07 ± 0.01 | 0.46 ± 0.01 | 0.26 ± 0.01 | 0.30 ± 0.02 | 0.91 ± 0.05 | 0.35 ± 0.02 | 0.52 ± 0.03 | 1.70 ± 0.08 | 0.38 ± 0.02 | 0.83 ± 0.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Vietro, N.; Aresta, A.M.; Gubitosa, J.; Rizzi, V.; Zambonin, C. Assessing the Conformity of Plasticizer-Free Polymers for Foodstuff Packaging Using Solid Phase Microextraction Coupled to Gas Chromatography/Mass Spectrometry. Separations 2024, 11, 25. https://doi.org/10.3390/separations11010025

De Vietro N, Aresta AM, Gubitosa J, Rizzi V, Zambonin C. Assessing the Conformity of Plasticizer-Free Polymers for Foodstuff Packaging Using Solid Phase Microextraction Coupled to Gas Chromatography/Mass Spectrometry. Separations. 2024; 11(1):25. https://doi.org/10.3390/separations11010025

Chicago/Turabian StyleDe Vietro, Nicoletta, Antonella Maria Aresta, Jennifer Gubitosa, Vito Rizzi, and Carlo Zambonin. 2024. "Assessing the Conformity of Plasticizer-Free Polymers for Foodstuff Packaging Using Solid Phase Microextraction Coupled to Gas Chromatography/Mass Spectrometry" Separations 11, no. 1: 25. https://doi.org/10.3390/separations11010025

APA StyleDe Vietro, N., Aresta, A. M., Gubitosa, J., Rizzi, V., & Zambonin, C. (2024). Assessing the Conformity of Plasticizer-Free Polymers for Foodstuff Packaging Using Solid Phase Microextraction Coupled to Gas Chromatography/Mass Spectrometry. Separations, 11(1), 25. https://doi.org/10.3390/separations11010025