Research on Angle and Stiffness Cooperative Tracking Control of VSJ of Space Manipulator Based on LESO and NSFAR Control

Abstract

:1. Introduction

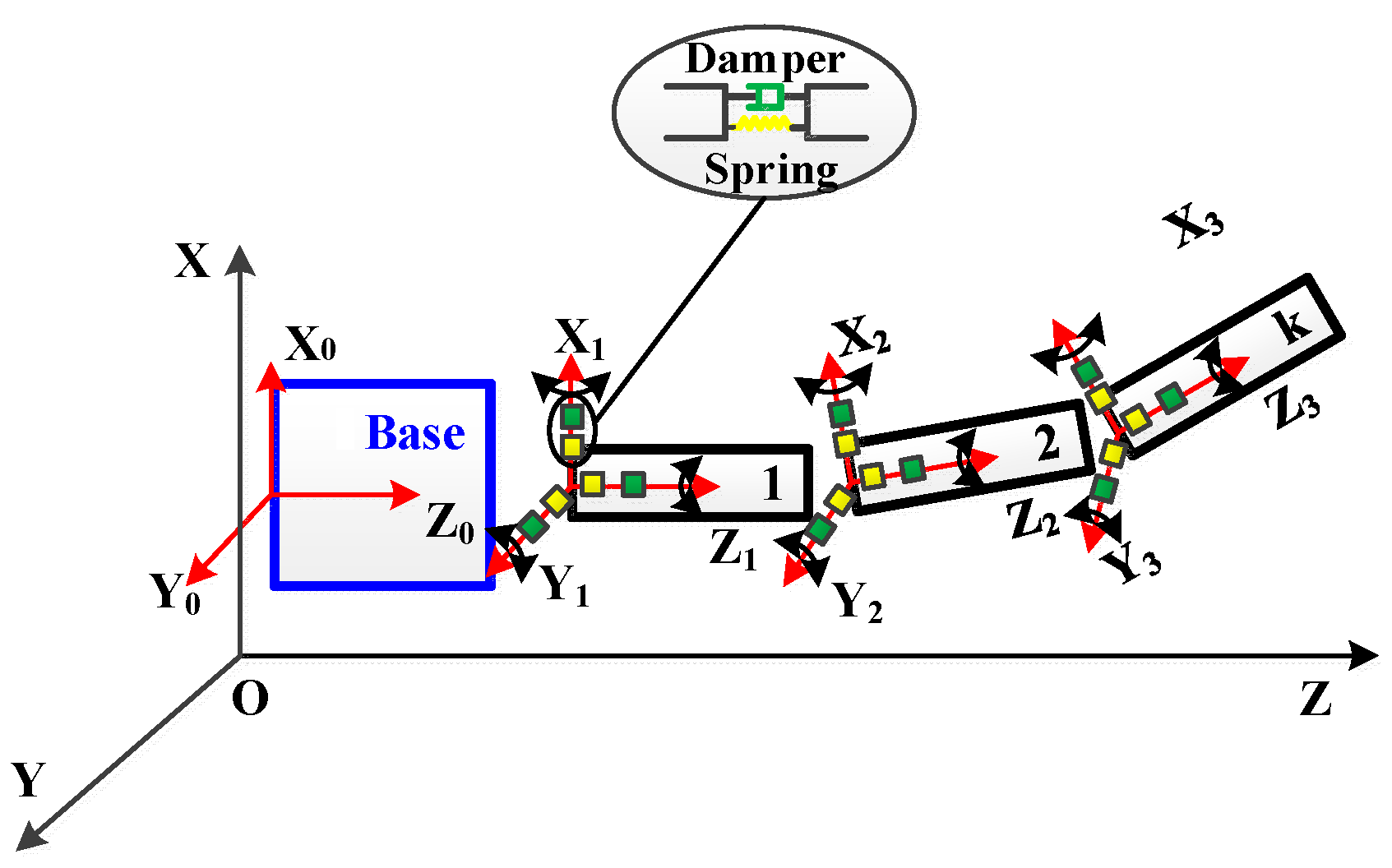

2. Structural Design and Dynamic Model Construction of Space Manipulator VSJ

2.1. Space Manipulator VSJ Design

2.2. Dynamic Model Construction

3. Control Algorithm Construction

3.1. The Linear Extended State Observer Design

3.2. Neural State Feedback Adaptive Robust Control Based on RBFNN

3.2.1. Design of Neural State Feedback Adaptive Robust Control Based on RBFNN

3.2.2. Stability Analysis of State Feedback Adaptive Robust Controller Based on RBFNN

3.2.3. Schematic Diagram of the Control Algorithm

4. Simulation

4.1. Simulation Setting

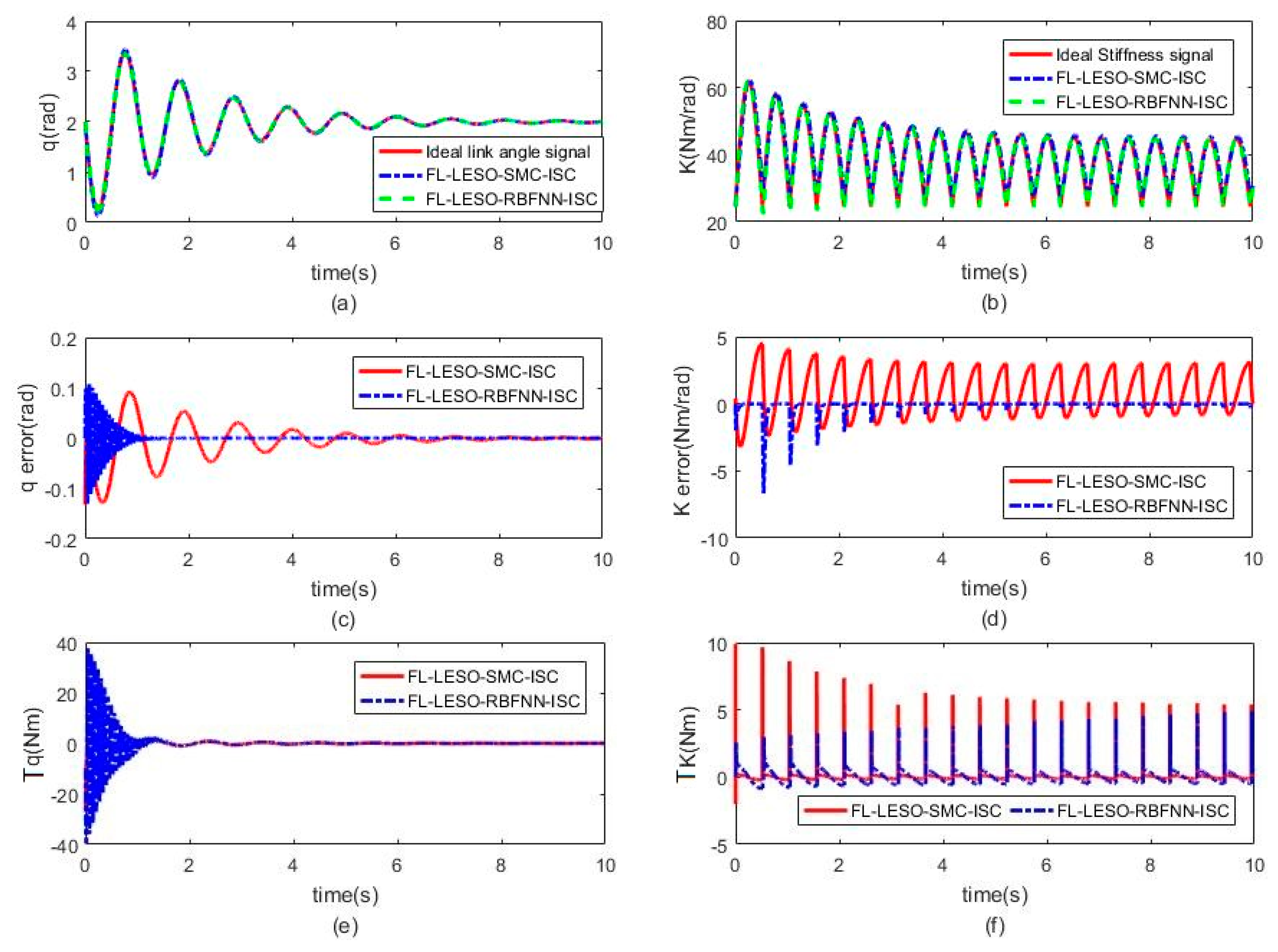

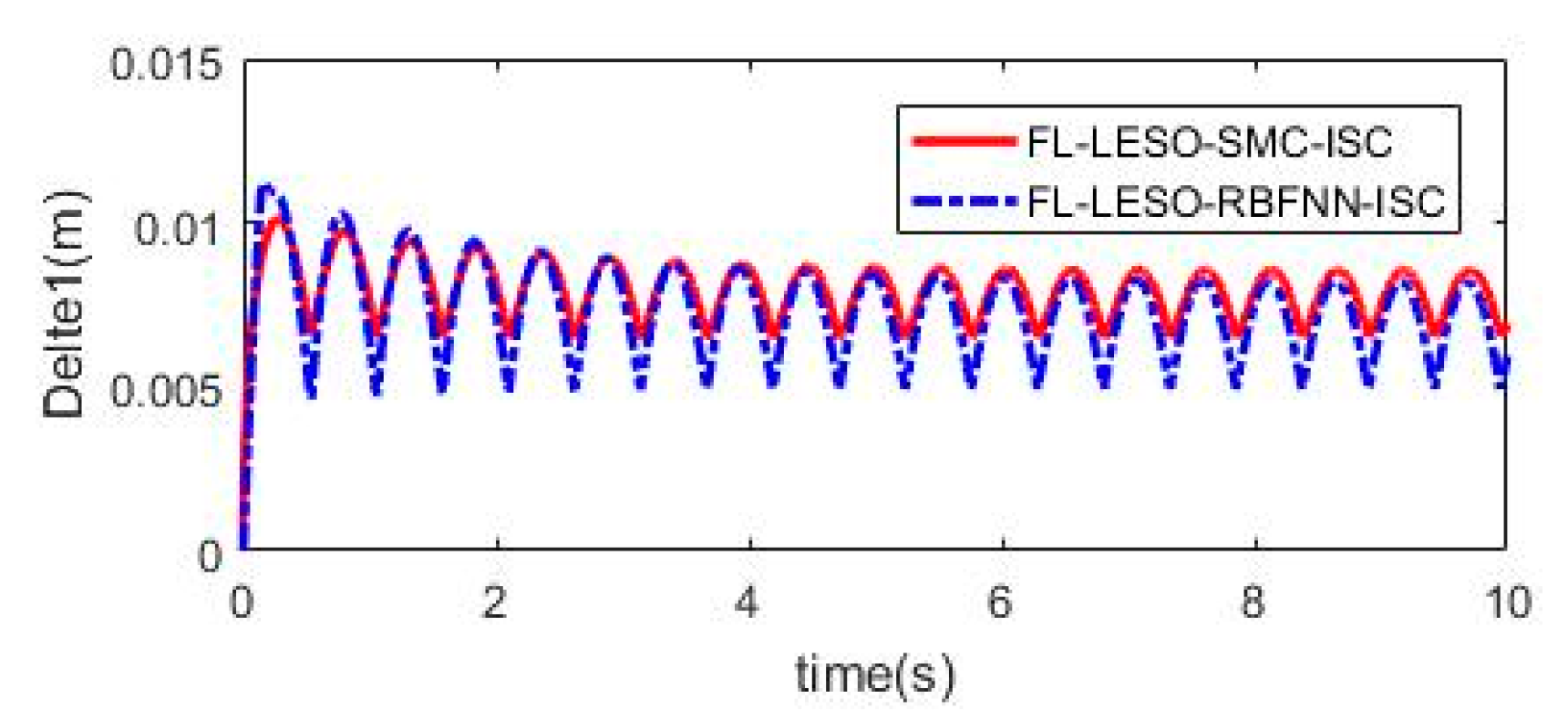

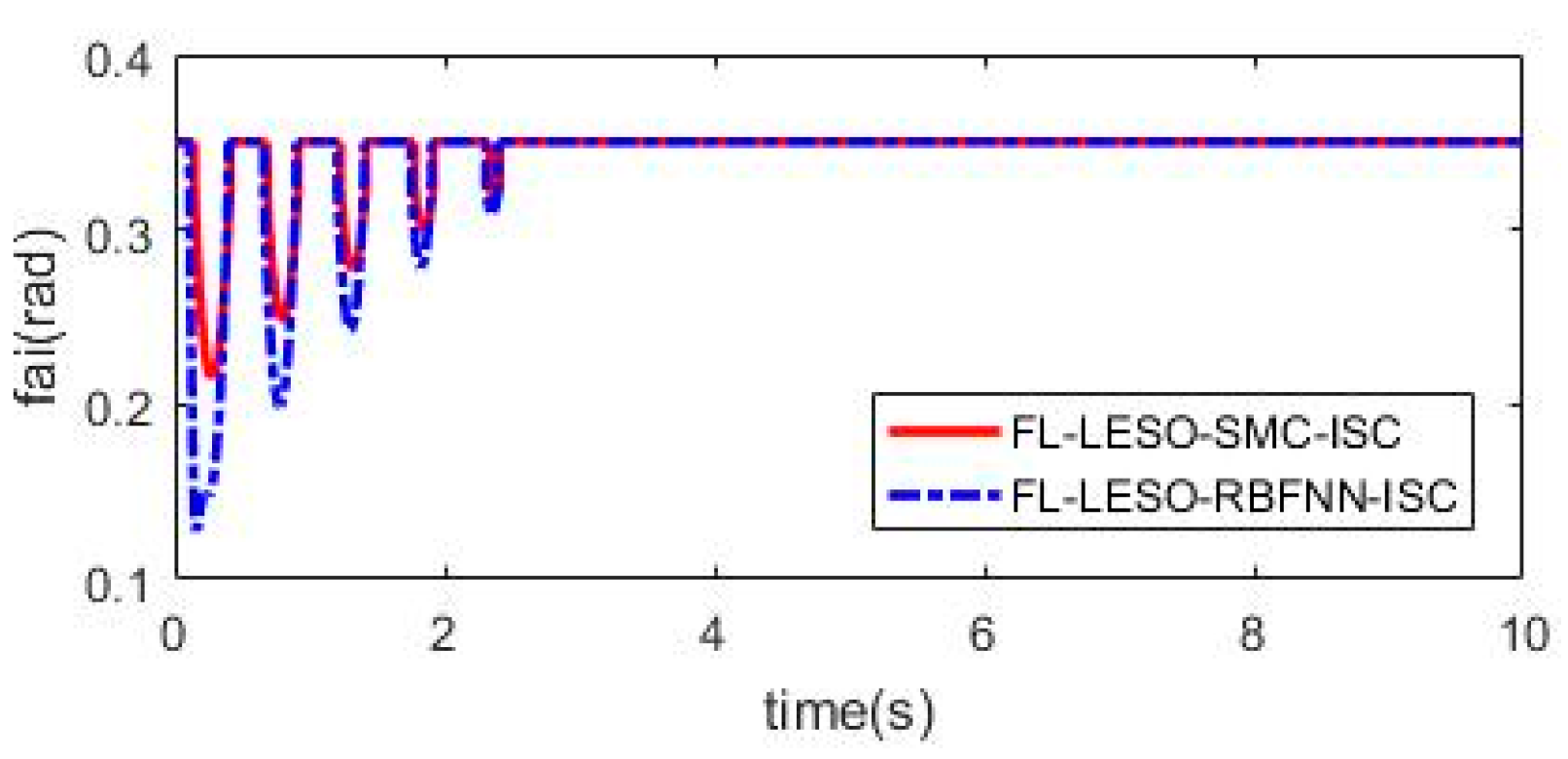

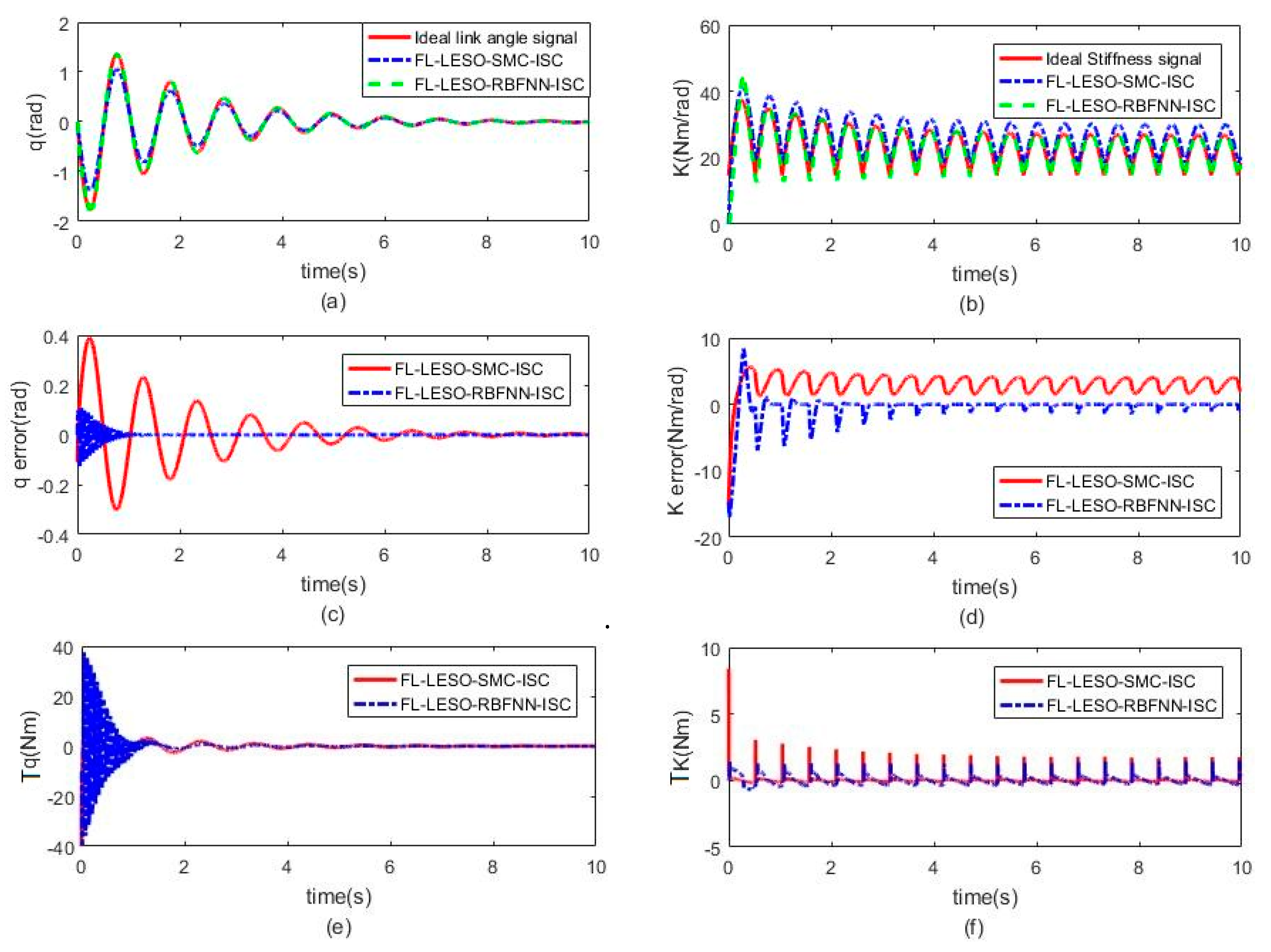

4.2. Simulation Results

5. Experiment

5.1. Experimental Setting

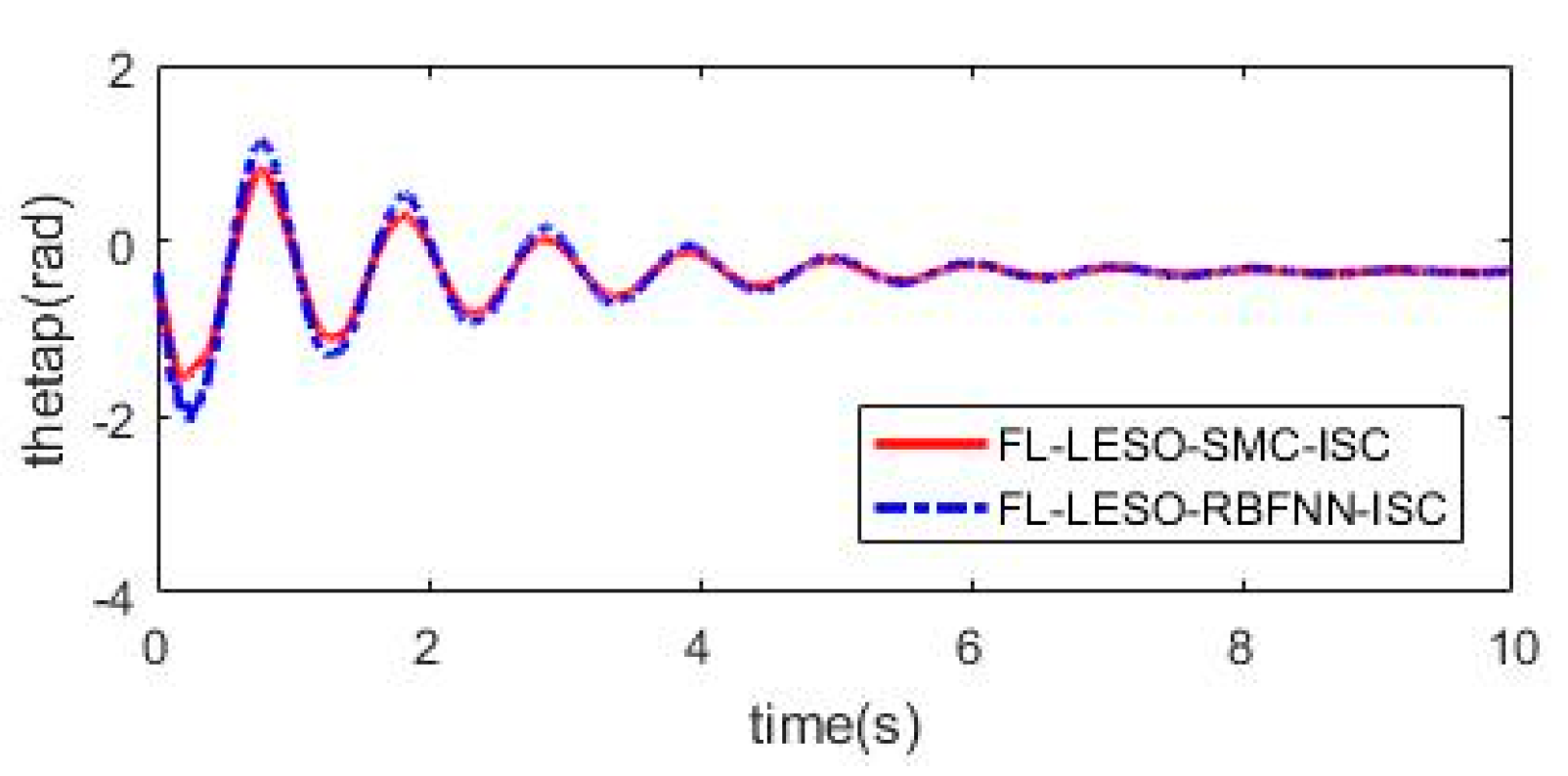

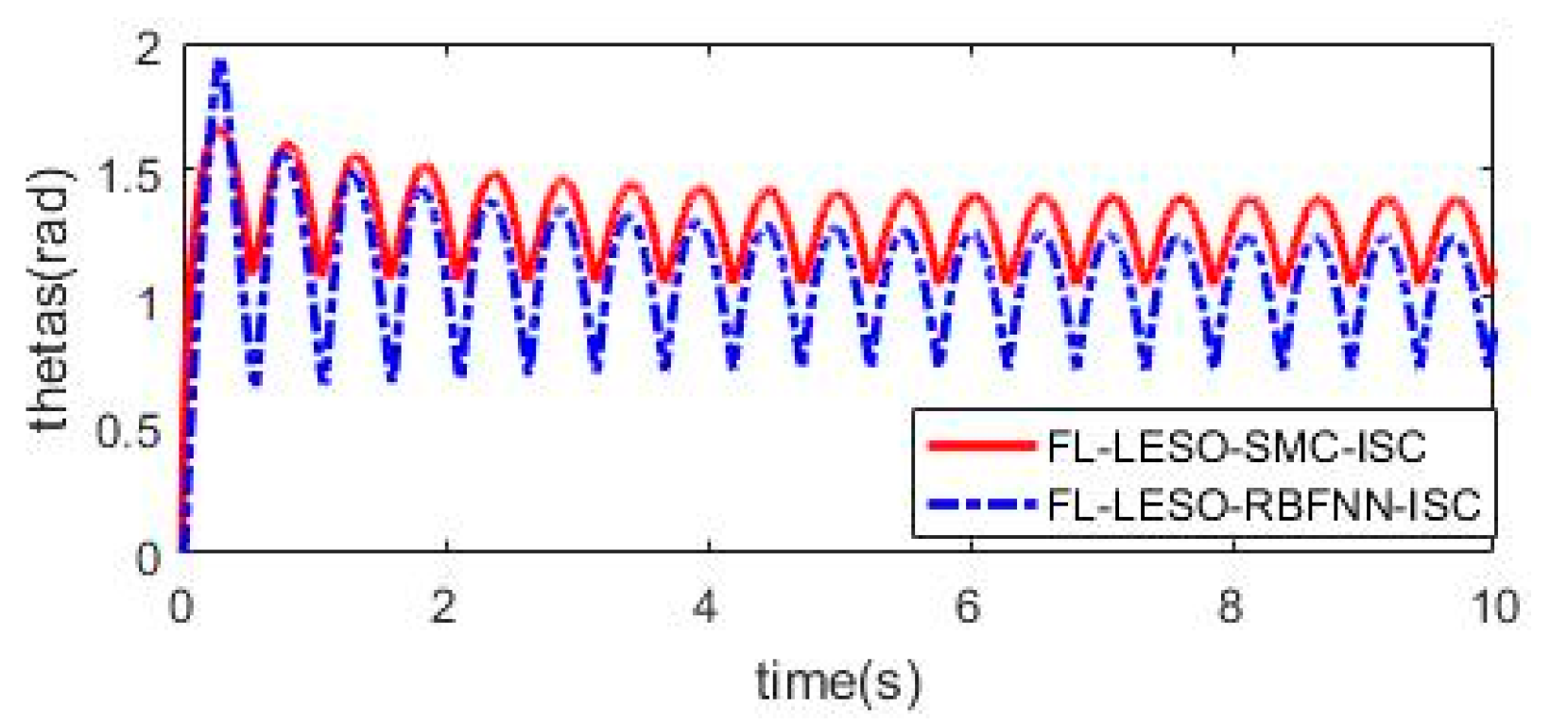

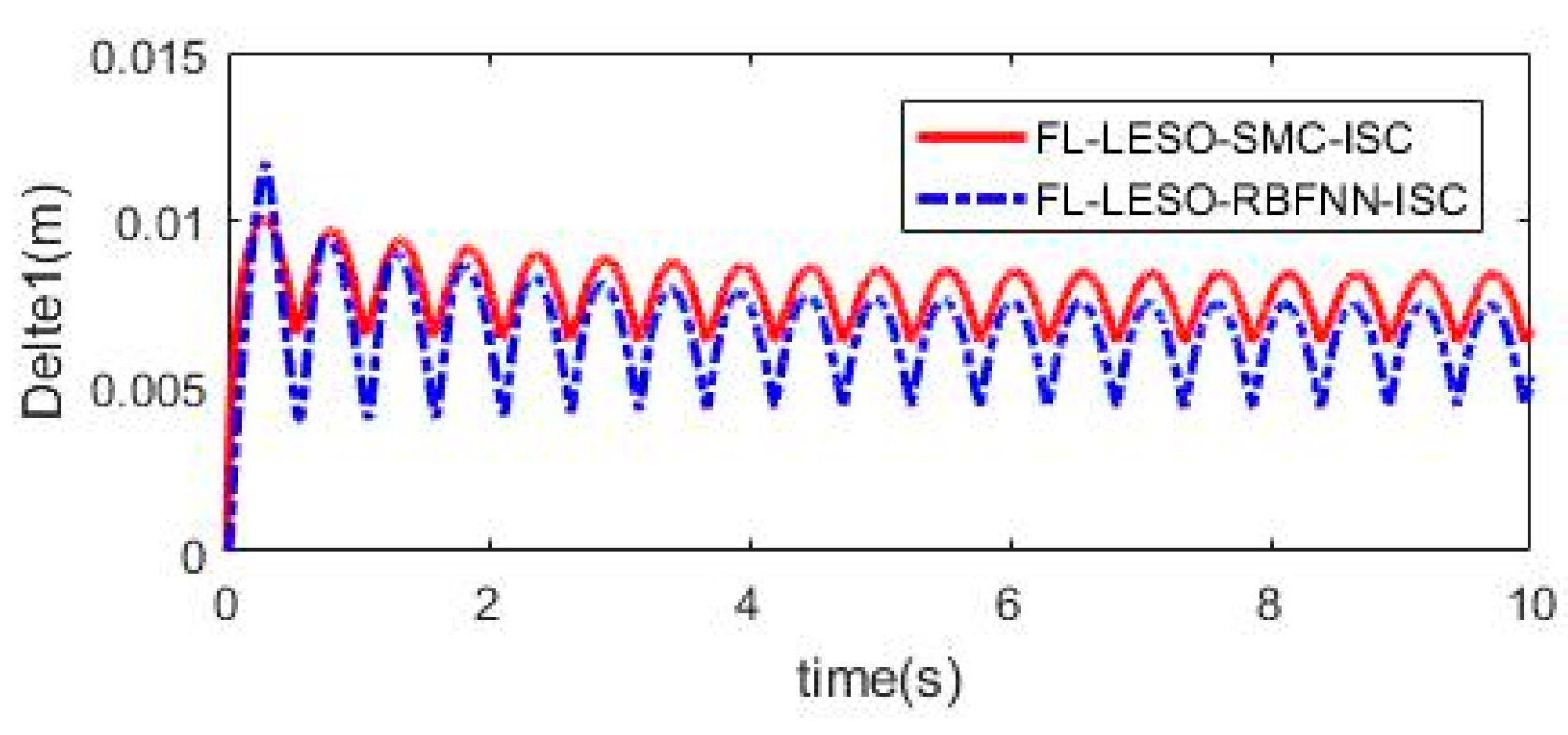

5.2. Experimental Results

6. Discussion

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Spacenews. Available online: https://spacenews.com/intelsat-still-searching-for-cause-of-is-29e-loss-replacement-satellite-tbd/ (accessed on 30 April 2019).

- Li, W.J.; Cheng, D.Y.; Liu, X.G.; Wang, Y.B.; Shi, W.H.; Tang, Z.X.; Gao, F.; Zeng, F.M.; Chai, H.Y.; Cong, Q.; et al. On-orbit service (OOS) of spacecraft: A review of engineering developments. Prog. Aerosp. Sci. 2019, 108, 32–120. [Google Scholar] [CrossRef]

- Liang, B.; Xu, W.F. Space Robot: Modeling, Planning, and Control, 1st ed.; Tsinghua University Press: Beijing, China, 2017; pp. 26–27. [Google Scholar]

- Ellery, A. Tutorial Review on Space Manipulators for Space Debris Mitigation. Robotics 2019, 8, 34. [Google Scholar] [CrossRef]

- Flores-Abad, A.; Crain, A.; Nandayapa, M.; Garcia-Teran, M.A.; Ulrich, S. Disturbance observer-based impedance control for a compliance capture of an object in space. In Proceedings of the 2018 AIAA Guidance, Navigation, and Control Conference, Kissimmee, FL, USA, 8–12 January 2018; p. 1329. [Google Scholar]

- Yoon, H.; Chung, S.; Kang, H.; Hwang, M. Trapezoidal Motion Profile to Suppress Residual Vibration of Flexible Object Moved by Robot. Electronics 2019, 8, 30. [Google Scholar] [CrossRef]

- Meng, D.; She, Y.; Xu, W.; Lu, W.; Liang, B. Dynamic modeling and vibration characteristics analysis of flexible-link and flexible-joint space manipulator. Multibody Syst. Dyn. 2018, 43, 321–347. [Google Scholar] [CrossRef]

- Dong, Z.H.; Wang, J.; Yang, F. On-Orbit Soft Contact Technology of Space Target, 7th–13th ed.; National Defense Industry Press: Beijing, China, 2017; pp. 136–297. [Google Scholar]

- Khan, O.; Pervaiz, M.; Ahmad, E.; Iqbal, J. On the derivation of novel model and sophisticated control of flexible joint manipulator. Rev. Roum. Sci. Tech.-Ser. Electrotech. Energetique 2017, 62, 103–108. [Google Scholar]

- Guo, J.; Tian, G. Robust Tracking Control of the Variable Stiffness Actuator Based on the Lever Mechanism. Asian J. Control 2019, in press. [Google Scholar] [CrossRef]

- Yang, Y.B. The Dynamics Modeling and Vibration Suppression Research of Flexible Joint Flexible Link Manipulators. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2015. [Google Scholar]

- Jafari, A.; Vu, H.Q.; Iida, F. Determinants for stiffness adjustment mechanisms. J. Intell. Robot. Syst. 2016, 82, 435–454. [Google Scholar] [CrossRef]

- Lee, J.; Wahrmund, C.; Jafari, A. A novel mechanically overdamped actuator with adjustable stiffness (mod-awas) for safe interaction and accurate positioning. Actuators 2017, 6, 22. [Google Scholar] [CrossRef]

- Jafari, A.; Tsagarakis, N.; Caldwell, D. Energy efficient actuators with adjustable stiffness: A review on AwAS, AwAS-II and CompACT VSA changing stiffness based on lever mechanism. Ind. Robot 2015, 42, 242–251. [Google Scholar] [CrossRef]

- Tsagarakis, N.G.; Sardellitti, I.; Caldwell, D.G. A new variable stiffness actuator (CompAct-VSA): Design and modelling. In Proceedings of the 2011 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Francisco, CA, USA, 25–30 September 2011; pp. 378–383. [Google Scholar]

- Sun, J.; Guo, Z.; Zhang, Y.; Xiao, X.; Tan, J. A novel design of serial variable stiffness actuator based on an archimedean spiral relocation mechanism. IEEE/ASME Trans. Mechatron. 2018, 23, 2121–2131. [Google Scholar] [CrossRef]

- Sun, J.; Guo, Z.; Sun, D.; He, S.; Xiao, X. Design, modeling and control of a novel compact, energy-efficient, and rotational serial variable stiffness actuator (SVSA-II). Mech. Mach. Theory 2018, 130, 123–136. [Google Scholar] [CrossRef]

- Awad, M.I.; Gan, D.; Hussain, I.; Az-Zu’bi, A.; Stefanini, C.; Khalaf, K.; Seneviratne, L.D. Design of a novel passive Binary-Controlled Variable Stiffness Joint (BpVSJ) towards passive haptic interface application. IEEE Access 2018, 6, 63045–63057. [Google Scholar] [CrossRef]

- Grosu, V.; Rodriguez-Guerrero, C.; Grosu, S.; Vanderborght, B.; Lefeber, D. Design of smart modular variable stiffness actuators for robotic-assistive devices. IEEE/ASME Trans. Mechatron. 2017, 22, 1777–1785. [Google Scholar] [CrossRef]

- Cai, R.F. Design and Control Research of a New Type Flexible Joint with Variable Stiffness. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2017. [Google Scholar]

- Weckx, M.; Mathijssen, G.; Si Mhand Benali, I.; Furnemont, R.; Van Ham, R.; Lefeber, D.; Vanderborght, B. A two-degree of freedom variable stiffness actuator based on the maccepa concept. Actuators 2014, 3, 20–40. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, Y.; Zhang, C.; Guo, Z.; Xiao, X. Mechanical design of a compact serial variable stiffness actuator (SVSA) based on lever mechanism. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; pp. 33–38. [Google Scholar]

- Grebenstein, M.; Albu-Schäffer, A.; Bahls, T.; Chalon, M.; Eiberger, O.; Friedl, W.; Höppner, H. The DLR hand arm system. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 3175–3182. [Google Scholar]

- Buondonno, G.; De Luca, A. Efficient computation of inverse dynamics and feedback linearization for VSA-based robots. IEEE Robot. Autom. Lett. 2016, 1, 908–915. [Google Scholar] [CrossRef]

- Jovanović, K.; Lukić, B.; Potkonjak, V. Feedback linearization for decoupled position/stiffness control of bidirectional antagonistic drives. Facta Univ. Ser. Electron. Energet. 2017, 31, 51–61. [Google Scholar] [CrossRef]

- Sun, X.R. Reaserch of Biped Robot with Variable-Stiffness Ankle. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2016. [Google Scholar]

- Petit, F.; Daasch, A.; Albu-Schäffer, A. Backstepping control of variable stiffness robots. IEEE Trans. Control Syst. Technol. 2015, 23, 2195–2202. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, X.; Lu, H. Quasi-Finite-Time Control of Antagonistic Actuated Robots Using Mapping Filtered Forwarding Techniques. J. Intell. Robot. Syst. 2017, 86, 49–62. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, X.; Lu, H. Forwarding-based dynamic surface control for antagonistic actuated robots. IET Control Theory Appl. 2016, 10, 1763–1770. [Google Scholar] [CrossRef]

- Lukić, B.Z.; Jovanović, K.M.; Kvaščcev, G.S. Feedforward neural network for controlling qbmove maker pro variable stiffness actuator. In Proceedings of the 2016 13th Symposium on Neural Networks and Applications (NEUREL), Belgrade, Serbia, 22–24 November 2016. [Google Scholar]

- Huh, S.H.; Bien, Z. Robust sliding mode control of a robot manipulator based on variable structure-model reference adaptive control approach. IET Control Theory Appl. 2007, 1, 1355–1363. [Google Scholar] [CrossRef]

- Guo, Z.; Pan, Y.; Sun, T.; Zhang, Y.; Xiao, X. Adaptive neural network control of serial variable stiffness actuators. Complexity 2017, 2017, 5361246. [Google Scholar] [CrossRef]

- Psomopoulou, E.; Theodorakopoulos, A.; Doulgeri, Z.; Rovithakis, G.A. Prescribed performance tracking of a variable stiffness actuated robot. IEEE Trans. Control Syst. Technol. 2015, 23, 1914–1926. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Z.; Yang, C. Adaptive neural network based variable stiffness control of uncertain robotic systems using disturbance observer. IEEE Trans. Ind. Electron. 2016, 64, 2236–2245. [Google Scholar] [CrossRef]

- Liu, X.; Yang, C.; Chen, Z.; Wang, M.; Su, C.Y. Neuro-adaptive observer based control of flexible joint robot. Neurocomputing 2018, 275, 73–82. [Google Scholar] [CrossRef]

- Jia, P. Control of Flexible Joint Robot Based on Motor State Feedback and Dynamic Surface Approach. J. Control Sci. Eng. 2019, 2019, 5431636. [Google Scholar] [CrossRef]

- Guo, J.S. Mechanical Design and Tracking Control of the Variable Stiffness Joints. Ph.D. Thesis, Shandong University, Shandong, China, 2018. [Google Scholar]

- Liu, C.; Liu, G.; Fang, J. Feedback linearization and extended state observer-based control for rotor-AMBs system with mismatched uncertainties. IEEE Trans. Ind. Electron. 2016, 64, 1313–1322. [Google Scholar] [CrossRef]

| Parameters | Value | Unit |

|---|---|---|

| 0.09 | Kg m2 | |

| 0.2 | N m/rad | |

| 0.105 | Kg m2 | |

| 0.00082 | Kg m2 | |

| VSJ Angle Control Motor Equivalent Damping Coefficient | 10.255 | N m/rad |

| VSJ Stiffness Control Motor Equivalent Damping Coefficient | 0.158 | N m/rad |

| Stiffness coefficient of the internal spring of the joint | 10,000 | N/m |

| Length of the inner lever chute of the joint | 0.015 | m |

| Gear rack gear ratio n | 0.006 | m/rad |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| 0.4 × | 0.5 × | ||

| 0.4 × | 0.3 N m | ||

| 0.5 × | 0.2 N m | ||

| 0.5 × | 5 N m | ||

| 0.5 × |

| Algorithm | Parameters | Value | Parameters | Value |

|---|---|---|---|---|

| FL-LESO-SMC-ISC | (150,150) | |||

| (2000,500,40) | (1/15, 1/15) | |||

| 50 | (50,30) | |||

| (5,5) | [−40.0 N m, 40.0 N m] | |||

| (5,5) | [−10.0 N m, 10.0 N m] | |||

| FL-LESO-RBFNN- ISC | 2 | |||

| (10000,5000,800,50) | 20 | |||

| (100,20) | (0.3, 0.35) | |||

| [−5,−4,−3,−2,−1,0,1,2,3,4,5] | (0.3, 0.35) | |||

| [−40,−30,−20,−10,−0,10,20,30,40] | (0.5, 0.5) | |||

| 2 | (0.1,0.1) | |||

| 20 | [−40.0 N m, 40.0 N m] | |||

| [−5,−4,−3,−2,−1,0,1,2,3,4,5] | [−10.0 N m, 10.0 N m] | |||

| [−40,−30,−20,−10,−0,10,20,30,40] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, X.; Hong, J.-C.; Dong, Z.-H. Research on Angle and Stiffness Cooperative Tracking Control of VSJ of Space Manipulator Based on LESO and NSFAR Control. Electronics 2019, 8, 893. https://doi.org/10.3390/electronics8080893

Ye X, Hong J-C, Dong Z-H. Research on Angle and Stiffness Cooperative Tracking Control of VSJ of Space Manipulator Based on LESO and NSFAR Control. Electronics. 2019; 8(8):893. https://doi.org/10.3390/electronics8080893

Chicago/Turabian StyleYe, Xin, Jia-Cai Hong, and Zheng-Hong Dong. 2019. "Research on Angle and Stiffness Cooperative Tracking Control of VSJ of Space Manipulator Based on LESO and NSFAR Control" Electronics 8, no. 8: 893. https://doi.org/10.3390/electronics8080893

APA StyleYe, X., Hong, J.-C., & Dong, Z.-H. (2019). Research on Angle and Stiffness Cooperative Tracking Control of VSJ of Space Manipulator Based on LESO and NSFAR Control. Electronics, 8(8), 893. https://doi.org/10.3390/electronics8080893