Comparison of Compressed Air Energy Storage, Compressed Carbon Dioxide Energy Storage, and Carnot Battery: Principles, Thermal Integration, and Engineering Demonstrations

Abstract

1. Introduction

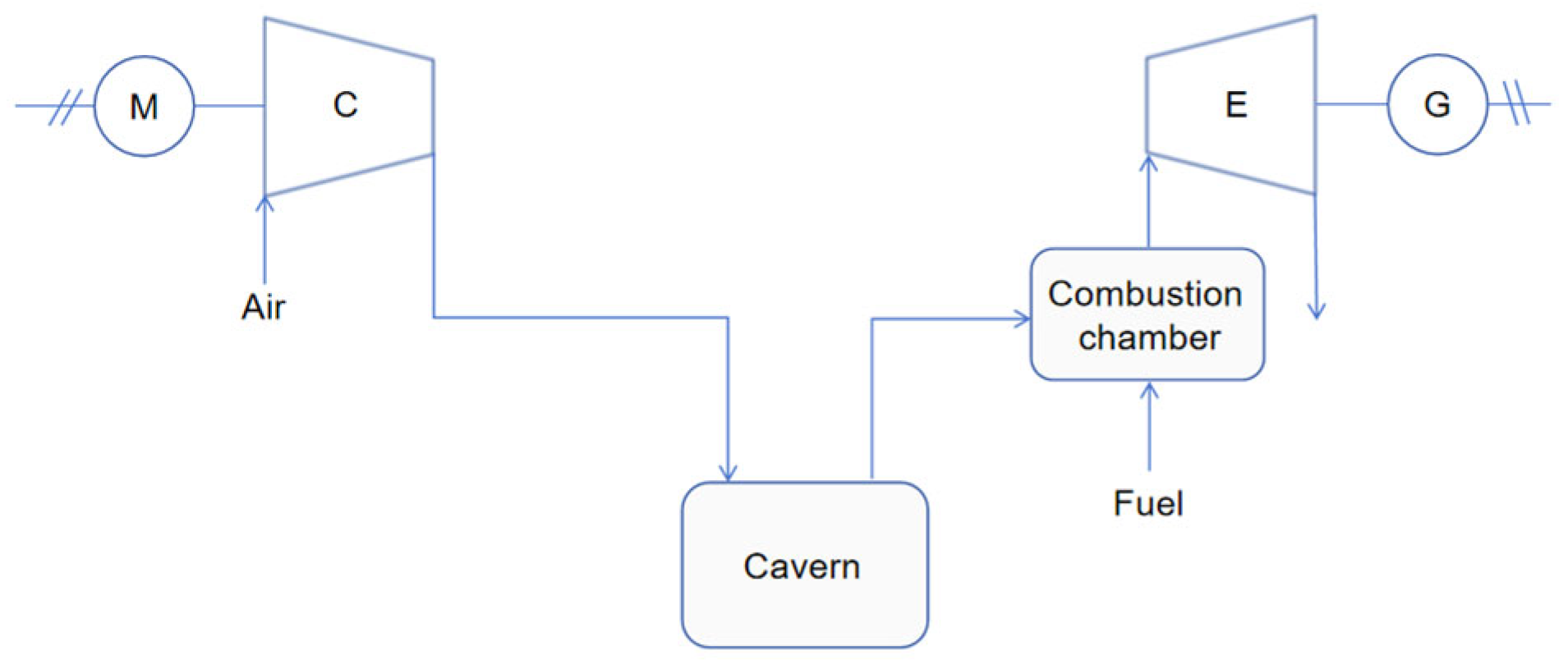

2. Compressed Air Energy Storage (CAES)

2.1. Principles

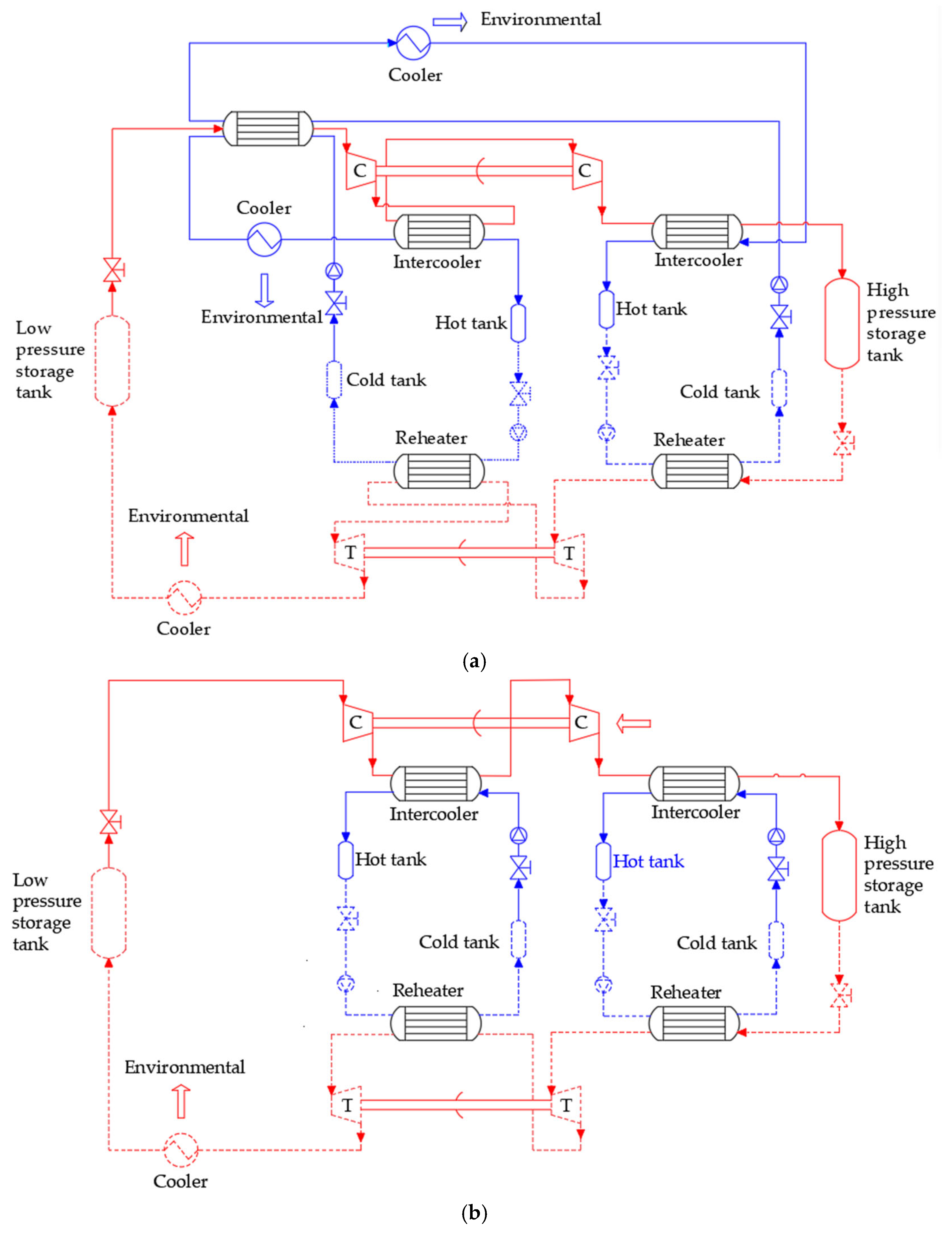

2.2. Thermal Integration

2.3. Demonstrations

- (1)

- Thermal management optimization, including optimizing heat exchanger designs, adopting shared heat exchangers, refining compression heat recovery mechanisms (e.g., multistage molten salt thermal storage optimization and advanced mid-temperature waste heat regeneration), and integrating phase change materials (PCMs) such as Al-Si alloys (melting point: 580 °C) and composite salts, as well as thermochemical storage technologies like MgO/Mg(OH)2.

- (2)

- Critical component innovation, encompassing high-temperature turbomachinery (compressors/expanders) operational under >600 °C conditions via ceramic matrix composites and adaptive sealing architectures, cost-effective metal-clad composite storage vessels as geological reservoir alternatives, advanced liquid piston systems incorporating spray cooling and modified porous media for near-isothermal compression, pressure-flexible containment solutions enabling stable S-CAES operation, advanced cryogenic liquefaction, and cold storage systems for cost-effective LAES applications.

- (3)

- Distributed energy system integration for commercial/industrial behind-the-meter applications via modular CAES platforms (<100 kWe capacity) employing reciprocating/screw compressors, integration with industrial air compression infrastructure.

- (4)

- Deeper grid-scale renewable energy hybridization through seasonal storage solutions combining salt cavern reservoirs with cascaded thermal storage.

- (5)

- Hybrid system energy demonstrations, such as establishing “heat–electricity–gas–cooling–hydrogen–carbon” hybrid energy networks and industrial waste heat/cold utilization (e.g., preheating expander intake air using steel plant waste heat), coupling LNG cold energy with LAES systems.

- (6)

- Digital twin and AI-enabled operational optimization for real-time thermal dispatch strategies and electricity ancillary service.

3. Compressed CO2 Energy Storage (CCES)

3.1. Principles

3.2. Thermal Integration

3.3. Demonstrations

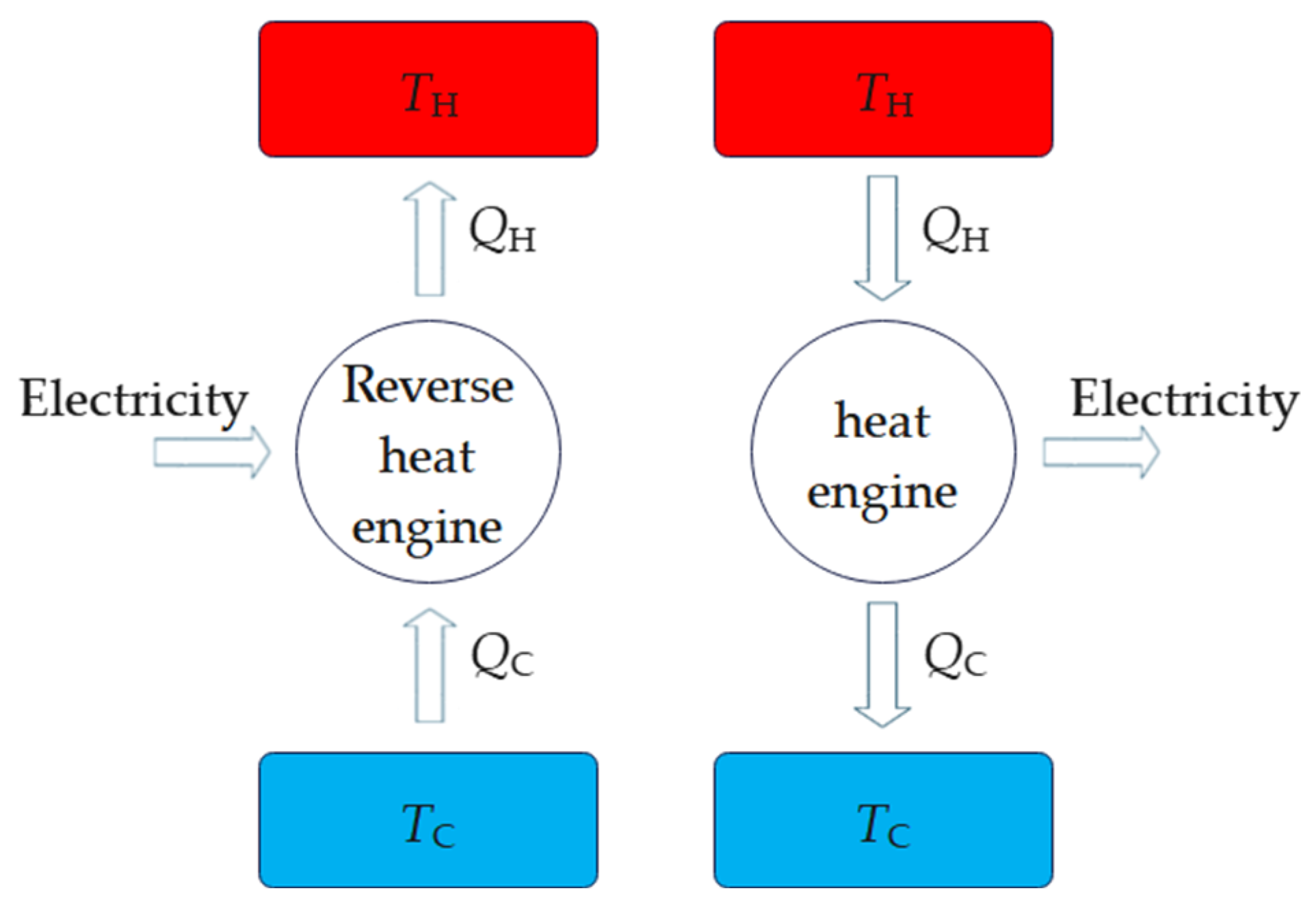

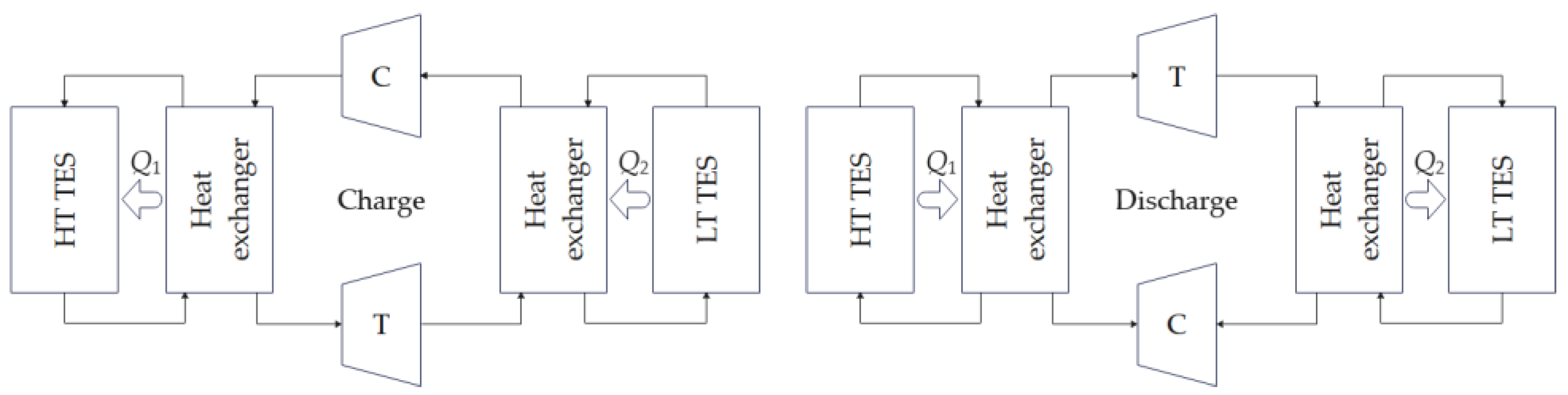

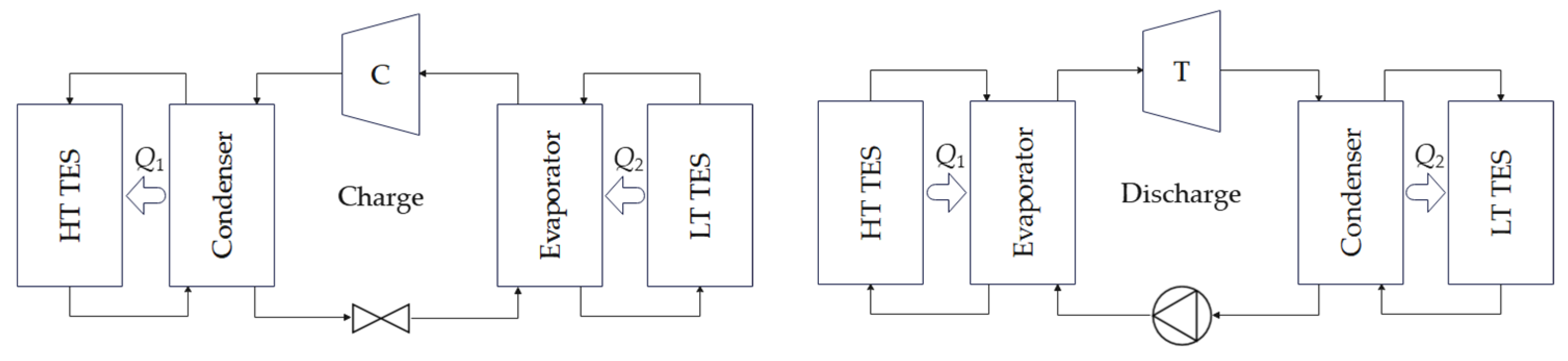

4. Carnot Battery

4.1. Principles

4.1.1. Electrically Heated Systems

4.1.2. Brayton Cycle Systems

4.1.3. Rankine Cycle Systems

4.2. Thermal Integration

4.3. Demonstrations

- (1)

- System Configuration Limitations:

- (2)

- Low TRL and System Complexity:

- (3)

- Component Sensitivity:

- (4)

- Equipment Limitations:

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- van de Ven, D.J.; Mittal, S.; Nikas, A.; Xexakis, G.; Gambhir, A.; Hermwille, L.; Fragkos, P.; Obergassel, W.; Gonzalez-Eguino, M.; Filippidou, F.; et al. Energy and socioeconomic system transformation through a decade of IPCC-assessed scenarios. Nat. Clim. Change 2025, 15, 218–226. [Google Scholar] [CrossRef]

- Aridi, R.; Aridi, M.; Pannier, M.L.; Lemenand, T. Eco-environmental, and social impacts of producing electricity with various renewable energy sources. Energy 2025, 320, 135139. [Google Scholar] [CrossRef]

- Depledge, J.; Saldivia, M.; Peñasco, C. Glass half full or glass half empty?: The 2021 Glasgow Climate Conference. Clim. Policy 2022, 22, 147–157. [Google Scholar] [CrossRef]

- Li, H.; Ding, R.; Su, W.; Lin, X.; Guan, S.; Ye, Q.; Zheng, Z.; Wang, J. A comprehensive performance comparison between compressed air energy storage and compressed carbon dioxide energy storage. Energy Convers. Manag. 2024, 319, 118972. [Google Scholar] [CrossRef]

- Dewevre, F.; Lacroix, C.; Loubar, K.; Poncet, S. Carbon dioxide energy storage systems: Current researches and perspectives. Renew. Energy 2024, 224, 120030. [Google Scholar] [CrossRef]

- Vecchi, A.; Knobloch, K.; Liang, T.; Kildahl, H.; Sciacovelli, A.; Engelbrecht, K.; Li, Y.; Ding, Y. Carnot Battery development: A review on system performance, applications and commercial state-of-the-art. J. Energy Storage 2022, 55, 105782. [Google Scholar] [CrossRef]

- Zhang, X.; Gao, Z.; Zhou, B.; Guo, H.; Xu, Y.; Ding, Y.; Chen, H. Advanced compressed air energy storage systems: Fundamentals and applications. Engineering 2024, 34, 246–269. [Google Scholar] [CrossRef]

- Qiong, Z.; Liang, W.; Yujie, X.; Chen, H. Research progress in pumped heat electricity storage system: A review. Proc. CSEE 2018, 38, 178–185. [Google Scholar]

- Feng, H.; Sheng, J.; Zhang, H. Research progress on the thermal energy storage and utilization of compressed air energy storage system. J. Eng. Therm. Energy Power 2024, 39, 10–19. [Google Scholar]

- Guan, S.; Zhong, S.; Li, H.; Ding, R.; Su, W.; Lin, X.; Tang, Z.; Du, J. Research status and development trend of compressed CO2 energy storage technology. Energy Storage Sci. Technol. 2025, 14, 240–254. [Google Scholar]

- Liang, Y.; Li, P.; Xing, L.; Su, W.; Li, W.; Xu, W. Current status of thermodynamic electricity storage: Principle, structure, storage device and demonstration. J. Energy Storage 2024, 80, 110347. [Google Scholar] [CrossRef]

- Sun, J.; Tao, J.; Hu, Y.; Cao, X.; Yang, Y. Summary of research on power storage technology based on heat pump at home and abroad. Energy Storage Sci. Technol. 2024, 13, 1963–1976. [Google Scholar]

- Hao, J.; Yue, Y.; Zhang, J.; Yang, J.; Li, X.; Song, Y.; Zhang, Z. Research status and development prospect of carbon dioxide energy-storage technology. Energy Storage Sci. Technol. 2022, 11, 3285. [Google Scholar]

- Ma, H.; Tong, Y.; Wang, X.; Wang, H. Advancements and assessment of compressed carbon dioxide energy storage technologies: A comprehensive review. RSC Sustain. 2024, 2, 2731–2750. [Google Scholar] [CrossRef]

- Jankowski, M.; Pałac, A.; Sornek, K.; Goryl, W.; Homa, M.; Filipowicz, M. Status and development perspectives of the compressed air energy storage (CAES) technologies—A literature review. Energies 2024, 17, 2064. [Google Scholar] [CrossRef]

- Bazdar, E.; Sameti, M.; Nasiri, F.; Haghighat, F. Compressed air energy storage in integrated energy systems: A review. Renew. Sustain. Energy Rev. 2022, 167, 112701. [Google Scholar] [CrossRef]

- Wan, M.; Wang, Y.; Li, J.; Lu, Y.; Zhao, T.; Wu, Y. Research progress and prospect of compressed air energy storage technology. IIE 2023, 45, 26–31. [Google Scholar]

- Burian, O.; Dančová, P. Compressed air energy storage (CAES) and liquid air energy storage (LAES) technologies—A comparison review of technology possibilities. Processes 2023, 11, 3061. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Zhang, Z.; Hao, J.; Zheng, P.; Yu, Z.; Yang, J.; Jing, Y.; Yue, Y. Research progress of compressed carbon dioxide energy storage system. Energy Storage Sci. Technol. 2023, 12, 1928–1945. [Google Scholar]

- Dumont, O.; Frate, G.F.; Pillai, A.; Lecompte, S.; De Paepe, M.; Lemort, V. Carnot battery technology: A state-of-the-art review. J. Energy Storage 2020, 32, 101756. [Google Scholar] [CrossRef]

- Frate, G.F.; Ferrari, L.; Desideri, U. Rankine Carnot batteries with the integration of thermal energy sources: A review. Energies 2020, 13, 4766. [Google Scholar] [CrossRef]

- Sharma, S.; Mortazavi, M. Pumped thermal energy storage: A review. Int. J. Heat Mass Transf. 2023, 213, 124286. [Google Scholar] [CrossRef]

- Rabi, A.M.; Radulovic, J.; Buick, J.M. Pumped Thermal Energy Storage Technology (PTES): Review 2023. Thermo 2023, 3, 396–411. [Google Scholar] [CrossRef]

- Novotny, V.; Basta, V.; Smola, P.; Spale, J. Review of carnot battery technology commercial development. Energies 2022, 15, 647. [Google Scholar] [CrossRef]

- Hao, F.; Mu, A.; Lv, Z.; Zhou, H. A comprehensive review of liquid piston compressed air energy storage for sustainable renewable energy integration. J. Energy Storage 2024, 98, 113071. [Google Scholar] [CrossRef]

- Liang, T.; Zhang, T.; Lin, X.; Alessio, T.; Legrand, M.; He, X.; Kildahl, H.; Lu, C.; Chen, H.; Romagnoli, A.; et al. Liquid air energy storage technology: A comprehensive review of research, development and deployment. Prog. Energy 2023, 5, 012002. [Google Scholar] [CrossRef]

- Qi, J.; Liu, Z.; Zhao, Y.; Yin, H.; Zhu, F. Optimizing compressed air energy storage with organic Rankine cycle and ejector refrigeration for sustainable power and cooling provision. Energy 2024, 308, 132949. [Google Scholar] [CrossRef]

- Bushehri, M.; Zolfaghari, S.; Soltani, M.; Nabat, M.; Nathwani, J. A comprehensive study of a green hybrid multi-generation compressed air energy storage (CAES) system for sustainable cities: Energy, exergy, economic, exergoeconomic, and advanced exergy analysis. Sustain. Cities Soc. 2024, 101, 105078. [Google Scholar] [CrossRef]

- Nabat, M.; Yu, H.; Arabkoohsar, A. A comprehensive and comparative study of an innovative constant-pressure compressed air energy storage (CP-CAES) system. Sustain. Cities Soc. 2024, 102, 105163. [Google Scholar] [CrossRef]

- Fu, W.; Sun, W.; Huo, X. Design and thermodynamic investigation of a waste heat-assisted compressed air energy storage system integrating thermal energy storage and organic Rankine cycle. Energy Technol. 2024, 12, 2300838. [Google Scholar] [CrossRef]

- Lu, Y.; Xu, J.; Chen, X.; Tian, Y.; Zhang, H. Design and thermodynamic analysis of an advanced liquid air energy storage system coupled with LNG cold energy, ORCs and natural resources. Energy 2023, 275, 127538. [Google Scholar] [CrossRef]

- Esmaeilion, F.; Soltani, M. Technical and economic assessments of a novel multigeneration system based on desalination and liquid air energy storage. Desalination 2024, 580, 117497. [Google Scholar] [CrossRef]

- Xue, X.; Li, S.; Shi, T.; Xu, G.; Zheng, L.; Chang, S. Performance analysis of a compressed air energy storage incorporated with a biomass power generation system. Appl. Therm. Eng. 2024, 248, 123281. [Google Scholar] [CrossRef]

- Qin, H.; Chen, W.; Zhang, T.; Ma, L.; Xue, X.; Zhang, X. Thermal analysis and parameter optimization of advanced adiabatic compressed air energy storage with parabolic trough solar collector auxiliary reheating. J. Energy Storage 2025, 110, 115104. [Google Scholar] [CrossRef]

- Zheng, Z.; Chen, G.; Xie, N.; Cui, S.; Zhong, S.; Mei, S.; Zhong, G. Thermodynamic performance analysis of a coupled system of solar energy and AA-CAES. J. Phys. Conf. Ser. 2024, 2823, 012007. [Google Scholar] [CrossRef]

- Zhang, K.; Cao, Z.; Deng, J. Design and performance optimization of a novel CAES system integrated with coaxial casing geothermal utilization. Appl. Therm. Eng. 2024, 256, 124111. [Google Scholar] [CrossRef]

- Zhang, Q.; Taleghani, A.; Elsworth, D. Underground energy storage using abandoned oil & gas wells assisted by geothermal. J Energy Storage 2025, 110, 115317. [Google Scholar]

- Barogh, A.; Moghimi, M. Deep neural network optimization of a continuous solar-geothermal-driven plant with integrated thermal and mechanical energy storage: Incorporating bypass mechanism. Energy 2024, 303, 131885. [Google Scholar] [CrossRef]

- Mei, S.; Zhang, T.; Zhang, X.; Wang, Y.; Wang, G.; Lu, Q.; Xue, X. Research and engineering practice of non-supplementary combustion compressed air energy storage: Taking Jintan national demonstration project as an example. Exp. Technol. Manag. 2022, 39, 1–8. [Google Scholar]

- SD Xinhua Net. Available online: http://www.sd.xinhuanet.com/20250314/79db9a1687a54db094260b05255e64d9/c.html (accessed on 14 March 2025).

- CSPPLAZA. Available online: https://www.cspplaza.com/article-27008-1.html (accessed on 19 August 2025).

- ESPLAZA. Available online: https://esplaza.com.cn/article-9404-1.html (accessed on 19 August 2025).

- Wulanchabu Science and Technology Bureau. Available online: https://kjj.wulanchabu.gov.cn/snkjdt/1558657.html (accessed on 19 August 2025).

- Baijiahao. Available online: https://baijiahao.baidu.com/s?id=1677772843099437357&wfr=spider&for=pc (accessed on 19 August 2025).

- iQilu News. Available online: https://sdxw.iqilu.com/share/YS0yMS0xNTYzNzE4NQ==.html (accessed on 19 August 2025).

- Jiangsu State-owned Assets Supervision and Administration Commission. Available online: https://jsgzw.jiangsu.gov.cn/art/2024/4/29/art_61944_11231248.html (accessed on 29 April 2024).

- China Industrial Energy Conservation and Clean Production Association. Available online: http://www.cies.net.cn/news/show-212.html (accessed on 19 August 2025).

- ESPLAZA. Available online: https://www.esplaza.com.cn/article-1980-1.html (accessed on 19 August 2025).

- Li, H.; Liu, C.; He, Q. Research progress of carbon dioxide compressor in energy storage system. Therm. Power Gener. 2023, 52(12), 1–10. [Google Scholar]

- Zhang, X.; Wang, G. Thermodynamic analysis of a novel energy storage system based on compressed CO2 fluid. Int. J. Energy Res. 2017, 41, 1487–1503. [Google Scholar] [CrossRef]

- Wang, M.; Zhao, P.; Wu, Y.; Dai, Y. Performance analysis of a novel energy storage system based on liquid carbon dioxide. Appl. Therm. Eng. 2015, 91, 812–823. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, Z.; Chen, J.; Sun, M. Optimization of low-carbon operation in a combined electrical, thermal, and cooling integrated energy system with liquid carbon dioxide energy storage and green certificate and carbon trading mechanisms. Processes 2025, 13, 372. [Google Scholar] [CrossRef]

- Yin, L.; Ju, Y.; Lin, Q. An integrated solution of energy storage and CO2 reduction: Trans-critical CO2 energy storage system combining carbon capture with LNG cold energy. J. Clean. Prod. 2024, 482, 144228. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, J.; Xu, H.; Yao, Z.; Tian, Y. Thermodynamic performances of a novel multi-mode solar-thermal-assisted liquid carbon dioxide energy storage system. J. Energy Storage 2024, 97, 112843. [Google Scholar] [CrossRef]

- Fu, Y.; Cai, L.; Qi, C.; Zhai, J. Thermodynamic and economic analyses of the biomass gasification Allam cycle integrated with compressed carbon energy storage. Energy 2024, 303, 131984. [Google Scholar] [CrossRef]

- Tang, J.; Li, Q.; Werle, S.; Wang, S.; Yu, H. Development and comprehensive thermo-economic analysis of a novel compressed CO2 energy storage system integrated with high-temperature thermal energy storage. Energy 2024, 303, 131941. [Google Scholar] [CrossRef]

- Zhang, N.; Chen, J.; Liu, B.; Ji, X. Optimized scheduling of integrated energy systems with integrated demand response and liquid carbon dioxide storage. Processes 2024, 12, 292. [Google Scholar] [CrossRef]

- Liu, Z.; Guan, H.; Shao, J.; Jin, X.; Su, W.; Zhang, H.; Li, H.; Sun, D.; Wei, T. Thermodynamic and advanced exergy analysis of a trans-critical CO2 energy storage system integrated with heat supply and solar energy. Energy 2024, 302, 131507. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, H.; Zhao, H.; Sun, Q.; Zhang, C.; Xin, G. Thermodynamic analysis of ternary coupled system based on combined heating and power unit, steam ejector and compressed carbon dioxide energy storage. J. Energy Storage 2024, 104, 114748. [Google Scholar] [CrossRef]

- Hao, J.; Zheng, P.; Li, Y.; Zhang, Z.; Zhang, J.; Yang, J.; Yue, Y.; Li, X. Study on the operational feasibility domain of combined heat and power generation system based on compressed carbon dioxide energy storage. Energy 2024, 291, 130122. [Google Scholar] [CrossRef]

- Wang, R.; Song, P.; Wei, M.; Tian, R.; Sun, X.; Zhuge, W.; Zhang, Y. Performance evaluation of liquid CO2 battery for SOFC energy system load management. Appl. Energy 2025, 377, 124453. [Google Scholar] [CrossRef]

- Zhang, Y.; Liang, T.; Yang, K. An integrated energy storage system consisting of compressed carbon dioxide energy storage and organic Rankine cycle: Exergoeconomic evaluation and multi-objective optimization. Energy 2022, 247, 123566. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, X.; Xu, J.; Lu, Y. Thermodynamic and economic performance analysis of a liquid carbon dioxide energy storage system coupled with absorption refrigeration cycle. Energy 2025, 319, 135054. [Google Scholar] [CrossRef]

- Gao, C. Performance investigation of solar-assisted supercritical liquid carbon dioxide energy storage systems. J. Energy Storage 2025, 108, 115096. [Google Scholar] [CrossRef]

- Li, Y.; Cui, J.; Yu, H.; Tang, D.; Zhang, G.; Liu, Y. The impacts of geothermal gradients on compressed carbon dioxide energy storage in aquifers. Renew. Energy 2024, 231, 120954. [Google Scholar] [CrossRef]

- Qiao, L.; Pu, W.; Wu, B.; Liu, R.; Song, N. Performance study of a supercritical carbon dioxide energy storage system with non-uniform graded compression heat recovery. Energy 2024, 313, 133876. [Google Scholar] [CrossRef]

- Li, F.; Li, P.; Ding, R.; Su, W.; Ou, S.; Xing, L.; Lin, X. Thermo-economic analysis on trans-critical compressed CO2 energy storage system integrated with the waste heat of liquid-cooled data center. J. Energy Storage 2024, 103, 114292. [Google Scholar] [CrossRef]

- ESPLAZA. Party Building Leads Energy Storage to New Ventures, Joint Efforts Create Future—“Chain Party Building” Joint Activity & Roof-Sealing Ceremony of Huadian-Dongfang Electric Mulei Compressed CO2 Energy Storage Project. Available online: https://esplaza.com.cn/article-10301-1.html (accessed on 21 August 2025).

- Baijiahao. Available online: https://baijiahao.baidu.com/s?id=1783616150823212182 (accessed on 15 August 2025).

- China Electronics Standardization Institute. Available online: https://www.esplaza.com.cn/article-4206-1.html (accessed on 22 July 2025).

- China Government Procurement Network. Available online: http://www.ccgp.gov.cn/cggg/zygg/gkzb/202504/t20250409_24417880.htm (accessed on 3 June 2025).

- People’s Daily Online. Available online: http://jl.people.com.cn/n2/2025/0324/c349771-41173814.html (accessed on 18 May 2025).

- Feng, G.; Li, Y.; Cheng, X.; Hou, B.; Qu, D.; Xu, R.; Zhang, L. Key technologies and current applications of high-temperature Carnot batteries. Therm. Power Gener. 2024, 53, 1–9. [Google Scholar]

- Kim, Y.; Shin, D.; Lee, S.; Favrat, D. Isothermal transcritical CO2 cycles with TES (thermal energy storage) for electricity storage. Energy 2013, 49, 484–501. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, Y.; Zhao, W.; Li, C.; Xu, C.; Sun, H.; Yang, Q.; Tian, X.; Wang, D. The Carnot batteries thermally assisted by the steam extracted from thermal power plants: A thermodynamic analysis and performance evaluation. Energy Convers. Manag. 2023, 297, 117724. [Google Scholar] [CrossRef]

- Miao, Z.; Zhang, M.; Yan, P.; Xiao, M.; Xu, J. Thermodynamic analysis of a low-temperature Carnot battery promoted by the LNG cold energy. J. Energy Storage 2024, 88, 111619. [Google Scholar] [CrossRef]

- Su, Z.; Yang, L.; Song, J.; Jin, X.; Wu, X.; Li, X. Multi-dimensional comparison and multi-objective optimization of geothermal-assisted Carnot battery for photovoltaic load shifting. Energy Convers. Manag. 2023, 289, 117156. [Google Scholar] [CrossRef]

- Niu, J.; Wang, J.; Liu, X.; Dong, L. Optimal integration of solar collectors to Carnot battery system with regenerators. Energy Convers. Manag. 2023, 277, 116625. [Google Scholar] [CrossRef]

- Yin, S.; Bai, C.; Zheng, K.; Zhang, Y.; Yan, X.; Liu, Z. Geothermal energy-assisted pumped thermal energy storage, Configuration mapping. Energy Convers. Manag. 2025, 329, 119660. [Google Scholar] [CrossRef]

- Liang, Z.; Zheng, G.; Wu, G.; Pan, Z.; Hu, Z.; Xu, M.; Chen, H. Thermodynamic performance of organic rankine cycle based pumped thermal energy storage system with different working fluids. Heliyon 2025, 11, e41052. [Google Scholar] [CrossRef]

- Alnaqi, A.; Alsarraf, J.; Al-Rashed, A. Thermodynamic and economic evaluation with multi-objective optimization of a novel thermally integrated pumped thermal energy storage system. Therm. Sci. Eng. Prog. 2025, 58, 103211. [Google Scholar] [CrossRef]

- Li, Y.; Hu, P.; Ni, H. Thermal-economic analysis and optimization of a novel segmented energy storage Carnot battery. Appl. Therm. Eng. 2025, 125713. [Google Scholar] [CrossRef]

- Wu, D.; Ma, B.; Zhang, J.; Chen, Y.; Shen, F.; Chen, X.; Wen, C.; Yang, Y. Working fluid pair selection of thermally integrated pumped thermal electricity storage system for waste heat recovery and energy storage. Appl. Energy 2024, 371, 123693. [Google Scholar] [CrossRef]

- Wang, P.; Li, Q.; Wang, S.; He, C.; Wu, C. Off-design performance evaluation of thermally integrated pumped thermal electricity storage systems with solar energy. Energy Convers. Manag. 2024, 301, 118001. [Google Scholar] [CrossRef]

- Migliari, L.; Petrollese, M.; Cau, G.; Cocco, D. Techno-economic assessment and grid impact of Thermally-Integrated Pumped Thermal Energy Storage (TI-PTES) systems coupled with photovoltaic plants for small-scale applications. J. Energy Storage 2024, 77, 109898. [Google Scholar] [CrossRef]

- Sun, X.; Shi, L.; Zhang, M.; Tian, H.; Hu, P.; Pei, G.; Shu, G. Efficient and flexible thermal-integrated pumped thermal energy storage through composition adjustment. Carbon Neutral. 2024, 3, 11. [Google Scholar] [CrossRef]

- Subires, A.; Rovira, A.; Muñoz, M. Proposal and study of pumped thermal energy storage to improve economic results of concentrated solar power with hybrid Rankine–Brayton propane cycle. Energies 2024, 17, 2005. [Google Scholar] [CrossRef]

- Miao, L.; Liu, M.; Zhang, K.; Yan, J. Design and performance evaluation of thermal energy storage system with hybrid heat sources integrated within a coal-fired power plant. J. Energy Storage 2024, 82, 110611. [Google Scholar] [CrossRef]

- Poletto, C.; Dumont, O.; De Pascale, A.; Lemort, V.; Ottaviano, S.; Thomé, O. Control strategy and performance of a small-size thermally integrated Carnot battery based on a Rankine cycle and combined with district heating. Energy Convers. Manag. 2024, 302, 118111. [Google Scholar] [CrossRef]

- Poletto, C.; De Pascale, A.; Ottaviano, S.; Dumont, O.; Branchini, L. Techno-economic assessment of a Carnot battery thermally integrated with a data center. Appl. Therm. Eng. 2025, 260, 124952. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, M.; Li, J.; Yan, L.; Zhang, J.; Wang, Z.; Tian, H. Feasibility analysis of a Carnot battery energy storage system for waste heat recovery of liquid cooling units in data centers. Energy Storage Sci. Technol. 2024, 13, 3921. [Google Scholar]

- Lin, X.; Sun, P.; Zhong, W.; Wang, J. Thermodynamic analysis and operation investigation of a cross-border integrated energy system based on steam Carnot battery. Appl. Therm. Eng. 2023, 220, 119804. [Google Scholar] [CrossRef]

- Morandin, M.; Mercangöz, M.; Hemrle, J.; Maréchal, F.; Favrat, D. Thermoeconomic design optimization of a thermo-electric energy storage system based on transcritical CO2 cycles. Energy 2013, 58, 571–587. [Google Scholar] [CrossRef]

- F6S Profile, Echogen Storage Systems | Distributed Systems. Available online: https://www.f6s.com/company/echogenstoragesystems (accessed on 22 August 2025).

- Peregrine Turbine Technologies, Technology. Available online: https://www.peregrineturbine.com/technology (accessed on 22 August 2025).

- Karthauser, J. Low-Temperature (80–120 °C) Carnot Battery and Its Potential for the Integrated Energy System, 2nd ed.; DLR: Stuttgart, Germany, 2020. [Google Scholar]

- Novotny, V.; Mach, S.; Rathan, M.; Basta, V.; Spale, J. Modelling and experimental development of a waste heat upgrade integrated ORC Carnot battery with stone dust thermal storage. In Proceedings of the 6th International Seminar on ORC Power Systems, Munich, Germany, 11–13 October 2021; pp. 11–13. [Google Scholar]

- The Engineer. Available online: https://www.theengineer.co.uk/content/news/newcastle-university-connects-first-grid-scale-pumped-heat-energy-storage-system (accessed on 19 July 2025).

- Yunnan Provincial Government. Available online: https://www.yn.gov.cn/ztgg/zdly/zdjsxm/sgxx/202401/t20240101_292802.html (accessed on 19 July 2025).

- Sohu, I.T. Available online: https://it.sohu.com/a/839103948_120093798 (accessed on 10 August 2025).

- China Reports Network. Available online: http://msgc.chinareports.org.cn/index.php/msgc/news/10493.html (accessed on 5 June 2025).

- China Three Gorges Corporation. Available online: https://eps.ctg.com.cn/cms/channel/1ywgg1/240614678.htm (accessed on 28 May 2025).

- WeChat Official Account [Industry Analysis]. Available online: https://mp.weixin.qq.com/s?__biz=MzA3NzE2Mzc4NA==&mid=2650356994&idx=1&sn=d10634ae799add2b8bdbb2652f6ba7b2 (accessed on 15 August 2025).

- Sohu News. Available online: https://news.sohu.com/a/827535494_120253635 (accessed on 3 July 2025).

- China Energy Engineering Corporation. Available online: http://www.ece.tech.ceec.net.cn/art/2025/3/28/art_26827_2515367.html (accessed on 20 June 2025).

- University of Science and Technology of China. Available online: https://icn.ustc.edu.cn/2022/1031/c32651a579265/page.htm (accessed on 10 May 2025).

| Integration Modes | RTE (%) | ERTE (%) | Payback Period (Year) | Ref. |

|---|---|---|---|---|

| CAES, organic Rankine cycle and ejector refrigeration (ORCERC) | 58.63 | 65.85 | 2.88 | [27] |

| CAES, HTES, ORC, reverse osmosis (RO) | 73.54 | 55.01 | 3.3 | [28] |

| CAES, HTES, PHES, multi-effect desalination (MED) | 62.18 | 57.84 | 3.82 | [29] |

| Waste heat (WH), CAES, ORC, tube-in-tube thermal energy storage unit | / | / | / | [30] |

| LNG, LAES | 240.7 | / | / | [31] |

| LAES, RO, MED | 65.8 | 59.6 | / | [32] |

| CAES, biomass gasification power generation system | 84.9 | 80.46 | 4.2 | [33] |

| CAES, parabolic trough solar collector (PTSC) | / | / | / | [34] |

| CAES, solar collector | 78.22 | / | / | [35] |

| CAES, geothermal energy | 64.26 | / | 12.17 | [36] |

| CAES, geothermal energy | increased by ~9.5 | / | / | [37] |

| CAES, solar collector, geothermal energy, MED, PEM electrolyzer, single-effect absorption chiller (SEAC) generator | 46 | / | / | [38] |

| Project | Type | State | Technical Sources | Power Output/Capacity or Duration | Storage Device | TES | RTE (%) | Ref. |

|---|---|---|---|---|---|---|---|---|

| Kraftwerk Huntorf Plant | DCAES | Operation | Alstom | 290 MW/580 MWh | Salt cavern | / | 41.7 | [11,17] |

| Angas advanced CAES Project | AACAES | Under construction | Hydrostor | 5 MW/10 MWh | Underground zinc mine | Pressurized water | / | [11] |

| Goderich advanced CAES Facility | IA-CAES | 1.75 MW/7 MWh | Underwater air bag | / | [11] | |||

| UCAES Aruba Project | 1 MW | / | [11] | |||||

| Highview Pilot Plant | LAES | Operation | Highview Power Storage | 350 kW/2450 kWh | Cryogenic vessel | Packed bed regenerator (Quartzite filling) | 8 | [11,15] |

| Pilsworth Grid Scale Demo Plant | 5 MW/15 MWh | / | / | [11,15] | ||||

| TICC-500 | AACAES | Operation | Tsinghua University | 500 kW/500 kWh | Steel tank | Pressurized water (120 °C) | 33 | [17] |

| Wulanchabu Multi-source TES CAES (10 MW) Energy Hub Project | Under construction | 10 MW/40–60 MWh | Salt cavern | Phase change material (PCM) and sensible heat | 65 | [42,43] | ||

| Jintan National Advanced CAES Pilot Project | Operation | 60 MW/300 MWh | High-temperature synthetic thermal oil (360 °C) | 61.2 | [17,39] | |||

| Datong Yungang Mine Tunnel-based CAES Plant | Under construction | 60 MW/240 MWh | Coal mine roadway | Cascaded molten salt-water | 60 | [44] | ||

| Huaineng Jiangsu Jintan 2 × 350 MW CAES Project | Tsinghua University/Xi’an Thermal Power Research Institute Co., Ltd. (TPRI) | 2 × 350 MW/2 × 1400 MWh | Salt cavern | Pressurized water | >70 | [42] | ||

| 1.5 MW SCAES Demo Project | SCAES | Construction completion | Institute of Engineering Thermophysics | 1.5 MW | / | / | 52.1 | [17] |

| Zhangjiakou 100 MW Advanced CAES Demo Project | 100 MW/400 MWh | Artificial underground gas Storage | Supercritical thermal energy storage | 70.4 | [17] | |||

| Feicheng 660 MW Advanced CAES Demo Project | Under construction | 660 MW/2640 MWh | Salt cavern | 75 | [40] | |||

| Feicheng Salt Cavern Advanced CAES Peak-shaving Plant (Phase II) | Operation | 300 MW/1800 MWh | High efficiency compact regenerative heat exchanger | 72.1 | [45] | |||

| Jiangsu Guoxin Suyan (Huai’an) CAES Project | Under construction | 2 × 300 MW/2 × 1200 MWh | A wide-temperature thermal storage system with medium-to-high-temperature coupling (180–360 °C) utilizing ternary salt (NaNO3/KNO3/NaNO2) and pressurized water as heat storage media | >71 | [46] | |||

| PowerChina (Feicheng) 2 × 300 MW Salt Cavern CAES Plant | AACAES | Under construction | Hebei Electric Power Design & Research Institute Co., Ltd. | 2 × 300 MW/1800 MWh | Salt cavern | High-temperature and high-pressure sequential cycling TES equipment and control technology (224 °C) | >70 | [47] |

| Yingcheng 300 MW CAES Demo Project | AACAES | Operation | China Energy Construction Digital Technology Group Co., Ltd. | 300 MW/1500 MWh | Salt cavern | Pressurized water (180 °C) | 70 | [17] |

| Tai’an 350 MW Salt Cavern CAES Demo Project | Under construction | 350 MW/1400 MWh | Molten salt (325 °C) | >70 | [48] | |||

| Yumen 300 MW CAES Demo Project | 300 MW/1800 MWh | Artificial cavern chambers | Cascaded molten salt-water | 72.5 | [17] | |||

| Jieneng Baoqing 350 MW/1750 MWh CAES Demo Project | AACAES | Under construction | Northeast Electric Power Design Institute Co., Ltd. | 350 MW/1750 MWh | Artificial cavern chambers | Cascaded molten salt-water | 73.8 | [41] |

| Tongwei Compressed Air and Lithium Battery Shared Energy Storage Power Station | AACAES | Under construction | Shanghai Complete Equipment Engineering Institute | 10 MW/110 MWh | Steel tank | Pressurized water | / | [42] |

| Integration Modes | RTE (%) | ERTE (%) | ESD (kWh/m3) | Ref. |

|---|---|---|---|---|

| LCES, CHP, waste heat boiler (WHB), gas boiler (GB), power-to-gas (P2G), electric chiller (EC) | / | / | / | [52] |

| CCES, LNG, ORC, natural gas combined cycle (NGCC), cryogenic CO2 capture | 68.49 | 59.3 | / | [53] |

| LCES, solar collector, ORC | 62.1 | / | 21.74 | [54] |

| CCES, biomass gasification Allam cycle | 62.04 | / | / | [55] |

| CCES, HTEM | 50.43 | / | 16.6 | [56] |

| LCES, gas turbine (GT), GB, WHB, heat pump (HP), EC, absorption chiller (AC) | / | / | / | [57] |

| TCCES, solar energy, heat supply | 77.19 | 68.03 | / | [58] |

| CCES, coal-fired CHP | 75.75 | / | / | [59] |

| VLCCES-CHP | 66.7 | / | / | [60] |

| LCES, SOFC | 62.88 | / | 14.26 | [61] |

| CCES, ORC | 66.64 | / | / | [62] |

| LCES, WH, ARC | 400.99 | 63.31 | 10.78 | [63] |

| LCES, solar energy, WH | 51.65 | / | / | [64] |

| CCES in aquifers (CCESA), geothermal energy | 95.1 | / | / | [65] |

| SCCES, CO2 HP | 80.1 | / | / | [66] |

| TCCES, the WH of liquid-cooled data center | 64.67 (single-stage compression), 67.41 (double-stage compression) | / | [67] |

| Project | State | Technical Sources | Power Output/Capacity or Duration | Storage Device | RTE (%) | Type | Ref. |

|---|---|---|---|---|---|---|---|

| Sardinia CCES Demo/Replication Project | Operation/Under construction | Italian Energy Dome | 2.5/4 MWh, 20 MW/100 MWh | Flexible bladder, pressure tank | 75 | VL | [10] |

| CCES demo Project | Lab demo | Tianjin University of Commerce | 300 W/100 s | Flexible bladder | 8.6–18.7 | VV | [11] |

| Dongfang Electric CCES and Flywheel project | Operation | Dongfang Electric Corporation, Xi’an Jiaotong University, Bairang New Energy Technology (Shenzhen) Co., Ltd. | 10 MW/20 MWh | Flexible bladder, pressure tank | 55 | VL | [10] |

| Wuhu Conch 10 MW/80 MWh CCES Demo Project | 10 MW/80 MWh | 60–65 | VL | [10] | |||

| Huadian Mulei 1000 MW CCES plant | Under construction | 100 MW/1000 MWh | 60 | VL | [68] | ||

| Gu’an CCES Experimental Project | Demo | Technical Institute of Physics and Chemistry, Beijing BoruiDing Power Technology Co., Ltd. | Hundred-kilowatt level | Pressure tank | / | LL | [10] |

| Vision Energy Xiangzhou 100 MW/200 MWh CCES Demo Project | Plan | 100 MW/200 MWh | Flexible bladder, pressure tank | / | VL | [69] | |

| China Energy Group Haixi Dachaidan 40 MW/160 MWh CCES Project | Plan | China Energy Investment Group Co., Ltd. | 40 MW/160 MWh | Flexible bladder, pressure tank | / | VL | [70] |

| Harbin Institute of Technology Adsorption-Compression CO2 Energy Storage (ACCES) Demo Project | Under construction | Harbin Institute of Technology | MW level | Adsorption-based storage unit, pressure tank | / | AC | [71] |

| Jilin Oilfield Supercritical CO2 Pipeline-Integrated Long-Duration Energy Storage Demo Project | Plan | China National Petroleum Corporation | / | Supercritical CO2 pipeline, subsurface oil displacement reservoir | / | VS | [72] |

| Integration Modes | RTE (%) | Ref. |

|---|---|---|

| CB, coal-fired power plant | 59.39–114.67 | [75] |

| LNG, HP/ORC | 222.47 | [76] |

| PTES, geothermal energy | 137.16 | [77] |

| CB, solar energy | 450 | [78] |

| HP/ORC PTES, geothermal energy | 66.8–105.6 | [79] |

| HP/ORC PTES, WH | 71.6 | [80] |

| Cascade HP/ORC PTES, geothermal energy | / | [81] |

| Segmented HP/ORC CB, WH | 74.13 | [82] |

| HP/ORC PTES, WH | 101.29 | [83] |

| HP/ORC PTES, solar energy | 74.47 (variable pressure mode), 74.34 (constant pressure mode) | [84] |

| HP/ORC PTES, PV, WH | 28.2 | [85] |

| Composition-adjustable HP/ORC PTES, WH | increased by 4.4–18.3 | [86] |

| HP/Rankin–Brayton cycle | / | [87] |

| TES, coal-fired power plants | 62.97 | [88] |

| HP/ORC CB, WH, PV, district heating | / | [89] |

| HP/ORC CB, PV, the WH of the data center | increased by 30 | [90] |

| HP/ORC, the WH of the data center | 0.50 (Harbin), 0.43 (Nanjing), 0.39 (Guangzhou) | [91] |

| Company or Project | Charging/Discharging | TES | Power Output/Capacity or Duration | RTE (%) | State | Ref. |

|---|---|---|---|---|---|---|

| MAN/ABB | CO2 Transcritical Heat Pump/CO2 Transcritical Rankine Cycle | Water (120 °C), ice | MW level/~5 h | 45 | Design | [93] |

| Echogen | CO2 Transcritical Heat Pump, Fluidized Bed Heating/CO2 Transcritical Rankine Cycle | Sand (300–350 °C), ice | 25 MW/250 MWh | 60 | Design | [11,94] |

| Peregrine Turbine Technologies | Electric Heating/CO2 Brayton cycle | Graphite aluminum alloy (800 °C) | 1 MW/8 MWh | 45 | CO2 turbine/ compressor testing | [95] |

| Climeon | HP/ORC | Water (e.g., district heating system) | 80 kW to MW/ Hours | 25–60 | Concept | [96] |

| TC Mach | HP/ORC | Stone dust | kW level/Hours | / | Concept | [97] |

| Isentropic Company | Reverse/Forward Brayton Cycle (Ar) | Mineral gravel (~500 °C) | 150 kW/600 kWh | / | Demo | [98] |

| Siemens Gamesa | Electric Heating/Steam Rankine cycle | Volcanic rock bed (~600 °C) | 100 MW/2400 MWh | 25–40 | Demo | [73] |

| SPIC Luliang MW-Scale PTES (Compressed Air with Thermal Energy Storage, CASE) Pilot Project | Reverse/Forward Brayton Cycle (Air) | Lava (560 °C) | 1 MW/4 MWh | / | Under construction | [99] |

| Shouhang HighTech Feicheng 100 MW/400 MWh Compressed CO2-Molten Salt Energy Storage Project | Reverse/Forward Brayton Cycle (CO2) | Lava (560 °C) | 100 MW/400 MWh | ≥63 (up to 76% with optimization) | Under construction | [100] |

| Shouhang Energy Group Changji Independent Energy Storage Project | Reverse/Forward Brayton Cycle (CO2) | Lava (560 °C) | 200 MW/800 MWh | 64 | Under construction | [101] |

| Three Gorges Group Liquid-Cooled Data Center CO2 Energy Storage System | CO2 Transcritical Heat Pump/CO2 Transcritical Rankine Cycle | Water | ≥100 kW/0.5 h | / | Bidding completion | [102] |

| Three Gorges Group Kubuqi 2 × 300 MW Molten Salt Energy Storage Project | Electric Heating, Steam Heating/Steam Rankine Cycle | Lava | 2 × 300 MW/730 MWh | / | Under construction | [103] |

| Longyuan (Qinghai) High-Rate Molten Salt Energy Storage Heating Supply Demo Project | Electric Heating/Steam Rankine Cycle | Lava | 50 MW/300 MWh | / | Under construction | [104] |

| Tongxiang Juneng Qitai Hybrid Energy Storage and Energy Supply Demo Project | Electric Heating/Steam Rankine Cycle | Lava | 343 MWht Molten Salt Energy Storage System with 6.5 MW Power Generation Unit | / | Under construction | [105] |

| China Nylon City Molten Salt Energy Storage Demo Project | Electric Heating, Industrial Park WH/Steam Rankine Cycle | Lava | / | / | Under construction | [104] |

| University of Science and Technology of China (USTC)/Conch Group PTES Project | HP/ORC | / | / | ≥60 | / | [106] |

| Technology | Power Range | Capacity Range (MWh) | RTE (%) | |

|---|---|---|---|---|

| CAES | ≤660 MW | ≤2800 | ≤75 | |

| [11] | ≤500 MW | ≤1980 | / | |

| VLCCES | ≤100 MW | ≤1000 | ≤75 | |

| [11] | ≤20 MW | ≤200 | ≤55 | |

| LCES | Hundred-kilowatt level | / | / | |

| VSCCES | / | / | / | |

| ACCCES | MW level | / | / | |

| Electric Heating/Steam Rankine Cycle CB | [11] | ≤100 MW | ≤2400 | 25–40 |

| [11] | ≤100 MW | ≤2400 | 25–40 | |

| Electric Heating, Steam Heating/Steam Rankine Cycle CB | ≤300 MW | ≤730 | / | |

| Reverse/Forward Brayton Cycle (CO2) CB | ≤200 MW | ≤800 | ≤64 (up to 76% with performance optimization) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Lin, Y.; Zhou, L.; Qian, H.; Zhang, J.; Peng, Y. Comparison of Compressed Air Energy Storage, Compressed Carbon Dioxide Energy Storage, and Carnot Battery: Principles, Thermal Integration, and Engineering Demonstrations. Processes 2025, 13, 2882. https://doi.org/10.3390/pr13092882

Zhang S, Lin Y, Zhou L, Qian H, Zhang J, Peng Y. Comparison of Compressed Air Energy Storage, Compressed Carbon Dioxide Energy Storage, and Carnot Battery: Principles, Thermal Integration, and Engineering Demonstrations. Processes. 2025; 13(9):2882. https://doi.org/10.3390/pr13092882

Chicago/Turabian StyleZhang, Shengbai, Yuyu Lin, Lin Zhou, Huijin Qian, Jinrui Zhang, and Yulan Peng. 2025. "Comparison of Compressed Air Energy Storage, Compressed Carbon Dioxide Energy Storage, and Carnot Battery: Principles, Thermal Integration, and Engineering Demonstrations" Processes 13, no. 9: 2882. https://doi.org/10.3390/pr13092882

APA StyleZhang, S., Lin, Y., Zhou, L., Qian, H., Zhang, J., & Peng, Y. (2025). Comparison of Compressed Air Energy Storage, Compressed Carbon Dioxide Energy Storage, and Carnot Battery: Principles, Thermal Integration, and Engineering Demonstrations. Processes, 13(9), 2882. https://doi.org/10.3390/pr13092882