A Laser Shock-Based Disassembly Process for Adhesively Bonded Ti/CFRP Parts

Abstract

1. Introduction

2. Materials and Methods

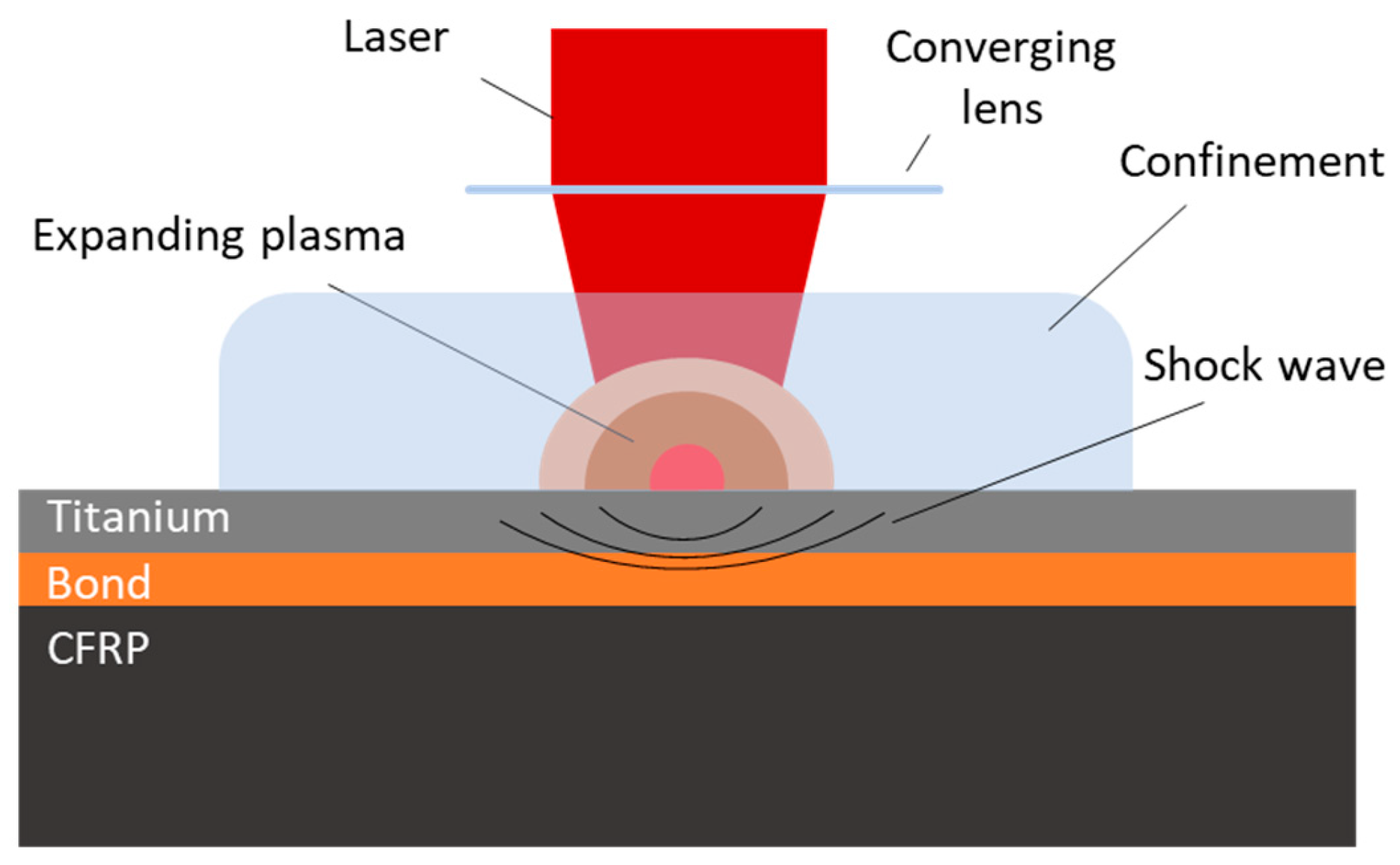

2.1. The Laser Shock Technique

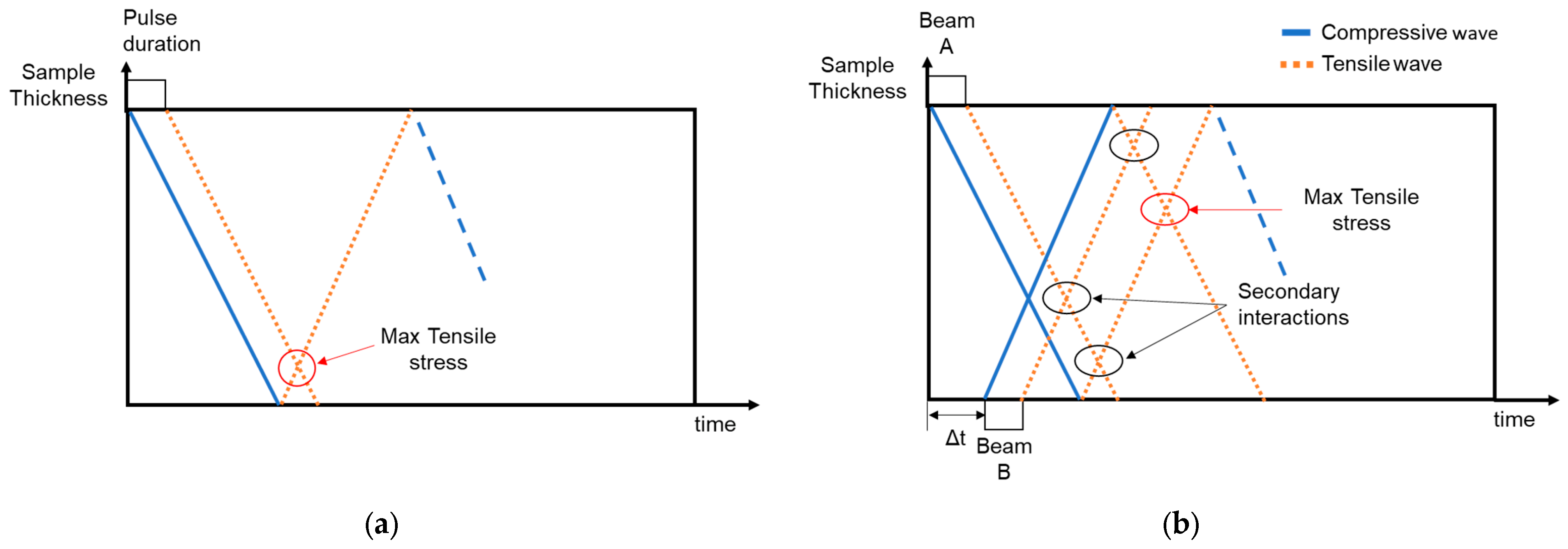

2.1.1. The Laser-Shock Principle

2.1.2. Laser-Shock Configurations

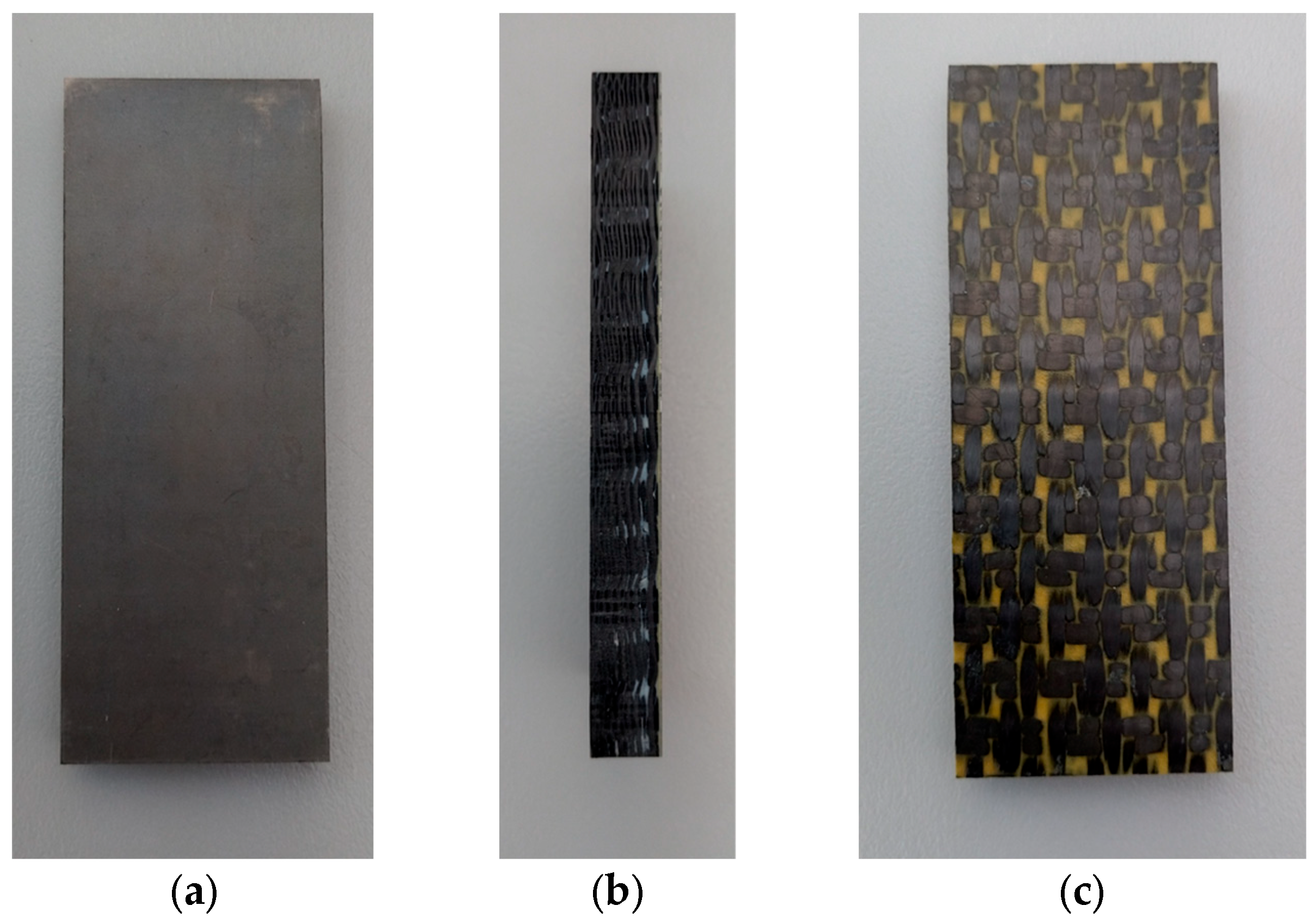

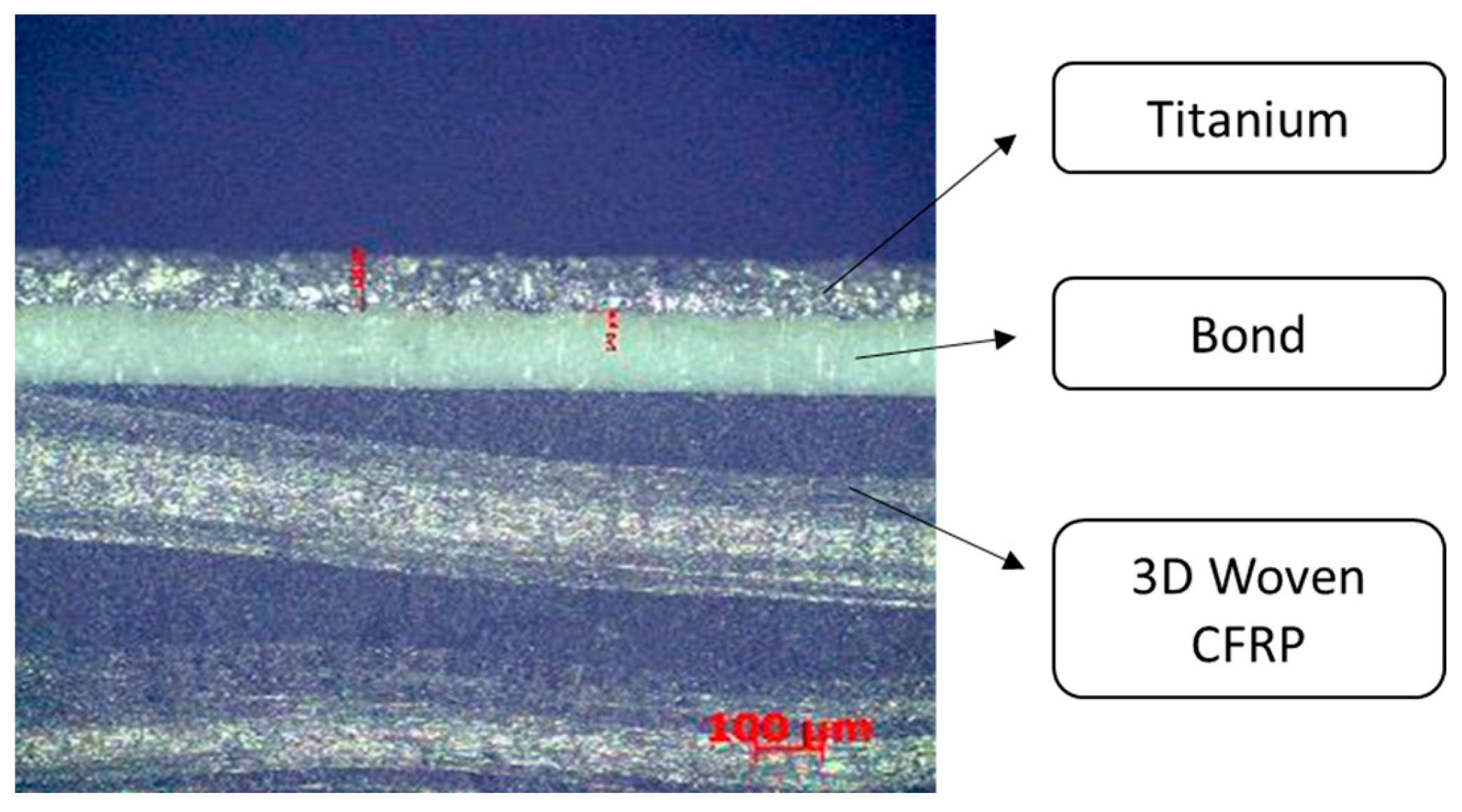

2.2. Materials and Specimens

2.3. Laser Specifications

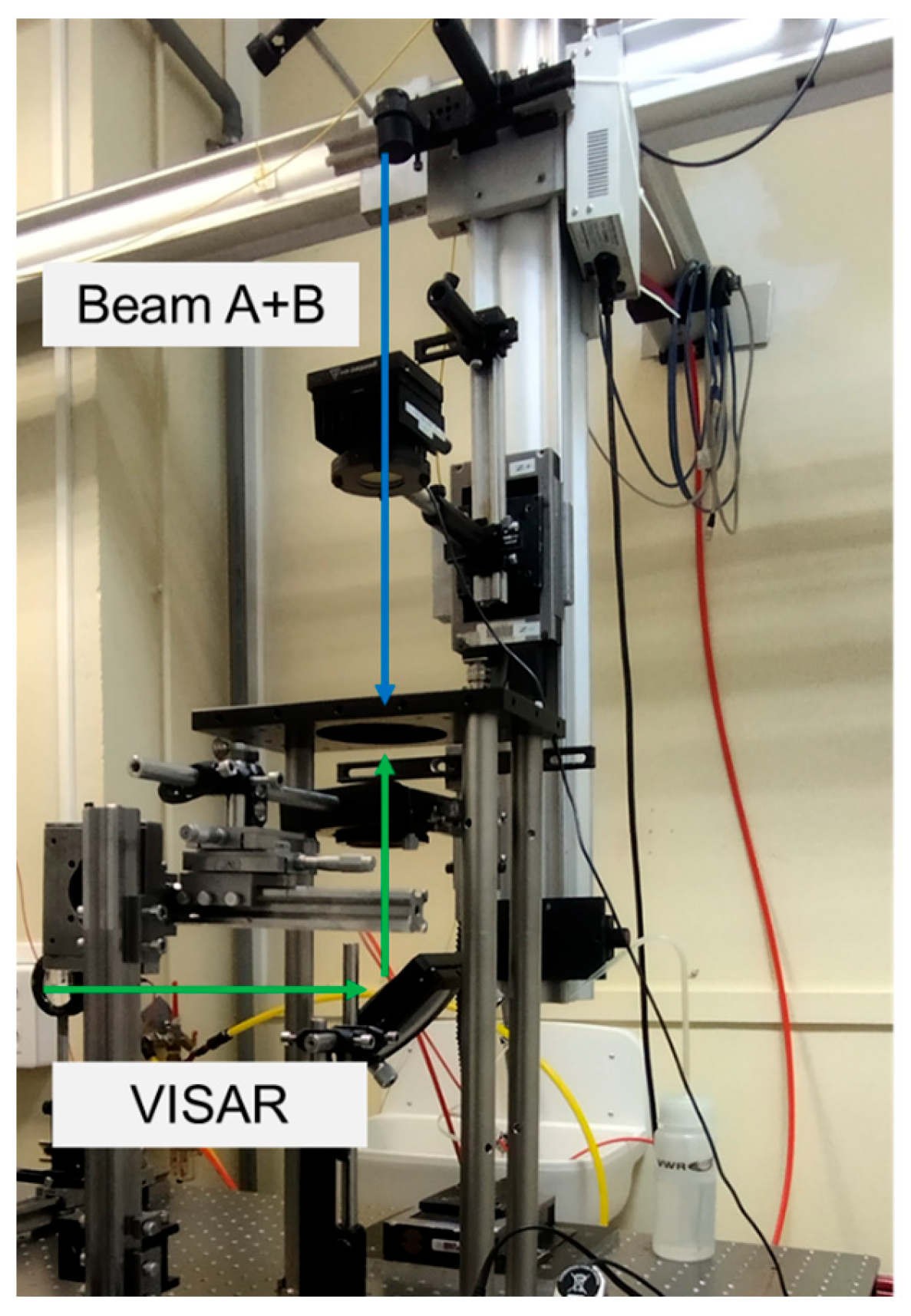

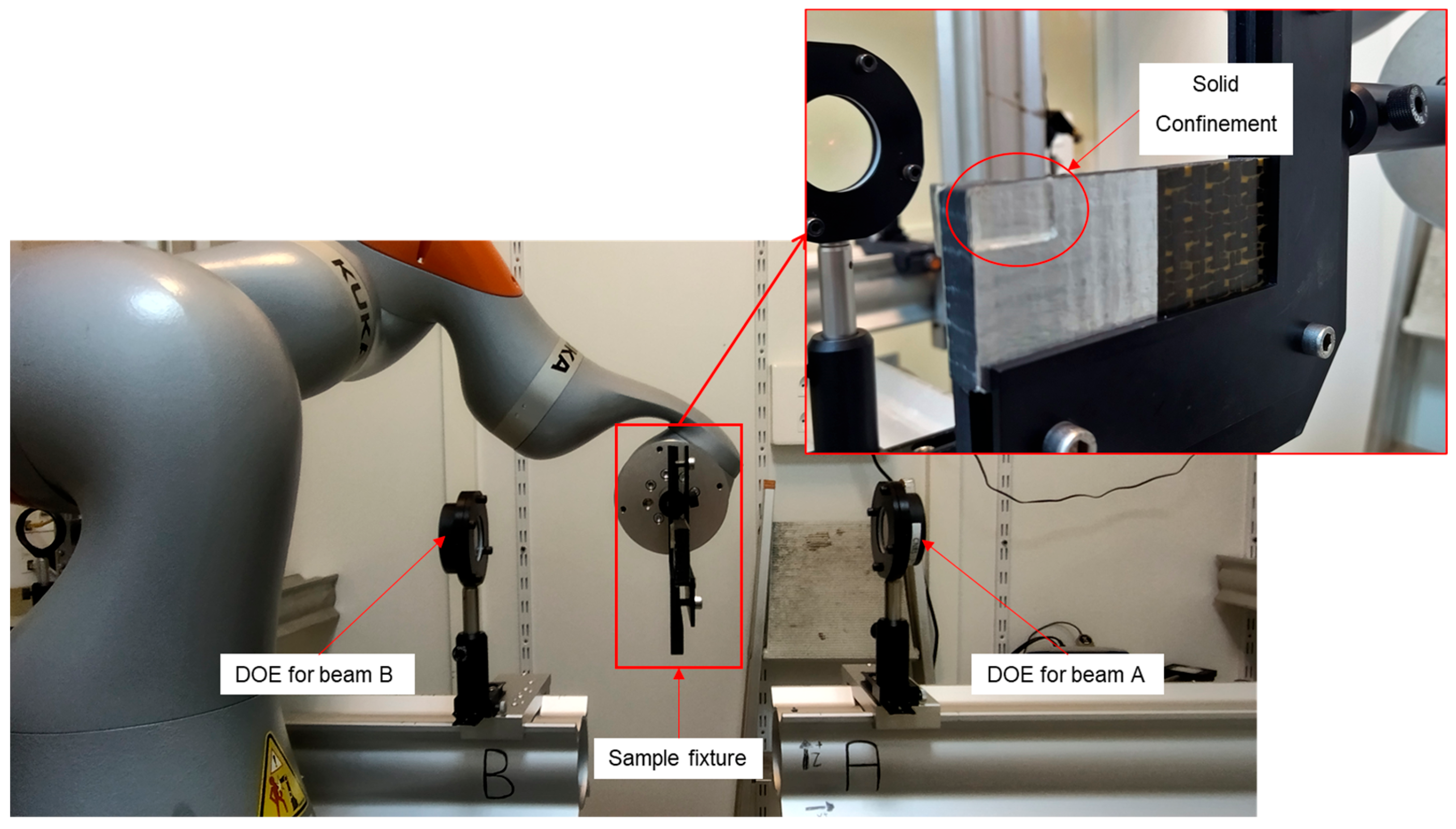

2.4. Experimental

2.4.1. Single-Sided Shot Configuration

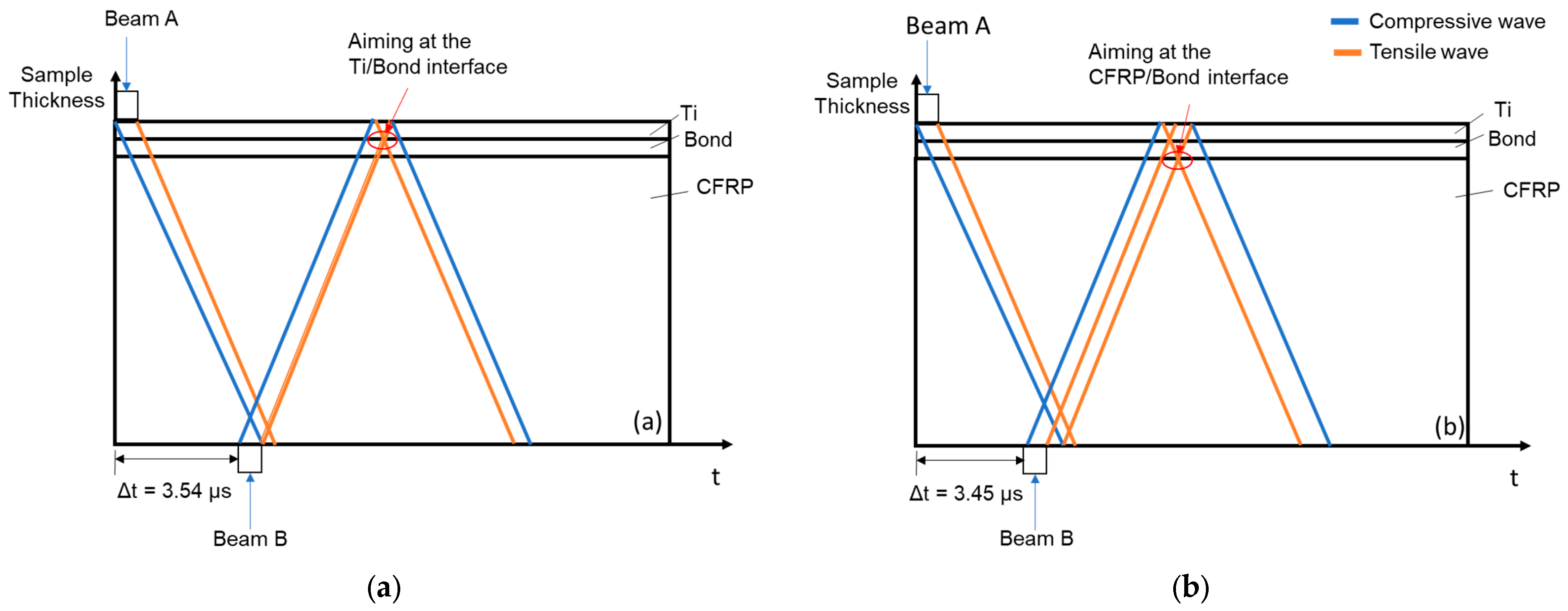

2.4.2. Symmetric Laser Configuration

3. Results

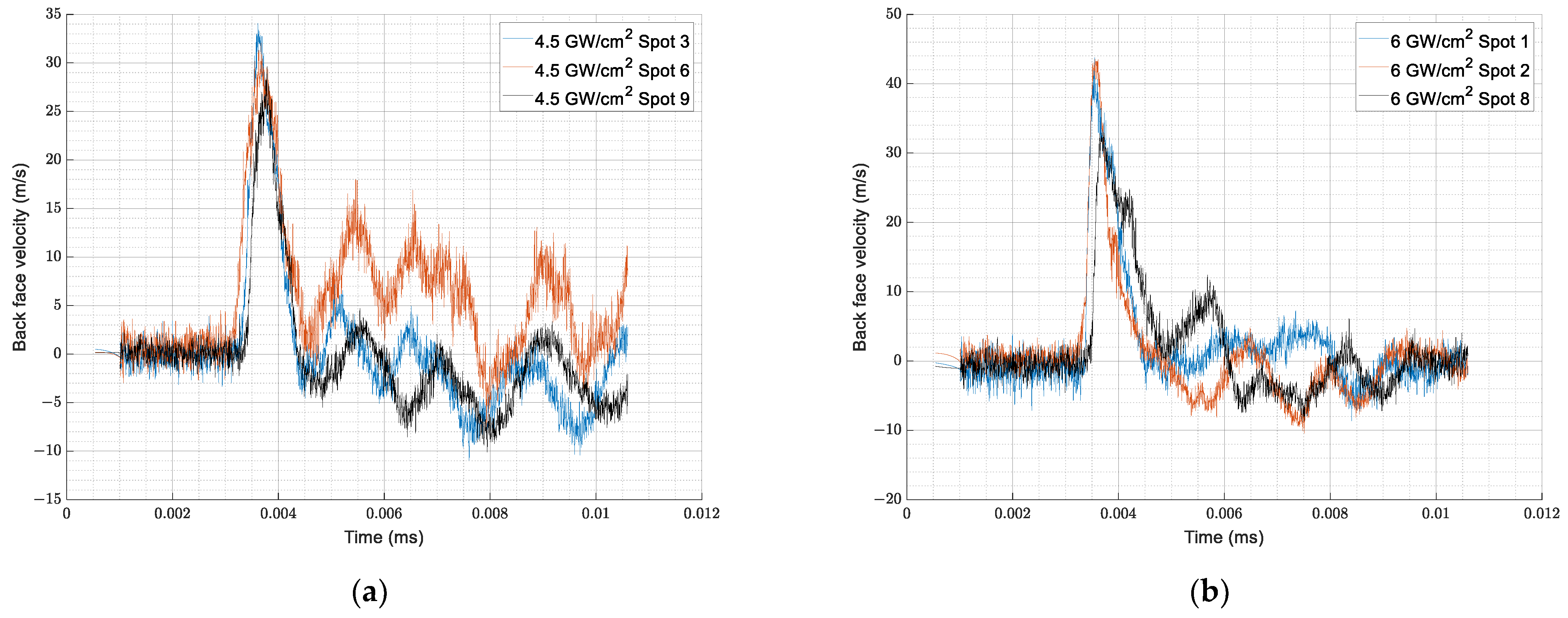

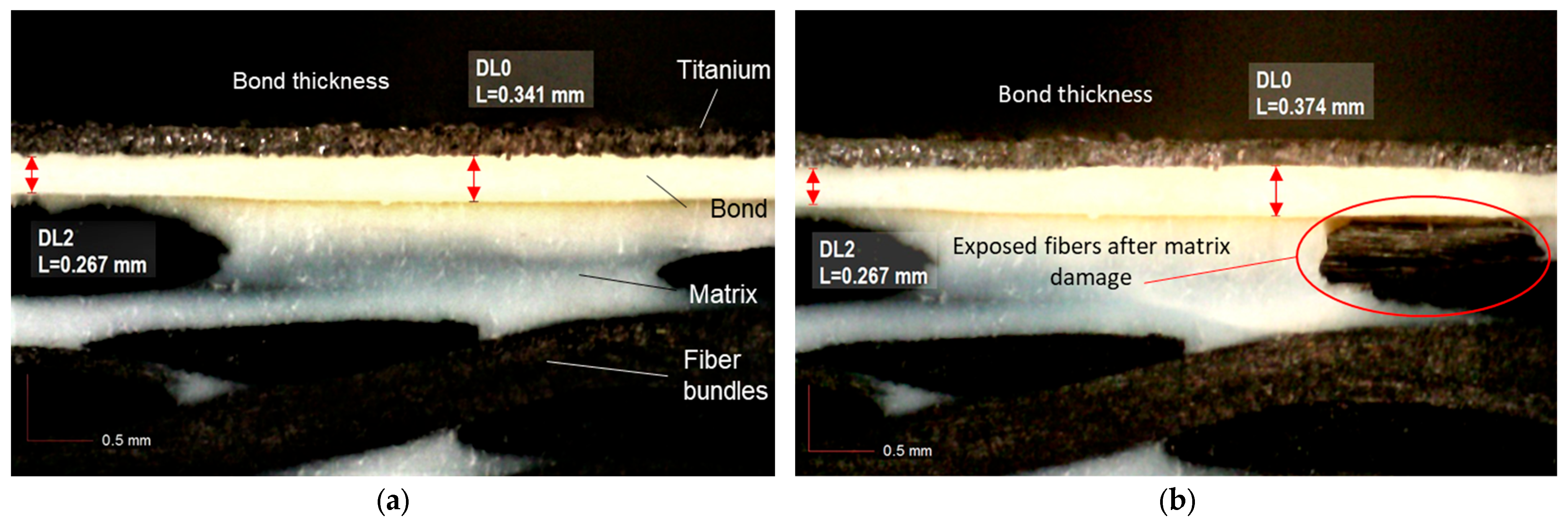

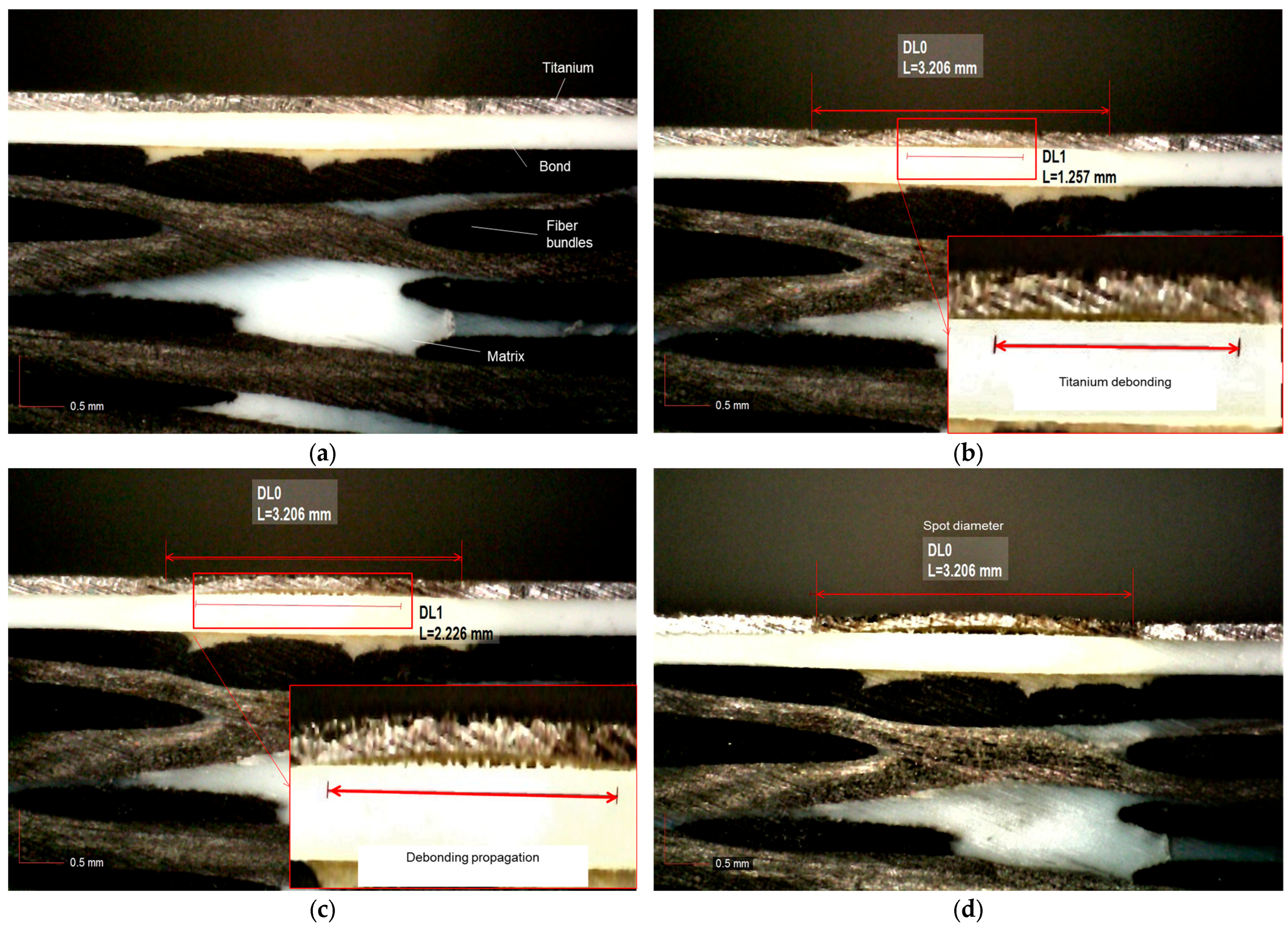

3.1. Single-Sided Configuration Results

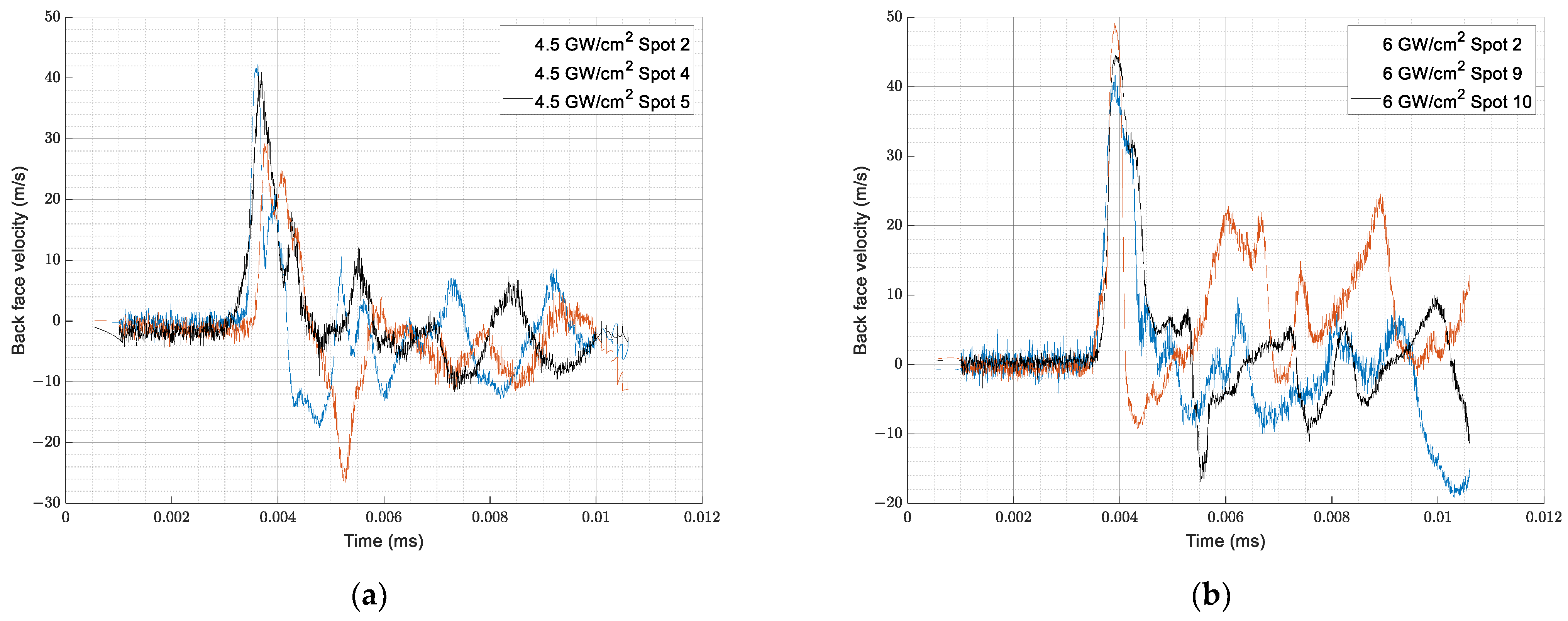

3.2. Symmetric Configuration Results

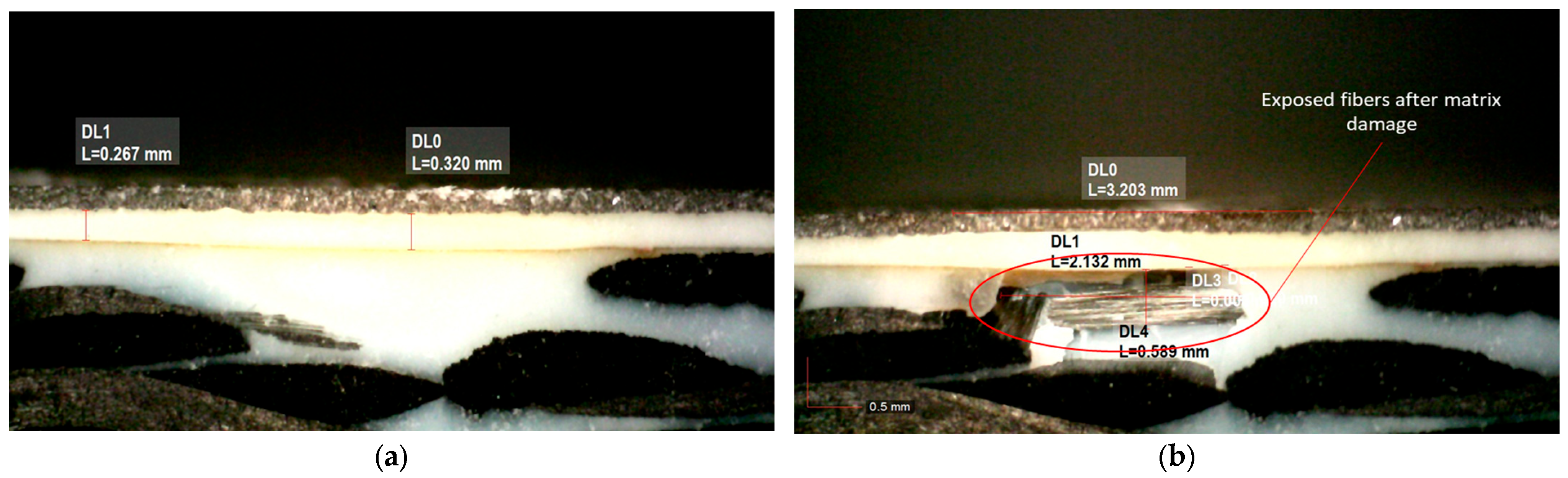

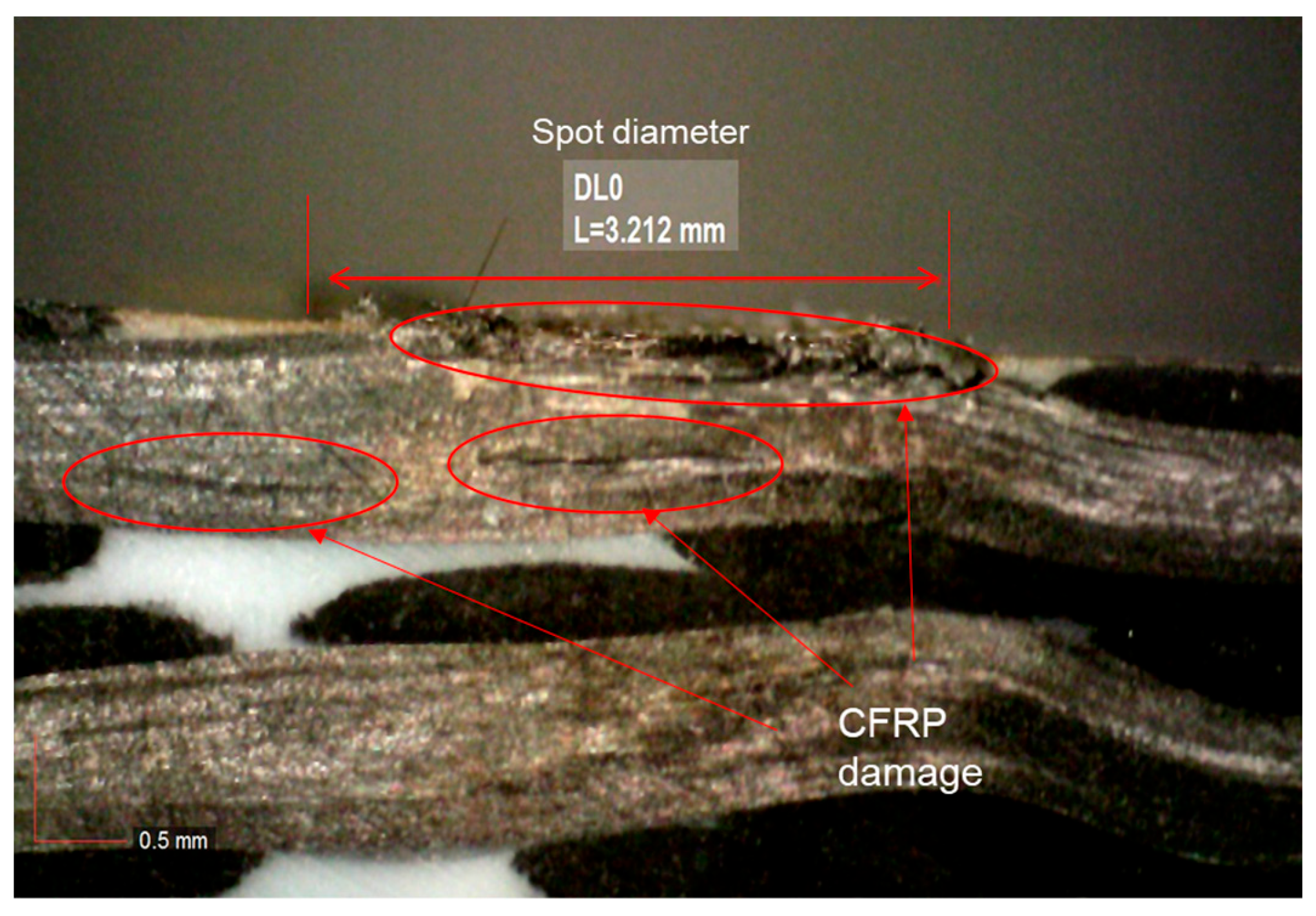

3.2.1. Symmetric Shots Targeted at the Adhesive/CFRP Interface

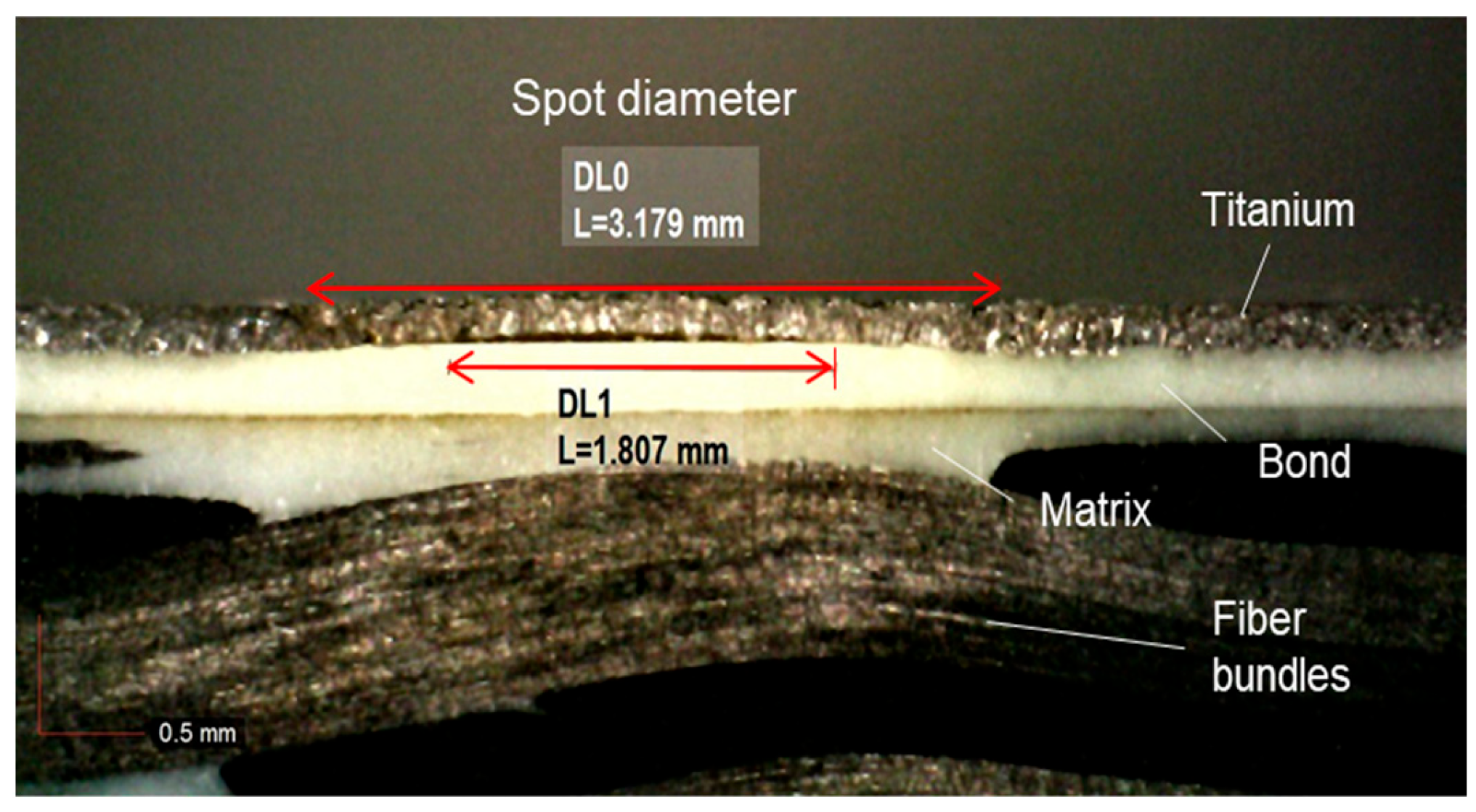

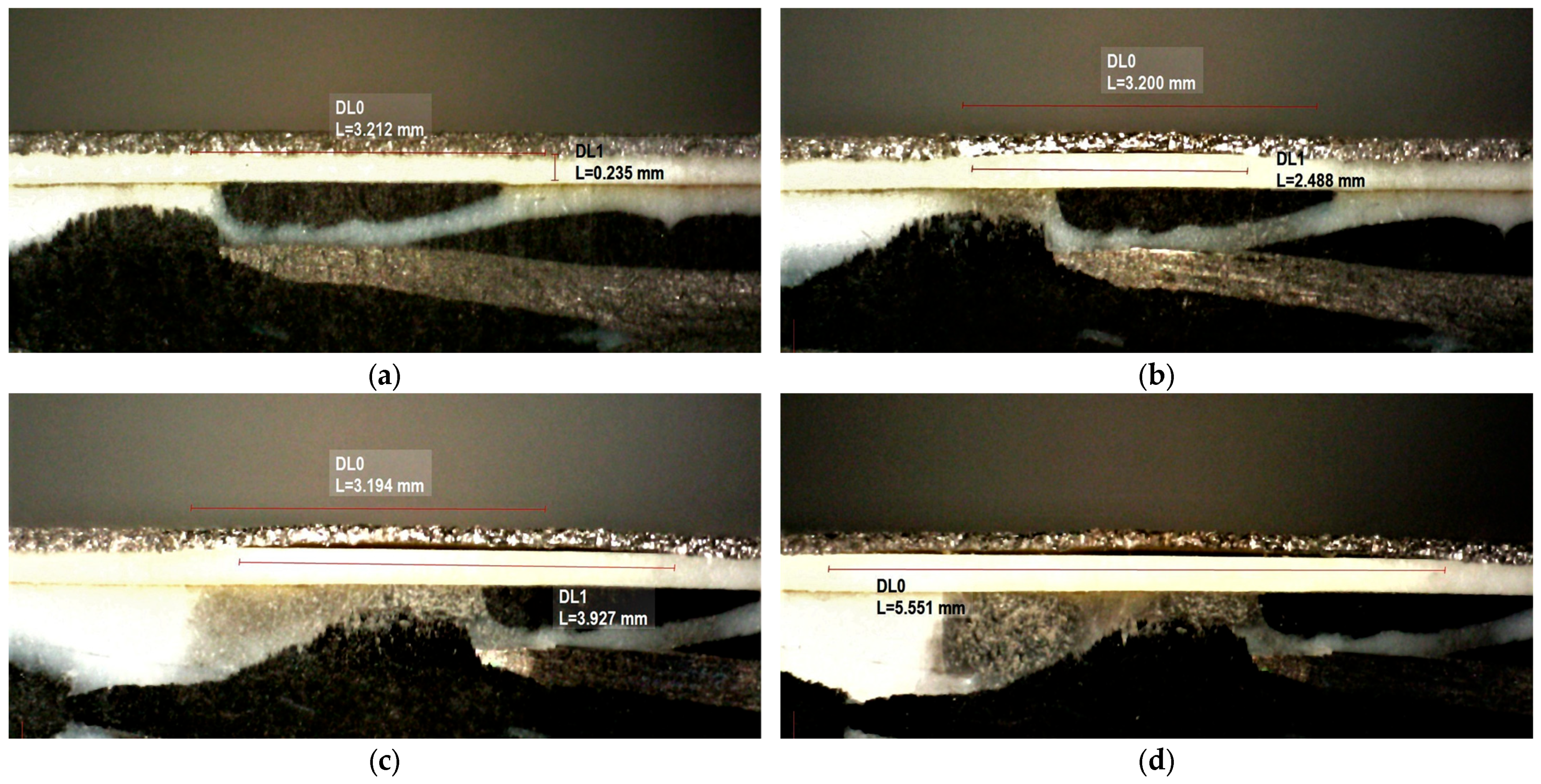

3.2.2. Symmetric Shots Targeted at the Adhesive/Ti Interface

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, W.; Huang, H.; Zhu, L.; Liu, Z. Integrating Carbon Fiber Reclamation and Additive Manufacturing for Recycling CFRP Waste. Compos. Part B Eng. 2021, 215, 108808. [Google Scholar] [CrossRef]

- Meyer, L.O.; Schulte, K.; Grove-Nielsen, E. CFRP-Recycling Following a Pyrolysis Route: Process Optimization and Potentials. J. Compos. Mater. 2009, 43, 1121–1132. [Google Scholar] [CrossRef]

- Dauguet, M.; Mantaux, O.; Perry, N.; Zhao, Y.F. Recycling of CFRP for High Value Applications: Effect of Sizing Removal and Environmental Analysis of the SuperCritical Fluid Solvolysis. Procedia CIRP 2015, 29, 734–739. [Google Scholar] [CrossRef]

- Moslehi, A.; Ajji, A.; Heuzey, M.; Rahimizadeh, A.; Lessard, L. Polylactic Acid/Recycled Wind Turbine Glass Fiber Composites with Enhanced Mechanical Properties and Toughness. J. Appl. Polym. Sci 2022, 139, 51934. [Google Scholar] [CrossRef]

- Sabaghi, M.; Cai, Y.; Mascle, C.; Baptiste, P. Sustainability Assessment of Dismantling Strategies for End-of-Life Aircraft Recycling. Resour. Conserv. Recycl. 2015, 102, 163–169. [Google Scholar] [CrossRef]

- Zhao, X.; Verhagen, W.J.C.; Curran, R. Disposal and Recycle Economic Assessment for Aircraft and Engine End of Life Solution Evaluation. Appl. Sci. 2020, 10, 522. [Google Scholar] [CrossRef]

- Tserpes, K. Adhesive Bonding of Aircraft Structures. In Revolutionizing Aircraft Materials and Processes; Pantelakis, S., Tserpes, K., Eds.; Springer: Cham, Switzerland, 2020; pp. 337–357. ISBN 978-3-030-35346-9. [Google Scholar]

- Sato, C.; Carbas, R.J.C.; Marques, E.A.S.; Akhavan-Safar, A.; da Silva, L.F.M. Effect of Disassembly on Environmental and Recycling Issues in Bonded Joints. In Adhesive Bonding; Elsevier: Amsterdam, The Netherlands, 2021; pp. 407–436. ISBN 978-0-12-819954-1. [Google Scholar]

- Hutchinson, A.; Liu, Y.; Lu, Y. Overview of Disbonding Technologies for Adhesive Bonded Joints. J. Adhes. 2017, 93, 737–755. [Google Scholar] [CrossRef]

- Banea, M.D. Debonding on Demand of Adhesively Bonded Joints: A Critical Review. Rev. Adhes Adhes. 2019, 7, 33–50. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M.; Carbas, R.J.C. Debonding on Command of Adhesive Joints for the Automotive Industry. Int. J. Adhes. Adhes. 2015, 59, 14–20. [Google Scholar] [CrossRef]

- Piazza, G.; Burczyk, M.; Gerini-Romagnoli, M.; Belingardi, G.; Nassar, S.A. Effect of Thermally Expandable Particle Additives on the Mechanical and Reversibility Performance of Adhesive Joints. J. Adv. Join. Process. 2022, 5, 100088. [Google Scholar] [CrossRef]

- Ivetic, G. Three-Dimensional FEM Analysis of Laser Shock Peening of Aluminium Alloy 2024-T351 Thin Sheets. Surf. Eng. 2011, 27, 445–453. [Google Scholar] [CrossRef]

- Le Bras, C.; Rondepierre, A.; Seddik, R.; Scius-Bertrand, M.; Rouchausse, Y.; Videau, L.; Fayolle, B.; Gervais, M.; Morin, L.; Valadon, S.; et al. Laser Shock Peening: Toward the Use of Pliable Solid Polymers for Confinement. Metals 2019, 9, 793. [Google Scholar] [CrossRef]

- Ecault, R.; Touchard, F.; Boustie, M.; Berthe, L.; Dominguez, N. Numerical Modeling of Laser-Induced Shock Experiments for the Development of the Adhesion Test for Bonded Composite Materials. Compos. Struct. 2016, 152, 382–394. [Google Scholar] [CrossRef]

- Sagnard, M.; Ecault, R.; Touchard, F.; Boustie, M.; Berthe, L. Development of the Symmetrical Laser Shock Test for Weak Bond Inspection. Opt. Laser Technol. 2019, 111, 644–652. [Google Scholar] [CrossRef]

- Arrigoni, M. Inputs of Numerical Simulation into the Development of Shock Adhesion Tests on Advanced Materials. Int. J. Struct. Glass Adv. Mater. Res. 2020, 4, 1–9. [Google Scholar] [CrossRef]

- Ecault, R.; Touchard, F.; Berthe, L.; Boustie, M. Laser Shock Adhesion Test Numerical Optimization for Composite Bonding Assessment. Compos. Struct. 2020, 247, 112441. [Google Scholar] [CrossRef]

- Tserpes, K.; Papadopoulos, K.; Unaldi, S.; Berthe, L. Development of a Numerical Model to Simulate Laser-Shock Paint Stripping on Aluminum Substrates. Aerospace 2021, 8, 233. [Google Scholar] [CrossRef]

- Ünaldi, S.; Papadopoulos, K.; Rondepierre, A.; Rouchausse, Y.; Karanika, A.; Deliane, F.; Tserpes, K.; Floros, G.; Richaud, E.; Berthe, L. Towards Selective Laser Paint Stripping Using Shock Waves Produced by Laser-Plasma Interaction for Aeronautical Applications on AA 2024 Based Substrates. Opt. Laser Technol. 2021, 141, 107095. [Google Scholar] [CrossRef]

- Papadopoulos, K.; Tserpes, K. Analytical and Numerical Modeling of Stress Field and Fracture in Aluminum/Epoxy Interface Subjected to Laser Shock Wave: Application to Paint Stripping. Materials 2022, 15, 3423. [Google Scholar] [CrossRef]

- Ghrib, M.; Berthe, L.; Mechbal, N.; Rébillat, M.; Guskov, M.; Ecault, R.; Bedreddine, N. Generation of Controlled Delaminations in Composites Using Symmetrical Laser Shock Configuration. Compos. Struct. 2017, 171, 286–297. [Google Scholar] [CrossRef]

- Fabbro, R.; Peyre, P.; Berthe, L.; Scherpereel, X. Physics and Applications of Laser-Shock Processing. J. Laser Appl. 1998, 10, 265–279. [Google Scholar] [CrossRef]

- Fairand, B.P.; Clauer, A.H. Laser Generation of High-amplitude Stress Waves in Materials. J. Appl. Phys. 1979, 50, 1497–1502. [Google Scholar] [CrossRef]

- Davison, L.W. Fundamentals of Shock Wave Propagation in Solids; Shock wave and high pressure phenomena; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 978-3-540-74568-6. [Google Scholar]

- Scius-Bertrand, M.; Videau, L.; Rondepierre, A.; Lescoute, E.; Rouchausse, Y.; Kaufman, J.; Rostohar, D.; Brajer, J.; Berthe, L. Laser Induced Plasma Characterization in Direct and Water Confined Regimes: New Advances in Experimental Studies and Numerical Modelling. J. Phys. D Appl. Phys. 2021, 54, 055204. [Google Scholar] [CrossRef]

- Kormpos, P.; Tserpes, K.; Floros, G. Towards Simulation of Disassembly of Bonded Composite Parts Using the Laser Shock Technique. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1226, 012081. [Google Scholar] [CrossRef]

- Kormpos, P.; Unaldi, S.; Ayad, M.; Berthe, L.; Tserpes, K. Towards the Development of a Laser Shock-Based Disassembly Process for Adhesively Bonded Structural Parts: Experiments and Numerical Simulation. In Proceedings of the 20th European Conference on Composite Materials—Composites Meet Sustainability B, Lausanne, Switzerland, 26–30 June 2022; pp. 873–880. [Google Scholar] [CrossRef]

| Experiment | Number of Specimens | Laser Intensity | Number of Shots |

|---|---|---|---|

| Titanium side shots with VISAR | 4 | 1.2 GW/cm2 | 40 (10/specimen) |

| 3 GW/cm2 | |||

| 4.5 GW/cm2 | |||

| 6 GW/cm2 | |||

| CFRP side shots with VISAR | 4 | 1.2 GW/cm2 | 40 (10/specimen) |

| 3 GW/cm2 | |||

| 4.5 GW/cm2 | |||

| 6 GW/cm2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kormpos, P.; Unaldi, S.; Berthe, L.; Tserpes, K. A Laser Shock-Based Disassembly Process for Adhesively Bonded Ti/CFRP Parts. Processes 2023, 11, 506. https://doi.org/10.3390/pr11020506

Kormpos P, Unaldi S, Berthe L, Tserpes K. A Laser Shock-Based Disassembly Process for Adhesively Bonded Ti/CFRP Parts. Processes. 2023; 11(2):506. https://doi.org/10.3390/pr11020506

Chicago/Turabian StyleKormpos, Panagiotis, Selen Unaldi, Laurent Berthe, and Konstantinos Tserpes. 2023. "A Laser Shock-Based Disassembly Process for Adhesively Bonded Ti/CFRP Parts" Processes 11, no. 2: 506. https://doi.org/10.3390/pr11020506

APA StyleKormpos, P., Unaldi, S., Berthe, L., & Tserpes, K. (2023). A Laser Shock-Based Disassembly Process for Adhesively Bonded Ti/CFRP Parts. Processes, 11(2), 506. https://doi.org/10.3390/pr11020506