Dynamic Line Rating and Transformer-Life-Loss-Related Unit Commitment Under Extreme High-Temperature Conditions

Abstract

1. Introduction

2. Dynamic Line Rating Calculation Model Considering Temperature Effects

2.1. Thermal Balance Theory of Transmission Lines

2.2. Dynamic Line Rating Calculation Model

3. Transformer Life Loss Model Based on Ambient Temperature

3.1. Transformer Internal Temperature Rise and Hot-Spot Temperature Calculation Model

3.2. Transformer Life Loss Cost Model

4. Unit Commitment Involving Transformer Life Loss Minimizer and Dynamic Line Rating Constraints

4.1. Objective Function

4.2. Constraints

- 1.

- Wind turbine unit

- 2.

- Electric power balance constraints

- 3.

- Generation output limits of thermal power units

- 4.

- Ramp rate constraints

- 5.

- Spinning reserve constraints

- 6.

- Transmission line flow constraints

- 7.

- Interface constraints

- 8.

- Temperature-dependent transmission capacity constraint

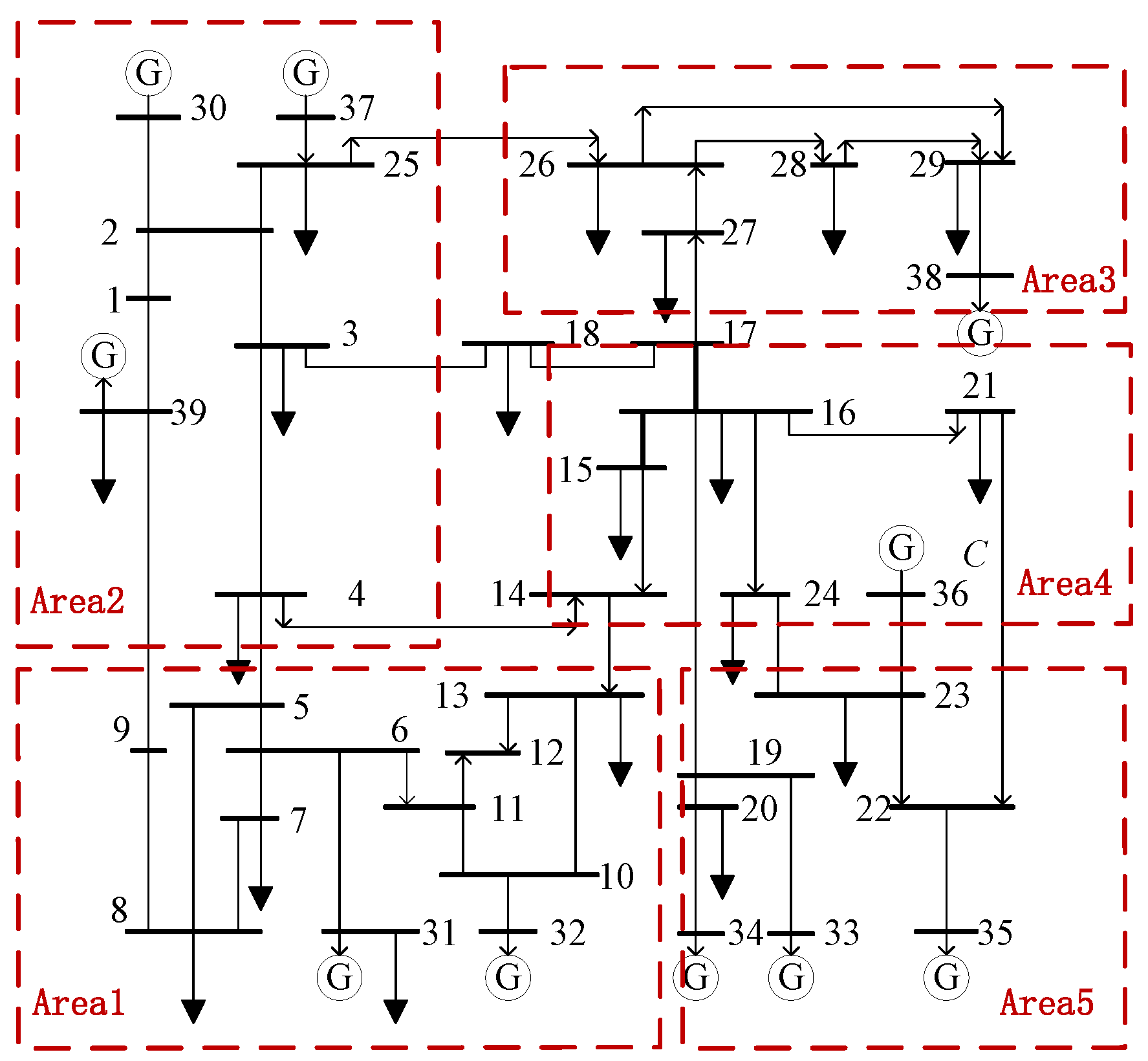

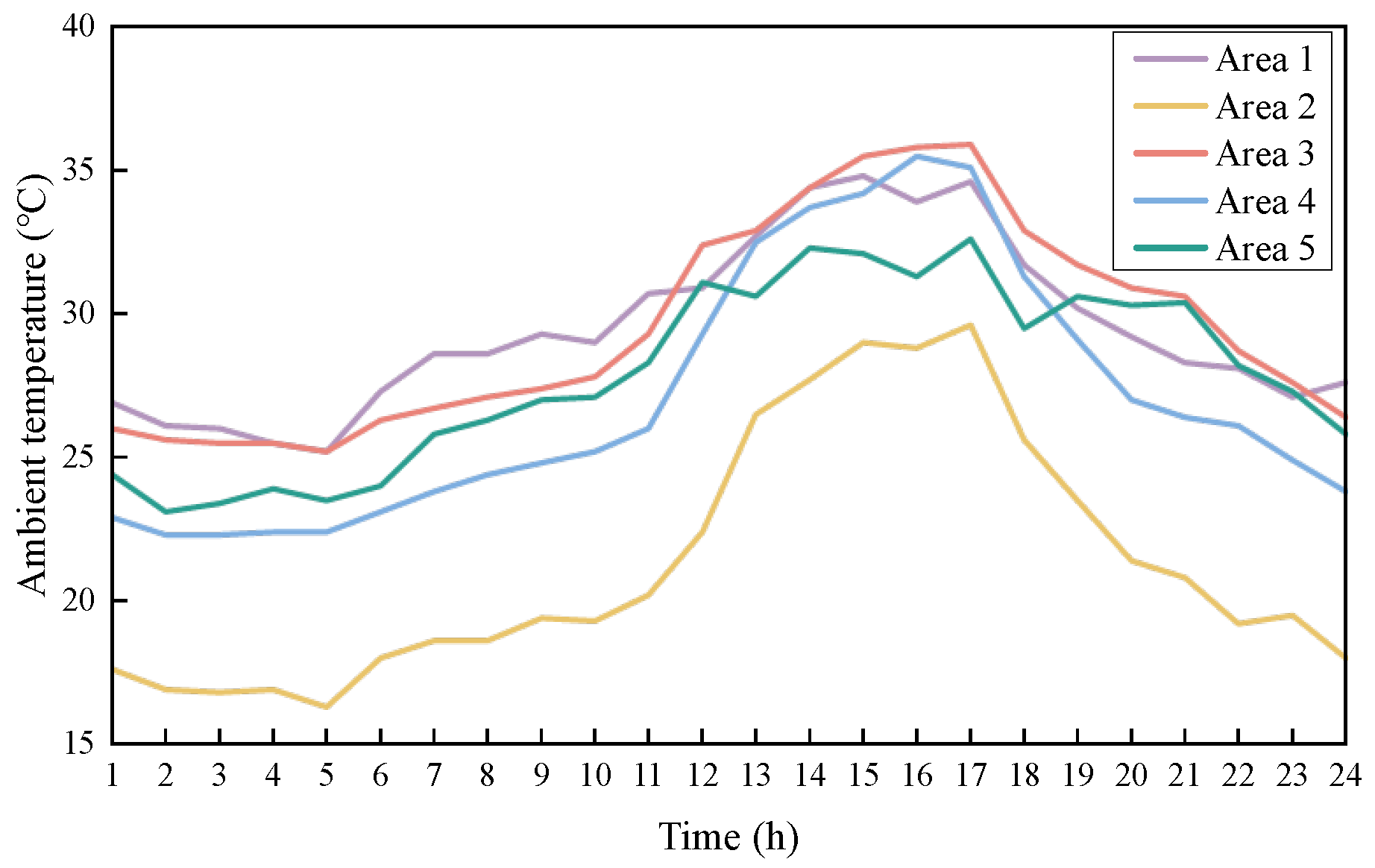

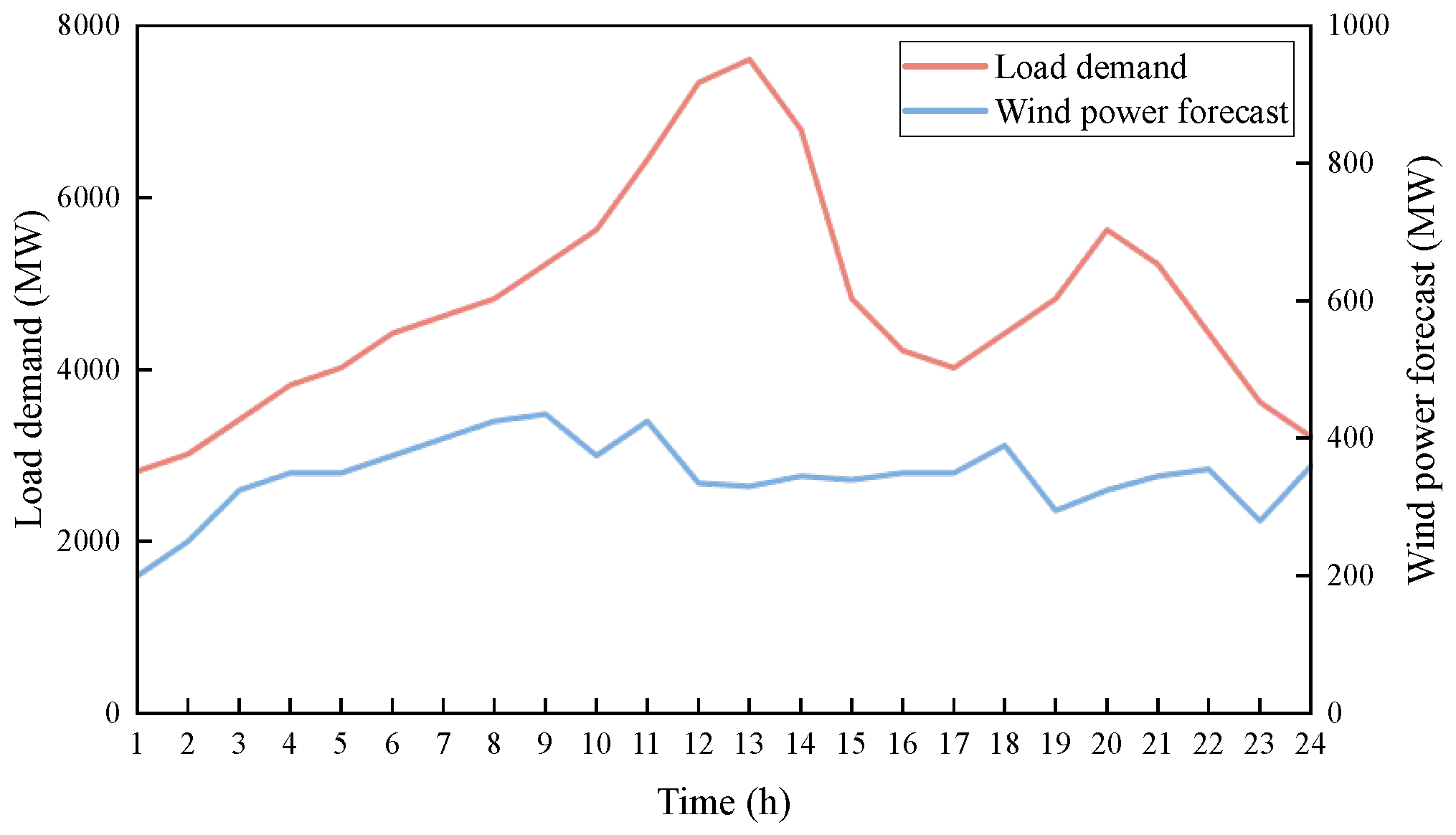

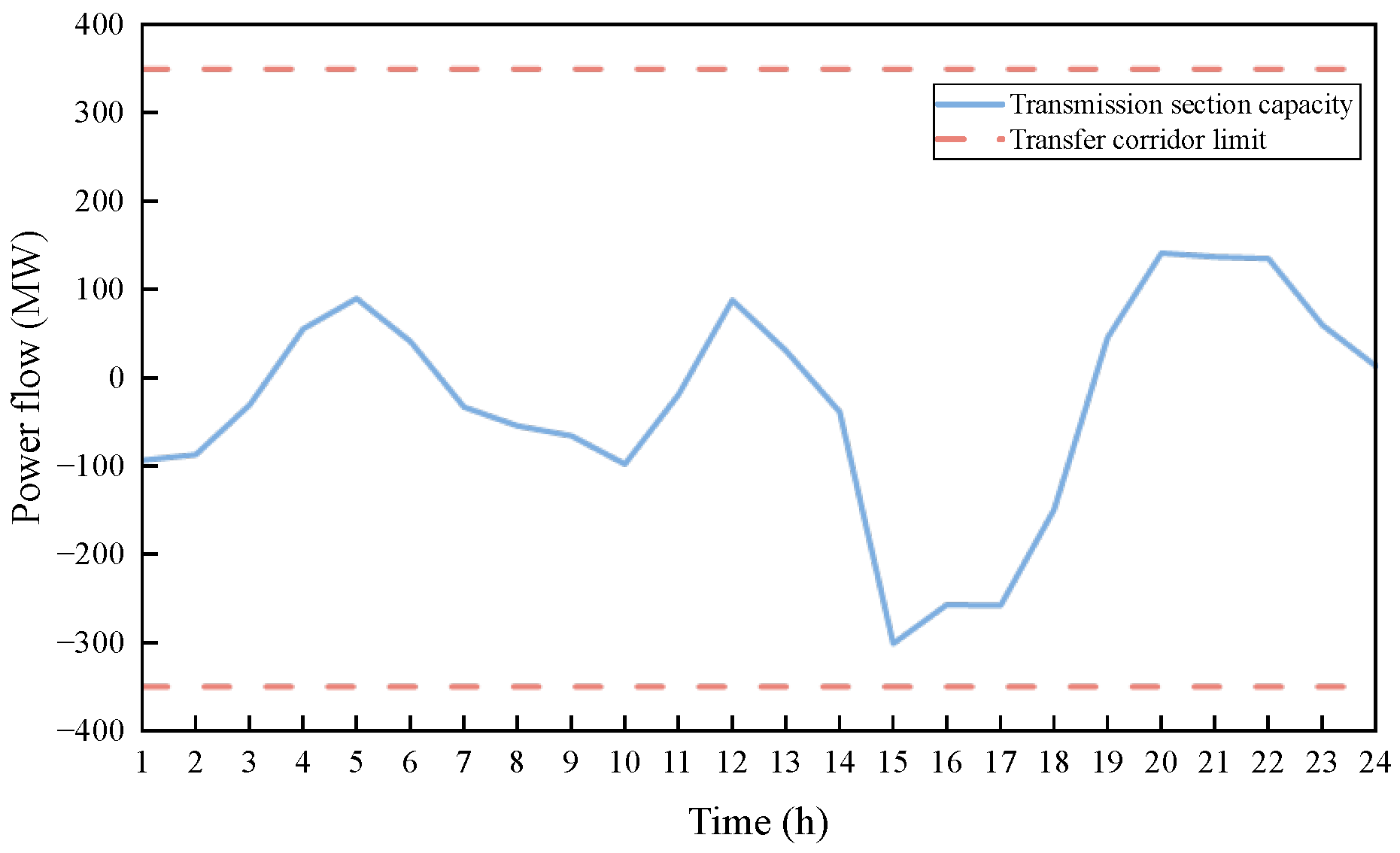

5. Case Study

6. Conclusions

- The proposed dynamic ampacity calculation model, based on thermal equilibrium theory, enables real-time transmission capacity assessment by accounting for the impacts of ambient temperature, wind speed, and solar radiation on the conductor temperature rise. The simulation results demonstrate a 12% improvement in transmission capacity utilization in high-temperature regions compared to conventional static line rating methods, effectively alleviating transmission bottlenecks caused by extreme heat.

- By considering the combined effects of ambient temperature and the load ratio on transformer hot-spot temperature and employing linear damage accumulation theory, the developed transformer aging cost function achieves a 69% reduction in transformer aging costs, significantly extending transformer service life.

- The proposed UC model simultaneously optimizes generation costs, transformer aging losses, and wind curtailment penalties. Case studies show that compared to conventional methods, this approach reduces wind curtailment by 12.5% and decreases total operating costs by 4.9%, substantially enhancing both the economic efficiency and operational security of power dispatch under extreme high-temperature conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Parameters | |

| The convective heat transfer coefficient | |

| The radiative heat transfer coefficient | |

| The solar irradiance | |

| The wind direction factor | |

| The additional loss process factor. | |

| The calculation coefficient for the average increase in the temperature of the transformer insulating oil. | |

| The ratio of the heating center height to the cooling height. | |

| The hot-spot factor accounting for increased eddy current losses at the winding ends | |

| The design life of the transformer | |

| The Arrhenius reaction rate constant | |

| The wind curtailment penalty coefficient | |

| The minimum generation outputs of the i-th thermal power unit | |

| The maximum generation outputs of the i-th thermal power unit | |

| The forecasted wind power output. | |

| The capacity limit of interface | |

| The maximum ramp-up rate of the i-th thermal unit | |

| The maximum ramp rate during unit start-up | |

| The maximum ramp rate during unit shutdown | |

| Variables | |

| The convective heat loss per unit length, W | |

| The surface area of the conductor, m2 | |

| The conductor temperature, °C | |

| The ambient temperature, °C | |

| The wind speed, m/s | |

| The overall conductor diameter, m | |

| The thermal resistance of the transmission line under ambient conditions, °C·m/W | |

| The conductor resistance per unit length at ambient temperature, Ω/m | |

| The thermal resistance of the transmission line at the maximum conductor temperature, °C·m/W | |

| The steady-state conductor temperature, °C | |

| The initial temperature, °C | |

| The stray losses, W | |

| The average oil temperature rise, °C | |

| The top-oil temperature correction value, °C | |

| The thermal load of the oil tank, W/m2 | |

| The temperature difference in the high-voltage or low-voltage winding | |

| The ambient temperature, °C | |

| The ultimate hot-spot temperature, °C | |

| The top-oil temperature rise over ambient at the rated load, °C | |

| The ratio of load loss to no-load loss at the rated current | |

| The load factor | |

| The initial investment cost of the transformer, CNY | |

| The allowable total loss over the design life | |

| The duration of the i-th operating condition, s | |

| The hot-spot temperature, °C | |

| The generation cost of thermal units, CNY | |

| The transformer life loss costs, CNY | |

| The wind curtailment penalty cost, CNY | |

| The start-up and shutdown cost of thermal units, CNY | |

| The wind curtailment amount at time t, W | |

| The actual output of the w-th wind turbine at hour t, W | |

| The curtailed wind power of the -th wind turbine at hour t, W | |

| The start-up/shutdown status of the i-th thermal unit at hour t | |

| The output power of the i-th thermal unit at hour t, W | |

| The generation shift distribution factor of the l-th line with respect to the j-th generator | |

| The distribution factor of the l-th line with respect to the load at node n | |

| The output power of the j-th generator at time t, W | |

| The load demand at node n at time t, W |

References

- Qin, Z.; Chen, X.; Hou, Y.; Liu, H.; Yang, Y. Coordination of Preventive, Emergency and Restorative Dispatch in Extreme Weather Events. IEEE Trans. Power Syst. 2022, 37, 2624–2638. [Google Scholar] [CrossRef]

- Trakas, D.N.; Hatziargyriou, N.D. Strengthening Transmission System Resilience Against Extreme Weather Events by Undergrounding Selected Lines. IEEE Trans. Power Syst. 2022, 37, 2808–2820. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, J.; Jiang, Z.; Gong, H.; Fan, X.; Lin, Y.; Wang, Q.; Gao, B. Effect of Testing Temperature Gradients on Dielectric Polarization Parameters of Transformer Oil-Paper Insulation. IEEE Trans. Dielectr. Electr. Insul. 2025, 32, 1460–1467. [Google Scholar] [CrossRef]

- Ilunga, K.G.; Swanson, A.G.; Ijumba, N.M.; Stephen, R. Experimental Investigation of the Effect of Conductor Temperature on Corona Performance in Overhead Transmission Lines. IEEE Access 2024, 12, 122114–122125. [Google Scholar] [CrossRef]

- Albizu, I.; Fernandez, E.; Alberdi, R.; Bedialauneta, M.T.; Mazon, A.J. Adaptive Static Line Rating for Systems with HTLS Conductors. IEEE Trans. Power Deliv. 2018, 33, 2849–2855. [Google Scholar] [CrossRef]

- González-Cagigal, M.; Rosendo-Macías, J.A.; Bachiller-Soler, A.; Del-Pino-López, J.C. Reliability Assessment of Dynamic Line Rating Methods Based on Conductor Temperature Estimation. Electr. Power Syst. Res. 2024, 233, 110449. [Google Scholar] [CrossRef]

- Bhattarai, B.P.; Gentle, J.P.; McJunkin, T.; Hill, P.J.; Myers, K.S.; Abboud, A.W.; Hengst, D. Improvement of Transmission Line Ampacity Utilization by Weather-Based Dynamic Line Rating. IEEE Trans. Power Deliv. 2018, 33, 1853–1863. [Google Scholar] [CrossRef]

- Gezegin, C.; Ozgonenel, O.; Dirik, H. A Monitoring Method for Average Winding and Hot-Spot Temperatures of Single-Phase, Oil-Immersed Transformers. IEEE Trans. Power Deliv. 2021, 36, 3196–3203. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.; Yu, Z.; Miao, Y.; Li, P.; Xu, Z. Analysis Method of Transformer Fatigue Life and Damage Under Multiple Short-Circuit Conditions. IEEE Trans. Appl. Supercond. 2024, 34, 1–4. [Google Scholar] [CrossRef]

- Paramane, S.B.; Joshi, K.; Van der Veken, W.; Sharma, A. CFD Study on Thermal Performance of Radiators in a Power Transformer: Effect of Blowing Direction and Offset of Fans. IEEE Trans. Power Deliv. 2014, 29, 2596–2604. [Google Scholar] [CrossRef]

- Fathi, S.; Ghahremani, A.; Shafii, M.B.; Sadr, M.; Salehzehi, A. Improving Transformer Cooling Performance Through Advanced Heat Pipes Integration. Appl. Therm. Eng. 2025, 267, 125775. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, X.; Fan, X.; Wang, K.; Zhuo, R.; Zhang, W.; Liang, S.; Hao, J.; Liu, J. A Prediction Model of Hot Spot Temperature for Split-Windings Traction Transformer Considering the Load Characteristics. IEEE Access 2021, 9, 22605–22615. [Google Scholar] [CrossRef]

- Bagheri, A.; Mobayen, S.; Osali, N. An MIQCP-based multi-objective optimal operation strategy for renewables-integrated smart distribution systems considering transformer loss of life and environmental emissions. Electr. Power Syst. Res. 2025, 239, 111252. [Google Scholar] [CrossRef]

- Hosseinkhanloo, M.; Kalantari, N.T.; Behjat, V.; Ravadanegh, S.N. Optimal exploitation of power transformer fleet considering loss of life and economic evaluation based on failure probability. Electr. Power Syst. Res. 2022, 213, 108801. [Google Scholar] [CrossRef]

- Shaker, H.; Fotuhi-Firuzabad, M.; Aminifar, F. Fuzzy Dynamic Thermal Rating of Transmission Lines. IEEE Trans. Power Deliv. 2012, 27, 1885–1892. [Google Scholar] [CrossRef]

- Wang, M.; Yang, M.; Wang, J.; Wang, M.; Han, X. Contingency Analysis Considering the Transient Thermal Behavior of Overhead Transmission Lines. IEEE Trans. Power Syst. 2018, 33, 4982–4993. [Google Scholar] [CrossRef]

- Davidzon, M.I. Newton’s law of cooling and its interpretation. Int. J. Heat Mass Transf. 2012, 55, 5397–5402. [Google Scholar] [CrossRef]

- Ngoko, B.; Sugihara, H.; Funaki, T. Validation of a Simplified Model for Estimating Overhead Conductor Temperatures under Dynamic Line Ratings—Comparison with the CIGRE Model. IEEJ Trans. Power Energy 2018, 138, 284–296. [Google Scholar] [CrossRef]

- Frank, S.; Sexauer, J.; Mohagheghi, S. Temperature-Dependent Power Flow. IEEE Trans. Power Syst. 2013, 28, 4007–4018. [Google Scholar] [CrossRef]

- Luo, C.; Li, Z.; Yang, B.; Zhao, Z.; Li, C. Hot-Spot Dynamic Temperature Rise of Oil-Immersed Transformer Through FBG-Based Multipoint Sensing System. IEEE Sensors J. 2025, 25, 25743–25753. [Google Scholar] [CrossRef]

- Hashmi, M.; Lehtonen, M.; Hänninen, S. Effect of Climate Change on Transformers Loading Conditions in the Future Smart Grid Environment. Open J. Appl. Sci. 2013, 3, 24–29. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, C.; Li, J.; Song, W.; Qi, Z.; Wu, Y.; Wu, X. MCoR-Miner: Maximal Co-Occurrence Nonoverlapping Sequential Rule Mining. IEEE Trans. Knowl. Data Eng. 2023, 35, 9531–9546. [Google Scholar] [CrossRef]

- Djamali, M.; Tenbohlen, S. Malfunction Detection of the Cooling System in Air-Forced Power Transformers Using Online Thermal Monitoring. IEEE Trans. Power Deliv. 2017, 32, 1058–1067. [Google Scholar] [CrossRef]

- GB/T 38969-2020; Guide on Technology for Power System. Standards Press of China: Beijing, China, 2020.

- Zhou, H.; Ju, P.; Xue, Y.; Zhu, J. Probabilistic Equivalent Model of DFIG-based Wind Farms and Its Application in Stability Analysis. J. Mod. Power Syst. Clean Energy 2016, 4, 248–255. [Google Scholar] [CrossRef]

| Unit Number | Max Output/MW | Min Output/MW | Power Generation Consumption Coefficient | ||

|---|---|---|---|---|---|

| a/CNY·MW−2 | b/CNY·MW−2 | c/CNY·MW−2 | |||

| 1 | 1500 | 500 | 0.00048 | 16.19 | 1000 |

| 2 | 1200 | 400 | 0.00031 | 17.26 | 970 |

| 3 | 750 | 200 | 0.002 | 16.6 | 700 |

| 4 | 800 | 200 | 0.00211 | 16.5 | 680 |

| 5 | 1000 | 300 | 0.00398 | 19.7 | 450 |

| 6 | 750 | 200 | 0.00712 | 22.26 | 370 |

| 7 | 900 | 250 | 0.00079 | 27.74 | 480 |

| 8 | 950 | 250 | 0.00413 | 25.92 | 660 |

| 9 | 800 | 200 | 0.00222 | 27.27 | 665 |

| 10 | 500 | 100 | 0.00173 | 27.79 | 670 |

| Model | Generation Cost/ (104 CNY) | Start-Up/Shutdown Cost/ (104 CNY) | Wind Curtailment Cost/(104 CNY) | Transformer Loss Cost/ (104 CNY) | Total Cost/ (104 CNY) |

|---|---|---|---|---|---|

| TL-TF model | 7.01 | 0.5 | 0.21 | 0.04 | 7.76 |

| Con- Model | 7.12 | 0.67 | 0.24 | 0.13 | 8.16 |

| Wind Curtailment Penalty Coefficient CNY/(MW·h) | Transformer Investment Cost (104 CNY) | Generation Cost/ (104 CNY) | Start-Up/Shutdown Cost/ (104 CNY) | Wind Curtailment Cost/ (104 CNY) | Transformer Loss Cost/ (104 CNY) | Total Cost/ (104 CNY) |

|---|---|---|---|---|---|---|

| 100 | 230 | 7.15 | 0.30 | 0.45 | 0.03 | 7.93 |

| 300 | 230 | 6.99 | 0.43 | 0.32 | 0.04 | 7.78 |

| 500 | 230 | 7.01 | 0.50 | 0.21 | 0.04 | 7.76 |

| 1000 | 230 | 6.97 | 0.72 | 0.13 | 0.05 | 7.87 |

| 500 | 190 | 7.07 | 0.53 | 0.21 | 0.07 | 7.88 |

| 500 | 260 | 7.05 | 0.52 | 0.20 | 0.08 | 7.85 |

| Temperature Multiplier (λ) | Life Loss Cost (Con-Model)/(104 CNY) | Life Loss Cost (TL-TF Model)/(104 CNY) | Cost Reduction |

|---|---|---|---|

| 0.9 | 0.082 | 0.030 | 63.4% |

| 1.0 | 0.130 | 0.040 | 69.2% |

| 1.1 | 0.189 | 0.051 | 73.0% |

| 1.2 | 0.285 | 0.680 | 76.1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, H.; Lu, L.; Yang, K.; Shen, L.; Wen, Y.; Wang, Q. Dynamic Line Rating and Transformer-Life-Loss-Related Unit Commitment Under Extreme High-Temperature Conditions. Electronics 2025, 14, 4027. https://doi.org/10.3390/electronics14204027

Zhou H, Lu L, Yang K, Shen L, Wen Y, Wang Q. Dynamic Line Rating and Transformer-Life-Loss-Related Unit Commitment Under Extreme High-Temperature Conditions. Electronics. 2025; 14(20):4027. https://doi.org/10.3390/electronics14204027

Chicago/Turabian StyleZhou, Hong, Liang Lu, Ke Yang, Li Shen, Yiyu Wen, and Qing Wang. 2025. "Dynamic Line Rating and Transformer-Life-Loss-Related Unit Commitment Under Extreme High-Temperature Conditions" Electronics 14, no. 20: 4027. https://doi.org/10.3390/electronics14204027

APA StyleZhou, H., Lu, L., Yang, K., Shen, L., Wen, Y., & Wang, Q. (2025). Dynamic Line Rating and Transformer-Life-Loss-Related Unit Commitment Under Extreme High-Temperature Conditions. Electronics, 14(20), 4027. https://doi.org/10.3390/electronics14204027