Quantitative Sensory Interpretation of Rheological Parameters of a Cream Formulation

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Preparation of Niosomes

2.2.2. Preparation of Creams

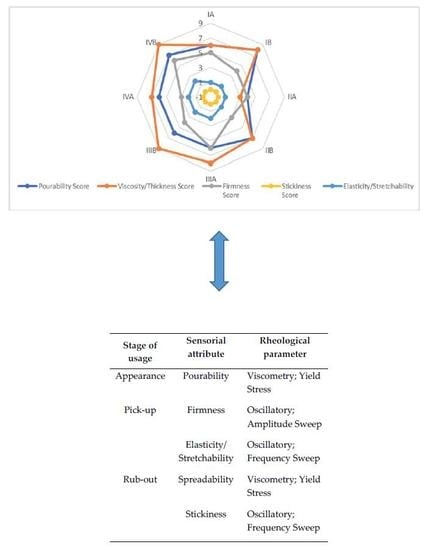

2.2.3. Sensory Lexicons and Definitions

2.2.4. Instrumental Rheology and Sensory Characterization

- Yield Stress: pourability and spreadability—a stress range of 0.001 Pa to 10,000 Pa at a ramp time of 2 min and a decade of 10 was applied.

- Strain Amplitude Sweep with LVR Determination: firmness—the samples were oscillated over a shear stress range of 0.001 Pa to 10,000 Pa, at a frequency of 1 Hz and a decade of 10.

- Frequency Sweep: stickiness and elasticity or stretchability—the samples were oscillated over a frequency range of 50 to 0.05 Hz, at a % strain within the LVR.

2.2.5. Statistical Analysis

3. Results and Discussion

3.1. Rheology and Sensory Characterization

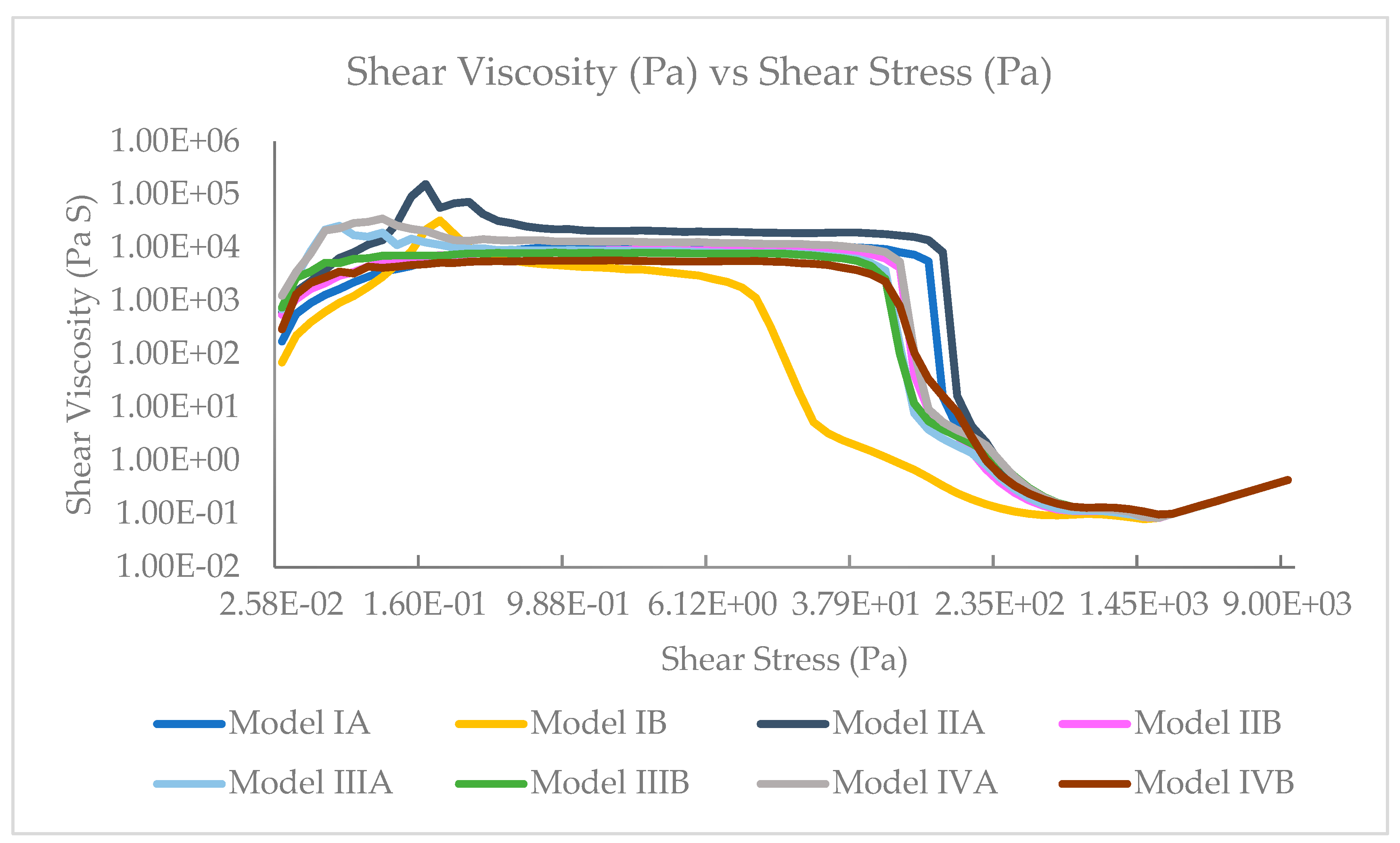

3.1.1. Yield Stress: Pourability and Spreadability

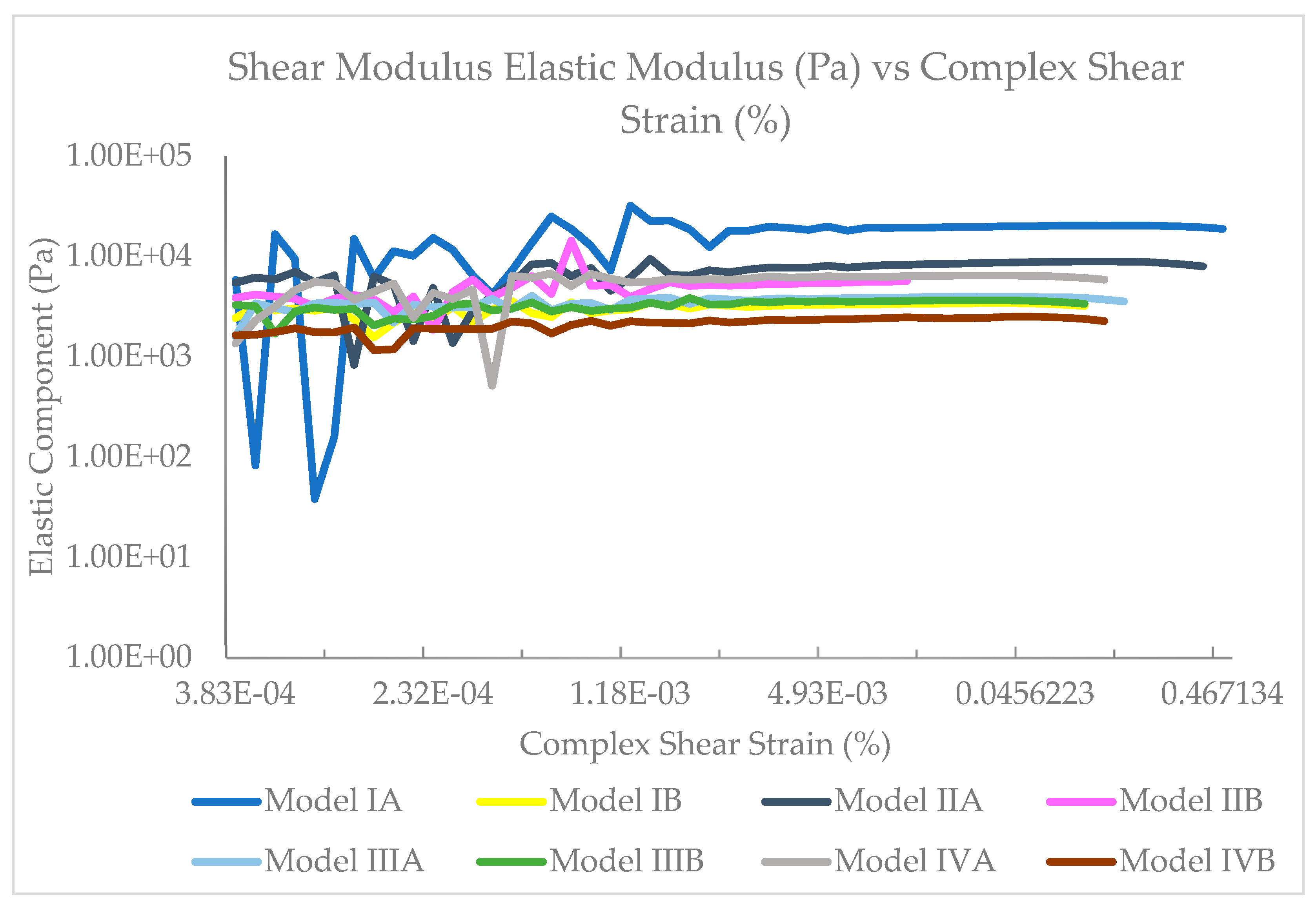

3.1.2. Stress (Strain) Amplitude Sweep with LVR Determination: Firmness

3.1.3. Frequency Sweep; Stickiness and Elasticity or Stretchability

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chang, W.C.; Wu, T.Y. Exploring types and characteristics of product forms. Int. J. Des. 2007, 1, 1–3. [Google Scholar]

- Liao, S.H.; Hsieh, C.L.; Huang, S.P. Mining product maps for new product development. Expert Syst. Appl. 2008, 34, 1–50. [Google Scholar] [CrossRef]

- Durán, S.S.; Sánchez, J.S. Sensory Studies. In Bee Products-Chemical and Biological Properties; Springer: Berlin/Heidelberg, Germany, 2017; pp. 21–41. [Google Scholar]

- Bonod, I.; Sandoz, J.C.; Loublier, Y.; Pham-Delègue, M.H. Learning and discrimination of honey odours by the honeybee. Apidologie 2003, 34, 2–147. [Google Scholar] [CrossRef][Green Version]

- Galán-Soldevilla, H.; Ruiz-Pérez-Cacho, M.P.; Jimenez, S.S.; Villarejo, M.J.; Manzanares, A.B. Development of a preliminary sensory lexicon for floral honey. Food Qual. Prefer. 2005, 16, 1–71. [Google Scholar] [CrossRef]

- Serra Bonvehi, J.; Ventura Coll, F. Characterization of citrus honey (Citrus spp.) produced in Spain. J. Agric. Food Chem. 1995, 43, 2053–2057. [Google Scholar] [CrossRef]

- Piana, M.L.; Oddo, L.P.; Bentabol, A.; Bruneau, E.; Bogdanov, S.; Declerck, C.G. Sensory analysis applied to honey: State of the art. Apidologie 2004, 35, S26–S37. [Google Scholar] [CrossRef]

- ISO 6658:2017. Sensory Analysis—Methodology—General Guidance, International Organization for Standardization. ISO. 2019. Available online: https://www.iso.org/standard/65519.html (accessed on 20 September 2019).

- Murray, J.M.; Delahunty, C.M.; Baxter, I.A. Descriptive sensory analysis: Past, present and future. Food Res. Int. 2001, 34, 6–461. [Google Scholar] [CrossRef]

- Pensé-Lhéritier, A.M. Recent developments in the sensorial assessment of cosmetic products: A review. Int. J. Cosmet. Sci. 2015, 37, 465–473. [Google Scholar] [CrossRef] [PubMed]

- Gilbert, L.; Savary, G.; Grisel, M.; Picard, C. Predicting sensory texture properties of cosmetic emulsions by physical measurements. Chemom. Intell. Lab. Syst. 2013, 124, 21–31. [Google Scholar] [CrossRef]

- Montenegro, L.; Rapisarda, L.; Ministeri, C.; Puglisi, G. Effects of lipids and emulsifiers on the physicochemical and sensory properties of cosmetic emulsions containing vitamin E. Cosmetics 2015, 2, 35–47. [Google Scholar] [CrossRef]

- Varela, P.; Ares, G. Sensory profiling, the blurred line between sensory and consumer science. A review of novel methods for product characterization. Food Res. Int. 2012, 48, 2–893. [Google Scholar] [CrossRef]

- Tabilo-Munizaga, G.; Barbosa-Cánovas, G.V. Rheology for the food industry. J. Food Eng. 2005, 67, 147–156. [Google Scholar] [CrossRef]

- Cheng, D.C. Yield stress: A time-dependent property and how to measure it. Rheol. Acta 1986, 25, 5–542. [Google Scholar] [CrossRef]

- Barnes, H.A. The yield stress—A review or ‘παντα ρει’—Everything flows? J. Non-Newton. Fluid Mech. 1999, 81, 133–178. [Google Scholar] [CrossRef]

- Stokes, J.R.; Telford, J.H. Measuring the yield behaviour of structured fluids. J. Non-Newton. Fluid Mech. 2004, 124, 137–146. [Google Scholar] [CrossRef]

- Rueda, M.M.; Auscher, M.C.; Fulchiron, R.; Perie, T.; Martin, G.; Sonntag, P.; Cassagnau, P. Rheology and applications of highly filled polymers: A review of current understanding. Prog. Polym. Sci. 2017, 66, 22–53. [Google Scholar] [CrossRef]

- Ho, K.Y.; Dodou, K. Rheological studies on pressure-sensitive silicone adhesives and drug-in-adhesive layers as a means to characterise adhesive performance. Int. J. Pharm. 2007, 333, 24–33. [Google Scholar] [CrossRef]

- Souto, E.B.; Gohla, S.H.; Müller, R.H. Rheology of nanostructured lipid carriers (NLC®) suspended in a viscoelastic medium. Die Pharm. Int. J. Pharm. Sci. 2005, 60, 9–671. [Google Scholar]

- Mason, T.G. New fundamental concepts in emulsion rheology. Curr. Opin. Colloid Interface Sci. 1999, 4, 231–238. [Google Scholar] [CrossRef]

| Phase | INCI | Composition (%) | IA | IB | IIA | IIB | IIIA | IIIB | IVA | IVB |

|---|---|---|---|---|---|---|---|---|---|---|

| Oil | Stearyl Alcohol | Stearyl Alcohol | 1 | 1 | 1 | 1 | ||||

| Simmondsia Chinensis Seed Oil | Jojoba Oil | 4 | 4 | 5 | 5 | 5 | 5 | |||

| Adansonia Digitata Seed Oil | Baobab Oil | 4 | 4 | 5 | 5 | 5 | 5 | |||

| Cocos nucifera | Coconut Oil | 5 | 5 | 5 | 5 | |||||

| Water | Glycerin | Glycerine | 5 | 5 | 5 | 5 | 5 | 5 | ||

| Propylene Glycol | Propylene Glycol | 5 | 5 | |||||||

| Aqua | Water | 73.7 | 78.7 | 71.7 | 76.7 | 71.7 | 76.7 | 71.7 | 76.7 | |

| Active | - | Entrapped Active | 5 | 5 | 5 | 5 |

| Stage of Usage | Sensorial Attribute | Description | Rheological Parameter |

|---|---|---|---|

| Appearance | Pourability | Ability of a product to flow or be pumped out of the container when a force is applied. | Viscometry; Yield Stress |

| Pick-up | Firmness | The degree to which the product is able to hold its shape or structure in the presence of force. | Oscillatory; Amplitude Sweep |

| Elasticity/ Stretchability | It is the ability of the product to deform or expand (strain) by resisting an external force (stress). | Oscillatory; Frequency Sweep | |

| Rub-out | Spreadability | The force required to cause flow of the product. | Viscometry; Yield Stress |

| Stickiness | Ability of product to attach to the skin, yielding a sticky skin feel. | Oscillatory; Frequency Sweep |

| Score | Yield Stress Values (Pa) | Viscosity/Thickness (Pa S) | Strain Amplitude Sweep (Pa) |

|---|---|---|---|

| 0 | 181–200 | 171,000–190,000 | <0.010 |

| 1 | 161–180 | 151,000–170,000 | 0.011–0.020 |

| 2 | 141–160 | 131,000–150,000 | 0.021–0.040 |

| 3 | 121–140 | 111,000–130,000 | 0.041–0.060 |

| 4 | 101–120 | 91,000–110,000 | 0.061–0.080 |

| 5 | 81–100 | 71,000–90,000 | 0.081–0.100 |

| 6 | 61–80 | 51,000–70,000 | 0.101–0.200 |

| 7 | 41–60 | 31,000–50,000 | 0.201–0.400 |

| 8 | 21–40 | 11,000–30,000 | 0.401–0.600 |

| 9 | 0–20 | <10,000 | 0.601–0.800 |

| Score | Yield Stress Values (Pa)—Pourability | Viscosity/Thickness (Pa S)—Spreadability | Strain Amplitude Sweep (Pa)—Firmness |

|---|---|---|---|

| 0 | 151–200 | 151,000–200,000 | <0.200 |

| 1 | 101–150 | 101,000–150,000 | 0.201–0.400 |

| 2 | 51–100 | 51,000–100,000 | 0.401–0.600 |

| 3 | 0–50 | <50,000 | 0.601–0.800 |

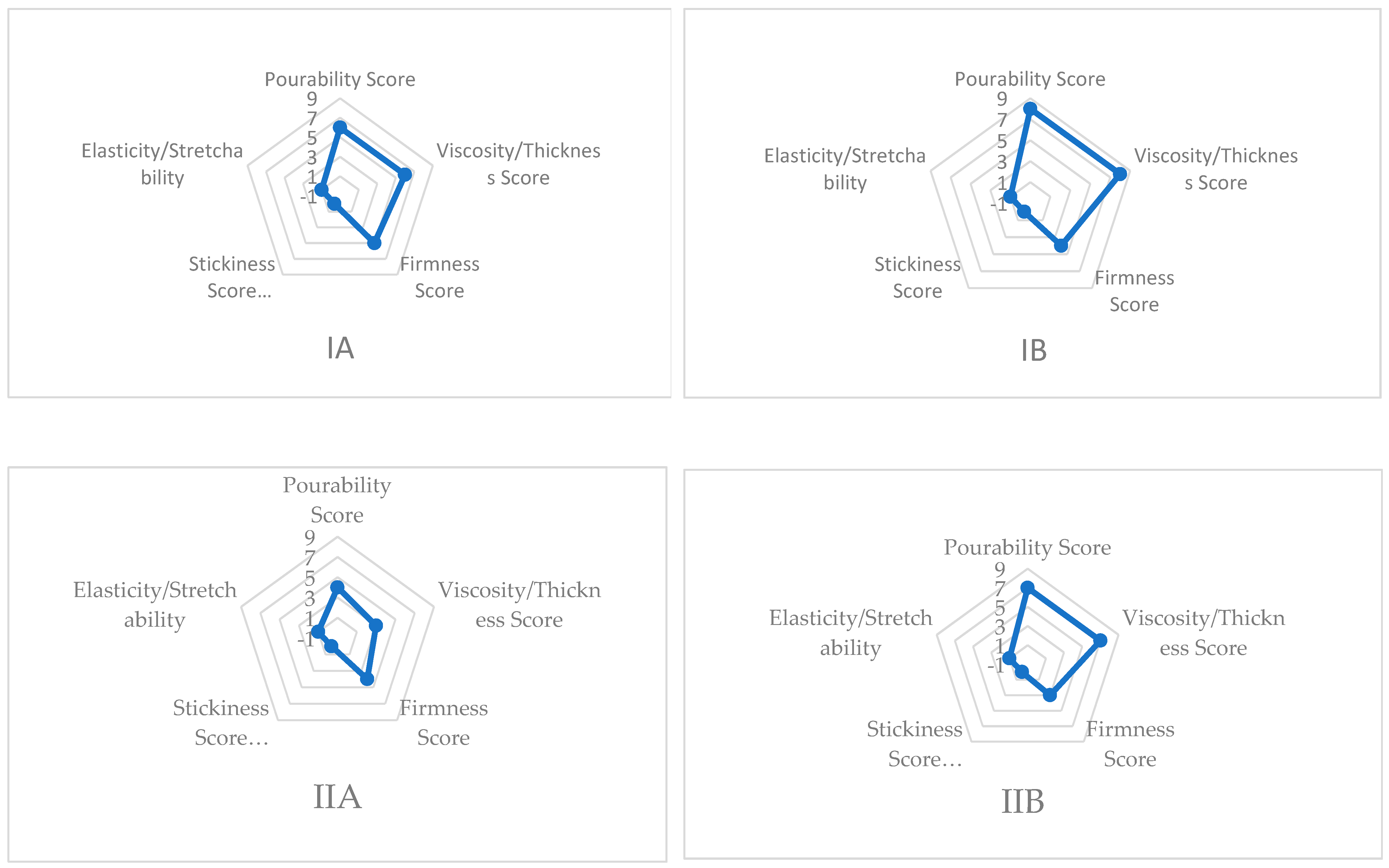

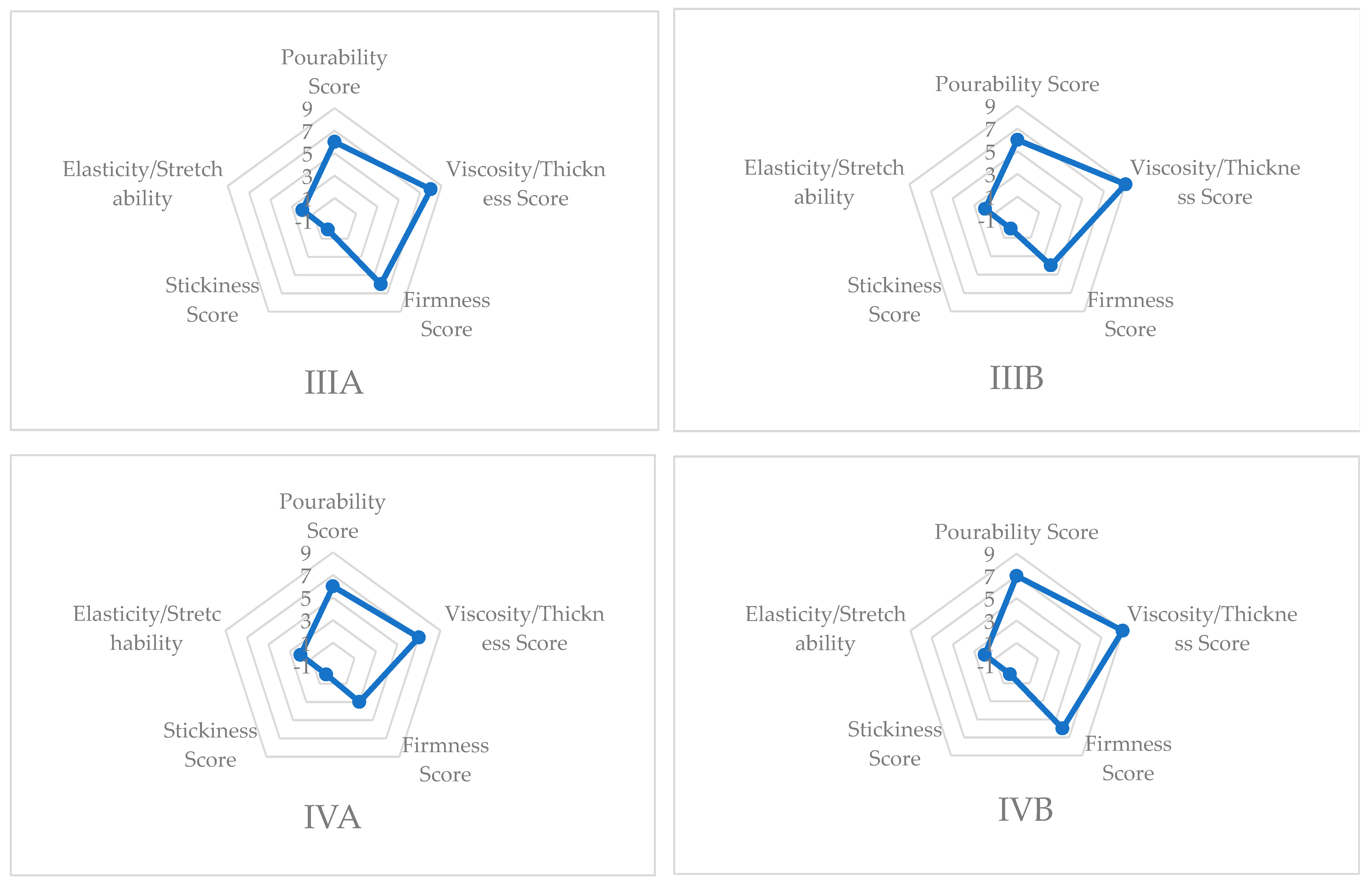

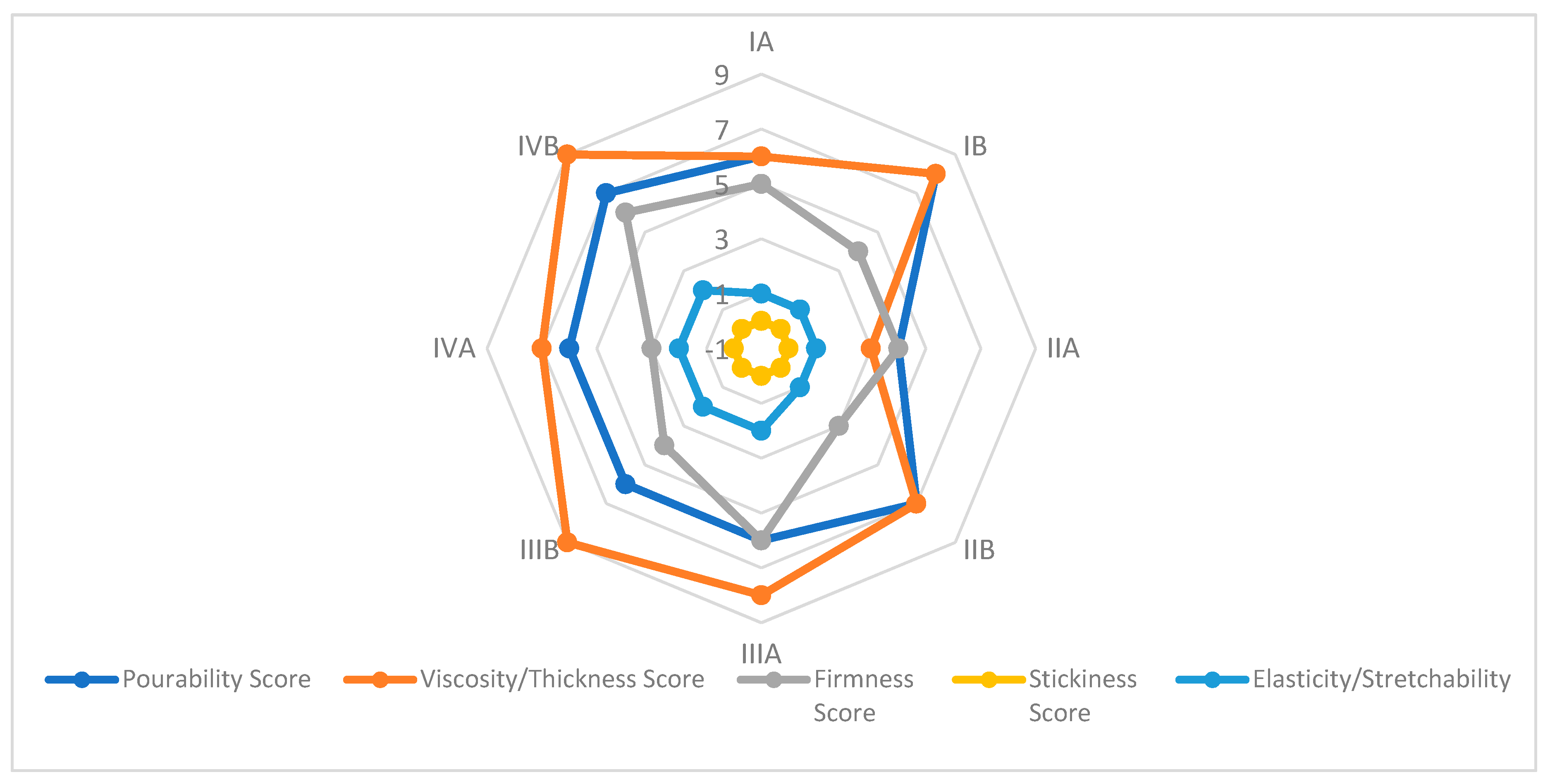

| Model | Mean Yield Stress (Pa) | Pourability Score | Mean Viscosity/ Thickness (PaS) | Spreadability Score | Mean Shear Strain within the LVR | Firmness Score |

|---|---|---|---|---|---|---|

| IA | 79 ± 15.8 | 6 | 53,270 ± 3010 | 6 | 9.755E−002 ± 6.028E−003 | 5 |

| IB | 26 ± 15.5 | 8 | 21,590 ± 1090 | 8 | 7.206E−002 ± 6.513E−003 | 4 |

| IIA | 112 ± 22.3 | 4 | 117,302 ± 36,498 | 3 | 7.268E−002 ± 6.628E−003 | 4 |

| IIB | 48 ± 15.2 | 7 | 34,358 ± 9249 | 7 | 5.077E−002 ± 2.341E−002 | 3 |

| IIIA | 66 ± 10.5 | 6 | 20,100 ± 3874 | 8 | 1.022E−001 ± 9.295E−003 | 6 |

| IIIB | 67 ± 10.5 | 6 | 8085 ± 15 | 9 | 6.844E−002 ± 2.498E−002 | 4 |

| IVA | 75 ± 7.5 | 6 | 38,050 ± 4550 | 7 | 4.910E−002 ± 1.007E−002 | 3 |

| IVB | 46 ± 9.2 | 7 | 4767 ± 1067 | 9 | 1.272E−001 ± 1.905E−003 | 6 |

| Score | Elasticity/Stretchability | Stickiness |

|---|---|---|

| 0 | Non-Stretchy | Non-Sticky |

| 1 | Moderately Stretchy | Moderately Sticky |

| 2 | Stretchy | Sticky |

| 3 | Very Stretchy | Very Sticky |

| Model | Stickiness | Score | Elasticity/Stretchability | Score |

|---|---|---|---|---|

| IA | Non-Sticky | 0 | Moderately Stretchy | 1 |

| IB | Non-Sticky | 0 | Moderately Stretchy | 1 |

| IIA | Non-Sticky | 0 | Moderately Stretchy | 1 |

| IIB | Non-Sticky | 0 | Moderately Stretchy | 1 |

| IIIA | Non-Sticky | 0 | Stretchy | 2 |

| IIIB | Non-Sticky | 0 | Stretchy | 2 |

| IVA | Non-Sticky | 0 | Stretchy | 2 |

| IVB | Non-Sticky | 0 | Stretchy | 2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adejokun, D.A.; Dodou, K. Quantitative Sensory Interpretation of Rheological Parameters of a Cream Formulation. Cosmetics 2020, 7, 2. https://doi.org/10.3390/cosmetics7010002

Adejokun DA, Dodou K. Quantitative Sensory Interpretation of Rheological Parameters of a Cream Formulation. Cosmetics. 2020; 7(1):2. https://doi.org/10.3390/cosmetics7010002

Chicago/Turabian StyleAdejokun, Deborah Adefunke, and Kalliopi Dodou. 2020. "Quantitative Sensory Interpretation of Rheological Parameters of a Cream Formulation" Cosmetics 7, no. 1: 2. https://doi.org/10.3390/cosmetics7010002

APA StyleAdejokun, D. A., & Dodou, K. (2020). Quantitative Sensory Interpretation of Rheological Parameters of a Cream Formulation. Cosmetics, 7(1), 2. https://doi.org/10.3390/cosmetics7010002