Research on Stability Design of Differential Drive Fork-Type AGV Based on PID Control

Abstract

1. Introduction

2. AGV Theoretical Analysis of In-Situ Steering Stability

2.1. AGV Unstable Steering Due to Side Slip

2.2. AGV Unstable Steering Due to Slipping of Drive Wheels

2.3. AGV Unstable Steering due to the Difference in Acceleration Values of the Two Drive Wheels

3. AGV Simulation Analysis

3.1. Simulation Model Establishment

- Fillets and chamfers that do not affect AGV stability are ignored;

- Elements that do not affect the strength and stiffness of AGV are ignored;

- The number of parts in the model can be reduced, and the calculation speed can be accelerated by setting some connecting parts as a bonding relationship;

- The chain drive part of the fork-type AGV is removed. For this kind of flexible part, it needs to be built in the ADAMS software (Mechanical Dynamics Inc, Winter Haven, FL, USA) environment to reflect its actual stress condition;

- In addition, as shown in Figure 6, the fork in the fork-type AGV model is relatively complex, and this topic is aimed at the dynamics research of the fork-type AGV steering simulation. Therefore, before importing Adams, the fork in the AGV model is removed, and then a simplified fork with the same size, volume and weight is created in the ADAMS software;

- The simulation model includes the AGV model and the corresponding operating environment, and a large area of a rectangular block should be assembled in the place where the AGV’s four wheels have contact as the AGV running road.

3.2. Motion Simulation of Fork-Type AGV

3.2.1. Effect of Velocity on AGV Steering Stability

3.2.2. Effect of Acceleration on AGV Steering Stability

3.2.3. Effect of Static Friction Coefficient on AGV Steering Stability

4. AGV Optimization

4.1. Optimization of AGV’s Motion Parameters

4.1.1. Calculation of AGV Steering Acceleration

4.1.2. Calculation of AGV Steering Speed Value

4.2. AGV Control Strategy Optimization

4.2.1. AGV Steering Control System Hardware Design

Control Unit Design

Tracking Unit Design

Communication Unit Design

Drive Unit Design

4.2.2. AGV Steering Control System Software Design

5. Conclusions

- In this paper, three kinds of unstable situations of fork-type AGV in-situ steering are analyzed theoretically: Sideslip in the process of AGV in-situ steering, slip in the driving wheel, and difference in acceleration between the two driving wheels. The physical model and the corresponding mathematical model are established, and the structure and motion parameters that affect the stability of AGV in-situ steering are obtained: the steering angular velocity, acceleration, eccentricity, the static friction coefficient between the ground and the driving wheel, and the moment of inertia (related to the size and weight of AGV body) when AGV is turning;

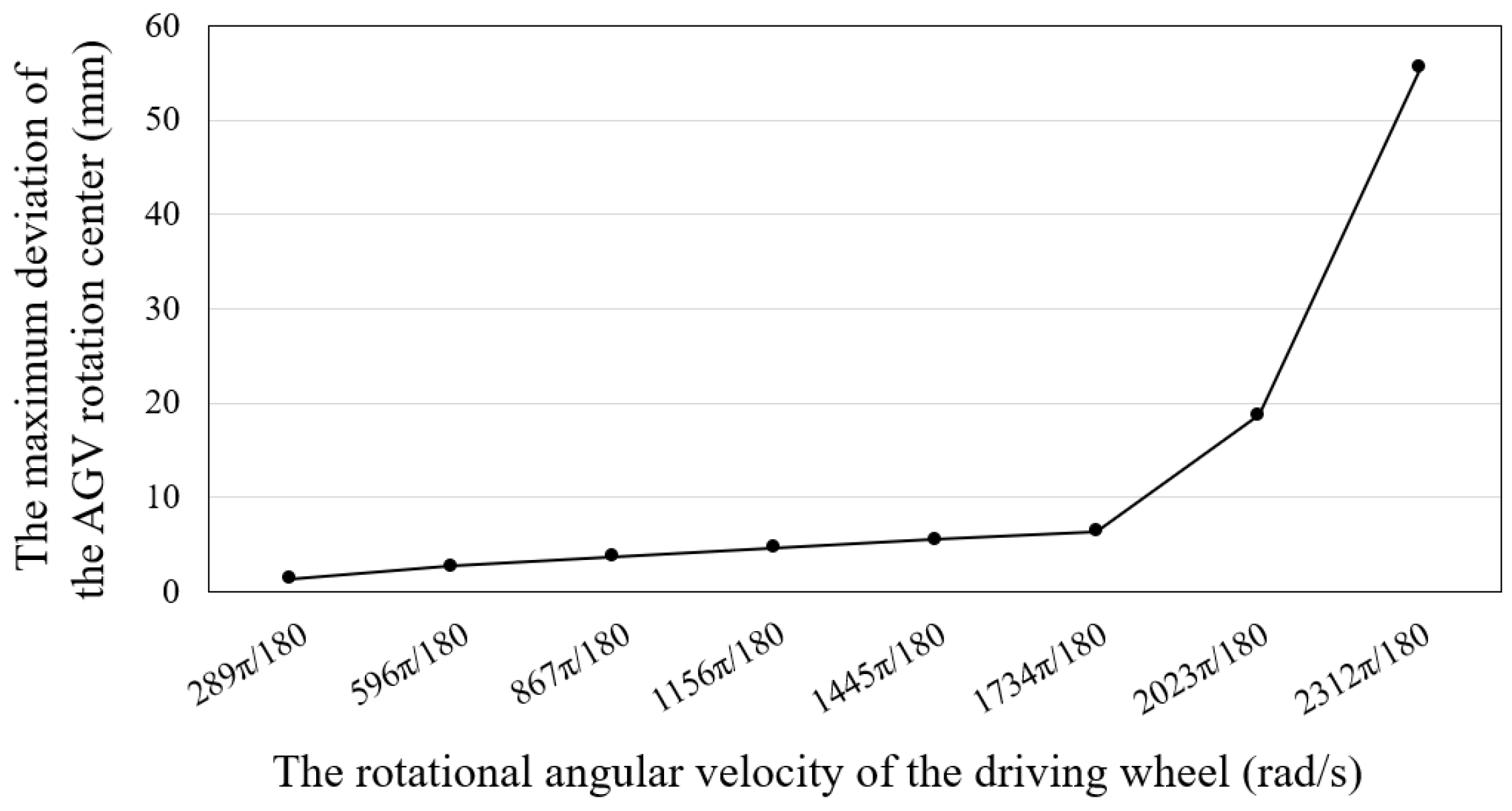

- The simulation model of the fork-type AGV’s in-situ steering is established by using ADAMS software. Based on the simulation experiment of the motion parameters which influence the stability of the AGV’s in-situ steering obtained from the previous theoretical analysis, the effects of speed, acceleration, and the static friction coefficient on the stability of the AGV’s in-situ steering are analyzed. It is found that when the speed increases to 2023π/180 rad/s, the in-situ steering stability of the AGV decreases significantly; when the acceleration time is less than 0.3 s, the maximum deviation of AGV rotation center increases significantly, and the AGV slips; when the static friction coefficient between the AGV’s driving wheel and the ground increases from 0.1 to 0.3, the steering stability of the AGV improves significantly. This is consistent with the results of the theoretical derivation, which verifies the rationality of the theoretical derivation;

- Reasonable suggestions are made for the speed and acceleration of AGV in-situ steering. Aiming at the deviation of the AGV’s rotation center during the AGV’s in-situ steering, the corresponding steering control strategy is obtained through research. The flexible and stable fuzzy adaptive PID control algorithm is used to design the corresponding steering control strategy. The hardware and software of the corresponding AGV in-situ steering control system are designed to realize AGV steering control. After debugging, the optimized forklift AGV turned to work stably, meeting the actual work requirements.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| AGV | Automated Guided Vehicle |

| QR code | Two-dimensional code |

| CAN | Controller Area Network |

| PLC | Programmable Logic Controller |

| m | Mass |

| g | Acceleration of gravity |

| B | Track of left and right wheels |

| l | Track of front and rear wheels |

| e | Eccentricity(m) |

| H | Centroid height |

| fR | Rolling friction coefficient |

| μS | Coefficient of static friction |

References

- Long, J.; Zhang, C.L. The Summary of AGV Guidance Technology. Adv. Mater. Res. 2012, 591–593, 1625–1628. [Google Scholar] [CrossRef]

- Field, B.F.; Kasper, G. Automated Guided Vehicle. U.S. Patent 4,996,468, 20 February 1991. [Google Scholar]

- Vis, I.F.A. Survey of research in the design and control of automated guided vehicle systems. Oper. Res. 2006, 46, 435–436. [Google Scholar] [CrossRef]

- Rashidi, H.; Tsang, E.P.K. A complete and an incomplete algorithm for automated guided vehicle scheduling in container terminals. Comput. Math. Appl. 2011, 61, 630–641. [Google Scholar] [CrossRef]

- Nana, G. Research on Plan for AGV Applied to Automated Logistics System. Master’s Thesis, Xi’an University of Science and Technology, Xi’an, China, 2010. [Google Scholar]

- Čerić, V. Simulation Study of an Automated Guided-vehicle System in a Yugoslav Hospital. J. Oper. Res. Soc. 2017, 41, 299–310. [Google Scholar] [CrossRef]

- Ganesharajah, T.; Hall, N.G.; Sriskandarajah, C. Design and operational issues in AGV-served manufacturing systems. Ann. Oper. Res. 1998, 76, 109–154. [Google Scholar] [CrossRef]

- Umar, U.A.; Ariffin, M.K.A.; Ismail, N.; Tang, S.H. Hybrid multiobjective genetic algorithms for integrated dynamic scheduling and routing of jobs and automated-guided vehicle (AGV) in flexible manufacturing systems (FMS) environment. Int. Ournal Adv. Manuf. Technol. 2015, 81, 2123–2141. [Google Scholar] [CrossRef]

- Fazlollahtabar, H.; Saidi-Mehrabad, M. Methodologies to Optimize Automated Guided Vehicle Scheduling and Routing Problems: A Review Study. J. Intell. Robot. Syst. 2015, 77, 525–545. [Google Scholar] [CrossRef]

- Butdee, S.; Suebsomran, A. Automatic guided vehicle control by vision system. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management, Hong Kong, China, 8–11 December 2009. [Google Scholar]

- Wang, M.S.; Chen, S.C.; Chuang, P.H.; Wu, S.Y.; Hsu, F.S. Neural Network Control-Based Drive Design of Servomotor and Its Application to Automatic Guided Vehicle. Math. Probl. Eng. 2015, 2015, 612932. [Google Scholar] [CrossRef]

- Weyns, D.; Holvoet, T. Architectural design of a situated multiagent system for controlling automatic guided vehicles. Int. J. Agent Oriented Softw. Eng. 2008, 2, 90–128. [Google Scholar] [CrossRef]

- Weitao, W. The Overall Scheme and Key Technology Research of Logistics Transportation AGV. Master’s Thesis, Shenyang Ligong University, Shenyang, China, 2013. [Google Scholar]

- Rehman, N.U.; Asghar, S.; Usman, M.; Fong, S.; Cho, K.; Park, Y.W. High level classification recommended decision making for Autonomous Ground Vehicle (AGV). J. Comput. Theoret. Nanosci. 2016, 13, 4284–4292. [Google Scholar] [CrossRef]

- Xuesong, G.; Yuhao, L.; Liqiang, Z.; Zhihua, C. Pure Rolling Steering System Design and Research on Non-sideslip Steering Control for Wheeled AGV. Trans. Chin. Soc. Agric. Mach. 2018, 56, 101230. [Google Scholar]

- Kodagoda, K.R.S.; Wijesoma, W.S.; Teoh, E.K. Fuzzy speed and steering control of an AGV. IEEE Trans. Control Syst. Technol. 2002, 10, 112–120. [Google Scholar] [CrossRef]

- Hidehiko, Y.; Takayoshi, Y. Intelligent AGV Control of Autonomous Decentralized FMS by Oblivion and Memory. Key Eng. Mater. 2010, 447–448, 326–330. [Google Scholar]

- Cho, H.; Song, H.; Park, M.; Kim, J.; Woo, S.; Kim, S. Independence localization system for Mecanum wheel AGV. In Proceedings of the IEEE RO-MAN, Gyeongju, Korea, 26–29 August 2013. [Google Scholar]

- Xiaolong, J. The Key Technology Research on Magnetic Guided and Double Wheels Differential Speed Automated Guided Vehicle. Master’s Thesis, Hefei University of Technology, Hefei, China, 2016. [Google Scholar]

- Qingfu, Z.; Huaixing, W. Optimization design of the small stacking robot fork device. Manuf. Autom. 2013, 35, 1–3. [Google Scholar]

- Binbin, S.; Nanyi, L.; Lihui, W. Stability Analysis on Fork-type AGV Based on ANSYS. Taiyuan Sci. Technol. 2016, 115–116, 120. [Google Scholar]

- Huang, C.; Shirong, Y. Stability Analysis of Forklift Based on ADAMS. Mach. Build. Autom. 2015, 4, 108–111. [Google Scholar]

- Yongyan, W. Theoretical Mechanics; Science Press: Beijing, China, 2019; pp. 309–312. [Google Scholar]

- Rui, C. The Stabilization Research of Fork-Type AGV Based on Virtual Prototyping Technology and Structure Optimization. Master’s Thesis, Mechanical Science Research Institute, Beijing, China, 2015. [Google Scholar]

- Sa, L. Research on Motion Stability of Drive-Module of Four-Wheel Independent-Steering AGV. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2019. [Google Scholar]

- Jinchang, Z. Optimal Design Parking and Steering Stability Analysis of AGV. Master’s Thesis, North University of China, Taiyuan, China, 2019. [Google Scholar]

- Peng, Z. Research on Structural Design and Stability of Pallet Type AGV Forklift. Master’s Thesis, Anhui University of Science and Technology, Huainan, China, 2019. [Google Scholar]

- Ping, F. Design of Compressor Oil Injection Management System Based on RS485 and Ethernet Communicatio. Master’s Thesis, Qingdao University, Qingdao, China, 2017. [Google Scholar]

- Lifang, T. Research on Design and Test of Wheeled AGV System of Picking Robot Based on Pure-Rolling Steering. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2016. [Google Scholar]

- Shuo, Z. Detailed application of TIA Botu software and S7-1200/1500 PLC; Electronic Industry Press: Beijing, China, 2017; pp. 254–273. [Google Scholar]

| Physical Quantity | Symbol |

|---|---|

| Mass (kg) | m |

| Track of left and right wheels (m) | B |

| Track of front and rear wheels (m) | l |

| Eccentricity (m) | e |

| Centroid height (m) | H |

| Rolling friction coefficient | |

| Coefficient of static friction |

| Name of Parts | Material | Modulus of Elasticity (N/mm2) | Poisson’s Ratio | Density (kg/mm3) |

|---|---|---|---|---|

| Body frame/fork/counterweight | Steel | 2.07 × 105 | 0.29 | 7.801 × 10−6 |

| Wheel | Polyurethane | 8300 | 0.28 | 1.5 × 10−6 |

| Working pavement | Concrete | 3.5 × 104 | 0.15 | 2.4 × 10−6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Dong, R.; Zhang, R.; Qin, D. Research on Stability Design of Differential Drive Fork-Type AGV Based on PID Control. Electronics 2020, 9, 1072. https://doi.org/10.3390/electronics9071072

Wang T, Dong R, Zhang R, Qin D. Research on Stability Design of Differential Drive Fork-Type AGV Based on PID Control. Electronics. 2020; 9(7):1072. https://doi.org/10.3390/electronics9071072

Chicago/Turabian StyleWang, Tingting, Ruoyan Dong, Rui Zhang, and Dongchen Qin. 2020. "Research on Stability Design of Differential Drive Fork-Type AGV Based on PID Control" Electronics 9, no. 7: 1072. https://doi.org/10.3390/electronics9071072

APA StyleWang, T., Dong, R., Zhang, R., & Qin, D. (2020). Research on Stability Design of Differential Drive Fork-Type AGV Based on PID Control. Electronics, 9(7), 1072. https://doi.org/10.3390/electronics9071072