Multiphysics Mathematical Modeling and Flow Field Analysis of an Inflatable Membrane Aeroshell in Suborbital Reentry

Abstract

:1. Introduction

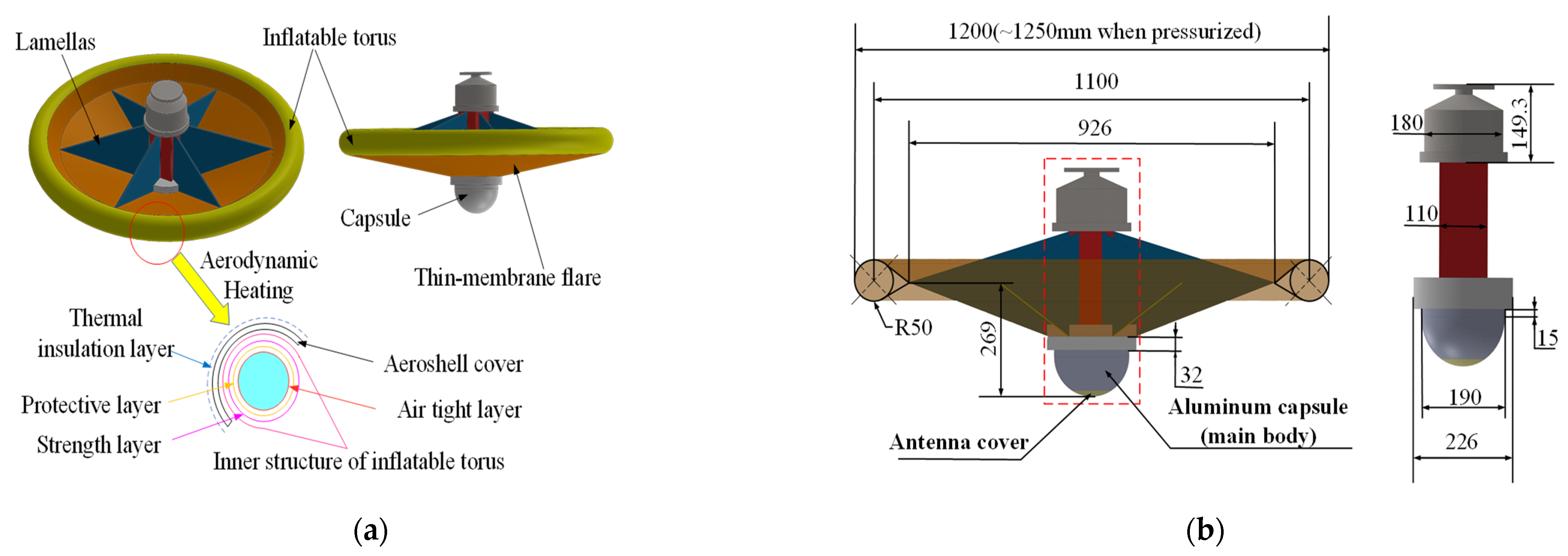

2. Inflatable Membrane Aeroshell

2.1. Configuration of the Membrane Reentry Vehicle

2.2. Flight Sequence

2.3. Attitude Motion

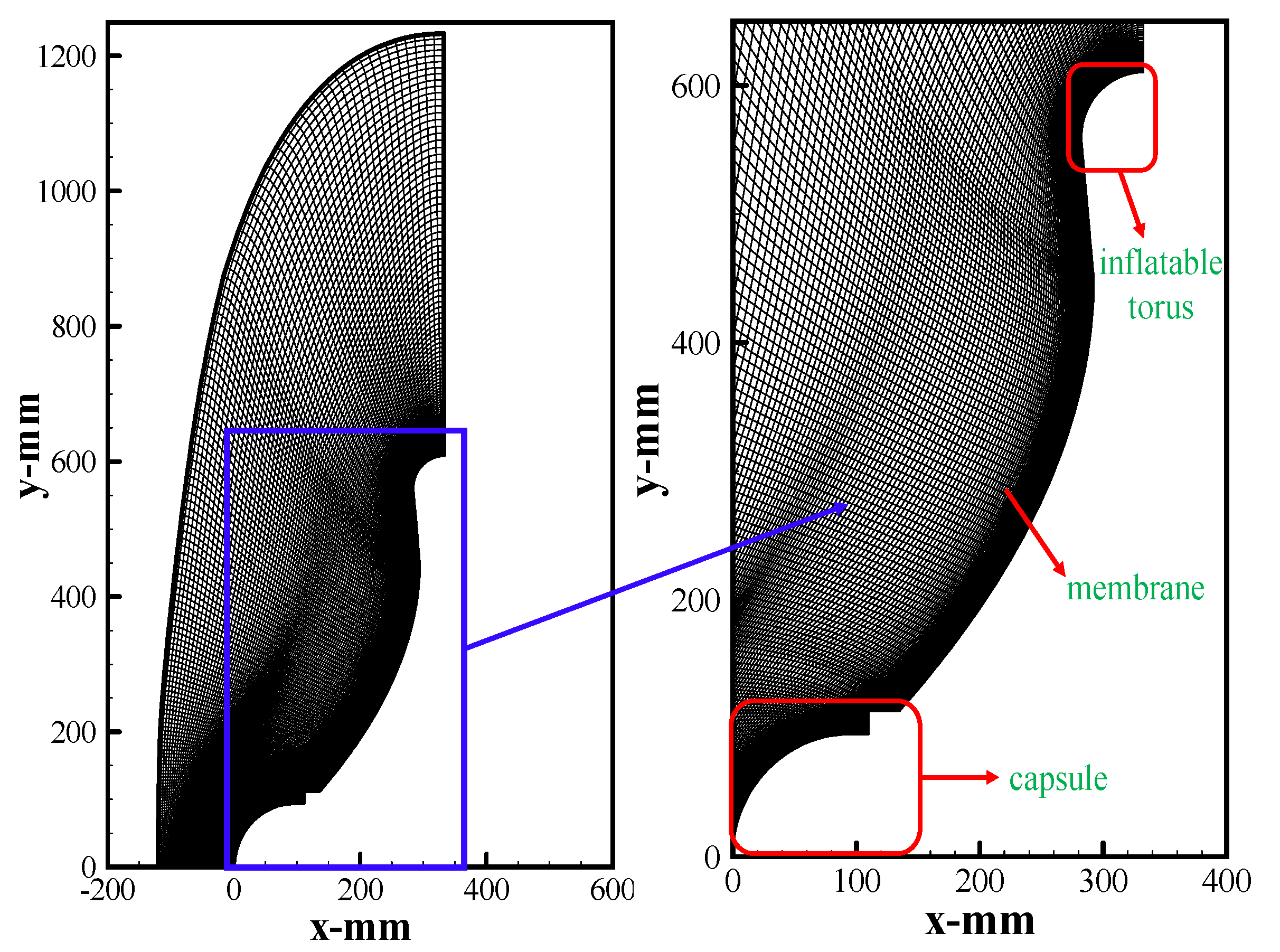

3. Simulation Framework

3.1. Heat Conduction Equations

3.1.1. Capsule Part

3.1.2. Membrane Part

3.2. Flow Field Equations

3.3. Boundary and Calculation Conditions

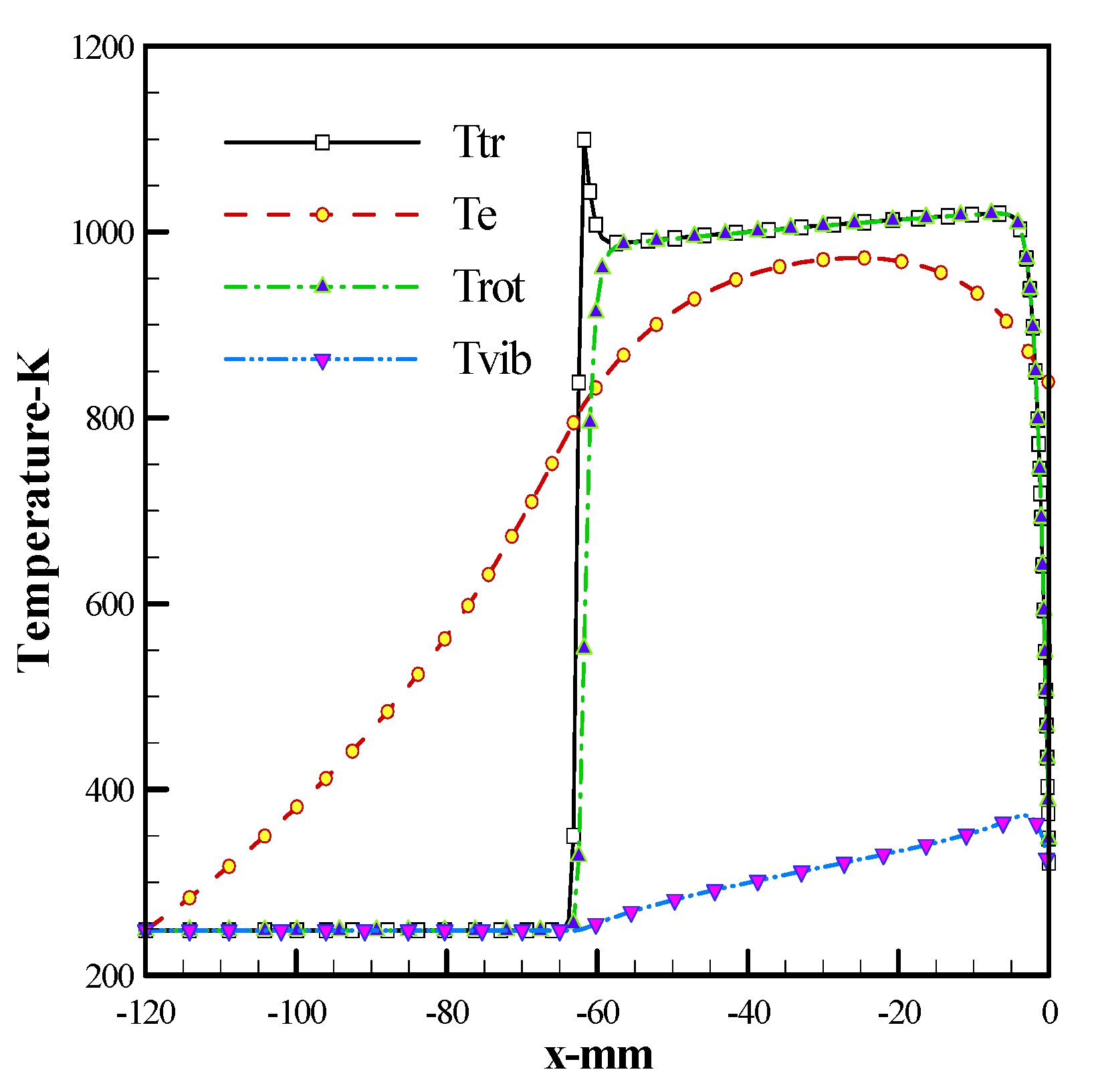

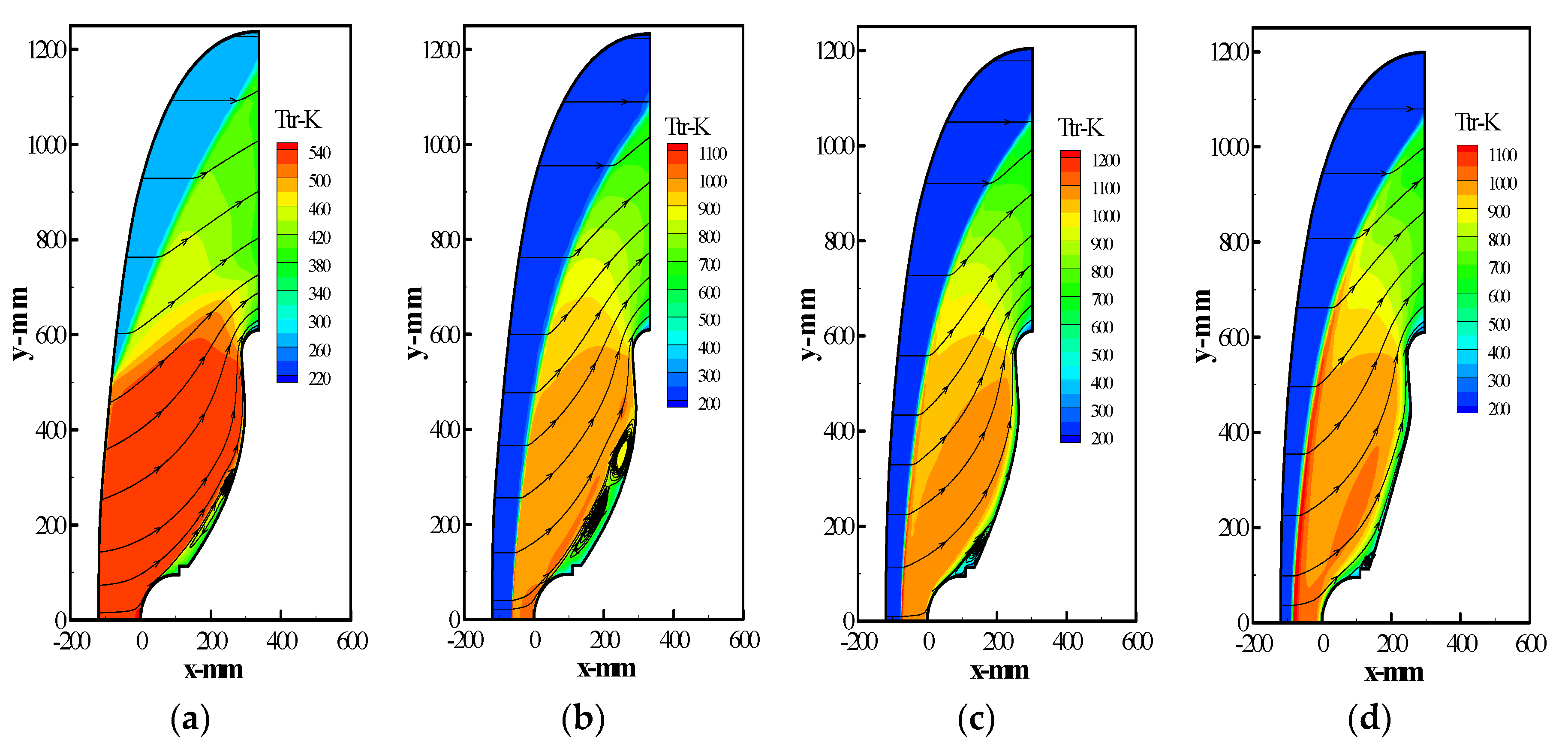

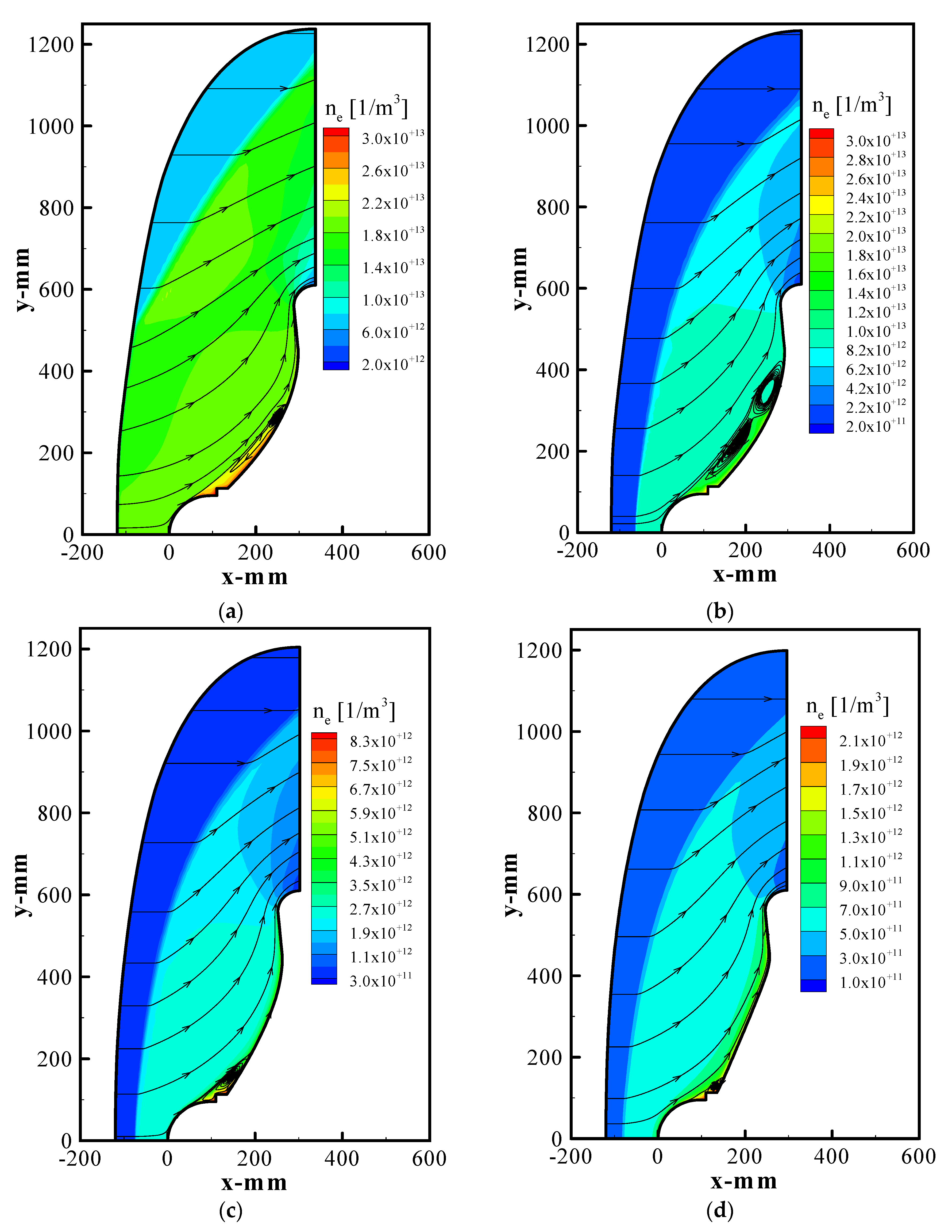

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, R.X.; Wang, Z.W.; Zheng, H.W.; Song, H.W. Comparison of Strategies for Coupled Flow-Thermal Analysis of Thermal Protection System at Hypersonic Flight Condition. Int. J. Aeronaut. Space Sci. 2019, 21, 347–362. [Google Scholar] [CrossRef]

- Takahashi, Y.; Koike, T.; Oshima, N.; Yamada, K. Aerothermodynamic analysis for deformed membrane of inflatable aeroshell in orbital reentry mission. Aerosp. Sci. Technol. 2019, 92, 858–868. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, J.H.; Kim, K. A Numerical Study on the Effect of the Umbilical Plate on Longitudinal Controllability of a Low Aspect Ratio Launch Vehicle. Int. J. Aeronaut. Space Sci. 2019, 20, 870–878. [Google Scholar] [CrossRef]

- Yang, M.F.; Zhang, W.; Peng, J.; Zhang, G. Technical advancements and significance of circumlunar return and reentry spacecraft. Sci. China Technol. Sci. 2015, 58, 738–745. [Google Scholar] [CrossRef]

- Wei, J.Z.; Tan, H.F.; Wang, W.Z.; He, X.D. New Trends in Inflatable Re-Entry Aeroshell. J. B. Univ. Aeronaut. Astronaut. 2013, 34, 881–890. [Google Scholar]

- Hong, Y.; Xue, G. The feasibility analysis of the application of TPV system in reentry. Sci. China Technol. Sci. 2010, 53, 3310–3315. [Google Scholar]

- Reynier, P.; Evans, D. Postflight Analysis of Inflatable Reentry and Descent Technology Blackout During Earth Reentry. J. Spacecr. Rockets 2009, 46, 800–809. [Google Scholar] [CrossRef]

- Clark, I.G.; Hutchings, A.L.; Tanner, C.L.; Braun, R.D. Supersonic Inflatable Aerodynamic Decelerators for Use On Future Robotic Missions to Mars. J. Spacecr. Rockets 2009, 46, 340–352. [Google Scholar] [CrossRef] [Green Version]

- Rohrschneider, R.R.; Braun, R.D. Survey of Ballute Technology for Aerocapture. J. Spacecr. Rocket. 2007, 44, 10–23. [Google Scholar] [CrossRef] [Green Version]

- Yamada, K.; Abe, T.; Suzuki, K.; Honma, N.; Koyama, M.; Nagata, Y.; Abe, D.; Kimura, Y.; Hayashi, A.K.; Akita, D.; et al. Deployment and Flight Test of Inflatable Membrane Aeroshell Using Large Scientific Balloon. In Proceedings of the 21st AIAA Aerodynamic Decelerator Systems Technology Conference and Seminar, Dublin, Ireland, 23–26 May 2011. [Google Scholar]

- Yamada, K.; Akita, D.; Sato, E.; Suzuki, K.; Narumi, T.; Abe, T. Flare-Type Membrane Aeroshell Flight Test at Free Drop from a Balloon. J. Spacecr. Rockets 2009, 46, 606–614. [Google Scholar] [CrossRef]

- Kusano, Y.; Nakashino, K. Experimental and Numerical Study of Structural Strength of Flare-Type Membrane Aeroshell with Inflatable Ring. Trans. JSASS Aerosp. Tech. Jpn. 2014, 12, 99–105. [Google Scholar] [CrossRef]

- Yamada, K.; Koyama, M.; Kimura, Y.; Suzuki, K.; Abe, T.; Hayashi, A.K. Hypersonic Wind Tunnel Test of a Flare-type Membrane Aeroshell for Atmospheric Entry Capsules. Trans. JSASS Aerosp. Tech. Jpn. 2010, 8, 27–32. [Google Scholar] [CrossRef]

- Yamada, K.; Abe, T.; Suzuki, K.; Imamura, O.; Akita, D. Reentry Demonstration Plan of Flare-type Membrane Aeroshell for Atmospheric Entry Vehicle Using a Sounding Rocket. In Proceedings of the 21st AIAA Aerodynamic Decelerator Systems Technology Conference and Seminar, Dublin, Ireland, 23–26 May 2011. [Google Scholar]

- Yamada, K.; Nagata, Y.; Abe, T.; Suzuki, K.; Imamura, O.; Akita, D. Suborbital Reentry Demonstration of Inflatable Flare-Type Thin-Membrane Aeroshell Using a Sounding Rocket. J. Spacecr. Rockets 2015, 52, 275–284. [Google Scholar] [CrossRef]

- Yamada, K.; Nagata, Y.; Abe, T.; Suzuki, K.; Imamura, O.; Akita, D. Reentry Demonstration of Flare-type Membrane Aeroshell for Atmospheric Entry Vehicle using a Sounding Rocket. In Proceedings of the AIAA Aerodynamic Decelerator Systems (ADS) Conference, Daytona Beach, FL, USA, 25–28 March 2013. [Google Scholar]

- Nagata, Y.; Yamada, K.; Abe, T.; Suzuki, K. Attitude Dynamics for Flare-type Membrane Aeroshell Capsule in Re-entry Flight Experiment. In Proceedings of the AIAA Aerodynamic Decelerator Systems (ADS) Conference, Daytona Beach, FL, USA, 25–28 March 2013. [Google Scholar]

- Takahashi, Y.; Ha, D.; Oshima, N.; Yamada, K.; Abe, T.; Suzuki, K. Aerodecelerator Performance of Flare-Type Membrane Inflatable Vehicle in Suborbital Reentry. J. Spacecr. Rockets 2017, 54, 993–1004. [Google Scholar] [CrossRef] [Green Version]

- Takahashi, Y.; Yamada, K.; Abe, T.; Suzuki, K. Aerodynamic Heating Around Flare-Type Membrane Inflatable Vehicle in Suborbital Reentry Demonstration Flight. J. Spacecr. Rockets 2015, 52, 1530–1541. [Google Scholar] [CrossRef] [Green Version]

- Takahashi, Y.; Yamada, K.; Abe, T. Examination of Radio Frequency Blackout for an Inflatable Vehicle During Atmospheric Reentry. J. Spacecr. Rockets 2014, 51, 430–441. [Google Scholar] [CrossRef] [Green Version]

- Takahashi, Y.; Yamada, K.; Abe, T. Radio Frequency Blackout Possibility for an Inflatable Reentry Vehicle. In Proceedings of the 42nd AIAA Fluid Dynamics Conference and Exhibit, New Orleans, LA, USA, 25–28 June 2012. [Google Scholar]

- Gilbert, C.; Mazoue, F.; Ortega, G.; Pichkhadze, K.; Costa, R.D. New Space Application Opportunities Based on the Inflatable Reentry & Descent Technology IRDT. In Proceedings of the Aiaa International Air & Space Symposium & Exposition: The Next 100 Years, Dayton, OH, USA, 14–17 July 2013. [Google Scholar]

- Marraffa, L.; Vennemann, D.; Anschuetz, U.; Walther, S.; Stelter, C.S.; Pitchkhadze, K.M.; Finchenko, V.S. IRDT—Inflatable Re-entry and Descent Technology. Hot Struct. Therm. Prot. Syst. Space Veh. 2003, 521, 19–28. [Google Scholar]

- Litton, D.K.; Bose, D.M.; Cheatwood, F.M.; Hughes, S.; Wright, H.S.; Lindell, M.C.; Derry, S.D.; Olds, A. Inflatable Reentry Vehicle Experiment (IRVE)—4 Overview. In Proceedings of the 21st AIAA Aerodynamic Decelerator Systems Technology Conference and Seminar, Dublin, Ireland, 23–26 May 2011. [Google Scholar]

- Carlson, L.A.; Horn, W.J. New thermal and trajectory model for high-altitude balloons. J. Aircr. 1983, 20, 500–507. [Google Scholar] [CrossRef]

- Yos, J. Transport properties of nitrogen, hydrogen, oxygen, and air to 30,000 K. In Proceedings of the Research and Advanced Developm Ent Division Avco Corporation, Wilmington, NC, USA, 22 March 1963. [Google Scholar]

- Gupta, R.N.; Yos, J.M.; Thompson, R.A. A review of reaction rates and thermodynamic and transport properties for the 11-species air model for chemical and thermal nonequilibrium calculations to 30,000 K. NTRS 1990, 1, 1–68. [Google Scholar]

- Shima, E.; Kitamura, K. Parameter-Free Simple Low-Dissipation AUSM-Family Scheme for All Speeds. AIAA J. 2011, 49, 1693–1709. [Google Scholar] [CrossRef]

- Jameson, A.; Yoon, S. Lower-upper implicit schemes with multiple grids for the Euler equations. AIAA J. 1987, 25, 929–935. [Google Scholar] [CrossRef]

- Yamada, K.; Suzuki, K. A Particle-Based Model and Its Validation for Deformation Analysis of Membrane Aeroshell. J. Jpn Soc. Aeronaut. Space Sci. 2005, 53, 51–60. [Google Scholar]

| Time, s | Altitude, km | Case |

|---|---|---|

| 0 | 0 | The rocket launched as planned |

| 60 | 70 | The front cone of the rocket opened automatically |

| 90 | 100 | The aeroshell cover was deployed under external conditions |

| 95 | 106 | CO2 was injected into the torus |

| 100 | 111 | The aircraft disengaged from the rocket |

| 191 | 150 | The vehicle reached the highest point of the orbit |

| 320 | 70 | The acceleration of the vehicle decreases gradually |

| 400 | 32 | Velocity became less than 150 m/s and attained equilibrium |

| 1320 | 0 | Splashdown |

| Polyimide Resin | Aluminum | |

|---|---|---|

| Density, kg/m3 | 1400 | 2700 |

| Specific heat, J/(kg·K) | 1050 | 900 |

| Heat conductivity, W/(m·K) | 0.290 | 237 |

| Emissivity | 0.9 | 0.3 |

| Elapsed Time, s | 316 | 324 | 332 | 344 |

| Altitude, km | 77.0 | 68.0 | 58.0 | 47.0 |

| Velocity, m/s | 1284.5 | 1324.5 | 1249.5 | 749.7 |

| Density, kg/m3 | 3.03 × 10−5 | 1.12 × 10−4 | 4.24 × 10−4 | 1.67 × 10−3 |

| Temperature, K | 203.7 | 221.5 | 248.3 | 263.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, M.; Qiu, Z.; Lv, B.; Takahashi, Y. Multiphysics Mathematical Modeling and Flow Field Analysis of an Inflatable Membrane Aeroshell in Suborbital Reentry. Mathematics 2022, 10, 832. https://doi.org/10.3390/math10050832

Yu M, Qiu Z, Lv B, Takahashi Y. Multiphysics Mathematical Modeling and Flow Field Analysis of an Inflatable Membrane Aeroshell in Suborbital Reentry. Mathematics. 2022; 10(5):832. https://doi.org/10.3390/math10050832

Chicago/Turabian StyleYu, Minghao, Zeyang Qiu, Bo Lv, and Yusuke Takahashi. 2022. "Multiphysics Mathematical Modeling and Flow Field Analysis of an Inflatable Membrane Aeroshell in Suborbital Reentry" Mathematics 10, no. 5: 832. https://doi.org/10.3390/math10050832

APA StyleYu, M., Qiu, Z., Lv, B., & Takahashi, Y. (2022). Multiphysics Mathematical Modeling and Flow Field Analysis of an Inflatable Membrane Aeroshell in Suborbital Reentry. Mathematics, 10(5), 832. https://doi.org/10.3390/math10050832