Effects of Different Drying Methods and Temperature on the Drying Behavior and Quality Attributes of Cherry Laurel Fruit

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Determination of Dry Matter Content and Drying Time

2.2.2. Extraction Procedure

2.2.3. Determination of Total Phenolic Content (TPC)

2.2.4. Determination of Total Flavonoid Content (TFC)

2.2.5. Total Anthocyanin Content (TAC)

2.2.6. Antioxidant Capacity by DPPH Method

2.2.7. Determination of Phenolic Profile

2.2.8. SEM Analysis

2.2.9. Color Measurement

2.2.10. Determination of Rehydration Ratio

2.2.11. Statistical Analysis

3. Result and Discussion

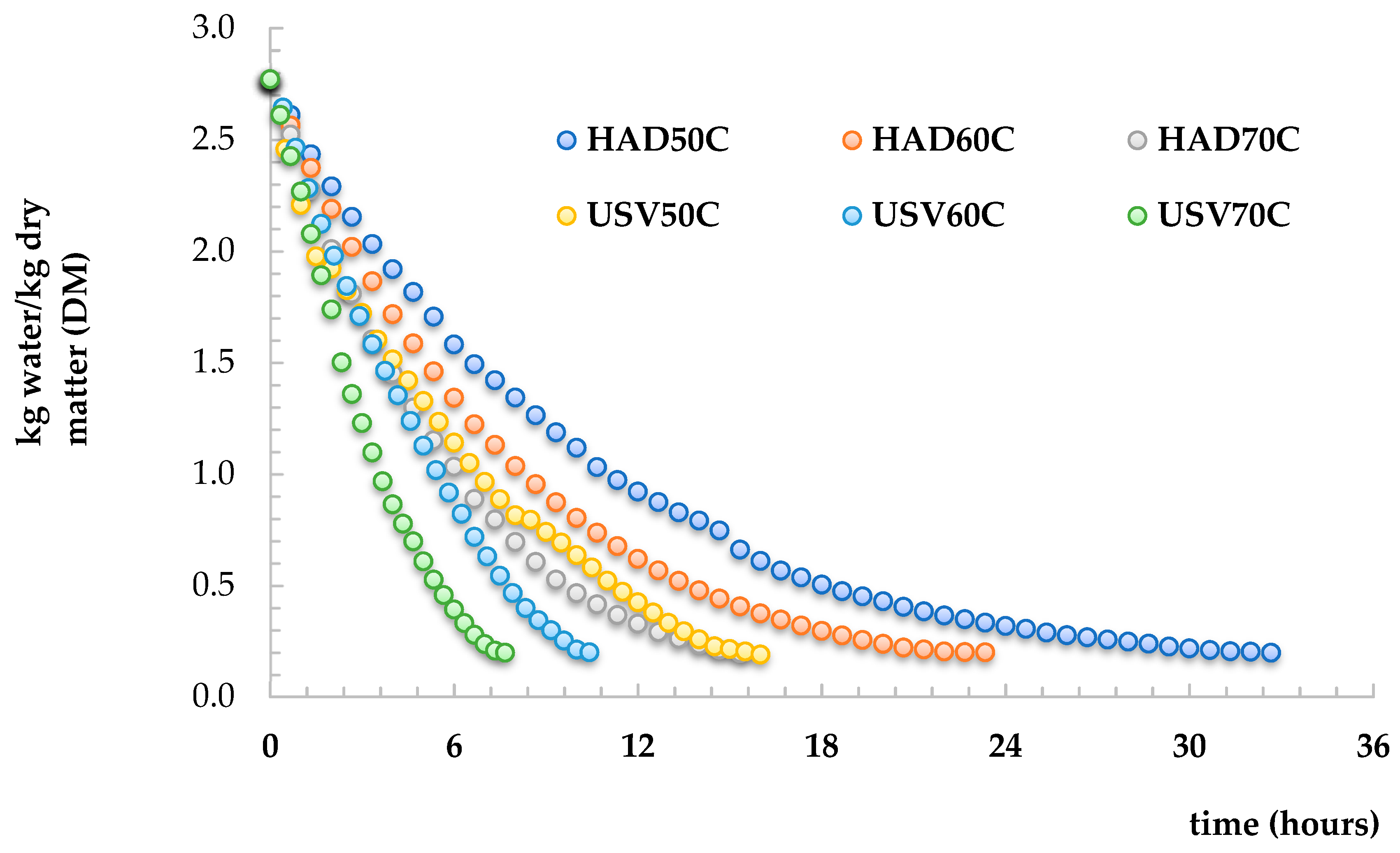

3.1. Drying Kinetic of Cherry Laurel for HAD and USV

3.2. Effect of Drying Methods on Bioactive Properties of Cherry Laurel

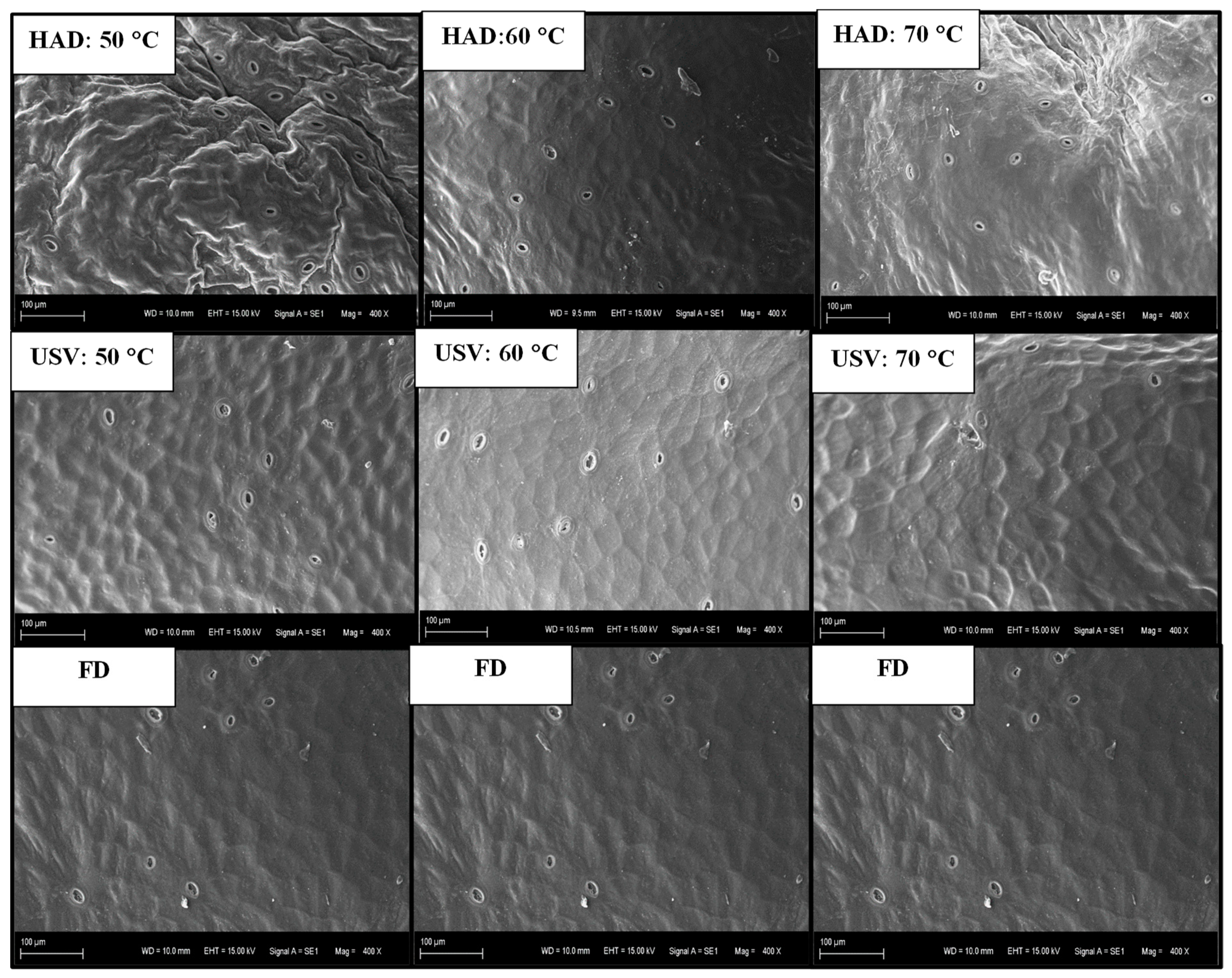

3.3. The Effect on Microstructural Properties of Cherry Laurel

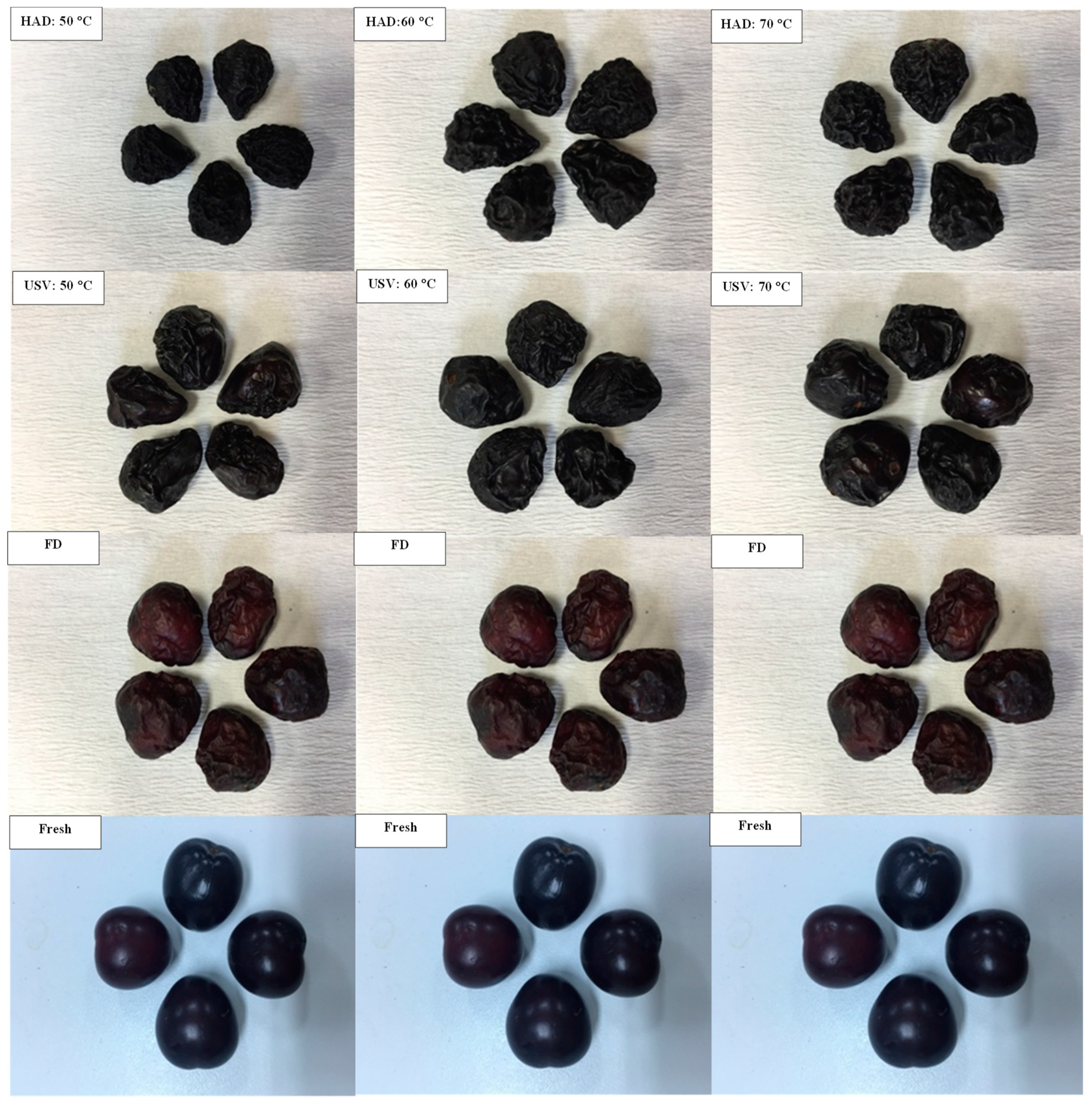

3.4. The Effect on Cherry Laurel Color

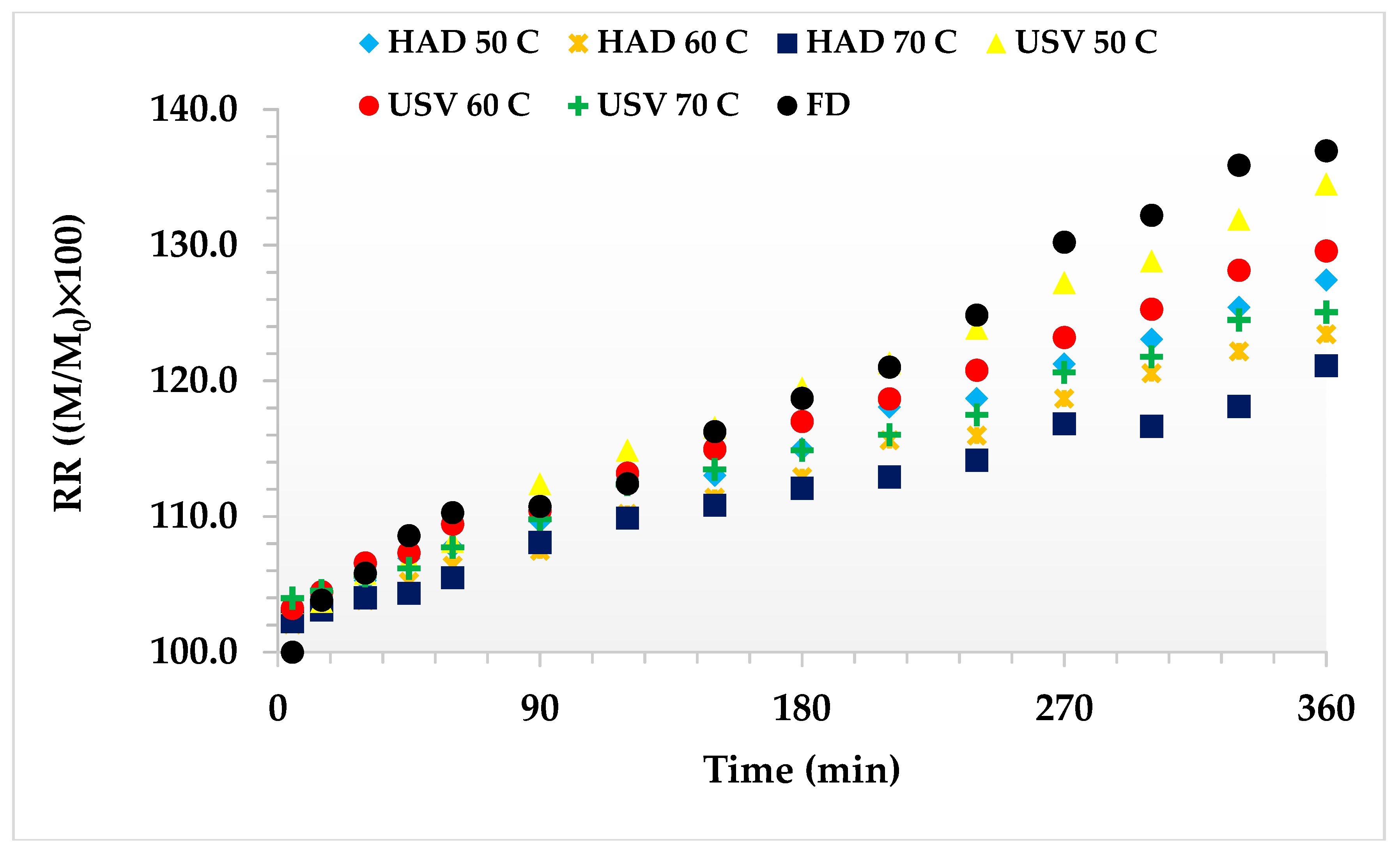

3.5. Effect on Rehydration Characteristic of Dried Cherry Laurel

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Celik, O.F.; Demirkol, M.; Durmus, Y.; Tarakci, Z. Effects of drying method on the phenolics content and antioxidant activities of cherry laurel (Prunus laurocerasus L.). J. Food Meas. Charact. 2020, 14, 48–54. [Google Scholar] [CrossRef]

- Capanoglu, E.; Boyacioglu, D.; de Vos, R.C.H.; Hall, R.D.; Beekwilder, J. Procyanidins in fruit from Sour cherry (Prunus cerasus) differ strongly in chainlength from those in Laurel cherry (Prunus lauracerasus) and Cornelian cherry (Cornus mas). J. Berry Res. 2011, 1, 137–146. [Google Scholar] [CrossRef]

- Gao, Q.H.; Wu, C.S.; Wang, M.; Xu, B.N.; Du, L.J. Effect of drying of jujubes (Ziziphus jujuba Mill.) on the contents of sugars, organic acids, α-tocopherol, β-carotene, and phenolic compounds. J. Agric. Food Chem. 2012, 60, 9642–9648. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, M.M.; Rodriguez, A.; Mascheroni, R.H. Color, texture, rehydration ability and phenolic compounds of plums partially osmodehydrated and finish-dried by hot air. J. Food Process. Preserv. 2015, 39, 2647–2662. [Google Scholar] [CrossRef]

- Calín-Sánchez, Á.; Figiel, A.; Hernández, F.; Melgarejo, P.; Lech, K.; Carbonell-Barrachina, Á.A. Chemical Composition, Antioxidant Capacity, and Sensory Quality of Pomegranate (Punica granatum L.) Arils and Rind as Affected by Drying Method. Food Bioprocess. Technol. 2013, 6, 1644–1654. [Google Scholar] [CrossRef]

- Singh, D.B.; Ambrose, K. Effect of convective drying on quality of anardana. Indian J. Hortic. 2008, 65, 413–416. [Google Scholar]

- Wojdyło, A.; Figiel, A.; Legua, P.; Lech, K.; Carbonell-Barrachina, Á.A.; Hernández, F. Chemical composition, antioxidant capacity, and sensory quality of dried jujube fruits as affected by cultivar and drying method. Food Chem. 2016, 207, 170–179. [Google Scholar] [CrossRef]

- Başlar, M.; Kılıçlı, M.; Toker, O.S.; Sağdıç, O.; Arici, M. Ultrasonic vacuum drying technique as a novel process for shortening the drying period for beef and chicken meats. Innov. Food Sci. Emerg. Technol. 2014, 26, 182–190. [Google Scholar] [CrossRef]

- Başlar, M.; Kılıçlı, M.; Yalınkılıç, B. Dehydration kinetics of salmon and trout fillets using ultrasonic vacuum drying as a novel technique. Ultrason. Sonochem. 2015, 27, 495–502. [Google Scholar] [CrossRef]

- Tekin, Z.H.; Başlar, M.; Karasu, S.; Kilicli, M. Dehydration of green beans using ultrasound-assisted vacuum drying as a novel technique: Drying kinetics and quality parameters. J. Food Process. Preserv. 2017, 41, e13227. [Google Scholar] [CrossRef]

- Tekin, Z.H.; Baslar, M. The effect of ultrasound-assisted vacuum drying on the drying rate and quality of red peppers. J. Therm. Anal. Calorim. 2018, 132, 1131–1143. [Google Scholar] [CrossRef]

- Kayacan, S.; Karasu, S.; Akman, P.K.; Goktas, H.; Doymaz, I.; Sagdic, O. Effect of different drying methods on total bioactive compounds, phenolic profile, in vitro bioaccessibility of phenolic and HMF formation of persimmon. LWT 2020, 118. [Google Scholar] [CrossRef]

- Kaya, A.; Aydin, O. Experimental investigation of drying kinetics of cherry laurel. J. Food Process. Eng. 2008, 31, 398–412. [Google Scholar] [CrossRef]

- Talih, M.; Dirim, S.N. Determination of the drying characteristics of cherry laurel (Laurocerasus officinalis Roem.) puree in a freeze-dryer. Bulg. Chem. Commun. 2018, 50, 467–477. [Google Scholar]

- Singleton, V.L. Citation Classic—Colorimetry of total phenolics with phosphomolybdic-Phosphotungstıc acid reagents. Curr. Contents Agric. Biol. Environ. Sci. 1985, 48, 18. [Google Scholar]

- Zhishen, J.; Mengcheng, T.; Jianming, W. The determination of flavonoid contents in mulberry and their scavenging effects on superoxide radicals. Food Chem. 1999, 64, 555–559. [Google Scholar] [CrossRef]

- Giusti, M.; Wrolstad, R. Characterization and Measurement of Anthocyanins by UV-Visible Spectroscopy. Curr. Protoc. Food Anal. Chem. 2001. [Google Scholar] [CrossRef]

- Singh, R.P.; Chidambara Murthy, K.N.; Jayaprakasha, G.K. Studies on the Antioxidant Activity of Pomegranate (Punica granatum) Peel and Seed Extracts Using in Vitro Models. J. Agric. Food Chem. 2002, 50, 81–86. [Google Scholar] [CrossRef]

- Aksoy, A.; Karasu, S.; Akcicek, A.; Kayacan, S. Effects of different drying methods on drying kinetics, microstructure, color, and the rehydration ratio of minced meat. Foods 2019, 8. [Google Scholar] [CrossRef]

- Isik, A.; Ozdemir, M.; Doymaz, I. Effect of hot air drying on quality characteristics and physicochemical properties of bee pollen. Food Sci. Technol. 2019, 39, 224–231. [Google Scholar] [CrossRef]

- Doymaz, I.; Karasu, S. Effect of air temperature on drying kinetics, colour changes and total phenolic content of sage leaves (Salvia officinalis). Qual. Assur. Saf. Crops Foods 2018, 10, 269–276. [Google Scholar] [CrossRef]

- Chen, Y.; Li, M.; Dharmasiri, T.S.K.; Song, X.; Liu, F.; Wang, X. Novel ultrasonic-assisted vacuum drying technique for dehydrating garlic slices and predicting the quality properties by low field nuclear magnetic resonance. Food Chem. 2020, 306, 125625. [Google Scholar] [CrossRef]

- Madrau, M.A.; Piscopo, A.; Sanguinetti, A.M.; Del Caro, A.; Poiana, M.; Romeo, F.V.; Piga, A. Effect of drying temperature on polyphenolic content and antioxidant activity of apricots. Eur. Food Res. Technol. 2008, 228, 441. [Google Scholar] [CrossRef]

- Orphanides, A.; Goulas, V.; Gekas, V. Effect of Drying Method on the Phenolic Content and Antioxidant Capacity of Spearmint. Czech. J. Food Sci. 2013, 31, 509–513. [Google Scholar] [CrossRef]

- Li, W.; Li, Y.; Bi, J.; Ji, Q.; Zhao, X.; Zheng, Q.; Tan, S.; Gao, X. Effect of hot air drying on the polyphenol profile of Hongjv (Citrus reticulata Blanco, CV. Hongjv) peel: A multivariate analysis. J. Food Biochem. 2020, 44. [Google Scholar] [CrossRef]

- Teles, A.S.C.; Chávez, D.W.H.; Gomes, F.d.S.; Cabral, L.M.C.; Tonon, R.V. Effect of temperature on the degradation of bioactive compounds of Pinot Noir grape pomace during drying. Braz. J. Food Technol. 2018, 21. [Google Scholar] [CrossRef]

- Kroehnke, J.; Szadzińska, J.; Stasiak, M.; Radziejewska-Kubzdela, E.; Biegańska-Marecik, R.; Musielak, G. Ultrasound- and microwave-assisted convective drying of carrots—Process kinetics and product’s quality analysis. Ultrason. Sonochem. 2018, 48, 249–258. [Google Scholar] [CrossRef]

- Witrowa-Rajchert, D.; Rza, M. Effect of Drying Method on the Microstructure and Physical Properties of Dried Apples. Drying Technol. 2009, 27, 903–909. [Google Scholar] [CrossRef]

- Yao, L.; Fan, L.; Duan, Z. Effect of different pretreatments followed by hot-air and far-infrared drying on the bioactive compounds, physicochemical property and microstructure of mango slices. Food Chem. 2020, 305, 125477. [Google Scholar] [CrossRef]

- Zotarelli, M.F.; Porciuncula, B.D.A.; Laurindo, J.B. A convective multi-flash drying process for producing dehydrated crispy fruits. J. Food Eng. 2012, 108, 523–531. [Google Scholar] [CrossRef]

- Puig, A.; Perez-Munuera, I.; Carcel, J.A.; Hernando, I.; Garcia-Perez, J.V. Moisture loss kinetics and microstructural changes in eggplant (Solanum melongena L.) during conventional and ultrasonically assisted convective drying. Food Bioprod. Process. 2012, 90, 624–632. [Google Scholar] [CrossRef]

- Chen, D.; Xing, B.; Yi, H.; Li, Y.; Zheng, B.; Wang, Y.; Shao, Q. Effects of different drying methods on appearance, microstructure, bioactive compounds and aroma compounds of saffron (Crocus sativus L.). LWT 2020, 120, 108913. [Google Scholar] [CrossRef]

- Xu, Y.; Xiao, Y.; Lagnika, C.; Li, D.; Liu, C.; Jiang, N.; Song, J.; Zhang, M. A comparative evaluation of nutritional properties, antioxidant capacity and physical characteristics of cabbage (Brassica oleracea var. Capitate var L.) subjected to different drying methods. Food Chem. 2020, 309, 124935. [Google Scholar] [CrossRef] [PubMed]

- Bhandari, B.R.; Adhikari, B. Drying Technologies in Food Processing; Blackwell Publishing Ltd.: Hoboken, NJ, USA, 2008; pp. 55–89. [Google Scholar]

- Guiné, R.P.F.; Barroca, M.J. Effect of drying treatments on texture and color of vegetables (pumpkin and green pepper). Food Bioprod. Process. 2012, 90, 58–63. [Google Scholar] [CrossRef]

- Miranda, M.; Vega-Gálvez, A.; García, P.; Di Scala, K.; Shi, J.; Xue, S.; Uribe, E. Effect of temperature on structural properties of Aloe vera (Aloe barbadensis Miller) gel and Weibull distribution for modelling drying process. Food Bioprod. Process. 2010, 88, 138–144. [Google Scholar] [CrossRef]

- Vega-Gálvez, A.; Zura-Bravo, L.; Lemus-Mondaca, R.; Martinez-Monzó, J.; Quispe-Fuentes, I.; Puente, L.; Di Scala, K. Influence of drying temperature on dietary fibre, rehydration properties, texture and microstructure of Cape gooseberry (Physalis peruviana L.). J. Food Sci. Technol. 2015, 52, 2304–2311. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, Q.S.; Zhao, B. Comparison of drying methods on drying efficiency and physicochemical quality of okra (Abelmoschus esculentus) cultivated in China. J. Food Process. Eng. 2019, 42, 10. [Google Scholar] [CrossRef]

- Ricce, C.; Rojas, M.L.; Miano, A.C.; Siche, R.; Augusto, P.E.D. Ultrasound pre-treatment enhances the carrot drying and rehydration. Food Res. Int. 2016, 89, 701–708. [Google Scholar] [CrossRef]

| Method | Temperature (°C) | TPC mg GAE/100 g Sample (DM) | TFC mg Catechin/100 g Sample (DM) | TA Cyanidin 3-Glucoside/100 g Sample (DM) | DPPH mg Trolox Equivalent (TE)/100 g Samples (DM) |

|---|---|---|---|---|---|

| Fresh | 839.66 ± 8.01 Aa | 1568.93 ± 21.96 Bb | 110.41 ± 5.94 Bb | 17.31 ± 0.70 Aa | |

| HAD | 50 | 311.88 ± 9.27 Dc | 209.03 ± 14.82 Ed | 39.93 ± 2.17 Ed | 5.71 ± 0.35 Dc |

| 60 | 487.56 ± 5.26 Cc | 335.23 ± 6.91 Dd | 54.22 ± 4.79 Dd | 7.41 ± 0.29 Cc | |

| 70 | 580.81 ± 10.03 Bc | 768.43 ± 11.71 Cd | 76.22 ± 2.67 Cd | 8.52 ± 0.34 Bc | |

| USV | 50 | 465.64 ± 10.15 Db | 396.63 ± 5.91 Eb | 61.64 ± 2.37 Dc | 7.53 ± 0.68 Db |

| 60 | 614.05 ± 4.20 Cb | 556.94 ± 16.30 Db | 82.13 ± 5.56 Cc | 9.24 ± 0.17 Cb | |

| 70 | 674.4 ± 13.85 Bb | 811.52 ± 10.97 Cb | 102.49 ± 1.76 Bc | 11.79 ± 0.56 Bb | |

| FD | 851.47 ± 6.73 Aa | 1853.13 ± 11.92 Aa | 135.52 ± 4.83 Aa | 17.13 ± 0.27 Aa |

| Samples | Phenolic Compounds mg/100 g Sample(DM) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gallic Acid | Protocatechuic Acid | Catechin | p-Hydroxybenzoic Acid | Syringic Acid | Caffeic Acid | Vanillic Acid | Chlorogenic Acid | Ferulic Acid | Cinnamic Acid | Epicatechin | Rutin | Quercetin | |

| Fresh | 0.327 ± 0.009 | 0.349 ± 0.005 | 5.502 ± 0.0087 bB | 0.515 ± 0.021 | 10.222 ± 0.105 bB | 0.221 ± 0.007 | 14.857 ± 0.120 bB | 70.31 ± 1.000 bB | 0.065 ± 0.007 | 0.059 ± 0.001 | 63.679 ± 0.240 bB | 1.581 ± 0.026 | 0.304 ± 0.011 |

| HAD | |||||||||||||

| 50 °C | 0.223 ± 0.001 | 0.058 ± 0.000 | 0.537 ± 0.021 dE | 0.147 ± 0.011 | 5.244 ± 0.085 dE | 0.188 ± 0.013 | 1.010 ± 0.050 dE | 9.136 ± 0.050 dE | 0.036 ± 0.001 | 0.070 ± 0.050 | 9.150 ± 0.50 dE | 2.141 ± 0.030 | 1.915 ± 0.055 |

| 60 °C | 0.025 ± 0.005 | 0.092 ± 0.002 | 1.275 ± 0.017 dD | 0.176 ± 0.007 | 7.082 ± 0.150 dD | 0.355 ± 0.019 | 2.130 ± 0.100 dD | 12.181 ± 0.063 dD | 0.007 ± 0.000 | 0.215 ± 0.005 | 11.671 ± 0.110 dD | 0.444 ± 0.158 | 1.224 ± 0.006 |

| 70 °C | 0.013 ± 0.001 | 0.055 ± 0.000 | 1.537 ± 0.020 dC | 0.377 ± 0.008 | 8.888 ± 0.130 dC | 0.588 ± 0.020 | 4.400 ± 0.140 dC | 15.075 ± 0.026 dC | 0.017 ± 0.001 | 0.048 ± 0.001 | 47.693 ± 0.815 dC | 0.248 ± 0.002 | 1.389 ± 0.102 |

| USV | |||||||||||||

| 50 °C | 0.038 ± 0.000 | 0.122 ± 0.003 | 1.904 ± 0.016 cE | 0.105 ± 0.007 | 5.523 ± 0.200 cE | 0.110 ± 0.003 | 5.000 ± 0.176 cE | 7.518 ± 0.183 cE | 0.041 ± 0.003 | 0.037 ± 0.001 | 3.171 ± 0.060 cE | 0.229 ± 0.010 | 0.994 ± 0.090 |

| 60 °C | 0.029 ± 0.000 | 0.159 ± 0.010 | 2.703 ± 0.181 cD | 0.138 ± 0.002 | 7.169 ± 0.100 cD | 0.276 ± 0.090 | 7.640 ± 0.226 cD | 11.563 ± 0.552 cD | 0.022 ± 0.030 | 0.050 ± 0.001 | 15.714 ± 0.252 cD | 1.162 ± 0.0572 | 0.304 ± 0.007 |

| 70 °C | 0.075 ± 0.006 | 0.158 ± 0.022 | 2.988 ± 0.016 cC | 0.229 ± 0.007 | 9.186 ± 0.065 cC | 0.566 ± 0.005 | 9.400 ± 0.141 cC | 60.095 ± 0.650 cC | 0.110 ± 0.120 | 0.126 ± 0.008 | 54.738 ± 0.610 cC | 0.834 ± 0.012 | 0.391 ± 0.015 |

| FD | 0.323 ± 0.002 | 0.483 ± 0.010 | 6.664 ± 0.100 aA | 0.124 ± 0.004 | 15.478± 0.200 aA | 0.285 ± 0.010 | 16.617 ± 0.200 aA | 103.653 ± 1.291 aA | 0.141 ± 0.095 | 0.667 ± 0.011 | 86.177 ± 0.644 aA | 2.647 ± 0.520 | 1.455 ± 0.075 |

| Methods | Temperature (°C) | L* | a* | b* | ΔL | Δa | Δb | ΔE |

|---|---|---|---|---|---|---|---|---|

| Fresh | 29.23 ± 0.08 Bb | 9.15 ± 1.75 Bb | −4.15 ± 0.27 Dd | |||||

| FD | 35.45 ± 0.51 Aa | 16.91 ± 2.38 Aa | 2.25 ± 0.35 Aa | 6.22 ± 1.33 Aa | 7.76 ± 0.03 Aa | 1.19 ± 0.11 Bc | 10.12 ± 0.11 Bc | |

| HAD | 50 | 23.18 ± 0.16 De | 0.95 ± 0.50 Cd | −2.5 ± 0.55 Cc | 6.05 ± 0.07 Aa | 8.21 ± 0.15 Aa | 6.65 ± 0.09 Aa | 12.34 ± 0.19 Aa |

| 60 | 27.53 ± 0.20 Cc | 2.57 ± 0.09 Cc | −1.27 ± 0.02 Bb | 1.17 ± 0.05 Bc | 6.58 ± 0.05 b | 5.42 ± 0.05 Ab | 9.26 ± 0.26 Bc | |

| 70 | 25.94 ± 0.33 Cd | 1.25 ± 0.33 Dd | −2.37 ± 0.13 Bc | 3.29 ± 0.95 Bb | 7.91 ± 0.50 Aa | 6.74 ± 0.05 Aa | 11.13 ± 0.05 Ab | |

| USV | 50 | 27.92 ± 0.32 Cc | 1.16 ± 0.07 Cd | −1.99 ± 0.03 Bb | 1.31 ± 0.05 Bc | 8.09 ± 0.03 Aa | 6.14 ± 0.37 Ab | 10.16 ± 0.03 Ba |

| 60 | 27.71 ± 0.15 Cc | 1.19 ± 0.16 Dd | −2.27 ± 0.15 Cb | 1.53 ± 0.09 Bcb | 7.96 ± 0.01 Aab | 6.02 ± 0.15 Ab | 10.74 ± 0.01 Aa | |

| 70 | 27.31 ± 0.90 Cc | 2.10 ± 0.08 Cc | −3.00 ± 0.09 Cc | 1.93 ± 1.15 Cb | 7.05 ± 0.07 Ab | 7.15 ± 0.09 Aa | 10.89 ± 0.15 Aa | |

| FD | 35.45 ± 0.51 Aa | 16.91 ± 2.38 Aa | 2.25 ± 0.35 Aa | 6.22 ± 1.33 Aa | 7.76 ± 0.03 Aa | 1.19 ± 0.11 Bc | 10.12 ± 0.11 a |

| Methods | M | K1 | K2 | R2 | |

|---|---|---|---|---|---|

| HAD | 50 °C | 102.04 ± 0.01 | 12.38 ± 0.90 cA | 0.91 ± 0.05 cA | 0.9946 |

| 60 °C | 102.30 ± 0.45 | 14.92 ± 0.05 bA | 1.26 ± 0.01 bA | 0.9979 | |

| 70 °C | 102.13 ± 0.04 | 16.06 ± 0.07 aA | 1.51 ± 0.01 aA | 0.9945 | |

| USV | 50 °C | 102.68 ± 0.11 | 10.09 ± 0.01 cB | 0.38 ± 0.02 cB | 0.9989 |

| 60 °C | 104.22 ± 0.25 | 11.04 ± 0.03 bB | 0.41 ± 0.02 bB | 0.9984 | |

| 70 °C | 103.72 ± 0.25 | 15.38 ± 0.01 aB | 0.49 ± 0.01 aB | 0.9968 | |

| FD | 102.161 ± 0.09 | 8.04 ± 0.05 dC | 0.10 ± 0.01 dC | 0.9955 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turkmen, F.; Karasu, S.; Karadag, A. Effects of Different Drying Methods and Temperature on the Drying Behavior and Quality Attributes of Cherry Laurel Fruit. Processes 2020, 8, 761. https://doi.org/10.3390/pr8070761

Turkmen F, Karasu S, Karadag A. Effects of Different Drying Methods and Temperature on the Drying Behavior and Quality Attributes of Cherry Laurel Fruit. Processes. 2020; 8(7):761. https://doi.org/10.3390/pr8070761

Chicago/Turabian StyleTurkmen, Fatma, Salih Karasu, and Ayse Karadag. 2020. "Effects of Different Drying Methods and Temperature on the Drying Behavior and Quality Attributes of Cherry Laurel Fruit" Processes 8, no. 7: 761. https://doi.org/10.3390/pr8070761

APA StyleTurkmen, F., Karasu, S., & Karadag, A. (2020). Effects of Different Drying Methods and Temperature on the Drying Behavior and Quality Attributes of Cherry Laurel Fruit. Processes, 8(7), 761. https://doi.org/10.3390/pr8070761