Human Health Impacts of Aviation Biofuel Production: Exploring the Application of Different Life Cycle Impact Assessment (LCIA) Methods for Biofuel Supply Chains

Abstract

1. Introduction

2. Materials and Methods

2.1. Overview of LCIA Methods Compared in This Study

2.1.1. Impact Category

2.1.2. Model Structure and Inputs

2.1.3. Temporal and Spatial Scales

2.1.4. Uncertainties

2.2. Methodology

2.2.1. Goal and Scope Definition

2.2.2. Life Cycle Inventory

Inventories of Aviation Fuel Production

Allocation Method

2.2.3. Impact Assessment: Comparison among Different Methods

- For midpoint human carcinogenic toxicity (HCT): USEtox 2 (r + i) (Only USEtox 2 (r + i) is included in the comparative analysis, as according to the developers of this method, practitioners should always use indicative CFs together with recommended CFs to calculate toxicity in empirical studies. Thus, USEtox 2 (r) is excluded.), ReCiPe 2016 (E) (ReCiPe 2016 (I) is excluded from the comparative analysis as its timeframe is 20 years, which is significantly shorter than the remaining methods.), ReCiPe 2016 (H), IMPACT 2002+, and TRACI;

- For midpoint human non-carcinogenic toxicity (HNCT): USEtox 2 (r + i), ReCiPe 2016 (E), ReCiPe 2016 (H), IMPACT 2002+, and TRACI;

- For midpoint fine particulate matter (FPM): ReCiPe 2016 (E), ReCiPe 2016 (H), IMPACT 2002+, and TRACI;

- For midpoint photochemical smog (PS): ReCiPe 2016 (E), ReCiPe 2016 (H), IMPACT 2002+, and TRACI;

- For endpoint human health (HH): ReCiPe 2016 (E), ReCiPe 2016 (H), and IMPACT 2002+.

3. Results and Discussion

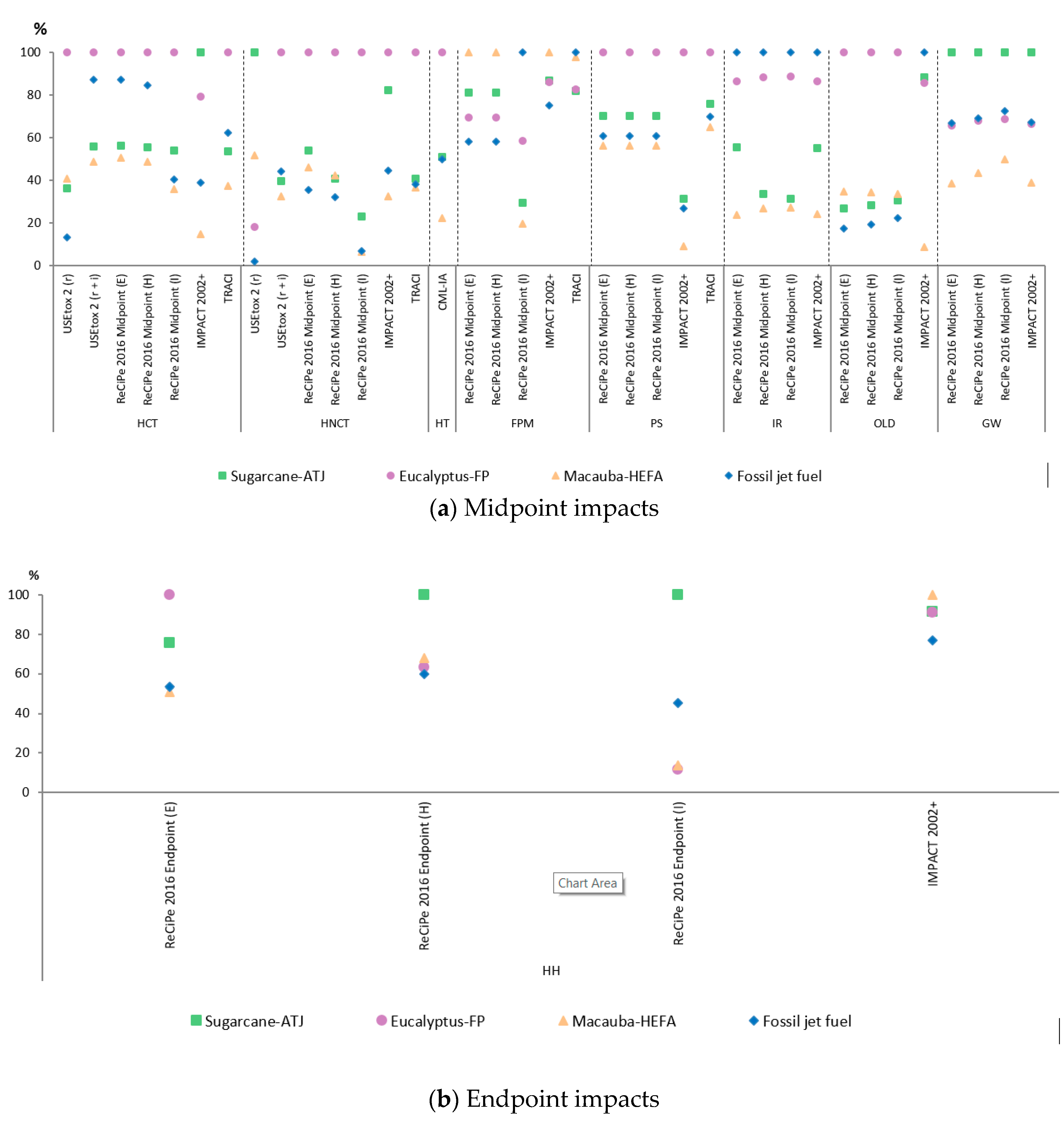

3.1. Relative Ranking of Aviation Biofuel Alternatives

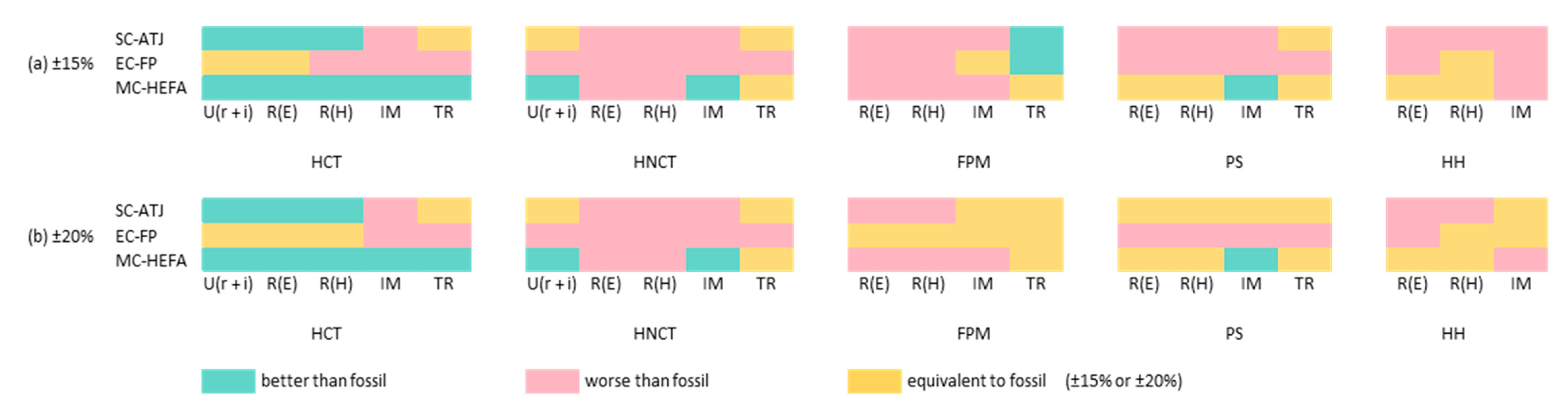

3.2. How do Aviation Biofuel Alternatives Perform Compared to Fossil Jet Fuel?

3.3. Contribution Analysis

3.3.1. Human Carcinogenic and Non-Carcinogenic Toxicity

3.3.2. Fine Particulate Matter

3.3.3. Photochemical Smog

3.3.4. Human Health

3.3.5. Fossil Jet Fuel

3.4. Sensitivity Analysis

3.5. Improvement Opportunities for Aviation Biofuel Alternatives

3.6. Lessons Learned for Selecting LCIA Methods for Human Health Assessment

- What are the spatial, temporal, and value choice specifications of the LCA study?

- What is the preferred level of impact assessment (midpoint or endpoint)?

- Which human health impact categories are of interest?

- Which method(s) include as many CFs as possible for assessing all input substances?

- Are there any environmental compartments and exposure pathways of particular interest?

- What can be the potential “hotspots” of the LCA study?

- Which method(s) include as many CFs as possible for assessing potential “hotspots”?

- If multiple methods appear suitable, do they lead to consistent results? If not, a sensitivity analysis is recommended to provide insights into the differences.

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- International Air Transport Association (IATA). 2014. IATA 2015 Report on Alternative Fuels. Available online: https://www.iata.org/publications/Documents/2015-report-alternative-fuels.pdf (accessed on 10 March 2019).

- International Civil Aviation Organization (ICAO). 2016. Resolution A39-3: Consolidated Statement of Continuing ICAO Policies and Practices Related to Environmental Protection—Climate Hange (39th General Assembly). Available online: https://www.icao.int/environmental-protection/Documents/Resolution_A39_3.pdf (accessed on 3 May 2019).

- Bailis, R.E.; Baka, J.E. Greenhouse gas emissions and land use change from Jatropha curcas-based jet fuel in Brazil. Environ. Sci. Technol. 2010, 44, 8684–8691. [Google Scholar] [CrossRef]

- Cox, K.; Renouf, M.; Dargan, A.; Turner, C.; Klein-Marcuschamer, D. Environmental life cycle assessment (LCA) of aviation biofuel from microalgae, Pongamia pinnata, and sugarcane molasses. Biofuels Bioprod. Biorefin. 2014, 8, 579–593. [Google Scholar] [CrossRef]

- de Jong, S.; Antonissen, K.; Hoefnagels, R.; Lonza, L.; Wang, M.; Faaij, A.; Junginger, M. Life-cycle analysis of greenhouse gas emissions from renewable jet fuel production. Biotechnol. Biofuels 2017, 10, 64. [Google Scholar] [CrossRef]

- Elgowainy, A.; Han, J.; Wang, M.; Carter, N.; Stratton, R.; Hileman, J.; Malwitz, A.; Balasubramanian, S. Life-Cycle Analysis of Alternative Aviation Fuels in GREET (No. ANL/ESD/12-8); Argonne National Laboratory: Oak Ridge, TN, USA, 2012.

- Han, J.; Elgowainy, A.; Cai, H.; Wang, M.Q. Life-cycle analysis of bio-based aviation fuels. Bioresour. Technol. 2013, 150, 447–456. [Google Scholar] [CrossRef]

- Santos, C.I.; Silva, C.C.; Mussatto, S.I.; Osseweijer, P.; van der Wielen, L.A.; Posada, J.A. Integrated 1st and 2nd generation sugarcane bio-refinery for jet fuel production in Brazil: Techno-economic and greenhouse gas emissions assessment. Renew. Energy 2017, 129, 733–747. [Google Scholar] [CrossRef]

- Shonnard, D.R.; Williams, L.; Kalnes, T.N. Camelina-derived jet fuel and diesel: Sustainable advanced biofuels. Environ. Prog. Sustain. 2010, 29, 382–392. [Google Scholar] [CrossRef]

- Staples, M.D.; Malina, R.; Olcay, H.; Pearlson, M.N.; Hileman, J.I.; Boies, A.; Barrett, S.R. Lifecycle greenhouse gas footprint and minimum selling price of renewable diesel and jet fuel from fermentation and advanced fermentation production technologies. Energy Environ. Sci. 2014, 7, 1545–1554. [Google Scholar] [CrossRef]

- Prussi, M.; O’Connell, A.; Lonza, L. Analysis of current aviation biofuel technical production potential in EU28. Biomass Bioenergy 2019, 130, 105371. [Google Scholar] [CrossRef]

- Chuck, C. (Ed.) Biofuels for Aviation: Feedstocks, Technology and Implementation; Academic Press: Cambridge, MA, USA, 2016; ISBN 978-0-12-804568-8. [Google Scholar]

- Crossin, E.M. Aviation Biofuels Life Cycle Assessment; RMIT University: Melbourne, Australia, 2014. [Google Scholar]

- Kim, S.; Dale, B.E. Life cycle assessment of fuel ethanol derived from corn grain via dry milling. Bioresour. Technol. 2008, 99, 5250–5260. [Google Scholar] [CrossRef]

- Tsang, M.; Fox-Lent, C.; Wallace, S.; Welp, T.; Bates, M.; Linkov, I. Life-cycle impacts of soybean and algae biodiesel: Case study of US marine vessels. Biofuels Bioprod. Biorefin. 2015, 9, 567–580. [Google Scholar] [CrossRef]

- de Jong, S.; Hoefnagels, R.; Faaij, A.; Slade, R.; Mawhood, R.; Junginger, M. The feasibility of short-term production strategies for renewable jet fuels—A comprehensive techno-economic comparison. Biofuels Bioprod. Biorefin. 2015, 9, 778–800. [Google Scholar] [CrossRef]

- Yang, Y. Life cycle freshwater ecotoxicity, human health cancer, and noncancer impacts of corn ethanol and gasoline in the US. J. Clean. Prod. 2013, 53, 149–157. [Google Scholar] [CrossRef]

- Yang, Y.; Bae, J.; Kim, J.; Suh, S. Replacing gasoline with corn ethanol results in significant environmental problem-shifting. Environ. Sci. Technol. 2012, 46, 3671–3678. [Google Scholar] [CrossRef]

- Pizzol, M.; Christensen, P.; Schmidt, J.; Thomsen, M. Impacts of “metals” on human health: A comparison between nine different methodologies for Life Cycle Impact Assessment (LCIA). J. Clean. Prod. 2011, 19, 646–656. [Google Scholar] [CrossRef]

- Rosenbaum, R.K.; Bachmann, T.M.; Gold, L.S.; Huijbregts, M.A.; Jolliet, O.; Juraske, R.; Koehler, A.; Larsen, H.F.; MacLeod, M.; Margni, M.; et al. USEtox—The UNEP-SETAC toxicity model: Recommended characterisation factors for human toxicity and freshwater ecotoxicity in life cycle impact assessment. Int. J. Life Cycle Assess. 2008, 13, 532. [Google Scholar] [CrossRef]

- Weldu, Y.W.; Assefa, G.; Jolliet, O. Life cycle human health and ecotoxicological impacts assessment of electricity production from wood biomass compared to coal fuel. Appl. Energy 2017, 187, 564–574. [Google Scholar] [CrossRef]

- Galdos, M.; Cavalett, O.; Seabra, J.E.; Nogueira, L.A.; Bonomi, A. Trends in global warming and human health impacts related to Brazilian sugarcane ethanol production considering black carbon emissions. Appl. Energy 2013, 104, 576–582. [Google Scholar] [CrossRef]

- Parada, M.P.; Osseweijer, P.; Duque, J.A. Sustainable biorefineries, an analysis of practices for incorporating sustainability in biorefinery design. Ind. Crops Prod. 2017, 106, 105–123. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Huijbregts, M.; Jolliet, O.; MacLeod, M.; Margni, M.; van de Meent, D.; Rosenbaum, R.K.; McKone, T.E. Building a model based on scientific consensus for life cycle impact assessment of chemicals: The search for harmony and parsimony. Environ. Sci. Technol. 2008, 42, 7032–7037. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.D.M.; Hollander, A.; Zijp, M.; van Zelm, R. ReCiPe 2016: A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level Report I: Characterization. Rijksinstituut voor Volksgezondheid en Milieu RIVM. Available online: https://rivm.openrepository.com/handle/10029/620793 (accessed on 21 March 2019).

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A new life cycle impact assessment methodology. Int. J. Life Cycle Assess. 2003, 8, 324. [Google Scholar] [CrossRef]

- Hauschild, M. Spatial differentiation in life cycle impact assessment: A decade of method development to increase the environmental realism of LCIA. Int. J. Life Cycle Assess. 2006, 11, 11–13. [Google Scholar] [CrossRef]

- Hauschild, M.; Potting, J. Spatial Differentiation in Life Cycle Impact Assessment-The EDIP2003 Methodology; Institute for Product Development, Technical University of Denmark: Miljøstyrelsen Copenhagen, Denmark, 2005. [Google Scholar]

- Guinée, J.B. Handbook on life cycle assessment operational guide to the ISO standards. Int. J. Life Cycle Assess. 2002, 7, 311–313. [Google Scholar] [CrossRef]

- Bare, J.; Young, D.; Qam, S.; Hopton, M.; Chief, S. Tool for the Reduction and Assessment of Chemical and other Environmental Impacts (TRACI); US Environmental Protection Agency: Washington, DC, USA, 2012.

- Hauschild, M.; Goedkoop, M.; Guinée, J.; Heijungs, R.; Huijbregts, M.A.J.; Jolliet, O.; De Schryver, A. Recommendations for Life Cycle Impact Assessment in the European Context-Based on Existing Environmental Impact Assessment Models and Factors; European Commission-DG Joint Research Centre, JRC: Publications Office of the European Union: Luxembourg, 2011; Available online: http://lct.jrc.ec.europa.eu/assessment/projects (accessed on 26 October 2018).

- Fantke, P. UNEP/SETAC Scientific Consensus Model for Characterizing Human Toxicological and Ecotoxicological Impacts of Chemical Emissions in Life Cycle Assessment; USEtox® International Center Hosted at the Technical University of Denmark: Lyngby, Demark, 2017. [Google Scholar]

- Huijbregts, M.A.; Steinmann, Z.J.; Elshout, P.M.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Humbert, S.; De Schryver, A.; Bengoa, X.; Margni, M.; Jolliet, O. IMPACT 2002+: User Guide, 2012.

- van Zelm, R.; Huijbregts, M.A.; van de Meent, D. USES-LCA 2.0—A global nested multi-media fate, exposure, and effects model. Int. J. Life Cycle Assess. 2009, 14, 282. [Google Scholar] [CrossRef]

- Goedkoop, M.J. The Eco-Indicator 99 a Damage Oriented Method for Life Cycle Impact Assessment Methodology Report; Pre Concultants: Amersfoort, The Netherlands, 1999. [Google Scholar]

- McKone, T.E. CalTOX, a Multimedia Total Exposure Model for Hazardous-Waste Sites; Lawrence Livermore National Lab.: Livermore, CA, USA, 1993. [Google Scholar]

- Carter, W.P. Development of ozone reactivity scales for volatile organic compounds. Air Waste 1994, 44, 881–899. [Google Scholar] [CrossRef]

- Carter, W.P. Development of the SAPRC-07 chemical mechanism. Atmos. Environ. 2010, 44, 5324–5335. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Wenzel, H. Environmental Assessment of Products—Scientific Background; Kluwer Academic Publishers: London UK, 1998. [Google Scholar]

- Wenzel, H.; Hauschild, M.Z.; Alting, L. Environmental Assessment of Products—Volume 1: Methodology, Tools and Case Studies in Product Development; Chapman & Hall Publishers: London, UK, 1997. [Google Scholar]

- Alves, C.M.; Valk, M.; de Jong, S.; Bonomi, A.; van der Wielen, L.A.; Mussattom, S.I. Techno-economic assessment of biorefinery technologies for aviation biofuels supply chains in Brazil. Biofuels Bioprod. Biorefin. 2016, 11, 67–91. [Google Scholar] [CrossRef]

- Wang, Z.; Kamali, F.P.; Osseweijer, P.; Posada, J.A. Socioeconomic effects of aviation biofuel production in Brazil: A scenarios-based Input-Output analysis. J. Clean. Prod. 2019, 230, 1036–1050. [Google Scholar] [CrossRef]

- Maga, D.; Thonemann, N.; Hiebel, M.; Sebastião, D.; Lopes, T.F.; Fonseca, C.; Gírio, F. Comparative life cycle assessment of first-and second-generation ethanol from sugarcane in Brazil. Int. J. Life Cycle Assess. 2019, 24, 266–280. [Google Scholar] [CrossRef]

- Saraiva, A.B.; Valle, R.A.; Bosque, A.E., Jr.; Berglin, N.; v Schenck, A. Provision of pulpwood and short rotation eucalyptus in Bahia, Brazil–Environmental impacts based on lifecycle assessment methodology. Biomass Bioenergy 2017, 105, 41–50. [Google Scholar] [CrossRef]

- Silva, D.A.; Pavan, A.L.; de Oliveira, J.A.; Ometto, A.R. Life cycle assessment of offset paper production in Brazil: Hotspots and cleaner production alternatives. J. Clean. Prod. 2015, 93, 222–233. [Google Scholar] [CrossRef]

- Fernández-Coppel, I.A.; Barbosa-Evaristo, A.; Corrêa-Guimarães, A.; Martín-Gil, J.; Navas-Gracia, L.M.; Martín-Ramos, P. Life cycle analysis of macauba palm cultivation: A promising crop for biofuel production. Ind. Crops Prod. 2018, 125, 556–566. [Google Scholar] [CrossRef]

- Atsonios, K.; Kougioumtzis, M.A.; Panopoulos, K.D.; Kakaras, E. Alternative thermochemical routes for aviation biofuels via alcohols synthesis: Process modeling, techno-economic assessment and comparison. Appl. Energy 2015, 138, 346–366. [Google Scholar] [CrossRef]

- Wang, W.C.; Tao, L. Bio-jet fuel conversion technologies. Renew. Sustain. Energy Rev. 2016, 53, 801–822. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, C.; Liu, Y.; Zhai, Y.; Zhang, R. Two-step catalytic hydrodeoxygenation of fast pyrolysis oil to hydrocarbon liquid fuels. Chemosphere 2013, 93, 652–660. [Google Scholar] [CrossRef]

- Pearlson, M.; Wollersheim, C.; Hileman, J.A. techno-economic review of hydroprocessed renewable esters and fatty acids for jet fuel production. Biofuels Bioprod. Biorefin. 2013, 7, 89–96. [Google Scholar] [CrossRef]

- Bhagwan, R.; Habisreuther, P.; Zarzalis, N.; Turrini, F. An experimental comparison of the emissions characteristics of standard jet A-1 and synthetic fuels. Flow Turbul. Combust. 2014, 92, 865–884. [Google Scholar] [CrossRef]

- Corporan, E.; Edwards, T.; Shafer, L.; DeWitt, M.J.; Klingshirn, C.; Zabarnick, S.; West, Z.; Striebich, R.; Graham, J.; Klein, J. Chemical, thermal stability, seal swell, and emissions studies of alternative jet fuels. Energy Fuels 2011, 25, 955–966. [Google Scholar] [CrossRef]

- Stratton, R.W.; Wolfe, P.J.; Hileman, J.I. Impact of aviation non-CO2 combustion effects on the environmental feasibility of alternative jet fuels. Environ. Sci. Technol. 2011, 45, 10736–10743. [Google Scholar] [CrossRef]

- Suh, S.; Weidema, B.; Schmidt, J.H.; Heijungs, R. Generalized make and use framework for allocation in life cycle assessment. J. Ind. Ecol. 2010, 14, 335–353. [Google Scholar] [CrossRef]

- International Standards Organisation (ISO). Environmental Management. Life Cycle Assessment. Principles and Framework; ISO 14040:2006; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Dreyer, L.C.; Niemann, A.L.; Hauschild, M.Z. Comparison of three different LCIA methods: EDIP97, CML2001 and Eco-indicator 99. Int. J. Life Cycle Assess. 2003, 8, 191–200. [Google Scholar] [CrossRef]

- Gloria, T.; Russell, A.; Atherton, J.; Baker, S.; Cook, M. Ecological Toxicity Methods and Metals. An examination of two case studies (8 pp+ 1). Int. J. Life Cycle Assess. 2006, 11, 26–33. [Google Scholar] [CrossRef]

- Khan, A.A.; de Jong, W.; Jansens, P.J.; Spliethoff, H. Biomass combustion in fluidized bed boilers: Potential problems and remedies. Fuel Process. Technol. 2009, 90, 21–50. [Google Scholar] [CrossRef]

- James, A.; Thring, R.; Helle, S.; Ghuman, H. Ash management review—Applications of biomass bottom ash. Energies 2012, 5, 3856–3873. [Google Scholar] [CrossRef]

- Robertson, G.P.; Vitousek, P.M. Nitrogen in agriculture: Balancing the cost of an essential resource. Annu. Rev. Environ. Resour. 2009, 34, 97–125. [Google Scholar] [CrossRef]

| Method | USEtox2 | ReCiPe2016 | IMPACT2002+ | EDIP2003 | CML-IA | TRACI | ||

|---|---|---|---|---|---|---|---|---|

| Reference | [20,24,32] | [25,33] | [26,34] | [27,28] | [31] | [30,35] | ||

| Model structure | Multimedia | √ | √ | √ | × | √ | √ | |

| HCT a (cases) | √ | × | × | × | × | √ | ||

| HNCT b (cases) | √ | × | × | × | × | √ | ||

| HCT a (kg 1,4DCB-eq) | × | √ | × | × | × | × | ||

| HNCT b (kg 1,4DCB-eq) | × | √ | × | × | × | × | ||

| HCT a (kg C2H3Cl-eq) | × | × | √ | × | × | × | ||

| HNCT b (kg C2H3Cl-eq) | × | × | √ | × | × | × | ||

| HT c (kg 1,4DCB-eq) | × | × | × | × | √ | × | ||

| FPM d (kg PM2.5-eq) | × | √ | × | × | × | × | ||

| RI e (kg PM2.5-eq) | × | × | √ | × | × | × | ||

| HHP f (kg PM2.5-eq) | × | × | × | × | × | √ | ||

| Midpoint | FPM d (kg PM2.5-eq) | × | √ | × | × | × | × | |

| POF g (kg NOx-eq) | × | √ | × | × | × | × | ||

| Impact | PO h (kg Ethylene-eq) | × | × | √ | × | × | × | |

| PSF i (kg O3-eq) | × | × | × | × | × | √ | ||

| OLD j (kg CFC-11-eq) | × | √ | √ | × | × | × | ||

| IR k (Bq Carbon-14-eq) | × | × | √ | × | × | × | ||

| IR k (Bq Co-60-eq) | × | √ | × | × | × | × | ||

| GW l (kg CO2-eq) | × | √ | × | × | × | × | ||

| HTP m-air (person·yr) | × | × | × | √ | × | × | ||

| HTP m-water (person·yr) | × | × | × | √ | × | × | ||

| HTP m -soil (person·yr) | × | × | × | √ | × | × | ||

| Endpoint | HH n (DALY) | √ | √ | √ | × | × | × | |

| CTUh o (cases/kg) | √ | × | × | × | × | √ | ||

| HTP m (kg 1,4DCB-eq/kg) | × | √ | × | × | √ | × | ||

| HTP m (kg chloroethylene-eq/kg) | × | × | √ | × | × | × | ||

| RIP p (kg PM2.5-eq/kg) | × | × | √ | × | × | × | ||

| PMFP q (kg PM2.5 into air-eq/kg) | × | √ | × | × | × | √ | ||

| POP r (kg Ethylene into air-eq/kg) | × | × | √ | × | × | √ | ||

| HOFP s (kg NOx into air-eq/kg) | × | √ | × | × | × | × | ||

| Midpoint | SFP t (kg O3 into air-eq/kg) | × | × | × | × | × | √ | |

| ODP u (kg CFC-11 into air-eq/kg) | × | √ | √ | × | × | × | ||

| CF | IRP v (kBqCarbon-14-eq/kBq) | × | × | √ | × | × | × | |

| IRP v (kBq Co-60 into air eq/kBq) | × | √ | × | × | × | × | ||

| GWP w (kg CO2-eq/kg) | × | √ | √ | × | × | × | ||

| HTCF x (m3/g) | × | × | × | √ | × | × | ||

| CDUh y (DALY/kg) | √ | × | × | × | × | × | ||

| Endpoint | ECFhum z (DALY/kg) | × | √ | √ | × | × | × | |

| ECFhum z (DALY/m3) | × | √ | × | × | × | × | ||

| Scale | Temporal | Long term/infinite | √ | √ | √ | √ | √ | × |

| 20 years | × | √ | × | × | × | × | ||

| 100 years | × | √ | × | × | × | × | ||

| Spatial | Global | √ | √ | × | × | √ | √ | |

| Europe | √ | × | √ | √ | × | × | ||

| ±North America | √ | × | × | × | × | √ | ||

| Enviro. Comp. aa | Air | √, detailed | √, detailed | √, general | √, general | √, general | √, detailed | |

| Water | √, detailed | √, detailed | √, general | √, general | √, detailed | √, detailed | ||

| Soil | √, detailed | √, detailed | √, detailed | √, general | √, detailed | √, detailed | ||

| Exposure pathway | Inhalation | √, general | √, general | √, general | √, general | √, general | √, general | |

| Ingestion | √, detailed | √, detailed | √, general | √, detailed | √, detailed | √, detailed | ||

| Dermal exposure | × | × | √, general | √, general | × | × | ||

| Databases | USEtox 2 | √ | √ | × | × | √ | √ | |

| USES-LCA 2.0 | × | √ | × | × | √ | × | ||

| CalTox | × | × | × | × | × | √ | ||

| IMPACT 2002 | × | × | √ | × | × | × | ||

| Eco-indicator 99 | × | × | √ | × | × | × | ||

| EDIP 97 | × | × | × | √ | × | × | ||

| Secondary data from literature or other data bases | √ | √ | √ | √ | √ | √ | ||

| Supply Chain | Conversion Pathway | Product Fraction | Allocation Method | ||

|---|---|---|---|---|---|

| Mass | Energy | Economic | |||

| SC-ATJ a | Juice-ATJ | Jet fuel | 0.81 | 0.80 | 0.89 |

| Diesel | 0.11 | 0.12 | 0.08 | ||

| Naphtha | 0.03 | 0.03 | 0.02 | ||

| Propane | 0.05 | 0.05 | 0.01 | ||

| Bagasse-FP | Jet fuel | 0.42 | 0.42 | 0.54 | |

| Diesel | 0.33 | 0.32 | 0.28 | ||

| Naphtha | 0.19 | 0.20 | 0.16 | ||

| Propane | 0.06 | 0.06 | 0.02 | ||

| EC-FP | Jet fuel | 0.41 | 0.40 | 0.52 | |

| Diesel | 0.37 | 0.37 | 0.30 | ||

| Naphtha | 0.22 | 0.23 | 0.18 | ||

| MC-HEFA b | Oil-HEFA | Jet fuel | 0.55 | 0.54 | 0.69 |

| Diesel | 0.26 | 0.26 | 0.21 | ||

| Naphtha | 0.08 | 0.08 | 0.07 | ||

| Propane | 0.11 | 0.12 | 0.03 | ||

| Woody biomass-FP | Jet fuel | 0.41 | 0.42 | 0.52 | |

| Diesel | 0.37 | 0.37 | 0.30 | ||

| Naphtha | 0.22 | 0.21 | 0.18 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Osseweijer, P.; Posada, J.A. Human Health Impacts of Aviation Biofuel Production: Exploring the Application of Different Life Cycle Impact Assessment (LCIA) Methods for Biofuel Supply Chains. Processes 2020, 8, 158. https://doi.org/10.3390/pr8020158

Wang Z, Osseweijer P, Posada JA. Human Health Impacts of Aviation Biofuel Production: Exploring the Application of Different Life Cycle Impact Assessment (LCIA) Methods for Biofuel Supply Chains. Processes. 2020; 8(2):158. https://doi.org/10.3390/pr8020158

Chicago/Turabian StyleWang, Zhizhen, Patricia Osseweijer, and John A. Posada. 2020. "Human Health Impacts of Aviation Biofuel Production: Exploring the Application of Different Life Cycle Impact Assessment (LCIA) Methods for Biofuel Supply Chains" Processes 8, no. 2: 158. https://doi.org/10.3390/pr8020158

APA StyleWang, Z., Osseweijer, P., & Posada, J. A. (2020). Human Health Impacts of Aviation Biofuel Production: Exploring the Application of Different Life Cycle Impact Assessment (LCIA) Methods for Biofuel Supply Chains. Processes, 8(2), 158. https://doi.org/10.3390/pr8020158