Assessing the Critical Multifunctionality Threshold for Optimal Electrical, Thermal, and Nanomechanical Properties of Carbon Nanotubes/Epoxy Nanocomposites for Aerospace Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composites Preparation

2.3. Characterization Techniques

2.3.1. Optical Microscopy

2.3.2. Scanning Electron Microscopy

2.3.3. X-ray Microcomputed Tomography (Micro-CT)

2.3.4. Electrical Measurements

2.3.5. Thermogravimetric Analysis

2.3.6. Nanomechanical Assessment

3. Results and Discussion

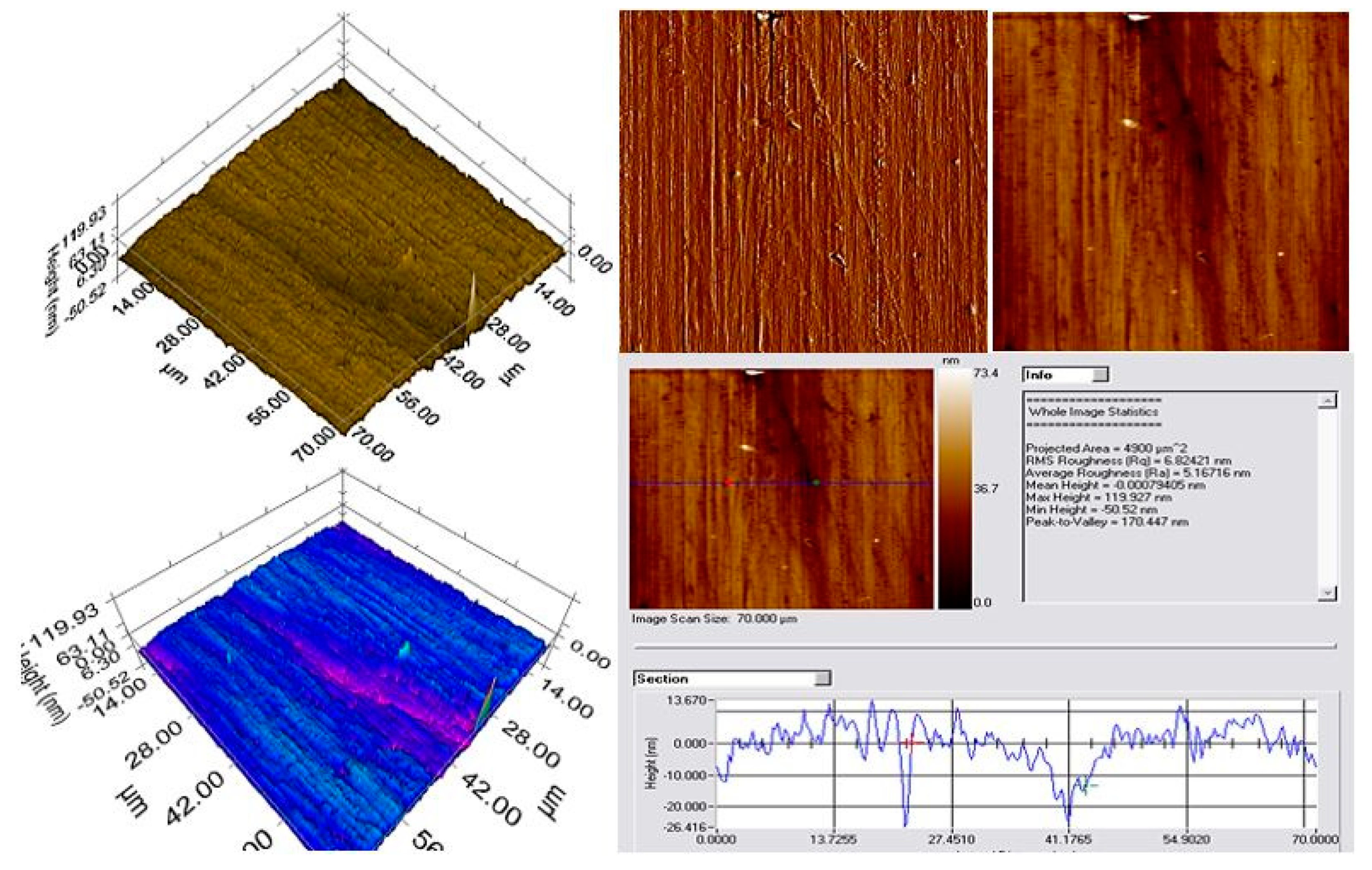

3.1. Dispersion Characterization

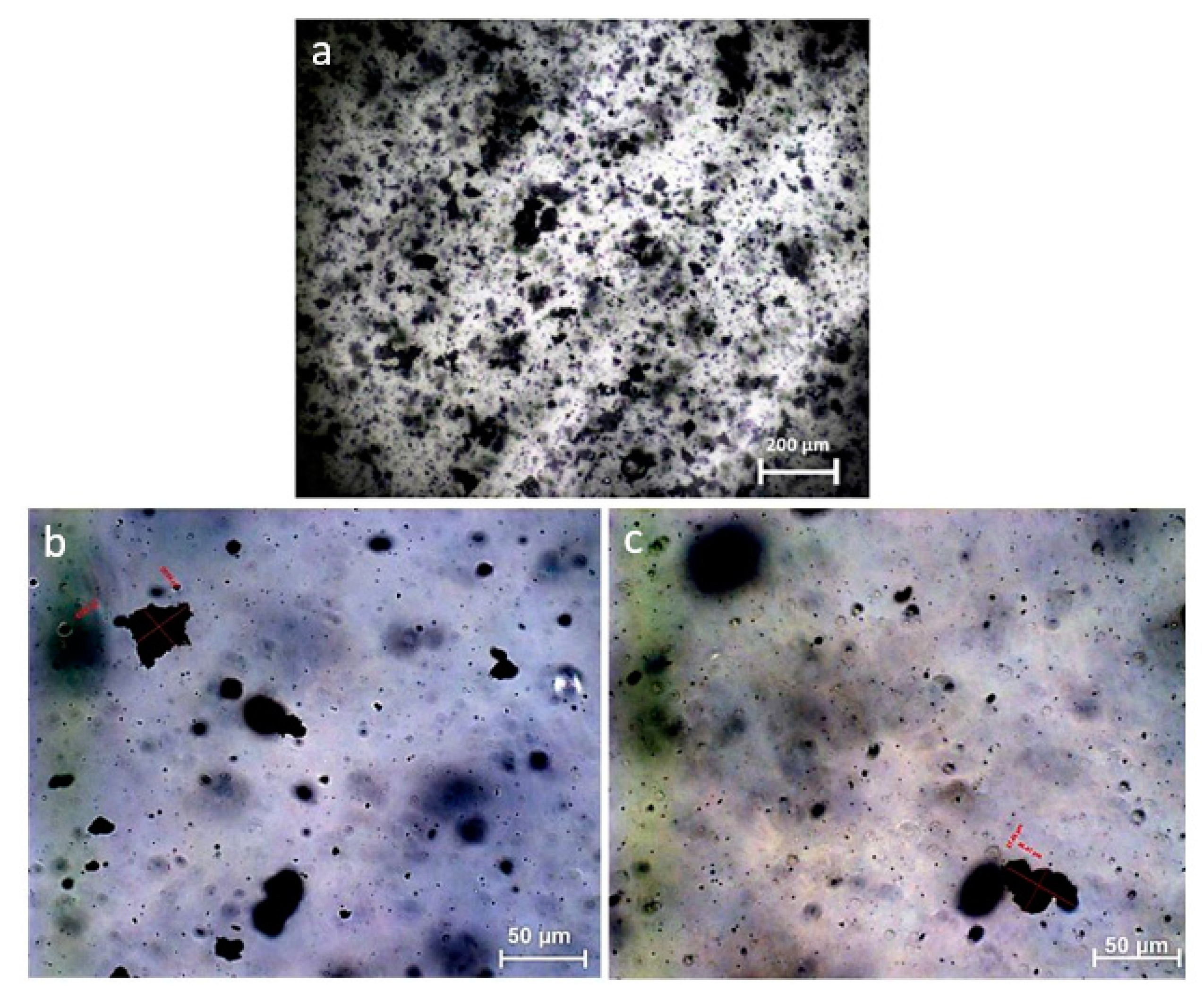

3.1.1. Optical Microscopy

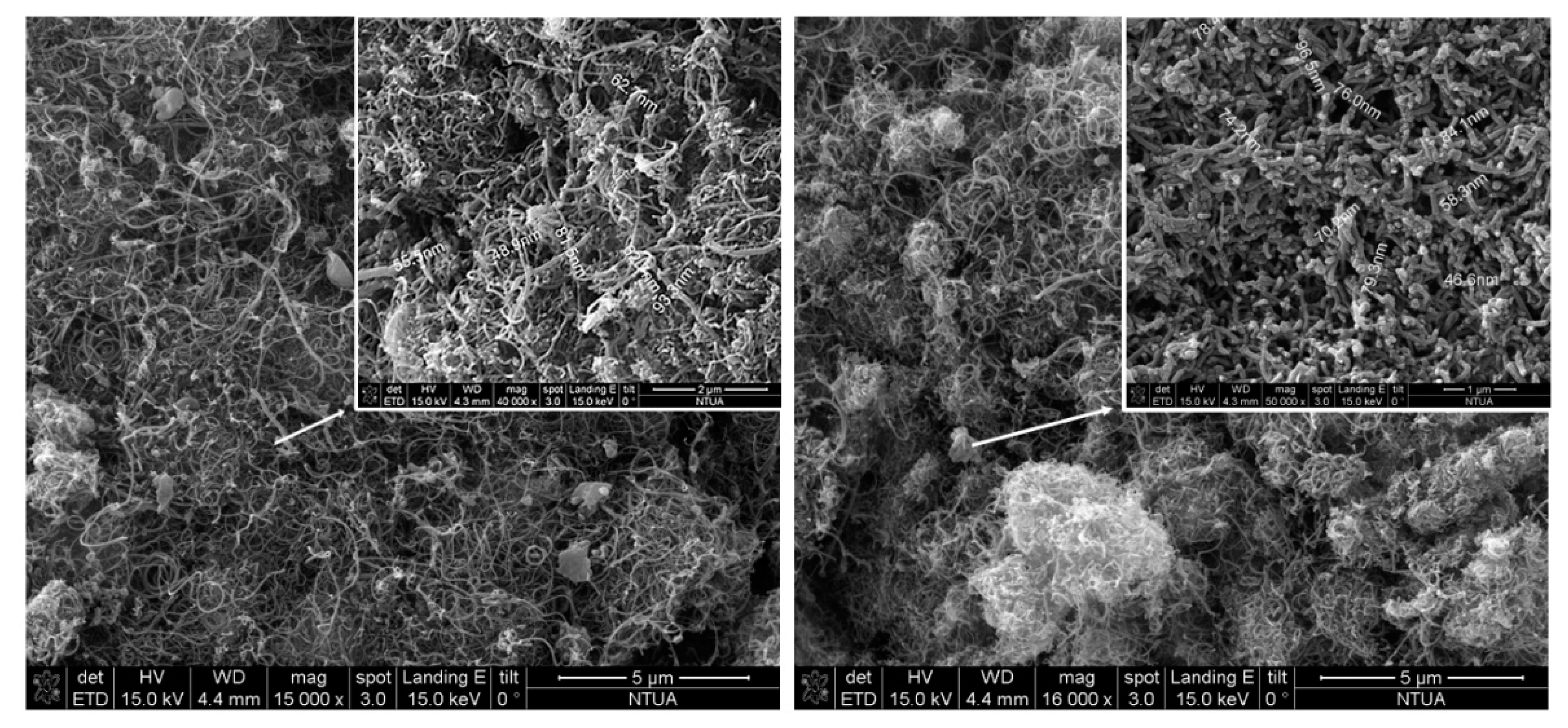

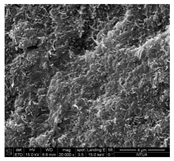

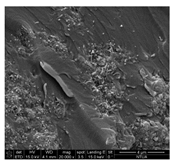

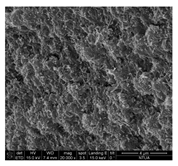

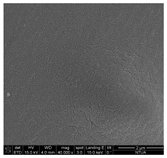

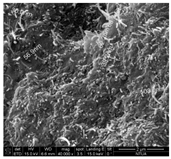

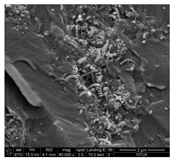

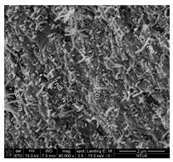

3.1.2. Study of Cryo-Fractured Surface

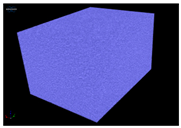

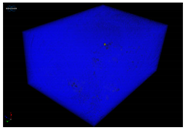

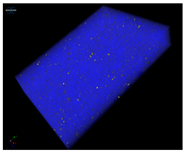

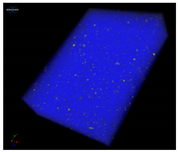

3.1.3. Evaluation of Dispersion through Micro-CT

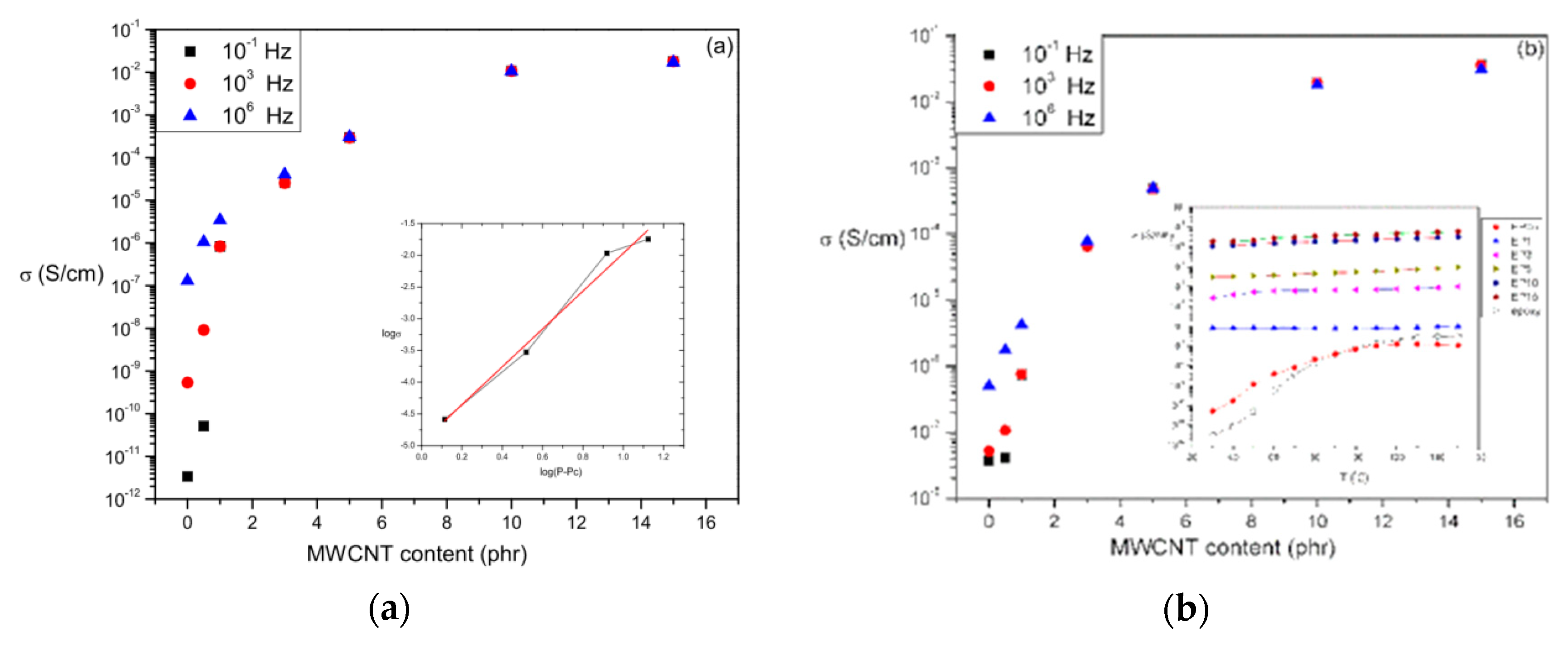

3.2. Electrical Conductivity Evaluation

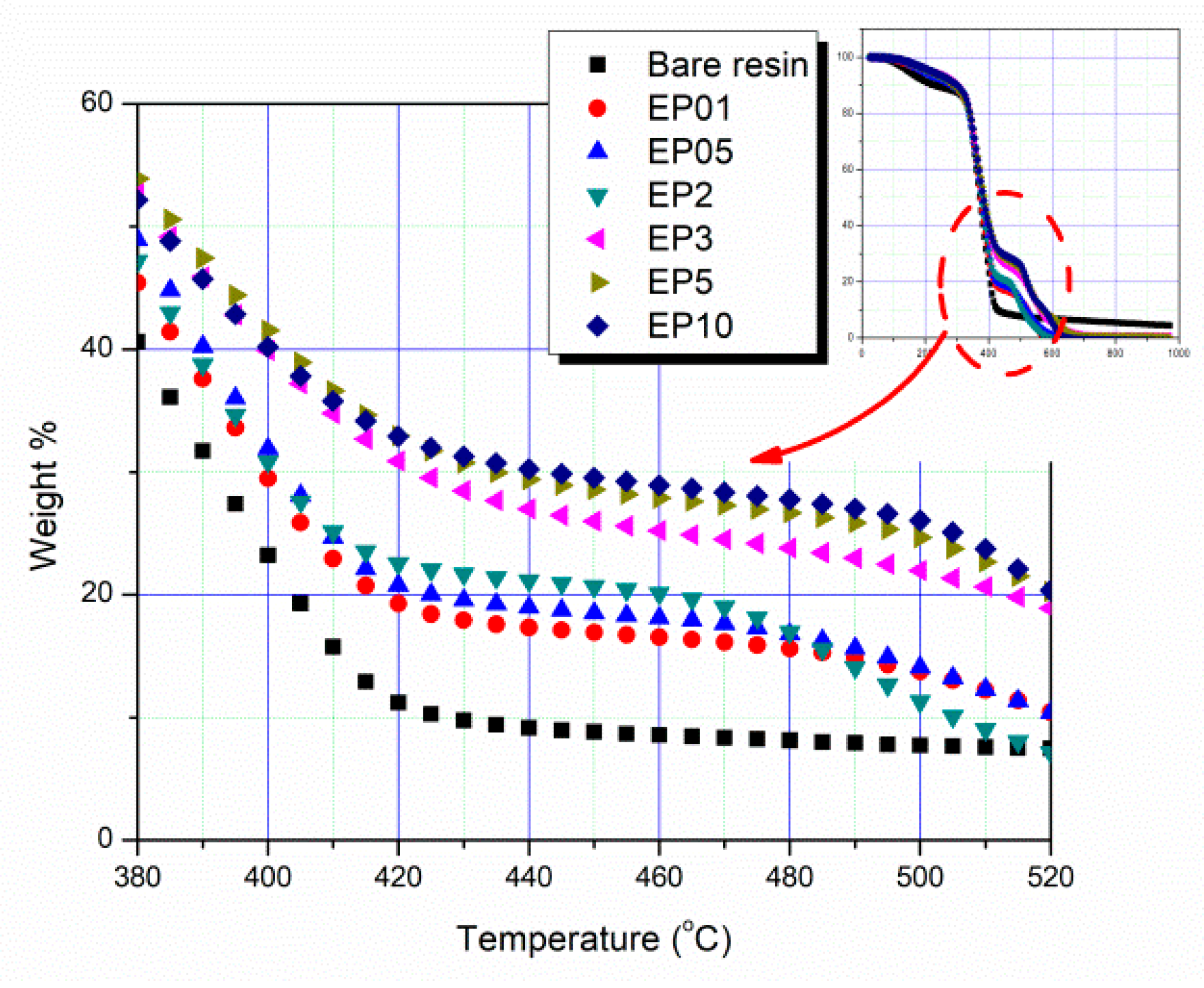

3.3. Thermal Decomposition Evaluation

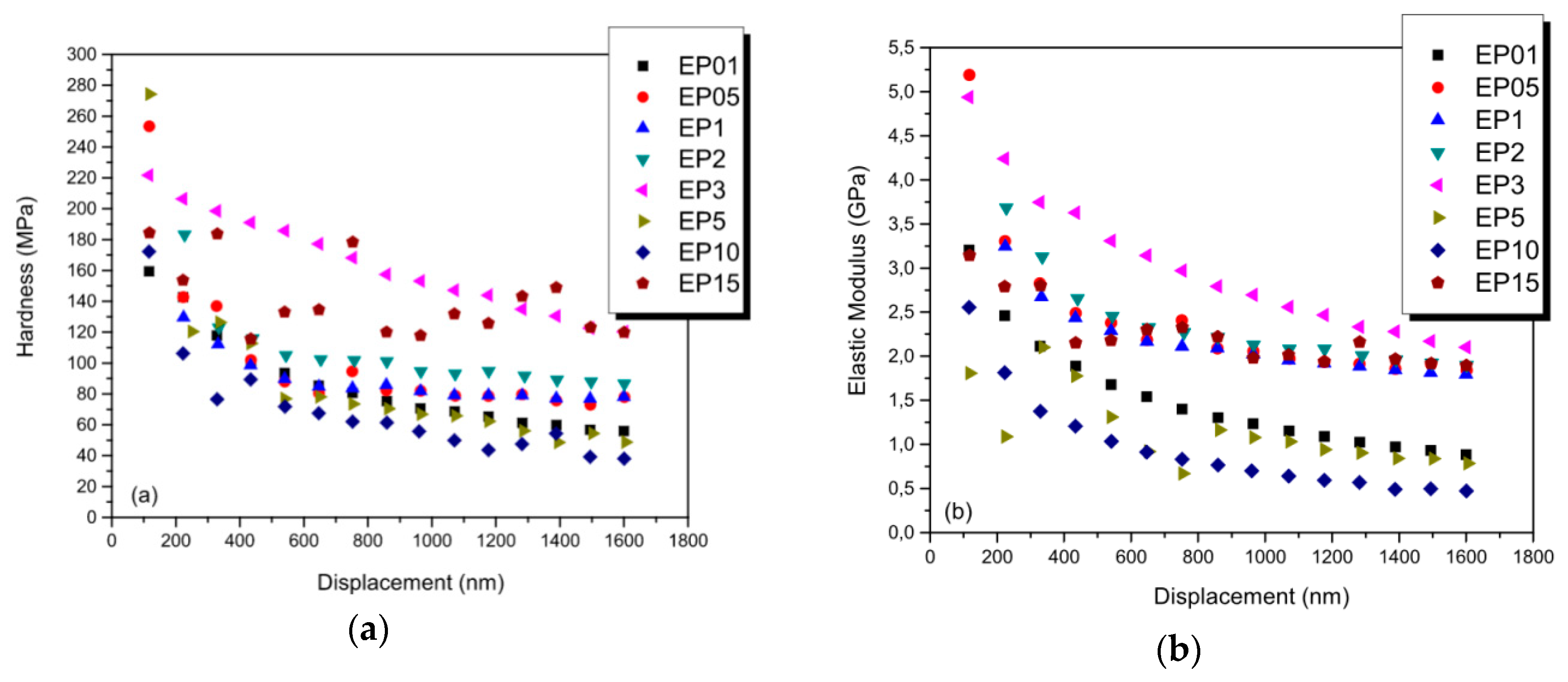

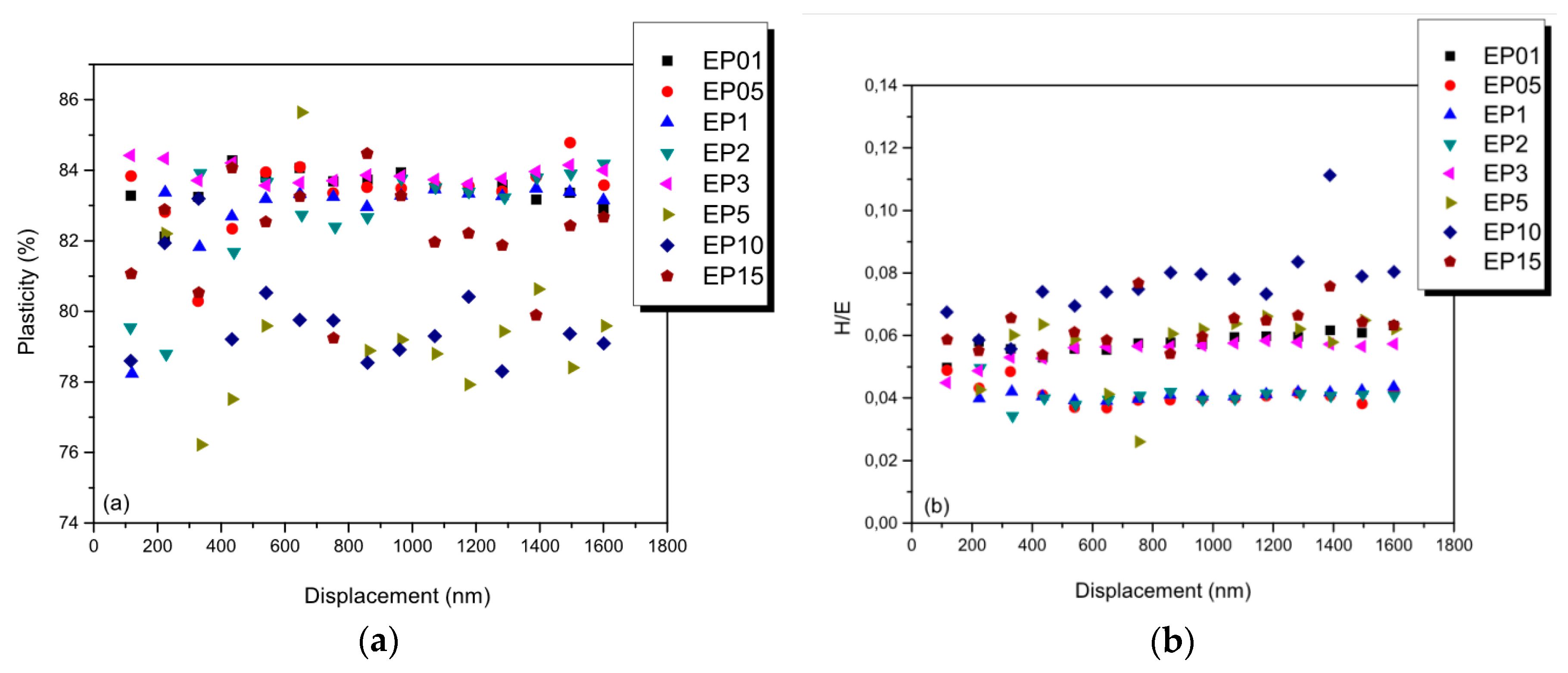

3.4. Nanomechanical Characterization

4. Conclusions

- From the optical microscopy in transmittance mode, it could be observed that MWCNT bundles were homogenously dispersed within the epoxy matrix for the samples with low MWCNT content. From the SEM analysis it was proven that when the concentration increased, MWCNTs were uniformly dispersed in the whole matrix. Finally, from the micro-CT it was evident that for MWCNT contents of 3 phr and higher, a homogenous dispersion could be achieved, covering the entire volume of the specimen.

- Conductivity increased with MWCNT content, and at a critical concentration it raised abruptly up to seven orders of magnitude, signifying the transition from the insulating to conductive behavior. Through thermogravimetric analysis, the thermal stability was showed to increase with increasing MWCNT content.

- Variations in conductivity with filler content can be studied in terms of percolation theory, and the determined percolation threshold and critical exponent, at 0.1 Hz and 30 °C, were 1.7 and 2.8, respectively.

- EP3 exhibited improved nanomechanical properties, while increasing concentration further revealed decreasing H and E values. The dispersion of MWCNTs has a great impact on nanomechanical properties, and should be taken into consideration.

- There was a large increase in the stiffness of the system, which resulted in reducing the energy dissipated during the experiment. However, there was more tube–tube slip in the system at higher concentrations, since percolation, coupled to a better dispersion, leads to a higher contact surface among MWCNTs. For the EP5, EP10, and EP15 samples, the dissipated energy increased.

- There was considerable improvement in the wear resistance due to the addition of MWCNTs. Moreover, lower deviation of H/E values revealed the good dispersion in the matrix, with impacts in almost-stable behavior at resistance to wear.

Author Contributions

Funding

Conflicts of Interest

References

- Tjong, S.C. Structural and mechanical properties of polymer composites. Mater. Sci. Eng. R Rep. 2006, 53, 73–197. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T.W. Processing–structure multifunctional property relationship in carbon nanotube/epoxy composites. Carbon 2006, 14, 3022–3029. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Z.; Zhao, G.; Liu, Y. Influence of carbon black with different concentration on dynamic properties and heat buildup of semi-efficient natural rubber composites. Micro Nano Lett. 2016, 11, 402–406. [Google Scholar] [CrossRef]

- Quilter, A. Composites in Aerospace (White Paper). Available online: https://ihsmarkit.com/pdf/Composites-Aerospace-Applications-whitepaper_264558110913046532.pdf (accessed on 29 December 2018).

- Ghori, S.W.; Siakeng, R.; Rasheed, M.; Saba, N.; Jawaid, M. The role of advanced polymer materials in aerospace. In Sustainable Composites for Aerospace Applications; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Sawston, UK, 2018; pp. 19–34. [Google Scholar]

- Taraghi, I.; Fereidoon, A.; Mohyeddin, A. The effect of MWCNTs on the mechanical properties of woven Kevlar/epoxy composites. Steel Compos. Struct. 2014, 17, 825–834. [Google Scholar] [CrossRef]

- Selmi, A.; Friebel, C.; Doghri, I.; Hassis, H. Prediction of the elastic properties of single walled carbon nanotubes reinforced polymers. Compos. Sci. Technol. 2007, 67, 2071–2084. [Google Scholar] [CrossRef]

- Giraldo, L.F.; Lopez, B.L.; Bostow, W. Effect of the type of carbon nanotubes on tribological properties of polyamide. Polym. Eng. Sci. 2009, 49, 896–902. [Google Scholar] [CrossRef]

- Gojnya, F.H.; Wichmann, M.H.G.; Köpke, U.; Fiedler, B.; Schulte, K. Carbon nanotube reinforced epoxy composites: Enhanced stiffness and fracture toughness at low nanotube content. Compos. Sci. Technol. 2004, 15, 2363–2371. [Google Scholar] [CrossRef]

- Kao, C.C.; Young, R.J. Assessment of interface damage during the deformation of carbon nanotubes composites. J. Mater. Sci. 2010, 45, 1425–1431. [Google Scholar] [CrossRef]

- Lagoudas, D.C.; Piyush, R.; Thakre, A.; Benzerga, A. Nanoindentation of CNT Reinforced Epoxy Nanocomposites; Department of Aerospace Engineering, Texas A & M University: College Station, TX, USA, 2012. [Google Scholar]

- Tan, B. Nanomechanics: Aeronautics and Aerospace Prospective. J. Aeronaut. Aerosp. Eng. 2012, 1, 117. [Google Scholar] [CrossRef]

- Sandler, J.K.W.; Kirk, J.E.; Kinloch, L.A.; Shaffer, M.S.P.; Windle, A.H. Ultralow electrical percolation threshold in carbonnanotube epoxy composites. Polymer 2003, 44, 5893–5899. [Google Scholar] [CrossRef]

- ALsafee, A.B.; Al Ajaj, I.A.; Khalil, A. Electrical conductivity of untreated multiwalled carbon nanotube/epoxy composites. Int. J. Appl. Innov. Eng. Manag. 2014, 3, 22–31. [Google Scholar]

- Logakis, E.; Skordos, A.A. Lightning strike performance of carbon nanotube loaded aerospace composites. In Proceedings of the ECCM15—15th European Conference on Composite Materials, Venice, Italy, 24–28 June 2012. [Google Scholar]

- Allaoui, A.; El Bounia, N. How carbon nanotubes affect the cure kinetics and glass transition temperature of their epoxy composites?—A review. Express Polym. Lett. 2009, 3, 588–594. [Google Scholar] [CrossRef]

- Meador, M.A. High temperature polymer matrix composites. In Aeropropulsion ’87; Session 1: Aeropropulsion Materials Research; NASA Lewis Research Center: Cleveland, OH, USA; p. 15.

- Allaoui, A.; Bai, S.; Cheng, H.; Bai, J. Mechanical and electrical properties of a MWNT/epoxy composite. Compos. Sci. Technol. 2002, 62, 1993–1998. [Google Scholar] [CrossRef]

- Lillehei, P.T.; Kim, J.-W.; Gibbons, L.J.; Park, C. A quantitative assessment of carbon nanotube dispersion in polymer matrices. Nanotechnology 2009, 20, 325708. [Google Scholar] [CrossRef]

- Trompeta, A.F.; Koklioti, M.A.; Perivoliotis, D.K.; Lynch, I.; Charitidis, C.A. Towards a holistic environmental impact assessment of carbon nanotube growth through chemical vapour deposition. J. Clean. Prod. 2016, 129, 384–394. [Google Scholar] [CrossRef]

- Zhou, H.; Han, G.; Xiao, Y.; Chang, Y.; Zhai, H.-J. A comparative study on long and short carbon nanotubes-incorporated polypyrrole/poly(sodium 4-styrenesulfonate) nanocomposites as high-performance supercapacitor electrodes. Synth. Mater. 2015, 209, 405–411. [Google Scholar] [CrossRef]

- May, C.A. Resins for Aerospace. Appl. Polym. Sci. 1985, 285, 557–580. [Google Scholar] [CrossRef]

- Wei, R.; Tu, L.; You, Y.; Zhan, C.; Wang, Y.; Liu, X. Fabrication of crosslinked single-component polyarylene ether nitrile composite with enhanced dielectric properties. Polymer 2018, 161, 162–169. [Google Scholar] [CrossRef]

- High Performance Polymers in the Aerospace and Automotive Sectors, Frost and Sullivan. Available online: https://store.frost.com/high-performance-polymers-in-the-aerospace-and-automotive-sectors.html#section1 (accessed on 29 December 2018).

- Schilde, C.; Schlomann, M.; Overbeck, A.; Linke, S.; Kwade, A. Thermal, mechanical and electrical properties of highly loaded CNT epoxy composites: A model for the electric conductivity. Compos. Sci. Technol. 2015, 117, 183–190. [Google Scholar] [CrossRef]

- AlQadhi, M.; Merah, N.; Khan, Z.; Mezghani, K.; Gasem, Z.; Adinoyi, M.J. Effect of sonication and high shear mixing parameters on nanoclay dispersion in epoxy. In Proceedings of the ECCM15—15th European Conference on Composite Materials, Venice, Italy, 24–28 June 2012. [Google Scholar]

- Liu, C.-X.; Choi, J.W. Improved Dispersion of Carbon Nanotubes in Polymers at High Concentrations. Nanomaterials 2012, 2, 329–347. [Google Scholar] [CrossRef] [PubMed]

- AlQadhi, M.; Merah, N. Method for Preparation of Epoxy Clay Nanocomposites. U.S. Patent 9334387B2, 10 September 2013. [Google Scholar]

- Huang, Y.Y.; Ahir, S.V.; Terentjev, E.M. Dispersion rheology of carbon nanotubes in a polymer matrix. Phys. Rev. B 2006, 73, 125422. [Google Scholar] [CrossRef]

- Berkovich, A.R.; Hower, J.C.; Jacques, D.; Rantell, T. Fabrication of Carbon Multiwall Nanotube/Polymer Composites by Shear Mixing. 2001. Available online: https://acs.omnibooksonline.com/data/papers/2001_37.3.pdf (accessed on 30 November 2018).

- Charitidis, C.A. Nanomechanical and nanotribological properties of carbonbased thin films: A review. J. Refract. Met. Hard Mater. 2010, 28, 51–70. [Google Scholar] [CrossRef]

- Koumoulos, E.P.; Charitidis, C.A.; Papageorgiou, D.P.; Papathanasiou, A.G.; Boudouvis, A.G. Nanomechanical and Nanotribological Properties of Hydrophobic Fluorocarbon Dielectric Coating on Tetraethoxysilane for Electrowetting Applications. Surf. Coat. Technol. 2012, 206, 3823–3831. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Sneddon, I.N. Boussinesq’s problem for a rigid cone. Math. Proc. Camb. Philos. Soc. 1948, 44, 492–507. [Google Scholar] [CrossRef]

- King, R.B. Elastic analysis of some punch problems for a layered medium. Int. J. Solids Struct. 1987, 23, 1657–1664. [Google Scholar] [CrossRef]

- Bei, H.; George, E.P.; Hay, J.L.; Pharr, G.M. Influence of Indenter Tip Geometry on Elastic Deformation during Nanoindentation. Phys. Rev. Lett. 2005, 95, 045501. [Google Scholar] [CrossRef]

- Kim, H.; Bae, H.; Yu, J.; Kima, S. Thermal conductivity of polymer composites with the geometrical characteristics of graphene nanoplatelets. Sci. Rep. 2016, 6, 26825. [Google Scholar] [CrossRef]

- Bellucci, S.; Balasubramanian, C.; Micciulla, F.; Rinaldi, G. CNT composites for aerospace applications. J. Exp. Nanosci. 2007, 2, 193–206. [Google Scholar] [CrossRef]

- Psarras, G. Charge transport properties in carbon black/polymer composites. J. Polym. Sci. Part B 2007, 45, 2535–2545. [Google Scholar] [CrossRef]

- Psarras, G. Conductivity and dielectric characterization of polymer nanocomposites. In Polymer Nanocomposites: Physical Properties and Applications; Woodhead Publishing Limited: Cambridge, UK, 2010; pp. 31–69. [Google Scholar]

- Pontikopoulos, P.; Psarras, G. Dynamic percolation and dielectric response in multiwall carbon nanotubes/poly(ethylene oxide) composites. SAM 2013, 5, 1420. [Google Scholar] [CrossRef]

- Saito, S.; Sasabe, H.; Nakajima, T.; Yada, K. Dielectric relaxation and electrical conduction of polymers as a function of pressure and temperature. J. Polym. Sci. A2 1968, 6, 1297. [Google Scholar] [CrossRef]

- Xu, F.; Sun, L.X.; Zhang, J.; Qi, Y.N.; Yang, L.N.; Ru, H.Y.; Wang, C.Y.; Meng, X.; Lan, X.F.; Jiao, Q.Z.; et al. Thermal stability of carbon nanotubes. J. Therm. Anal. Calorim. 2010, 102, 785–791. [Google Scholar] [CrossRef]

- Si Eun, L.; Seho, C.; YoungSeak, K. Mechanical and thermal properties of MWCNT reinforced epoxy nanocomposites by vacuum assisted resin transfer molding. Carbon Lett. 2014, 15, 32–37. [Google Scholar]

- Baldissera, A.F.; de Miranda, K.L.; Bressy, C.; Martin, C.; Margaillan, A.; Ferreira, C.A. Using Conducting Polymers as Active Agents for Marine Antifouling Paints. Mater. Res. 2015, 18, 1129–1139. [Google Scholar] [CrossRef]

- Koumoulos, E.P.; Charitidis, C.A.; Daniolos, N.M.; Pantelis, D.I. Nanomechanical properties of friction stir welded AA6082T6 aluminum alloy. Mater. Sci. Eng. B 2011, 176, 1585–1589. [Google Scholar] [CrossRef]

- Li, Y.; Yu, T.; Pui, T.; Chen, P.; Zheng, L.; Liao, K. Fabrication and characterization of recyclable carbon nanotube/polyvinyl butyral composite fiber. Compos. Sci. Technol. 2011, 71, 1665–1670. [Google Scholar] [CrossRef]

- Zhuang, G.S.; Sui, G.X.; Sun, Z.S.; Yang, R. Pseudoreinforcement effect of multiwalled carbon nanotubes in epoxy matrix composites. J. Appl. Polym. Sci. 2006, 102, 3664–3672. [Google Scholar] [CrossRef]

- Fiedler, B.; Gojny, F.H.; Wichmann, M.H.; Nolte, M.C.; Schulte, K. Fundamental aspects of nanoreinforced composites. Compos. Sci. Technol. 2006, 66, 3115–3125. [Google Scholar] [CrossRef]

- Cheng, Y.T.; Cheng, C.M. What is indentation hardness? Surf. Coat. Technol. 2000, 133–134, 417–424. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. Design criteria for wear resistant nanostructured and glassy metal coatings. Surf. Coat. Technol. 2004, 177–178, 317–324. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. Optimization of Nanostructured Tribological Coatings. In Nanostructured Coatings; Springer: New York, NY, USA, 2007. [Google Scholar]

| Primary Structural Parts | Secondary Structural Parts |

|---|---|

| Wings | Doors |

| Tails surfaces | Antenna dishes |

| Fuselages sections | Center wing boxes |

| Rocket motor castings | Landing gear doors |

| Engine nacelles and cowls | Floor beams |

| Horizontal and vertical stabilisers | Tall cones |

| Pressure bulkheads | Flap track panels |

| Mag. | Bare Resin | EP05 | EP3 | EP15 |

|---|---|---|---|---|

| ×600 |  |  |  |  |

| ×10,000 |  |  |  |  |

| ×20,000 |  |  |  |  |

| ×40,000 |  |  |  |  |

| Bare Resin | EP05 | EP1 | EP2 |

|---|---|---|---|

|  |  |  |

| EP3 | EP5 | EP10 | EP15 |

|  |  |  |

| Sample | Hardness (H) (MPa) | Elastic Modulus (E) (GPa) |

|---|---|---|

| EP01 | 60 ± 3 | 0.8 ± 0.4 |

| EP05 | 80 ± 3 | 2.0 ± 0.1 |

| EP1 | 80 ± 4 | 2.0 ± 0.2 |

| EP2 | 90 ± 5 | 2.0 ± 0.1 |

| EP3 | 140 ± 6 | 2.4 ± 0.1 |

| EP5 | 50 ± 4 | 0.7 ± 0.1 |

| EP10 | 40 ± 3 | 0.5 ± 0.1 |

| EP15 | 140 ± 5 | 2.0 ± 0.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trompeta, A.-F.A.; Koumoulos, E.P.; Stavropoulos, S.G.; Velmachos, T.G.; Psarras, G.C.; Charitidis, C.A. Assessing the Critical Multifunctionality Threshold for Optimal Electrical, Thermal, and Nanomechanical Properties of Carbon Nanotubes/Epoxy Nanocomposites for Aerospace Applications. Aerospace 2019, 6, 7. https://doi.org/10.3390/aerospace6010007

Trompeta A-FA, Koumoulos EP, Stavropoulos SG, Velmachos TG, Psarras GC, Charitidis CA. Assessing the Critical Multifunctionality Threshold for Optimal Electrical, Thermal, and Nanomechanical Properties of Carbon Nanotubes/Epoxy Nanocomposites for Aerospace Applications. Aerospace. 2019; 6(1):7. https://doi.org/10.3390/aerospace6010007

Chicago/Turabian StyleTrompeta, Aikaterini-Flora A., Elias P. Koumoulos, Sotirios G. Stavropoulos, Theodoros G. Velmachos, Georgios C. Psarras, and Costas A. Charitidis. 2019. "Assessing the Critical Multifunctionality Threshold for Optimal Electrical, Thermal, and Nanomechanical Properties of Carbon Nanotubes/Epoxy Nanocomposites for Aerospace Applications" Aerospace 6, no. 1: 7. https://doi.org/10.3390/aerospace6010007

APA StyleTrompeta, A.-F. A., Koumoulos, E. P., Stavropoulos, S. G., Velmachos, T. G., Psarras, G. C., & Charitidis, C. A. (2019). Assessing the Critical Multifunctionality Threshold for Optimal Electrical, Thermal, and Nanomechanical Properties of Carbon Nanotubes/Epoxy Nanocomposites for Aerospace Applications. Aerospace, 6(1), 7. https://doi.org/10.3390/aerospace6010007