Extraction and Recovery of Valuable Metals from Waste and Mineral Materials: Editorial Review

1. Overview

1.1. Demand and Supply of High-Tech Metals

1.2. Secondary Sources and Optimization of Existing Primary Production Processes

1.3. Environmental Aspect

1.4. Low and Intermediate Temperature Extraction Processes

2. Review of Contributions

Data Availability Statement

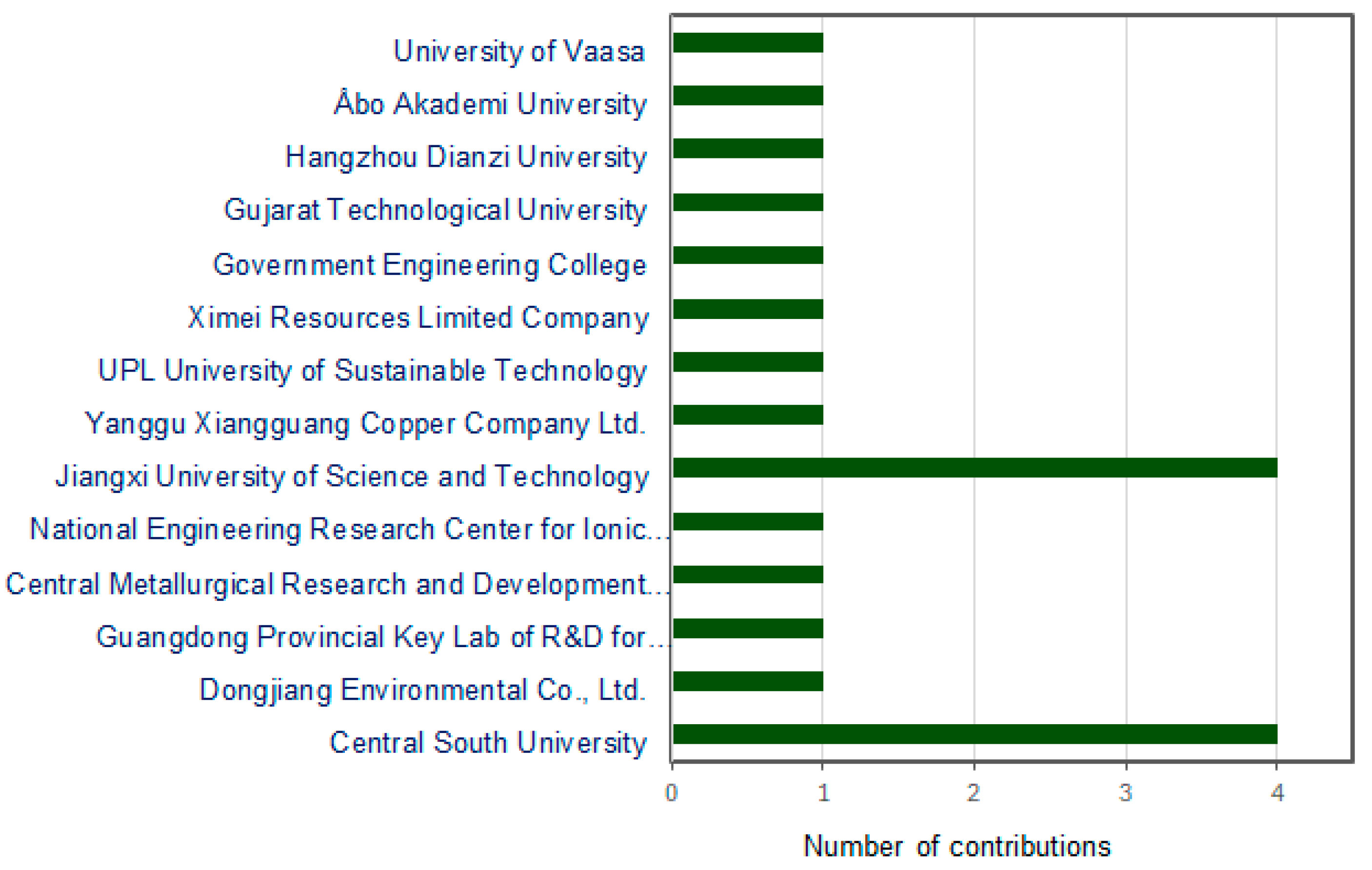

Acknowledgments

Conflicts of Interest

List of Contributions

- Niu, F.; Liu, G.; Zhu, J.; Pan, J.; Qi, T.; Wang, S.; Li, X.; Wang, S.; Yang, Y. Reaction Behavior of Kaolinite in Sulfur-Bearing Sodium Aluminate Solution under the Simulated Bayer Process. Processes 2023, 11, 2630. https://doi.org/10.3390/pr11092630

- Lan, Q.; Yang, Y.; Xie, Z.; Guo, H.; Liu, D.; Zhang, X. Molecular Dynamics Calculation of the Coordination Behavior of Yb (III) in Sodium Carbonate Solution. Processes 2023, 11, 2624. https://doi.org/10.3390/pr11092624

- Abdelgalil, M.S.; El-Barawy, K.; Ge, Y.; Xia, L. The Recovery of TiO2 from Ilmenite Ore by Ammonium Sulfate Roasting–Leaching Process. Processes 2023, 11, 2570. https://doi.org/10.3390/pr11092570

- Li, S.; Yang, S.; Zhao, P.; Chen, Y.; Tang, C.; Lai, Y.; Deng, C.; Wang, C. Anodic Behavior of Hafnium in Anhydrous Electrodissolution-Coupled Hafnium Alkoxide Synthesis. Processes 2023, 11, 564. https://doi.org/10.3390/pr11020564

- Prajapati, S.B.; Gautam, A.; Gautam, S.; Yao, Z.; Tesfaye, F.; Lü, X. Co-Pyrolysis Behavior, Kinetic and Mechanism of Waste-Printed Circuit Board with Biomass. Processes 2023, 11, 229. https://doi.org/10.3390/pr11010229

- Zeng, H.; Liu, F.; Zhou, S.; Liao, C.; Chen, F.; Zeng, Y. Leaching Behavior of the Main Metals from Copper Anode Slime during the Pretreatment Stage of the Kaldor Furnace Smelting Process. Processes 2022, 10, 2510. https://doi.org/10.3390/pr10122510

- Chen, F.; Liu, F.; Wang, L.; Wang, J. Comparison of the Preparation Process of Rare Earth Oxides from the Water Leaching Solution of Waste Nd-Fe-B Magnets’ Sulfate Roasting Products. Processes 2022, 10, 2310. https://doi.org/10.3390/pr10112310

References

- Orlova, S.; Rassõlkin, A. Permanent Magnets in Sustainable Energy: Comparative Life Cycle Analysis. Energies 2024, 17, 6384. [Google Scholar] [CrossRef]

- European Commission. A European Green Deal. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 15 December 2024).

- European Commission. Fit for 55: Delivering the EU’s 2030 Climate Target on the Way to Climate Neutrality. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52021DC0550 (accessed on 18 December 2024).

- European Commission—Press Release. Closing the Loop: Commission Adopts Ambitious New Circular Economy Package to Boost Competitiveness, Create Jobs and Generate Sustainable Growth. Available online: http://europa.eu/rapid/press-release_IP-15-6203_en.htm (accessed on 2 January 2025).

- Iloeje, C.O.; Tesfaye, F.; Anderson, A.E.; Hamuyuni, J. Recovery of Rare Earth and Critical Metals from Unconventional Sources. JOM 2022, 74, 990–992. [Google Scholar] [CrossRef]

- Van Gosen, B.S.; Verplanck, P.L.; Seal, R.R., II; Long, K.R.; Gambogi, J. Rare-earth elements. In Critical Mineral Resources of the United States—Economic and Environmental Geology and Prospects for Future Supply, 1st ed.; Schulz, K.J., DeYoung, J.H., Jr., Seal, R.R., II, Bradley, D.C., Eds.; Professional Paper 1802; USGS: Reston, VA, USA, 2017; pp. O1–O31. [Google Scholar]

- Sethurajan, M.; Lens, P.N.L.; Horn, H.A.; Figueiredo, L.H.A.; van Hullebusch, E.D. Leaching and Recovery of Metals. In Sustainable Heavy Metal Remediation, 1st ed.; Rene, E., Sahinkaya, E., Lewis, A., Lens, P., Eds.; Springer: Cham, Switzerland, 2017; Volume 2, pp. XII, 278. [Google Scholar]

- Chen, F.; Liu, F.; Wang, L.; Wang, J. Comparison of the Preparation Process of Rare Earth Oxides from the Water Leaching Solution of Waste Nd-Fe-B Magnets’ Sulfate Roasting Products. Processes 2022, 10, 2310. [Google Scholar] [CrossRef]

- Prajapati, S.B.; Gautam, A.; Gautam, S.; Yao, Z.; Tesfaye, F.; Lü, X. Co-Pyrolysis Behavior, Kinetic and Mechanism of Waste-Printed Circuit Board with Biomass. Processes 2023, 11, 229. [Google Scholar] [CrossRef]

- Maroufi, S.; Nekouei, R.K.; Hossain, R.; Assefi, M.; Sahajwalla, V. Recovery of Rare Earth (i.e., La, Ce, Nd, and Pr) Oxides from End-of-Life Ni-MH Battery via Thermal Isolation. ACS Sustain. Chem. Eng. 2018, 6, 11811. [Google Scholar] [CrossRef]

- Tunsu, C.; Petranikova, M.; Gergoric, M.; Ekberg, C.; Retegan, T. Reclaiming rare earth elements from end-of-life products: A review of the perspectives for urban mining using hydrometallurgical unit operations. Hydrometallurgy 2015, 156, 239. [Google Scholar] [CrossRef]

- Wickleder, M.S. Inorganic Lanthanide Compounds with Complex Anions. Chem. Rev. 2002, 102, 2011–2087. [Google Scholar] [CrossRef]

- Abdelgalil, M.S.; El-Barawy, K.; Ge, Y.; Xia, L. The Recovery of TiO2 from Ilmenite Ore by Ammonium Sulfate Roasting–Leaching Process. Processes 2023, 11, 2570. [Google Scholar] [CrossRef]

| Contribution Order | Processing Method Considered | Extraction/Recovery/Synthesis | Source Raw Material (Mineral/Waste) | Target Material Production |

|---|---|---|---|---|

| I | Bayer Process | Extraction | Mineral | Al |

| II | Precipitation | Extraction | Mineral | REE |

| III | Roasting-leaching | Recovery | Mineral | TiO2 |

| IV | Electrodissolution-coupled synthesis | Synthesis | Mineral | Hf(OR)4, R is alkyl |

| V | Pyrolysis | Recovery | Waste | Cu, PGM, Ag, Au |

| VI | Leaching | Recovery | Mineral/Waste | Cu, Ni, PGM, Ag, Au |

| VII | Leaching | Recovery | Waste | REE |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tesfaye, F.; Shen, L.; Moroz, M.; Demesa, A.G. Extraction and Recovery of Valuable Metals from Waste and Mineral Materials: Editorial Review. Processes 2025, 13, 359. https://doi.org/10.3390/pr13020359

Tesfaye F, Shen L, Moroz M, Demesa AG. Extraction and Recovery of Valuable Metals from Waste and Mineral Materials: Editorial Review. Processes. 2025; 13(2):359. https://doi.org/10.3390/pr13020359

Chicago/Turabian StyleTesfaye, Fiseha, Leiting Shen, Mykola Moroz, and Abayneh Getachew Demesa. 2025. "Extraction and Recovery of Valuable Metals from Waste and Mineral Materials: Editorial Review" Processes 13, no. 2: 359. https://doi.org/10.3390/pr13020359

APA StyleTesfaye, F., Shen, L., Moroz, M., & Demesa, A. G. (2025). Extraction and Recovery of Valuable Metals from Waste and Mineral Materials: Editorial Review. Processes, 13(2), 359. https://doi.org/10.3390/pr13020359