Compressive Behaviour of Coconut Fibre (Cocos nucifera) Reinforced Concrete at Elevated Temperatures

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

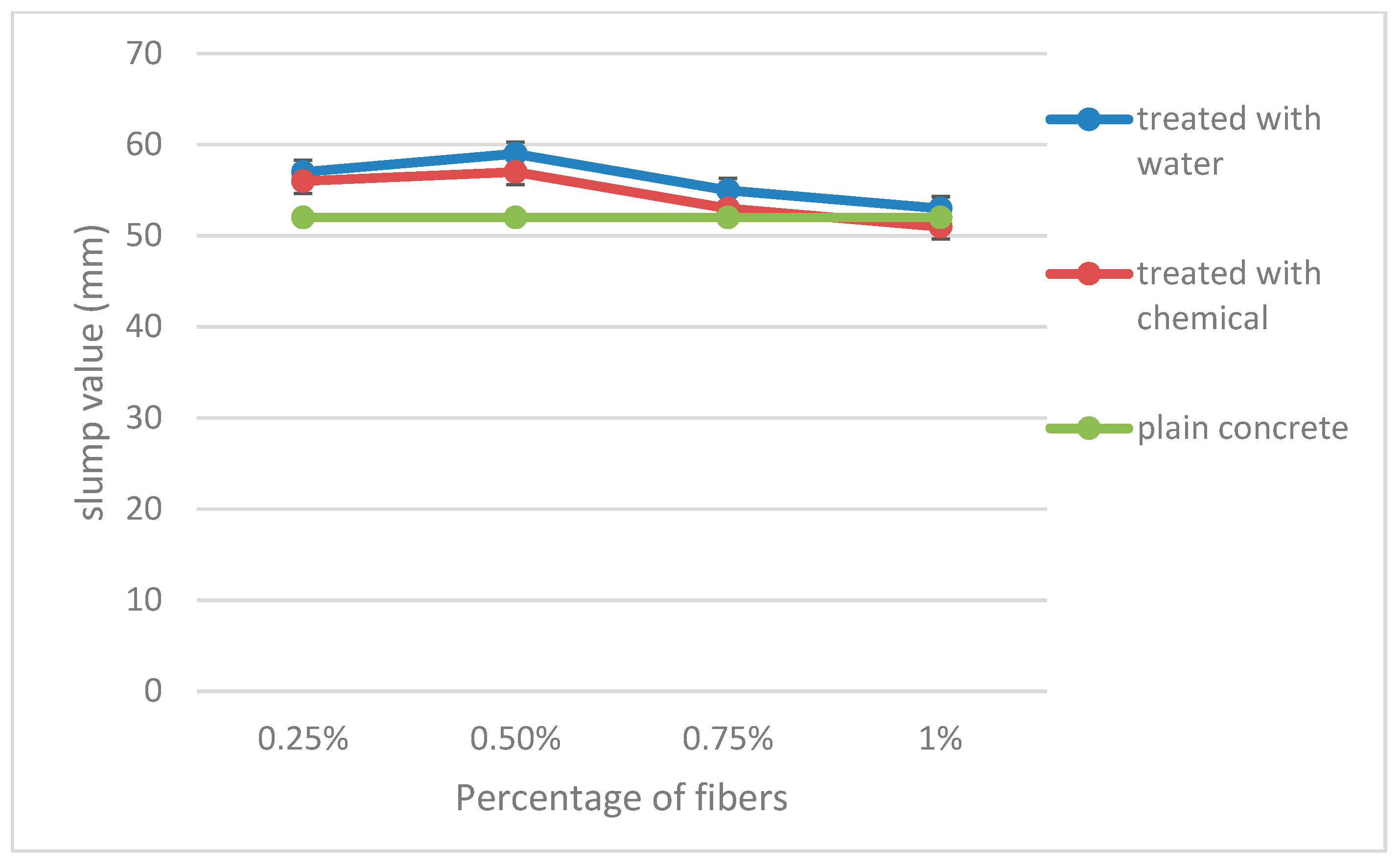

3.1. Test on Fresh Concrete

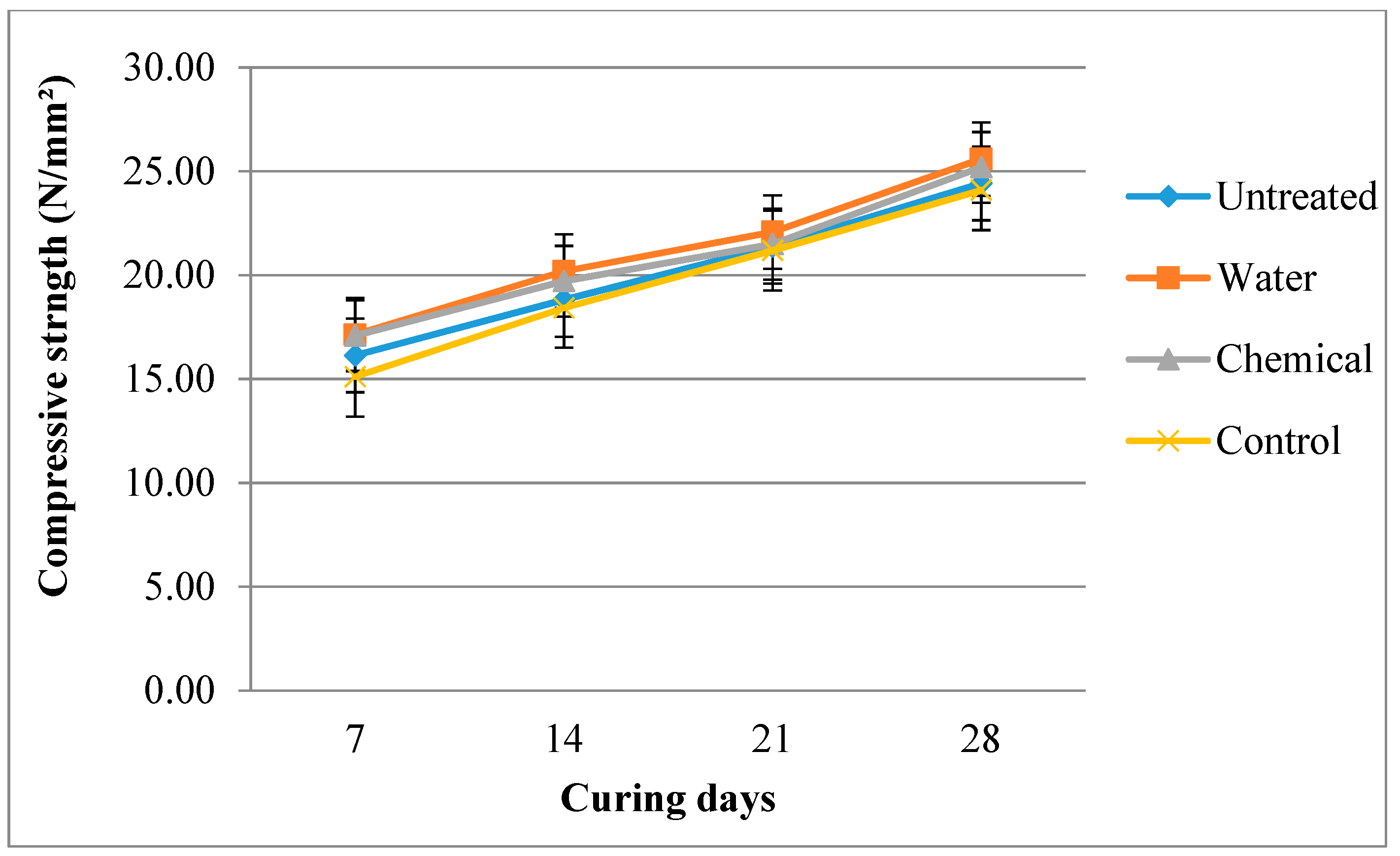

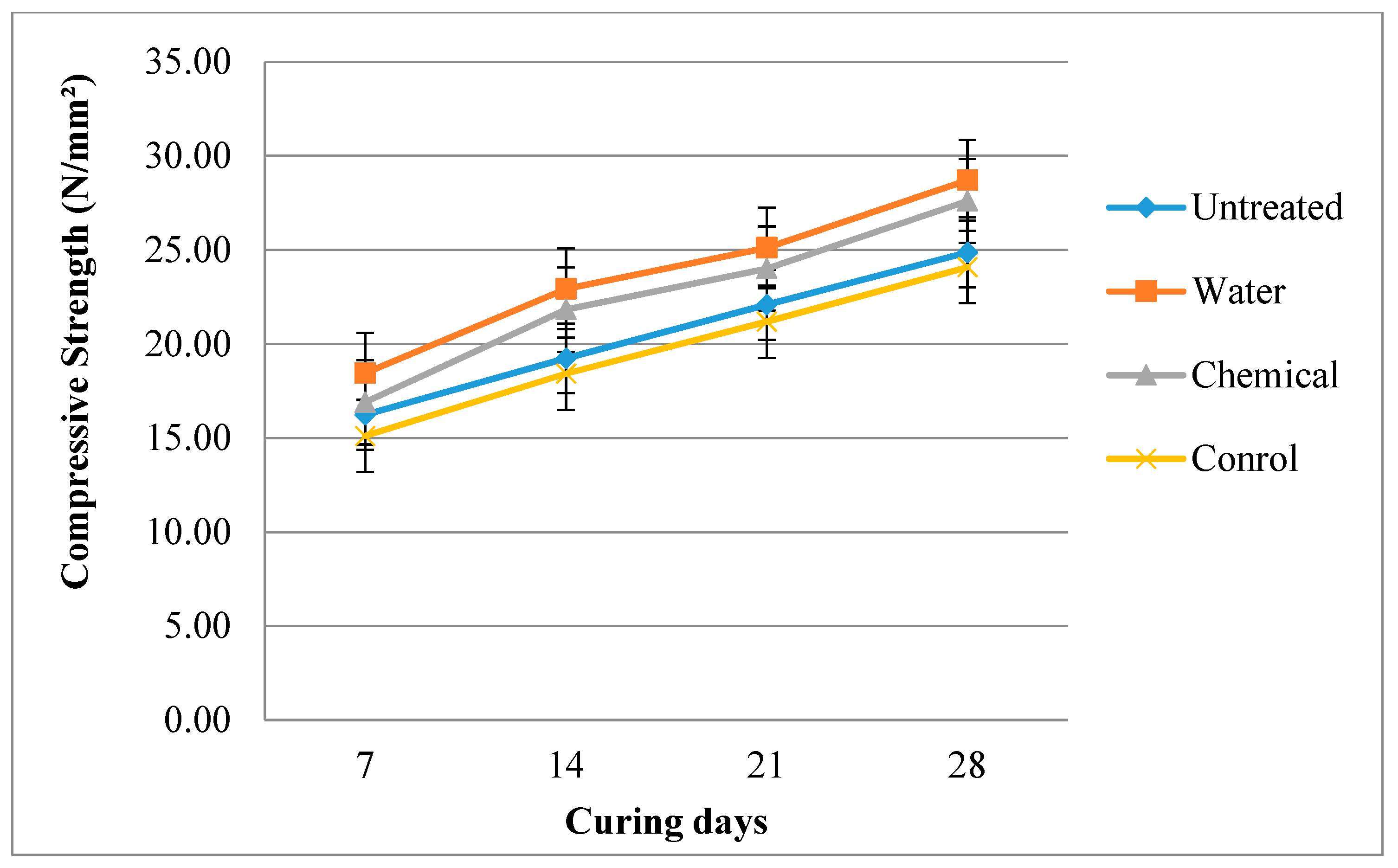

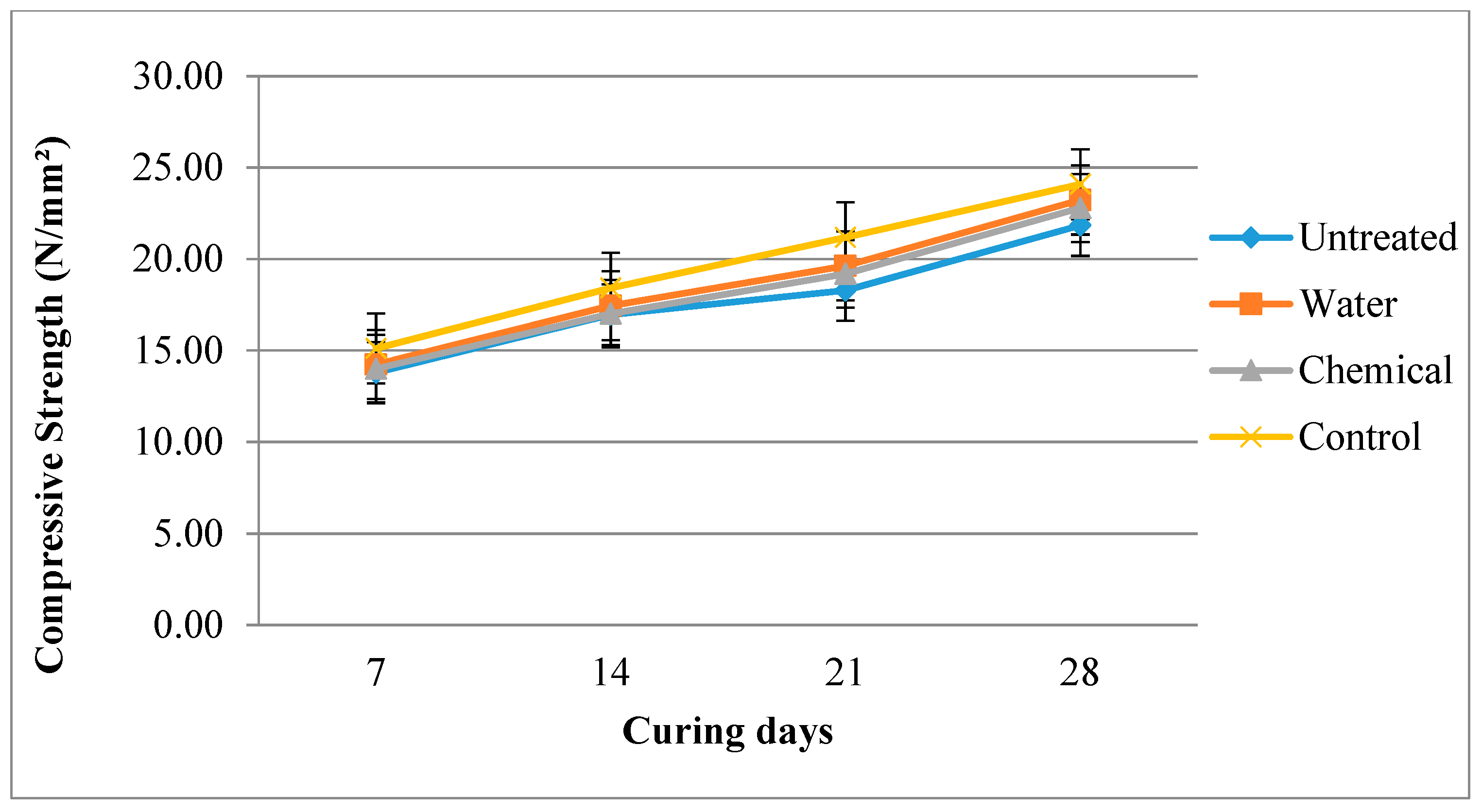

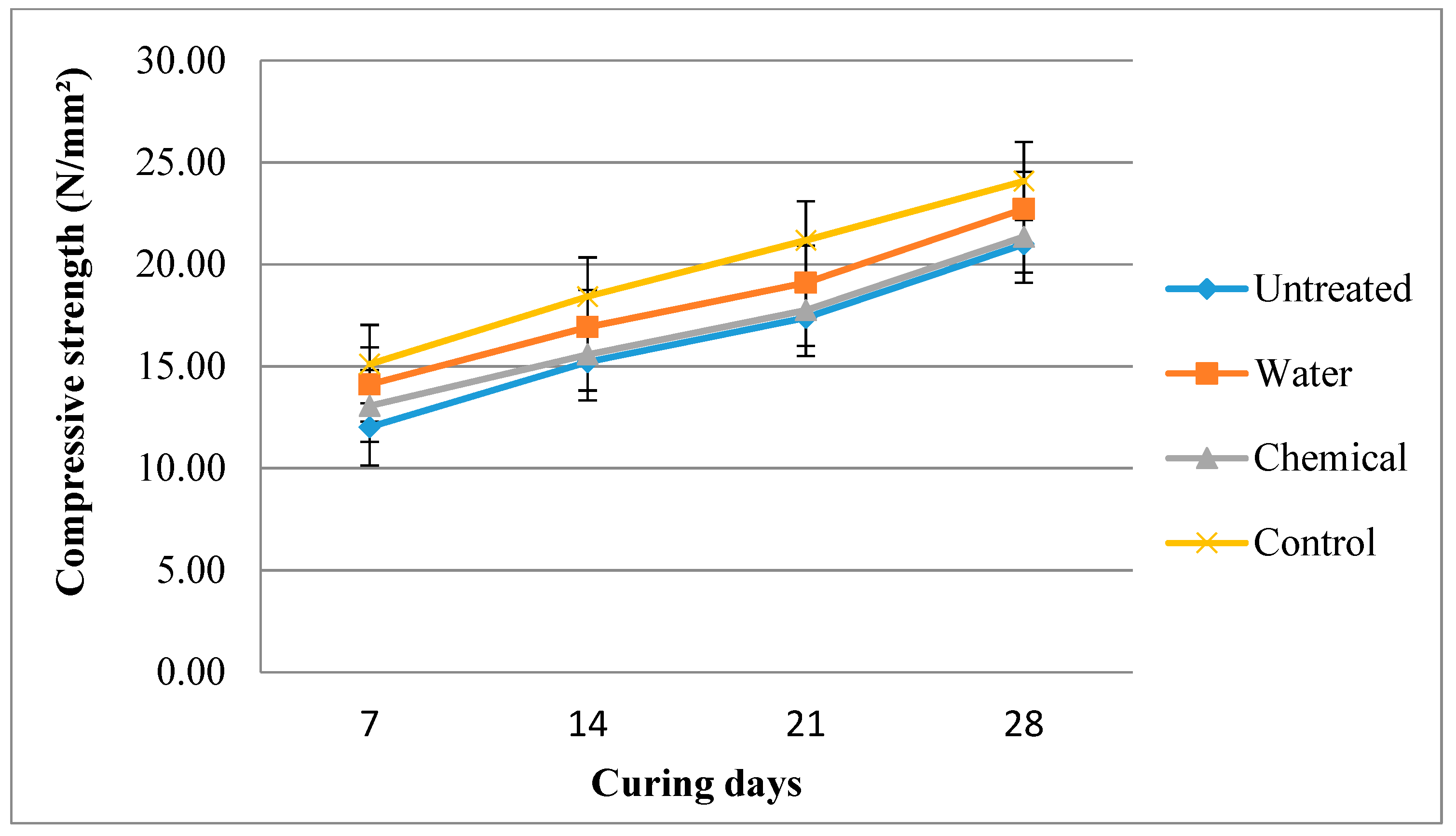

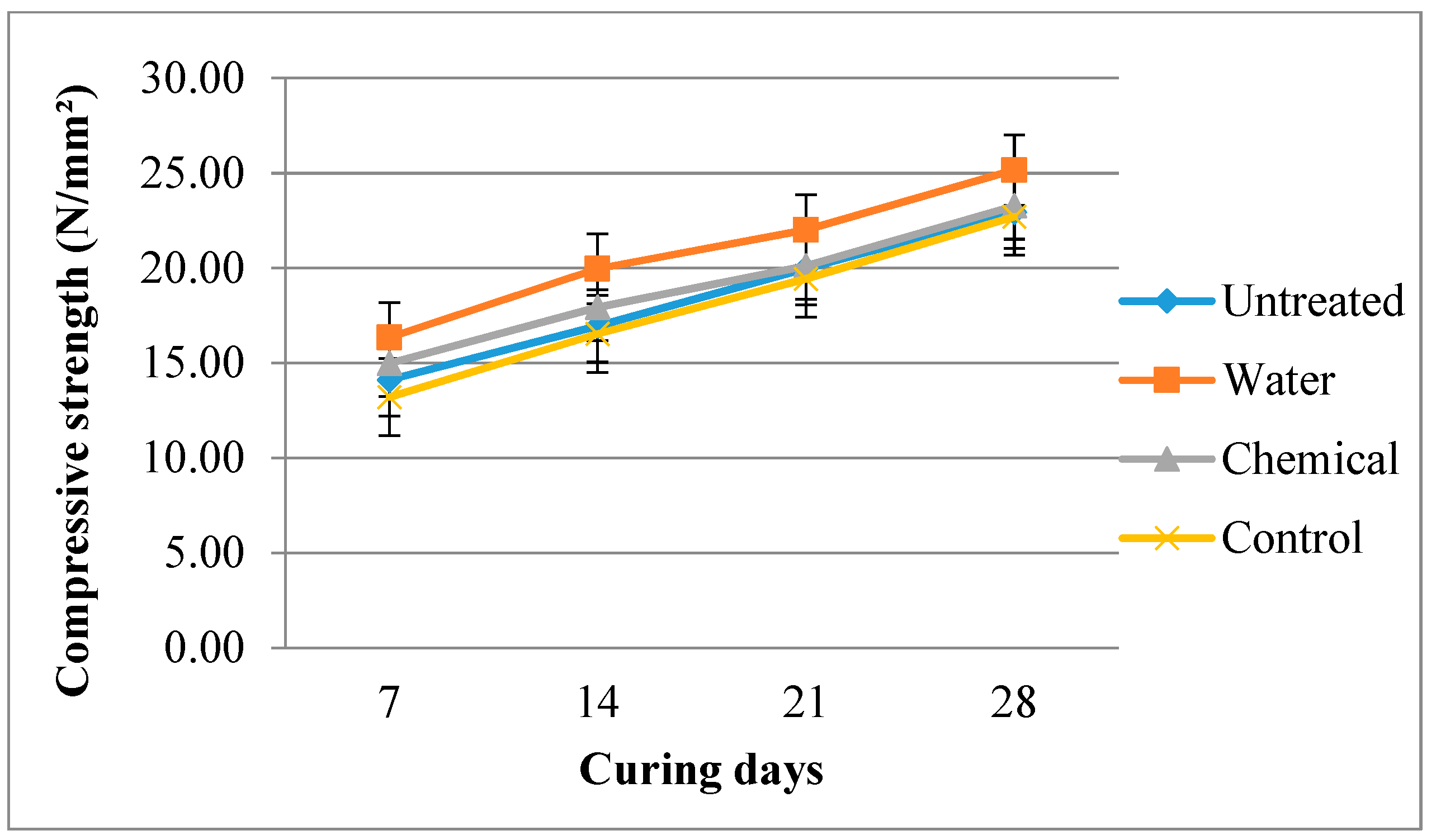

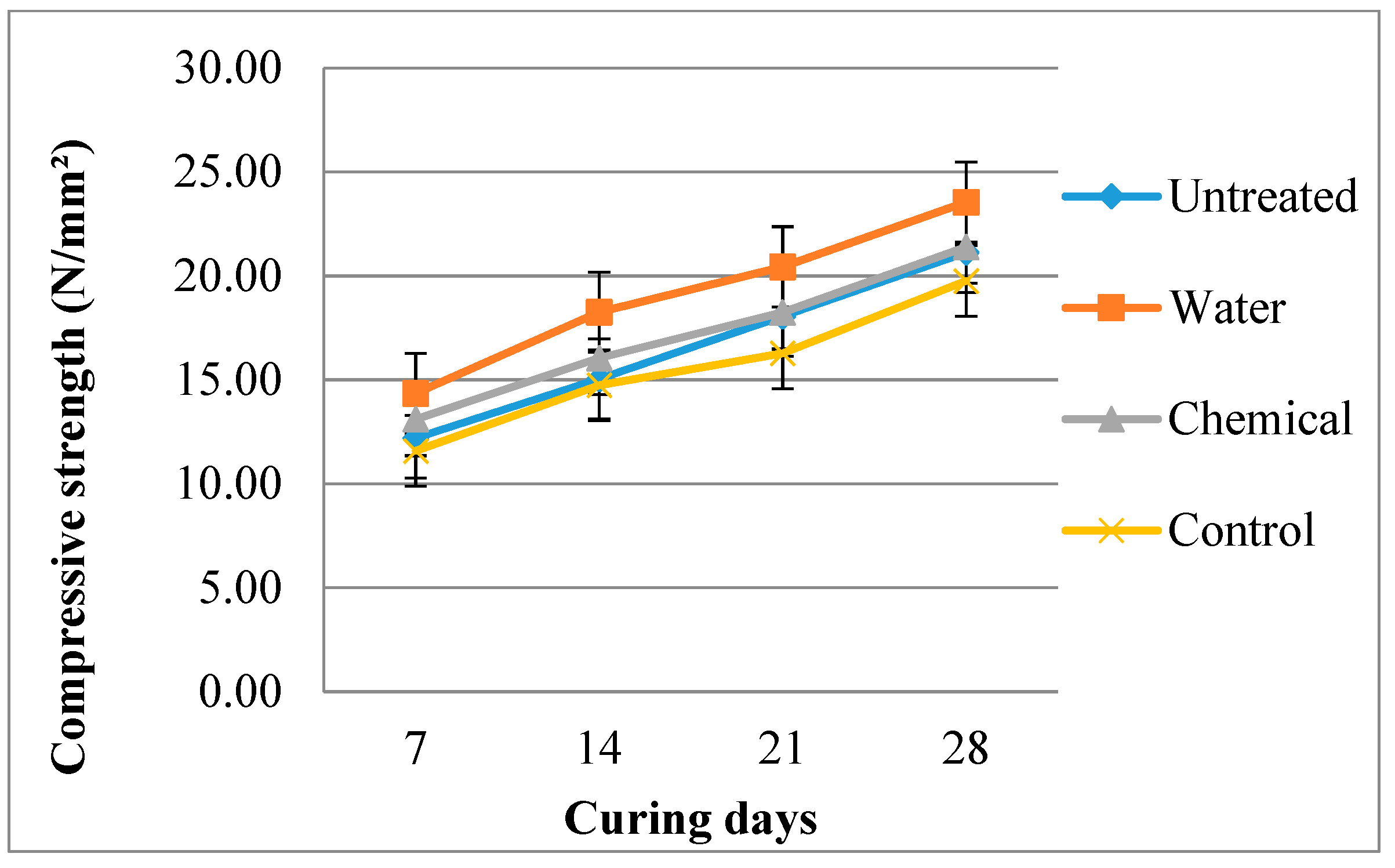

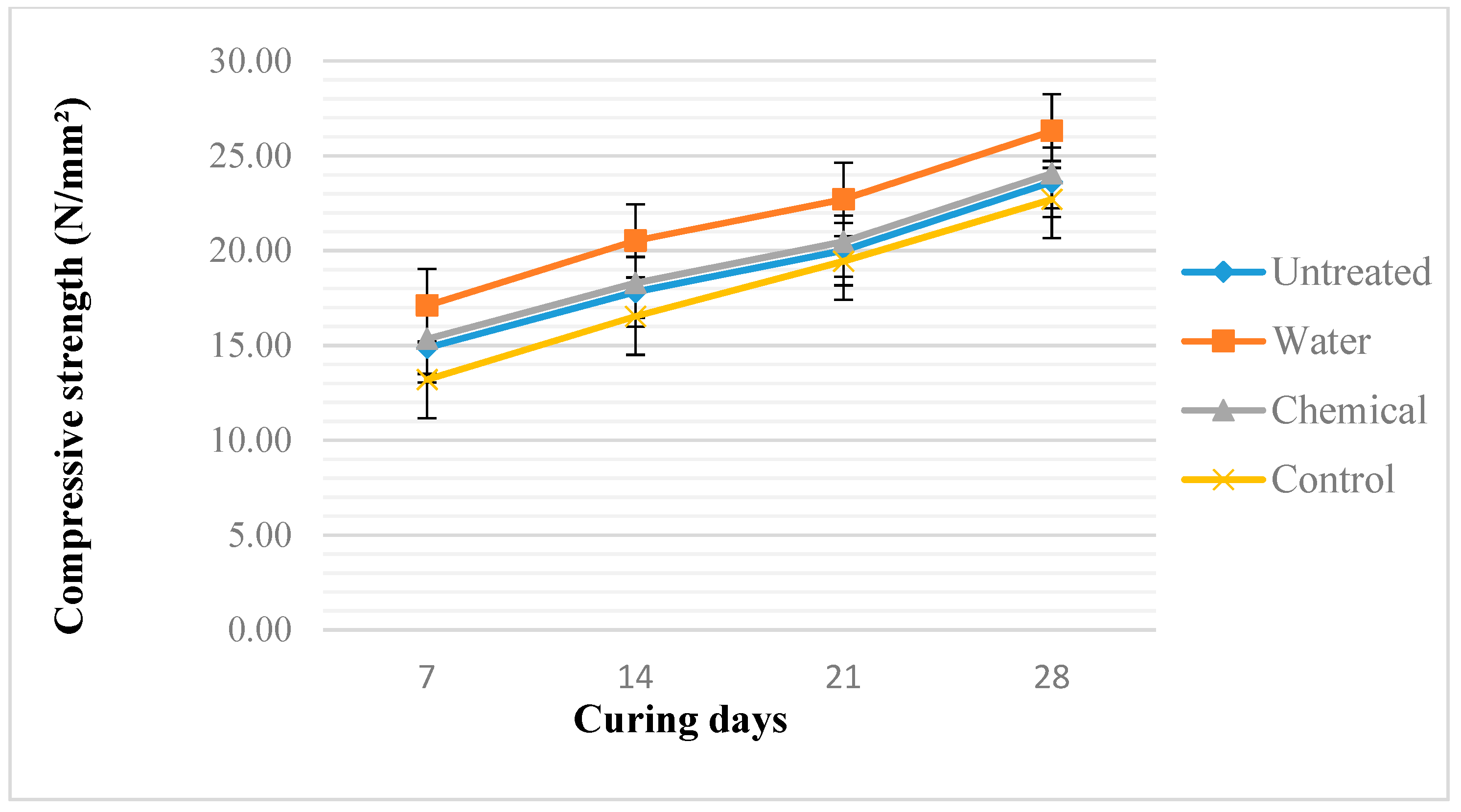

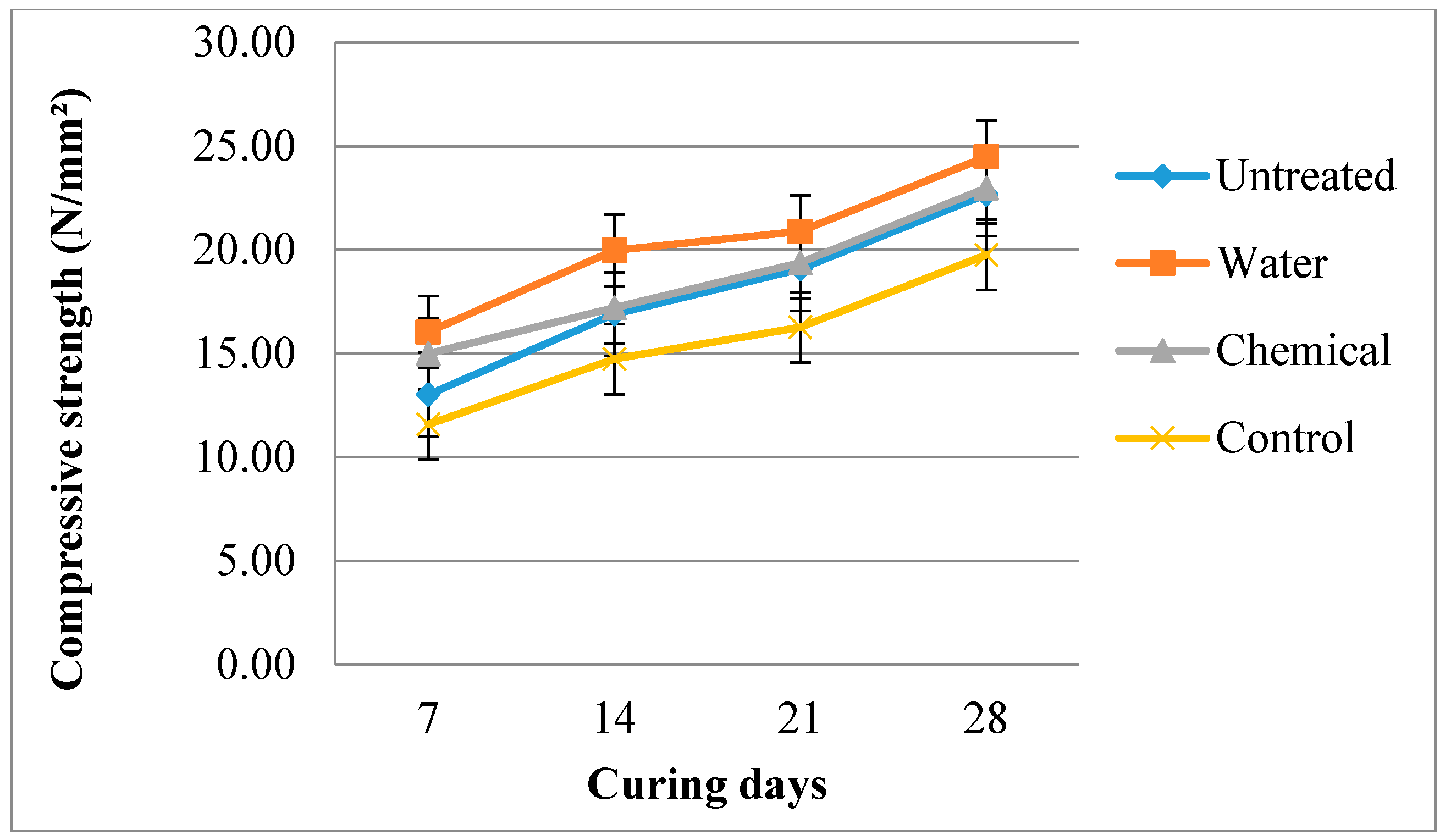

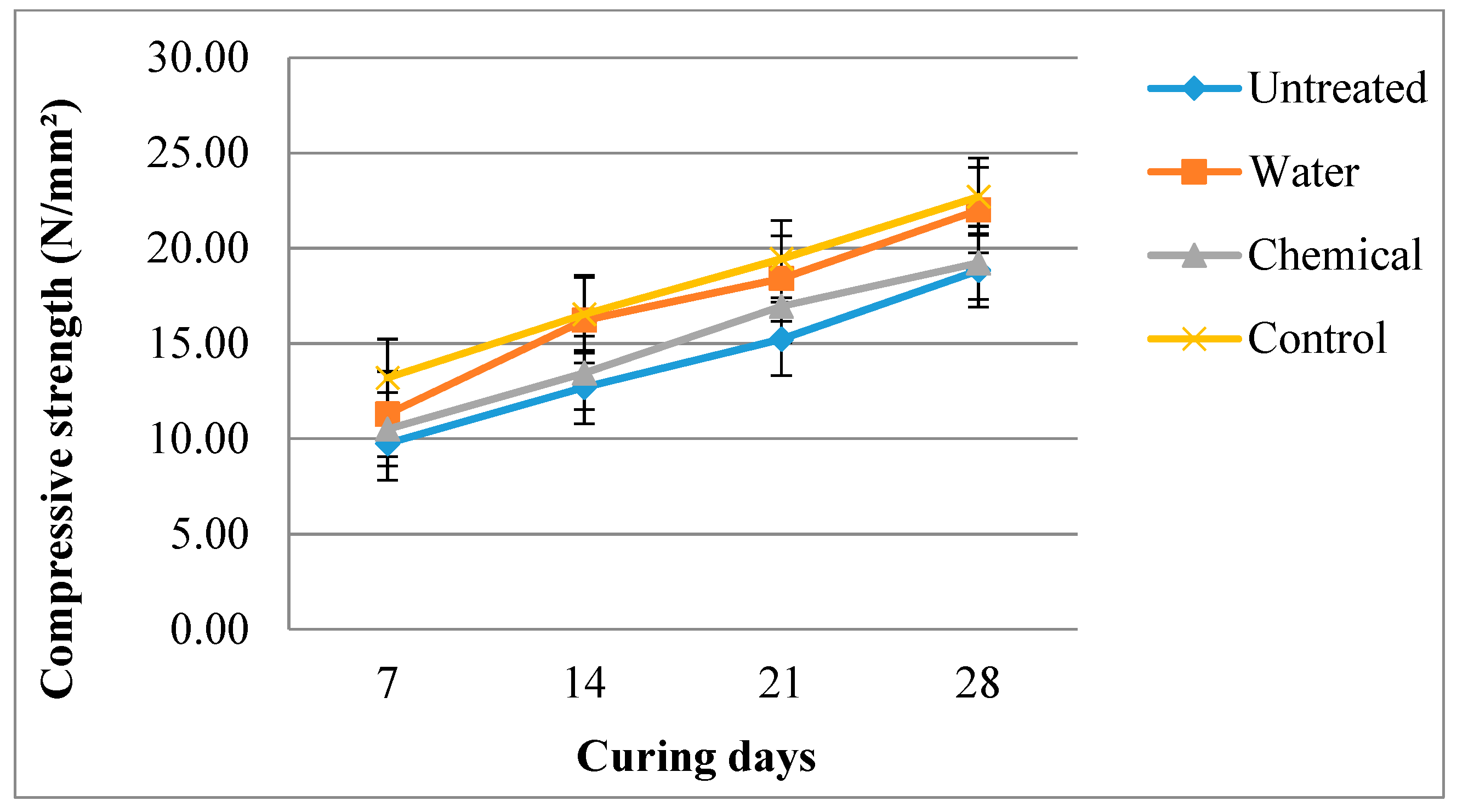

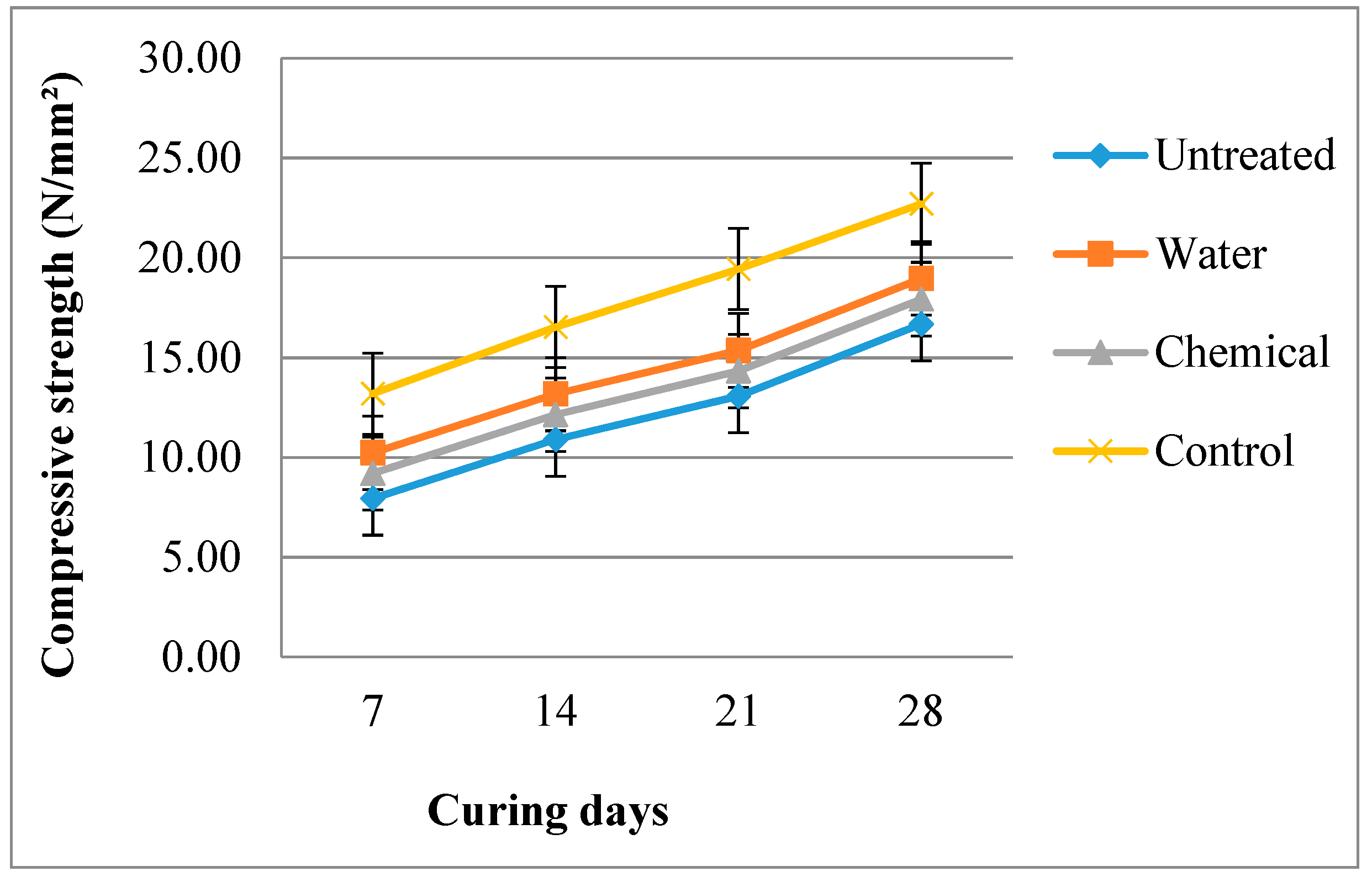

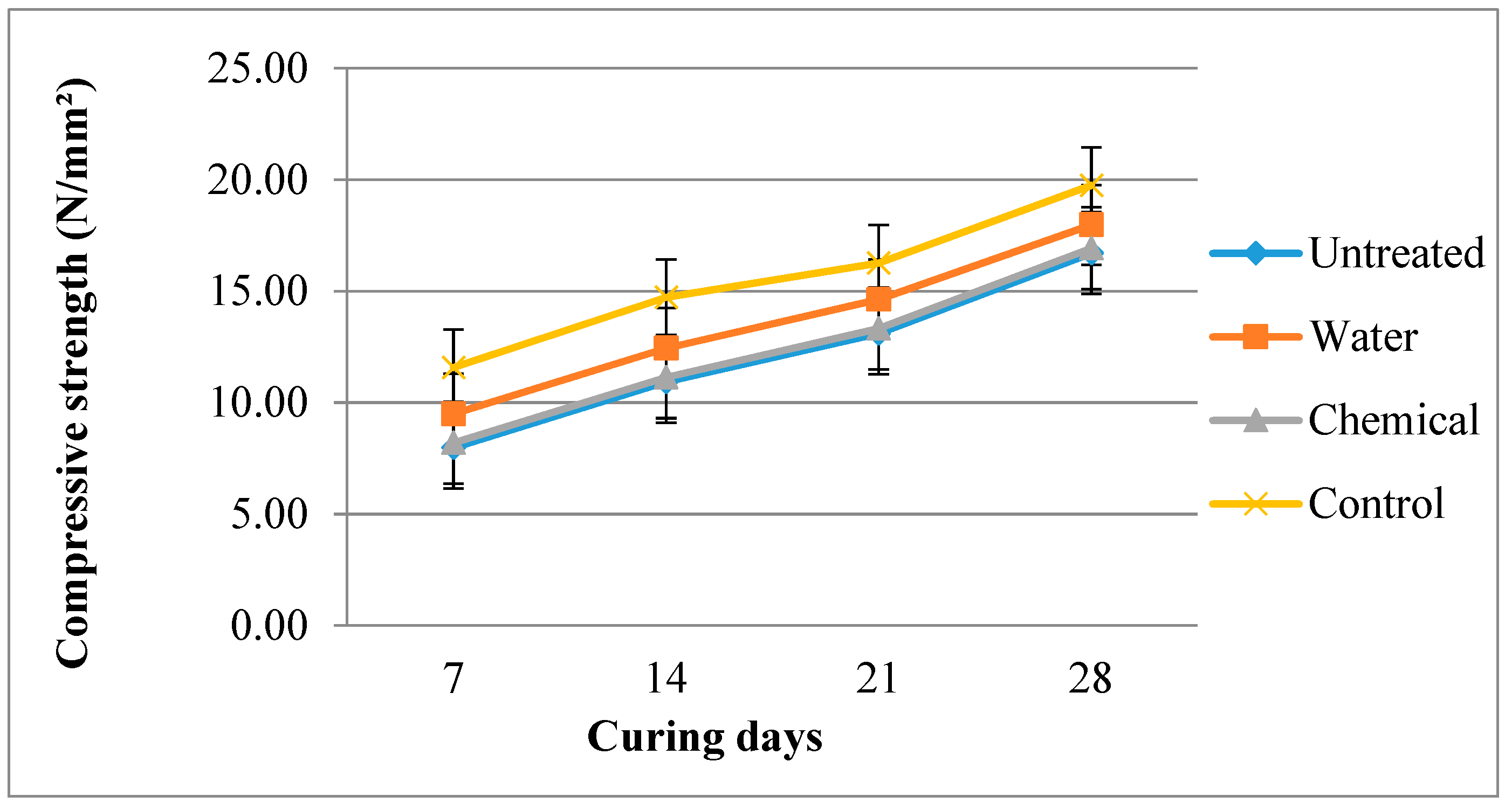

3.2. Tests on Hardened Concrete

3.3. Fire Resistance Test

4. Conclusions

- (1)

- The lowest slump value was recorded at 0.5% coconut fibre, indicating lower workability.

- (2)

- All slump values signified a medium workability, which is also acceptable.

- (3)

- When the concrete cubes were subjected to higher temperatures, the strength reduced.

- (4)

- Untreated coconut fibres exhibited higher compressive strength when compared to the control experiment and the water- and chemically treated fibres.

- (5)

- When the compressive strength of plain concrete that had been subjected to varying temperatures was compared with that of coconut fibre reinforced concrete (CFRC) that had been subjected to the same amount of temperature, the compressive strength of coconut fibre reinforced concrete increased significantly.

- (6)

- There was an increase in strength up to 0.5% fibre. Beyond 0.5% fibre, there was a decrease in strength.

- (7)

- The presence of coconut fibre gives concrete a great ductility, thereby preventing fragile collapse.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Emmanuel, A.O.; Oladipo, F.A.; Olabode, O. Investigation of salinity effect on compressive strength of reinforced concrete. J. Sustain. Dev. 2012, 5, 74–82. [Google Scholar] [CrossRef]

- Lau, A.; Anson, M. Effect of high temperatures on high performance steel fibre reinforced concrete. Cem. Concr. Res. 2006, 36, 1698–1707. [Google Scholar] [CrossRef]

- Shrinkar, P.; Kakade, D.N.; Wadkar, A.P. Effect of elevated on compressive strength and flexural strength of fibre reinforced concrete. Int. J. Concr. Technol. 2017, 3, 1–14. [Google Scholar]

- Ashfaque, A.J.; Samiullah, S. Effect of steel fibers on the compressive and flexural strength of concrete. Int. J. Adv. Appl. Sci. 2018, 5, 16–21. [Google Scholar]

- Abass, A.O.; Silverster, O.A.; John, M. Experimental investigation of the physical and mechanical properties of Sisal fiber-reinforced concrete. Fibers 2018, 6, 53. [Google Scholar]

- Sina, A.; Nima, R. Effect of cement-polymer properties on mechanical response of fiber-reinforced concrete on mechanical properties of fiber-reinforced concrete. ASCE J. Nanomech. Micromech. 2017, 7, 04017002. [Google Scholar]

- Faezeh, S.; Nima, R. Nanostructural characteristics and interfacial properties of polymer fibers in cement matrix. ACS. Appl. Mater. Interfaces 2016, 7, 17278–17286. [Google Scholar] [CrossRef]

- Novak, J.; Kohoutkkova, A. Fibres reinforced concrete exposed to elevated temperature. IOP Conf. Ser. Mater. Sci. Eng. 2017, 246, 012065. [Google Scholar] [CrossRef]

- Oksman, K.; Skrifvars, M.; Selin, J.F. Natural fibers as reinforcement in polylactic acid (PLA). Comp. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Neves, R.; Branco, F.; de Brito, J. Field assessment of the relationship between natural and accelerate concrete carbonation resistance. Cem. Concr. Comp. 2013, 41, 9–15. [Google Scholar] [CrossRef]

- Dhandhania, V.; Sawant, S. Coir fiber reinforced concrete. J. Text. Sci. Eng. 2014, 4, 163. [Google Scholar]

- Oorkalan, A.; Chithra, S. Effect of coconut coir pith as partial substitute for river sand in eco-friendly concrete. Mater. Today Proc. 2019. [Google Scholar] [CrossRef]

- Sisomphon, K.; Franke, L. Carbonation rates of concretes containing high volume of pozzolanic materials. Cem. Concr. Res. 2007, 37, 1647–1653. [Google Scholar] [CrossRef]

- Bergado, D.T.; Long, P.V.; Murthy, B.R.S. A case study of geotextile-reinforced embankment on soft groud geotext. Geomembraces 2002, 20, 343–365. [Google Scholar]

- Abbass, M. Coconut fiber as fiber reinforcement: A review. Int. J. Civ. Eng. 2015, 10, 62–65. [Google Scholar]

- Archanaa, D.; Ragavendra, S.; PraveenReddy, I. Fibre Reinforced Concrete. A case study. In Proceedings of the 33rd National Convention of Architectural Engineers and National Seminar on “Architectural Engineering Aspect for Sustainable Building Envelopes” ArchEn, BuilEn-2017, by Institution of Engineers Indian in Association with Indian Association of Structural Engineers at: Institution of Engineers Khairatabad, Khairtabad, India, 10–11 November 2017. [Google Scholar]

- De La Serna, J.; Karakouzian, M. Coir Fiber Reinforced Concrete. 2018. Available online: https://digitalscholarship.unlv.edu/aanapisi_posters/48 (accessed on 29 October 2019).

- Ali, M. Coconut fibre: A versatile material and Its applications in engineering. J. Civ. Eng. Constr. Technol. 2011, 2, 189–197. [Google Scholar]

- Das, G.; Biswas, S. Physical, Mechanical and Water Absorption Behaviour of Coir Fiber Reinforced Epoxy Composites Filled with Al2O3 Particulates. Mater. Sci. Eng. 2016, 115, 012012. [Google Scholar] [CrossRef]

- Arsyad, M.; Wardana, I.; Irawan, Y.S. The morphology of coconut fiber surface under chemical treatment. Material (Rio de Janeiro) 2015, 20, 167–177. [Google Scholar] [CrossRef]

- Choumanidis, D.; Badogiannis, E.; Nomikos, P.; Sofianos, A. The effect of different fibres on the flexural bahaviour of concrete exposed to normal and elevated temperatures. Constr. Build. Mater. 2016, 129, 266–277. [Google Scholar] [CrossRef]

- Ahmed, S.J.; Islam, M.S. Influence of jute fiber on concrete properties. Constr. Build. Mater. 2018, 189, 768–776. [Google Scholar]

- Mulinari, D.B.; Baptista, C.A.R.P.; Souza, J.; Voorwald, H.J.C. Mechanical properties of Coconut fibers reinforced polyester composites. Procedia Eng. 2011, 10, 2074–2079. [Google Scholar] [CrossRef]

- Asasutjarit, C.; Hirrunlabh, J.; Khedar, J.; Paguenet, M.; Quenard, D. Coconut coir cement board. In Proceedings of the 10th International Conference on the Durability of Building Materials and Components, Hyon, Frame, TT3-103, Lyon, France, 17–20 April 2005. [Google Scholar]

- Ede, A.N.; Aina, A.O. Effects of Coconut Husk and Propylene Fiber on the Fire Resistance of Concrete. Int. J. Eng. Sci. Manag. 2015, 5, 171–179. [Google Scholar]

- Im, D.; Sancharoen, P.; Julnipitawong, P.; Tangtermsirikul, S. Effects of chloride content on thermal properties of concrete. Int. J. GEOMATE 2018, 14, 135–142. [Google Scholar] [CrossRef]

- Ji, Y.; Yuan, Y.; Shen, J.; Ma, Y.; Lai, S. Comparison of concrete carbonation process under natural condition and high CO2 concentration environments. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2010, 25, 515–522. [Google Scholar] [CrossRef]

- Imhaz, A.M.; Ashfaque, A.J.; Samiullah, S.; Mohammad, T.L.; Zahid, H. Influence of fibre length on the behaviour of polypropylene fibre reinforced cement concrete. Civ. Eng. J. 2018, 4, 2124–2131. [Google Scholar]

- Nanayakkara, N.H.A.S.Y.; Ismail, M.G.M.U.; Wijesundara, R.L.C. Characterization and determination of properties of Sri Lankan coconut fibres. J. Nat. Fibers 2005, 2, 69–81. [Google Scholar] [CrossRef]

- American Society for Testing and Materials (ASTM). Standard Specification for Portland Cement; ASTM C150; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- American Society for Testing and Materials (ASTM). Standard for Sampling Freshly Mixed Concrete; ASTM C172/C172M-14; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- American Society for Testing and Materials (ASTM). Practice for Making and Curing Concrete Test Specimens in the Field; ASTM C31/C31M; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- American Society for Testing and Materials (ASTM). Standard Test Methods for Compressive Strength of Concrete Specimens; ASTM C39; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- British Standards Institution (BS). Fire tests on Building Materials and Structures Part 20. In Methord for Determination of the Fire Resistance of Elements of Construction (General Principles); BS 467: Part 20; British Standards Institution: London, UK, 1987. [Google Scholar]

- Mahyuddin, R.; Wai, H.K.; Noor, F.A. Strength and durability of coconut-fibre-reinforced concrete in aggressive environment. Mater. Des. 2012, 38, 554–566. [Google Scholar]

| Workability | Slump (mm) |

|---|---|

| Very low | 0–25 |

| Low | 25–50 |

| Medium | 50–100 |

| High | 100–175 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bamigboye, G.; Ngene, B.; Aladesuru, O.; Mark, O.; Adegoke, D.; Jolayemi, K. Compressive Behaviour of Coconut Fibre (Cocos nucifera) Reinforced Concrete at Elevated Temperatures. Fibers 2020, 8, 5. https://doi.org/10.3390/fib8010005

Bamigboye G, Ngene B, Aladesuru O, Mark O, Adegoke D, Jolayemi K. Compressive Behaviour of Coconut Fibre (Cocos nucifera) Reinforced Concrete at Elevated Temperatures. Fibers. 2020; 8(1):5. https://doi.org/10.3390/fib8010005

Chicago/Turabian StyleBamigboye, Gideon, Ben Ngene, Omotolani Aladesuru, Oluwaseun Mark, Dunmininu Adegoke, and Kayode Jolayemi. 2020. "Compressive Behaviour of Coconut Fibre (Cocos nucifera) Reinforced Concrete at Elevated Temperatures" Fibers 8, no. 1: 5. https://doi.org/10.3390/fib8010005

APA StyleBamigboye, G., Ngene, B., Aladesuru, O., Mark, O., Adegoke, D., & Jolayemi, K. (2020). Compressive Behaviour of Coconut Fibre (Cocos nucifera) Reinforced Concrete at Elevated Temperatures. Fibers, 8(1), 5. https://doi.org/10.3390/fib8010005