1. Introduction

Passiflora is a genus with a large number of species mainly originating from north, central, and south America. Particularly, Colombia has the highest biodiversity of Passiflora species in the world, with a record 167 species, 24% more than Brazil and more than double of those found in Peru and Venezuela [

1]. Some of these species reached commercial relevance in the international market, and their production increased during recent years. In Colombia, the total fruit production of the genus Passiflora was approximately 221 kt/yr in 2017 and slightly increased to 226 kt/yr in 2019 [

2]. Among the different species, passion fruit (

Passiflora edulis), “granadilla” (

Passiflora ligularis), “gulupa” (

Passiflora edulis Sims fo

edulis), and “curuba” (

Passiflora mollissima) are highly demanded mainly in The Netherlands, Canada, Spain, France, and Germany, among other countries. However, as most of the fruits are commercialized in fresh, a large fraction of the production does not fulfill the standards for their exportation thus generating postharvesting losses. When possible, the nonconforming products are commercialized locally or processed in extraction plants to preserve the fruit pulp under frozen conditions or to use in industrial foods. Nevertheless, a major share of fruits is lost in the production chain or simply not harvested. In this regard, the transformation and valorization of Passiflora products are paramount to enhancing the economic situation of rural producers.

Nowadays, with the increasing trend for the consumption of natural-based products, there is a great potential for the valorization of Passiflora fruits and their derivates as cosmetic ingredients, mainly to exploit their high content of alpha-hydroxy acids (AHA), the pleasant fruit-like essential oils, and aroma compounds from the flowers and pulp, and the vegetable oils from the seeds. On the one hand, AHAs were used as chemical exfoliation agents because they are capable to penetrate the surface of the skin reaching the deeper layers [

3]. These results in a gentle scrubbing action that reduces excessive epidermal keratinization, thinning the stratum corneum, and renovating the epidermis [

4]. Then, Passifloraceaes extracts can be used as exfoliation agents considering their high content of AHA such as citric acid; for instance, the content of citric acid in

P. mollissima and

P. edulis Sims fo

edulis, can be higher than 3.2 g/L [

5,

6]. On the other hand, biobased compounds from essential oils, pulp extracts, and seed oils can provide different cosmeceutical actions. In a recent study, it was found that the seed oil of

P. edulis var.

edulis has a high content of triacylglycerides of different fatty acids including linoleic (78.77 ± 0.06%), oleic (11.57 ± 0.02%), palmitic (7.79 ± 0.02%), and stearic (1.85 ± 0.05%). This highly unsaturated oil was processed via ultrasound-assisted nano emulsification, and the resulting product demonstrated high in vivo efficacy as emollient, increasing hydration and skin elasticity after topical application [

7].

In particular, the potential exfoliating action of Passifloraceaes is attractive for natural-based cosmetics. Exfoliants are fundamental ingredients in high value-added antiaging skin creams, enabling the removal of dead skin cells and mitigating age signs and dullness. Exfoliation can be achieved either by chemical procedures where dead skin cells are removed by interacting with organic acids (i.e., AHA), or by physical processes (e.g., scrubbing, abrasion). In the latter, skin-cleaning agents are solid materials from natural origin (

ca. clay or fine seed dust) or obtained by chemical synthesis (fine particles of polystyrene or polyethylene). The solid particles have sizes in between 100–1000 µm, and in solid-state they remove the surface layer of the skin by mechanical abrasion leaving a fresh and smooth surface [

8]. While synthetic particles can be tailored for specific size distributions, in the case of naturally occurring granular particles, they do not have uniform sizes or shapes, and they are generally available in small particle sizes between 250 and 600 µm [

9]. However, the size distribution of bioderived solid particles (e.g., seeds, shells) could be adjusted by controlled grinding. In this regard, incorporating Passifloraceaes extracts and ground seeds in cosmetics would enable to provide a combined chemical-physical exfoliating action.

Despite the incorporation of natural-based ingredients in cosmetics being a common practice, the design and engineering of novel cosmetic products is a difficult task. In general, cosmetics are microstructured media that require a defined formulation and a specific set of processing conditions to ensure effective action and physicochemical and biological stability. Currently, cosmetic design methodologies are usually based upon expensive and time-consuming trial and error experimental procedures, and this could become a limiting factor to enable the incorporation of novel ingredients, such as Passifloraceaes extracts and seeds. To overcome this issue, recently, an optimization-based methodology was developed to accelerate the design and formulation of cosmetic emulsions. In this methodology, heuristics including type and amounts of ingredients, negative or positive synergies, legal regulations, and ingredients suppliers’ recommendations among other experience-based knowledge are transformed into algebraic restrictions of a mathematical model [

10]. Together with equations to compute physicochemical properties and suitable mixing rules, the mathematical model is then used to obtain an optimal formulation of ingredients based upon a specific goal (e.g., performance, cost, sustainability). This technique was successfully applied in the design of skincare emulsions, saving time and resources during product development [

6,

10].

In this context, the aim of this work was to develop a heuristic-based cosmetic emulsion that incorporated ground seeds from three Passiflora fruits as an exfoliating ingredient. Once designed, the formulations were prototyped and assessed to determine the influence of drying, milling, and sieving of Passiflora seeds in the characteristics of the final exfoliant product. A comparison with a commercial product containing passion fruit seeds was also performed. Finally, the physicochemical stability of the exfoliant proto-type was evaluated after thermal shock.

2. Materials and Methods

2.1. Materials

Mature fruits of “gulupa” (P. edulis Sims fo edulis), “curuba” (Passiflora mollissima), and “granadilla” (Passiflora ligularis) were purchased in local markets of Bogota (Colombia). Passion fruit (“maracuyá”, P. edulis) ground seeds were obtained from QuimiEsencias (Bogotá, Colombia) and used as a reference for comparison. Xanthan gum, octyldodecanol, and stearic acid were obtained from ChemEssences (Bogotá, Colombia). Cetyl alcohol, mineral oil, propylene glycol, and glycerin were obtained from Disproalquímicos (Bogotá, Colombia). The glyceryl stearate was obtained from CRODA (Bogotá, Colombia). Propylparaben was obtained from Ciacomeq (Bogotá, Colombia) and sodium hydroxide from Brenntag (Bogotá, Colombia).

2.2. Obtention of Passiflora Ground Seeds

One kilogram of each Passiflora fruits (

P. ligularis,

P. edulis Sims fo

edulis, and

P. mollissima) was separately subjected to two different extraction processes (i.e., processes A and B) to obtain the ground seeds. The yield in each process was calculated using Equation (1):

2.2.1. Process A

The seeds of each fruit were manually extracted from the fresh fruits and filtered through a plastic strainer to remove as much water as possible. The remaining solids were ground for one minute with a high-speed extractor (Magic Bullet NutriBullet). The mixture was homogeneously distributed on a grid coated with aluminum foil and dried in an oven (Binder Red Line, model RE 115) at 60 °C for 48 h. Finally, the dry solid was ground with a high-speed extractor (Magic Bullet NutriBullet) for ten seconds.

2.2.2. Process B

Here, the same as Process A was followed but the remaining solids from the initial filtration were not previously ground. Instead, the solids were distributed on a grid coated with aluminum foil and dried in an oven (Binder Red Line, model RE 115) at 60 °C for 72 h. Afterward, the dried seeds were ground for fifteen seconds with a high-speed extractor (Magic Bullet NutriBullet).

2.3. Physicochemical Characterization of Ground Seeds

2.3.1. Proximate Analysis

The chemical composition of ground seeds was determined following the procedure established by AOAC [

11]. The reference commercial product (passion fruit powdered seeds) was also analyzed. A 20 g sample of each of the six ground seeds (i.e., three fruits × two processes) were analyzed by duplicate.

2.3.2. Sieving Separation

The ground seeds were separated in a sieve (To-Tap, Testing Sieve Shaker, The W.S. Tyler Company, Cleveland, OH, USA) by particle size using six standard Tyler test sieves. Each sample of ground seeds was placed on the top sieve and the stack was placed on sifting equipment that vibrated for a fixed time (10 min). The weight of the solids collected on each sieve was then determined and their mass expressed as a fraction or percentage of the total sample. The standard Tyler test sieves used were: 16 (1.2 mm), 18 (1.0 mm), 35 (0.5 mm), 50 (0.3 mm), 140 (0.105 mm), and 200 (0.0074 mm).

The corresponding particle size distribution of the ground seeds was characterized by using a differential and cumulative analysis. In the differential analysis, the percentage of fraction retained by each sieve (%∆

ϕ) is defined as the ratio between the fraction retained in the ith mesh (

mi) and the sum of the masses retained in all m sieves (

) [

12] as shown in the Equation (2).

Likewise, in the cumulative analysis, the percentage of cumulative retained fraction (%φ) is defined as the sum of the fractions retained from the smallest mesh number to the ith [

12] and is calculated as follows Equation (3):

2.3.3. Hardness

Hardness was assessed by using a TA-TX PLUS texture analyzer (Stable Micro Systems Ltd.a., Godalming, United Kingdom). Compression tests were performed with a 25 mm diameter cylinder (P/25) and using a 25 kg load cell. All experiments were performed four times and conducted at 18 °C; results were expressed as kg.

2.3.4. Morphology

The morphology of the surface of ground seeds was evaluated by image analysis with scanning electron microscopy (SEM) (Zeiss LEO Gemini 1530, Germany). The samples were coated with a thin layer of gold by thermal evaporation prior to analysis.

2.4. Formulation of the Exfoliant

The composition of the exfoliant formula base was previously obtained by means of a mathematical heuristic model developed by Arrieta–Escobar et al. [

6,

10]. From an initial list of sixteen possible ingredients organized in 4 main subsets: eight emollients, two fatty alcohols, three thickening polymers, and three surfactants. Some known heuristic rules regarding amounts and combinations of these ingredients, together with models for the emulsion viscosity, allow defining a space of feasible alternative formulations. The optimization problem for a minimum cost was solved using GAMS/CPLEX software. Thus, the final formulation was obtained.

Table 1 shows the corresponding formulation of the exfoliant.

The exfoliant formula base was prepared as follows: the xanthan gum was dispersed in water at 70 °C under constant stirring at 2500 rpm with an Ultraturrax T18 (IKA, Germany). The ingredients 3 to 7 (oily phase) from

Table 1 were separately weighed, mixed, and heated to 70°C in an oven (Memmert GmbH + Co. KG, Germany). Once homogenized, the oily phase was added over the aqueous phase under constant agitation for 15 min with an Ultraturrax T18 (IKA, Germany). After this, the mixture was placed in an ice bath, maintaining the agitation. Then, the required amount of ingredients, 8 to 10, were weighed, mixed, and added to the previously formed emulsion. Finally, the sodium hydroxide was added with magnetic stirring (2800 rpm), and the entire emulsion was homogenized for 10 min and removed from the ice bath. At that time, the Passiflora powdered seeds of each fruit were separately added at 5% of the total weight (equal to the commercial product from

P. edulis used as reference) and mixed until obtaining a homogeneous emulsion. Subsequently, each product was placed in plastic zip-lock bags and then transferred into white polyethylene bottles for final storage.

2.5. Exfoliant Characterization

2.5.1. Droplet Size

The droplet size of the particles within the dispersant phase of the emulsions was monitored by means of optical microscopy (Motic B3 Professional series DMB3-223, Motic). Three samples of each emulsion were placed on a slide and covered separately with a coverslip. The slide was placed under the microscope using the 40× objective to visualize the emulsion droplets. Each slide sample was photographed at different locations and the images obtained were processed using ImageJ software, previously calibrated. At least 300 drops were analyzed for each emulsion and finally, the data was processed using the Microsoft Excel® data analysis tool.

2.5.2. pH and Texture

A dilution of 1 g of each product sample was made in 10 mL of distilled water and pH was measured by triplicate using a 370-pH meter (Jenway, London, UK).

Texture measurement was carried out in duplicate by using a TA-TX PLUS texture analyzer (Stable Micro Systems Ltd.a., Godalming, UK) to characterize texture properties of each sample, i.e., viscosity index, cohesivity, firmness, and consistency. For this purpose, the Back Extrusion Rig (A/BE) attachment was used. It consists of a sample container and a disc plunger, which performs a compression test that extrudes the product upwards and around the edge of the disc (35 mm diameter disc, P35, was used). A total of 120 mL of each sample was used, and measurements were performed at a temperature of 20 °C in duplicate.

2.5.3. Rheological Analysis

The rheological behavior of samples was measured in duplicate in a rheometer (Brookfield Instruments, model C-VDR), to determine the shear strength and viscosity in the emulsions as a function of deformation. Cone and plate geometry were used, where the angle of the plate corresponded to 4° and a gap of 1.5 mm. Each sample was placed on the previously vacuum-coupled plate and the gap was adjusted. The measurements were carried out at a constant temperature of 20 °C in a strain rate range between 0.001/s and 1500/s.

2.6. Stability Storage Test

All the prototypes obtained, including the formula base without ground seeds, were subjected to preliminary stability tests. These consisted in subjecting the samples to alternating heating and cooling cycles (thermal shocks) to evaluate their physical stability under different temperature conditions. These tests were carried out in duplicate and the products were stored in successive cycles of 24 h each at 45 °C (in an oven, Binder Red Line RE 115, Binder GmbH, Tuttlingen, Germany), 14 °C, and −4 °C (in a freezer Whirlpool, Medellín, Colombia), At the end of these three cycles, the physical characteristics of the products were observed and compared with their initial appearance.

In addition, pH, droplet size, texture, and rheology measurements were performed on each of the products as it was above explained. After carrying out the thermal cycles corresponding to the preliminary stability tests, the samples were left at room temperature for 24 h to carry out the relevant measurements.

2.7. Statistical Analyses

Characterization results were analyzed by analysis of variance (ANOVA) and Tukey’s tests using the software Infostat Version 2020 to determine the differences between samples. Differences at probability level p ≤ 0.05 were considered significant.

3. Results and Discussion

3.1. Ground Seed Characterization

The corresponding yield of seeds obtained after extraction from the fresh fruits for the three Passiflora species is shown in

Table 2. As expected, the preliminary drying of filtered seeds during extraction does not play a role in the seeds’ yield, so both extraction processes were equally effective in the recovery of the material. Regarding the species, the yield for

P. mollissima was the lowest in comparison to the other two fruits that have a fairly similar yield. This is because

P. mollissima has a much higher water and pulp content (>60% wt.) in comparison with

P. ligularis (avg. 45% wt.) and

P. edulis Sims (44% wt.). The pulp adhered to the seeds was not completely removed during the extraction process which enabled to retain of some of the AHA presented in the fresh fruit.

The results of proximate analysis, moisture, and hardness of ground seeds are summarized also in

Table 2. The commercial reference product (

P. edulis) has a higher dry matter content which is expected because, for biological stability reasons, the water content must be kept as low as possible in cosmetic ingredients. In the case of the extracted seeds, additional moisture removal could be achieved in further experiments to fulfill similar specifications of the commercial product. In particular, as

P. mollissima has the higher water content in the pulp but the drying process was similar for all samples, its moisture content was higher. Nonetheless, the moisture content of all samples is low enough to ensure their preservation for further use.

The commercial sample has lower protein, fat, extractable organic materials, and ash content than the extracted seeds for the three Passiflora fruits. This indicates that the commercial seeds were previously subjected to extraction, washing, and/or scrubbing to remove vegetable oils and adhered pulp during their process. Comparatively, in the here-extracted seeds, some of the pulp and oils were left after their recovery to retain some of the functional chemicals of the fruit. As expected,

P. mollissima ground seeds had the lowest amount of dry matter, protein, and fat because this fruit has a much larger water content in the pulp. However, despite the larger moisture content, the hardness value obtained by the two methods for

P. mollissima seed powder is comparable to those exhibited by

P. edulis (reference) and higher than those exhibited by

P. edulis Sims fo

edulis, and

P. ligularis. This is interesting because even with a high-water content that could soften the seeds, their structure can withstand higher compression forces. Nonetheless, even if the hardness of abrasive particles is a relevant parameter to define their use as exfoliant material [

13], the abrasive character of the exfoliating agents mainly depends on the force exerted by the consumer when applying the final products. Finally, in accordance with the data reported by Ramaiya et al. [

14], both

P. edulis exhibited the lowest ash value, while

P. ligularis has the largest content. The commercial product has a very low ash content which can be related to the removal of organic materials during its processing. In the case of the extracted seeds, the high content of inorganic ashes might have a negative role in the stability of emulsions. This is because ashes could be extracted in the aqueous phase affecting the ionic nature. Further studies are required to understand the impact of ashes on the stability of cosmetic emulsions when using seeds as ingredients.

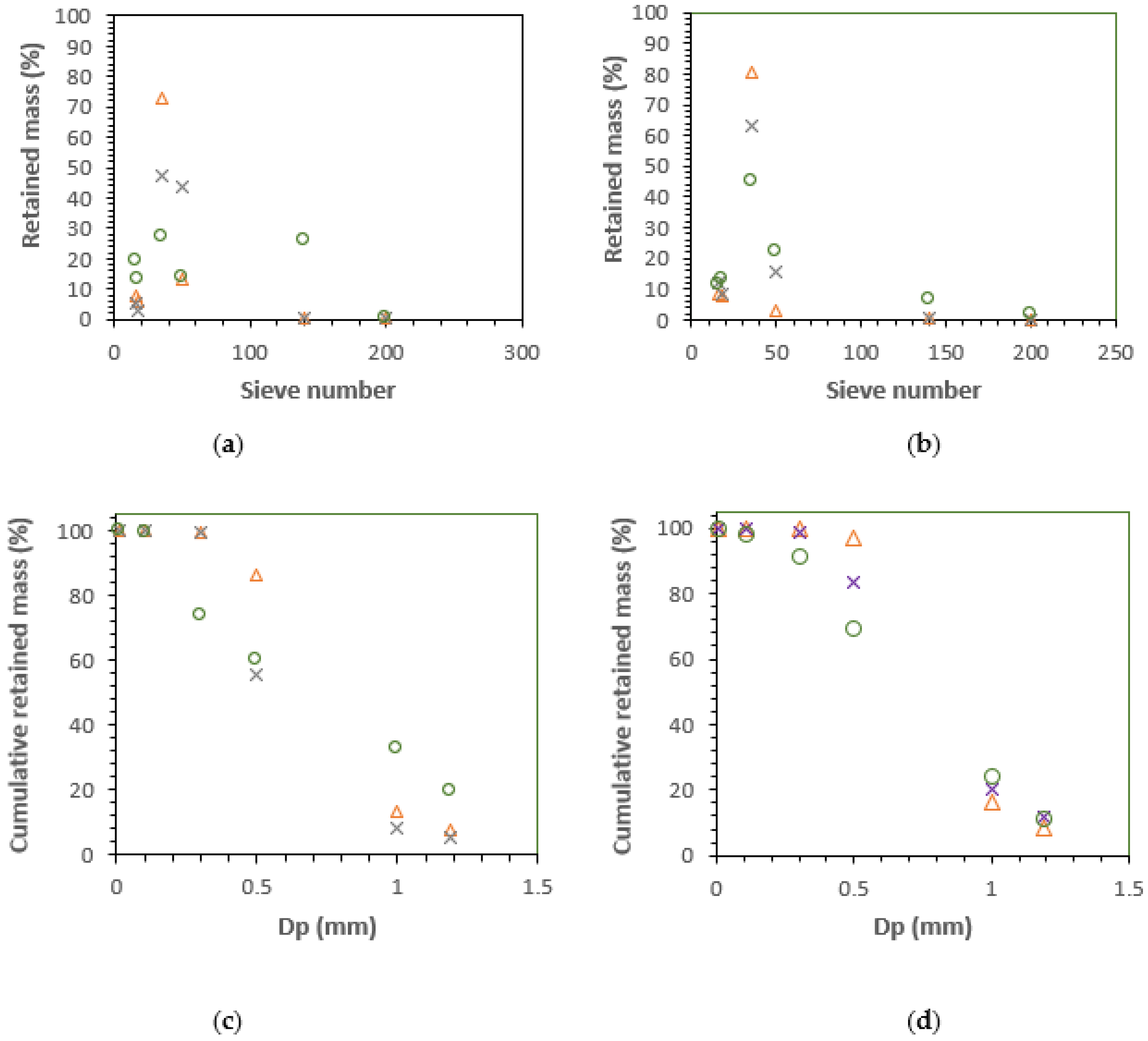

The results obtained from sieving separation are presented in

Figure 1a,b, as a particle size differential analysis. In this case, the retained fraction was plotted versus the standard sieve number. The large fraction of particles in all samples were retained above sieve 35 for both processes; this corresponds to an average characteristic size between 0.5 mm and 1 mm. In

Figure 1c,d, the results are presented as the retained fraction accumulated above each sieve. Thus, despite all samples exhibiting similar behavior,

P. mollissima samples presented slightly larger particle sizes. This is consistent with their slightly high hardness and the high content of water that reduces grinding effectiveness.

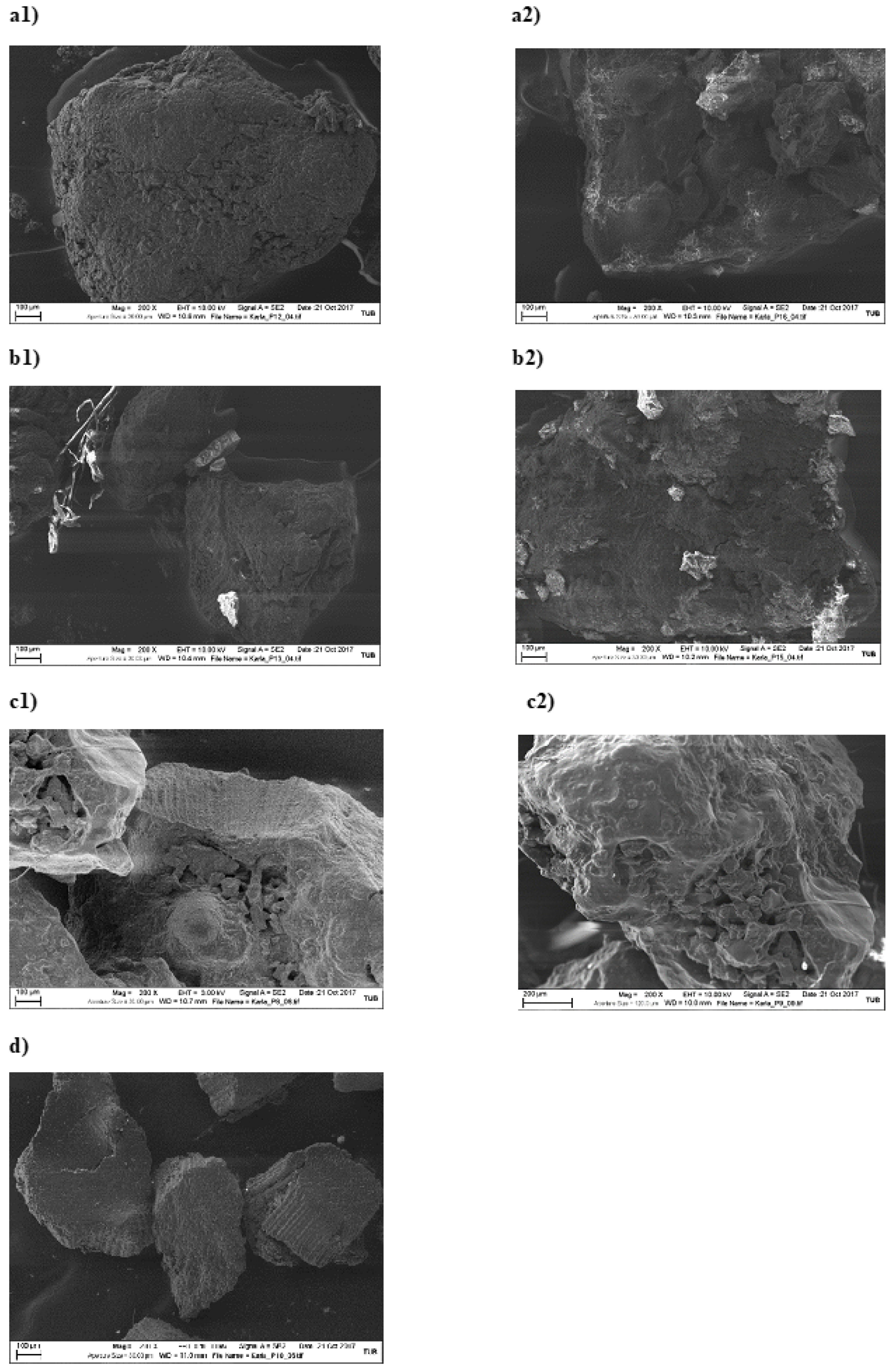

Regarding the morphology of the particles, which is observed in the images of

Figure 2, all samples have a non-uniform, irregular, and rough surface. The seeds have a porous surface that is typical of dried biomass. The hydrostatic pressure gradients within the channels and interstices of the wet seeds help form a porous structure within the solid during the drying process [

15]. In addition, all seeds have a large number of edges, spikes, and irregularities, which are desired features for more efficient exfoliation action. Interestingly, the reference product (

P. edulis) has a smoother and less porous surface, with fewer cracks and deformities than the other three seeds. This is consistent with pretreated materials that were subjected to the previous extraction of organic materials and conditioning.

3.2. Exfoliant Prototype Characterization

Considering the major importance of organoleptic properties in cosmetic products, all the samples were initially assessed by a visual inspection. The base emulsion was a homogeneous and highly viscous white products. The prototype made with the reference P. edulis powder was a homogeneous white emulsion with black dots. The prototypes using P. mollissima and P. edulis Sims fo edulis were homogeneous viscous beige emulsions with black and brown dots, respectively. The prototype made with P. ligularis was a homogeneous and dark beige viscous emulsion with black dots. As expected, the reference Passiflora powdered seeds did not cause any change in the color of the base emulsion, which is consistent with pretreatment for organics removal. In comparison, all powdered seeds obtained in this work changed the initial white color of the base emulsion into a beige color of different shades. This is also a confirmation that some of the compounds from the dry pulp adhered to the seeds were extracted into the media. While this can have valuable outcomes such as providing chemical exfoliating action and possibly antioxidant activity, darkening might be a negative characteristic for the final cosmetic product. In this case, the obtained Passiflora seeds might be better suited as ingredients for dark-colored cosmetic products (e.g., clays, muds, charcoal exfoliants, or chocolate masks).

After pH characterization of prepared emulsions (see

Table 3), the base emulsion had a neutral pH, being the highest of all the samples. However, this value was highly affected by the addition of ground seeds.

P. edulis Sims fo

edulis and

P. mollissima seeds highly reduced the pH of the base formulation. This decrease in pH is attributed to the extraction of carboxylic acids present in the seeds, particularly considering their high content of some alpha-hydroxy acids in Passifloraceas. In contrast, powdered seeds of

P. edulis, the standard commercial product, caused a slight change in the pH of the emulsion [

13]. Again, this is consistent with pretreated seeds that are free of extractable organic compounds.

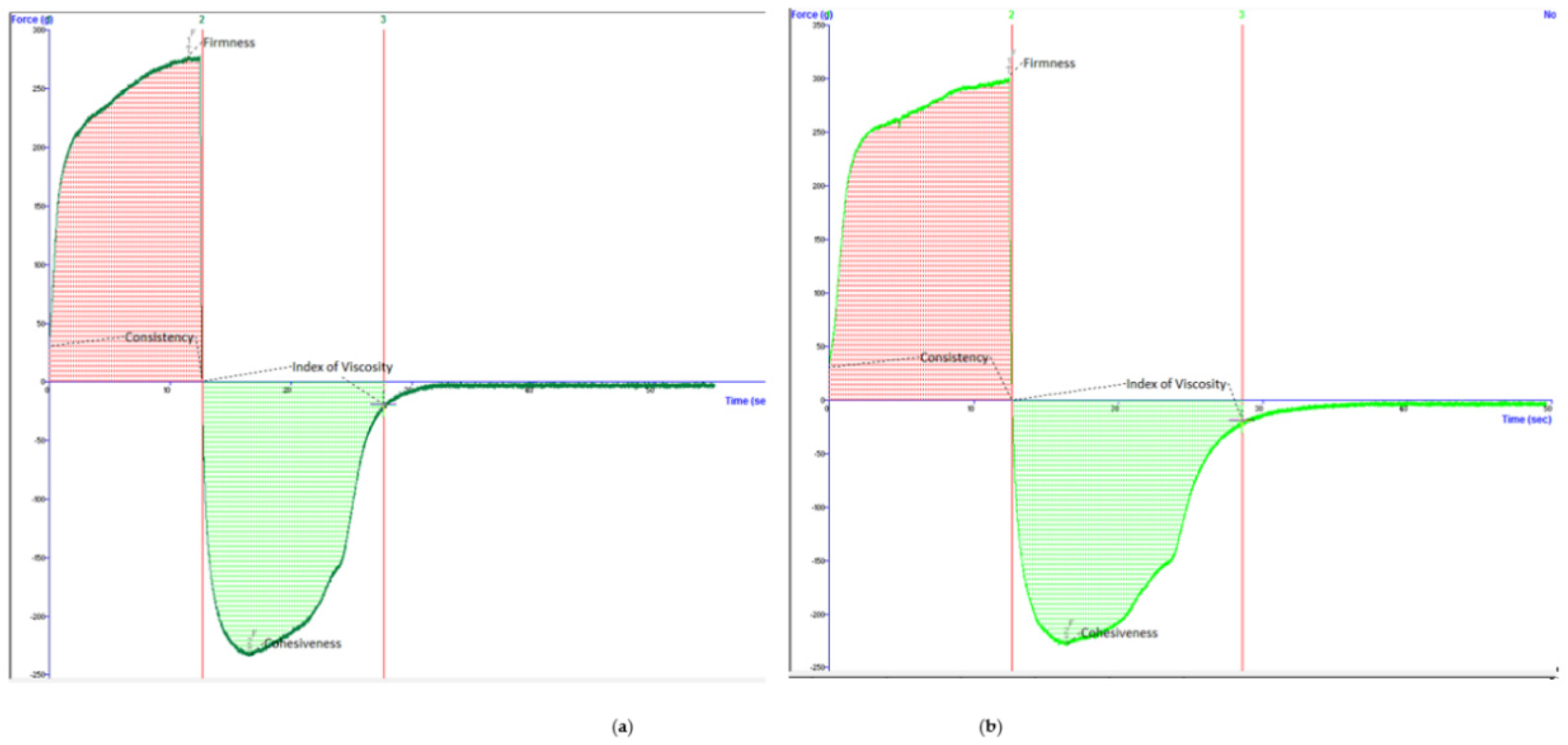

Figure 3a shows the texture analysis curve (TA) for the base emulsion in which the change caused by deformation forces is tracked over time. The initial portion of the TA curve consists of two linear sections intersecting at a point called the yield point. This point corresponds to the transition of the sample from an elastic state to a plastic state and represents the point where the emulsion begins to flow under the application of stress [

16].

During the texture analysis test, at time zero the test tube contacts the surface of the sample and penetrates it at a certain speed, causing deformation and exerting resistance on the sample. The maximum penetration resistance force corresponds to the positive peak. The positive and negative peak areas are associated with the cohesion work of the sample and the adhesion work of the specimen, respectively [

17]. All the samples analyzed with this methodology presented a similar behavior to that of the base emulsion. The differences are related to the texture parameters of each sample.

Table 3 summarizes the data of firmness, consistency, cohesivity, and viscosity index for each sample. According to these texture parameters, the formula base emulsion has higher firmness, consistency, cohesivity, and viscosity index than the other samples. This is directly related to the viscosity of the emulsion; since it is the thickest, its texture parameters exhibit higher values. Also, this is evidence of the impact caused by the extracted organic chemicals from the seeds. Different from the commercial seeds that are most probably pretreated and caused a minor change in the base emulsion, the extracted compounds in the dry pulp adhered to the seeds affected the rheologic properties of the base emulsion. This has to be confirmed in a further study because the change in emulsion properties after incorporating the here obtained exfoliating seeds might affect other sensorial attributes of the product (i.e., spreadability, fluency). Nonetheless, the observed differences were still minor, and as presented in further sections, all emulsions behave similarly when assessed by analytical methods. Also, the decrease of pH value influences the formation of sodium stearate, which affects the textural features of the emulsions.

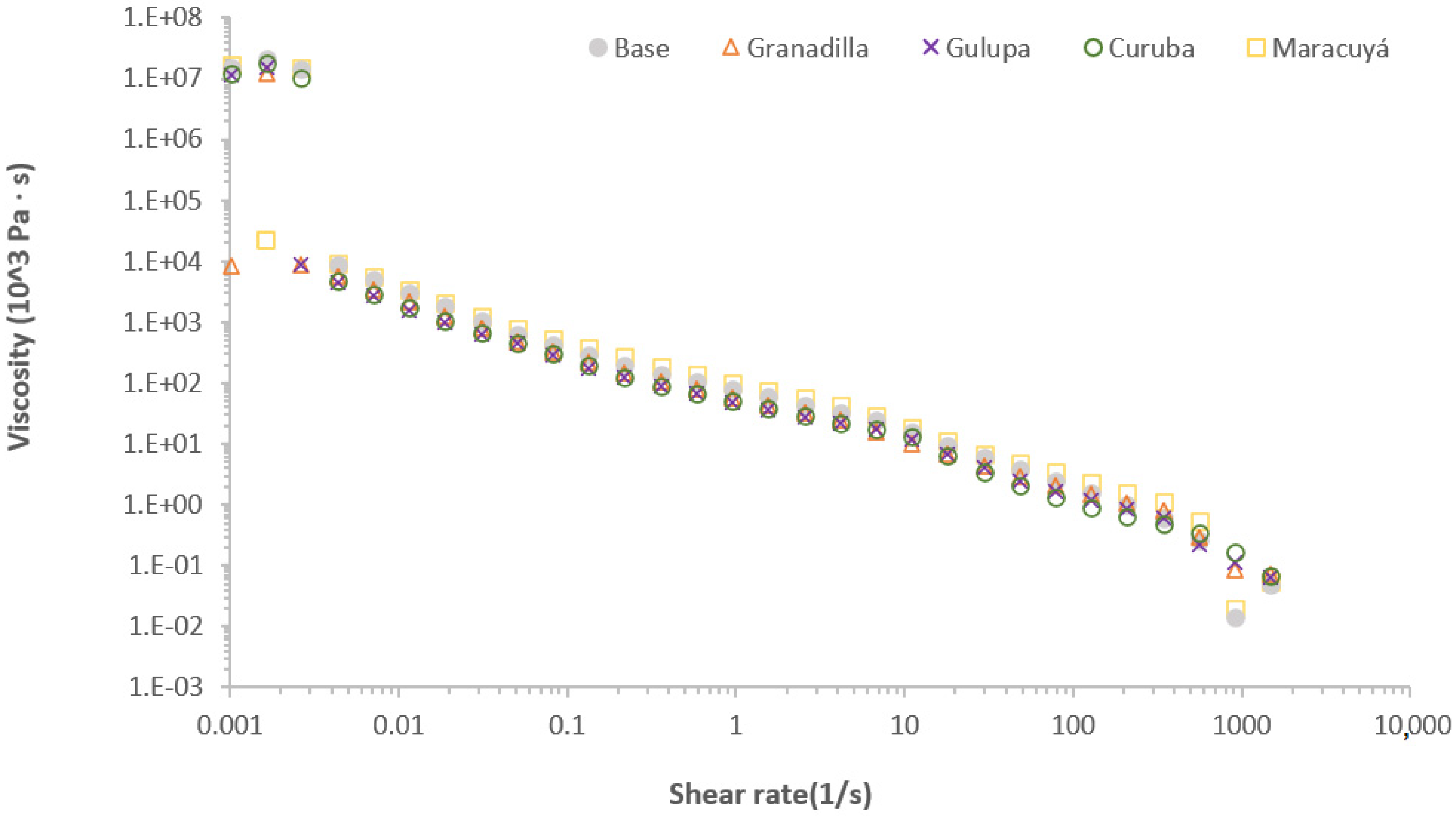

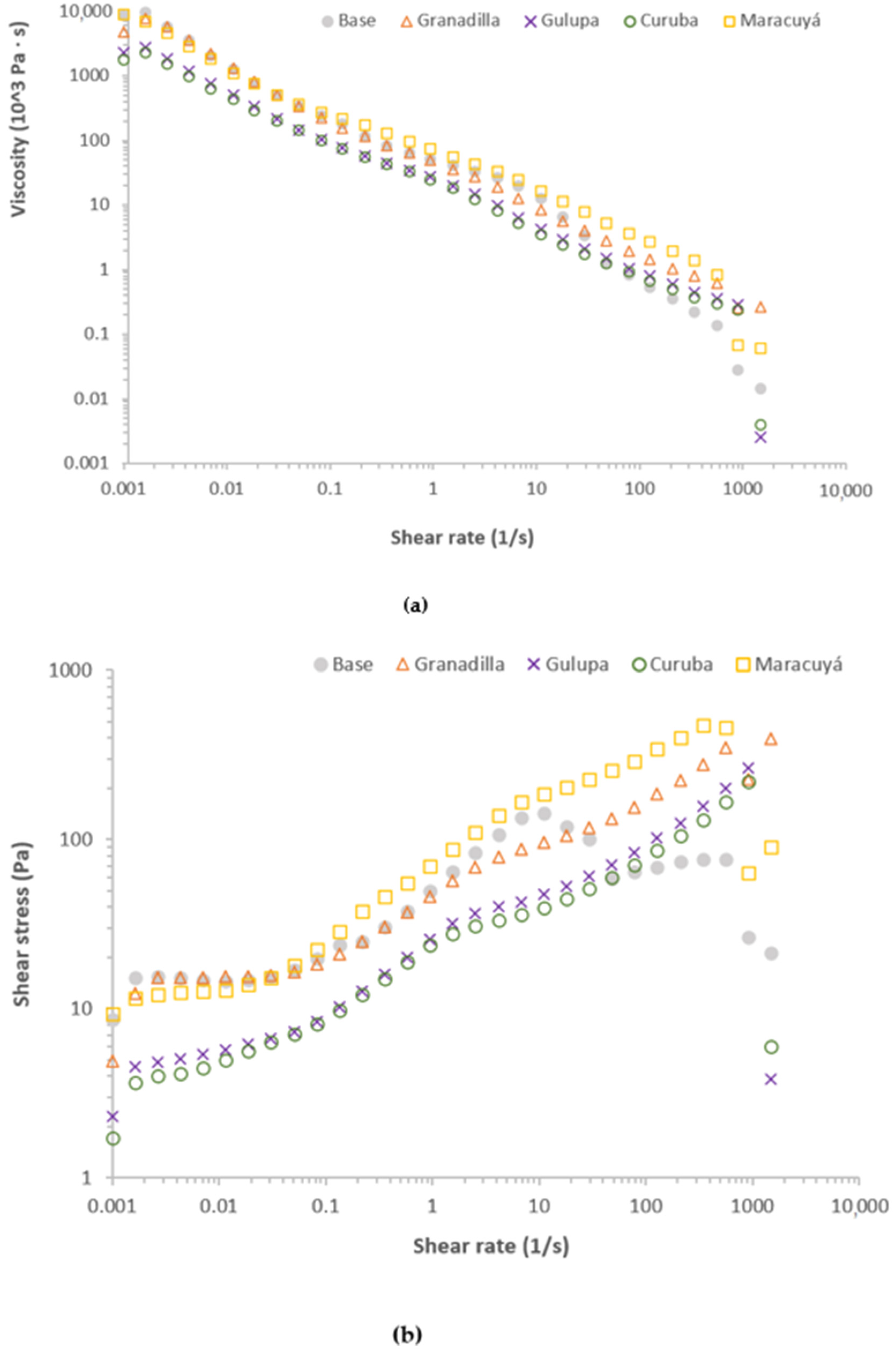

In general, all samples had a non-Newtonian behavior of a visco-elastic type (or visco-plastic), which is typical of emulsions used in cosmetic creams [

18]. The results obtained from the rheological characterization of samples are illustrated in

Figure 4. As noticed, all emulsions have similar rheological behavior and a similar viscosity. The slight differences with the base emulsion are caused by the addition of solid particles. This effect is less evident with the commercial product, which has less extractable organic materials. This indicates that extracted compounds from the obtained seeds are not only changing the pH but also the viscosity of the emulsion. The jump in the viscosity value is probably due to the yield stress of the emulsions, as it is a desired feature for this type of product that helps to prevent the suspending particles to sediment or separating from the bulk.

According to the shear stress results presented in

Figure 5, the base emulsion and the one prepared with the commercial seeds present slightly larger deformation stress than the other samples. This occurred because the prototypes emulsions prepared with ground Passiflora seeds exhibited lower viscosities, likely as a result of the extracted compounds. Nonetheless, changes are small, and all products behave similarly during stability tests, as discussed in the next section.

3.3. Stability Storage Test

Nonsignificant differences were observed in the samples subjected to thermal shocks. This result is positive because it shows no phase separation in the prototypes. However, the difference in the textural behavior (consistency and firmness) after the thermal shock of the emulsions could be related to the differences in pH, higher in the last two emulsions in which the viscosity increases. This higher pH could generate a partial neutralization of the stearic acid, present in the emulsion. This effect is not observed in emulsions with low pH values, for that reason their viscosities are lower. Despite an appearance change was expected as a result of the thermal treatment, the color of the prototypes did not change nor acquired unpleasant aromas. All emulsions remained homogeneous with no changes in perceived consistency. Although there was no instability in terms of emulsion separation in none of the samples, a thin water layer was observed on the surface of the emulsions with the ground seeds obtained in this study. This layer was very thin and disappeared at the time of homogenizing (15 min). The increase in temperature during the thermal shock may produce a higher extraction of acid components that change the pH such affecting viscosity.

The SEM images of the prototype emulsions before (left) and after the stability tests (right) are presented in

Figure 6. All samples had an average droplet size of 14.8 µm ± 1.66. This indicates that the presence of fruit seed powder does not change the drop size of the dispersed phase of the emulsion. On the other hand, stability tests did not cause an increase or decrease in droplet size either; however, greater coalescence (formation of joined droplets) can be observed. This is considered a characteristic factor prior to phase separation that can trigger emulsion rupture. This happens because the interface where the emulsifier is located is broken. A comparison between the pH values before and after thermal stability tests shows that, in general, the pH decreased in all the studied samples. This decrease was not significant in the case of the prototypes obtained with ground seeds of

P. edulis Sims fo

edulis and

P. mollissima. However, the sample with the highest pH change after testing was the base emulsion, indicating that there is greater instability from the emulsion formulation than from the ground seeds.

The texture analysis curve TA for the formula base emulsion after undergoing stability tests with temperature changes was presented in

Figure 3b. The behavior is the same as that observed in the sample prior stability tests; however, some changes in texture parameters are observed. For instance, an increase is observed in the areas of cohesion and adhesion, which implies an increase in the parameters of the base emulsion, as shown in

Table 3.

The texture parameters for most emulsions containing seeds showed a decrease with respect to the values obtained before the stability tests. This is related to the decrease in viscosity which, although small, represents changes in texture properties. An unexpected change was observed for the prototype with granadilla seeds since the values of the texture parameters slightly increased after stability tests. Finally, the sample of P. mollissima, was the one that presented a greater change in its texture parameters with respect to the initial values and with respect to the reference sample, which is also associated with its greater reduction of viscosity.

After performing thermal shocks during the stability tests (

Table 3), the behavior of the samples was the same, still exhibiting a non-Newtonian viscoelastic behavior. This fact suggests that the emulsions were also stable at the microstructure level. The viscosity of emulsions after the stability tests is presented in

Figure 7a, as well as changes in shear stress profiles

Figure 7b. The prototypes with ground seeds of

P. mollissima and

P. edulis Sims fo

edulis evidenced a decrease in the deformation stress in comparison to the product with granadilla seeds. However, these differences are minor, and all products still have a slightly small cutting effort than the base emulsion and the emulsion with commercial seeds.

The yield values of the two processes carried out did not differ greatly from each other for the fruits of P. edulis Sims fo edulis and P. ligularis; but in the case of P. mollissima, process A showed a higher yield than process B. Although the differences are not significant in performance, process B requires more drying time and only one grinding stage. Meanwhile, process A requires a shorter drying time and a second grinding stage.

According to the obtained results, the ground seeds are suitable for use in exfoliation since they have similar properties to commercial products, including their particle size distributions, hardness, and morphology. Likewise, exfoliating emulsions containing the here obtained ground seeds had similar behavior to those observed for the base emulsion and the emulsion with commercial seeds. This similar behavior was maintained even after a thermal stability test. An important outcome of this study was that the emulsions containing ground seeds reduced the pH, which is consistent with the extraction of organic acids. As the Passiflora genus is well known for the high content of AHA, the extracted acids may play a role in the chemical exfoliating capacity of the prepared emulsions. Further studies will be carried out for in vivo assessment to verify and quantify the exfoliating activity of the developed products.

4. Conclusions

This study focused on the extraction of Passiflora seeds from three different species (P. edulis Sims fo edulis, P. ligularis, and P. mollissima) and their further use as an exfoliating agent in a cosmetic emulsion. Extraction was carried out by two different methods, but there was no significant difference between them regarding yield and the characteristics of the extracted seeds. As such, it may be recommended to use the process that involved a shorter drying time and just one grinding stage. After characterization of ground seeds, most particles had sizes between 0.5–1 mm, similar to the commercial exfoliating seeds. The moisture content of the dry seeds was slightly higher than that of the P. mollissima product, which is consistent with the higher moisture content of the fruit pulp. This indicates that longer drying times are required to match the required specifications of the commercial product. Additionally, the obtained ground seeds had a large extractable material content, which indicated that the commercial product was pretreated or rinsed and that only the physical exfoliation action was exploited. Once the commercial and extracted seeds were used for the formulation of an exfoliating emulsion, the obtained seeds generated a reduction in the pH of emulsion. This behavior was expected as the Passiflora species have a high content of alpha-hydroxy acids. The extraction of such acidic compounds was intended to enable exploiting the chemical and physical exfoliating action of extracted seeds. Despite some compounds being extracted from the seeds into the emulsion, texture analysis and rheology characterization indicated minor changes with respect to the behavior of the base emulsion. This was also verified after performing thermal stability tests in the prepared prototype products. All prototypes exhibited a viscoelastic behavior, which is characteristic of emulsions in general. Further studies will be carried out for in vivo assessment to assess the exfoliating activity of the developed emulsions.