Impact of Different Dehydration Methods on Drying Efficiency, Nutritional and Physico-Chemical Quality of Strawberries Slices (Fragaria ananassa)

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Drying Processes

- Hot air-drying (HA)

- Freeze-drying (FD)

- PEF-assisted freeze-drying (PEFFD)

2.3. Scanning Electron Microscopy (SEM)

2.4. Physico-Chemical Analysis

- Moisture Content

- Rehydration capacity

- pH, titratable acidity, and water activity (aw)

- Ascorbic acid content

- Texture

- Color Parameters

2.5. Analysis of the Drying Kinetics

2.6. Sensory Evaluation

2.7. Statistical Analysis

3. Results and Discussion

3.1. Effect of Different Dehydration Methods on Microstructure

3.2. Effect of Different Dehydration Methods on Physical–Chemical Characteristics

- Moisture, rehydration, and aw

- pH, titratable acidity, ascorbic acid

- Texture

- Color

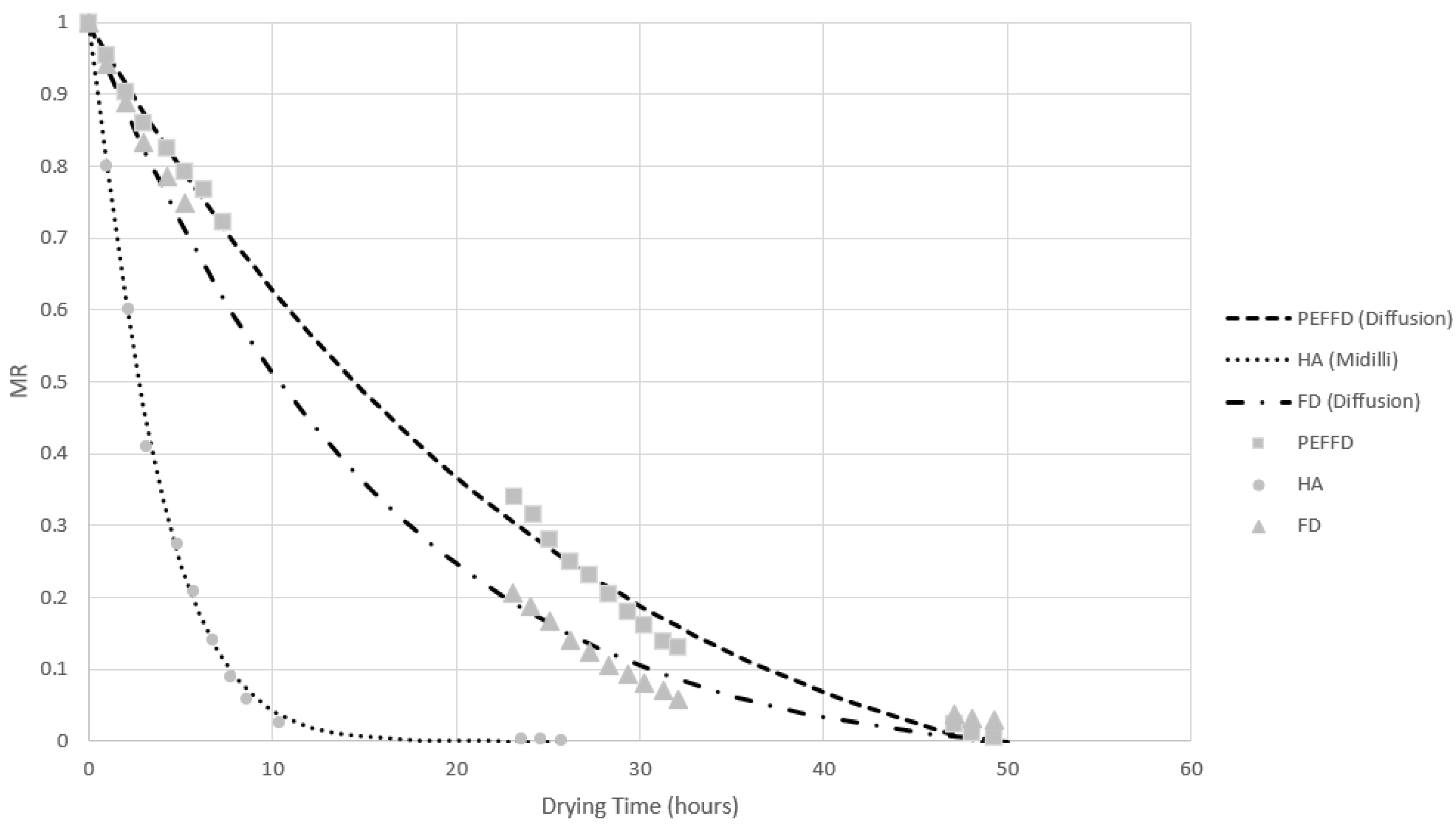

3.3. Drying Kinetics

3.4. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAOSTAT Crops. Food and Agriculture Organization of the United Nations. 2020. Available online: https://www.fao.org/faostat/en/#home (accessed on 1 June 2025).

- GlobalAgrimar, Frutos-Morango. GPP, Gabinete de Planeamento, Políticas e Administração Geral, Portugal. 2024. Available online: https://www.gpp.pt/index.php/produtos/produtos (accessed on 1 June 2025).

- Xu, B.; Chen, J.; Sylvain Tiliwa, E.; Yan, W.; Roknul Azam, S.M.; Yuan, J.; Wei, B.; Zhou, C.; Ma, H. Effect of Multi-Mode Dual-Frequency Ultrasound Pretreatment on the Vacuum Freeze-Drying Process and Quality Attributes of the Strawberry Slices. Ultrason. Sonochem. 2021, 78, 105714. [Google Scholar] [CrossRef]

- Zhang, L.; Qiao, Y.; Wang, C.; Liao, L.; Shi, D.; An, K.; Hu, J.; Wang, J.; Shi, L. Influence of High Hydrostatic Pressure Pretreatment on Properties of Vacuum-Freeze Dried Strawberry Slices. Food Chem. 2020, 331, 127203. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Liao, L.; Qiao, Y.; Wang, C.; Shi, D.; An, K.; Hu, J. Effects of Ultrahigh Pressure and Ultrasound Pretreatments on Properties of Strawberry Chips Prepared by Vacuum-Freeze Drying. Food Chem. 2020, 303, 125386. [Google Scholar] [CrossRef] [PubMed]

- Barba, F.J.; Parniakov, O.; Pereira, S.A.; Wiktor, A.; Grimi, N.; Boussetta, N.; Saraiva, J.A.; Raso, J.; Martin-Belloso, O.; Witrowa-Rajchert, D.; et al. Current Applications and New Opportunities for the Use of Pulsed Electric Fields in Food Science and Industry. Food Res. Int. 2015, 77, 773–798. [Google Scholar] [CrossRef]

- Cam, I.B.; Basunal Gulmez, H.; Eroglu, E.; Topuz, A. Strawberry Drying: Development of a Closed-Cycle Modified Atmosphere Drying System for Food Products and the Performance Evaluation of a Case Study. Dry. Technol. 2018, 36, 1460–1473. [Google Scholar] [CrossRef]

- Parniakov, O.; Bals, O.; Lebovka, N.; Vorobiev, E. Pulsed Electric Field Assisted Vacuum Freeze-Drying of Apple Tissue. Innov. Food Sci. Emerg. Technol. 2016, 35, 52–57. [Google Scholar] [CrossRef]

- Ando, Y.; Hagiwara, S.; Nabetani, H.; Sotome, I.; Okunishi, T.; Okadome, H.; Orikasa, T.; Tagawa, A. Improvements of Drying Rate and Structural Quality of Microwave-Vacuum Dried Carrot by Freeze-Thaw Pretreatment. LWT 2019, 100, 294–299. [Google Scholar] [CrossRef]

- Jiang, D.-L.; Wang, Q.-H.; Huang, C.; Sutar, P.P.; Lin, Y.-W.; Okaiyeto, S.A.; Lin, Z.-F.; Wu, Y.-T.; Ma, W.-M.; Xiao, H.-W. Effect of Various Different Pretreatment Methods on Infrared Combined Hot Air Impingement Drying Behavior and Physicochemical Properties of Strawberry Slices. Food Chem. X 2024, 22, 101299. [Google Scholar] [CrossRef]

- Nowak, D.; Jakubczyk, E. Effect of Pulsed Electric Field Pre-Treatment and the Freezing Methods on the Kinetics of the Freeze-Drying Process of Apple and Its Selected Physical Properties. Foods 2022, 11, 2407. [Google Scholar] [CrossRef]

- Raso, J.; Frey, W.; Ferrari, G.; Pataro, G.; Knorr, D.; Teissie, J.; Miklavčič, D. Recommendations Guidelines on the Key Information to Be Reported in Studies of Application of PEF Technology in Food and Biotechnological Processes. Innov. Food Sci. Emerg. Technol. 2016, 37, 312–321. [Google Scholar] [CrossRef]

- Pino-Hernández, E. Inovação e Qualidade Para a Indústria de Hortofrutícolas: Conservação, Extração e Liofilização Através de Tecnologias Emergentes Não Térmicas. In Lecturas Emergentes en Los Campos de la Ciencia, Tecnología y Técnica; Javier, F., Rodríguez, C., Budea, A.S., Eds.; Peter Lang: Lausanne, Switzerland, 2025; ISBN 9783631934548. [Google Scholar]

- Izli, N.; Polat, A. Freeze and Convective Drying of Quince (Cydonia Oblonga Miller.): Effects on Drying Kinetics and Quality Attributes. Heat Mass Transf. 2019, 55, 1317–1326. [Google Scholar] [CrossRef]

- Ansar; Nazaruddin; Azis, A.D. New Frozen Product Development from Strawberries (Fragaria Ananassa Duch.). Heliyon 2020, 6, e05118. [Google Scholar] [CrossRef] [PubMed]

- Chauhan, O.P.; Sayanfar, S.; Toepfl, S. Effect of Pulsed Electric Field on Texture and Drying Time of Apple Slices. J. Food Sci. Technol. 2018, 55, 2251–2258. [Google Scholar] [CrossRef] [PubMed]

- Ikhsan, L.N.; Chin, K.Y.; Ahmad, F. Methods of the Dehydration Process and Its Effect on the Physicochemical Properties of Stingless Bee Honey: A Review. Molecules 2022, 27, 7243. [Google Scholar] [CrossRef]

- Ghoshal, G. Comprehensive Review on Pulsed Electric Field in Food Preservation: Gaps in Current Studies for Potential Future Research. Heliyon 2023, 9, e17532. [Google Scholar] [CrossRef]

- Barbosa-Cánovas, G.V.; Anthony, J.; Fontana, J.; Schmidt, S.J.; Labuza, T.P. Water Activity in Foods: Fundamentals and Application; Barbosa-Cánovas, G.V., Fontana, A.J., Schmidt, S.J., Labuza, T.P., Eds.; Wiley: Hoboken, NJ, USA, 2020; Volume 2, ISBN 9781118768310. [Google Scholar]

- Zitouni, H.; Hssaini, L.; Ouaabou, R.; Viuda-Martos, M.; Hernández, F.; Ercisli, S.; Ennahli, S.; Messaoudi, Z.; Hanine, H. Exploring Antioxidant Activity, Organic Acid, and Phenolic Composition in Strawberry Tree Fruits (Arbutus unedo L.) Growing in Morocco. Plants 2020, 9, 1677. [Google Scholar] [CrossRef]

- Thuy, N.M.; Ha, H.T.N.; Tai, N.V. Kinetics of Ascorbic Acid Loss during Thermal Treatment in Different PH Buffer Solutions and the Presence of Oxygen. Food Res. 2020, 4, 1513–1519. [Google Scholar] [CrossRef]

- Toepfl, S.; Mathys, A.; Heinz, V.; Knorr, D. Review: Potential of High Hydrostatic Pressure and Pulsed Electric Fields for Energy Efficient and Environmentally Friendly Food Processing. Food Rev. Int. 2006, 22, 405–423. [Google Scholar] [CrossRef]

- Dewhirst, R.A.; Fry, S.C. The Oxidation of Dehydroascorbic Acid and 2,3-Diketogulonate by Distinct Reactive Oxygen Species. Biochem. J. 2018, 475, 3451–3470. [Google Scholar] [CrossRef]

- Qiu, J.; Vuist, J.E.; Boom, R.M.; Schutyser, M.A.I. Formation and Degradation Kinetics of Organic Acids during Heating and Drying of Concentrated Tomato Juice. LWT 2018, 87, 112–121. [Google Scholar] [CrossRef]

- Suehr, Q.J.; Chen, F.; Anderson, N.M.; Keller, S.E. Effect of PH on Survival of Escherichia Coli O157, Escherichia Coli O121, and Salmonella Enterica during Desiccation and Short-Term Storage. J. Food Prot. 2020, 83, 211–220. [Google Scholar] [CrossRef] [PubMed]

- Vieira da Silva Júnior, E.; Lins de Melo, L.; Batista de Medeiros, R.A.; Pimenta Barros, Z.M.; Azoubel, P.M. Influence of Ultrasound and Vacuum Assisted Drying on Papaya Quality Parameters. LWT 2018, 97, 317–322. [Google Scholar] [CrossRef]

- Gunness, P.; Kravchuk, O.; Nottingham, S.M.; D’Arcy, B.R.; Gidley, M.J. Sensory Analysis of Individual Strawberry Fruit and Comparison with Instrumental Analysis. Postharvest Biol. Technol. 2009, 52, 164–172. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, Y.; Zhu, C.; Wei, M. Effects of Different Drying Methods on the Physical Properties and Sensory Characteristics of Apple Chip Snacks. LWT 2022, 154, 112829. [Google Scholar] [CrossRef]

| Drying Methods | PEF Pre-Treatment | Freezing Temperature (°C) | Freezing Duration (h) | Condenser Temperature (°C) | Vacuum Pressure (mBar) | Drying Temperature (°C) | Air Flow (m·s−1) |

|---|---|---|---|---|---|---|---|

| HA | None | - | - | - | - | 60 ± 2 | 0.5 |

| FD | −40 | 4 | −67 | 0.055 | - | - | |

| PEFFD | 1 kV/cm, 27 A, 3.2 kJ/kg |

| No | Model Name | Model | References * |

|---|---|---|---|

| 1 | Page | [14] | |

| 2 | Two Term | ||

| 3 | Two Term Exponential | ||

| 4 | Diffusion Approach | ||

| 5 | Midilli et al |

| Characteristics | HA | FD | PEFFD | |

|---|---|---|---|---|

| Color (ΔE) | HA | 0 | 9.66 | 10.49 |

| FD | 9.66 | 0 | 6.96 | |

| Moisture content (%) | 13.79 ± 0.01 a | 9.49 ± 0.27 b | 8.87 ± 0.09 c | |

| aw | 0.290 ± 0.00 a | 0.286 ± 0.00 b | 0.284 ± 0.01 c | |

| Cutting strength (N) | 59.3 ± 7.9 a | 19.9 ± 3.4 b | 14.0 ± 3.2 c | |

| Rehydration (%) | 53.11 ± 0.12 c | 60.42 ± 0.08 b | 64.90 ± 0.10 a | |

| pH | 3.61 ± 0.01 a | 3.53 ± 0.01 a, b | 3.39 ± 0.09 b | |

| Titratable acidity (mg/100 g) | 27.03 ± 0.15 b | 30.07 ± 0.35 a | 30.35 ± 0.26 a | |

| Ascorbic acid (mg/100 g) | 6.48 ± 0.17 c | 44.63 ± 0.16 a | 36.99 ± 0.10 b | |

| Model | Treatment | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| HA | FD | PEFFD | |||||||

| R2 | X2 | RMSE | R2 | X2 | RMSE | R2 | X2 | RMSE | |

| PAGE | 0.999 | 0.00002 | 0.01323 | 0.998 | 0.00003 | 0.01564 | 0.994 | 0.00009 | 0.02753 |

| TwoTerms | 0.998 | 0.00003 | 0.01616 | 0.997 | 0.00005 | 0.02011 | 0.997 | 0.00005 | 0.01825 |

| TwoTermsExp | 0.998 | 0.00002 | 0.01342 | 0.996 | 0.00008 | 0.02133 | 0.994 | 0.00008 | 0.02692 |

| Diffusion | 0.998 | 0.00034 | 0.01654 | 0.997 | 0.00005 | 0.02035 | 0.997 | 0.00004 | 0.01824 |

| Midilli | 0.999 | 0.00021 | 0.01321 | 0.998 | 0.00003 | 0.01481 | 0.997 | 0.00004 | 0.01846 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antunes, P.; Dias, S.; Gonçalves, D.; Orvalho, T.; Evangelista, M.B.; Pino-Hernández, E.; Alves, M. Impact of Different Dehydration Methods on Drying Efficiency, Nutritional and Physico-Chemical Quality of Strawberries Slices (Fragaria ananassa). Processes 2025, 13, 2065. https://doi.org/10.3390/pr13072065

Antunes P, Dias S, Gonçalves D, Orvalho T, Evangelista MB, Pino-Hernández E, Alves M. Impact of Different Dehydration Methods on Drying Efficiency, Nutritional and Physico-Chemical Quality of Strawberries Slices (Fragaria ananassa). Processes. 2025; 13(7):2065. https://doi.org/10.3390/pr13072065

Chicago/Turabian StyleAntunes, Patrícia, Sara Dias, Diogo Gonçalves, Telma Orvalho, Marta B. Evangelista, Enrique Pino-Hernández, and Marco Alves. 2025. "Impact of Different Dehydration Methods on Drying Efficiency, Nutritional and Physico-Chemical Quality of Strawberries Slices (Fragaria ananassa)" Processes 13, no. 7: 2065. https://doi.org/10.3390/pr13072065

APA StyleAntunes, P., Dias, S., Gonçalves, D., Orvalho, T., Evangelista, M. B., Pino-Hernández, E., & Alves, M. (2025). Impact of Different Dehydration Methods on Drying Efficiency, Nutritional and Physico-Chemical Quality of Strawberries Slices (Fragaria ananassa). Processes, 13(7), 2065. https://doi.org/10.3390/pr13072065