Toluene Bioremediation by Using Geotextile-Layered Permeable Reactive Barriers (PRBs)

Abstract

1. Introduction

2. Materials and Methods

2.1. PRB Filling Material Preparation

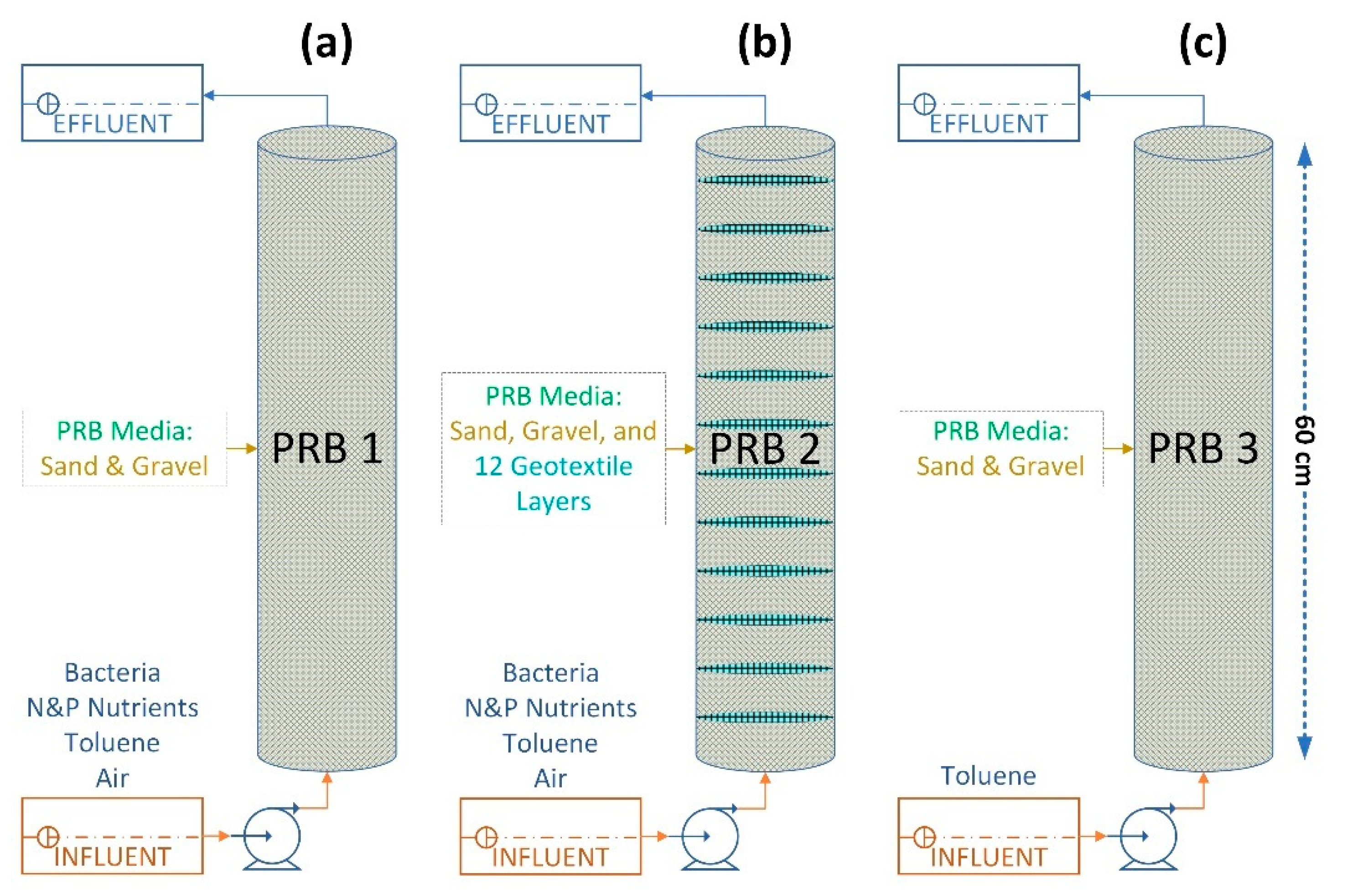

2.2. Configuration of the PRBs

2.3. Loading of the PRB Columns

2.4. Pore Volume and Porosity Tests

2.5. Flow Rate and Hydraulic Residence Time Tests

2.6. Bioaugmentation + Biostimulation (PRB-1 and PRB-2)

2.7. Natural Attenuation (PRB-3)

2.8. Oxygen Requirement

2.9. Effluent Analysis

2.9.1. Toluene Analysis

2.9.2. pH, DO, and Conductivity Analysis

2.10. Kinetic Model

3. Results

3.1. Results of Hydraulic Tests

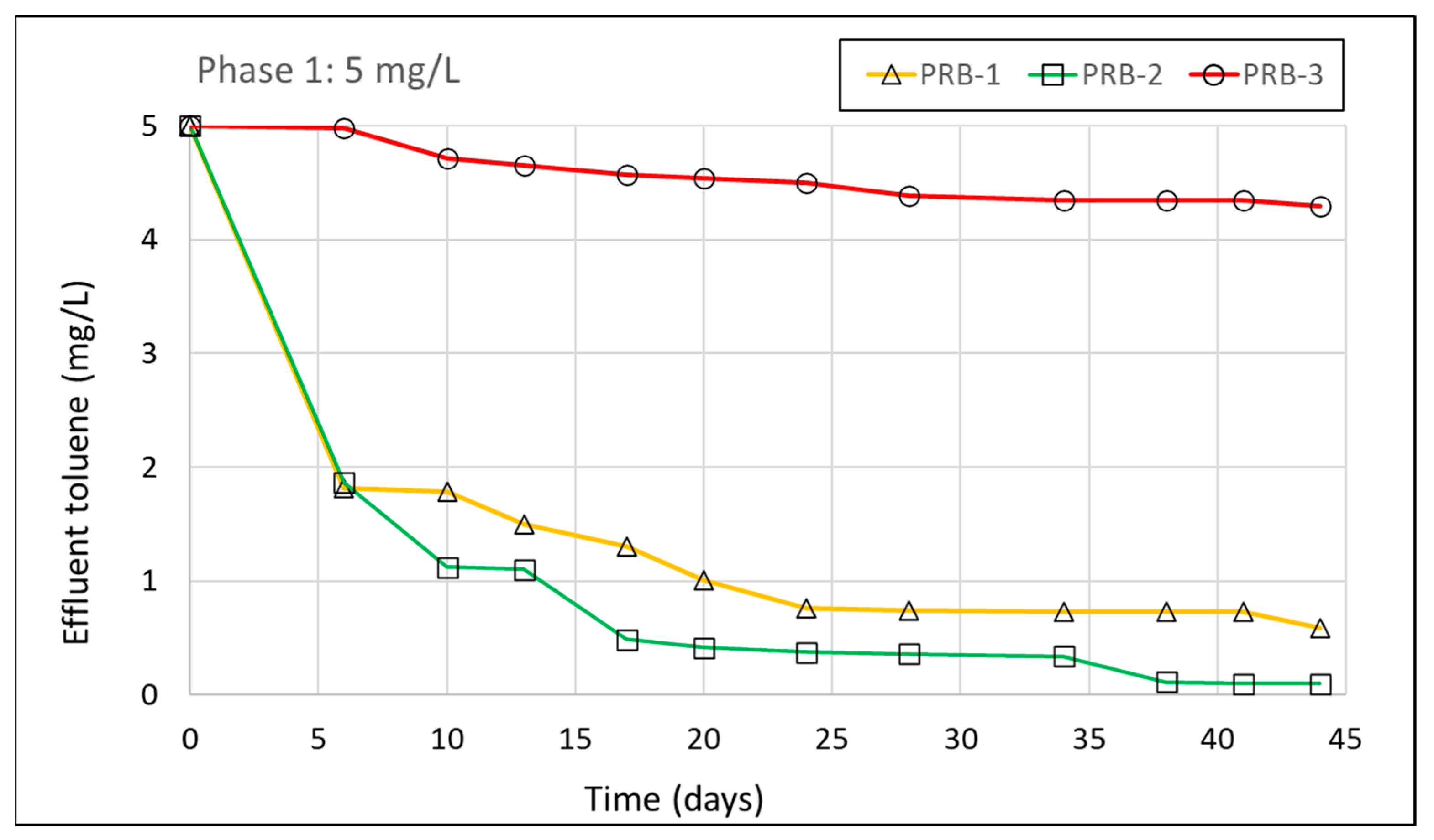

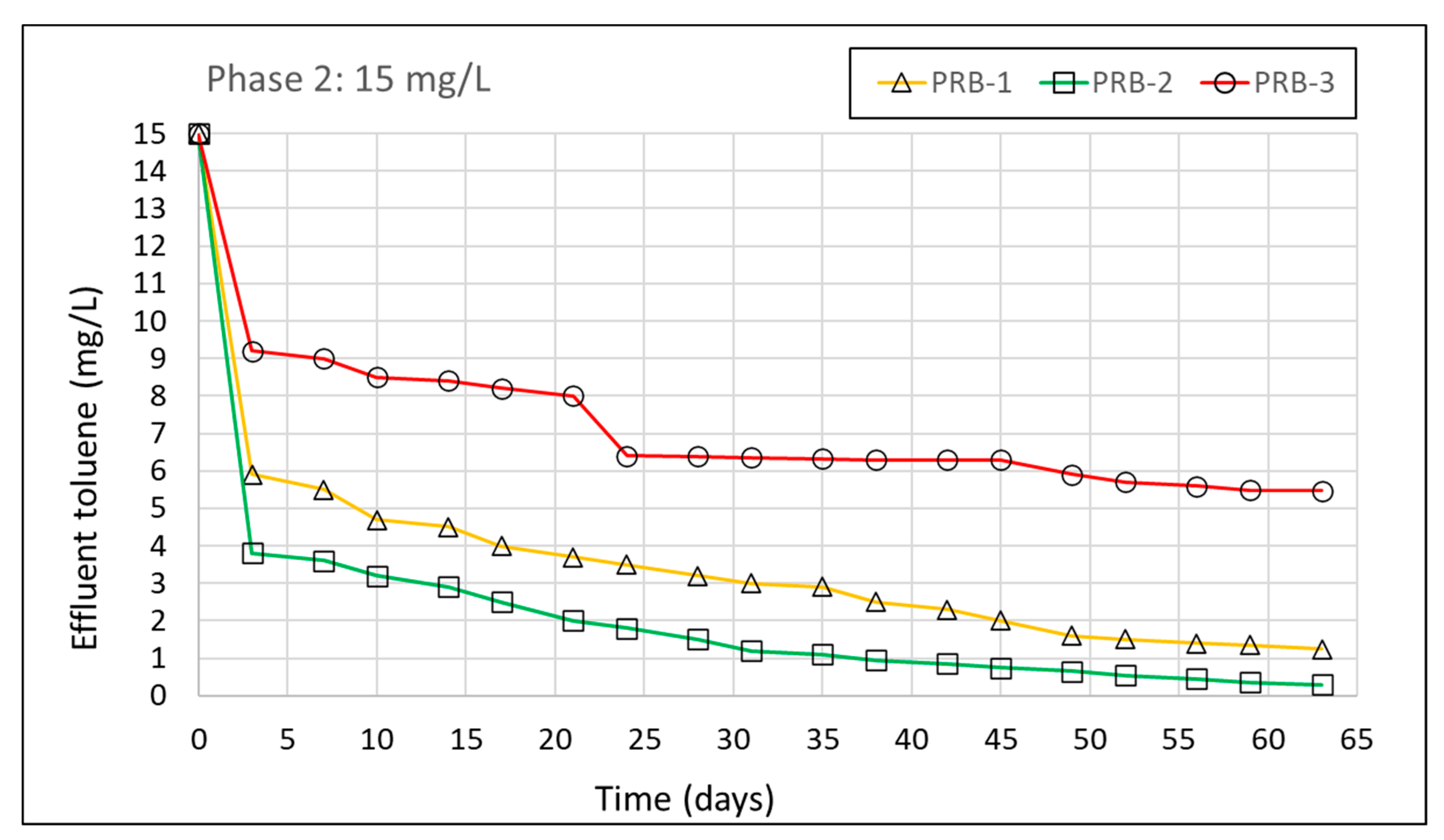

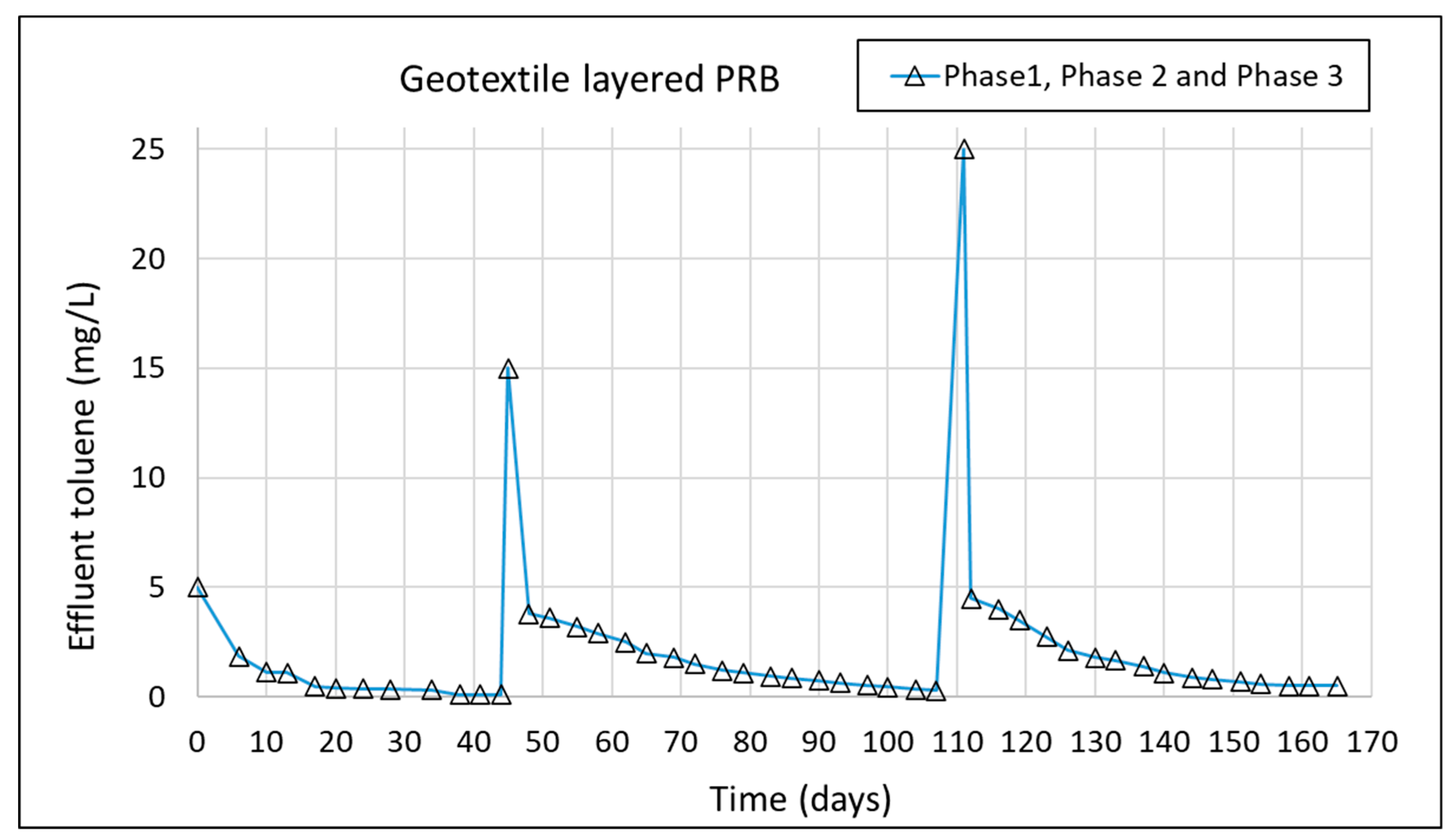

3.2. Toluene Removal Rates

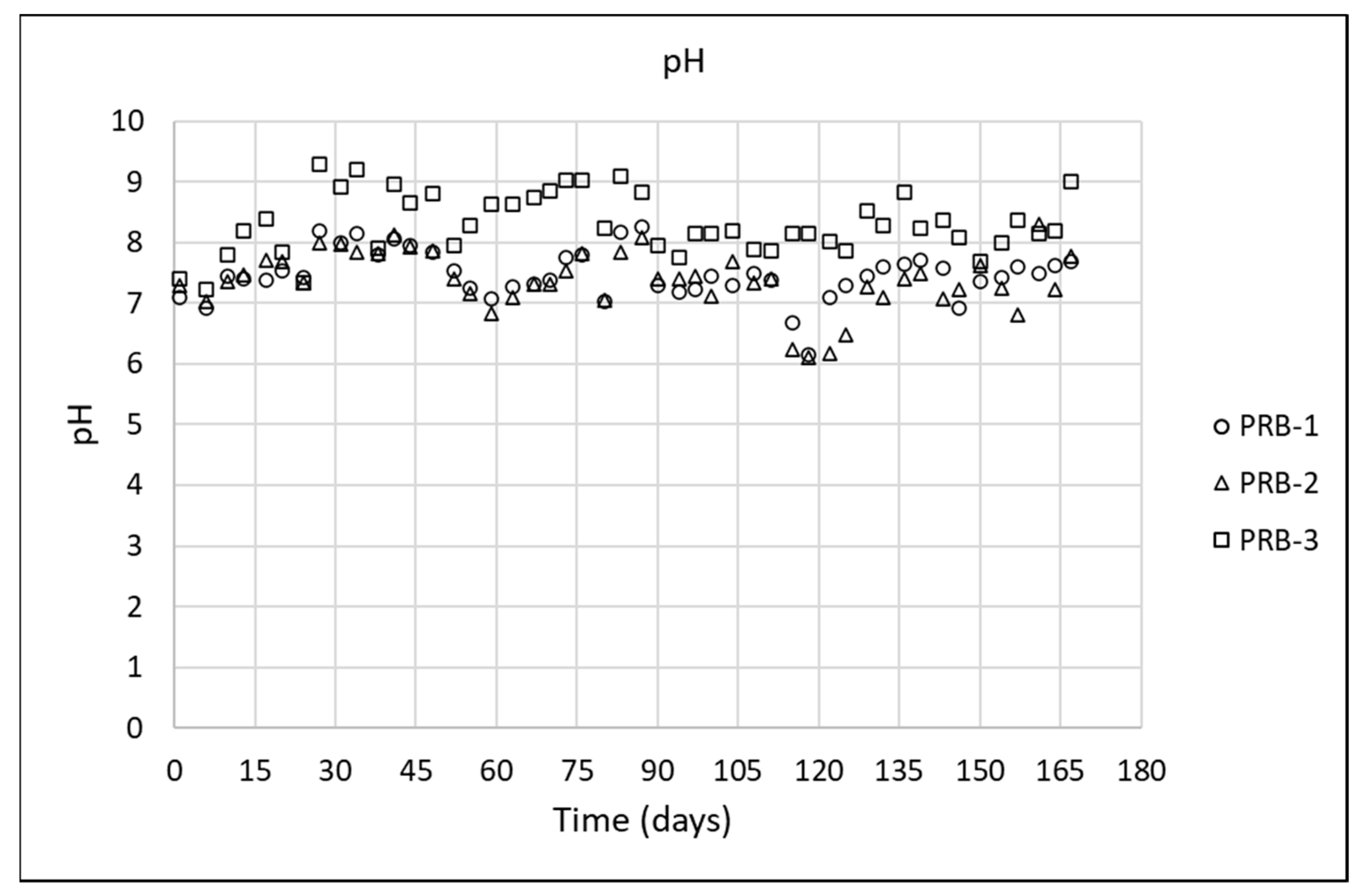

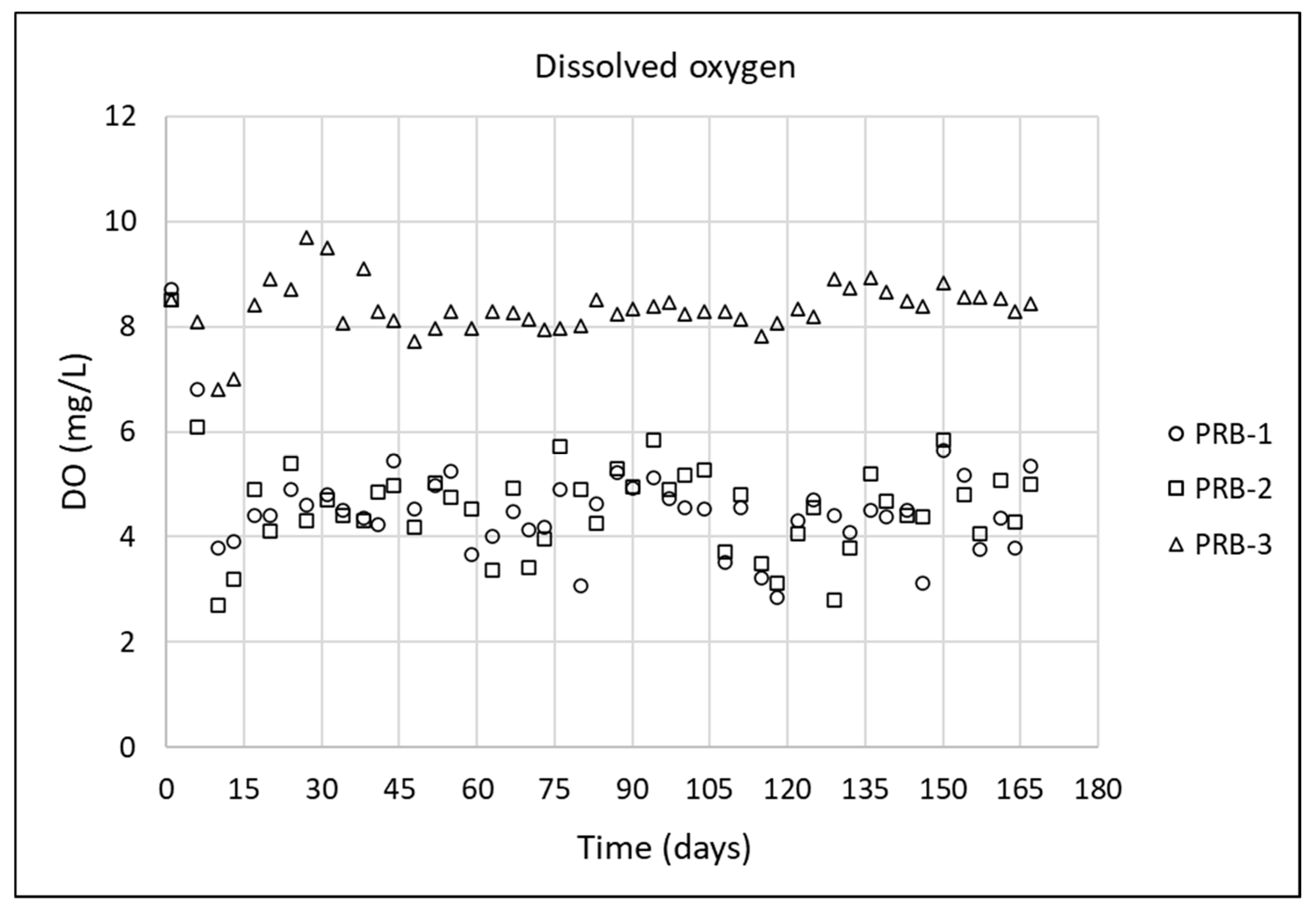

3.3. Conductivity, pH, and DO Results (All Phases Combined)

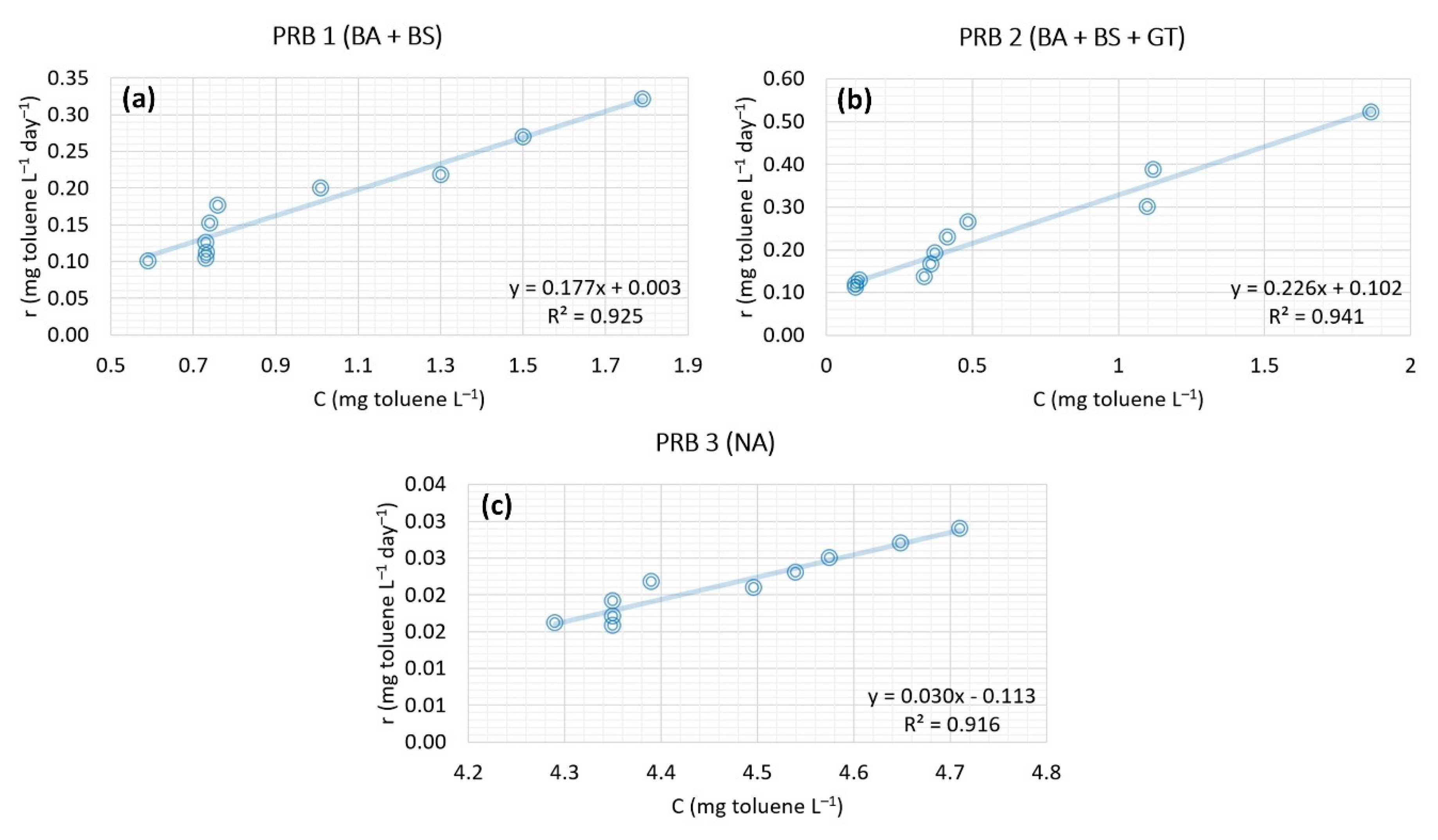

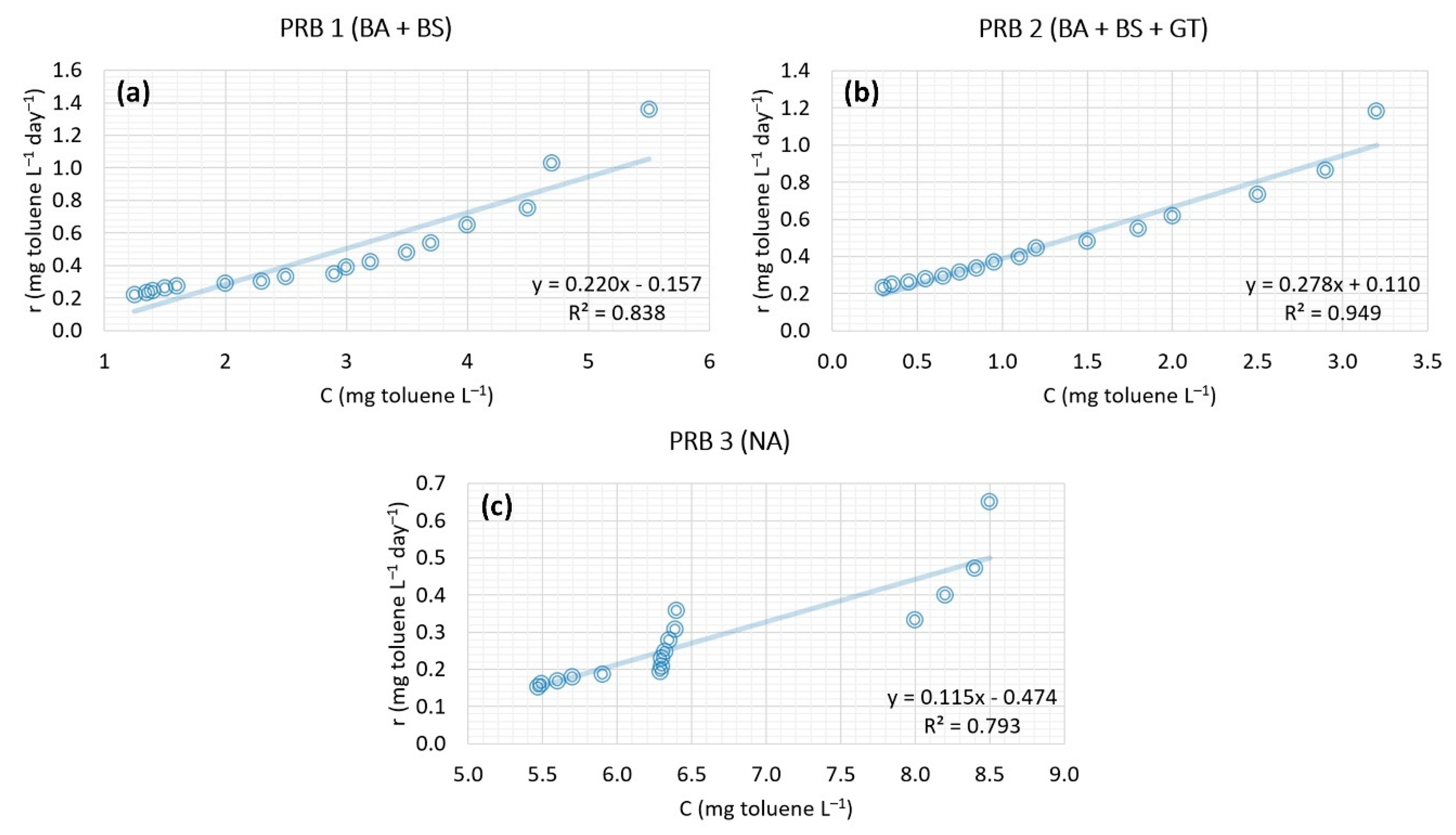

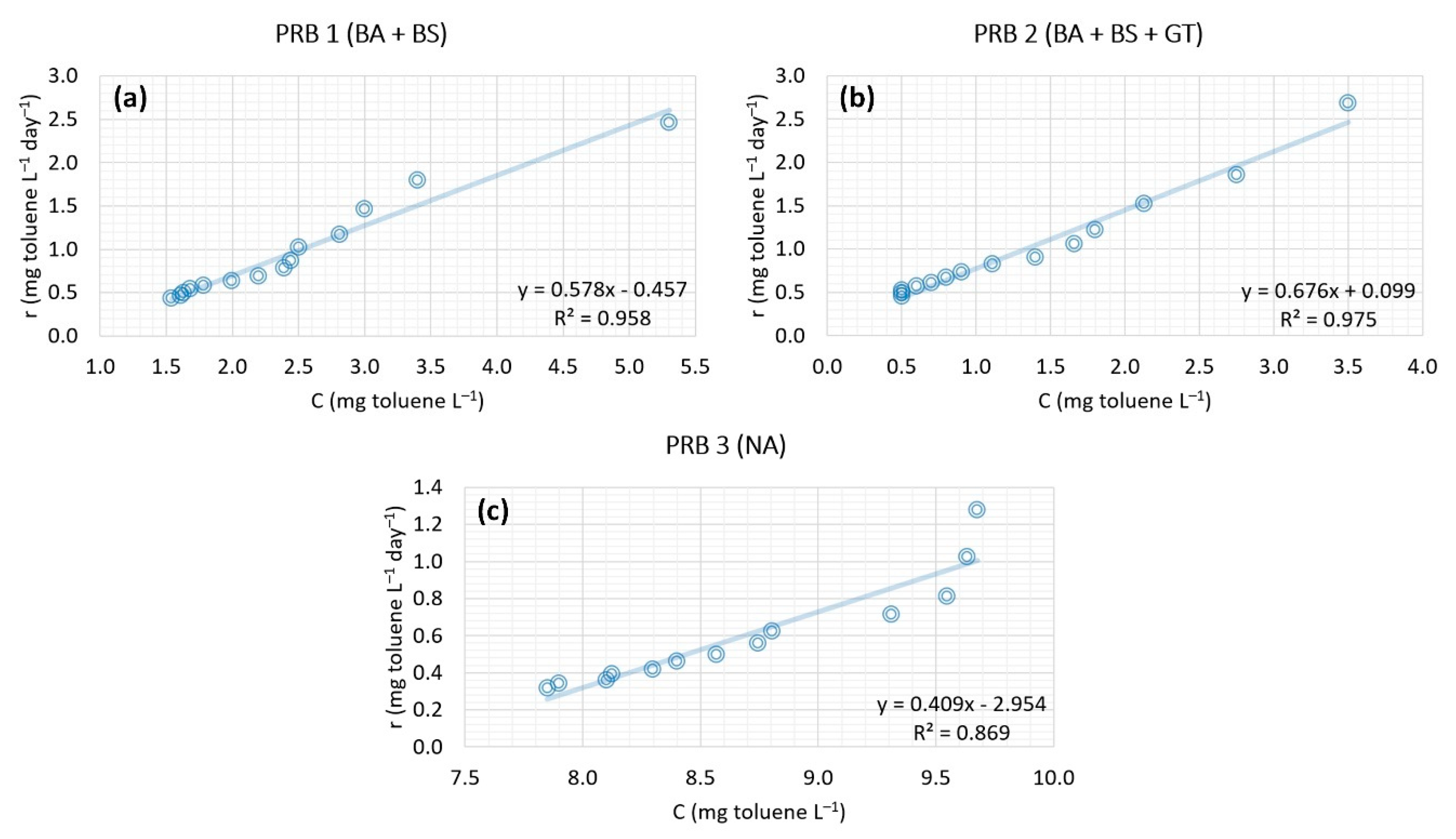

3.4. Bioremediation Kinetics

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thiruvenkatachari, R.; Vigneswaran, S.; Naidu, R. Permeable reactive barrier for groundwater remediation. J. Ind. Eng. Chem. 2008, 14, 145–156. [Google Scholar] [CrossRef]

- Upadhyay, S.; Sinha, A. Role of Microorganisms in Permeable Reactive Bio-Barriers (PRBBs) for Environmental Clean-Up: A Review. Glob. NEST J. 2018, 20, 269–280. [Google Scholar] [CrossRef]

- Capodici, M.; Morici, C.; Viviani, G. Batch Test Evaluation of Four Organic Substrates Suitable for Biological Groundwater Denitrification. Chem. Eng. Trans. 2014, 38, 43–48. [Google Scholar] [CrossRef]

- Liu, C.; Chen, X.; Mack, E.E.; Wang, S.; Du, W.; Yin, Y.; Banwart, S.A.; Guo, H. Evaluating a novel permeable reactive bio-barrier to remediate PAH-contaminated groundwater. J. Hazard. Mater. 2019, 368, 444–451. [Google Scholar] [CrossRef]

- Fan, C.; Gao, Y.; Zhang, Y.; Dong, W.; Lai, M. Remediation of lead and cadmium from simulated groundwater in loess region in northwestern China using permeable reactive barrier filled with environmentally friendly mixed adsorbents. Environ. Sci. Pollut. Res. 2018, 25, 1486–1496. [Google Scholar] [CrossRef]

- Frade, P.R.; Notini, L.; Santos, S.V.; Moreira, R.F.P.M.; Leão, M.M.D.; Amorim, C.C. Feasibility study of the use of basic oxygen furnace sludge in a permeable reactive barrier. J. Hazard. Mater. 2018, 351, 188–195. [Google Scholar] [CrossRef]

- Jun, D.; Yongsheng, Z.; Weihong, Z.; Mei, H. Laboratory study on sequenced permeable reactive barrier remediation for landfill leachate-contaminated groundwater. J. Hazard. Mater. 2009, 161, 224–230. [Google Scholar] [CrossRef]

- Zhou, D.; Li, Y.; Zhang, Y.; Zhang, C.; Li, X.; Chen, Z.; Huang, J.; Li, X.; Flores, G.; Kamon, M. Column test-based optimization of the permeable reactive barrier (PRB) technique for remediating groundwater contaminated by landfill leachates. J. Contam. Hydrol. 2014, 168, 1–16. [Google Scholar] [CrossRef]

- Das, D.B.; Mirzaei, M. Dynamic effects in capillary pressure relationships for two-phase flow in porous media: Experiments and numerical analyses. AIChE J. 2012, 58, 3891–3903. [Google Scholar] [CrossRef]

- Illangasekare, T.H.; Armbruster III, E.J.; Yates, D.N. Non-Aqueous-Phase Fluids in Heterogeneous Aquifers—Experimental Study. J. Environ. Eng. 1995, 121, 571–579. [Google Scholar] [CrossRef]

- Teramoto, E.H.; Chang, H.K. A Screening Model to Predict Entrapped LNAPL Depletion. Water 2020, 12, 334. [Google Scholar] [CrossRef]

- Chesnaux, R. Analytical closed-form solutions for assessing pumping cycles, times, and costs required for NAPL remediation. Environ. Geol. 2008, 55, 1381–1388. [Google Scholar] [CrossRef]

- Johnston, C.D. Selecting and Assessing Strategies for Remediating LNAPL in Soils and Aquifers; CRC Care Pty Ltd.: Adelaide, Australia, 2010; Volume 18. [Google Scholar]

- Iniesto, M.; Moreira, D.; Reboul, G.; Deschamps, P.; Benzerara, K.; Bertolino, P.; Saghaï, A.; Tavera, R.; López-García, P. Core microbial communities of lacustrine microbialites sampled along an alkalinity gradient. Environ. Microbiol. 2021, 23, 51–68. [Google Scholar] [CrossRef]

- Liang, X.; Zhuang, J.; Löffler, F.E.; Zhang, Y.; DeBruyn, J.M.; Wilhelm, S.W.; Schaeffer, S.M.; Radosevich, M. Viral and bacterial community responses to stimulated Fe(III)-bioreduction during simulated subsurface bioremediation. Environ. Microbiol. 2019, 21, 2043–2055. [Google Scholar] [CrossRef] [PubMed]

- Thompson, L.J.; Gray, V.; Lindsay, D.; Von Holy, A. Carbon:Nitrogen:Phosphorus ratios influence biofilm formation by Enterobacter cloacae and Citrobacter freundii. J. Appl. Microbiol. 2006, 101, 1105–1113. [Google Scholar] [CrossRef]

- Bashaar, Y.A. Nutrients requirements in biological industrial wastewater treatment. Afr. J. Biotechnol. 2004, 3, 236–238. [Google Scholar] [CrossRef]

- Yaman, C. Performance and Kinetics of Bioaugmentation, Biostimulation, and Natural Attenuation Processes for Bioremediation of Crude Oil-Contaminated Soils. Processes 2020, 8, 883. [Google Scholar] [CrossRef]

- AlSalka, Y.; Karabet, F.; Hashem, S. Development and optimisation of quantitative analytical method to determine BTEX in environmental water samples using HPLC-DAD. Anal. Methods 2010, 2, 1026. [Google Scholar] [CrossRef]

- Bahrami, A.; Mahjub, H.; Sadeghian, M.; Golbabaei, F. Determination of Benzene, Toluene and Xylene (BTX) Concentrations in Air Using HPLC Developed Method Compared to Gas Chromatography. Int. J. Occup. Hyg. 1970, 3, 12–17. [Google Scholar]

- Yusiasih, R.; Marvalosha, R.; Suci, S.D.S.; Yuliani, E.; Pitoi, M.M. Low volume liquid-liquid extraction for the determination of benzene, toluene, and xylene in water by GC-FID and HPLC-UV. IOP Conf. Ser. Earth Environ. Sci. 2019, 277, 012019. [Google Scholar] [CrossRef]

- Komilis, D.P.; Vrohidou, A.-E.K.; Voudrias, E.A. Kinetics of Aerobic Bioremediation of a Diesel-Contaminated Sandy Soil: Effect of Nitrogen Addition. Water Air Soil Pollut. 2010, 208, 193–208. [Google Scholar] [CrossRef]

- Chemlal, R.; Tassist, A.; Drouiche, M.; Lounici, H.; Drouiche, N.; Mameri, N. Microbiological aspects study of bioremediation of diesel-contaminated soils by biopile technique. Int. Biodeterior. Biodegrad. 2012, 75, 201–206. [Google Scholar] [CrossRef]

- Tellez, G.T.; Nirmalakhandan, N.; Gardea-Torresdey, J.L. Evaluation of biokinetic coefficients in degradation of oilfield produced water under varying salt concentrations. Water Res. 1995, 29, 1711–1718. [Google Scholar] [CrossRef]

- WHO. Guidelines for Drinking-Water Quality; World Health Organization: Geneva, Switzerland, 2011. [Google Scholar]

- Bernal, M.P.; Alburquerque, J.A.; Moral, R. Composting of animal manures and chemical criteria for compost maturity assessment. A review. Bioresour. Technol. 2009, 100, 5444–5453. [Google Scholar] [CrossRef] [PubMed]

- Jindrová, E.; Chocová, M.; Demnerová, K.; Brenner, V. Bacterial aerobic degradation of benzene, toluene, ethylbenzene and xylene. Folia Microbiol. 2002, 47, 83–93. [Google Scholar] [CrossRef]

- Madigan, M.T.; Martinko, J.M.; Parker, J. Brock Biology of Microorganisms, 9th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2000; ISBN 9780134261928. [Google Scholar]

- Fernández Rodríguez, M.D.; García Gómez, M.C.; Alonso Blazquez, N.; Tarazona, J.V. Soil Pollution Remediation. In Encyclopedia of Toxicology; Wexler, P., Ed.; Academic Press Inc.: Oxford, UK, 2014; pp. 344–355. ISBN 9780123864550. [Google Scholar]

- Brook, T.R.; Stiver, W.H.; Zytner, R.G. Biodegradation of Diesel Fuel in Soil Under Various Nitrogen Addition Regimes. Soil Sediment Contam. Int. J. 2001, 10, 539–553. [Google Scholar] [CrossRef]

- Shewfelt, K.; Lee, H.; Zytner, R.G. Optimization of nitrogen for bioventing of gasoline contaminated soil. J. Environ. Eng. Sci. 2005, 4, 29–42. [Google Scholar] [CrossRef]

- Rončević, S.; Dalmacija, B.; Ivančev-Tumbas, I.; Tričković, J.; Petrović, O.; Klašnja, M.; Agbaba, J. Kinetics of Degradation of Hydrocarbons in the Contaminated Soil Layer. Arch. Environ. Contam. Toxicol. 2005, 49, 27–36. [Google Scholar] [CrossRef] [PubMed]

- Yaman, C. Investigation of greenhouse gas emissions and energy recovery potential from municipal solid waste management practices. Environ. Dev. 2020, 33, 100484. [Google Scholar] [CrossRef]

- Korkut, N.E.; Yaman, C.; Küçükağa, Y. Greenhouse gas contribution of municipal solid waste collection: A case study in the city of Istanbul, Turkey. Waste Manag. Res. 2018, 36, 131–139. [Google Scholar] [CrossRef]

| Material | Average Diameter (mm) | % of SiO2 | % of Material in PRBs | % of Acid Solubility | Bulk Density (t/m3) | Specific Gravity |

|---|---|---|---|---|---|---|

| Silica sand | 1–2 | 98 ± 1 | 25% | 1 ± 0.5 | 1.5–1.70 | 2.55–2.70 |

| Silica sand | 2–3 | 98 ± 1 | 25% | 1 ± 0.5 | 1.5–1.70 | 2.55–2.70 |

| Silica sand | 3–6 | 90 ± 1 | 25% | 10 ± 0.5 | 1.5–1.70 | 2.55–2.70 |

| Silica gravel | 8–12 | 90 ± 1 | 25% | 10 ± 0.5 | 1.5–1.70 | 2.55–2.70 |

| Reactors | Geotextile Layers | Microbial Inoculum Addition (Bioaugmentation) | Nutrients Addition (Biostimulation) | Toluene Addition |

|---|---|---|---|---|

| PRB-1 (BS + BA) | No | Yes | Yes | Yes |

| PRB-3 (BS + BA + GT) | Yes | Yes | Yes | Yes |

| PRB-3 (NA) | No | No | No | Yes |

| Phase 1 (5 mg/L) | Phase 2 (15 mg/L) | Phase 3 (25 mg/L) | |

|---|---|---|---|

| NH4Cl (mg) | 0.525 | 1.57 | 2.63 |

| KH2PO4 (mg) | 0.159 | 0.478 | 0.796 |

| Initial dose of bacteria (mg) | 500 | 1500 | 2500 |

| Monthly maintenance dose of bacteria (mg) | 500 | 1500 | 2500 |

| Oxygen requirement (mg) | 15.6 | 46.9 | 78.2 |

| Geotextile Name | Location in PRB-2 | Thickness @ 2kPa (mm) | Apparent Opening Size (AOS) (µm) | Permeability (mm/s) | Polymer Type | Production Method |

|---|---|---|---|---|---|---|

| GT-1 | Layer 1 and 2 | 1.95 | 116.75 | 115.00 | PP | Needle punch |

| GT-2 | Layer 3 and 4 | 1.91 | 112.38 | 113.11 | PP | Needle punch |

| GT-3 | Layer 5 and 6 | 2.04 | 107.40 | 92.60 | PP | Needle punch |

| GT-4 | Layer 7 and 8 | 1.04 | 101.17 | 96.83 | PP | Aqua jet |

| GT-5 | Layer 9 and 10 | 1.20 | 88.00 | 80.00 | PET | Needle punch |

| GT-6 | Layer 11 and 12 | 1.40 | 84.00 | 60.00 | PET | Needle punch |

| PRB-1 | PRB-2 | PRB-3 | |

|---|---|---|---|

| Reactor volume (mL) | 4710 | 4710 | 4710 |

| Pore volume (mL) | 1060 | 1170 | 1150 |

| Hydraulic conductivity (cm/s) | 0.779 | 0.729 | 0.766 |

| Porosity (%) | 0.225 | 0.248 | 0.244 |

| Flow rate (mL/min) | 0.483 | 0.483 | 0.483 |

| Hydraulic residence time (h) | 36.57 | 40.37 | 39.68 |

| PRB-1 | PRB-2 | PRB-3 | |

|---|---|---|---|

| Phase 1 | k: 0.18 d−1 | k: 0.23 d−1 | k: 0.03 d−1 |

| t1/2: 3.91 d | t1/2: 3.06 d | t1/2: 22.95 d | |

| n = 1 | n = 1 | n = 1 | |

| R2: 0.93 | R2: 0.94 | R2: 0.92 | |

| Phase 2 | k: 0.22 d−1 | k: 0.28 d−1 | k: 0.11 d−1 |

| t1/2: 3.14 d | t1/2: 2.49 d | t1/2: 6.04 d | |

| n = 1 | n = 1 | n = 1 | |

| R2: 0.84 | R2: 0.95 | R2: 0.79 | |

| Phase 3 | k: 0.58 d−1 | k:0.68 d−1 | k: 0.41 d−1 |

| t1/2: 1.19 d | t1/2:1.02 d | t1/2: 1.69 d | |

| n = 1 | n = 1 | n = 1 | |

| R2: 0.96 | R2: 0.97 | R2: 0.87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yaman, C.; Anil, I.; Alagha, O.; Blaisi, N.I.; Yaman, A.B.; Qureshi, A.; Cevik, E.; Rehman, S.; Gunday, S.T.; Barghouthi, M. Toluene Bioremediation by Using Geotextile-Layered Permeable Reactive Barriers (PRBs). Processes 2021, 9, 906. https://doi.org/10.3390/pr9060906

Yaman C, Anil I, Alagha O, Blaisi NI, Yaman AB, Qureshi A, Cevik E, Rehman S, Gunday ST, Barghouthi M. Toluene Bioremediation by Using Geotextile-Layered Permeable Reactive Barriers (PRBs). Processes. 2021; 9(6):906. https://doi.org/10.3390/pr9060906

Chicago/Turabian StyleYaman, Cevat, Ismail Anil, Omar Alagha, Nawaf I. Blaisi, Ayse Burcu Yaman, Aleem Qureshi, Emre Cevik, Suriya Rehman, Seyda Tugba Gunday, and Mohammad Barghouthi. 2021. "Toluene Bioremediation by Using Geotextile-Layered Permeable Reactive Barriers (PRBs)" Processes 9, no. 6: 906. https://doi.org/10.3390/pr9060906

APA StyleYaman, C., Anil, I., Alagha, O., Blaisi, N. I., Yaman, A. B., Qureshi, A., Cevik, E., Rehman, S., Gunday, S. T., & Barghouthi, M. (2021). Toluene Bioremediation by Using Geotextile-Layered Permeable Reactive Barriers (PRBs). Processes, 9(6), 906. https://doi.org/10.3390/pr9060906