Gallium Nitride Normally Off MOSFET Using Dual-Metal-Gate Structure for the Improvement in Current Drivability

Abstract

1. Introduction

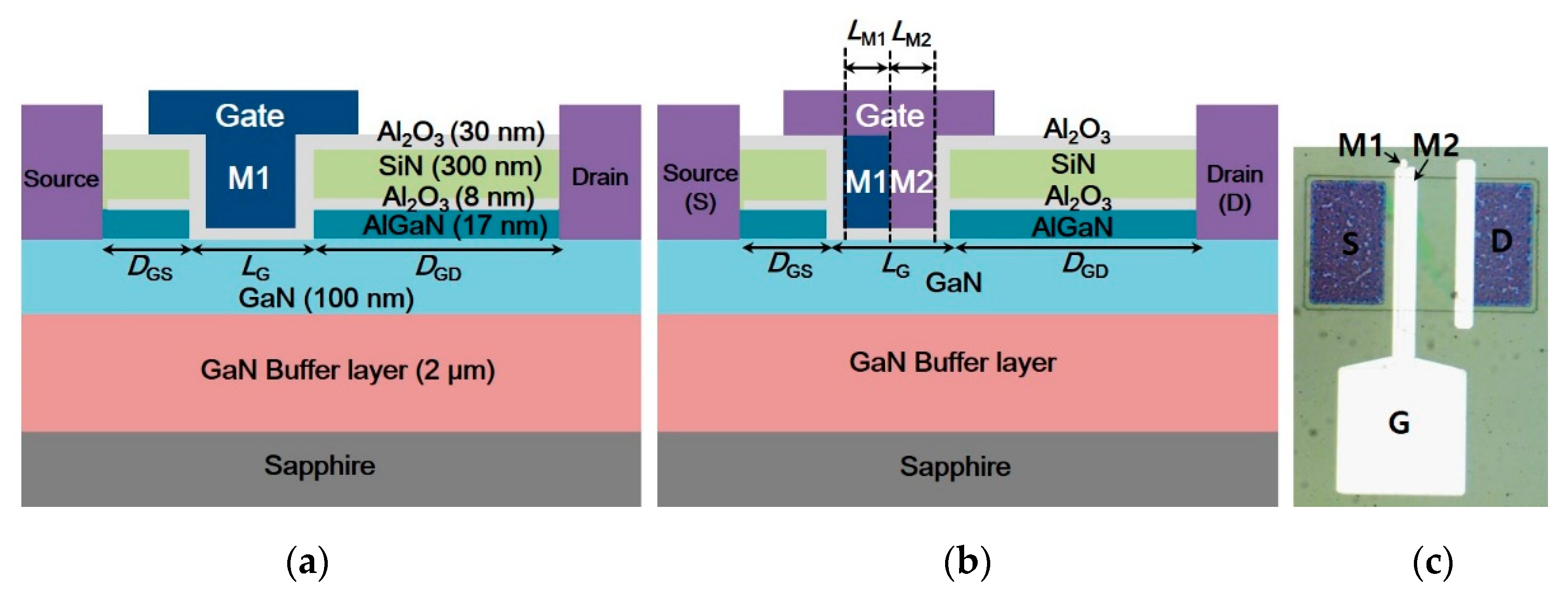

2. Structure and Fabrication

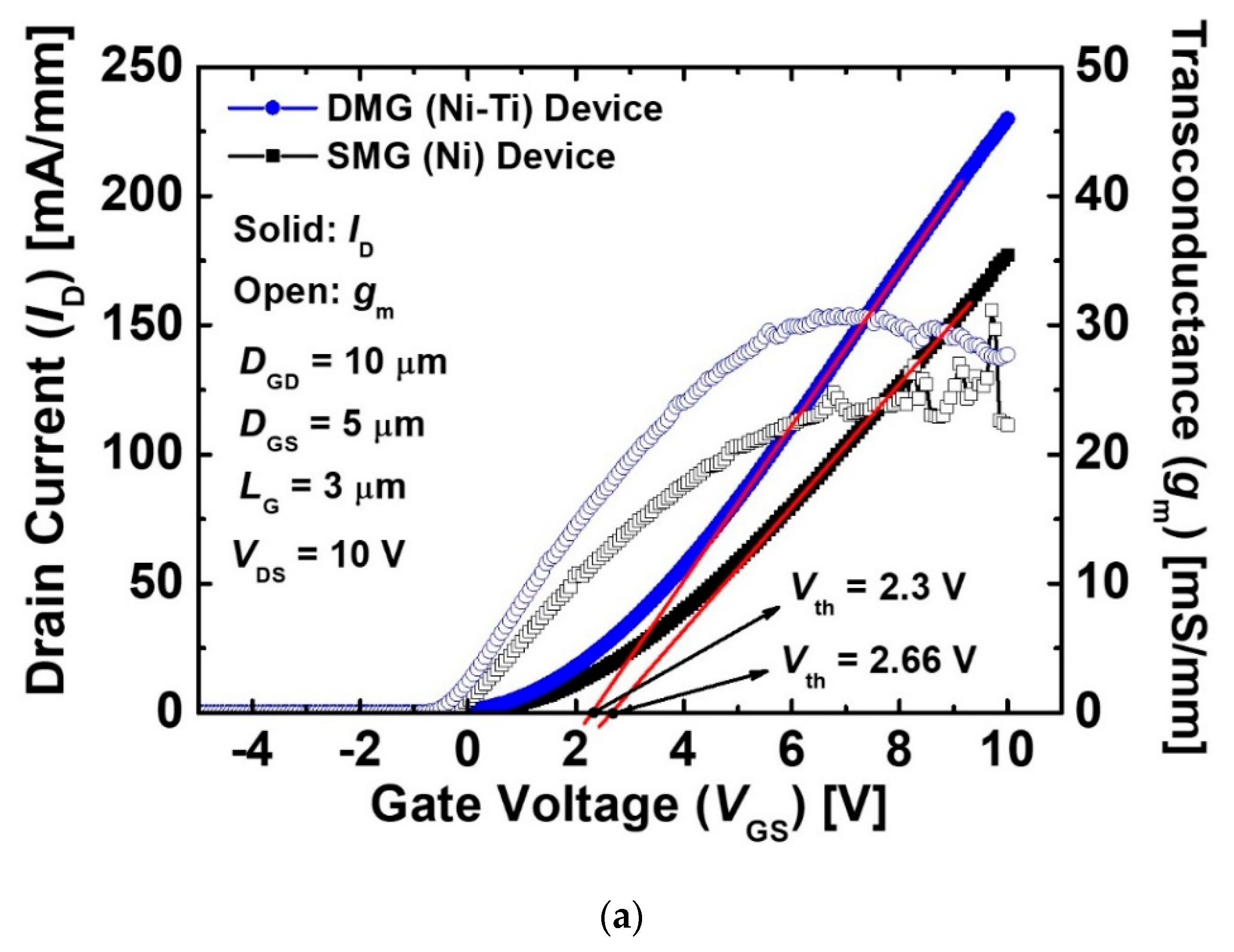

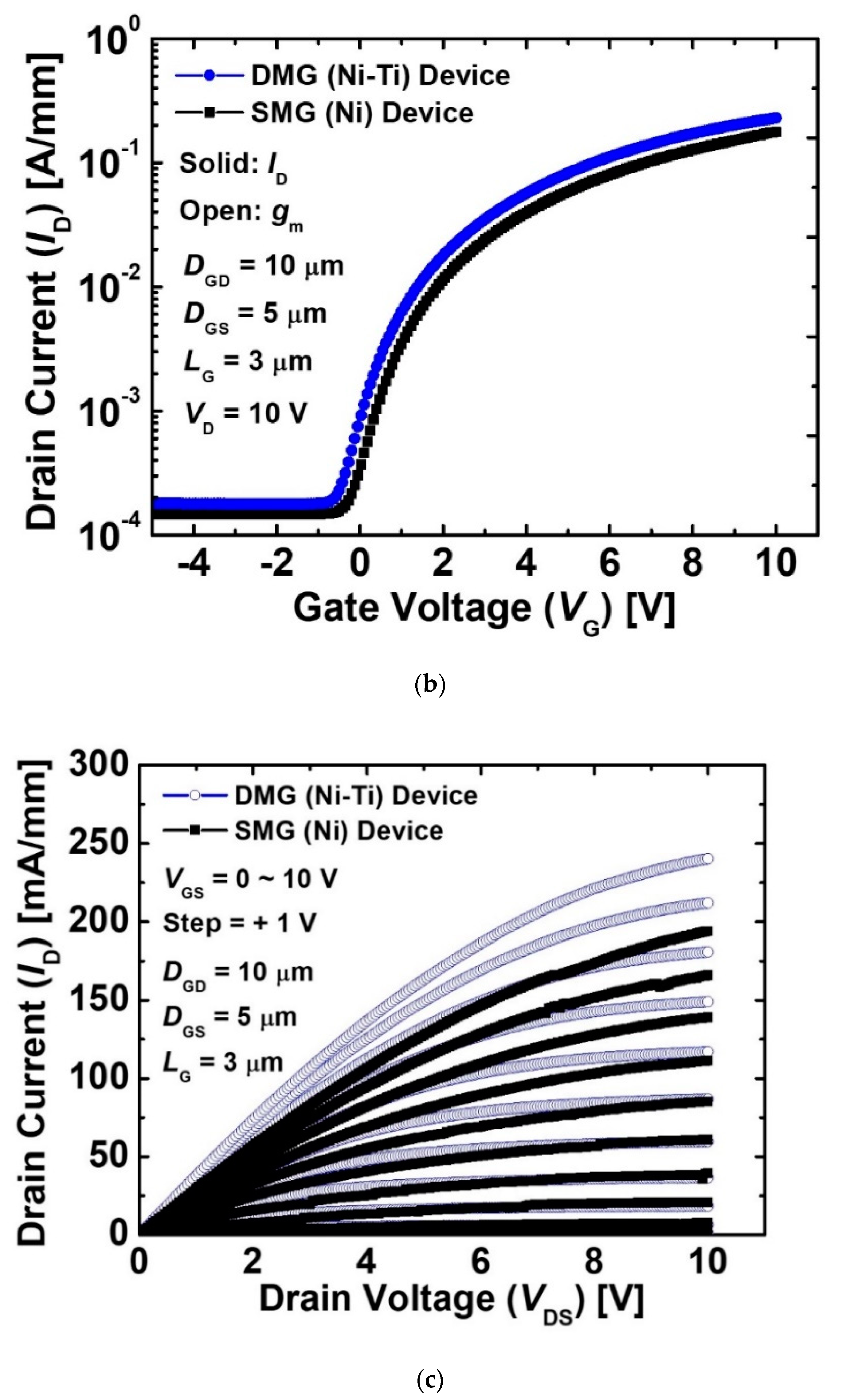

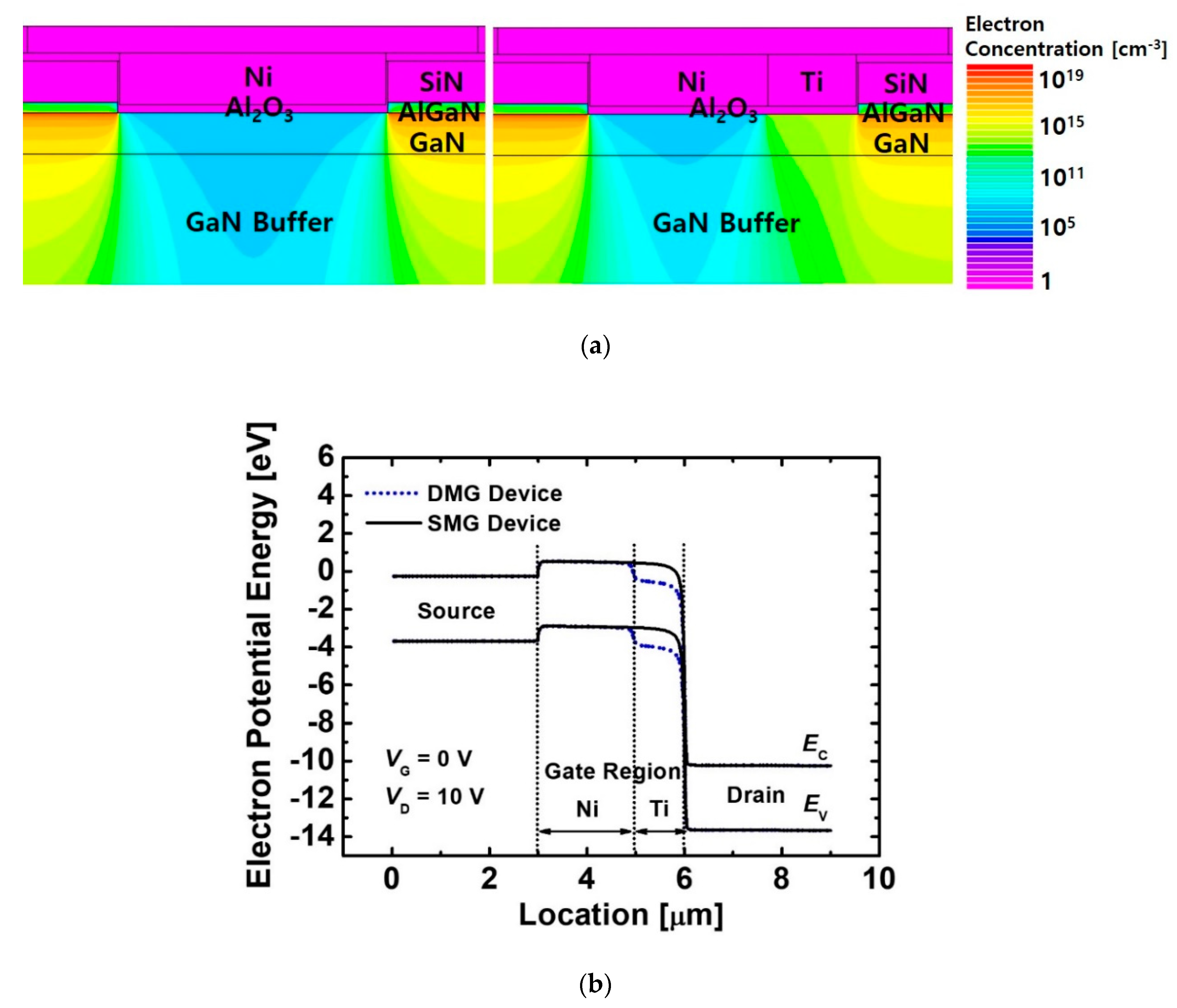

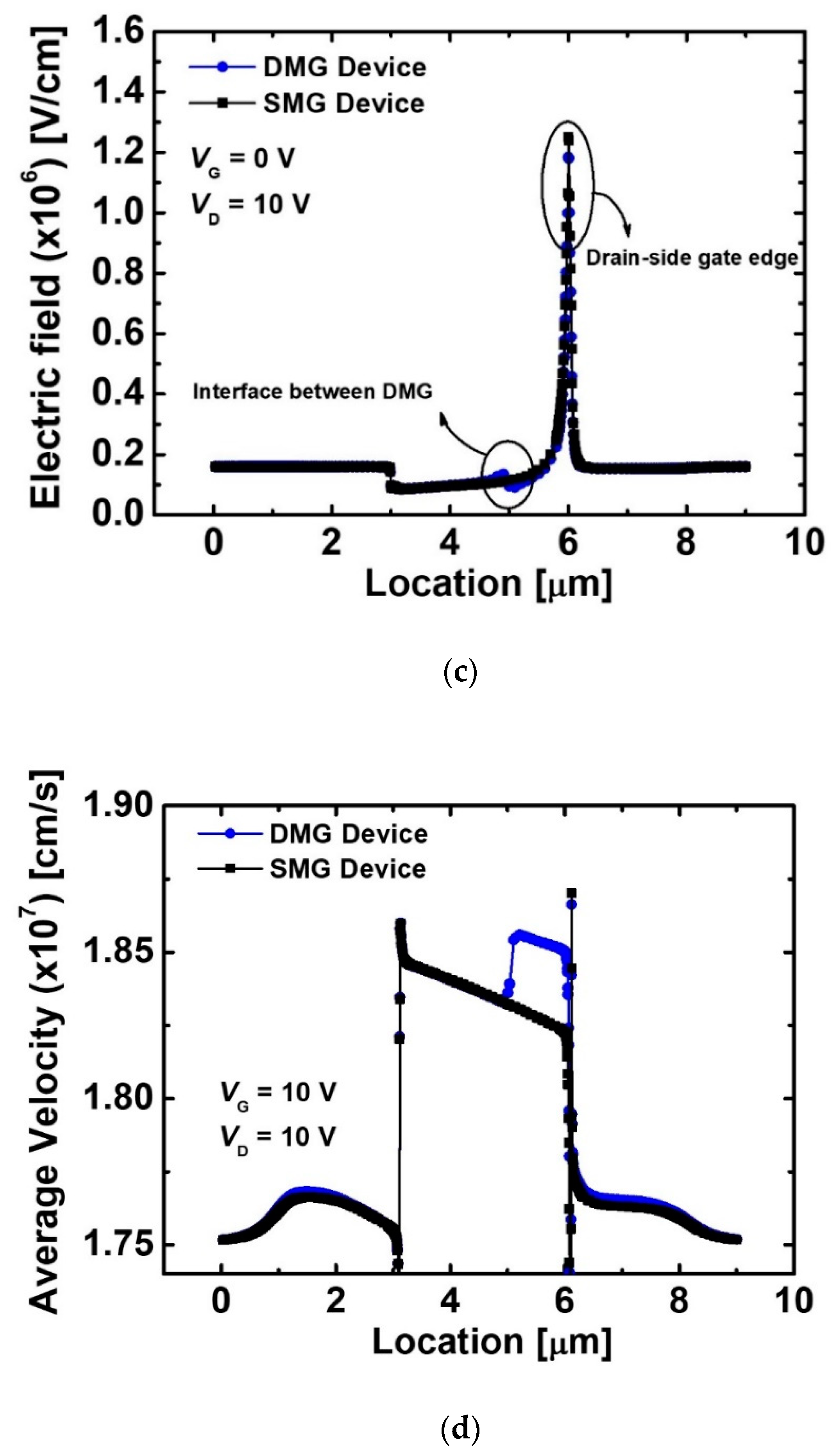

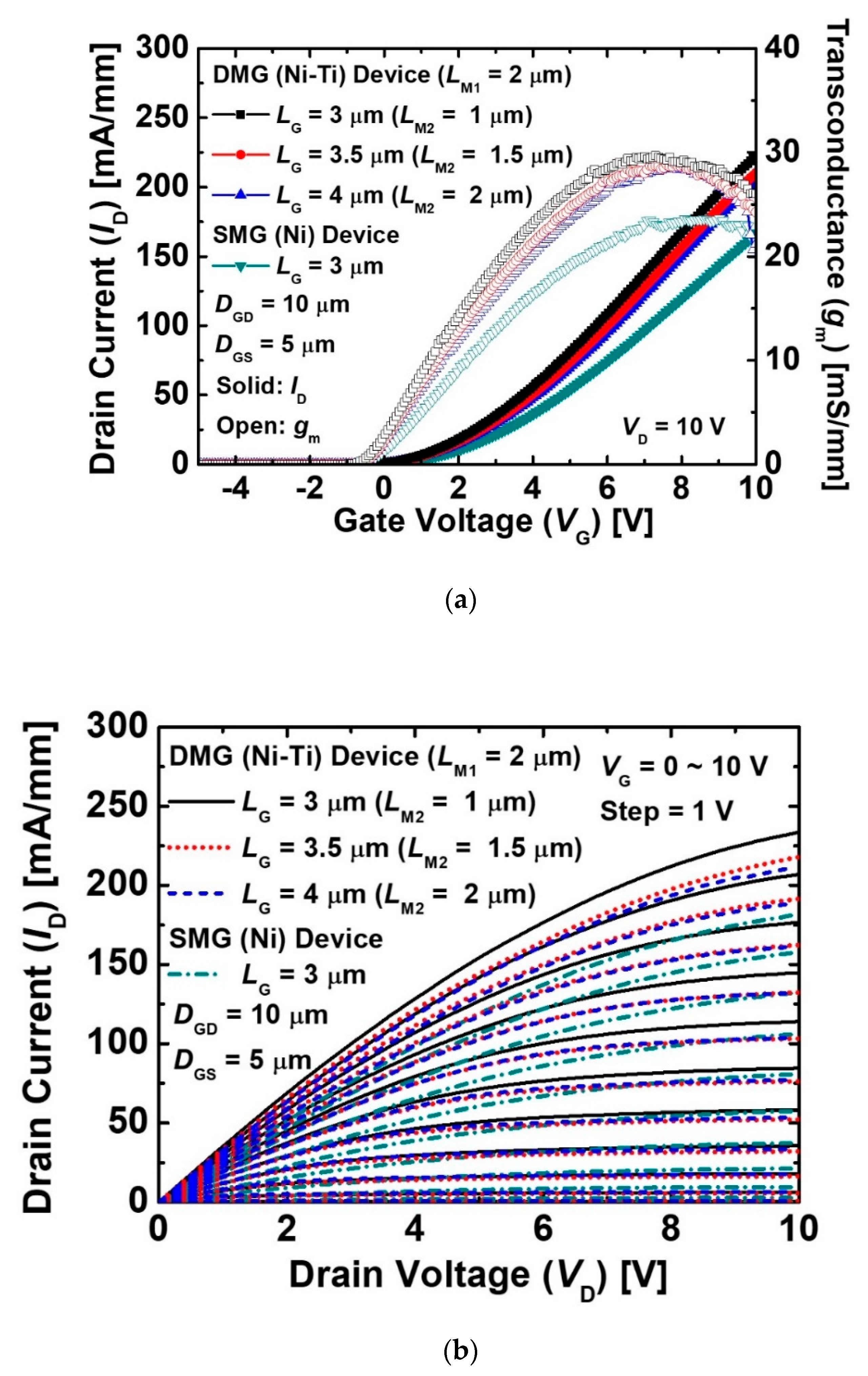

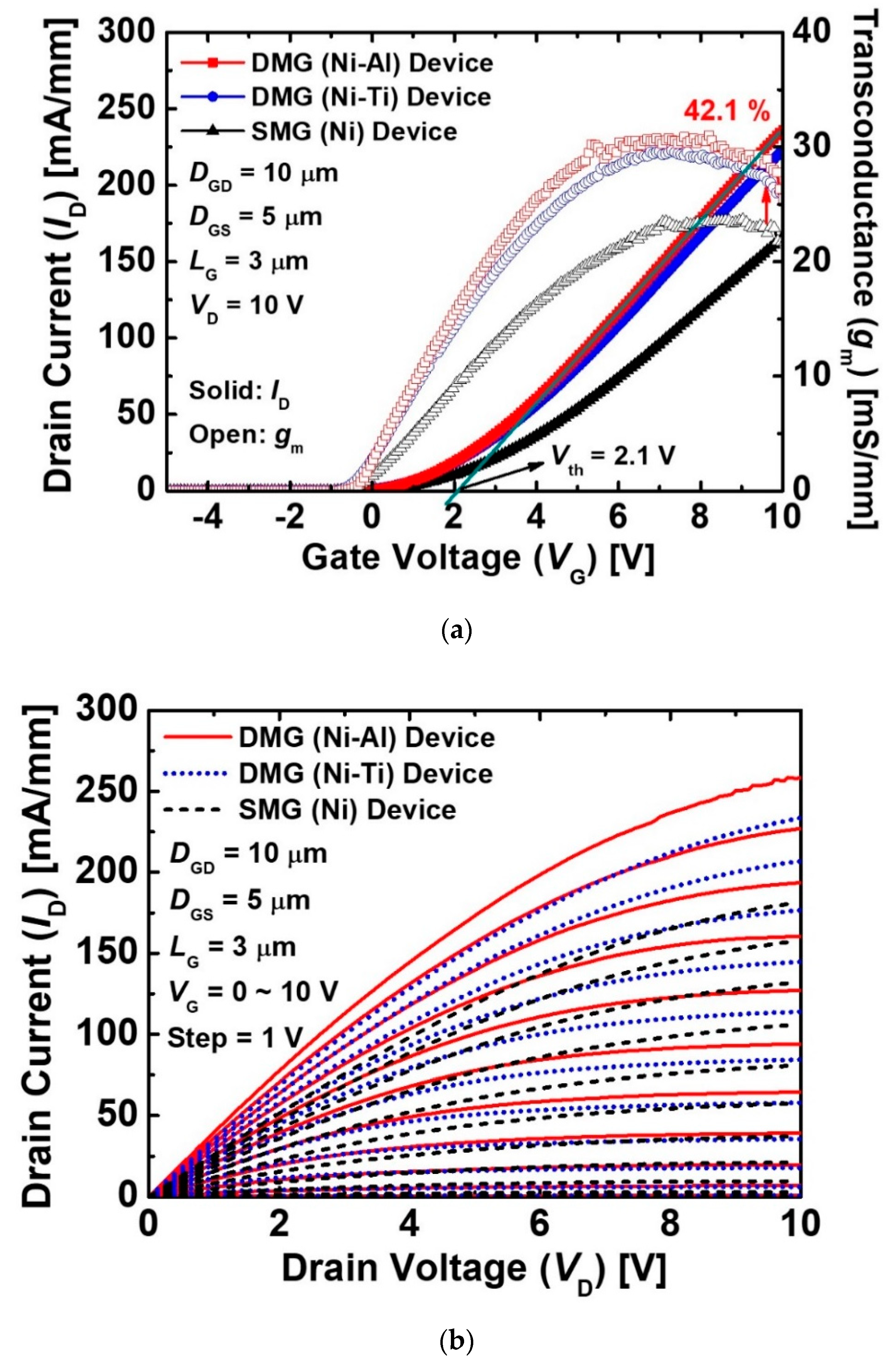

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mishra, U.K.; Parikh, P.; Wu, Y. AlGaN/GaN HEMTs—An overview of device operation and applications. Proc. IEEE 2002, 90, 1022–1031. [Google Scholar] [CrossRef]

- Baliga, B.J. Gallium nitride devices for power electronic applications. Semicon. Sci. Technol. 2013, 29, 074011. [Google Scholar] [CrossRef]

- Wu, Y.; Jacob-Mitos, M.; Moore, M.L.; Heikman, S. A 97.8% Efficient GaN HEMT Boost Converter With 300-W Output Power at 1 MHz. IEEE Electron. Device Lett. 2008, 29, 824–826. [Google Scholar] [CrossRef]

- Wang, B.; Dong, S.; Jiang, S.; He, C.; Hu, J.; Ye, H.; Ding, X. A Comparative Study on the Switching Performance of GaN and Si Power Devices for Bipolar Complementary Modulated Converter Legs. Energies 2019, 12, 1146. [Google Scholar] [CrossRef]

- Srivastava, P.; Das, J.; Visalli, D.; Hove, M.V.; Malinowski, P.E.; Marcon, D.; Lenci, S.; Geens, K.; Cheng, K.; Leys, M.; et al. Record Breakdown Voltage (2200 V) of GaN DHFETs on Si With 2-μm Buffer Thickness by Local Substrate Removal. IEEE Electron. Device Lett. 2011, 32, 30–32. [Google Scholar] [CrossRef]

- Roccaforte, F.; Greco, G.; Fiorenza, P.; Iucolano, F. An Overview of Normally-Off GaN-Based High Electron Mobility Transistors. Materials 2019, 12, 1599. [Google Scholar] [CrossRef]

- Saito, W.; Takada, Y.; Kuraguchi, M.; Tsuda, K.; Omura, I. Recessed-Gate Structure Approach Toward Normally OFF High-Voltage AlGaN/GaN HEMT for Power Electronics Applications. IEEE Trans. Electron. Devices 2006, 53, 356–362. [Google Scholar] [CrossRef]

- Oka, T.; Nozawa, T. AlGaN/GaN Recessed MIS-Gate HFET With High-Threshold-Voltage Normally-Off Operation for Power Electronics Applications. IEEE Electron. Device Lett. 2008, 29, 668–670. [Google Scholar] [CrossRef]

- Kim, K.-W.; Jung, S.-D.; Kim, D.-S.; Kang, H.-S.; Im, K.-S.; Oh, J.-J.; Ha, J.-B.; Shin, J.-K.; Lee, J.-H. Effects of TMAH Treatment on Device Performance of Normally Off Al2O3/GaN MOSFET. IEEE Electron. Device Lett. 2011, 32, 1376–1378. [Google Scholar] [CrossRef]

- Kim, D.-S.; Im, K.-S.; Kang, H.-S.; Kim, K.-W.; Bae, S.-B.; Mun, J.-K.; Nam, E.-S.; Lee, J.-H. Normally-Off AlGaN/GaN Metal-Oxide-Semiconductor Heterostructure Field-Effect Transistor with Recessed Gate and p-GaN Back-Barrier. Jpn. J. Appl. Phys. 2012, 51, 034101. [Google Scholar] [CrossRef]

- Asubar, J.T.; Kawabata, S.; Tokuda, H.; Yamamoto, A.; Kuzuhara, M. Enhancement-Mode AlGaN/GaN MIS-HEMTs With High VTH and High IDmax Using Recessed-Structure With Regrown AlGaN Barrier. IEEE Electron. Device Lett. 2020, 41, 693–696. [Google Scholar] [CrossRef]

- Hwang, I.; Kim, J.; Choi, H.S.; Choi, H.; Lee, J.; Kim, K.Y.; Park, J.-B.; Lee, J.C.; Ha, J.; Oh, J.; et al. p-GaN Gate HEMTs With Tungsten Gate Metal for High Threshold Voltage and Low Gate Current. IEEE Electron. Device Lett. 2013, 34, 202–204. [Google Scholar] [CrossRef]

- Ge, M.; Ruzzarin, M.; Chen, D.; Lu, H.; Yu, X.; Zhou, J.; Santi, C.D.; Zhang, R.; Zheng, Y.; Meneghini, M.; et al. Gate Reliability of p-GaN Gate AlGaN/GaN High Electron Mobility Transistors. IEEE Electron. Device Lett. 2019, 40, 379–382. [Google Scholar] [CrossRef]

- Huang, X.; Liu, Z.; Li, Q.; Lee, F.C. Evaluation and Application of 600 V GaN HEMT in Cascode Structure. IEEE Trans. Power Electron. 2014, 29, 2453–2461. [Google Scholar] [CrossRef]

- Feng, Z.H.; Zhou, R.; Xie, S.Y.; Yin, J.Y.; Fang, J.X.; Liu, B.; Zhou, W.; Chen, K.J.; Cai, S.J. 18-GHz 3.65-W/mm Enhancement-Mode AlGaN/GaN HFET Using Fluorine Plasma Ion Implantation. IEEE Electron. Device Lett. 2010, 31, 1386–1388. [Google Scholar] [CrossRef]

- Shen, F.; Hao, R.; Song, L.; Chen, F.; Yu, G.; Zhang, X.; Fan, Y.; Lin, F.; Cai, Y.; Zhang, B. Enhancement mode AlGaN/GaN HEMTs by fluorine ion thermal diffusion with high Vth stability. Appl. Phys. Express 2019, 12, 066501. [Google Scholar] [CrossRef]

- He, J.; Hua, M.; Zhang, Z.; Chen, K.J. Performance and VTH stability in E-Mode GaN Fully Recessed MIS-FETs and Partially Recessed MIS-HEMTs With LPCVD-SiNx/PECVD-SiNx Gate Dielectric Stack. IEEE Trans. Electron. Devices 2018, 65, 3185–3191. [Google Scholar] [CrossRef]

- Son, D.-H.; Jo, Y.-W.; Won, C.-H.; Lee, J.-H.; Seo, J.H.; Lee, S.-H.; Lim, J.-W.; Kim, J.H.; Kang, I.M.; Cristoloveanu, S.; et al. Nomally-off AlGaN/GaN-based MOS-HEMT with self-terminating TMAH wet recess etching. Solid State Electron. 2018, 141, 7–12. [Google Scholar] [CrossRef]

- Hahn, H.; Benkhelifa, F.; Ambacher, O.; Alam, A.; Heuken, M.; Yacoub, H.; Noculak, A.; Kalisch, H.; Vescan, A. GaN-on-Si Enhancement Mode Metal Insulator Semiconductor Heterostructure Field Effect Transistor with On-Current of 1.35 A/mm. Jpn. J. Appl. Phys. 2013, 52, 090204. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, C.; Zheng, X.; Ma, X.; He, Y.; Liu, K.; Li, A.; Peng, Y.; Zhang, C.; Hao, Y. Effects of recess depths on performance of AlGaN/GaN power MIS-HEMTs on the Si substrates and threshold voltage model of different recess depths for the using HfO2 gate insulator. Solid State Electron. 2020, 163, 107649. [Google Scholar] [CrossRef]

- Wu, I.-L.; Tang, S.-W.; Jiang, H.-J. Investigation of Recessed Gate AlGaN/GaN MIS-HEMTs with Double AlGaN Barrier Designs toward an Enhancement-Mode Characteristics. Micromachines 2020, 11, 163. [Google Scholar] [CrossRef] [PubMed]

- Long, W.; Ou, H.; Kuo, J.-M.; Chin, K.K. Dual-Material Gate (DMG) Field Effect Transistor. IEEE Trans. Electron. Devices 1999, 46, 865–870. [Google Scholar] [CrossRef]

- Jang, Y.I.; Lee, S.H.; Seo, J.H.; Yoon, Y.J.; Kwon, R.H.; Cho, M.S.; Kim, B.G.; Yoo, G.M.; Lee, J.-H.; Kang, I.M. Design and Analysis of AlGaN/GaN MIS HEMTs with a Dual-metal-gate Structure. J. Semicond. Technol. Sci. 2017, 17, 223–229. [Google Scholar]

- Jung, J.H.; Cho, M.S.; Jang, W.D.; Lee, S.H.; Jang, J.; Bae, J.-H.; Yoon, Y.J.; Kang, I.M. Fabrication of AlGaN/GaN MISHEMT with dual-metal gate electrode and its performances. Appl. Phys. A 2020, 126, 274. [Google Scholar] [CrossRef]

- Tapajna, M.; Kuzmik, J. A comprehensive analytical model for threshold voltage calculation in GaN based metal-oxide-semiconductor high-electron-mobility transistors. Appl. Phys. Lett. 2012, 100, 113509. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Park, B.-R.; Lee, J.-G.; Lim, J.; Cha, H.-Y. Forming Gas Post Metallization Annealing of Recessed AlGaN/GaN-on-Si MOSHFET. J. Semicond. Technol. Sci. 2015, 15, 16–21. [Google Scholar] [CrossRef]

- Ioannou-Sougleridis, V.; Karageorgiou, A.; Barlas, M.; Ladas, S.; Skarlatos, D. Interface properties of Al-Al2O3-Ge MIS capacitors and the effect of forming gas annealing. Microelectron. Eng. 2016, 159, 84–89. [Google Scholar] [CrossRef]

- Zhang, L.; Guo, Y.; Hassan, V.V.; Tang, K.; Foad, M.A.; Woicik, J.C.; Pianetta, P.; Robertson, J.; McIntyre, P.C. Interface Engineering for Atomic Layer Deposited Alumina Gate Dielectric on SiGe Substrates. ACS Appl. Mater. Interfaces 2016, 8, 19110–19118. [Google Scholar] [CrossRef]

- Fiorenza, P.; Greco, G.; Iucolano, F.; Patti, A.; Roccaforte, F. Channel Mobility in GaN Hybrid MOS-HEMT Using SiO2 as Gate Insulator. IEEE Trans. Electron. Devices 2017, 64, 2893–2899. [Google Scholar] [CrossRef]

- SILVACO. ATLAS User’s Manual; SILVACO International: Santa Clara, CA, USA, 2000. [Google Scholar]

- Ardaravicius, L.; Matulionis, A.; Liberis, J.; Kiprijanovic, O.; Ramonas, M.; Eastman, L.F.; Shealy, J.R.; Vertiatchikh, A. Electron drift velocity in AlGaN/GaN channel at high electric fields. Appl. Phys. Lett. 2003, 83, 4038–4040. [Google Scholar] [CrossRef]

- Barker, J.M.; Ferry, D.K.; Koleske, D.D.; Shul, R.J. Bulk GaN and AlGaN/GaN Heterostructure drift velocity measurements and comparison to theoretical models. J. Appl. Phys. 2005, 97, 063705. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, Y.J.; Lee, J.S.; Kim, D.-S.; Lee, J.-H.; Kang, I.M. Gallium Nitride Normally Off MOSFET Using Dual-Metal-Gate Structure for the Improvement in Current Drivability. Electronics 2020, 9, 1402. https://doi.org/10.3390/electronics9091402

Yoon YJ, Lee JS, Kim D-S, Lee J-H, Kang IM. Gallium Nitride Normally Off MOSFET Using Dual-Metal-Gate Structure for the Improvement in Current Drivability. Electronics. 2020; 9(9):1402. https://doi.org/10.3390/electronics9091402

Chicago/Turabian StyleYoon, Young Jun, Jae Sang Lee, Dong-Seok Kim, Jung-Hee Lee, and In Man Kang. 2020. "Gallium Nitride Normally Off MOSFET Using Dual-Metal-Gate Structure for the Improvement in Current Drivability" Electronics 9, no. 9: 1402. https://doi.org/10.3390/electronics9091402

APA StyleYoon, Y. J., Lee, J. S., Kim, D.-S., Lee, J.-H., & Kang, I. M. (2020). Gallium Nitride Normally Off MOSFET Using Dual-Metal-Gate Structure for the Improvement in Current Drivability. Electronics, 9(9), 1402. https://doi.org/10.3390/electronics9091402