An Active Learning Didactic Proposal with Human-Computer Interaction in Engineering Education: A Direct Current Motor Case Study

Abstract

1. Introduction

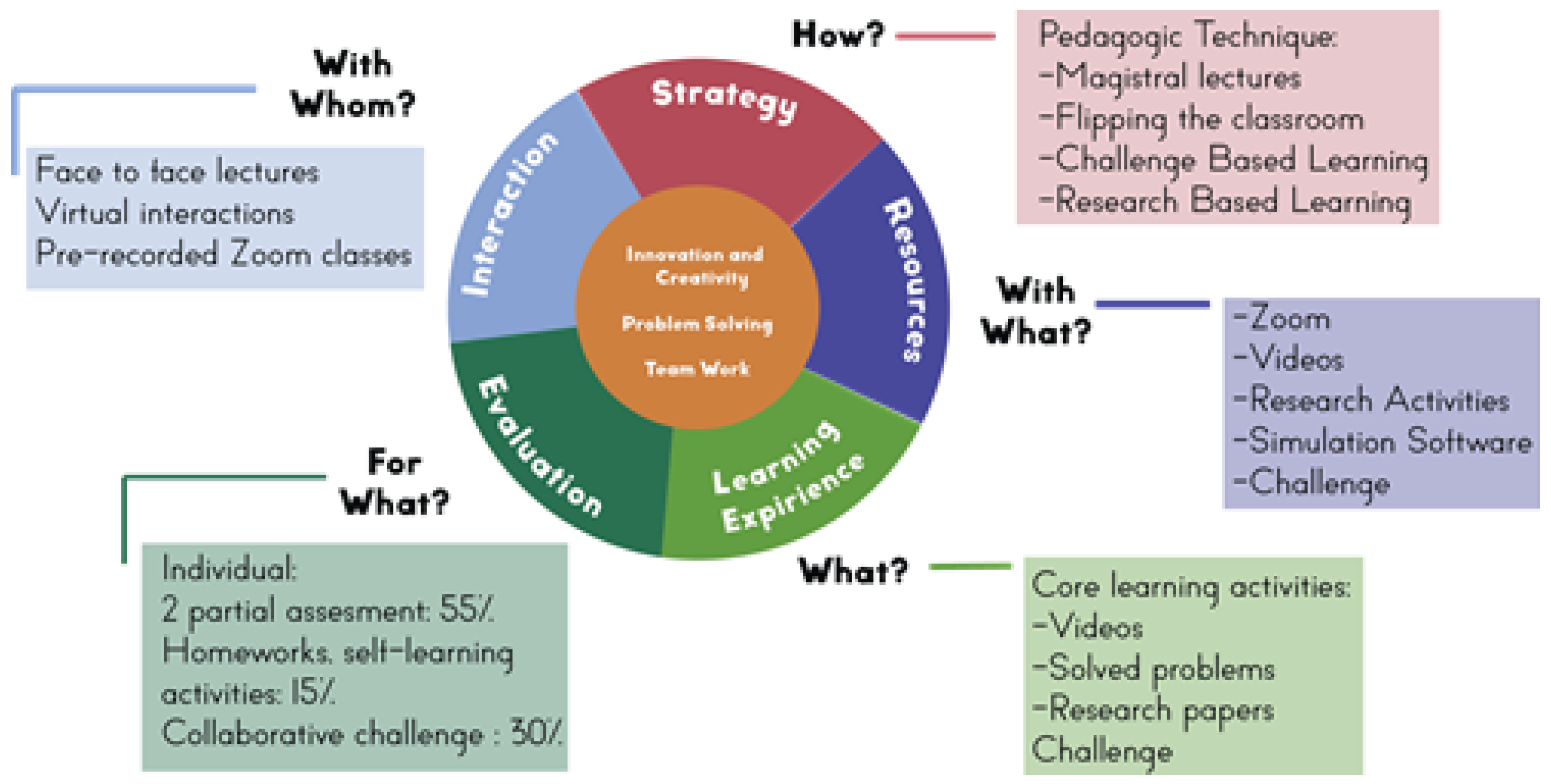

2. Method-DidacticProposal for an Active-Collaborative Learning Massive Flexible Digital Master Class

2.1. Educational Research Methodology

2.2. Disciplinary and Transversal Competencies

- The student obtains a mathematical model of the dynamics of a direct current motor (disciplinary).

- The student validates the mathematical model through simulation work (disciplinary).

- The student works collaboratively to develop effective communication and reasoning for complexity (transversal).

2.3. Didactic Techniques—Collaborative Learning and Flipped Classroom

2.4. Proposal—Didactic Design

2.5. Breakdown of Activities

- Session 1—Previous:

- I

- All participants review the description, competencies, expected outcomes, schedule, milestones, and policies related to the activity. The professor introduces the topic and remarks on the importance of dynamic models and automatic control in engineering. Herein, the competencies are illustrated, and the expected results and breakdown schedule is presented to the students.

- II

- Students (in teams) review the theory about mathematical modeling of DC motors in the textbook or in any other designated media.

- III

- Separately, each student develops the mathematical model, and later on, they incorporate both efforts into one single model that is the deliverable of the previous activity. They will also carry out a qualitative validation of the obtained model before moving on to the next stage. It is likely that one or both students will have to carry out this stage again if there are problems with the expected model behavior.

- IV

- Students review podcasts with introductory tutorials about Scilab.

- Session 1—During:

- I

- The professor summarizes the activity description and all related information.

- II

- The teacher presents the mathematical model, discusses results, and resolves doubts about the procedure.

- III

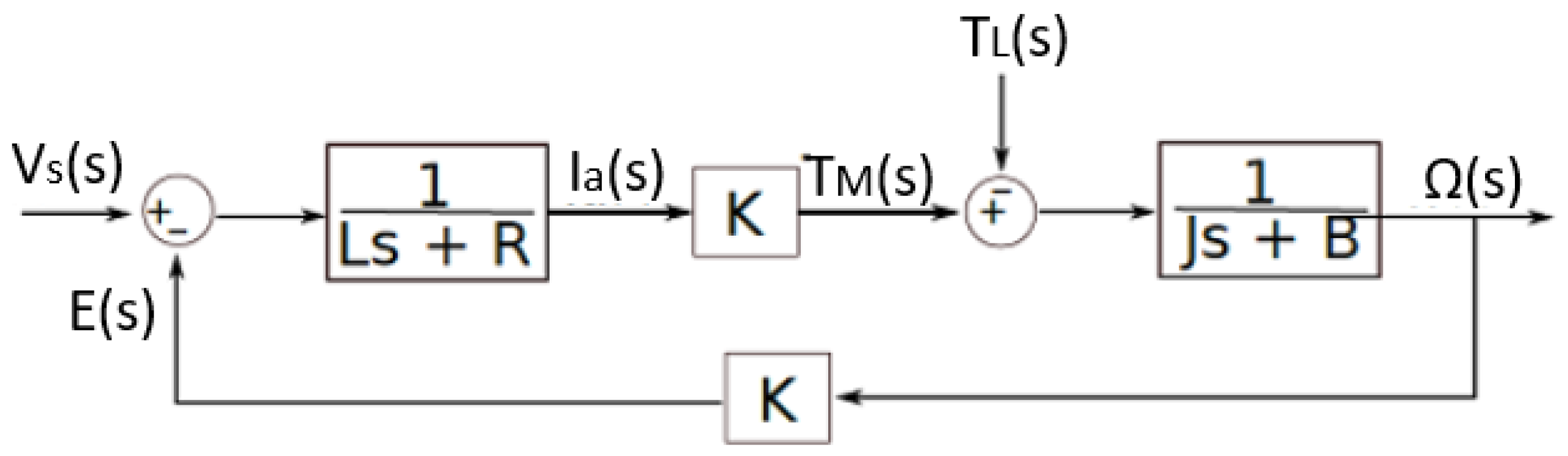

- In a plenary session, the obtaining of the block diagram that models the engine is presented and worked on, and the input and output relationships of interest are clarified.

- IV

- Each team builds the block diagram in Scilab. They will adjust parameters and review input–output relations.

- V

- The teams program the differential equations that represent the system and review the input–output relations.

- VI

- In a plenary activity, students compare differential equations versus the block diagram representations.

- Session 2—Previous:

- I

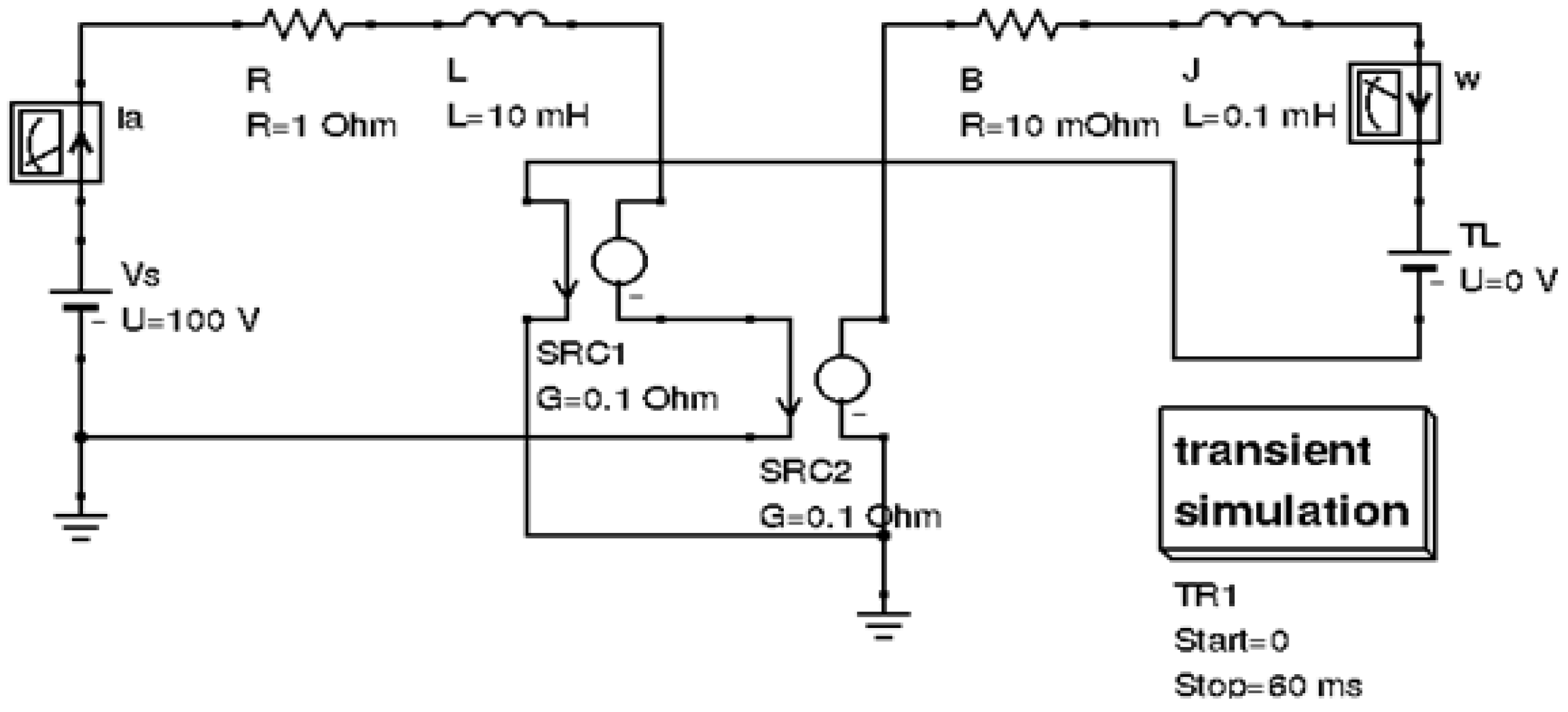

- Students review material to become familiar with it (Quite Universal Circuit Simulator), and solve introductory exercises.

- II

- (in teams) In Qucs, student A programs the electrical circuit that models the motor’s dynamics.

- III

- (in teams) In Scilab, student B validates the result in Qucs by programming a numerical analysis.

- IV

- Each student will explain to their partner what they did. The level of mastery must be such that each member must be able to understand and modify the partner’s work.

- Session 2—During:

- I

- Each member will work with the results of the other associate towards carrying out the following tests: no-load test with a constant supply voltage, no-load test with a pulse width modulation (PWM) supply voltage, and load test with a constant supply voltage.

- II

- The team share experience and results, and record observed similarities and differences.

- III

- The main findings are highlighted in a plenary activity.

- IV

- The professor will introduce control systems stability, Lyapunov stability analysis, and PID (proportional–integral–derivative) controllers.

- Session 3—Previous:

- I

- Students will reinforce the previously explained control-oriented topics through defined material (videos and preliminary examples).

- II

- The teams will start to develop the mathematical procedure to test stability in closed-loop with a PD controller, and the achievements will be delivered.

- Session 3—During:

- I

- In a plenary session, the professor will carry out the mathematical stability procedure and resolve queries.

- II

- Teamwork to simulate the closed-loop in Scilab will be accomplished.

- III

- Main results and conclusions are discussed among all participants.

- IV

- All activities are delivered in a single report (one per team).

2.6. Outcomes and Evidence

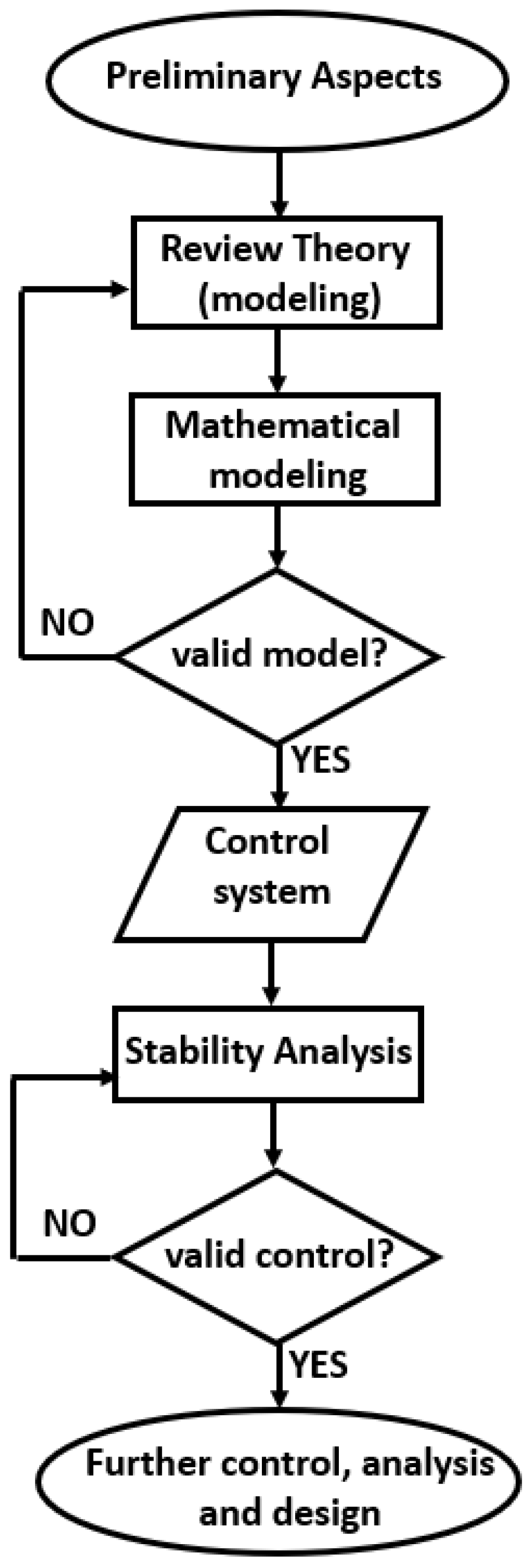

2.7. Competency-Oriented Flowchart

2.8. Activity Deployment

3. The Case Study: Modeling, Simulation, and Control of a DC Motor

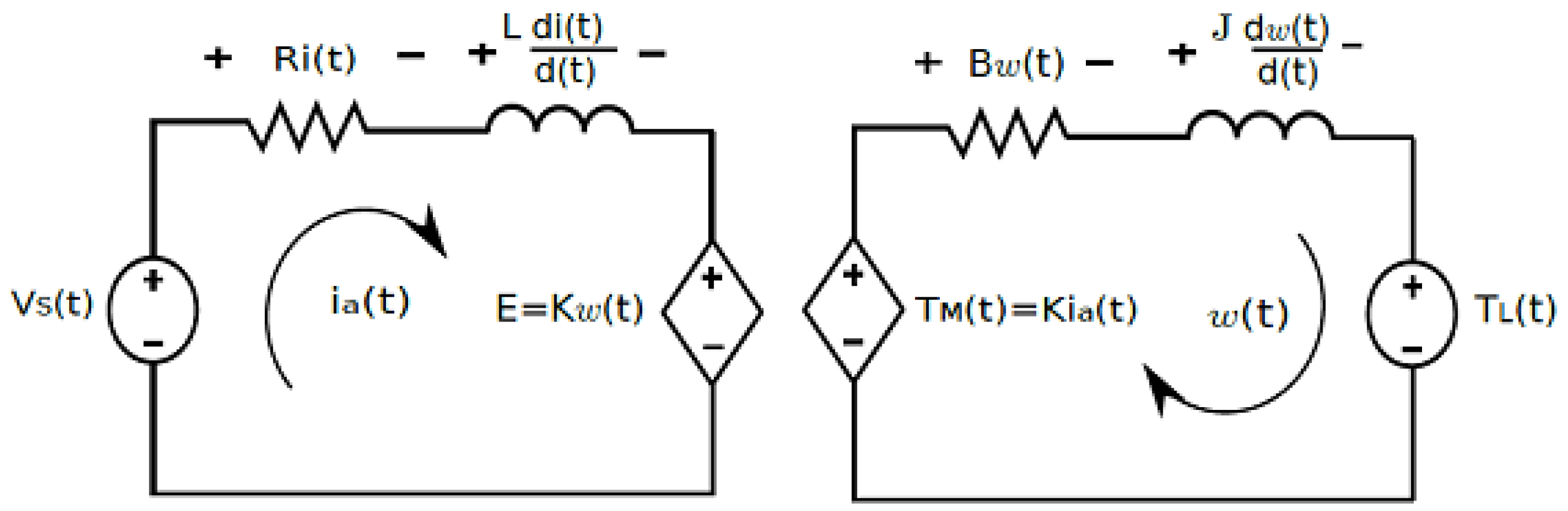

3.1. Mathematical Modeling—Understanding the System’s Dynamics

3.2. Circuit Simulation in Qucs—A Purely Electrical System

3.3. Numerical Simulation—A Validation in Scilab

3.4. Results in the Open-Loop

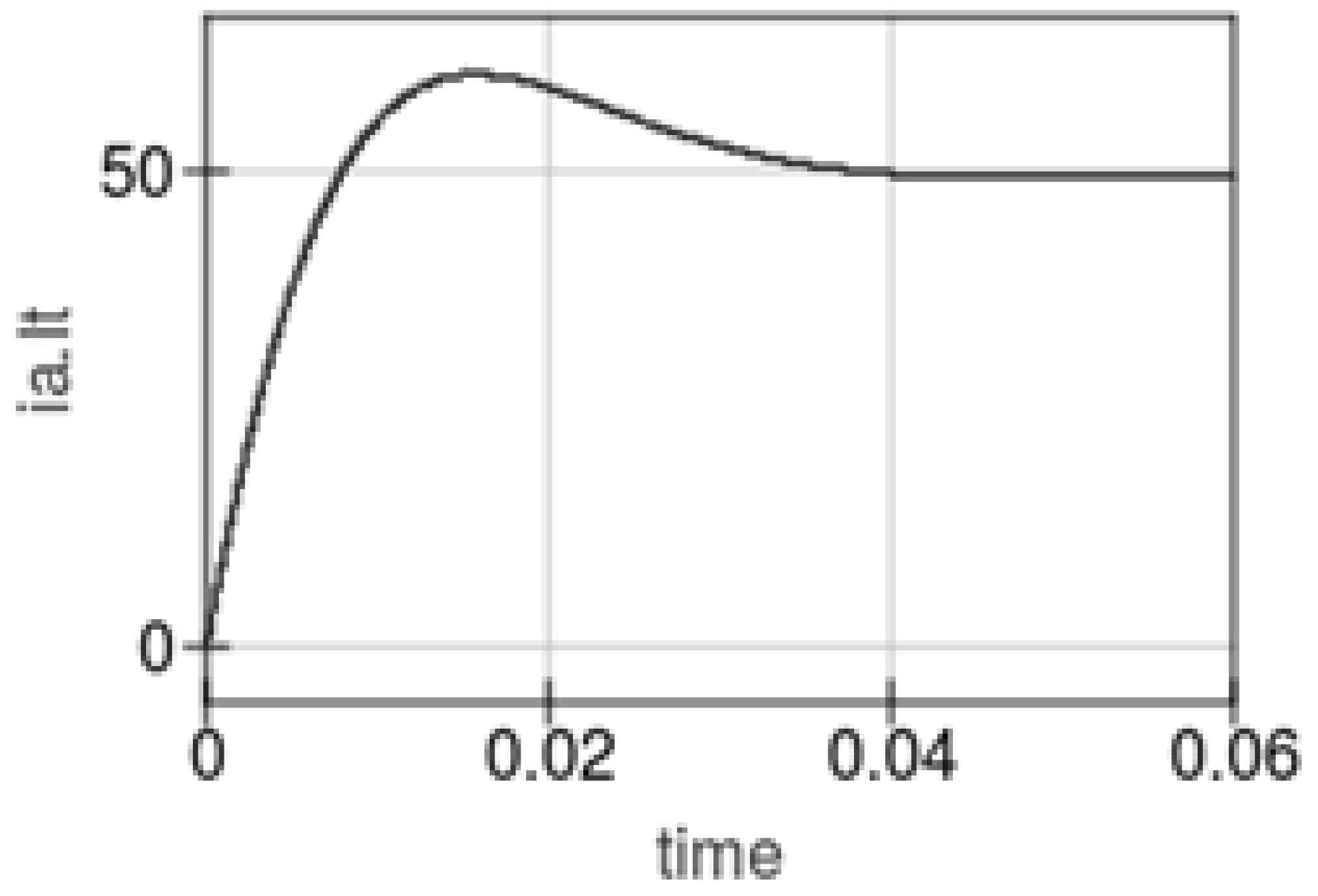

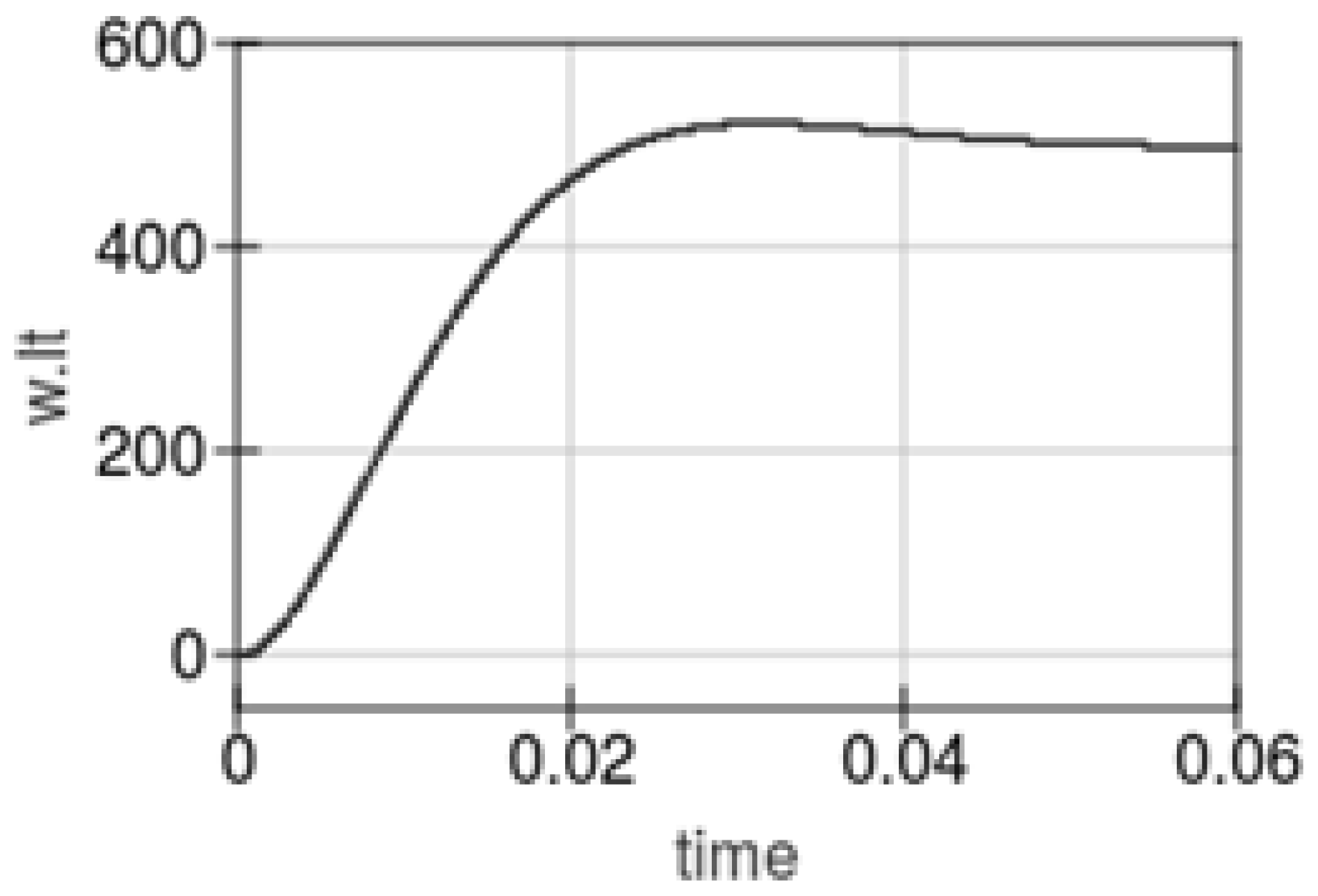

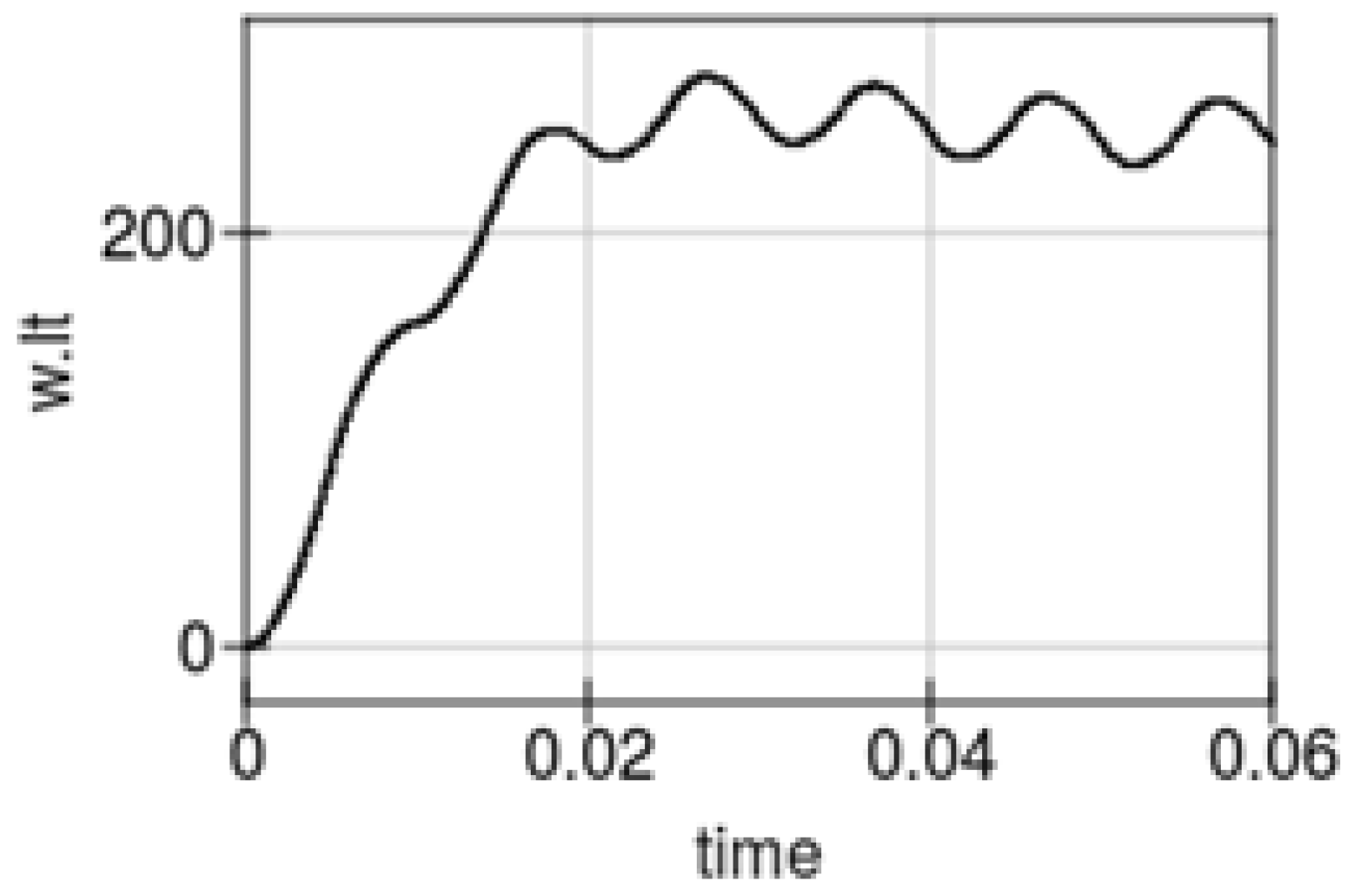

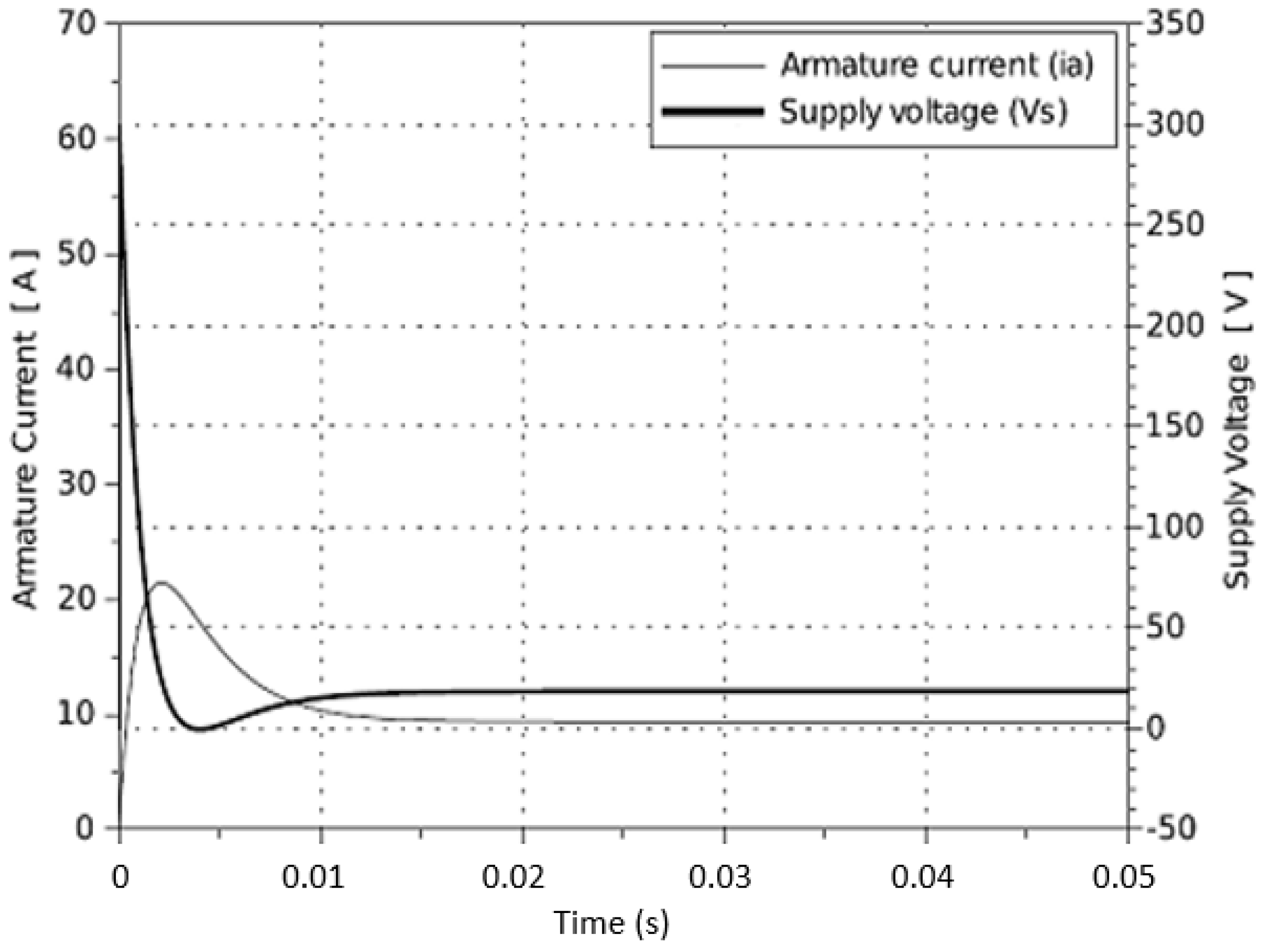

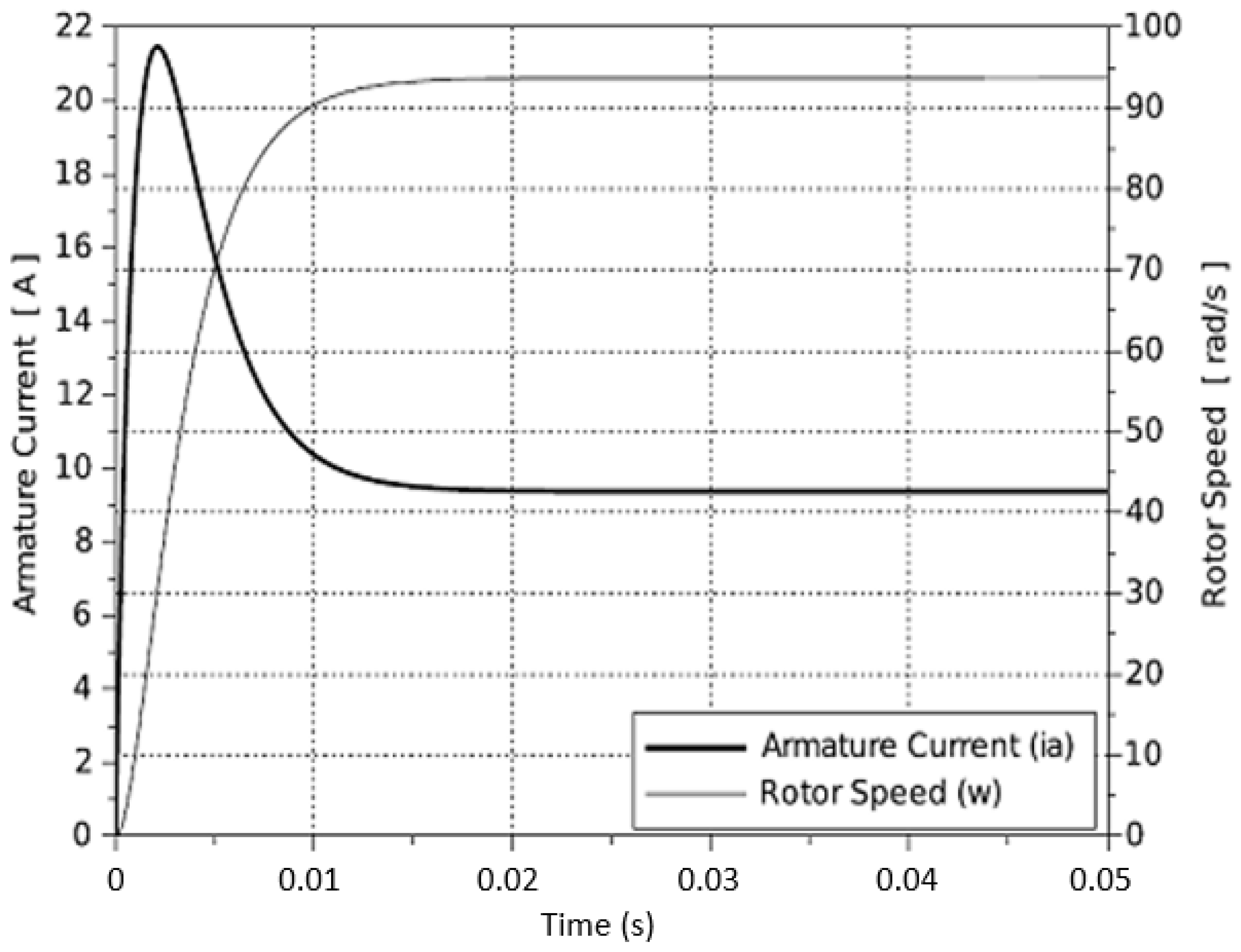

3.4.1. No-Load Test with a Constant Supply Voltage

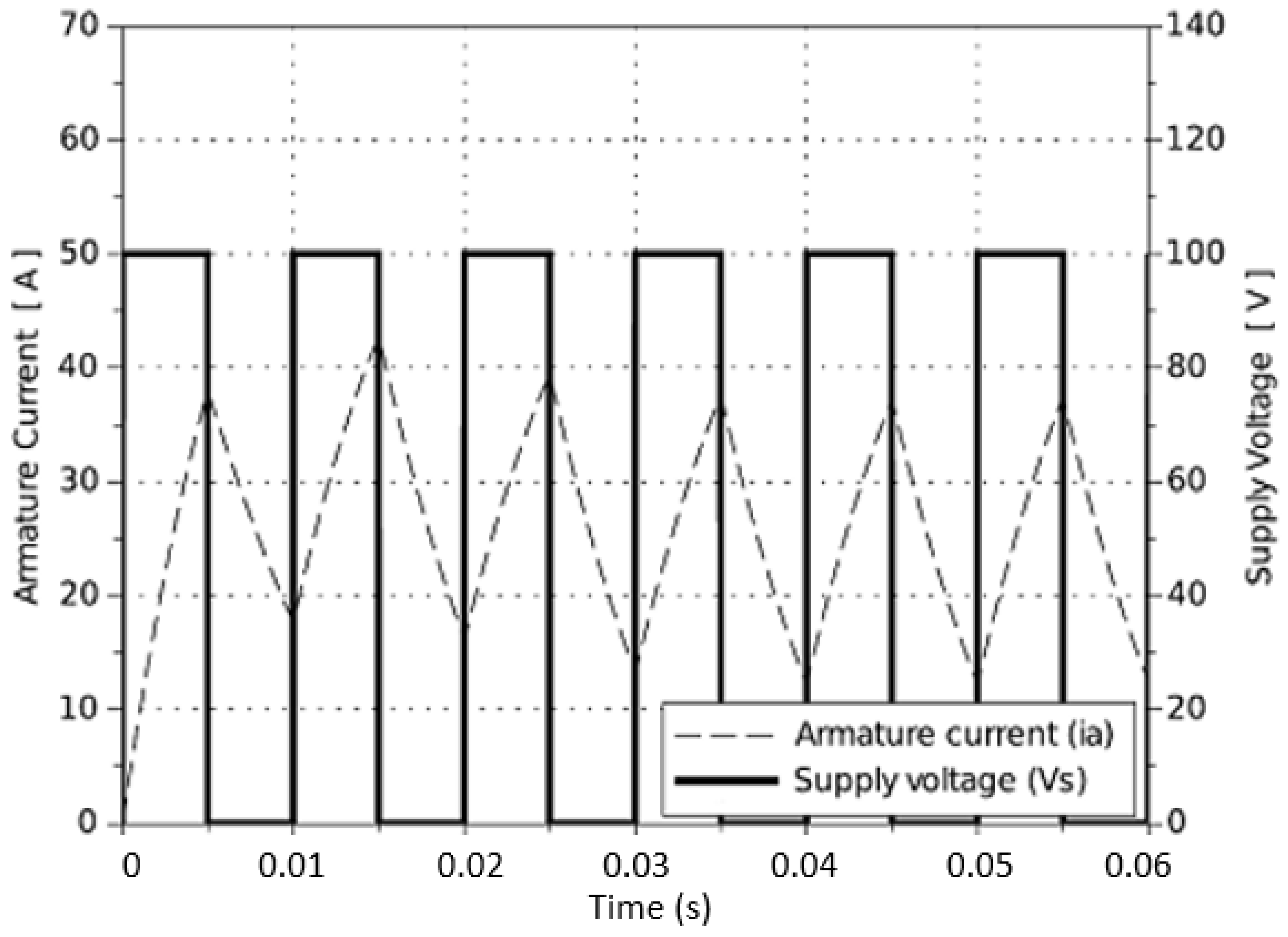

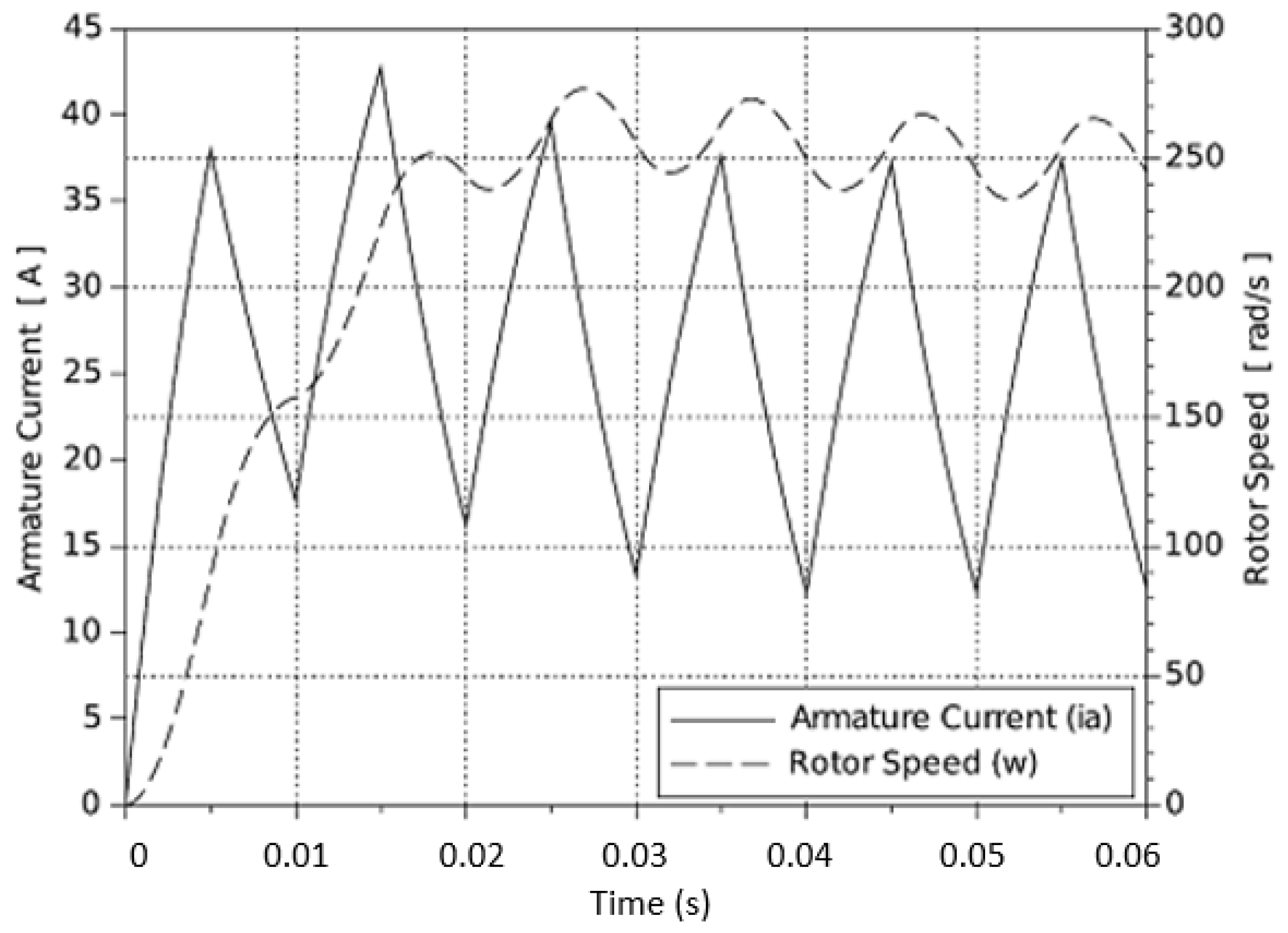

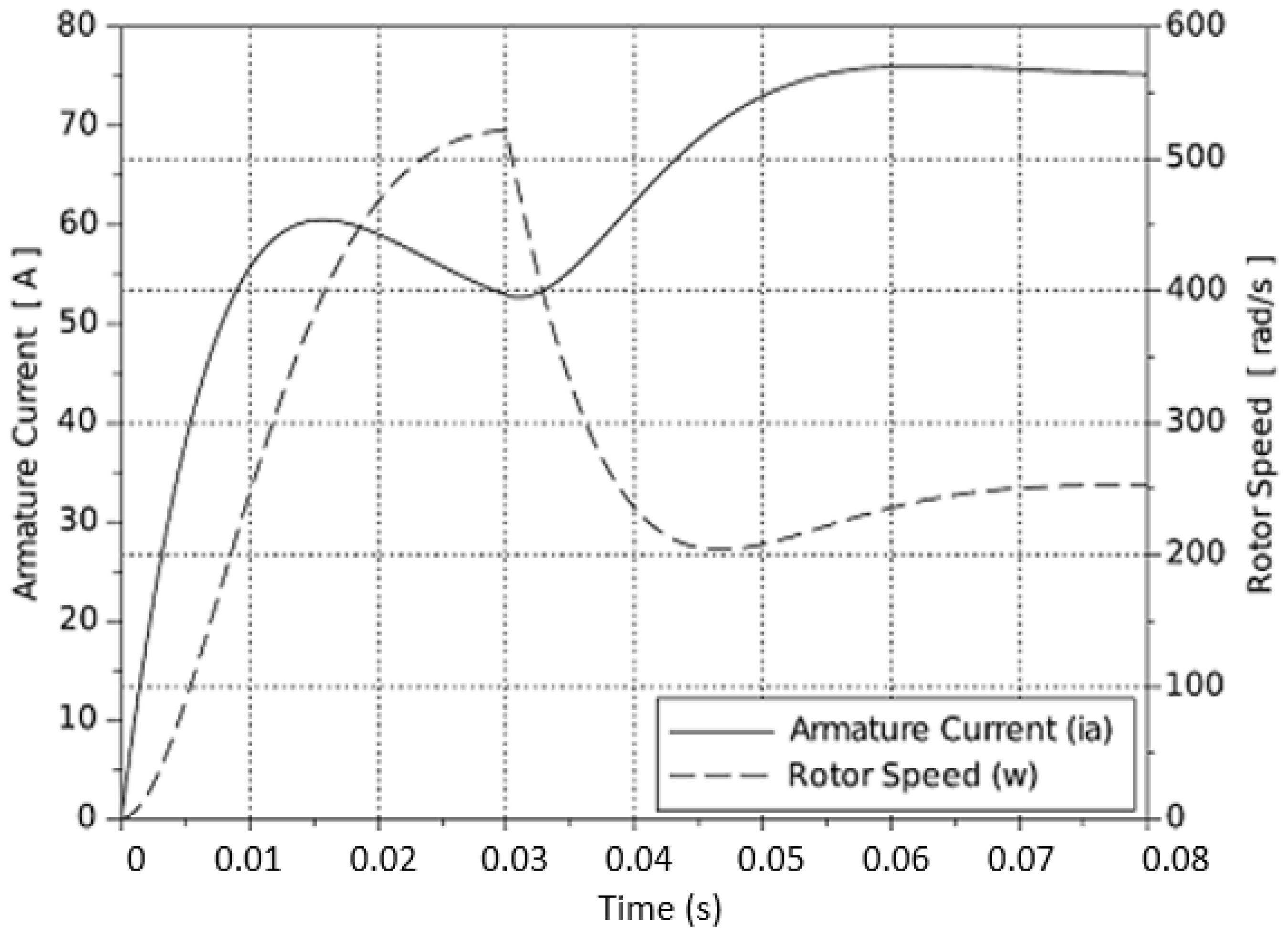

3.4.2. No-Load Test with a Pulse-Width-Modulated (PWM) Supply Voltage

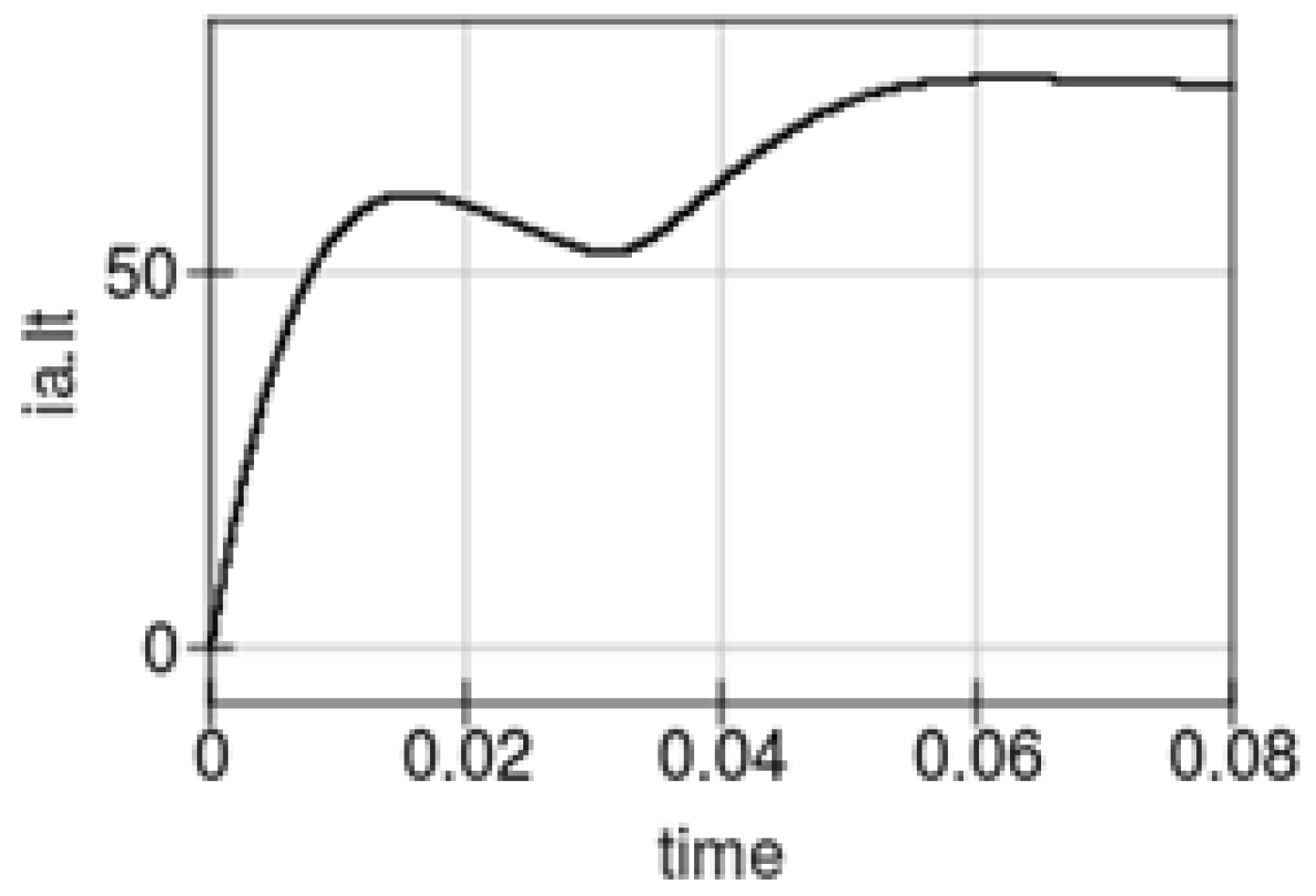

3.4.3. Load Test with a Constant Supply Voltage

3.5. Discrete PD Control and Stability Analysis

3.5.1. Discrete-Time PD Controller

3.5.2. Stability Analysis

3.6. Pd Control Simulations

4. Conclusions, Limitations, and Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Massive Flexible Digital Masterclass (MFDM)

- Strong understanding of the physical phenomena involved in an electrical engineering class.

- Strong understanding of the relationships between the equations and the behavior of the variables of interest, such as armature current, motor torque, and angular speed.

- Enhance the simulation skill of the students: the motor’s behavior is analyzed by means of a circuit simulator, where the effects of a specific supply voltage, load torque, and motor parameters can be studied in an agile, cheap, and reliable manner.

- Analogy between the direct current motor and an electrical circuit, where the first one involves electrical and mechanical variables, and the second one involves only electrical variables.

- Enhance the ability to identify, formulate, and solve electrical engineering problems.

- Enhance the ability to apply electrical engineering design.

- Enhance the ability to develop and conduct appropriate experimentation, analyze and interpret data, and use engineering judgment to draw conclusions.

Appendix B. Questionnaire

- The work scheme, presented in the activity’s breakdown, allows developing the transversal competence of effective communication and reasoning for complexity.(SA) Strongly Agree (A) Agree (N) Not sure (D) Disagree (SD) Strongly Disagree

- The activities in session 1, students and professor, allow the development of the competency of mathematical modeling of a direct current motor dynamic.(SA) Strongly Agree (A) Agree (N) Not sure (D) Disagree (SD) Strongly Disagree

- The simulation effort, individual and collaborative, along with the plenary sessions, contribute to validate the mathematical model.(SA) Strongly Agree (A) Agree (N) Not sure (D) Disagree (SD) Strongly Disagree

- The flipped classroom didactic technique enables, with an adequate balance, one to carry out the sequence of activities, with the purpose of developing the declared competencies.(SA) Strongly Agree (A) Agree (N) Not sure (D) Disagree (SD) Strongly Disagree

- The deployment proposal is proposed in the context of a Massive Flexible Digital Masterclass (MFDM). As a student who has participated in massive courses and some of them in remote format, do you consider this scheme adequate to develop the declared competencies?(SA) Strongly Agree (A) Agree (N) Not sure (D) Disagree (SD) Strongly Disagree

- The modeling, as defined in the activity for the simulation approach, as a pure electric circuit, allows modeling the dynamics of a permanent magnet electric current motor.(SA) Strongly Agree (A) Agree (N) Not sure (D) Disagree (SD) Strongly Disagree

- The activities to analyze and design the control system (flipped classroom, teamwork, simulations, and plenary wrap-up) are sufficient for understanding the relationship between automatic control and motors, as well as their importance as elements of an automatic control loop where it is required to ensure stability.(SA) Strongly Agree (A) Agree (N) Not sure (D) Disagree (SD) Strongly Disagree

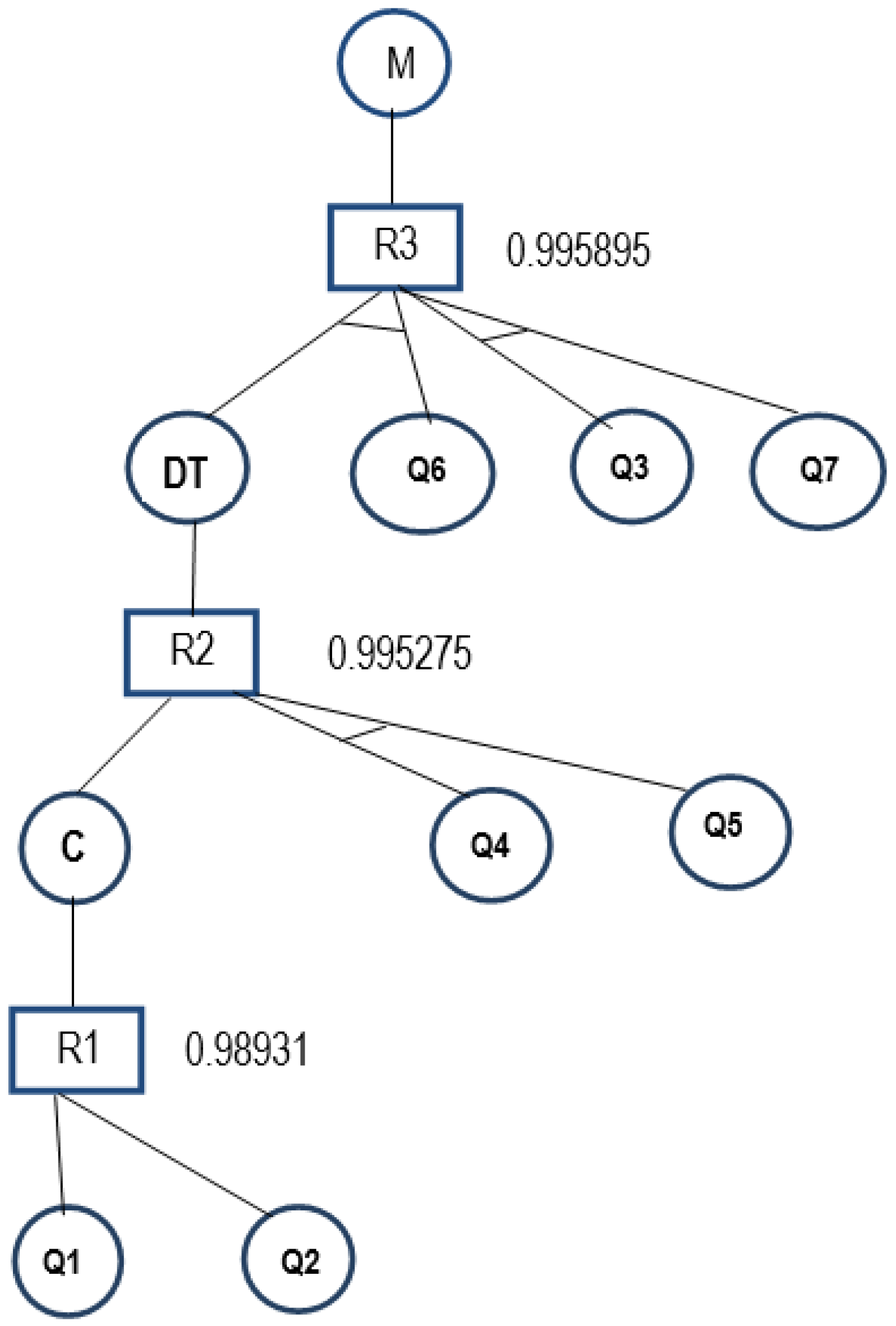

Appendix C. Survey Validation through a Rule-Based System

- To validate the seven-question Likert scale survey, a ruled-based methodology, developed in [50], is applied. The following procedure was conducted to develop this expert system:Based on their meaning, the seven questions were categorized into three groups: competencies (C), mechatronics (M), and didactic techniques (DT), and the groups were as follows: Questions 1 and 2 in C category as C-1 and C-2, respectively; Questions 3, 6, and 7, in M, as M-1, M-2, and M-3, respectively; and Questions 4 and 5 in DT category as DT-1 and DT-2, respectively.

| Q | R1 | f1 | R2 | f2 | R3 | f3 | R4 | f4 | R5 | f5 | fT | UL | UF | CUF |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C-1 | 0 | 0 | 0 | 0.000 | 1 | 0.059 | 13 | 0.765 | 3 | 0.176 | 1 | 0.274 | 0.726 | 0.989314 |

| C-2 | 0 | 0 | 0 | 0.000 | 3 | 0.176 | 6 | 0.353 | 8 | 0.471 | 1 | 0.039 | 0.961 | |

| M-1 | 0 | 0 | 0 | 0.000 | 0 | 0.000 | 14 | 0.824 | 3 | 0.176 | 1 | 0.368 | 0.632 | 0.995895 |

| M-2 | 0 | 0 | 0 | 0.000 | 5 | 0.294 | 9 | 0.529 | 3 | 0.176 | 1 | 0.078 | 0.922 | |

| M-3 | 0 | 0 | 0 | 0.000 | 1 | 0.059 | 11 | 0.647 | 5 | 0.294 | 1 | 0.143 | 0.857 | |

| DT-1 | 0 | 0 | 3 | 0.176 | 6 | 0.353 | 5 | 0.294 | 3 | 0.176 | 1 | 0.045 | 0.955 | 0.995275 |

| DT-2 | 0 | 0 | 1 | 0.059 | 4 | 0.235 | 10 | 0.588 | 2 | 0.118 | 1 | 0.105 | 0.895 |

- 3.

References

- Román-Graván, P.; Hervás-Gómez, C.; Martín-Padilla, A.H.; Fernández-Márquez, E. Perceptions about the Use of Educational Robotics in the Initial Training of Future Teachers: A Study on STEAM Sustainability among Female Teachers. Sustainability 2020, 12, 4154. [Google Scholar] [CrossRef]

- Renkl, A.; Atkinson, R.K.; Maier, U.H.; Staley, R. From example study to problem solving: Smooth transitions help learning. J. Exp. Educ. 2002, 70, 293–315. [Google Scholar] [CrossRef]

- Bonwell, C.; Eison, J. Active Learning: Creating Excitement in the Classroom. In 1991 ASHE-ERIC Higher Education Reports; ERIC Clearinghouse on Higher Education: Washington, DC, USA, 1991. [Google Scholar]

- Pardjono, P. Active Learning: The Dewey, Piaget, Vygotsky, and Constructivist Theory Perspectives. Psychol. J. Ilmu Pendidik. 2016, 9, 105376. [Google Scholar]

- Prince, M. Does Active Learning Work? A Review of the Research. J. Eng. Educ. 2004, 93, 223–231. [Google Scholar] [CrossRef]

- Sastry, V.L.N.; Rao, K.S.; Rao, N.V.; Clee, P.; Kumari, G.R. Effective and Active Learning in Classroom Teaching through Various Methods. In Proceedings of the IEEE 4th International Conference on MOOCs, Innovation and Technology in Education (MITE), Madurai, India, 9–10 December 2016; pp. 105–110. [Google Scholar] [CrossRef]

- Gren, L. A Flipped Classroom Approach to Teaching Empirical Software Engineering. IEEE Trans. Educ. 2020, 63, 155–163. [Google Scholar] [CrossRef]

- Tecnológico de Monterrey. Aprendizaje Colaborativo. Vicerrectoría Académica y de Innovación Educativa. Available online: https://innovacioneducativa.tec.mx/aprendizaje-colaborativo/ (accessed on 20 May 2020). (In Spanish).

- DeLozier, S.J.; Rhodes, M.G. Flipped Classrooms: A Review of Key Ideas and Recommendations for Practice. Educ. Psychol. Rev. 2017, 29, 141–151. [Google Scholar] [CrossRef]

- Ramírez-Mendoza, R.A.; López-Guajardo, E.A. Massive Flexible Digital Masterclss Model (MFDM); Tecnologico de Monterrey: Monterrey, Mexico, 2021. [Google Scholar]

- Prpić, J.; Melton, J.; Taeihagh, A.; Anderson, T. MOOCs and crowdsourcing: Massive courses and massive resources. First Monday 2015, 20. [Google Scholar] [CrossRef]

- Kulkarni, C.; Cambre, J.; Kotturi, Y.; Bernstein, M.S.; Klemmer, S. Talkabout: Making Distance Matter with Small Groups in Massive Classes. In Proceedings of the 18th ACM Conference on Computer Supported Cooperative Work & Social Computing (CSCW’15), Vancouver, BC, Canada, 14–18 March 2015; pp. 1116–1128. [Google Scholar] [CrossRef]

- Zavalani, O.; Kaçani, J. Mathematical modelling and simulation in engineering education. In Proceedings of the 15th International Conference on Interactive Collaborative Learning (ICL), Villach, Austria, 26–28 September 2012; pp. 1–5. [Google Scholar] [CrossRef]

- Litwin, P.; Stadnicka, D. Computer Modeling and Simulation in Engineering Education: Intended Learning Outcomes Development. In Advances in Manufacturing II. MANUFACTURING; Hamrol, A., Grabowska, M., Maletic, D., Woll, R., Eds.; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Zill, D.G. Advanced Engineering Mathematics; Jones & Bartlett Learning: Burlington, MA, USA, 2017. [Google Scholar]

- Mohan, N.; Underland, T.M. Power Electronics: Converters, Applications, and Design; John Wiley & Sons: Hoboken, NJ, USA, 2003; pp. 377–379. [Google Scholar]

- Sabir, M.M.; Khan, J. Optimal design of PID controller for the speed control of DC motor by using metaheuristic techniques. Adv. Artif. Neural Syst. 2014, 2014, 126317. [Google Scholar] [CrossRef]

- Hughes, A.; Drury, B. Electric Motors and Drives: Fundamentals, Types and Applications; Newnes: Oxford, UK, 2013; pp. 73–91. [Google Scholar]

- Aung, W.P. Analysis on modeling and simulink of DC motor and its driving system used for wheeled mobile robot. World Acad. Sci. Eng. Technol. Open Sci. Int. J. Electr. Comput. Eng. 2007, 1, 299–306. [Google Scholar]

- Said, A.; Rodriguez-Leal, E.; Soto, R.; Gordillo, J.L.; Garrido, L. Decoupled Closed Form Solution for Humanoid Lower Limb Kinematics. Math. Probl. Eng. 2015, 2015, 1–14. [Google Scholar] [CrossRef]

- Hearn, C.; Weeks, S.; Thompson, R.C.; Chen, D. Electric vehicle modeling utilizing DC motor equations. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Montreal, QC, Canada, 6–9 July 2010; pp. 670–675. [Google Scholar]

- Hwang, Y.-R.; Huang, S.-Y. System identification and integration design of an air/electric motor. Energies 2013, 6, 921–933. [Google Scholar] [CrossRef]

- Bitar, Z.; Samith, A.J.; Khamis, I. Modeling and simulation of series DC motors in electric car. Energy Procedia 2014, 50, 460–470. [Google Scholar] [CrossRef]

- Wu, W. DC motor parameter identification using speed step responses. Model. Simul. Eng. 2012, 2012, 189757. [Google Scholar] [CrossRef]

- Arduino. Available online: https://www.arduino.cc/ (accessed on 20 January 2020).

- Raspberry, P. The Raspberry Pi Foundation. Available online: https://www.raspberrypi.org/ (accessed on 22 January 2020).

- Abut, T. Modeling and Optimal Control of a DC Motor. Int. J. Eng. Trends Technol. 2016, 32, 146–150. [Google Scholar] [CrossRef]

- Sinha, N.K.; Dicenzo, C.D.; Szabados, B. Modeling and Optimal Control of a DC Motor. Modeling of DC motors for control applications. IEEE Trans. Ind. Electron. Control Instrum. 1974, IECI-21, 84–88. [Google Scholar] [CrossRef]

- Guldemir, H. Sliding mode speed control for DC drive systems. Math. Comput. Appl. 2003, 8, 377–384. [Google Scholar] [CrossRef]

- Bhushan, B.; Singh, M. Adaptive control of DC motor using bacterial foraging algorithm. Appl. Soft Comput. 2011, 11, 4913–4920. [Google Scholar] [CrossRef]

- Yelamarthi, K.; Drake, E.; Prewett, M. An Instructional Design Framework to Improve Student Learning in a First-Year Engineering Class. J. Inf. Technol. Educ. Innov. Pract. 2016, 15, 195–222. [Google Scholar] [CrossRef][Green Version]

- Villarroel, R.; Cornide-Reyes, H.; Munoz, R.; Barcelos, T. Flipped classroom + plickers, and experience to propitiate collaborative learning in software engineering. In Proceedings of the 36th International Conference of the Chilean Computer Science Society, Arica, Chile, 16–20 October 2017; pp. 1–7. [Google Scholar] [CrossRef]

- Soares, F.; de Moura Oliveira, P.B.; Leao, C.P. Your turn to learn—Flipped classroom in automation courses. In Lecture Notes in Electrical Engineering, Proceedings of the 14th APCA International Conference on Automatic Control and Soft Computing, Bragança, Portugal, 1–3 July 2020; Springer: Cham, Switzerland, 2020; Volume 695, p. 695. [Google Scholar] [CrossRef]

- Yan, J.; Li, L.; Yin, J.; Nie, Y. A comparison of flipped and traditional classroom learning: A case study in mechanical engineering. Int. J. Eng. Educ. 2018, 34, 1876–1887. [Google Scholar]

- Zamarron-Ramirez, A.; Arjona, M. Detection of Stator-Winding Turn-to-Turn Faults in Induction Motors, Based on Virtual Instrumentation. Int. J. Electr. Eng. Educ. 2010, 47, 63–72. [Google Scholar] [CrossRef]

- Fuertes, J.J.; Domínguez, M.; Prada, M.A.; Alonso, S.; Morán, A. A Virtual Laboratory of D.C. Motors for Learning Control Theory. Int. J. Electr. Eng. Educ. 2013, 50, 172–187. [Google Scholar] [CrossRef]

- Reis, A.; da Costa, F.H.; Xavier, G.L.; Alvarenga, E.B.; de Oliveira, J.C.; Guimarães, G.C. Comparative Performance Analysis of a Controlled D.C. and A.C. Motor Which Emulates Wind Turbines for Teaching and Research Purposes. Int. J. Electr. Eng. Educ. 2014, 51, 146–161. [Google Scholar] [CrossRef]

- Reck, R.M.; Sreenivas, R.S. Developing an Affordable and Portable Control Systems Laboratory Kit with a Raspberry Pi. Electronics 2016, 5, 36. [Google Scholar] [CrossRef]

- Chasiotis, I.D.; Karnavas, Y.L. A computer aided educational tool for design, modeling, and performance analysis of Brushless DC motor in post graduate degree courses. Comput. Appl. Eng. Educ. 2018, 24, 749–767. [Google Scholar] [CrossRef]

- Sami, S.; Obaid, Z.A.; Muhssin, M.T.; Hussain, A.N. Detailed modelling and simulation of different DC motor types for research and educational purposes. Int. J. Power Electron. Drive Syst. 2021, 12, 703–714. [Google Scholar] [CrossRef]

- Tudić, V.; Kralj, D.; Hoster, J.; Tropčić, T. Design and Implementation of a Ball-Plate Control System and Python Script for Educational Purposes in STEM Technologies. Sensors 2022, 22, 1875. [Google Scholar] [CrossRef]

- Gay, L.R.; Mills, G.E.; Airasian, P. Educational Research: Competencies for Analysis and Applications; Merrill Prentice Hall: Columbus, OH, USA, 2006. [Google Scholar]

- Trochim, W.; Donnelly, J. The Research Methods Knowledge Base; Thomson: Mason, OH, USA, 2007. [Google Scholar]

- Hernández, R.; Fernández, C.; Baptista, M. Metodología de la Investigación; McGraw-Hill: Mexico City, Mexico, 2014. [Google Scholar]

- He, X.; Ju, Y.; Liu, Y.; Zhang, B. Cloud-Based Fault Tolerant Control for a DC Motor System. J. Control Sci. Eng. 2017, 2017, 5670849. [Google Scholar] [CrossRef]

- Qucs. Quite Universal Circuit Simulator. Available online: http://qucs.sourceforge.net/ (accessed on 30 January 2020).

- Nakamura, S. Métodos Numéricos Aplicados con Software; Prentice Hall: Naucalpan, Mexico, 1992; pp. 292–295. ISBN 0-13-041047-0. [Google Scholar]

- Burden, R.; Faires, J. Numerical Analysis; Thomson Learning: Boston, MA, USA, 2002; pp. 266–273. ISBN 978-0-538-73351-9. [Google Scholar]

- Scilab. Scilab Enterprises. Available online: http://www.scilab.org/ (accessed on 20 January 2020).

- Espino-Román, P.; Davizon-Castillo, Y.; Olaguez-Torres, E.; Gamez-Wilson, J.; Said, A.; Hernandez-Santos, C. Development of a rule based system to validate an educational survey in a Likert scale. DYNA 2020, 95, 572. [Google Scholar] [CrossRef]

| Manuscript | Contribution | Software | Mathematical Modeling | Control Strategy |

|---|---|---|---|---|

| Zamarrón and Arjona (2010) [35] | Virtual instrumentation system for stator turn-to-turn winding-fault detection to prevent unexpected downtime or severe damage to induction motors (suitable for industry and academy) | LabVIEW | State–space | Fault detection |

| Fuertes et al. (2013) [36] | Modular equipment simulation to control a DC motor educational set. Part of a remote laboratory of automatic control | JAVA | Coupled ordinary differential equations | PID |

| Reis, et al. (2014) [37] | Modeling and control of motors that emulate wind turbines. Comparison of two approaches with DC and AC motors. | LabVIEW | Coupled ordinary differential equations | Frequency response |

| Reck and Sreenivas (2016) [38] | Affordable and portable laboratory kit design for control systems courses (DC motor plus Furuta inverted pendulum). | Raspberry pi and MATLAB | Physical and electric characteristics, step and frequency response | PID control |

| Chasiotis and Karnavas (2018) [39] | Educational platform to study brushless DC motor design and performance analysis | MATLAB | Dynamic equations from physical properties | Not reported |

| Samil, et al. (2021) [40] | Virtual laboratory of DC motors modeling | MATLAB | Dynamic equations from physical principles | Not reported |

| Tudic, et al. (2022) [41] | Design, manufacturing, assembly, programming, and optimization of a nonlinear mechatronic ball–plate prototype as a laboratory platform for engineering education. | Python | System Identification | PID control |

| Parameter | Description | Quantity | Unit |

|---|---|---|---|

| R | armature resistance | 1 | ohms |

| L | armature inductance | 10 | mH |

| B | armature friction | 10,000 | |

| J | armature J (rotor) | 100 | |

| K | electromechanical constant | 0.1 | Wb |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Said, A.; Félix-Herrán, L.C.; Davizón, Y.A.; Hernandez-Santos, C.; Soto, R.; Ramírez-Mendoza, R.A. An Active Learning Didactic Proposal with Human-Computer Interaction in Engineering Education: A Direct Current Motor Case Study. Electronics 2022, 11, 1059. https://doi.org/10.3390/electronics11071059

Said A, Félix-Herrán LC, Davizón YA, Hernandez-Santos C, Soto R, Ramírez-Mendoza RA. An Active Learning Didactic Proposal with Human-Computer Interaction in Engineering Education: A Direct Current Motor Case Study. Electronics. 2022; 11(7):1059. https://doi.org/10.3390/electronics11071059

Chicago/Turabian StyleSaid, Alejandro, Luis C. Félix-Herrán, Yasser A. Davizón, Carlos Hernandez-Santos, Rogelio Soto, and Ricardo A. Ramírez-Mendoza. 2022. "An Active Learning Didactic Proposal with Human-Computer Interaction in Engineering Education: A Direct Current Motor Case Study" Electronics 11, no. 7: 1059. https://doi.org/10.3390/electronics11071059

APA StyleSaid, A., Félix-Herrán, L. C., Davizón, Y. A., Hernandez-Santos, C., Soto, R., & Ramírez-Mendoza, R. A. (2022). An Active Learning Didactic Proposal with Human-Computer Interaction in Engineering Education: A Direct Current Motor Case Study. Electronics, 11(7), 1059. https://doi.org/10.3390/electronics11071059