Novel Switching Frequency FCS-MPC of PMSG for Grid-Connected Wind Energy Conversion System with Coordinated Low Voltage Ride Through

Abstract

1. Introduction

- Overcoming the variable switching frequency of the two-level converter problem by designing a modulation algorithm that obtains a fixed switching frequency.

- A coordinated pitch angle control and low voltage-ride through (LVRT) algorithm is designed and inserted in the vector control of the grid side converter (GSC) to supply reactive power to the grid during fault for ensuring safe operation of the inverter.

- A comparison with conventional FCS-MPC is made to show the effectiveness of the proposed method.

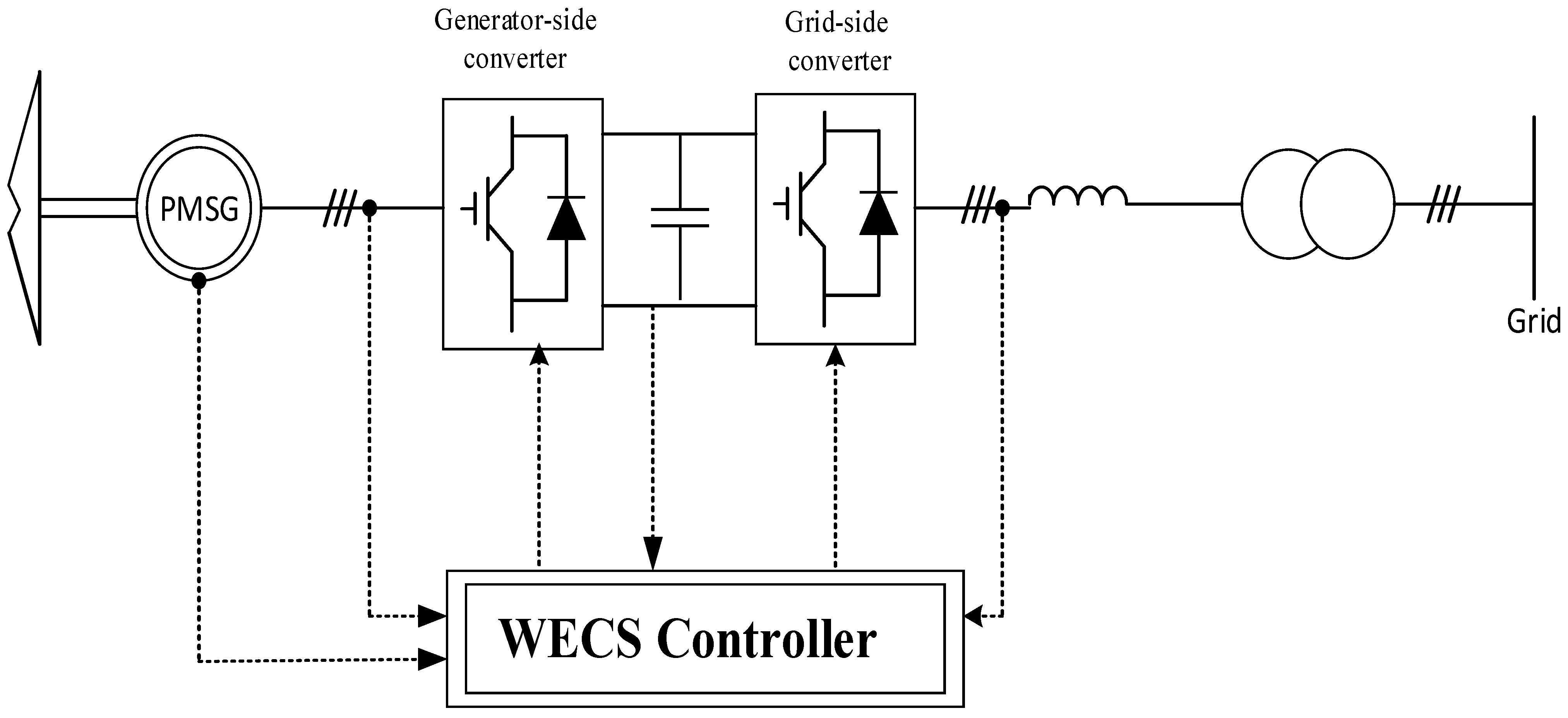

2. Principle of Wind Energy Conversion System

3. Mathematical Modeling of Direct-Driven Permanent Magnet Synchronous Generator

4. Modelling of Machine Side Converter

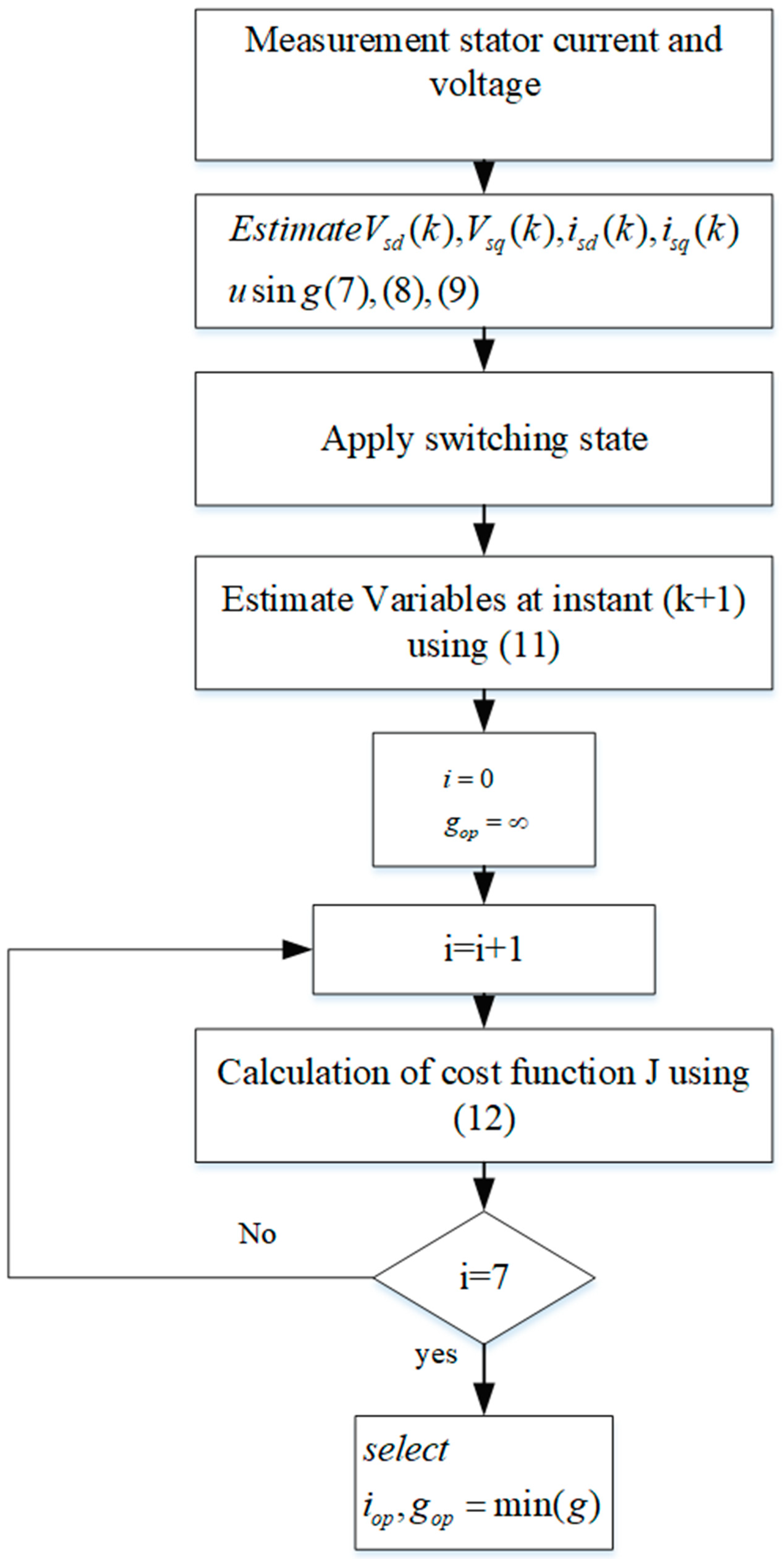

5. Conventional FCS-MPC of the MSC Scheme

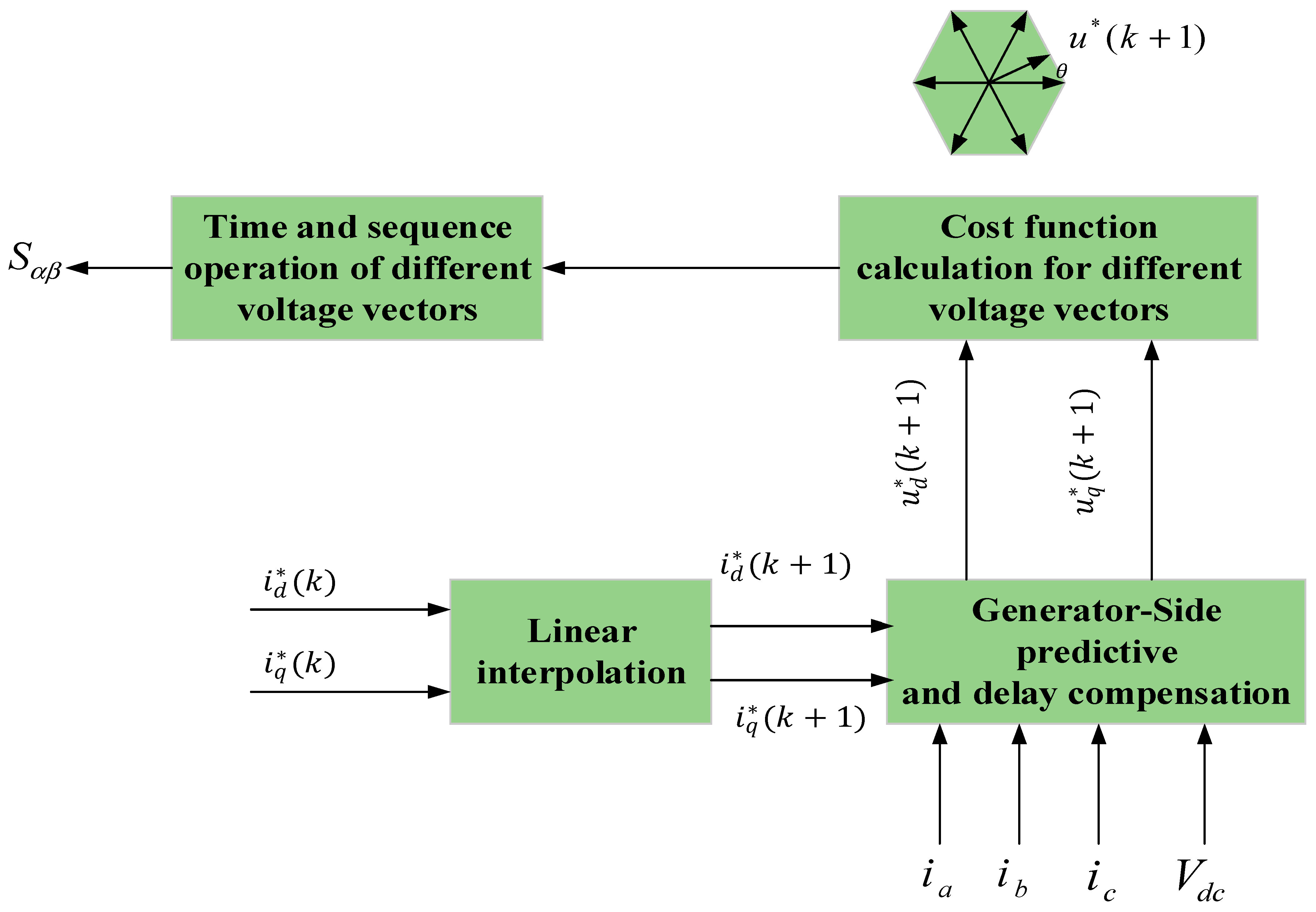

6. Proposed Modulated Model Predictive Control for the MSC

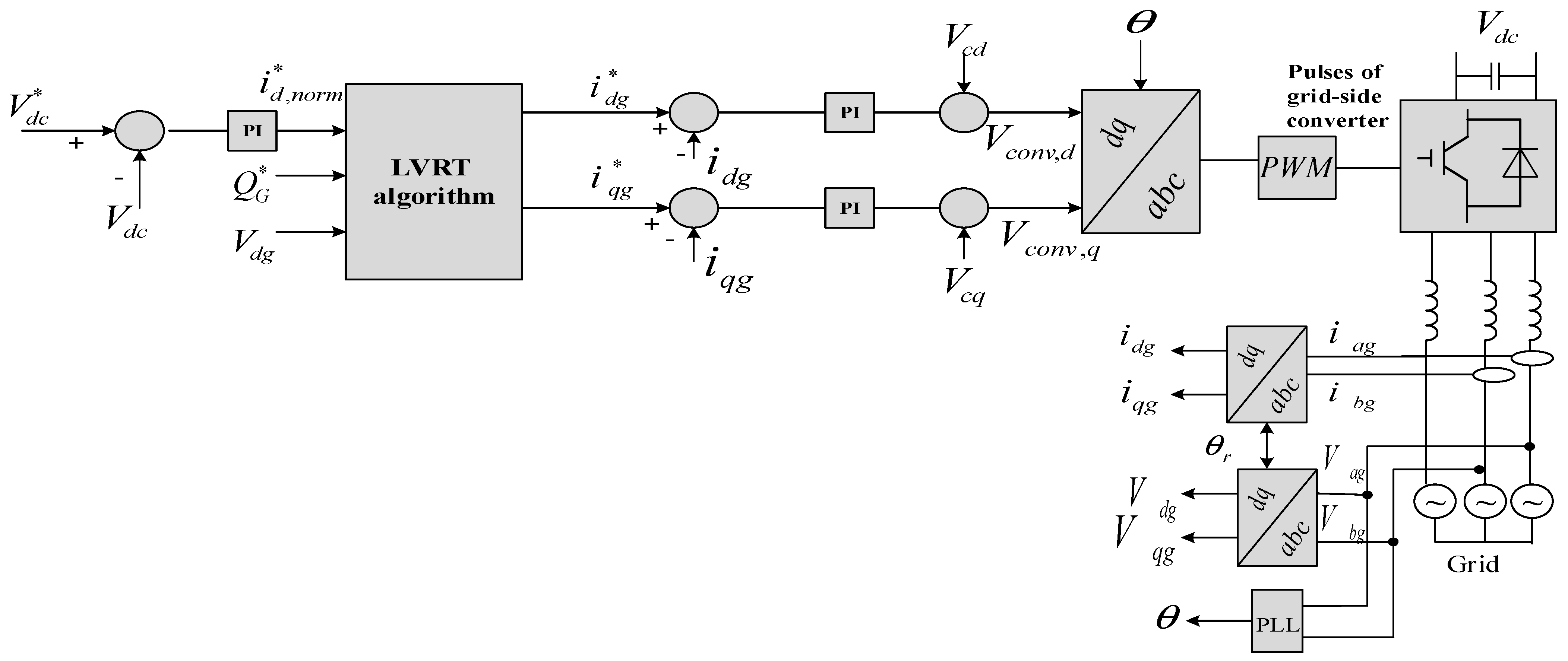

7. Modelling and Control of Grid-Side Converter

8. Coordinated Low Voltage-Ride through Algorithm

8.1. Control Strategy of Grid Side Converter

8.2. Pitch Angle Control Strategy

9. Simulation Results and Case Studies

10. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Variable | Definition |

| Pm | mechanical power |

| ρ | air density |

| Cp | the wind turbine power coefficient |

| Ar | Blade swept area |

| Vw | Wind speed |

| Vsd, Vsq | dq − axis stator voltage of the generator |

| isd, isq | dq − axis stator current of the generator |

| φsd, φsq | dq − axis stator flux linkage |

| Ld, Lq | dq − axis synchronous inductance |

| Te | electromagnetic torque |

| Rs | stator resistance |

| P | number of pole pairs |

| φr | rotor flux linkage. |

| ωe | angular rotor speed. |

| Vdg, Vqg | dq component of grid voltages |

| idg, iqg | dq component of grid currents |

| Rg, Lg | Filter resistance and inductance |

| vdc, vqc | dq component of grid-side converter voltages and is determined by the switching function S |

| ωg | Grid voltage angular frequency. |

References

- Mishra, R.; Saha, T.K. Performance Analysis of Model Predictive Technique Based Combined Control for PMSG-Based Distributed Generation Unit. IEEE Trans. Ind. Electron. 2020, 67, 8991–9000. [Google Scholar] [CrossRef]

- Zhang, Y.; Qu, C. Direct Power Control of a Pulse Width Modulation Rectifier Using Space Vector Modulation Under Unbalanced Grid Voltages. IEEE Trans. Power Electron. 2015, 30, 5892–5901. [Google Scholar] [CrossRef]

- Zhang, Y.; Qu, C. Table-based Direct Power Control for Three-Phase AC/DC Converters Under Unbalanced Grid Voltages. IEEE Trans. Power Electron. 2015, 30, 1. [Google Scholar] [CrossRef]

- Kalmbach, O.; Dirscherl, C.; Hackl, C.M. Discrete-Time DC-Link Voltage and Current Control of a Grid-Connected Inverter with LCL-Filter and Very Small DC-Link Capacitance. Energies 2020, 13, 5613. [Google Scholar] [CrossRef]

- Sebaaly, F.; Sharifzadeh, M.; Kanaan, H.Y.; Al-Haddad, K. Multilevel Switching Mode Operation of Finite Set Model Predictive Control for Grid-Connected Packed E-Cell (PEC) Inverter. IEEE Trans. Ind. Electron. 2020, 1. [Google Scholar] [CrossRef]

- Lyu, J.; Ma, B.; Yan, H.; Ji, Z.; Ding, J. A Modified Finite Control Set Model Predictive Control for 3L−NPC Grid−Connected Inverters Using Virtual Voltage Vectors. J. Electr. Eng. Technol. 2019, 15, 121–133. [Google Scholar] [CrossRef]

- Hu, J.; Zhu, J.; Lei, G.; Platt, G.; Dorrell, D.G. Multi-Objective Model-Predictive Control for High-Power Converters. IEEE Trans. Energy Convers. 2013, 28, 652–663. [Google Scholar]

- Miranda, H.; Member, S.; Cortés, P.; Yuz, J.I.; Rodríguez, J.; Member, S. Predictive Torque Control of Induction Machines Based on State-Space Models. IEEE Trans. Ind. Electron. 2009, 56, 1916–1924. [Google Scholar] [CrossRef]

- Antoniewicz, P.; Kazmierkowski, M.P. Virtual-Flux-Based Predictive Direct Power Control of AC/DC Converters with Online Inductance Estimation. IEEE Trans. Ind. Electron. 2008, 55, 4381–4390. [Google Scholar] [CrossRef]

- Geyer, T.; Papafotiou, G.; Morari, M. Model Predictive Direct Torque Control—Part I: Concept, Algorithm, and Analysis. IEEE Trans. Ind. Electron. 2009, 56, 1894–1905. [Google Scholar] [CrossRef]

- Papafotiou, G.; Kley, J.; Papadopoulos, K.G.; Bohren, P.; Morari, M. Model Predictive Direct Torque Control—Part II: Implementation and Experimental Evaluation. IEEE Trans. Ind. Electron. 2008, 56, 1906–1915. [Google Scholar] [CrossRef]

- Shehata, E. A comparative study of current control schemes for a direct-driven PMSG wind energy generation system. Electr. Power Syst. Res. 2017, 143, 197–205. [Google Scholar] [CrossRef]

- Abad, G.; Rodriguez, M.Á.; Poza, J. Two-Level VSC Based Predictive Direct Torque Control of the Doubly Fed Induction Machine with Reduced Torque and Flux Ripples at Low Constant Switching Frequency. IEEE Trans. Power Electron. 2008, 23, 1050–1061. [Google Scholar] [CrossRef]

- Vazquez, S.; Marquez, A.; Aguilera, R.; Quevedo, D.; Leon, J.I.; Franquelo, L.G. Predictive Optimal Switching Sequence Direct Power Control for Grid-Connected Power Converters. IEEE Trans. Ind. Electron. 2015, 62, 2010–2020. [Google Scholar] [CrossRef]

- Gendrin, M.; Gauthier, J.-Y.; Lin-Shi, X. A Predictive Hybrid Pulse-Width-Modulation Technique for Active-Front-End Rectifiers. IEEE Trans. Power Electron. 2017, 32, 5487–5496. [Google Scholar] [CrossRef]

- Zhang, Z.; Fang, H.; Gao, F.; Rodriguez, J.; Kennel, R. Multiple-Vector Model Predictive Power Control for Grid-Tied Wind Turbine System With Enhanced Steady-State Control Performance. IEEE Trans. Ind. Electron. 2017, 64, 6287–6298. [Google Scholar] [CrossRef]

- Tarisciotti, L.; Zanchetta, P.; Watson, A.; Clare, J.C.; Degano, M.; Bifaretti, S. Modulated Model Predictive Control for a Three-Phase Active Rectifier. IEEE Trans. Ind. Appl. 2015, 51, 1610–1620. [Google Scholar] [CrossRef]

- Tarisciotti, L.; Zanchetta, P.; Watson, A.; Bifaretti, S.; Clare, J.C. Modulated Model Predictive Control for a Seven-Level Cascaded H-Bridge Back-to-Back Converter. IEEE Trans. Ind. Electron. 2014, 61, 5375–5383. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, X.; Yuan, X.; Wang, Y.; Dai, P. Fast Model Predictive Control for Multilevel Cascaded H-Bridge STATCOM with Polynomial Computation Time. IEEE Trans. Ind. Electron. 2016, 63, 1. [Google Scholar] [CrossRef]

- Vijayagopal, M.; Zanchetta, P.; Empringham, L.; De Lillo, L.; Tarisciotti, L.; Wheeler, P. Control of a Direct Matrix Converter With Modulated Model-Predictive Control. IEEE Trans. Ind. Appl. 2017, 53, 2342–2349. [Google Scholar] [CrossRef]

- Yaramasu, V.; Wu, B.; Alepuz, S.; Kouro, S. Predictive Control for Low-Voltage Ride-Through Enhancement of Three-Level-Boost and NPC-Converter-Based PMSG Wind Turbine. IEEE Trans. Ind. Electron. 2014, 61, 6832–6843. [Google Scholar] [CrossRef]

- Liserre, M.; Cardenas, R.; Molinas, M.; Rodriguez, J. Overview of Multi-MW Wind Turbines and Wind Parks. IEEE Trans. Ind. Electron. 2011, 58, 1081–1095. [Google Scholar] [CrossRef]

- Carrillo, C.J.; Montaño, A.O.; Cidras, J.; Díaz-Dorado, E. Review of power curve modelling for wind turbines. Renew. Sustain. Energy Rev. 2013, 21, 572–581. [Google Scholar] [CrossRef]

- Erlich, I.; Bachmann, U. Grid code requirements concerning connection and operation of wind turbines in Germany. In Proceedings of the IEEE Power Engineering Society General Meeting, San Francisco, CA, USA, 16 June 2005; pp. 1–5. [Google Scholar]

- Irtija, N.; Sangoleye, F.; Tsiropoulou, E.E. Contract-Theoretic Demand Response Management in Smart Grid Systems. IEEE Access 2020, 8, 184976–184987. [Google Scholar] [CrossRef]

- Kim, C.; Kim, W. Coordinated Fuzzy-Based Low-Voltage Ride-Through Control for PMSG Wind Turbines and Energy Storage Systems. IEEE Access 2020, 8, 105874–105885. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, M.; Li, Y. Improved multi-objective model predictive control of permanent magnetic synchronous generator wind power system. J. Renew. Sustain. Energy 2015, 7, 053104. [Google Scholar] [CrossRef]

- Calle-Prado, A.; Alepuz, S.; Bordonau, J.; Nicolas-Apruzzese, J.; Cortes, P.; Rodriguez, J. Model Predictive Current Control of Grid-Connected Neutral-Point-Clamped Converters to Meet Low-Voltage Ride-Through Requirements. IEEE Trans. Ind. Electron. 2015, 62, 1503–1514. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, X.; Yang, S.; Xie, Z.; Wang, L.; Cao, R. Simplified model predictive direct torque control method without weighting factors for permanent magnet synchronous generator-based wind power system. IET Electr. Power Appl. 2017, 11, 793–804. [Google Scholar] [CrossRef]

- Yang, Y.; Wen, H.; Li, D. A Fast and Fixed Switching Frequency Model Predictive Control with Delay Compensation for Three-Phase Inverters. IEEE Access 2017, 5, 17904–17913. [Google Scholar] [CrossRef]

- Xie, W.; Wang, X.; Wang, F.; Xu, W.; Kennel, R.M.; Gerling, D.; Lorenz, R.D. Finite-Control-Set Model Predictive Torque Control with a Deadbeat Solution for PMSM Drives. IEEE Trans. Ind. Electron. 2015, 62, 5402–5410. [Google Scholar] [CrossRef]

- Nadour, M.; Essadki, A.; Nasser, T. Improving low-voltage ride-through capability of a multimegawatt DFIG based wind turbine under grid faults. Prot. Control. Mod. Power Syst. 2020, 5, 1–13. [Google Scholar] [CrossRef]

- Diab, A.A.Z.; Hassan, M.S.; Shoyama, M. Modified Adaptive Sliding Mode Control for Sensorless Direct-Drive Permanent Magnet Synchronous Generator Wind Turbines based on Fuzzy Logic Control. In Proceedings of the 2019 IEEE 4th International Future Energy Electronics Conference (IFEEC), Singapore, 25–28 November 2019; pp. 1–8. [Google Scholar]

- Xia, C.; Liu, T.; Shi, T.; Song, Z. A Simplified Finite-Control-Set Model-Predictive Control for Power Converters. IEEE Trans. Ind. Inform. 2014, 10, 991–1002. [Google Scholar] [CrossRef]

- Yaramasu, V.; Wu, B.; Chen, J. Model-Predictive Control of Grid-Tied Four-Level Diode-Clamped Inverters for High-Power Wind Energy Conversion Systems. IEEE Trans. Power Electron. 2014, 29, 2861–2873. [Google Scholar] [CrossRef]

| FCS_MPC | MMPC | |

|---|---|---|

| THD% | 5.82% | 5.27% |

| Total Execution time of Simulation (s) | 329.67 | 160.98 |

| Execution time of controller (s) | 1.5468 | 0.7553 |

| Reduction in time (%) | 51.17% | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghany, A.A.; Shehata, E.G.; Elsayed, A.-H.M.; Mohamed, Y.S.; Haes Alhelou, H.; Siano, P.; Diab, A.A.Z. Novel Switching Frequency FCS-MPC of PMSG for Grid-Connected Wind Energy Conversion System with Coordinated Low Voltage Ride Through. Electronics 2021, 10, 492. https://doi.org/10.3390/electronics10040492

Ghany AA, Shehata EG, Elsayed A-HM, Mohamed YS, Haes Alhelou H, Siano P, Diab AAZ. Novel Switching Frequency FCS-MPC of PMSG for Grid-Connected Wind Energy Conversion System with Coordinated Low Voltage Ride Through. Electronics. 2021; 10(4):492. https://doi.org/10.3390/electronics10040492

Chicago/Turabian StyleGhany, Asmaa A., E. G. Shehata, Abo-Hashima M. Elsayed, Yahia S. Mohamed, Hassan Haes Alhelou, Pierluigi Siano, and Ahmed A. Zaki Diab. 2021. "Novel Switching Frequency FCS-MPC of PMSG for Grid-Connected Wind Energy Conversion System with Coordinated Low Voltage Ride Through" Electronics 10, no. 4: 492. https://doi.org/10.3390/electronics10040492

APA StyleGhany, A. A., Shehata, E. G., Elsayed, A.-H. M., Mohamed, Y. S., Haes Alhelou, H., Siano, P., & Diab, A. A. Z. (2021). Novel Switching Frequency FCS-MPC of PMSG for Grid-Connected Wind Energy Conversion System with Coordinated Low Voltage Ride Through. Electronics, 10(4), 492. https://doi.org/10.3390/electronics10040492