Abstract

Food waste has emerged as a critical worldwide concern, resulting in environmental deterioration and economic detriment. Bio-based natural polymer coatings and films have emerged as a sustainable solution to food preservation challenges, particularly in reducing postharvest losses and extending shelf life. Compared to their synthetic counterparts, these polymers, such as chitosan, starch, cellulose, proteins, and alginate, are derived from renewable sources that are biodegradable, safe, and functional. Within this context, this review examines the various bio-based natural polymer coatings and films as biodegradable, edible alternatives to conventional packaging solutions. It examines the different fabrication methods, like solution casting, electrospinning, and spray coating, and incorporates antimicrobial agents to enhance performance. Emphasis is placed on their mechanical, barrier, and antimicrobial properties, their application in preserving fresh produce, how they promote food safety and environmental sustainability, and accompanying limitations. This review highlights the importance of bio-based natural polymer coatings and films as a promising, eco-friendly solution to enhancing food quality, safety, and shelf life while addressing global sustainability challenges.

1. Introduction

Globally, 1.3 billion tons of food are lost or wasted annually, accounting for roughly one-third of the food produced for human consumption [1]. The United Nations Food and Agriculture Organization (FAO) reported that fruit and vegetable waste accounts for about 60% of all food categories [2]. This waste includes by-products generated during processing, which typically range from 25% to 30% of the total product volume [1]. In addition, approximately 20% of food waste is generated during production, 1% during processing, 19% during distribution, and 60% at the consumer level [3]. Thus, various factors contribute to food waste. These include shrinkage during cooking, supply chain issues, strict consumer standards, and environmental factors like weather and soil runoff [4]. Regulatory restrictions also play a role [4]. These contribute to various environmental issues, like greenhouse gas emissions during food production, storage, transportation, and disposal. These wastes also lead to soil degradation, deforestation, and water and air contamination [5].

The consequences of these factors have necessitated a growing interest in extending the shelf life of food products, which has consequently prompted the advancement of food preservation techniques [6]. Beyond the primary goals of preservation against physical damage, microbial contamination, and unnecessary waste [7], various additional goals have been identified for each food preservation approach. These include enhancing value-added properties, providing dietary diversity, and mitigating challenges associated with seasonal production [4]. Recent findings have reported a growing demand for safe and healthy food products, with consumers increasingly avoiding artificial additives and preservatives. This trend is reshaping industry practices in food preservation [8]. Moreover, the rising perishability of food items and the necessity for long-distance transportation have intensified the demand for methods to prolong food shelf life [9]. Thus, effective preservation techniques are crucial to ensure food safety and quality throughout preparation, storage, and transportation [7].

Many developing countries have continued to depend on traditional methods of food preservation, such as evaporative cooling, smoking, salting, and sun drying. For instance, about 70% of food produced in Nigeria is processed using these conventional techniques [10]. Additionally, postharvest treatments involving chemical fungicides and synthetic waxes, such as polyethylene and petroleum-based waxes, remain prevalent in several nations to mitigate postharvest losses and extend the shelf life of perishable fruits and vegetables. However, due to their persistent application, these practices pose significant risks to environmental integrity and public health [11]. The constraints associated with agrochemical usage, the demand for healthy foods, and heightened environmental concerns have intensified the search for innovative preservation technologies alternatives [12]. These alternatives must be readily available, cost-effective, renewable, safe, and biodegradable materials [12]. In this context, natural polymers are becoming sustainable alternatives in food packaging, healthcare, energy storage, and electronics due to their safety and biocompatibility [13]. These polymers, encompassing polysaccharides, proteins, and nucleic acids, constitute integral components of biological systems and perform various essential functions [14].

Natural polymers, including cellulose and chitin, are essential for maintaining the structural integrity of cells in both plants and animals, while others confer biological protection against environmental factors [15]. Recent investigations have shown that using these polymers significantly contributes to developing advanced materials, such as films, membranes, coatings, hydrogels, and micro- and nanoparticle systems [16]. This is attributed to their natural abundance, renewability, and inherent negative carbon footprint, as they are derived from renewable resources [17]. These advantages have led to growing interest in sourcing these polymers from unconventional yet sustainable origins. One such emerging and eco-friendly source is fruit waste. Fruit waste offers a promising path for natural biopolymers due to its abundant bioactive compounds such as vitamins, carbohydrates, dietary fibers, lipids, carotenoids, and polyphenols. These compounds have demonstrated efficacy in fabricating films and edible coatings that enhance the shelf life of food products [18]. Notably, these bioactive components are predominantly located in the seeds, skin, rind, and pomace of various fruits.

Therefore, this review seeks to explore and assess different reports on using bio-based natural polymers as an edible coating/film to improve food safety. It aims to examine the efficacy of bio-based natural polymers in mitigating microbiological contamination and spoilage of food products. Additionally, this review will investigate scholarly studies on the mechanical, barrier, and antibacterial properties of these edible coatings and their applicability to various food packaging functions. Finally, it will identify the challenges and limitations of producing and utilizing bio-based edible coatings, including scalability, cost-effectiveness, and regulatory considerations.

2. Bio-Based Natural Polymers

Bio-based polymers are renewable resource materials used in various scientific, industrial, and consumer applications [19]. They have emerged as the most popular and preferred materials in the food sector and food packaging industries [20]. This is due to their lower carbon footprints and the sustainable nature of these materials [21]. Bio-based natural polymers include starch, chitosan, cellulose, chitin, and other polysaccharides and proteins [22]. However, not every polysaccharide can be used as a bio-renewable polymer [23]. These materials have garnered increased attention as packaging materials in the food industry, especially as an edible coating. Edible coatings are considered eco-friendly alternatives to synthetic packaging and are part of the growing demand for sustainable food preservation techniques [24]. They are thin layers of edible materials (mostly bio-based polymers) applied directly to the surface of food products to provide protection and enhance their shelf life [25]. Generally, edible polysaccharide coatings are water-soluble and have poor moisture barrier qualities. However, they have a relatively low O2 permeability. Edible coatings derived from polysaccharides are often applied to fresh, minimally processed fruits and vegetables [26] by creating a modified environment that lowers the rate of respiration [27]. Among polysaccharides, chitin and cellulose are the most significant due to their unique properties and sustainable origins [28]. These polymers exist naturally and have a diverse set of features and applications. Bio-based polymers have grown significantly in recent years in terms of technological advancements and commercial uses. This section will explore commonly used bio-based polysaccharide materials as edible coatings/films.

2.1. Chitosan-Based Edible Coatings/Films

Chitosan is a natural amino polysaccharide composed of numerous reactive functional groups, derived economically from marine waste materials, particularly the exoskeletons of seafood [29]. It is characterized as a cationic polymer that exhibits biocompatibility and non-toxicity [30,31]. Due to its numerous advantages, including its abundance, non-toxicity, film-forming ability, and capacity to carry active substances, chitosan has remained one of the most widely utilized polysaccharide-based coating materials [32]. Moreover, chitosan possesses antibacterial and antioxidant activities, making it suitable for food preservation applications [33]. The structural configuration of chitosan allows for numerous modifications through its hydroxyl and amino groups. These enhance its properties, enabling the formation of compounds with other polysaccharides [34].

It can be transformed into edible films by dissolving in diluted acid solutions, such as acetic and hydrochloric acid [35,36]. Some literature reports have revealed that chitosan edible coating can prevent postharvest infections on various fruits [37]. However, the antibacterial, antioxidant, mechanical, and conditioning properties of pure chitosan films have been deemed insufficient in practical applications [38]. Nevertheless, the United States Food and Drug Administration (FDA) recognizes chitosan as a Generally Recognized as Safe (GRAS) food ingredient [39]. Thus, it is underscored as an appropriate food packaging agent, leading to several studies on chitosan-based films and coatings for food preservation. For example, various fruits and vegetables, including papaya [40], tomatoes [41], mangoes [42], carrots [43], pomegranates [32], and bananas [44], have shown improved storage stability and extended shelf life when coated with chitosan-based films. Edible films and coatings have also been documented to exhibit significant antibacterial and antioxidant properties, prolonging the shelf life of fruits and vegetables, attributed to their capacity to scavenge free radicals, contributing to their antioxidant activity [45]. Compared to other polysaccharides, lipids, and protein-based coatings and films, chitosan-based coatings and films show greater promise because of their solubility [34]. Chitosan is soluble in glacial acetic acid [46], compared to cellulose, which is insoluble in water and only sparingly soluble in most polar solvents. Additionally, edible coatings/films made of chitosan have good mechanical and barrier qualities. Other documented examples of its application in the literature, such as films and edible coatings, have been summarized in Table 1.

Table 1.

A few examples of chitosan-based edible coating/film on food applications.

2.2. Starch-Based Coating/Films

Starch is one of the most abundant biopolymers, serving as the principal energy storage in many plants, including cereals (e.g., wheat, rice, maize), tubers (e.g., potatoes), roots (e.g., cassava), and legumes [54]. According to the literature report [55], this naturally occurring, biodegradable polymer can be utilized to develop functional food packaging materials due to its widespread availability in raw crops and unique physicochemical properties.

Among eco-friendly natural materials, starch-based materials are the most studied and used [56]. This is mainly due to its low cost, availability, organoleptic (flavorless, tasteless, odorless), optical (transparent, colorless), and barrier (carbon dioxide and oxygen permeability) qualities [57]. These characteristics are perfect for film formation, but the starch biopolymer’s mechanical qualities and water vapor permeability (WVP) are poor due to its hydrophilic nature [54,58].

Starch comprises two polysaccharides, amylose and amylopectin [59], and trace quantities of lipids and proteins [60]. The amylose gives starch its ability to form films; the molecular size of this linear chain polymer, which consists of α-(1-4)-anhydroglucose units, fluctuates between 200 and 800 kg/mol [61,62]. On the other hand, amylopectin is a highly branched polymer of 20–30 glucose moieties, linked by an α-(1-6) glycosidic branch of a short α-(1-4) chain. Its molecular weight is extremely high (5000–30,000 kg/mol) [63]. However, starch molecules are insoluble in water; hydrogen bonds cause this insolubility. Starch must be gelatinized in extra water for a good and consistent film-forming solution [64]. Gelatinization is when heating with water causes starch granules to swell, release amylose, and break apart their crystal structures, leading to a thick, gooey solution. This transition is essential for producing consistent film-forming solutions [64]. As gelatinized starch cools, it undergoes retrogradation (a process in which amylose and amylopectin chains realign and form hydrogen bonds). This molecular reordering leads to increased viscosity and the formation of a gel-like structure [65,66]. The distinctive phase transition behaviors directly affect the structural and functional characteristics of starch-based polymers. These inherent properties often result in materials with insufficient mechanical strength and barrier performance [67,68].

Therefore, enhancing the mechanical and barrier characteristics of starch-based packaging materials is essential. To improve the mechanical properties and lower the hydrophilic properties of starch-based packaging, it was proposed to incorporate mineral nanofillers into the polymer matrix instead of macrofillers [69]. This nanocomposite approach offers superior property enhancement while maintaining the biodegradable nature of the packaging. The industrial application of starch, particularly in the food packaging industry, benefits from its diverse character. It protects against moisture, oxygen, and microbial contamination in foods like fresh produce [70], dairy, and bakery products [71]. Some documented examples of its application in the literature, such as films and edible coatings, are summarized in Table 2.

Table 2.

Some examples of starch-based edible coating/film applications on food products.

2.3. Cellulose-Based Coatings/Films

Cellulose is among the most abundant organic polymers on Earth and plays a critical role in the structure of algae, green plants, and the cell walls of oomycetes [77]. Various sustainable sources, such as wood pulp and kenaf fiber, are utilized in cellulose production [78]. Up to 99% of the material can be bio-based [79]. Recently, it has attracted significant attention due to its inherent biodegradability. Its availability, renewability, biocompatibility, and abundance in the natural environment have further contributed to its increasing popularity [20,80,81,82]. Its mechanical strength is high compared to the plastic-based material [83]. It comprises millions of β (1 → 4) linked D-glucose units [84].

In the food industry, cellulose films are extensively used as edible packaging materials [21]. They demonstrate exceptional thermal stability while serving as an effective carrier for antioxidant and antimicrobial compounds [85]. Their UV-blocking capability and non-toxic properties make them particularly valuable for postharvest applications. These characteristics collectively enhance the preservation of nutritional quality and extend the shelf life of fresh produce [81]. These films demonstrate high efficacy in packaging a range of products. However, their lack of waterproof properties makes them unsuitable for cold storage or for containing wet food items [86]. It exhibits a high capacity for water absorption and demonstrates poor interfacial adhesion, thereby limiting its effectiveness [81].

Moreover, pure cellulose-based hydrogels often exhibit limitations in flexibility and functionality because of cellulose’s rigid crystalline structure and strong hydrogen bonding among glucose units, leading to a highly ordered and inflexible material [87]. Cellulose-derived hydrogels are typically synthesized from water-soluble cellulose derivatives such as methylcellulose (MC), ethyl cellulose (EC), and carboxymethylcellulose (CMC) through physical and/or chemical cross-linking methods [88].

Consequently, to address these limitations, it is essential to combine cellulose biopolymers with other polysaccharides (e.g., pectin, chitosan, or starch) to develop robust and sustainable films or coatings. Furthermore, incorporating bioactive compounds such as polyphenols, antimicrobials, and essential oils may improve their bioactive properties [81]. This synergistic combination enhances the composite’s performance by introducing antioxidant, antimicrobial, or pH-responsive properties while maintaining the structural integrity of the cellulose base. Examples of cellulose-based coating applications in the food sector are detailed in Table 3.

Table 3.

A few examples of cellulose-based edible coating/film applications on food products.

2.4. Alginate-Based Coating/Film

Alginate, a hydrophilic biopolymer with well-documented colloidal properties, is widely applied in food, printing, beverage, and pharmaceutical sectors as a multifunctional additive for thickening, stabilizing, emulsifying, chelating, encapsulating, and forming gels, films, and membranes [96]. It is derived from brown sea algae (Phaeophyceae), consisting of two uronic acids, β-D-mannuronic acid and α-L-guluronic acid [97]. This biopolymer is characterized by its affordability, homogeneity, transparency, water solubility, biocompatibility, and non-toxicity. These properties make it suitable for a diverse range of cell lines; however, it is noted for its limited mechanical strength [98].

Among biopolymers, alginate has been identified as particularly promising for applications demanding high oxygen barrier properties [99]. Alginate-based films and coatings have demonstrated considerable potential for encapsulating active or functional food ingredients, such as medicinal additives, tissue engineering materials, and enzymes [100]. Alginate coatings, in isolation, exhibit a deficiency in antioxidant and antifungal properties. They have shown efficacy in preserving the postharvest quality of various fruits, including peaches [101], sweet cherries [102], and tomatoes [103], effectively delaying the ripening process and extending the shelf life of fruits and vegetables [104]. Additional applications of alginate-based edible coatings/films are summarized in Table 4. However, alginate-based edible coatings/films are more susceptible to moisture damage because of their inherent hydrophilicity [105]. This drawback can lead to reduced barrier properties, increased water vapor permeability, and faster degradation of the coated product. Researchers have explored various strategies to improve moisture resistance, including cross-linking agents, hydrophobic additives, and nanocomposites [106]. Incorporating essential oils has proved to be an effective method of improving moisture [107]. Essential oils enhance hydrophobicity and contribute to active packaging by inhibiting microbial growth, thereby extending the shelf life of perishable foods [108].

Table 4.

Applications of alginate-based edible coating/films in food preservation.

2.5. Protein-Based Edible Coating/Film

Proteins are essential organic macromolecules composed of α-amino acids linked by peptide bonds, forming their primary structure [116,117]. The polypeptide backbone provides the framework for protein folding, which establishes the secondary structure, including α-helices, β-sheets, loops, and bends, stabilized by intramolecular interactions [118,119]. The tertiary structure arises from the overall three-dimensional arrangement of the protein, driven by interactions between the side chains of amino acids [119]. Some proteins also form quaternary structures, assembling multiple polypeptide chains into defined molecular aggregates. These aggregates are often reversible, loosely bound, and exhibit specific geometric arrangements [120].

Protein structure is critical in film formation as it governs the protein’s ability to interact with itself and other components [121]. Proteins are classified as fibrous or globular, each type serving distinct roles. Fibrous proteins, which are water-insoluble, are the primary structural components of animal tissues. In contrast, globular proteins are soluble in water and aqueous solutions of acids, bases, or salts, enabling diverse functional roles in biological systems [122,123]. The physicochemical properties of proteins are determined by the sequence and distribution of amino acid residues along the polymer chain [124]. Proteins are often modified using acids, bases, solvents, or heat to enhance their suitability for film production. These treatments enable the formation of durable systems by extending protein chains and promoting hydrogen, ionic, and covalent bonding. The uniform distribution of polar groups along the polymer chain further enhances the likelihood of intermolecular interactions critical for film strength [125].

The degree of chain-to-chain interactions influences the mechanical properties of protein-based films, such as strength and permeability. Films with stronger bonds exhibit lower permeability to vapors, liquids, and gases, making them practical barriers. Protein-based films are particularly adept at blocking oxygen, even at low relative humidity levels [126]. Commonly used proteins for edible film and coating production include whey, wheat gluten, gelatin, maize zein, casein, and soy protein. These materials offer functional and nutritional benefits, making them suitable for direct consumption [127]. A summary of applications of protein-based edible coatings/films is presented in Table 5.

Table 5.

Protein-based edible coating/films and their applications in food products.

2.6. Comparative Evaluation of Commonly Used Natural Biopolymer Properties

Following a detailed analysis of individual bio-based natural polymers, we summarize and compare their key properties to evaluate their suitability for food preservation. These polymers show different structural characteristics and barrier functionalities, antimicrobial efficacy, and practical applications in food systems [134,135]. Table 6 summarizes key biopolymers’ barrier properties, antimicrobial efficacy, and food applications. Among natural polymers, chitosan is remarkable for its intrinsic antimicrobial activity and strong barrier-forming capacity, which allows its application in food preservation [136,137]. Unlike polymers such as starch and cellulose, which do not possess inherent antimicrobial activity but are interesting because of their good film-forming and barrier properties after adding bioactive agents [138,139,140]. Alginate and protein-based films are suitable for food systems applications, particularly when reinforced with antimicrobials or plasticizers [141,142,143]. This comparison is valuable when choosing biopolymers for food preservation purposes, either to reduce oxygen transfer, increase microbiological barriers, or improve the texture of packaged food. Thus, the table in this context summarizes how these biopolymers align with specific preservation needs in food packaging systems.

Table 6.

Comparative overview of the major biopolymers based on barrier and antimicrobial properties in food applications.

2.7. Other Bio-Based Coating/Film Polymers

In addition to conventional biopolymers such as chitosan, starch, cellulose, alginate, and proteins, several other bio-based polymers and synthetic bio-alternatives have potential for coating and film applications in sustainable food preservation. These include poly (lactic acid) (PLA), polyhydroxyalkanoates (PHAs) like polyhydroxybutyrate (PHB), and novel developments such as non-isocyanate polyurethanes (NIPUs). These materials offer promising avenues due to their biodegradability, renewable origin, and physicochemical properties compatible with food contact applications.

Poly (lactic acid) (PLA), a synthetic biopolymer synthesized from lactic acid via ring-opening polymerization [151,152], is recognized for its superior optical clarity and biodegradability. Additionally, PLA exhibits favorable mechanical properties, moisture resistance [153], and exceptional transparency and printability [151]. It has also shown potential as a barrier for hydrophobic aroma compounds [154]. Additionally, PLA is recyclable, making it an environmentally friendly material [153]. Despite its relatively high production cost, PLA has gained traction in food packaging due to its processability and end-of-life compostability [155].

Similarly, polyhydroxyalkanoates (PHAs), specifically PHB and its copolymer PHBV, are bacterially synthesized from biomass [156] and exhibit semi-crystalline structures with good barrier and thermal properties [157]. However, due to their brittleness and narrow processing window, materials like PHB and PHB/V are unsuitable for technical applications such as deep-drawing films or injection molding in the food industry [158]. Also, their lack of high chemical recyclability has limited their potential [159]. To enhance their flexibility and toughness, they are often blended with other polymers or plasticizers for broader usability [156].

NIPU is a sixth widely used polymer that is synthesized from polycyclic carbonates and amines without the use of hazardous isocyanates [151,160,161]. In response to health and environmental concerns associated with traditional polyurethane (PU) synthesis, non-isocyanate polyurethane (NIPU) has garnered attention as a safer alternative [162], due to its excellent mechanical and physical properties. They are widely used in adhesives, seals, elasticity, rigid foams, and high-performance coatings [161]. Though still under development, NIPUs align with green chemistry principles and present reduced toxicity during manufacturing and application [163]. Despite their advantages, NIPUs face technical challenges such as slow reaction rates and lower molecular weights [164], which can affect their performance. Researchers have addressed these issues using reactive additives, catalysts, and optimized monomer structures to enhance polymerization efficiency [151,165]. Hybrid NIPUs (H-NIPUs), which combine NIPUs with other polymers like epoxies or acrylates, have shown improved mechanical properties and greater application potential [166].

The integration of these emerging polymers with natural biopolymers or nanofillers further enhances their mechanical, antimicrobial, and barrier properties, facilitating their application in advanced food packaging systems [167,168]. However, challenges such as production scalability, cost-efficiency, and regulatory compliance remain key limitations to their widespread adoption [169]. As research advances, the combination of synthetic bio-based polymers with plant or microbial-derived additives could yield next-generation materials that bridge the gap between performance and sustainability in active and intelligent packaging. Table 7 provides a comparative summary of the currently available synthetic bio-based polymers.

Table 7.

Other notable bio-based polymers for food coating/films.

3. Fabrication Techniques

Several fabrication techniques have been employed to produce diverse biopolymer-based films and coatings, each influencing the material’s mechanical barrier and antimicrobial properties [176]. Notable examples of these techniques include solvent casting, electrospinning, extrusion, and layer-by-layer assembly [177]. These methods offer distinct advantages depending on the intended application, as advancements in this field continue to enhance the performance of bio-based polymer films [178]. The fabrication techniques discussed in this section are limited to those relevant to the formation of films and edible coatings specifically for food packaging applications.

3.1. Solution Casting

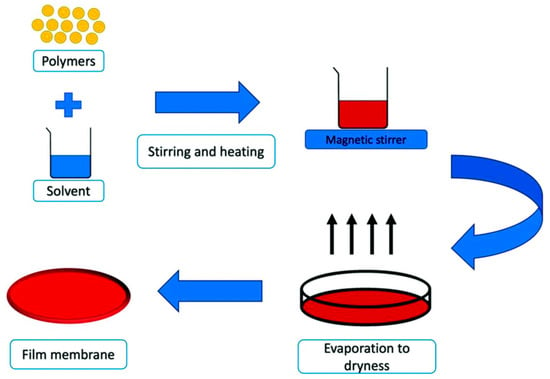

Solution casting is a popular material science and engineering manufacturing technique for producing thin films and membranes [179]. This method entails dissolving a substance in a solvent to create a homogeneous solution, which is poured or cast onto a flat surface, where the solvent evaporates, leaving a solid layer of the substance [180], as seen in Figure 1. Solvent casting is preferred over other technologies, such as salt leaching, spin coating, microfluidic spinning, and 3D printing, because of its low cost, simplicity, practicality, and ability to produce durable films with adequate mechanical properties and uniformity [181]. However, the qualities of materials generated through solvent casting might vary greatly across production batches due to environmental variables, which can impede manufacturing [182]. Furthermore, ensuring sterility across all manufacturing phases is challenging and might lead to batch contamination.

Figure 1.

Schematic diagram of the solution casting process [183]. Reproduced with permission from MDPI under the Creative Commons (CC BY) Copyright © 2023 license. Licensee MDPI.

This method has been extensively applied in the fabrication of biopolymer-based films such as chitosan, gelatin, pectin, and alginate. For instance, chitosan is frequently blended with plasticizers like glycerol to improve its flexibility and mechanical properties [184]. Gelatin films, known for their excellent oxygen barrier properties, exhibit improved strength and thermal stability when combined with starch or alginate [185]. Alginate films, prized for their biocompatibility, can be cross-linked with calcium ions to enhance water resistance and film strength [186,187]. Pectin-based films are often reinforced with starch to improve mechanical and moisture barrier properties [188].

3.2. Electrospinning

Electrospinning is an outstanding technique often used for creating continuous polymer fibers with controlled diameters and morphologies [189]. These nanofibers are deposited onto a collector surface, forming a fibrous mat or film with unique structural and functional characteristics [189]. This method is especially valuable for food packaging applications due to the high surface-area-to-volume ratio of electrospun nanofibers, which enhances their ability to incorporate and release active agents [190]. Furthermore, electro-spun nanofibers have more distinct properties, such as tunable chemical composition, Fiber diameter, pore structure, and morphologies (dense and hollow), which can be obtained by adjusting the following factors: Electrospinning solution properties such as composition, viscosity, conductivity, and surface tension [189,190]. Notably, electrospinning can thus be performed under ambient conditions without high temperatures, extensive chemical reactions, or complex equipment, making it a cost-effective and scalable method. Nevertheless, environmental parameters such as solution temperature and humidity, for inorganic materials, and post-treating parameters such as heating rates and temperatures significantly affect product structure [191]. Electrospinning setups generally consist of three major components: a syringe pump containing the polymer solution, a high-voltage DC power supply, and a collector [192]. When a high voltage is applied to the polymer solution, electrostatic repulsion overcomes surface tension, forming a Taylor cone (a pointed structure that forms at the tip of the needle or nozzle [193]) and ejecting a fine polymer jet. As this jet travels toward the collector, it undergoes stretching and thinning, solidifying into nanofibers upon solvent evaporation [194]. Figure 2 illustrates the setup and working principle of the electrospinning technique.

Figure 2.

A schematic demonstration of the electrospinning process and its key components [195]. Reproduced with permission from MDPI under the Creative Commons (CC BY) Copyright © 2022 license.

Compared to alternative methodologies, electrospinning technology is characterized by its simplicity, ease of control, and low cost, allowing it to be easily scaled up to generate diverse nanomaterials [191]. However, a notable challenge arises from the proximity of the collector to the charged polymer solution, which hinders complete solvent evaporation before the fiber jet arrives at the collector. This phenomenon results in a loosely structured web. Furthermore, the partial evaporation of solvent causes the fibers to adhere to both the collector and one another, thereby complicating the removal process [192]. Various electrospinning configurations can alter the morphology and structure of electrospun fibers, thereby enhancing protection against active agents and improving mechanical and barrier properties in active packaging systems [196]. Ref. [197] investigated the application of electrospinning to produce protein-based encapsulating structures utilizing whey protein isolate (WPI) without the incorporation of organic solvents or exposure to high temperatures. Their findings demonstrated that WPI could yield membranes possessing desirable attributes such as biodegradability, transparency, and odorlessness. These properties render WPI-based electrospun films advantageous for extending the shelf life of various food products by providing an effective protective layer.

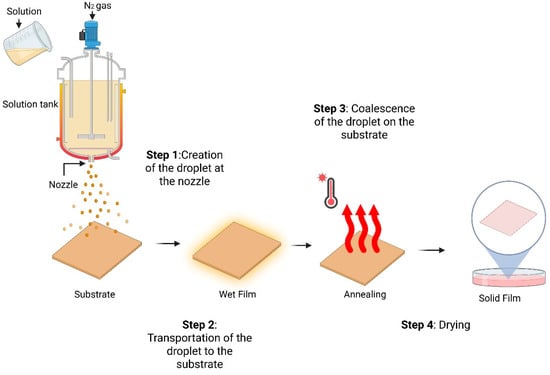

3.3. Spray Coating

Spray coating is spraying a polymer solution or suspension onto a substrate, forming a thin film as the solvent evaporates [198,199]. In this technique, a nozzle rapidly sprays tiny solution droplets across the preheated substrate [200]. The most widely used method is pneumatic spraying, which delivers the droplets via a fast-moving gas stream. The spray coating involves four main steps. First, droplets are generated through a process called atomization. These droplets then land and merge on the substrate, forming a wet film. Finally, the substrate undergoes annealing to produce the final film [201]. A schematic diagram of the entire coating process is shown in Figure 3. This approach enables homogeneous coating across wide regions and intricate shapes [202]. It is widely used to produce thin films for electrical devices, coatings, and protective layers. Spray coating techniques offer tremendous potential for large-scale production because these methods have no limitations in substrate size and low polymer use, promising to substitute the standard process, which is the spin coating method [203]. However, Spray coating poses challenges, such as increased film thickness and roughness [85]. Recent research has thus focused on optimizing the morphology of active layers using additives, solvent combinations, and post-thermal annealing [204], high-boiling-point solvents [205], and spray-coating methods [206].

Figure 3.

Schematic diagram of spray coating.

3.4. Extrusion

Extrusion is a continuous and high-throughput manufacturing technique widely employed for shaping thermoplastic polymers into films, sheets, and other functional structures. It is one of the oldest and most important polymer transformation processes, particularly suited for biopolymer film production in food packaging applications [207]. Following the report by [208], as illustrated in Figure 4, raw materials, including natural polymer powders and nanoparticles, are introduced into the extruder. As the mixture traverses the heated barrel of the extruder, the applied heat softens the materials, rendering them pliable for subsequent processing. The rotating screws within the extruder facilitate the blending of the heated components, exerting pressure and shear forces to ensure a uniform distribution of nanoparticles throughout the polymer matrix. The molten material is subsequently extruded through a die, forming thin sheets or films. The extruded material is then cooled by air or water, allowing the film to solidify into its final shape while preserving its structural integrity [209]. The solidified sheets are cut to the requisite dimensions and shapes before packaging as food-safe wrapping or containers. This method offers high production rates and the capacity to fabricate complex shapes [210]. Additionally, edible films can be produced from consumable materials utilizing dry processes, such as extrusion. Extrusion has demonstrated efficacy in generating films with desirable characteristics, including mechanical properties, thermal stability, and antibacterial activity [211]. The extrusion process often yields films exhibiting adequate mechanical properties and robust thermal stability [212]. However, some extruded films have been identified as exceptions, displaying inferior mechanical and oxygen barrier properties. For instance, ref. [213] developed films based on potato peel starch that were plasticized with glycerol; these films demonstrated high transparency, enhanced mechanical properties, improved thermal stability and flexibility, and increased biodegradation in seawater and soil, rendering them suitable for food packaging applications.

Figure 4.

Schematic diagram of an extrusion process [214]. Reproduced with permission from MDPI under the Creative Commons (CC BY) Copyright © 2022 license.

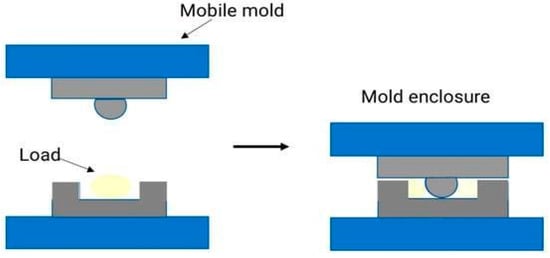

3.5. Compression Molding

Compression molding is a closed molding process used to produce various composite goods [215]. It remains one of the earliest industrial procedures developed for plastics and is sometimes referred to as “matching die molding” [215,216]. This method puts a pre-measured quantity of polymer or biopolymer composite material into a heated mold cavity. This material is then compressed using a matching mold plate under pressure and heat until it takes the shape of the mold. After forming, the resulting product is cooled and demolded, forming a solid film or component with the desired geometry [217] as illustrated in Figure 5. This approach is particularly suited for producing large, complex parts with superior mechanical strength and dimensional stability. Unlike injection molding, it typically incurs lower tooling costs and reduces material waste since it eliminates the need for runners, sprues, or gates [218]. Compression molding has various advantages over injection molding, including lower costs and fewer waste materials, whereas injection molding requires runners, sprues, and gates. Furthermore, the compression molding technique has a comparatively high production rate [219] because the mold cycle time is only a few minutes long [220]. For example, a starch–hydroxypropyl methylcellulose-based film was obtained by compression molding [221], and the addition of HPMC to starch significantly improved the tensile strength and elongation at the break of the films. Also, the films exhibited favorable mechanical properties, making them suitable for various packaging applications where flexibility and strength are crucial.

Figure 5.

Schematic diagram for the compression molding process [219]. Reproduced with permission from MDPI under the Creative Commons (CC BY) Copyright © 2023 license.

3.6. Three-Dimensional Printing

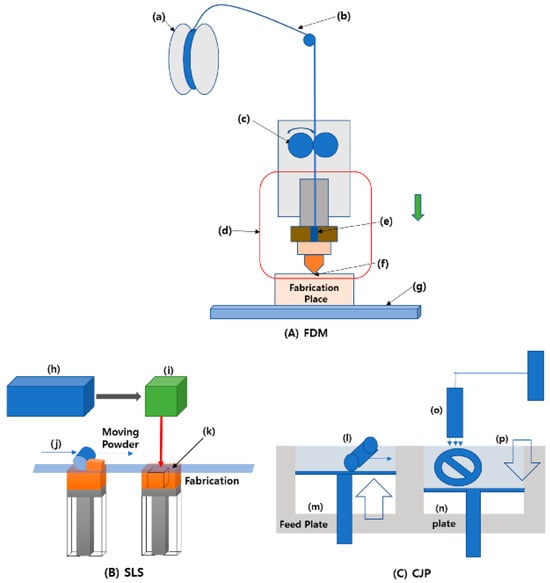

3D printing, also known as additive manufacturing, is the process of building products layer by layer from digital models [222]. It is a multidisciplinary technology that combines advanced machinery, computer science, numerical control systems, and materials science [223]. Recent advances in robotics have increased the importance of 3D printing in various industries, including automotive, medicine, textiles, civil engineering, military, and food [224]. It was initially industrialized for modeling plastics but has now been adapted for use in the food sector [225]. When used in food, this additive manufacturing technology is referred to as food-layered manufacturing [226]. This technology allows for the design and fabrication of food personalized to individual health needs and physical activities by controlling the quantity of printing material and nutritional content [227]. Various 3D printing processes, such as fused deposition modeling (FDM), color-jet printing, and selective laser sintering (SLS), use a variety of materials and technologies to produce complicated geometries with high precision (Figure 6) [228], with FDM (Figure 6A) being popular in small businesses due to it being the most affordable. This process involves pushing materials through nozzles at high temperatures and pressures, layering them individually [228]. This technology is commonly used for prototyping, biomedical implants, and custom production [229]. A study by [230] demonstrated that blending PLA with agricultural waste enhanced the film’s mechanical properties, making it more suitable for flexible packaging applications.

Figure 6.

Schematic diagram of 3D printing machinery. Diagram Label (A): Fused Deposition Modeling (FDM): (a) Coil reel; (b) Plastic filament; (c) Driving motor; (d) Extruder; (e) Molten paste chamber; (f) Nozzle tip; (g) FDM printer bed. Diagram Label (B) Selective laser sintering (SLS): (h) Laser; (i) Scanner system; (j) Roller; (k) Power bed. Diagram Label (C) Color-jet printing: (l) Roller; (m) Powder; (n) Build; (o) Color binder header; (p) Modeling part [228]. Reproduced with permission from MDPI under the license of Creative Commons (CC BY) Copyright © 2021.

3.7. Summary of Fabrication Techniques for Biopolymer-Based Films

Fabrication technique selection is essential because it governs structural, mechanical, and functional properties of biopolymer films/coatings by dictating their molecular interactions [219]. Solution casting, 3D printing, electrospinning, spray coating, molding, and extrusion represent key materials processing techniques with unique operational principles, advantages, and limitations [231,232,233,234]. These methods can be used in diverse fields such as biomedical, engineering, and pharmaceutical [235,236]. While these techniques have been explained in detail in the previous section, Table 8 summarizes their operational principles, advantages, and limitations associated with each method, facilitating a more informed selection based on specific application needs in food packaging and related fields.

Table 8.

Principles, advantages, and limitations of the fabrication techniques.

3.8. Nanocomposite Approaches

Nanocomposites are materials that have a nanoscale structure and improve the macroscopic qualities of products [251]. Nanocomposites represent sophisticated materials synthesized by integrating a matrix, commonly a polymer [252], with nanoscale reinforcing agents to enhance mechanical strength, thermal resilience, and electrical conductivity. These reinforcing agents may be nanoparticles, nanofibers, or nanoplates embedded within the matrix at the nanoscale [190]. Polymer nanocomposites can generally be categorized into three types: (i) intercalated nanocomposites, (ii) flocculated nanocomposites, and (iii) exfoliated nanocomposites [253]. At least one of the filler dimensions is on the nanoscale [254]. Nanocomposites have been reported to have varying degrees of property enhancements [255]. The production of nanocomposites involves adding nanoscale fillers, such as nanoparticles, nanotubes, or nanoclays, to a polymer matrix to improve its properties [256]. These materials exhibit better mechanical, thermal, and electrical properties than their bulk counterparts [257,258]. The poor mechanical and barrier qualities of some bio-based packaging materials, relative to conventional materials, can be enhanced by the integration of nanoparticles [259]. Solution mixing, melt blending, and in situ polymerization are some of the methods used to create nanocomposites [255]. Using composites that incorporate nanoparticles offers advantages over using bare nanoparticles alone, as they enhance monitoring capabilities and improve treatment processes [260]. In creating these composites, nanoparticles are combined with other materials, such as metals, polymers, or both organic and inorganic substances, leading to improved performance and functionality [261]. Nanocomposites have been reported to exhibit varying degrees of property enhancements (Table 9).

Table 9.

Nanofillers used in nanocomposite-based food packaging.

4. Properties of Bio-Based Natural Polymer Coatings/Films

Bio-based natural polymer coatings and films have emerged as potential solutions in a variety of industries due to their sustainable and environmentally friendly properties [23]. These materials, generated from renewable sources such as plants, animals, and microbes, have inherent biodegradability, which reduces environmental effects when compared to their petroleum-based counterparts [268]. However, barriers to the widespread adoption of bio-based natural polymer coatings and films include high costs and poor mechanical qualities [269]. To overcome these constraints and maximize their potential, researchers are continuously investigating novel structural configurations and processing methodologies [270]. This section summarizes an overview of the qualities of bio-based natural polymer coatings/films, providing light on their mechanical, barrier (gas and moisture), thermal stability, optical properties, antimicrobial activity, and environmental impact, as well as possible applications in a variety of industries.

4.1. Mechanical Properties

Mechanical properties are essential determinants of the performance and suitability of natural bio-based polymer coatings [271]. These properties, alongside unique physical, chemical, or biological design criteria, are necessary to ensure product safety and high quality for consumers. Over the past decade, various materials have been employed to develop biodegradable polymer composites aimed at enhancing their mechanical properties [272]. The incorporation of inorganic fillers into these polymers can significantly influence the mechanical characteristics and hydrophobicity of the resulting composites, which are critical for biomedical applications [273].

Mechanical properties encompass a range of factors that affect a material’s response to external forces and mechanical stresses. Key mechanical properties considered for natural bio-based polymer coatings include elongation at break, adhesion strength, flexural strength, modulus, coefficient of friction, hardness, impact resistance, and tensile strength.

- Elongation at break quantifies how much a material can stretch before breaking, with higher elongation values signifying increased ductility and flexibility, which are advantageous for coatings subjected to elongation or deformation [274].

- Adhesion strength refers to the bonding force between the coating and the substrate surface. According to literature reports, the tensile strength of composite films decreases with poor adhesion, underscoring the necessity for robust adhesion to prevent delamination or separation of the coating from the substrate, thereby ensuring long-term durability and performance [275,276].

- Tensile strength represents the maximum stress a material can withstand before failure under tension, indicating the coating’s ability to endure deformation under such conditions [277].

These mechanical properties are influenced by polymer synthesis, blends, additives, chemical modifications, or combinations thereof, as well as processing techniques. It is also crucial to evaluate the effects of low temperatures (e.g., frozen products stored at −18 °C) and humidity (e.g., packaging saturated with water due to high condensation, chopped fruits, etc.) on mechanical properties [278]. Naturally sourced materials present a viable option for food packaging, given their capacity for partial or complete biodegradation. However, these natural polymers often exhibit higher costs and limited mechanical strength. Therefore, it is essential to investigate diverse structural arrangements to achieve the desired product characteristics [279].

4.2. Barrier Properties (Gas and Moisture)

Packaging plays a vital role in safeguarding products from the external environment [280]. The packaging material should possess outstanding barrier properties to prevent the passage of various substances like moisture, gases, and lipids through the packaging wall [281]. It is widely acknowledged that quality packaging plays a pivotal role in promoting sustainability, driving technological advancements, and minimizing food loss by preventing the transfer of moisture and oxygen between products and their surroundings [282]. Barrier materials are essential for maintaining product quality, safety, and durability by preventing oxygen and water transfer, which are primary causes of food spoilage, making airtight seals and superior barriers key strategies for extending shelf life [283]. These materials find applicability across diverse sectors. The barrier film market, valued at USD 34.1 billion in 2023, is expected to reach USD 45.1 billion by 2028, driven by traditional plastics like PET, LDPE/HDPE, and PP, which pose environmental concerns [282].

4.3. Thermal Stability

Thermal stability refers to how well a material’s properties, such as oxidation resistance, structure, composition, and mechanical strength, remain unchanged or adapt to temperature changes [284,285]. These properties include oxidation, structure, composition, mechanical properties, and more [284]. Thermal stability addresses how temperature influences adhesive curing, the impact of high temperatures, and fire damage during production [286]. Various methods are employed to analyze the thermal characteristics of a substance. One such method is thermogravimetric analysis (TGA), which evaluates the alteration in mass, temperature of thermal degradation, and thermal stability of composite materials [287]. Moreover, thermal properties hold equal significance in structural uses like heat transfer from one end to another, the capacity to withstand loads at temperatures, material response, and maintaining dimensions at high temperatures [286].

The thermal characteristics of biopolymers are important in deciding their appropriateness for manufacturing and usage as a coating substance [288]. Polymers derived from renewable sources, such as PFA, demonstrate advantages like high thermal stability. Thermal analysis allows researchers to identify the exothermic crystallization peak, which provides insights into and helps model the crystallization behavior of new bio-based polyesters [289]. As the thermal stability of a nanostructure decreases, the coating material undergoes a transition to a typical crystalline form due to grain enlargement. This process causes the nanostructure to break down and leads to the formation of new crystalline phases [284]. Consequently, nanocomposite coatings lose their unique properties when exposed to elevated temperatures, resulting in changes to the film’s overall characteristics.

4.4. Optical Properties

Optical characteristics describe how materials intermingle with light; these characteristics govern how light is absorbed, transmitted, reflected, or scattered by a substance [290]. Scattering can alter the purity and appearance of films and coatings. The refractive index influences light bending, which is important for lens design and optical applications [291]. Opacity is critical in applications like protective coatings and food packaging [292]. The transmittance and reflectance of bio-based films are important considerations in determining their appropriateness for various applications. Reflectivity influences both the appearance and energy efficiency of materials; high reflectivity can reduce heat absorption [293]. Another important optical attribute of bio-based films is their capacity to absorb ultraviolet rays [294]. Absorbance properties are vital for food packaging, as UV light can destroy sensitive materials [295].

Chitosan and its derivatives exhibit effective UV-blocking qualities, which can be linked to the polymer’s inherent structural characteristics [296]. Incorporating natural extracts, such as green tea or turmeric, into biopolymer matrices can also improve UV protection due to their antioxidant characteristics [297]. Color is important in applications like packaging because it influences consumer perception [298]. The composition of bio-based films and any added substances can affect their hue. Natural pigments that provide extra health advantages, such as carotenoids from carrots or anthocyanins from berries, can add color to food [299,300]. The product’s hue influences both its visual appeal and its capacity to shield its contents from light exposure [301].

Natural polymers, including chitosan, cellulose, gelatin, and starch, have distinct structural features that affect their optical qualities [302]. Chitosan films, for example, are well-known for their transparency and UV-blocking properties, which are attributed to the presence of amino and hydroxyl functional groups that can interact with light [303]. Similarly, cellulose-based films have good light transmission, which is useful for packaging applications that need product visibility [304]. For bio-based natural polymer coatings and films to function well in a variety of applications, their optical characteristics are essential [81,305].

4.5. Antimicrobial Activity

The antimicrobial properties of bio-based natural polymer coatings and films have garnered significant attention due to their importance in applications related to food packaging, such as agricultural products, and biomedical devices, by preventing microbiological growth while also benefiting the environment [306]. Natural polymers, including chitosan, cellulose, and gelatin, have inherent antibacterial capabilities due to their biochemical composition [307]. Unlike other antimicrobial polymers, chitosan offers several advantages, including its natural origin and abundance, as well as its effective antimicrobial properties [283,308]. It is also safe for use in tissue engineering, drug delivery, wound dressing, food, and plant protection applications [309,310], having been approved by both the FDA and the EU [311].

In addition, chitosan has strong mechanical, barrier, and film-forming qualities; as a result, food packaging can greatly benefit from its use [283]. Chitosan, a derivative of chitin, contains amino groups that can break microbial cell membranes, resulting in cell death [312,313]. Thus, chitosan has drawn a lot of attention in active food packaging applications [314] due to its exceptional film-forming ability and antimicrobial qualities through electrostatic exchanges and interactions that disrupt the microbial cell and ultimately cause cell death through proper production of DNA or RNA [315]. Many natural polymers can gradually release antimicrobial compounds, offering long-term protection from infections [316].

Bio-based coatings with antibacterial characteristics are especially useful in the food industry. They can increase shelf life by preventing the growth of rotting organisms and diseases [317]. For example, chitosan-based films have been proven to minimize microbial contamination in fruits and vegetables, extending their storage life [318]. The addition of essential oils, such as oregano or thyme, to these films has been reported to increase their antibacterial activity [319]. Bio-based natural polymers are used in biomedical applications for wound dressings and drug delivery systems due to their biocompatibility and antibacterial qualities [309]. Gelatin-based films or coatings, for example, have been shown to have antibacterial properties against fungi, yeast, or common pathogens such as Staphylococcus aureus and Escherichia coli [320,321]. These films can help improve healing and avoid infections. Despite the potential antibacterial qualities of bio-based coatings, problems persist. Material stability, antibacterial activity variability, and food application regulatory approval are all important considerations [322].

More research is needed to improve the durability and effectiveness of these coatings by novel modifications such as nanotechnology and the addition of new bioactive substances [316]. Bio-based natural polymer coatings and films have thus demonstrated significant antimicrobial activity, making them valuable for food packaging and biomedical applications [323]. Nevertheless, continued research and development are needed to further enhance their efficacy and expand their practical uses, contributing to safer and more sustainable materials.

5. Enhancement Strategies

To improve the effectiveness of bio-based natural polymer coatings and films for food preservation, various approaches have been explored to enhance the application of these materials. These strategies focus on improving the mechanical barrier and antimicrobial properties of the films. Some of these approaches are discussed in this section.

5.1. Incorporation of Antimicrobial Agents

The inclusion of antimicrobial compounds such as essential oils and nanoparticles into diverse products is a promising approach to combating microbial contamination [259,324]. Their use in food packaging, medical gadgets, and other materials increases product safety while extending shelf life and improving health outcomes [325]. Nevertheless, several studies are still needed to optimize their use and ensure safety and efficacy in various applications [324]. Recently, numerous reports have been conducted on the use of natural biopolymers such as chitosan, organic acids, and essential oils [326]. Despite being a biopolymer for food packaging, chitosan has no appreciable antibacterial and equivocal antioxidant properties [327]. Hence, property enhancement is required as the antibacterial activity of chitosan could broaden its applications in food packaging.

An edible coating with antibacterial properties has the potential to avoid contamination in food products [328]. Consequently, materials such as essential oils (EOs) can be added to the edible film to improve its antibacterial capabilities [108]. Essential oils are hydrophobic liquids made up of volatile aromatic chemicals that have a variety of properties, including antibacterial, antioxidant, anti-inflammatory, analgesic, anti-depressive, and calming [329]. They are well-known in the pharmaceutical and medical fields, as well as the gastronomy and food packaging industries. The essential oils are derived from various parts of aromatic plants such as wood, roots, barks, seeds, peel, fruit, leaves, flowers, and entire plants [330]. The Food and Drug Administration (FDA) has certified essential oils (EOs), which are natural and highly efficient antimicrobials against bacteria and fungi, for use in food such as GRAS (generally recognized as safe) [331].

Additionally, some nanoparticles (like silver and ZnO nanoparticles) have recently gained attention as effective and safe materials for enhancing food packaging due to their antibacterial properties [332]. Their high surface area-to-volume ratio improves their contact with microbial cells, resulting in effective microbial suppression [333]. Silver nanoparticles are used in textiles, medical equipment, and wound dressings to help prevent infections and improve healing [328]. Similarly, other nanoparticles, like zinc oxide and titanium dioxide, have antibacterial properties and are employed in comparable applications [334]. The inclusion of antimicrobial compounds such as essential oils and nanoparticles into diverse products is a promising approach to combating microbial contamination [335]. Nevertheless, it is necessary to optimize their use and ensure their safety and efficacy in various applications. Several studies involving the use of these materials are summarized in Table 10.

Table 10.

The use of antimicrobial agents on bio-based polymers.

5.2. Crosslinking Methods

Crosslinking is a critical step that has a substantial impact on the mechanical and physicochemical properties of bio-printed constructions, as well as the biological behavior of loaded live cells [342]. Crosslinking techniques are often employed to enhance the barrier characteristics and mechanical integrity of biopolymer-based polymers utilized in food applications [26], making it crucial for developing resilient, sustainable packaging that is biodegradable and environmentally benign. There are different types of crosslinking, such as covalent, ionic, or physical, with covalent being the most stable [343].

Ionic interaction is a widely used method for crosslinking hydrogels in 3D bioprinting by adding multivalent cations to the polymer solution [342]. It allows for rapid crosslinking under mild conditions and physiological pH. However, it has limitations, such as weaker mechanical properties and the potential release of metal ions into the body [342]. Ionic interaction is commonly used for the 3D bioprinting of sodium alginate, an algae-derived anionic polysaccharide [344]. Carboxylic groups of adjacent polymer chains can bind with Mn+, resulting in an ionically crosslinked gel network [345]. The physicochemical and mechanical properties of alginate gels are influenced by the concentration of polymer solution [346]. The type of ionic crosslinker also affects material printability [347].

Calcium is a popular ionic crosslinker due to its high solubility in aqueous conditions, which results in quick gelation [348]. Due to the quick deposition of calcium ions outside the gel, the final 3D-printed structure may be less stable [349]. Adding ions to the polymer solution in 3D bioprinting must be controlled to ensure structural stability, as ionic crosslinkers can impact cell viability and proliferation [350]. While they protect cells from harsh conditions, they can also create non-physiological environments, reducing cell viability. Various cell types, including fibroblasts, myoblasts, endothelial cells, chondrocytes, and Schwann cells, have been incorporated into alginate solutions [342]. Excessive Ca2+ levels can be toxic and harm cell membranes [349].

Photo crosslinking is another notable crosslinking approach that is particularly important in 3D printing applications, as several 3D printing firms have used this crosslinking approach to manufacture their products [351]. Photo crosslinking is an efficient approach for transforming photocurable bioinks into 3D architectures [352]. It is inexpensive and can be done at room temperature, which saves electricity [353]. Other 3D bioprinting methods include stereolithography, digital light processing, laser-assisted approaches, and volumetric bioprinting [354]. These approaches use photo initiators to crosslink bioinks via chain-growth, step-growth, or redox-based processes. Additionally, thermal crosslinking, achieved by heating or chilling a polymer solution, is a simple method suitable for heat- or cold-resistant polymers, especially during 3D printing. However, it has a longer gelation time and lacks precise control over the degree of crosslinking [342]. Several studies involving the use of these materials are summarized in Table 11.

Table 11.

Application of bio-based natural polymer crosslinked coatings on food products.

5.3. Surface Modification Techniques

Numerous surface modification processes provide a range of properties, such as enhanced barrier properties, mechanical stability, and antimicrobial resistance, which are crucial for food packaging applications [359]. For a certain type of coating, choosing a suitable coating technique is necessary as it necessitates meticulous evaluation of mechanical stability, corrosion resistance, biocompatibility, and material properties since each approach presents distinct alternatives to create consistent coatings at room temperature [360]. It has also been used to deposit calcium orthophosphate coatings, which can have antimicrobial effects [361,362,363]. This method is frequently carried out using aqueous solutions, like wet-chemical deposition [361].

On the other hand, thermal spray coatings offer another method to enhance the mechanical and barrier properties of packaging films. There are various thermal spray processes, including flame spraying and plasma spraying, which provide dense coatings with improved adhesion and less porosity [243]. These processes can be particularly useful for creating robust, durable packaging materials. Plasma spraying is ideal for situations requiring higher density and lower porosity, ensuring better protection [364].

Micro-arc oxidation (MAO) is another technique used to improve surface properties such as corrosion resistance and wear resistance [365]. This technique has been effective in improving the properties of packaging materials that need to withstand harsh environments or maintain food quality for extended periods. Lastly, sol-gel coating is a chemical process that may produce films at low temperatures, making it ideal for coating sensitive bio-based materials [366]. The process uses liquid precursors, allowing for the formation of thin films without high energy consumption or degradation of sensitive components [367].

Sol-gel coatings are particularly beneficial for food packaging because they enhance barrier properties while maintaining the environmental benefits of low-energy consumption and minimal pollution [368]. In summary, various surface modification techniques such as electrodeposition, thermal spraying, MAO, and sol-gel coating are critical enhancement strategies in food packaging. These methods can significantly improve the mechanical strength, barrier properties, and antimicrobial functionality of bio-based packaging films, ensuring better food preservation and extending shelf life. Several studies involving the use of these materials are summarized in Table 12.

Table 12.

Surface modification methods on natural bio-based polymers.

6. Application for Food Preservation

As already established in previous sections, bio-based natural polymer coatings and films have gained significant attention in food preservation due to their ability to extend the shelf life of food products while maintaining quality and safety and being eco-friendliest to the environment [374,375,376]. These eco-friendly materials, thus, act as protective barriers against external factors like moisture, oxygen, and microbial contamination [377]. These materials function by creating a modified atmosphere around the food, which in turn minimizes oxidation, spoilage, and dehydration, and ultimately ensures that food products retain their nutritional value and sensory characteristics for longer periods [378]. Furthermore, the incorporation of active agents, such as antimicrobials and antioxidants, enhances the preservation properties of these films, making them ideal for various fresh and processed foods [379]. With growing consumer demand for sustainable packaging solutions, bio-based polymer coatings offer a promising approach to reducing food waste while supporting environmental sustainability. Their application thus ranges from fresh produce to different types of meats.

6.1. Fresh Produce

In contemporary agricultural practices, fruits and vegetables are recognized as essential produce due to their nutritional properties, such as dietary fiber, vitamins, minerals, etc. [380]. The preservation of postharvest quality is critical due to their high water content and respiratory activity [381]. Following harvest, fruits and vegetables naturally undergo a biological process known as respiration, during which the respiration rate elevates, leading to further maturation and eventual senescence [382]. During the packing and transit phases, these agricultural products are subjected to various physical stressors [383]. In this context, bio-based natural polymer coatings and films play a significant role by regulating the microenvironment, mitigating postharvest quality degradation, and extending shelf life due to their non-toxic properties. Table 13 details commonly utilized bio-based natural polymers, including polysaccharides such as gums, pectin, starch, chitosan, alginate, and cellulose [384].

These materials are typically translucent and edible, demonstrating excellent gas barrier properties conducive to maintaining freshness [288]. Although protein-based films are known to be moisture-sensitive, they are widely used owing to their robust mechanical properties. Additionally, lipids are incorporated into these films due to their hydrophobic characteristics, which help minimize water loss in fresh produce [385]. However, lipid films alone lack sufficient mechanical strength for standalone applications, necessitating their combination with other materials. Notably, the inclusion of lipids enhances the moisture barrier properties of the films [386]. Lastly, mucilage, although less well-known, is a promising substance derived from various plant species. The mucilage from Opuntia ficus-indica has garnered attention for its exceptional nutritional attributes, including high concentrations of calcium and potassium, excellent water retention capacity, and bioactive phytochemical properties.

These characteristics render it a favorable candidate for utilization in the food industry [387]. Mucilage-based coatings have the potential to effectively retain moisture and prolong shelf life [388]. For instance, coatings derived from Opuntia ficus-indica mucilage are particularly effective in preserving the quality of banana fruit and extending its shelf life [389]. Similarly, ref. [390] reported that cactus mucilage coatings enriched with ascorbic acid were highly efficient in maintaining the quality of roasted pecan nuts during storage. More examples of the application of edible coating/film on fruits and vegetables are in Table 13.

Table 13.

Application and research findings of specific bio-based natural polymer coatings/films on fruits and vegetables.

Table 13.

Application and research findings of specific bio-based natural polymer coatings/films on fruits and vegetables.

| Fruits and Vegetables | Edible Coating/Film Used | Outcomes | References |

|---|---|---|---|

| Pomegranate | Chitosan-based coating | Delayed fruit metabolic changes, higher antioxidant properties, maintained quality and reduced the fruit’s susceptibility to physiological disorders. | [298,391,392] |

| Arabic Gum and starch-based | The overall quality of the fruit was maintained, and shelf life was extended. | [393] | |

| Mango | Chitosan coating | Shelf life was extended, and the overall quality of the fruit was improved. | [42,394] |

| Banana | Opuntia ficus-indica mucilage coating | Extended the banana’s shelf life and preserved its quality. | [389] |

| Arabic Gum and chitosan | Coating efficiently maintained the quality of the bananas, preventing weight loss and preserving fruit firmness, and extended shelf life up to 33 days. | [395] | |

| Starch coating | The starch-based edible coating effectively delayed ethylene production, reduced respiration rates, and slowed chlorophyll degradation, helping to retain fruit firmness and reduce weight loss. This improved the commercial value of bananas and extended their shelf life by 12 days. | [396] | |

| Guava | Chitosan and alginate-based coating | Enhance the quality of fruit and retain the nutritional parameters. | [397] |

| Arabic Gum-based edible coating. | These applications reduced weight loss, decay, and Rhizopus rot while increasing marketability and delaying fruit softening. They preserved chlorophyll, vitamin C, and acidity, and slowed changes in TSS and TSS/acid ratios. Overall, the coatings significantly extended the shelf life compared to untreated fruits. | [398] | |

| carboxymethyl cellulose-based edible coating | The treatment effectively delayed weight loss and decay in guava fruit while maintaining firmness, sugars, acidity, ascorbic acid, phenol content, and sensory quality for up to 12. | [399] | |

| Mandarins | Arabic Gum–Zinc Oxide Nanoparticles Composite Coating | Gum Arabic enriched with ZnO-NPs effectively extended the storage period of ‘Kinnow’ mandarins by reducing rind disorders, minimizing metabolic rate and electrolyte leakage, and preserving fruit texture and overall quality. | [400] |

| Chitosan-based | The coating preserved bioactive compounds and organic acids effectively. | [47,401] | |

| Carboxymethyl cellulose coating | Effectively preserved the postharvest quality of “Kinnow” mandarins, improved membrane integrity and increased the activity of antioxidant enzymes. | [402] | |

| Alginate-based edible coating | Extended the shelf life after harvest and preserved the quality of the fruit. | [403] | |

| Pecan nuts | cactus mucilage coatings | Coatings effectively preserved the quality of microwave-roasted pecan nuts during storage, maintaining key physicochemical and phytochemical properties, reducing enzyme activities, and enhancing antioxidant properties. | [390] |

| Pear | Chitosan-based coating | The coating extended the post-harvest life of ‘Yali’ pears by reducing weight loss and maintaining quality. | [52] |

6.2. Meat and Seafood

The shelf life of some foods can be drastically shortened without the use of chemical additives or preservation methods; raw meat and seafood are especially susceptible [404]. Their high moisture and nutritional content, delicate connective tissues, and neutral pH all contribute to their perishability by providing the ideal conditions for microbial development and spoiling [405]. The initial microbial load and the preservation techniques used have a significant impact on shelf life [406,407]. Any physical, chemical, or sensory change that makes food unsuitable for human eating is referred to as food spoiling [408]. Microbial metabolism frequently causes this degradation, which breaks down dietary ingredients and results in unfavorable alterations in texture, appearance, and odor [409]. Microbial contamination is frequently caused by the natural microbiota of animals as well as environmental and handling factors during production [410]. This bacterial growth can lead to slime production, unpleasant smells, and structural deterioration, all of which can compromise the product’s quality and safety [411].

Factors such as vitamin E levels, fatty acid composition, and prooxidants like free iron significantly influence lipid oxidation, resulting in the formation of compounds that compromise color, nutritional value, and overall quality [412]. The breakdown of proteins, lipids, and carbohydrates, which occurs even at low temperatures (5 °C) due to enzymatic autolysis, leads to meat softening, discoloration, and the promotion of microbial growth and spoilage [413]. Globally, about 3.5 billion kg of poultry and meat are wasted annually across retail, foodservice, and consumer levels, causing major economic and environmental impacts. Microbial spoilage is a leading cause of this meat degradation [411]. Therefore, effective preservation of raw meat and seafood is crucial to prevent the loss of this nutritionally rich natural resource [414]. Recent research has primarily focused on the use of bio-based natural polymer coatings and films to maintain the quality of fresh meat and seafood, as shown in Table 14. Among these, chitosan-coated films have emerged as the most widely utilized bio-preservation films in meat products [354]. For example, ref. [415] studied the usage of an edible coating made of eugenol emulsion mixed with chitosan, and the findings showed that the coating helped preserve the meat’s red color for 14 days and prevented deterioration. Even after 14 days of storage, the meat’s pH, total microbial count, and TVB-N levels remained within acceptable quality criteria, suggesting that the shelf life was increased from 6 to 14 days. More examples in Table 14.

Table 14.

Application of bio-based natural polymer coatings/films on meat or seafood.

6.3. Bakery and Confectionery Products

Bakery products constitute one of the most significant staple foods consumed daily by individuals across the globe [422]. In many industrialized nations, biscuits represent a substantial segment of the confectionery industry, and their consumption is similarly experiencing rapid growth in emerging economies [423]. However, the impact of confectionery products on economic, environmental, and health sustainability is comparatively underrepresented; for instance, in developed countries, bread accounts for nearly half of the daily recommended carbohydrate intake [424]. Bakery items, such as cakes and bread, typically exhibit a short shelf life of three to five days at room temperature in the absence of preservatives [425]. During this period, they undergo various physical, chemical, and microbial changes. Physical and chemical alterations lead to a decline in freshness, texture, and flavor, while microbial spoilage caused by the growth of bacteria, yeast, and mold adversely affects their visual appeal [426]. The emergence of off-flavors and mycotoxins in bread products because of microbiological spoilage poses significant public health risks and results in considerable financial losses for both the baking industry and consumers [427].

To mitigate these challenges, preservation methods are essential; however, the most employed preservation techniques have demonstrated several notable disadvantages, including condensation issues, inadequate penetration capabilities, and high costs [4,7]. Advancements in food packaging technology have facilitated the development of active packaging systems, which encompass antimicrobial packaging, antioxidant packaging, moisture absorbers, ethanol emitters, and carbon dioxide emitters. Recent innovations in active packaging include the creation of nanomaterial packaging utilizing metallic nanoparticles, and edible coatings/films containing proteins [75], each of which presents distinct advantages and disadvantages. Several studies in bio-based natural polymer coatings/films for bakery products are summarized in Table 15.

Table 15.

Application of bio-based natural polymer coatings/films on bakery and confectionery products.

6.4. Dairy Products