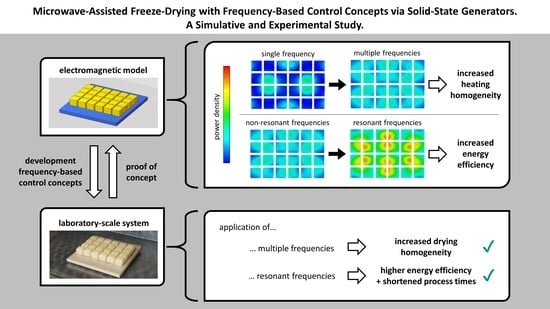

Microwave-Assisted Freeze-Drying with Frequency-Based Control Concepts via Solid-State Generators: A Simulative and Experimental Study

Abstract

1. Introduction

- Freezing of the product;

- Primary drying, in which frozen water is removed by sublimation;

- Secondary drying, in which the remaining water is removed from the product.

2. Materials and Methods

2.1. Electromagnetic Model

2.1.1. Governing Equations and Assumptions

2.1.2. Model Specifications

2.1.3. Simulation Procedure

2.1.4. Post-Processing

- Single Minimum Frequency (1MF)—the single frequency with the global minimum of energy efficiency;

- Single Resonant Frequency (1RF)—the single frequency with the global maximum of energy efficiency;

- Six Equidistant Frequencies (6EF)—frequencies from 2.4 GHz to 2.5 GHz in the interval 0.02 GHz;

- Six Resonant Frequencies (6RF)—six frequencies with the highest local maxima of energy efficiency.

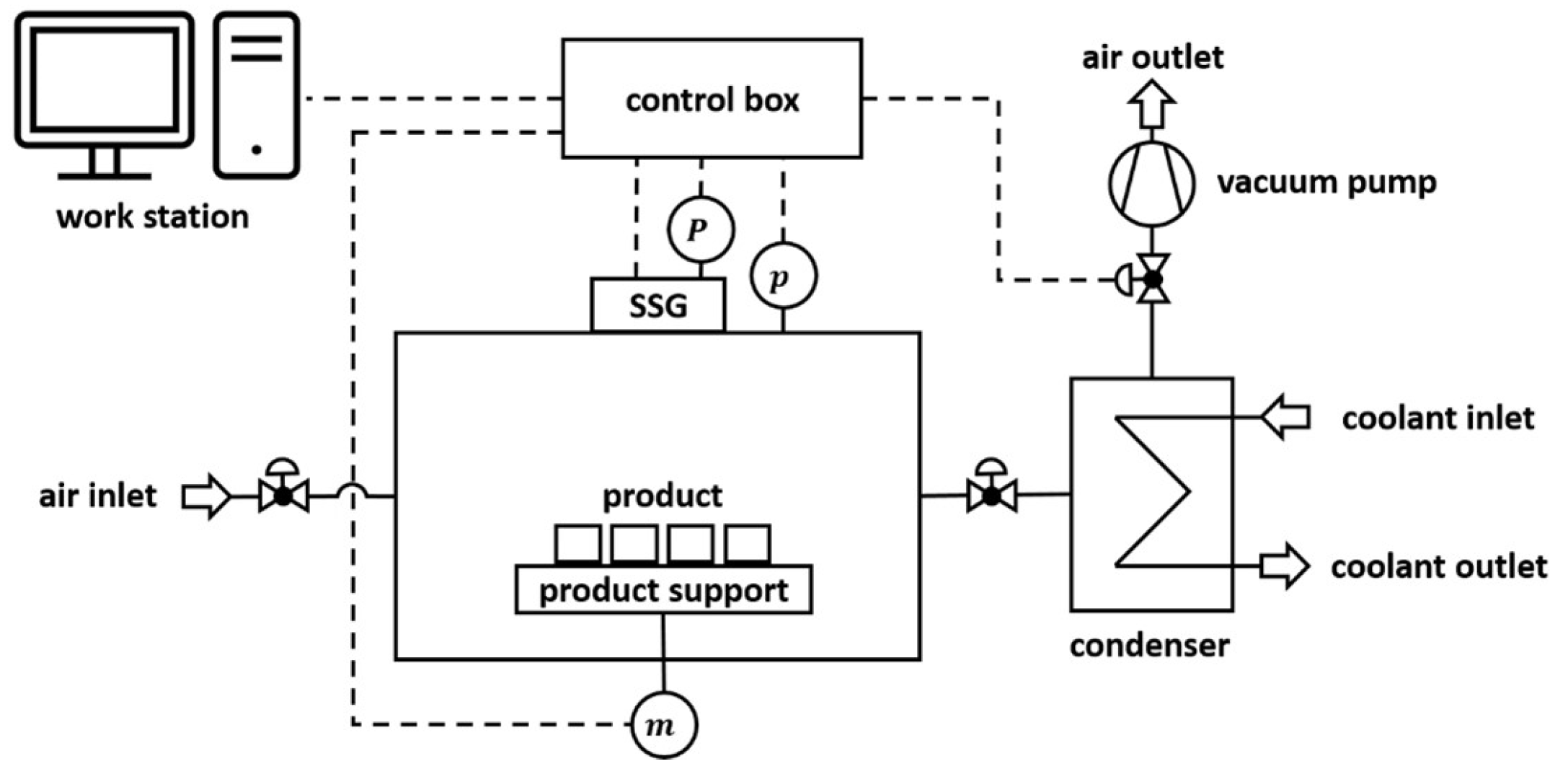

2.2. Experiments

2.2.1. Model Product

2.2.2. Dielectric Properties

2.2.3. MFD System

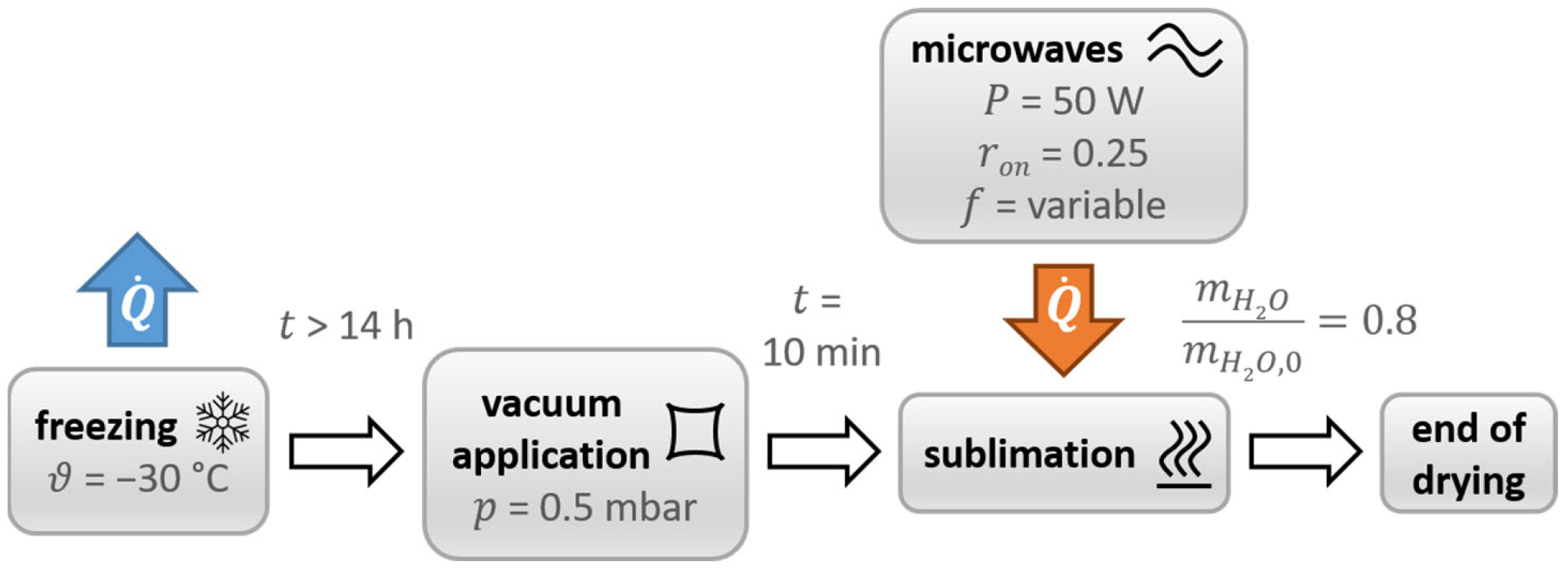

2.2.4. Process Characterization and Drying Procedure

3. Results and Discussion

3.1. Dielectric Properties

3.2. Model Verification

3.3. Model Validation

3.4. Effects of Drying State on Energy Efficiency

3.5. Effects of Control Concepts

3.5.1. Energy Efficiency

3.5.2. Heating Homogeneity

3.6. Experimental Proof of Concept

3.6.1. Energy Efficiency

3.6.2. Drying Homogeneity

3.7. Limitations and Future Work

- Simplification of the geometries of cavity and samples, as well as possible deviations in positions and dimensions;

- Temperature- and frequency-dependency of the dielectric properties are not taken into account;

- Exclusive simulation of the electromagnetic field at discrete times of drying, leading to no consideration of thermodynamic effects;

- Simplifying assumptions throughout drying, including a uniform retreat of the sublimation front in all samples and no shrinkage.

4. Conclusions

- Higher energy efficiency over the whole course of drying when applying energy-efficient resonant frequencies;

- More uniform heating homogeneity between products when targeting multiple frequencies;

- Insignificant effect on power distribution between frozen and dried regions in individual products. The distribution is mainly determined by the higher dielectric properties of the frozen region.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Coumans, W.J.; Kerkhof, P.J.A.M.; Bruin, S. Theoretical and Practical Aspects of Aroma Retention in Spray Drying and Freeze Drying. Dry. Technol. 1994, 12, 99–149. [Google Scholar] [CrossRef]

- Duan, X.; Yang, X.; Ren, G.; Pang, Y.; Liu, L.; Liu, Y. Technical aspects in freeze-drying of foods. Dry. Technol. 2016, 34, 1271–1285. [Google Scholar] [CrossRef]

- Lin, T.M.; Durance, T.; Scaman, C.H. Characterization of vacuum microwave, air and freeze dried carrot slices. Food Res. Int. 1998, 31, 111–117. [Google Scholar] [CrossRef]

- Bhatta, S.; Stevanovic Janezic, T.; Ratti, C. Freeze-Drying of Plant-Based Foods. Foods 2020, 9, 87. [Google Scholar] [CrossRef]

- Ratti, C. Hot air and freeze-drying of high-value foods: A review. J. Food Eng. 2001, 49, 311–319. [Google Scholar] [CrossRef]

- Franks, F. Freeze-drying of bioproducts: Putting principles into practice. Eur. J. Pharm. Biopharm. 1998, 45, 221–229. [Google Scholar] [CrossRef]

- Velardi, S.A.; Barresi, A.A. Development of simplified models for the freeze-drying process and investigation of the optimal operating conditions. Chem. Eng. Res. Des. 2008, 86, 9–22. [Google Scholar] [CrossRef]

- Clark, D.E.; Sutton, W.H. Microwave Processing of Materials. Annu. Rev. Mater. Sci. 1996, 26, 299–331. [Google Scholar] [CrossRef]

- Gitter, J.H.; Geidobler, R.; Presser, I.; Winter, G. Significant Drying Time Reduction Using Microwave-Assisted Freeze-Drying for a Monoclonal Antibody. J. Pharm. Sci. 2018, 107, 2538–2543. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, M.; Mujumdar, A.S. Effects of vacuum and microwave freeze drying on microstructure and quality of potato slices. J. Food Eng. 2010, 101, 131–139. [Google Scholar] [CrossRef]

- Duan, X.; Zhang, M.; Mujumdar, A.S.; Wang, S. Microwave freeze drying of sea cucumber (Stichopus japonicus). J. Food Eng. 2010, 96, 491–497. [Google Scholar] [CrossRef]

- Ma, Y.H.; Peltre, P.R. Freeze dehydration by microwave energy: Part, I. Theoretical investigation. AIChE J. 1975, 21, 335–344. [Google Scholar] [CrossRef]

- Ma, Y.H.; Peltre, P.R. Freeze dehydration by microwave energy: Part II. Experimental study. AIChE J. 1975, 21, 344–350. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, M.; Mujumdar, A.S.; Mothibe, K.J. Microwave-Assisted Pulse-Spouted Bed Freeze-Drying of Stem Lettuce Slices—Effect on Product Quality. Food Bioprocess Technol. 2013, 6, 3530–3543. [Google Scholar] [CrossRef]

- Ozcelik, M.; Heigl, A.; Kulozik, U.; Ambros, S. Effect of hydrocolloid addition and microwave-assisted freeze drying on the characteristics of foamed raspberry puree. Innov. Food Sci. Emerg. Technol. 2019, 56, 102183. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, M.; Mujumdar, A.S.; Lim, R.-X. Drying uniformity analysis of pulse-spouted microwave–freeze drying of banana cubes. Dry. Technol. 2016, 34, 539–546. [Google Scholar] [CrossRef]

- Ambros, S.; Mayer, R.; Schumann, B.; Kulozik, U. Microwave-freeze drying of lactic acid bacteria: Influence of process parameters on drying behavior and viability. Innov. Food Sci. Emerg. Technol. 2018, 48, 90–98. [Google Scholar] [CrossRef]

- Gitter, J.H.; Geidobler, R.; Presser, I.; Winter, G. Microwave-Assisted Freeze-Drying of Monoclonal Antibodies: Product Quality Aspects and Storage Stability. Pharmaceutics 2019, 11, 674. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, S.; Pan, Y.; Tang, Y.; Chen, G. Wave-absorbing material aided microwave freeze-drying of vitamin C solution frozen with preformed pores. Dry. Technol. 2020, 51, 2025–2038. [Google Scholar] [CrossRef]

- Witkiewicz, K.; Nastaj, J.F. Simulation Strategies in Mathematical Modeling of Microwave Heating in Freeze-Drying Process. Dry. Technol. 2010, 28, 1001–1012. [Google Scholar] [CrossRef]

- Park, J.; Cho, J.H.; Braatz, R.D. Mathematical modeling and analysis of microwave-assisted freeze-drying in biopharmaceutical applications. Comput. Chem. Eng. 2021, 153, 107412. [Google Scholar] [CrossRef]

- Luan, D.; Wang, Y.; Tang, J.; Jain, D. Frequency Distribution in Domestic Microwave Ovens and Its Influence on Heating Pattern. J. Food Sci. 2017, 82, 429–436. [Google Scholar] [CrossRef]

- Li, Z.Y.; Wang, R.F.; Kudra, T. Uniformity Issue in Microwave Drying. Dry. Technol. 2011, 29, 652–660. [Google Scholar] [CrossRef]

- Atuonwu, J.C.; Tassou, S.A. Quality assurance in microwave food processing and the enabling potentials of solid-state power generators: A review. J. Food Eng. 2018, 234, 1–15. [Google Scholar] [CrossRef]

- Bianchi, C.; Bonato, P.; Dughiero, F.; Canu, P. Enhanced power density uniformity for microwave catalytic reactions adopting solid-state generators: Comparison with magnetron technology. Chem. Eng. Process. Process Intensif. 2017, 120, 286–300. [Google Scholar] [CrossRef]

- Taghian Dinani, S.; Feldmann, E.; Kulozik, U. Effect of heating by solid-state microwave technology at fixed frequencies or by frequency sweep loops on heating profiles in model food samples. Food Bioprod. Process. 2021, 127, 328–337. [Google Scholar] [CrossRef]

- Yang, R.; Fathy, A.E.; Morgan, M.T.; Chen, J. Development of a complementary-frequency strategy to improve microwave heating of gellan gel in a solid-state system. J. Food Eng. 2022, 314, 110763. [Google Scholar] [CrossRef]

- Zhou, J.; Li, Y.; Li, N.; Liu, S.; Cheng, L.; Sui, S.; Gao, J. A multi-pattern compensation method to ensure even temperature in composite materials during microwave curing process. Compos. Part A 2018, 107, 10–20. [Google Scholar] [CrossRef]

- Yakovlev, V.V. Effect of frequency alteration regimes on the heating patterns in a solid-state-fed microwave cavity. J. Microw. Power Electromagn. Energy 2018, 52, 31–44. [Google Scholar] [CrossRef]

- Pozar, D.M. Microwave Engineering, 4th ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2012; pp. 300–302. ISBN 0470631554. [Google Scholar]

- Capozzi, L.C.; Barresi, A.A.; Pisano, R. Supporting data and methods for the multi-scale modelling of freeze-drying of microparticles in packed-beds. Data Brief 2019, 22, 722–755. [Google Scholar] [CrossRef]

- Chaurasiya, V.; Singh, J. An analytical study of coupled heat and mass transfer freeze-drying with convection in a porous half body: A moving boundary problem. J. Energy Storage 2022, 55, 105394. [Google Scholar] [CrossRef]

- Maxwell, J.C. VIII. A dynamical theory of the electromagnetic field. Phil. Trans. R. Soc. 1865, 155, 459–512. [Google Scholar] [CrossRef]

- Huray, P.G. Maxwell’s Equations; Wiley: Hoboken, NJ, USA, 2010; p. xiii. ISBN 978-0-470-54276-7. [Google Scholar]

- Llave, Y.; Mori, K.; Kambayashi, D.; Fukuoka, M.; Sakai, N. Dielectric properties and model food application of tylose water pastes during microwave thawing and heating. J. Food Eng. 2016, 178, 20–30. [Google Scholar] [CrossRef]

- Metaxas, A.C.; Meredith, R.J. Industrial Microwave Heating; IET: London, UK, 1988; p. 72. ISBN 978-1-84919-424-2. [Google Scholar]

- Guan, Y.; Nikawa, Y. Measurement of temperature-dependent complex permittivity for materials using cylindrical resonator under microwave irradiation. Electron. Commun. Jpn. 2007, 90, 1–8. [Google Scholar] [CrossRef]

- Więckowski, A.; Korpas, P.; Krysicki, M.; Dughiero, F.; Bullo, M.; Bressan, F.; Fager, C. Efficiency optimization for phase controlled multi-source microwave oven. Int. J. Appl. Electromagn. Mech. 2014, 44, 235–241. [Google Scholar] [CrossRef]

- Curet, S.; Rouaud, O.; Boillereaux, L. Microwave tempering and heating in a single-mode cavity: Numerical and experimental investigations. Chem. Eng. Process. Process Intensif. 2008, 47, 1656–1665. [Google Scholar] [CrossRef]

- Riedel, L. A test substance for freezing experiments. Kaltetechnik 1960, 12, 222–225. [Google Scholar]

- Deep, C.; Pratihar, A.K.; Sharma, M.K. Freezing time-temperature behavior and parametric study of cylindrical shaped tylose gel samples: A numerical and experimental study. Therm. Sci. Eng. Prog. 2021, 24, 100933. [Google Scholar] [CrossRef]

- Kaatze, U.; Uhlendorf, V. The Dielectric Properties of Water at Microwave Frequencies. Z. Phys. Chem. 1981, 126, 151–165. [Google Scholar] [CrossRef]

- Matzler, C.; Wegmuller, U. Dielectric properties of freshwater ice at microwave frequencies. J. Phys. D Appl. Phys. 1987, 20, 1623–1630. [Google Scholar] [CrossRef]

- Chamchong, M.; Datta, A.K. Thawing of foods in a microwave oven: I. Effect of power levels and power cycling. J. Microwave Power Electromagn. Energy 1999, 34, 9–21. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, M.; Mujumdar, A.S.; Jiang, H. Effect of salt and sucrose content on dielectric properties and microwave freeze drying behavior of re-structured potato slices. J. Food Eng. 2011, 106, 290–297. [Google Scholar] [CrossRef]

- Marti, J.; Mauersberger, K. A survey and new measurements of ice vapor pressure at temperatures between 170 and 250 K. Geophys. Res. Lett. 1993, 20, 363–366. [Google Scholar] [CrossRef]

- Du, Z.; Wu, Z.; Gan, W.; Liu, G.; Zhang, X.; Liu, J.; Zeng, B. Multi-Physics Modeling and Process Simulation for a Frequency-Shifted Solid-State Source Microwave Oven. IEEE Access 2019, 7, 184726–184733. [Google Scholar] [CrossRef]

- Pitchai, K.; Birla, S.L.; Subbiah, J.; Jones, D.; Thippareddi, H. Coupled electromagnetic and heat transfer model for microwave heating in domestic ovens. J. Food Eng. 2012, 112, 100–111. [Google Scholar] [CrossRef]

- Polaert, I.; Ledoux, A.; Estel, L.; Huyghe, R.; Thomas, M. Microwave Assisted Regeneration of Zeolite. Int. J. Chem. Reactor Eng. 2007, 5, A117. [Google Scholar] [CrossRef]

- Antonio, C.; Deam, R.T. Comparison of linear and non-linear sweep rate regimes in variable frequency microwave technique for uniform heating in materials processing. J. Mater. Process. Technol. 2005, 169, 234–241. [Google Scholar] [CrossRef]

- Ma, L.; Paul, D.-L.; Pothecary, N.; Railton, C.; Bows, J.; Barratt, L.; Mullin, J.; Simons, D. Experimental validation of a combined electromagnetic and thermal FDTD model of a microwave heating process. IEEE Trans. Microwave Theory Tech. 1995, 43, 2565–2572. [Google Scholar] [CrossRef]

- Bressan, F.; Dughiero, F.; Bullo, M.; Di Barba, P. Efficiency optimization of a two-port microwave oven: A robust automated procedure. COMPEL 2015, 34, 1213–1228. [Google Scholar] [CrossRef]

- Tang, Z.; Hong, T.; Liao, Y.; Chen, F.; Ye, J.; Zhu, H.; Huang, K. Frequency-selected method to improve microwave heating performance. Appl. Therm. Eng. 2018, 131, 642–648. [Google Scholar] [CrossRef]

- Tang, Z.; Zhang, S.; Hong, T.; Zhu, H.; Huang, K. Frequency-selected microwave heating: Its mathematical physics basis and characteristics. Int. J. RF Microwave Comput. Aided Eng. 2020, 30, 24. [Google Scholar] [CrossRef]

- Yang, R.; Fathy, A.E.; Morgan, M.T.; Chen, J. Development of online closed-loop frequency shifting strategies to improve heating performance of foods in a solid-state microwave system. Food Res. Int. 2022, 154, 110985. [Google Scholar] [CrossRef] [PubMed]

| Material | Relative Dielectric Constant /- | Relative Dielectric Loss Factor /- | Source |

|---|---|---|---|

| PEEK | 3.142 | 0.0085 | [37] |

| tylose gel, dried | 1.264 | 0.0473 | present study |

| tylose gel, frozen | 3.649 | 0.5807 | present study |

| vacuum | 1.000 | 0.0000 | per definition |

| Drying State z/% | 0 | 20 | 40 | 60 | 80 | 100 | W/m3 |

| 1MF |  |  |  |  |  |  | |

| 1RF |  |  |  |  |  |  | |

| 6EF |  |  |  |  |  |  | |

| 6RF |  |  |  |  |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sickert, T.; Kalinke, I.; Christoph, J.; Gaukel, V. Microwave-Assisted Freeze-Drying with Frequency-Based Control Concepts via Solid-State Generators: A Simulative and Experimental Study. Processes 2023, 11, 327. https://doi.org/10.3390/pr11020327

Sickert T, Kalinke I, Christoph J, Gaukel V. Microwave-Assisted Freeze-Drying with Frequency-Based Control Concepts via Solid-State Generators: A Simulative and Experimental Study. Processes. 2023; 11(2):327. https://doi.org/10.3390/pr11020327

Chicago/Turabian StyleSickert, Till, Isabel Kalinke, Jana Christoph, and Volker Gaukel. 2023. "Microwave-Assisted Freeze-Drying with Frequency-Based Control Concepts via Solid-State Generators: A Simulative and Experimental Study" Processes 11, no. 2: 327. https://doi.org/10.3390/pr11020327

APA StyleSickert, T., Kalinke, I., Christoph, J., & Gaukel, V. (2023). Microwave-Assisted Freeze-Drying with Frequency-Based Control Concepts via Solid-State Generators: A Simulative and Experimental Study. Processes, 11(2), 327. https://doi.org/10.3390/pr11020327