Study on the Structure of a Novel CMS@C12H22O14Fe Suppressant and Its Mechanism of Inhibiting Coal Dust Deflagration

Abstract

1. Introduction

2. Experiment

2.1. Preparation of Suppressors

2.1.1. Experimental Raw Materials

2.1.2. Preparation of Suppressor

2.2. Characterization and Analysis of Experimental Materials

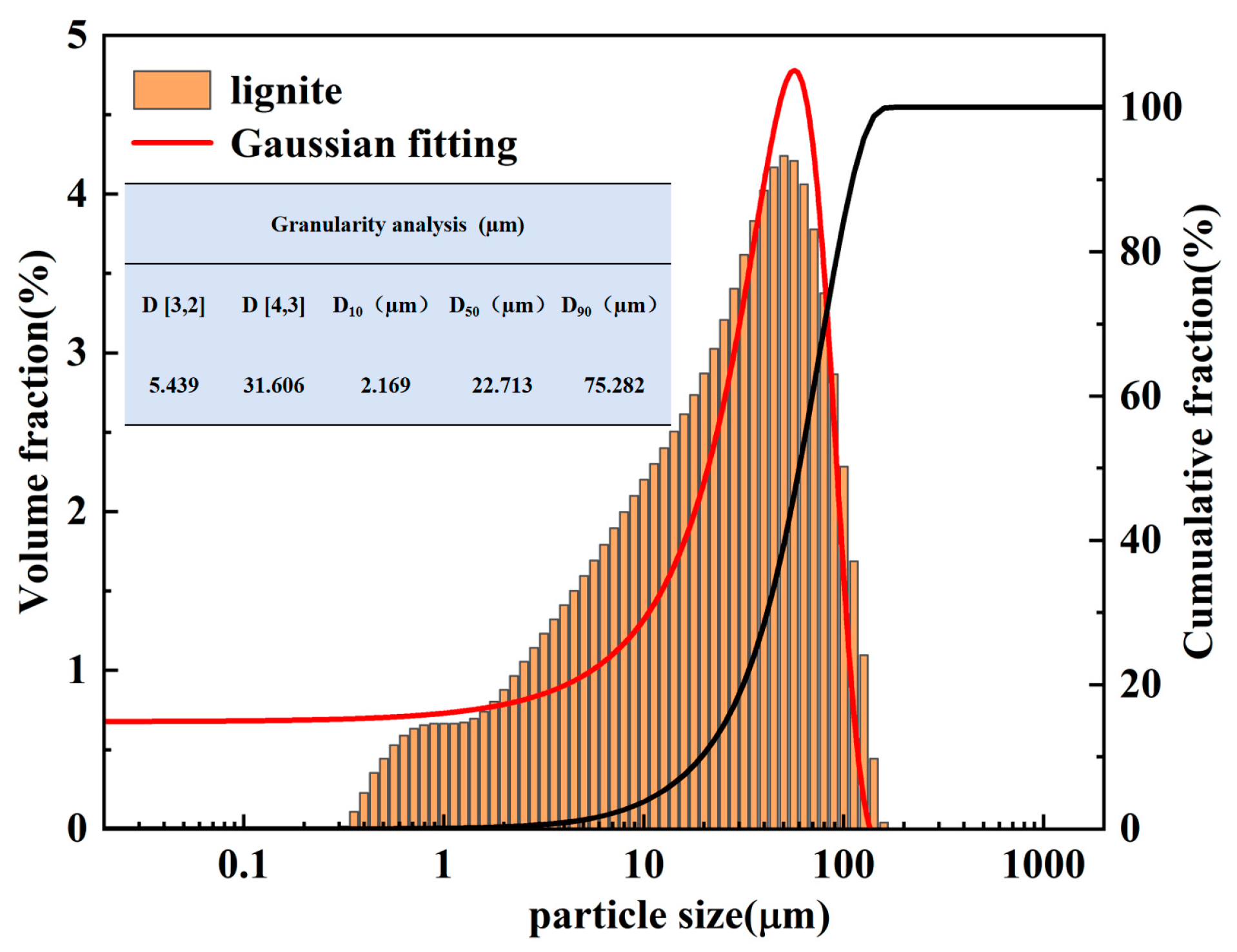

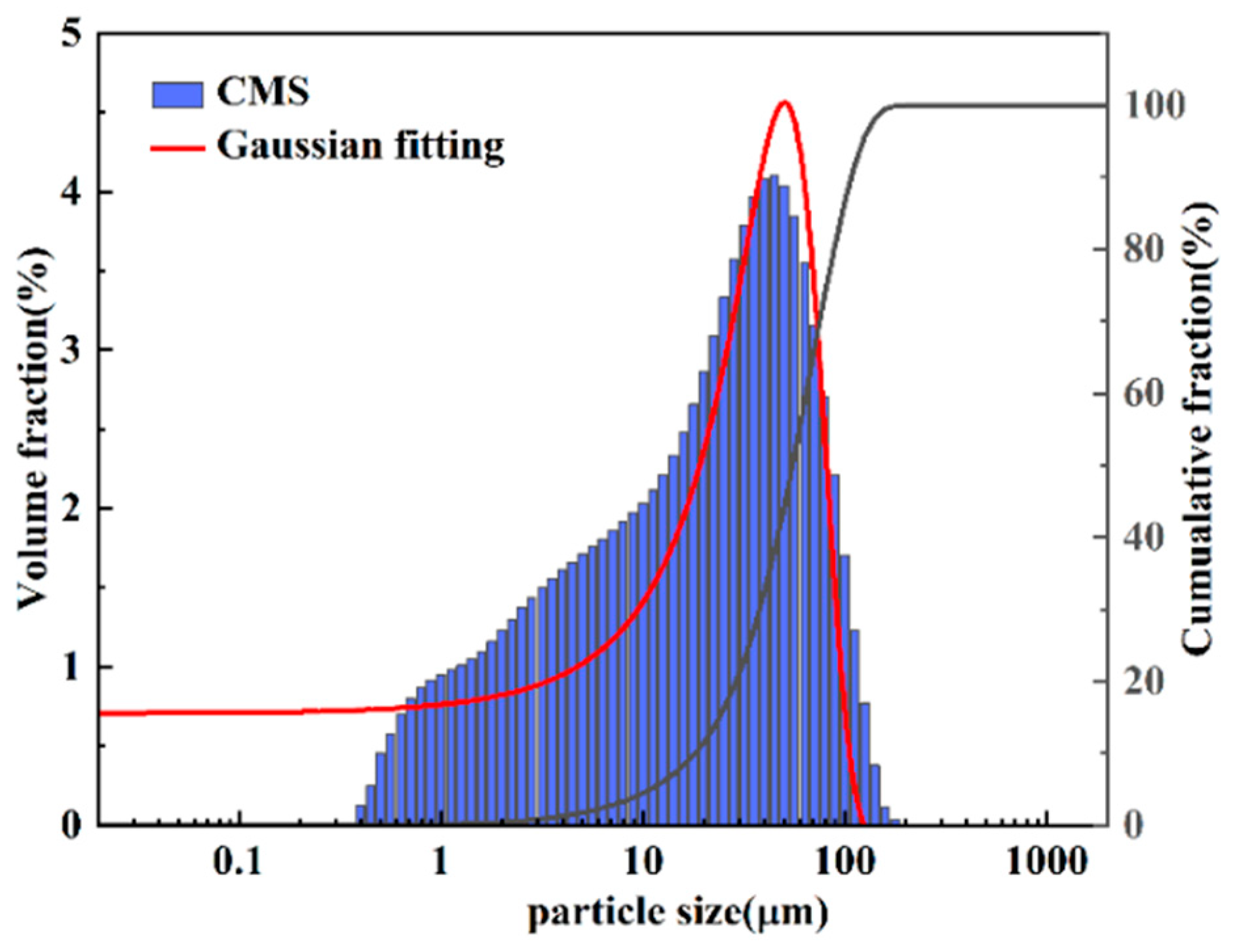

2.2.1. Particle Size Distribution

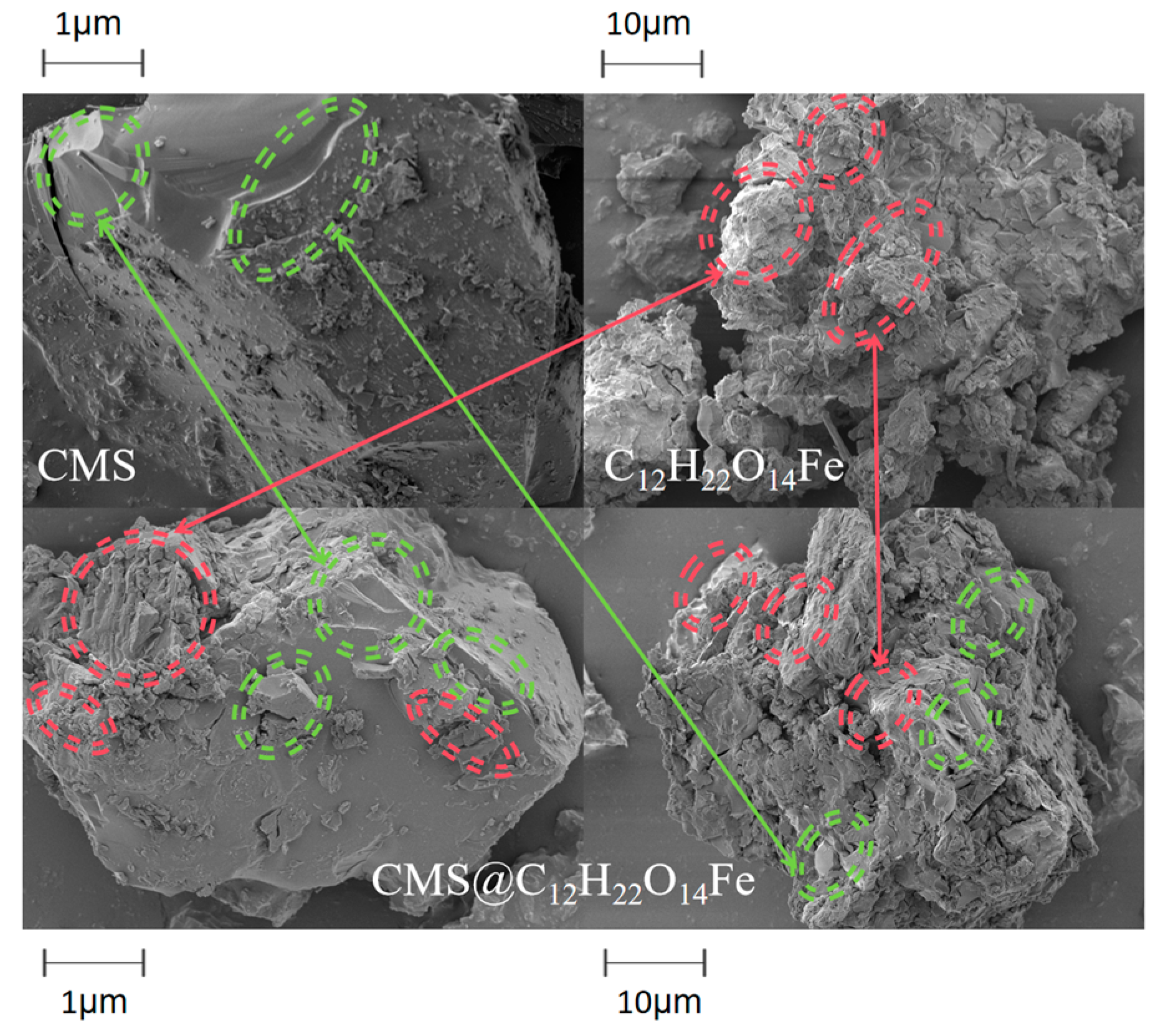

2.2.2. Morphological Analysis

2.2.3. X-Ray Diffraction Analysis

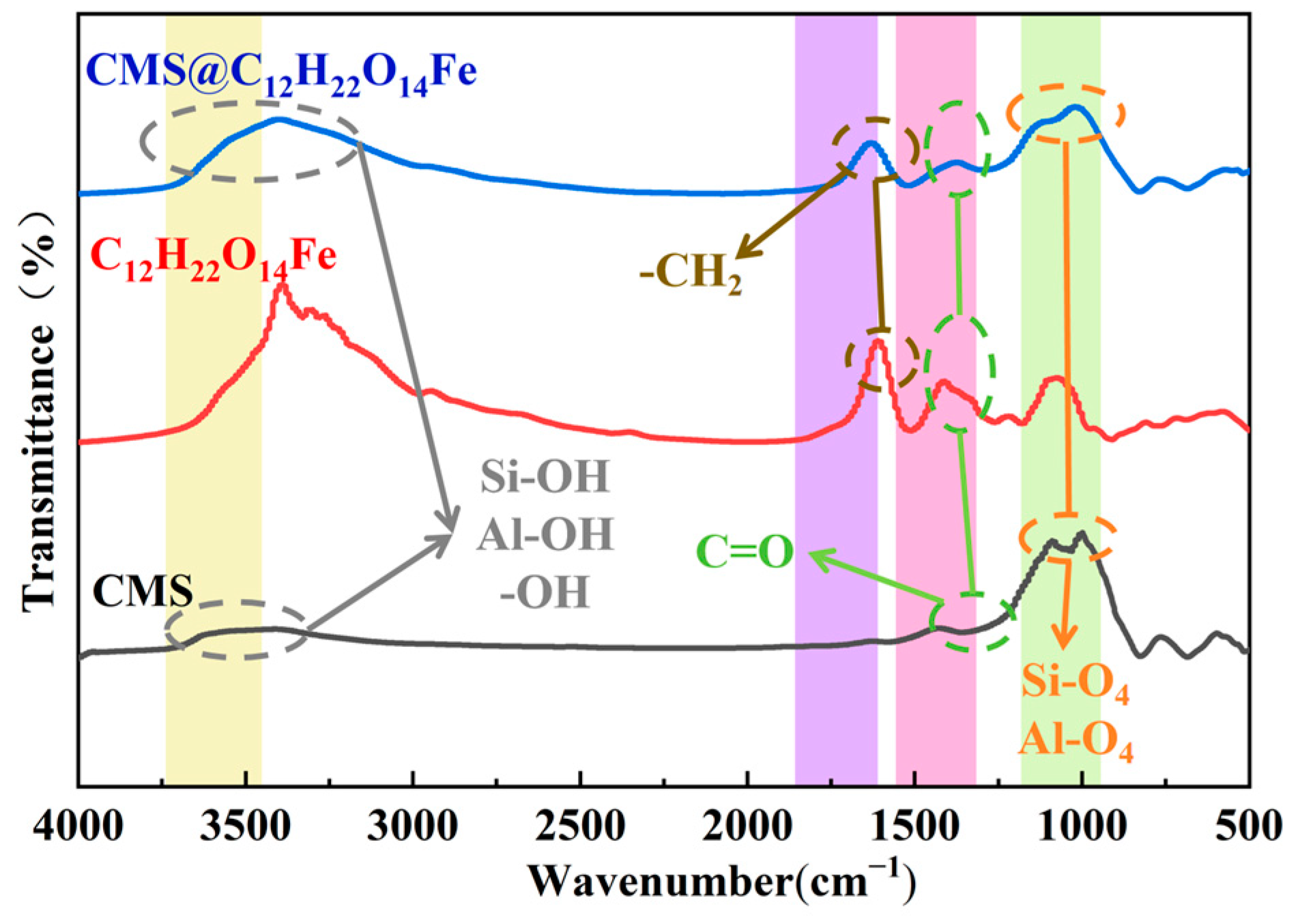

2.2.4. Infrared Spectrum Analysis

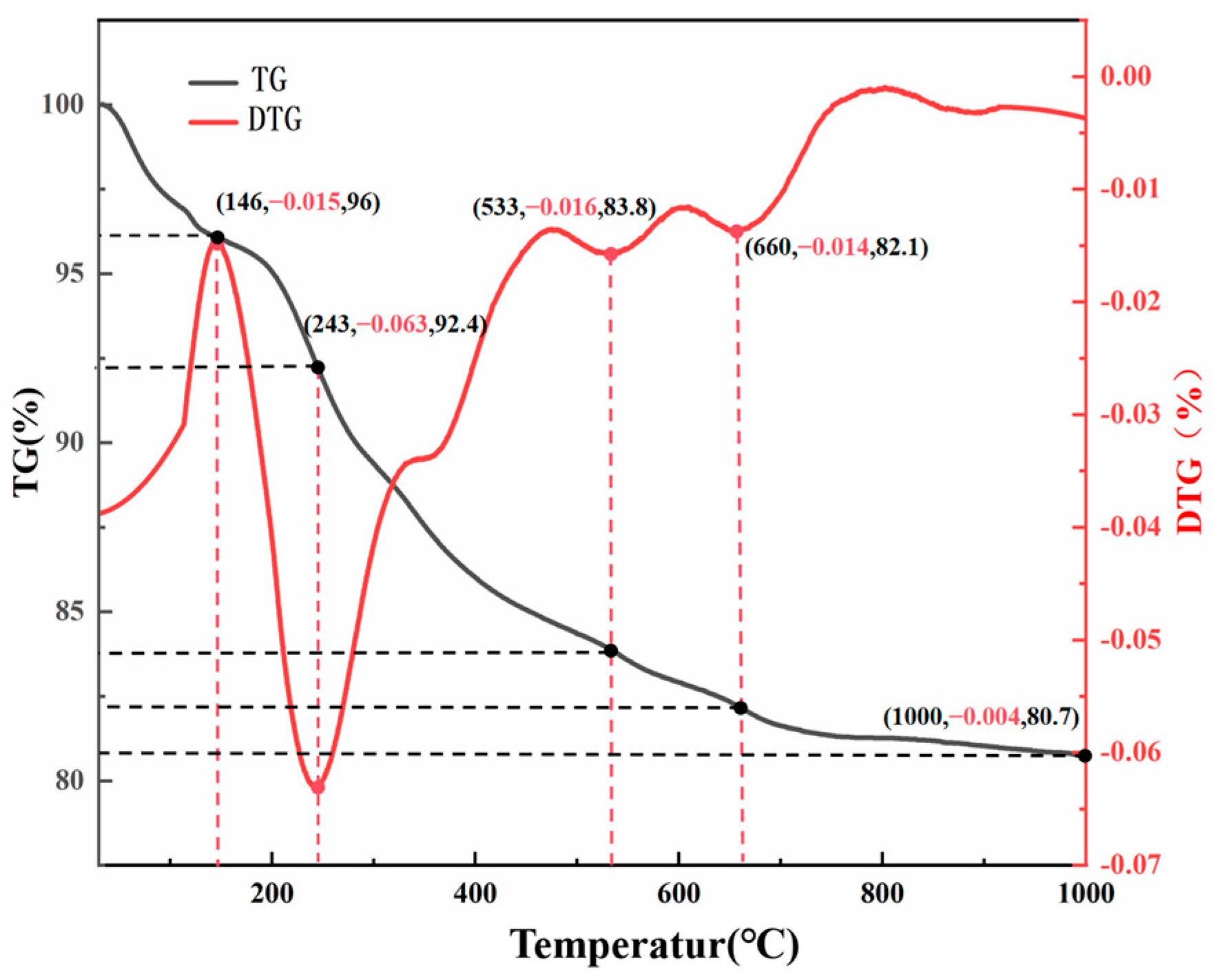

2.2.5. Thermogravimetric Analysis

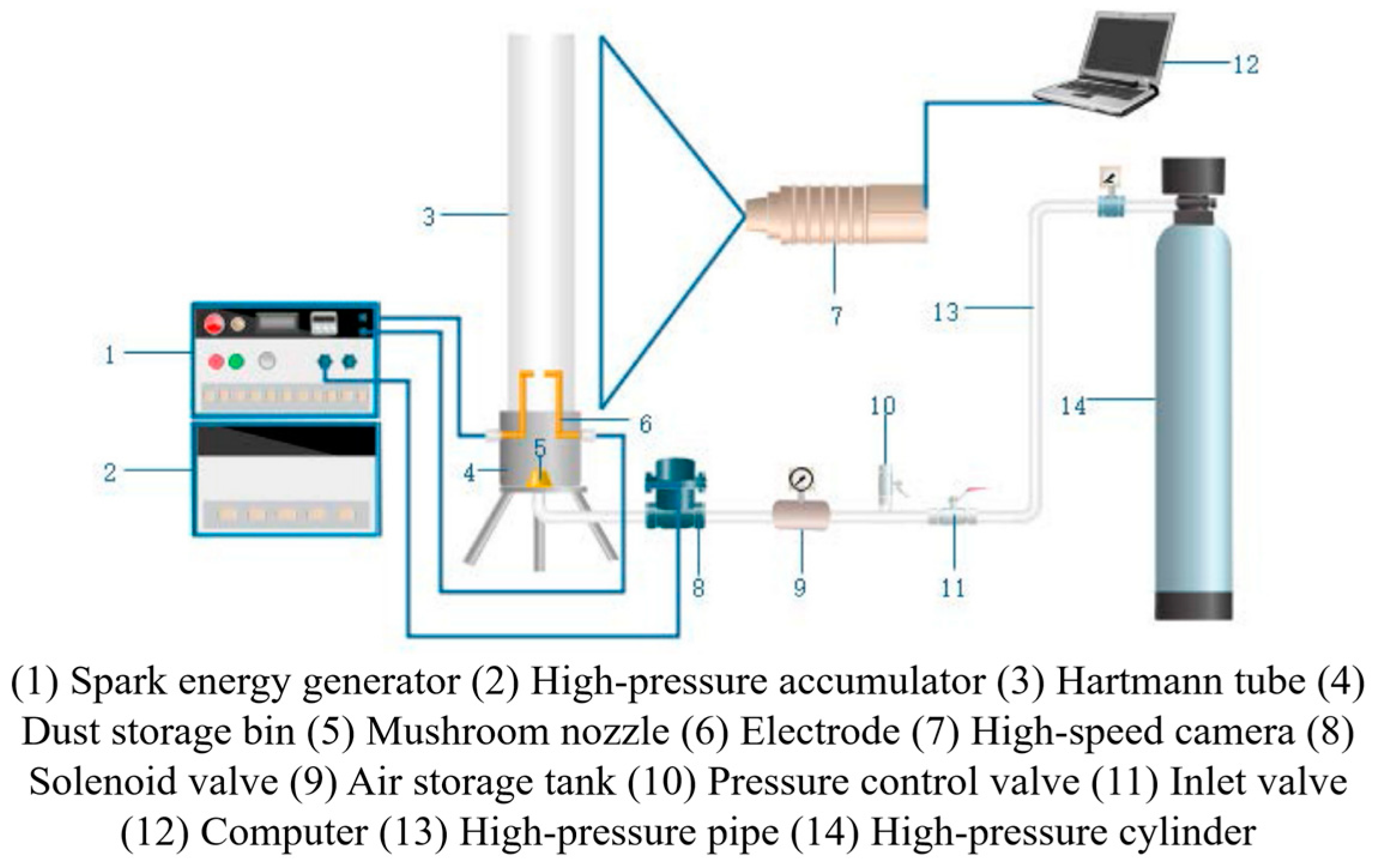

2.3. Experimental Equipment

3. Results and Analysis

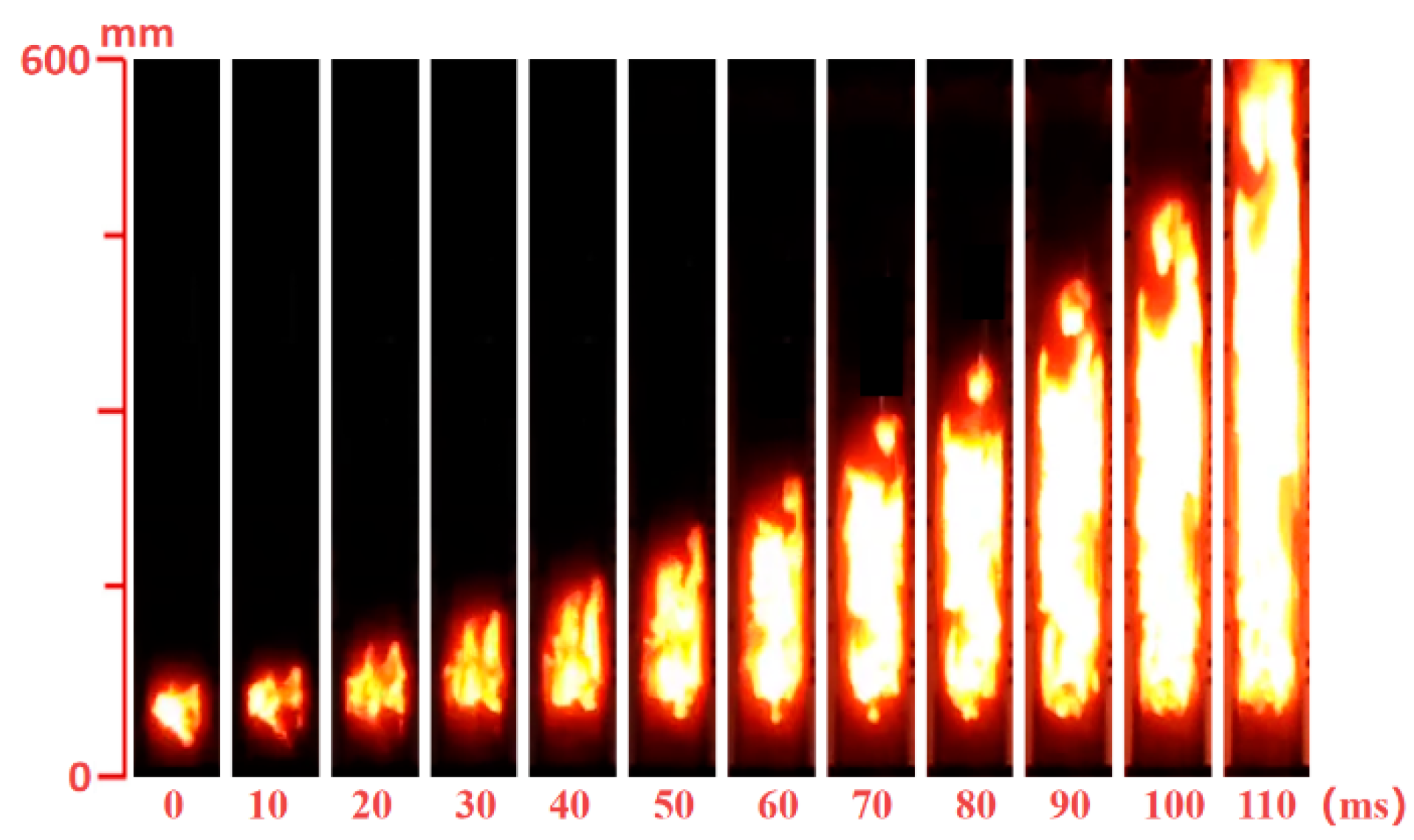

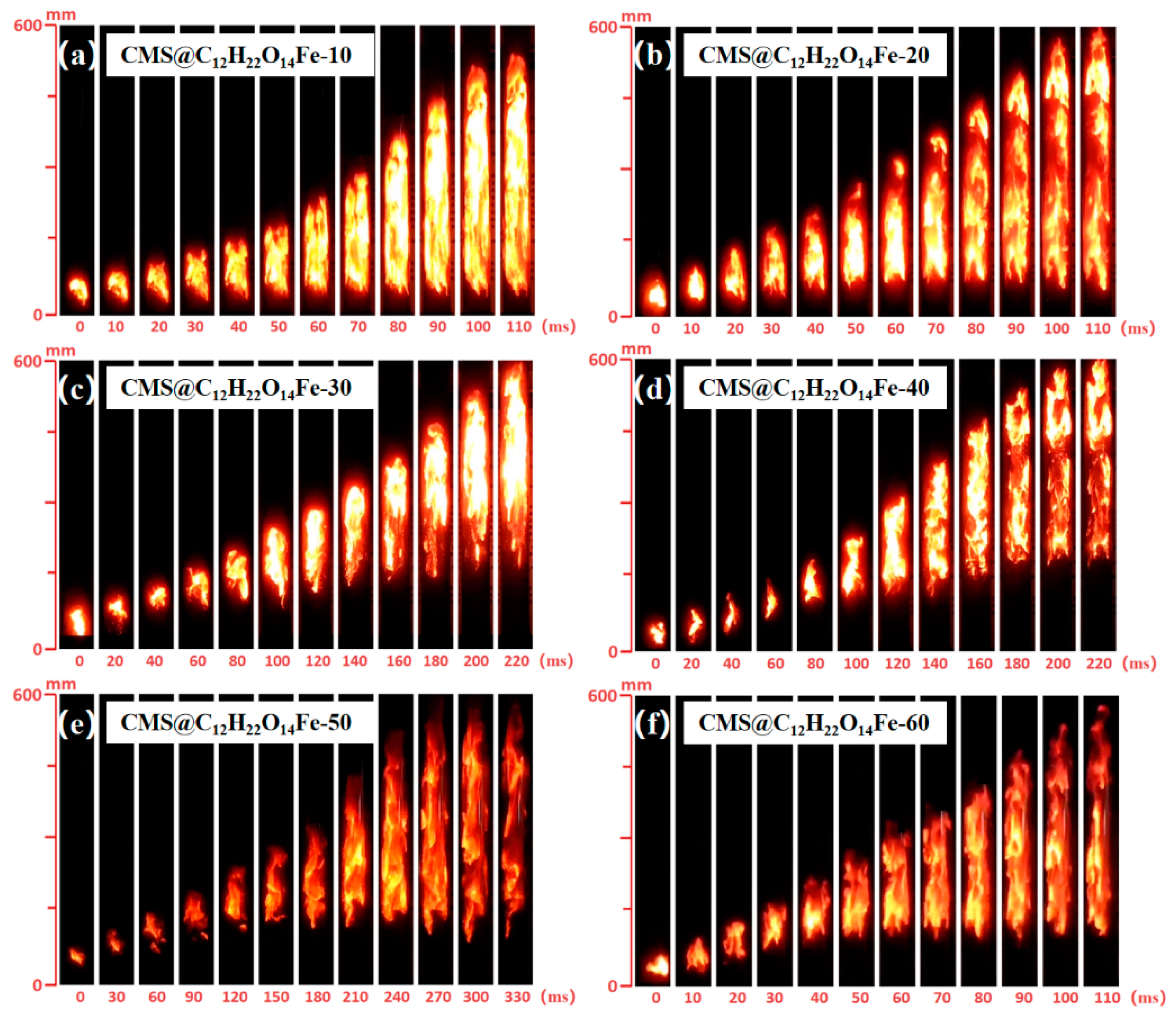

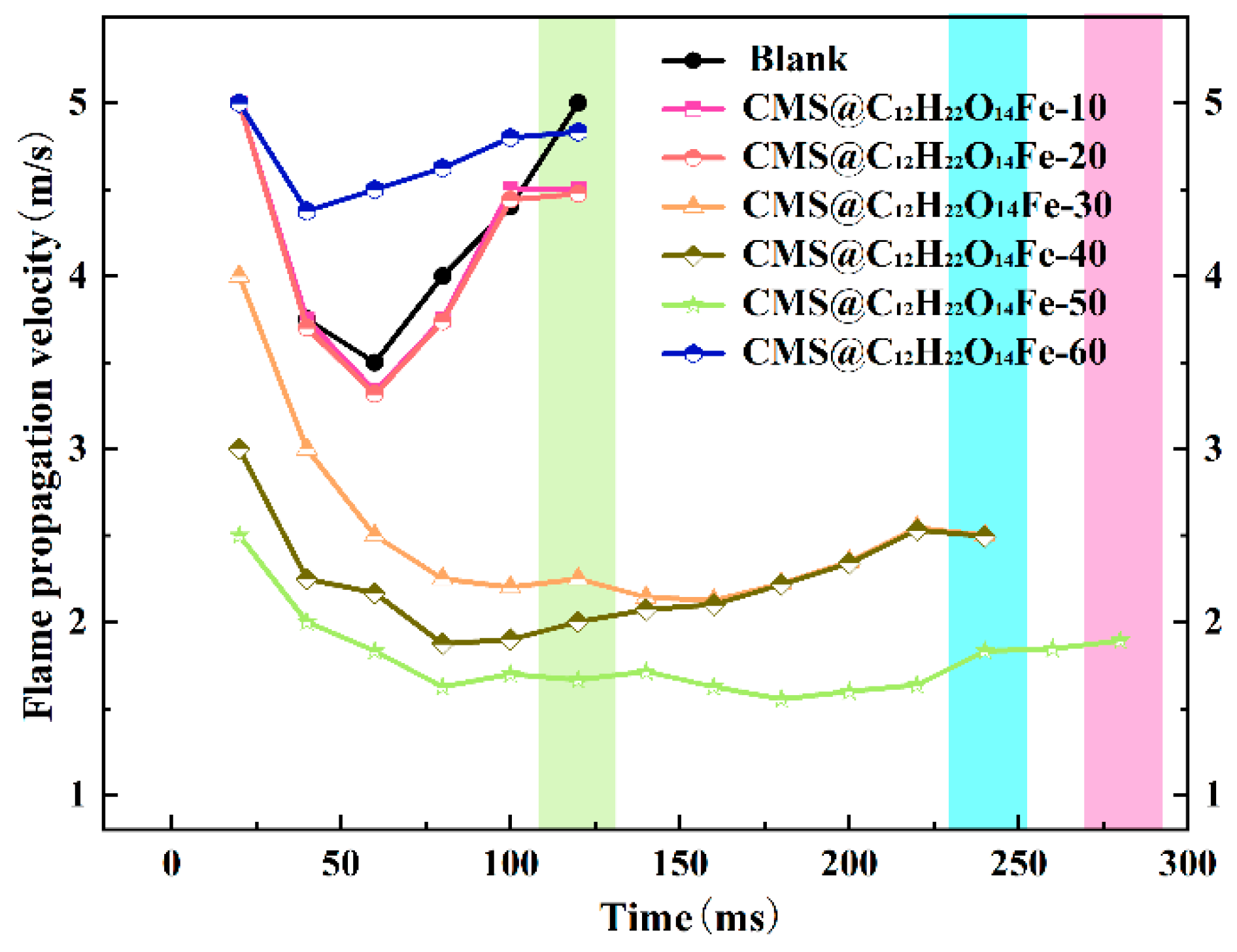

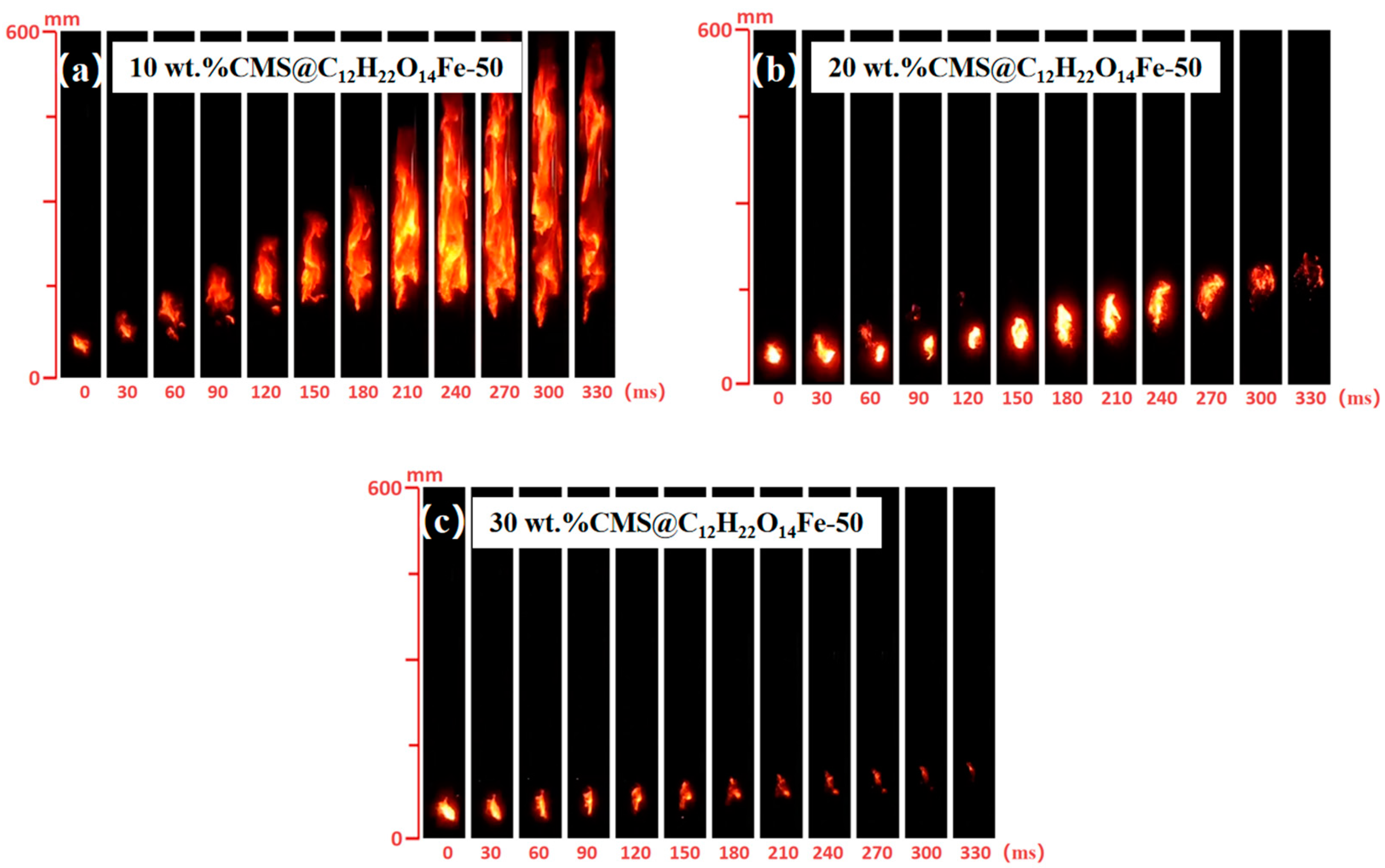

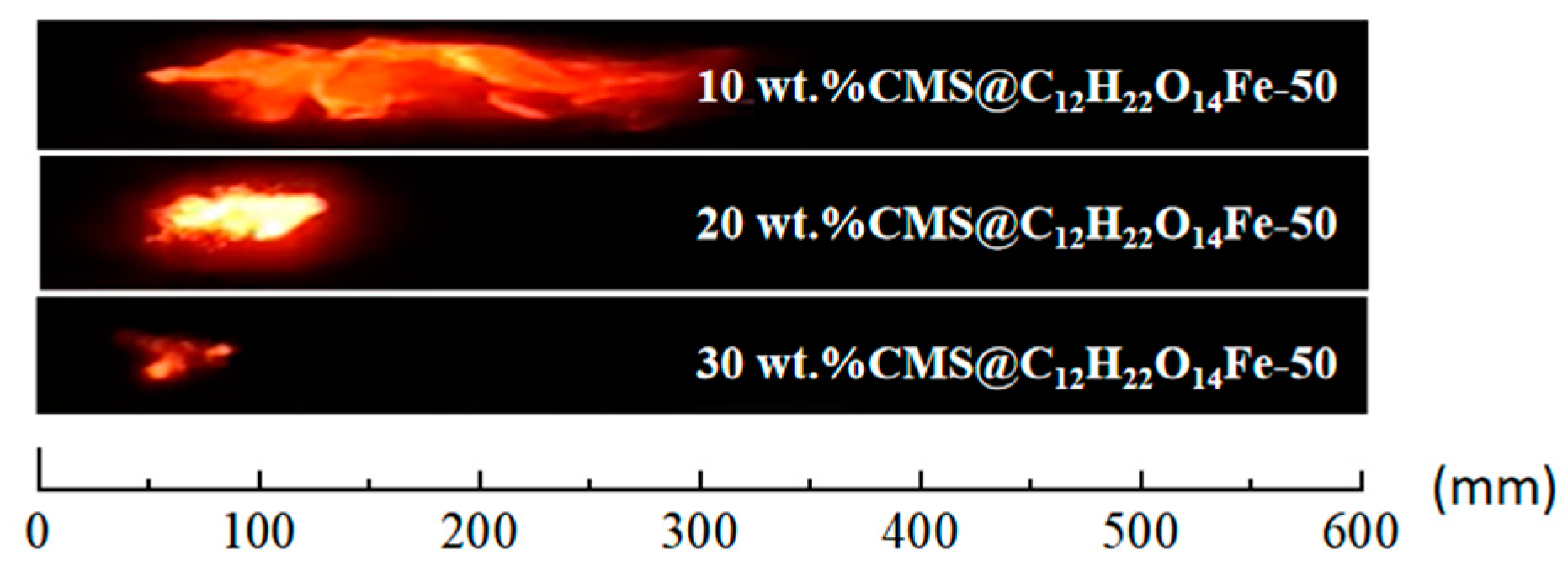

3.1. Analysis of Flame Propagation Inhibition of Lignite Coal Dust by CMS@C12H22O14Fe

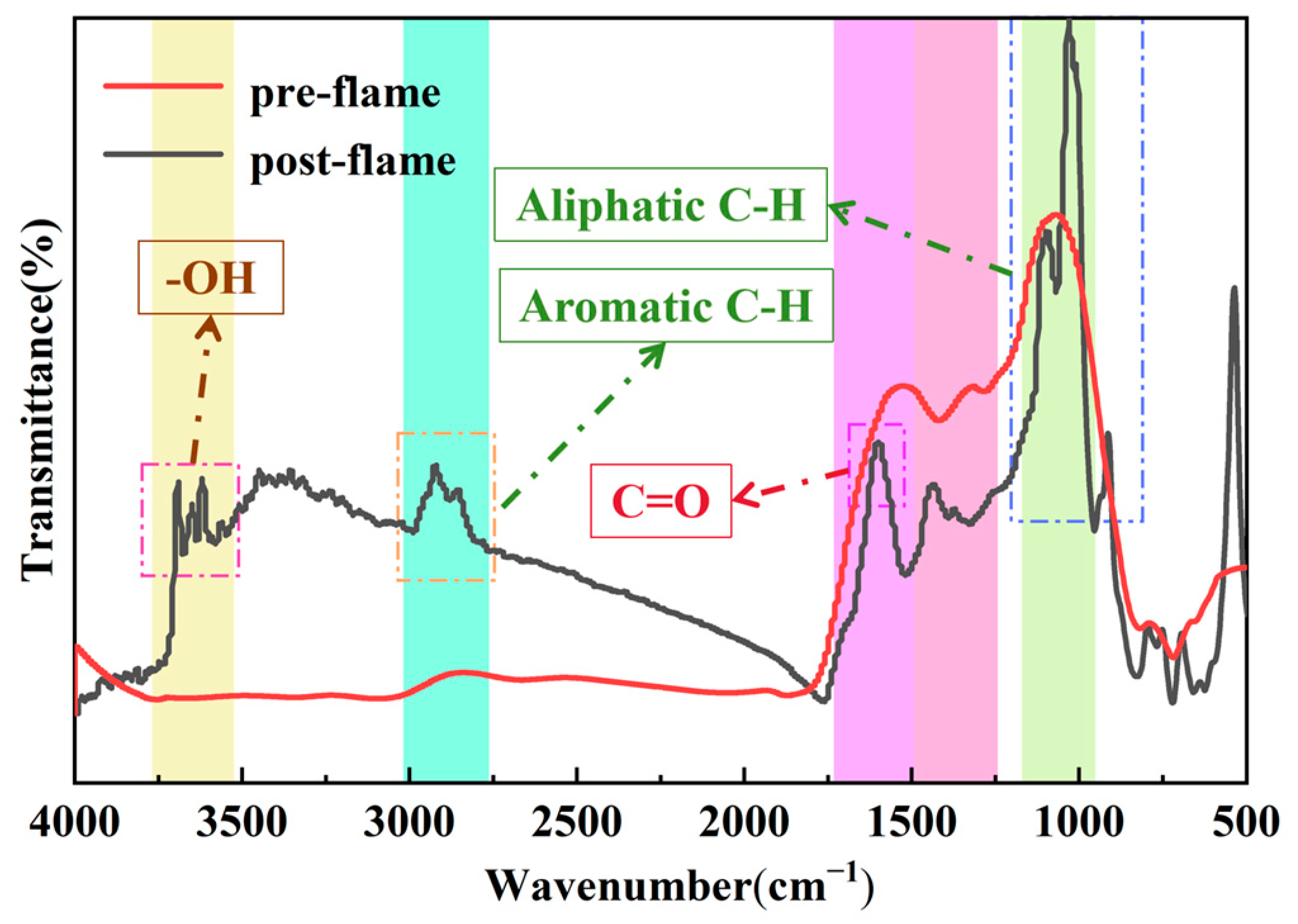

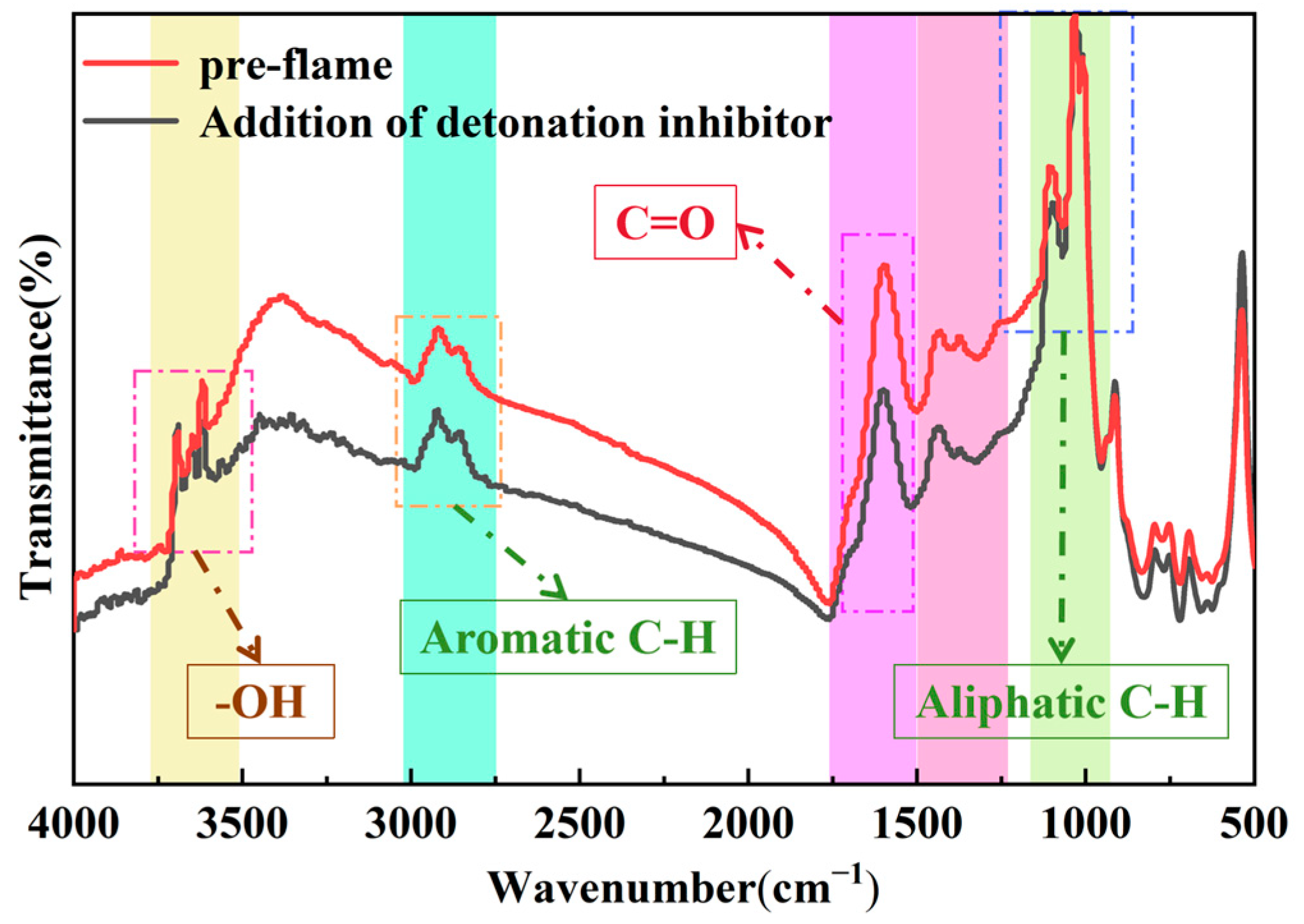

3.2. Infrared Analysis of Lignite Pulverized Coal Flame Suppression by CMS@C12H22O14Fe

3.3. Mechanism of Coal Dust Detonation Suppression by CMS@C12H22O14Fe

- (1)

- Physical inhibition

- (2)

- Chemical inhibition

4. Conclusions

- (1)

- The optimal loading of the active component was ascertained by regulating the loading of CMS@C12H22O14Fe when the addition was 10 wt.%. After a comprehensive analysis of the flame morphology, color, and propagation speed, it was discovered that with the increase in loading capacity, the flame propagation inhibited by the explosion suppressant showed a trend of first increasing and then decreasing.

- (2)

- When the loading of C12H22O14Fe was 50 wt.% in the suppressant, the flame suppression effect was the best.

- (3)

- The addition amount of CMS@C12H22O14Fe was further altered, and through re-analyzing the morphology, color, and propagation speed of the flame, it was ascertained that with the increase in the addition amount, the effect of explosion suppression was gradually enhanced. The flame could be suppressed when the addition amount of CMS@C12H22O14Fe-50 was 30 wt.%.

- (4)

- The FT-IR results of coal dust combustion before and after adding the 30 wt.% CMS@C12H22O14Fe-50 were compared. This comparative analysis further corroborates that the suppressant exhibits an excellent inhibitory effect on coal dust. In combination with the characterization analysis, this shows that the CMS@C12H22O14Fe suppressant undergoes the processes of dehydration, heat absorption, and chemical decomposition, which reveals the physical and chemical inhibitory mechanism of the CMS@C12H22O14Fe suppressant on coal dust.

- (5)

- The preparation of CMS@C12H22O14Fe composite powders by anti-solvent crystallization is an efficient and environmentally friendly technological route, but its process stability is limited by key parameters: the solubility of the active component (C12H22O14Fe) in deionized water, and the dispersion characteristics of the carrier material (CMS) in anhydrous ethanol. These parameters have a direct impact on the loading uniformity and coating efficiency of the active component. Especially in large-scale production scenarios, the control of particle size distribution and consistency of inhibitor loading may face engineering challenges. In the future, automated process control systems need to be developed to achieve industrial-grade batch stability by monitoring solvent ratios in real-time.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| MDPI | Multidisciplinary Digital Publishing Institute |

| DOAJ | Directory of Open-Access Journals |

| TLA | Three-letter acronym |

| LD | Linear dichroism |

References

- Cui, K. Dictionary of Safety Engineering; Chemical Industry Press: Beijing, China, 1995; p. 295. [Google Scholar]

- Wu, D.; Zhao, P.; Spitzer, S.H.; Krietsch, A.; Amyotte, P.; Krause, U. A review on hybrid mixture explosions: Safety parameters, explosion regimes and criteria, flame characteristics. J. Loss Prev. Process Ind. 2023, 82, 104969. [Google Scholar] [CrossRef]

- Guo, R.; Xu, C.; Li, N.; Huang, Y.; Zhang, Y.; Zhang, X. Suppression effect of nanocomposite inhibitor on Methane-Coal dust explosion flame propagation. Adv. Powder Technol. 2024, 35, 104314. [Google Scholar] [CrossRef]

- Pan, Z.; Zhang, Y.; Yan, K.; Chen, J.; Shi, W.; Li, R.; Yang, J. A novel ATH/SBA-15 suppressant prepared by in-situ synthesis and its inhibition mechanism on PE dust deflagration flame. Adv. Powder Technol. 2022, 33, 103871. [Google Scholar] [CrossRef]

- Cao, W.; Zhang, X.; Jia, Y.; Zhou, Z.; Li, W.; Xiao, Q.; Xu, S.; Jiao, F.; Zhao, F.; Xu, S.; et al. Energy output characteristics and safety design of Al-AlH3 composite dust for energetic material additive. Combust. Flame 2023, 254, 112842. [Google Scholar] [CrossRef]

- Jin, S.; Gao, W.; Huang, Z.; Bi, M.; Jiang, H.; Si, R.; Wen, G. Suppression characteristics of methane/coal dust explosions by active explosion suppression system in the large mining tunnel. Fire Saf. J. 2024, 150, 104251. [Google Scholar] [CrossRef]

- Qin, X.; Wei, X.; Shi, J.; Yan, Y.; Zhang, Y. Research on the Inhibition Effect of NaCl on the Explosion of Mg-Al Alloy Powder. ACS Omega 2024, 9, 8048–8054. [Google Scholar] [CrossRef]

- Yu, M.; Wang, F.; He, T.; Li, H.; Han, S.; Lou, R.; Zheng, K.; Yu, Y. Experimental exploration and mechanism analysis of the deflagration pressure of methane/pulverized coal blenders inhibited by modified Karoline-containing compound inhibitors. Fuel 2023, 333, 126353. [Google Scholar] [CrossRef]

- Wang, X. Study on the Inhibition Characteristics and Mechanism of Composite Powder Explosion Suppressant on Coal Dust Explosion. Ph.D. Thesis, Shandong University of Science and Technology, Qingdao, China, 2019. [Google Scholar] [CrossRef]

- Shang, S.; Bi, M.; Zhang, T.; Jiang, H.; Zhang, S.; Gao, W. Synthesis of green nanomaterial and discussion on its suppression performance and mechanism to aluminum dust explosion. Process Saf. Environ. Prot. 2021, 151, 355–364. [Google Scholar] [CrossRef]

- Kuang, K.; Chow, W.; Ni, X.; Ni, X.; Yang, D.; Zeng, W.; Liao, G. Fire suppressing performance of superfine potassium bicarbonate powder. Fire Mater. 2011, 35, 353–366. [Google Scholar] [CrossRef]

- Jiang, H.; Bi, M.; Gao, W.; Gan, B.; Zhang, D.; Zhang, Q. Inhibition of aluminum dust explosion by NaHCO3 with different particle size distributions. Hazard. Mater. 2018, 344, 902–912. [Google Scholar] [CrossRef]

- Wen, H.; Cao, W.; Wang, K.; Cheng, F.M. Experimental study on ABC dry powder to repress gas explosion. J. Saf. Sci. Technol. 2011, 7, 9–12. [Google Scholar]

- Dai, H.; Liang, G.; Yin, H. Experimental investigation on the inhibition of coal dust explosion by the composite inhibitor of carbamide and zeolite. Fuel 2021, 308, 121981. [Google Scholar] [CrossRef]

- Ni, X.; Kuang, K.; Yang, D.; Jin, X.; Liao, G. A new type of fire suppressant powder of NaHCO3/zeolite nanocomposites with core-shell structure. Fire Saf. J. 2009, 44, 968–975. [Google Scholar] [CrossRef]

- Jiang, H.; Bi, M.; Zhang, T.; Shang, S.; Gao, W. A novel reactive P-containing composite with an ordered porous structure for suppressing nano-Al dust explosions. Chem. Eng. J. 2021, 416, 129156. [Google Scholar] [CrossRef]

- Yuan, B.; Tao, H.; Sun, Y.; Wang, L.; Chen, X.; Tan, H. Study on synergistic suppression of methane explosion by porous mineral materials-ammonium polyphosphate composite powder. China Saf. Sci. J. 2021, 31, 41–46. [Google Scholar]

- Chen, J.; Chen, K.; Shi, W.; Pan, Z.; Yang, J.; Zhang, G.; Meng, X.; Zhang, Y. The preparation of novel core-shell suppressor and its suppression mechanism on coal dust explosion flame. Fuel 2022, 313, 122997. [Google Scholar] [CrossRef]

- Li, Y.; Meng, X.; Song, S.; Chen, J.; Ding, J.; Yu, X.; Zhu, Y.; Qin, Z. Piperazine pyrophosphate-functionalized Ni-MOF metal framework: Fabrication and synergistic explosion suppression mechanisms. Chem. Eng. J. 2024, 499, 155870. [Google Scholar] [CrossRef]

- Trace element content of Chinese Maifanshi (mg/kg). J. Feed Rev. 2002, 62. Available online: https://webvpn.sdust.edu.cn/https/77726476706e69737468656265737421fbf952d2243e635930068cb8/kcms2/article/abstract?v=tOz5m-jLbAXLLo4jissbpuxgPLYYYWwaD929DJw-IvcgNTsi-XscykNU5ZNksVFWmuLjr8kS4H6tDYvn8DO-OLwku7G9oRmYTdE_QomFNNHgVtbaYGqPoXEVJorwJM0TnYSyJemw4J1gr5b5gdz6PeD-nX00SK2sFSMK_D86ZVLONR7FA0nJFOnRM5X89ojr&uniplatform=NZKPT&language=CHS (accessed on 5 January 2025).

- Chen, L.; Li, F.; Fu, D.; Wang, H.; Zhao, Y. Determination of surface properties and adsorption mechanism of Chinese Maifan stone. J. Inn. Mong. Petrochem. Ind. 1998, 4, 19–21. [Google Scholar]

- Onifade, M.; Genc, B. A review of research on spontaneous combustion of coal. Int. J. Min. Sci. Technol. 2020, 30, 303–311. [Google Scholar] [CrossRef]

- Youssefi, R.; Segers, T.; Norman, F.; Maier, J.; Scheffknecht, G. Experimental Investigations of the Ignitability of Several Coal Dust Qualities. Energy 2021, 14, 6323. [Google Scholar] [CrossRef]

- Chen, K.; Zhang, Y.; Zhang, P.; Li, L.; Chen, J.; Pan, Z.; Li, R.; He, M. Study on the preparation of green suppressors and their characteristics in coal dust flame propagation inhibition. Adv. Powder Technol. 2022, 33, 103749. [Google Scholar] [CrossRef]

- Guo, X.; Hu, Z.; Fu, S.; Dong, Y.; Jiang, G.; Li, Y. Experimental study of the remediation of acid mine drainage by Maifan stones combined with SRB. PLoS ONE 2022, 17, e0261823. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Hu, Z.; Dong, Y.; Fu, S.; Li, Y. Study of the preparation of Maifan stone and SRB immobilized particles and their effect on treatment of acid mine drainage. RSC Adv. 2022, 12, 4595–4604. [Google Scholar] [CrossRef]

- Popoola, A.; Sanni, O.; Loto, C.A.; Popoola, O.M. Corrosion inhibition: Synergistic influence of gluconates on mild steel in different corrosive environments. synergetic interactions of corrosion inhibition tendency of two different gluconates on mild steel in different corrosive environments. Port. Electrochim. Acta 2015, 33, 353–370. [Google Scholar] [CrossRef]

- Ren, J.; Liu, J.; Feng, L. Research on the process of extracting minerals from Chinese Maifan stone. Compr. Util. Miner. 2020, 75–81+70. [Google Scholar]

- Ren, J.; Liu, J.; Feng, L. Adsorption of heavy metal ions by Chinese Maifan stone. Water Purif. Technol. 2018, 37, 88–94. [Google Scholar] [CrossRef]

- Tang, Q.; Wang, J.; Chen, S.; Zhang, P. Stability of ferrous gluconate solid by thermal analysis. J. China Pharm. Univ. 1987, 16–20. [Google Scholar]

- Liu, B. Preparation and desulfurization performance of LaMeOx/SBA-15 for hot coal gas. Appl. Catal. B Environ. 2011, 102, 27–36. [Google Scholar] [CrossRef]

- Chen, J. Surface chemistry and catalytic performance of amorphous NiB/Hβ catalyst for n -hexane isomerization. Appl. Surf. Sci. 2016, 390, 157–166. [Google Scholar] [CrossRef]

- Moosavi, A. Synthesis of mesoporous ZnO/SBA-15 composite via sonochemical route. Micro Nano Lett. 2012, 7, 130–133. [Google Scholar] [CrossRef]

- Liu, J.; Meng, X.; Yan, K.; Wang, Z.; Dai, W.; Wang, Z.; Li, F.; Yang, P.; Liu, Y. Study on the Effect and Mechanism of Ca(H2PO4)2 and CaCO3 Powders on inhibiting the explosion of Titanium Powder. Powder Technol. 2022, 395, 158–167. [Google Scholar] [CrossRef]

- Zhang, C.; Jin, P.; Chen, C.; Zhang, X.; Zhou, Z.; Geng, S.; Zhang, Y.; Lan, Y.; Shi, X.; Cao, W. Flame propagation characteristics and surface functional groups changes of corn starch dust during the combustion process. Powder Technol. 2023, 430, 118995. [Google Scholar] [CrossRef]

- Zhang, D. Study on Dynamic Adsorption Spreading of Different Non-Ionic Surfactants and Wetting Mechanism of Coal Dust. Ph.D. Thesis, Taiyuan University of Technology, Taiyuan, China, 2016. [Google Scholar]

- Wang, P.; Tan, X.; Zhang, L.; Li, Y.; Liu, R. Influence of particle diameter on the wettability of coal dust and the dust suppression efficiency via spraying. Process Saf. Environ. Prot. 2019, 132, 189–199. [Google Scholar] [CrossRef]

- Feng, L.; Zhao, G.; Zhao, Y.; Zhao, M.; Tang, J. Construction of the molecular structure model of the Shingle Lignite using TG-GC/MS and FTIR spectrometry data. Fuel 2017, 203, 924–931. [Google Scholar] [CrossRef]

- Jiang, H. Suppression mechanism of ultrafine water mist containing phosphorus compounds in methane/coal dust explosions. Energy 2022, 239, 121987. [Google Scholar] [CrossRef]

- Jiang, H. Effect of turbulence intensity on flame propagation and extinction limits of methane/coal dust explosions. Energy 2022, 239, 122246. [Google Scholar] [CrossRef]

- Gong, J.; Nie, B.; Peng, C.; Ge, Z. Research on the Explosion Reaction Mechanism of Volatile Gases from Coal Dust Pyrolysis. Combust. Sci. Technol. 2024. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, R.; Chen, J.; Yang, J.; Wang, F.; Pan, Z.; Shi, W.; Dongye, S.; Zhao, W. Study on the inhibition mechanism of green suppressants zinc borate and zinc silicate for oil shale based on flame propagation experiment and thermodynamic analysis. Energy 2023, 283, 129014. [Google Scholar] [CrossRef]

| Industrial Analysis (%) | |||

|---|---|---|---|

| Mad | Aad | Vad | FCad |

| 1.89 | 9.07 | 36.56 | 52.48 |

| Deionized Water (g/100 mL) | Anhydrous Ethanol (g/100 mL) | |

|---|---|---|

| C12H22O14Fe | 11.8 | indissolvable |

| CMS | insoluble | insoluble |

| D [2,3] | D [3,4] | D10 (µm) | D50 (µm) | D90 (µm) | |

|---|---|---|---|---|---|

| CMS | 4.767 | 28.347 | 1.625 | 19.751 | 68.688 |

| CMS@C12H22O14Fe | 6.256 | 34.531 | 2.370 | 28.258 | 76.947 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Yang, Y.; Han, J.; Dongye, S.; Wang, F.; Liu, W.; Wang, L.; Zhang, Y. Study on the Structure of a Novel CMS@C12H22O14Fe Suppressant and Its Mechanism of Inhibiting Coal Dust Deflagration. Processes 2025, 13, 650. https://doi.org/10.3390/pr13030650

Zhang Y, Yang Y, Han J, Dongye S, Wang F, Liu W, Wang L, Zhang Y. Study on the Structure of a Novel CMS@C12H22O14Fe Suppressant and Its Mechanism of Inhibiting Coal Dust Deflagration. Processes. 2025; 13(3):650. https://doi.org/10.3390/pr13030650

Chicago/Turabian StyleZhang, Yansong, Yang Yang, Jin Han, Shengjing Dongye, Fei Wang, Wenjie Liu, Lei Wang, and Yang Zhang. 2025. "Study on the Structure of a Novel CMS@C12H22O14Fe Suppressant and Its Mechanism of Inhibiting Coal Dust Deflagration" Processes 13, no. 3: 650. https://doi.org/10.3390/pr13030650

APA StyleZhang, Y., Yang, Y., Han, J., Dongye, S., Wang, F., Liu, W., Wang, L., & Zhang, Y. (2025). Study on the Structure of a Novel CMS@C12H22O14Fe Suppressant and Its Mechanism of Inhibiting Coal Dust Deflagration. Processes, 13(3), 650. https://doi.org/10.3390/pr13030650