Durability of Recycled Steel Fiber Reinforced Concrete in Chloride Environment

Abstract

1. Introduction

2. Experimental Program

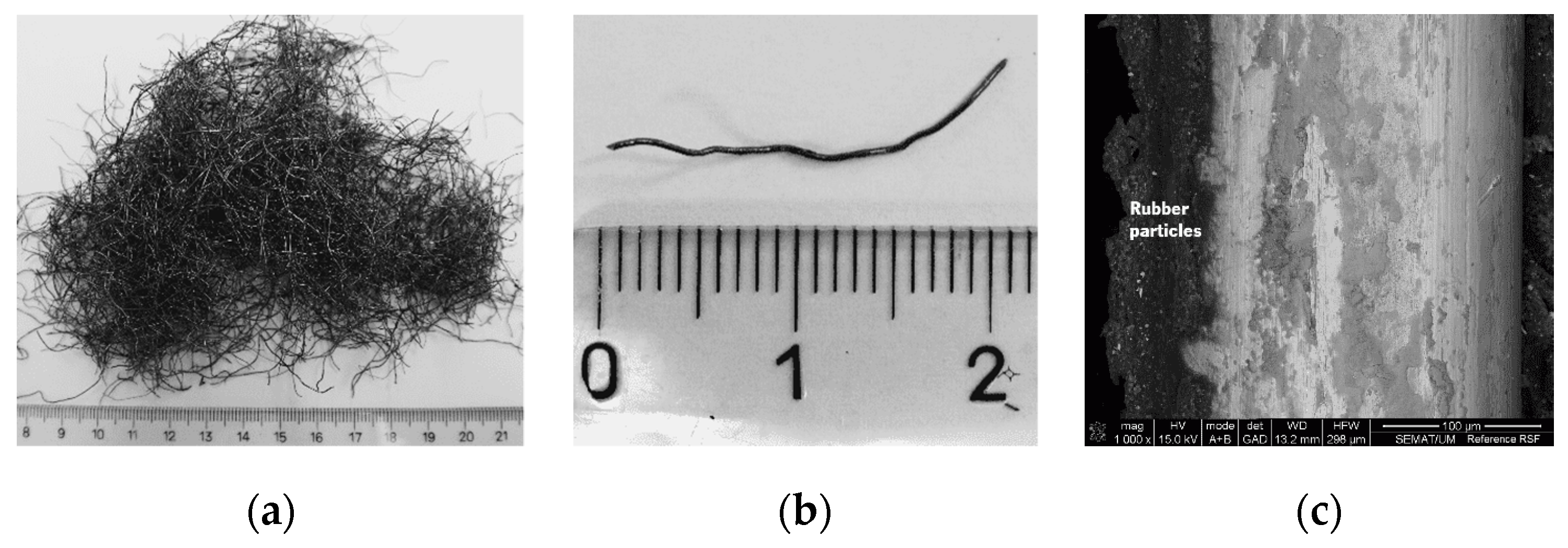

2.1. Materials and Mix Compositions

2.2. Test Procedures

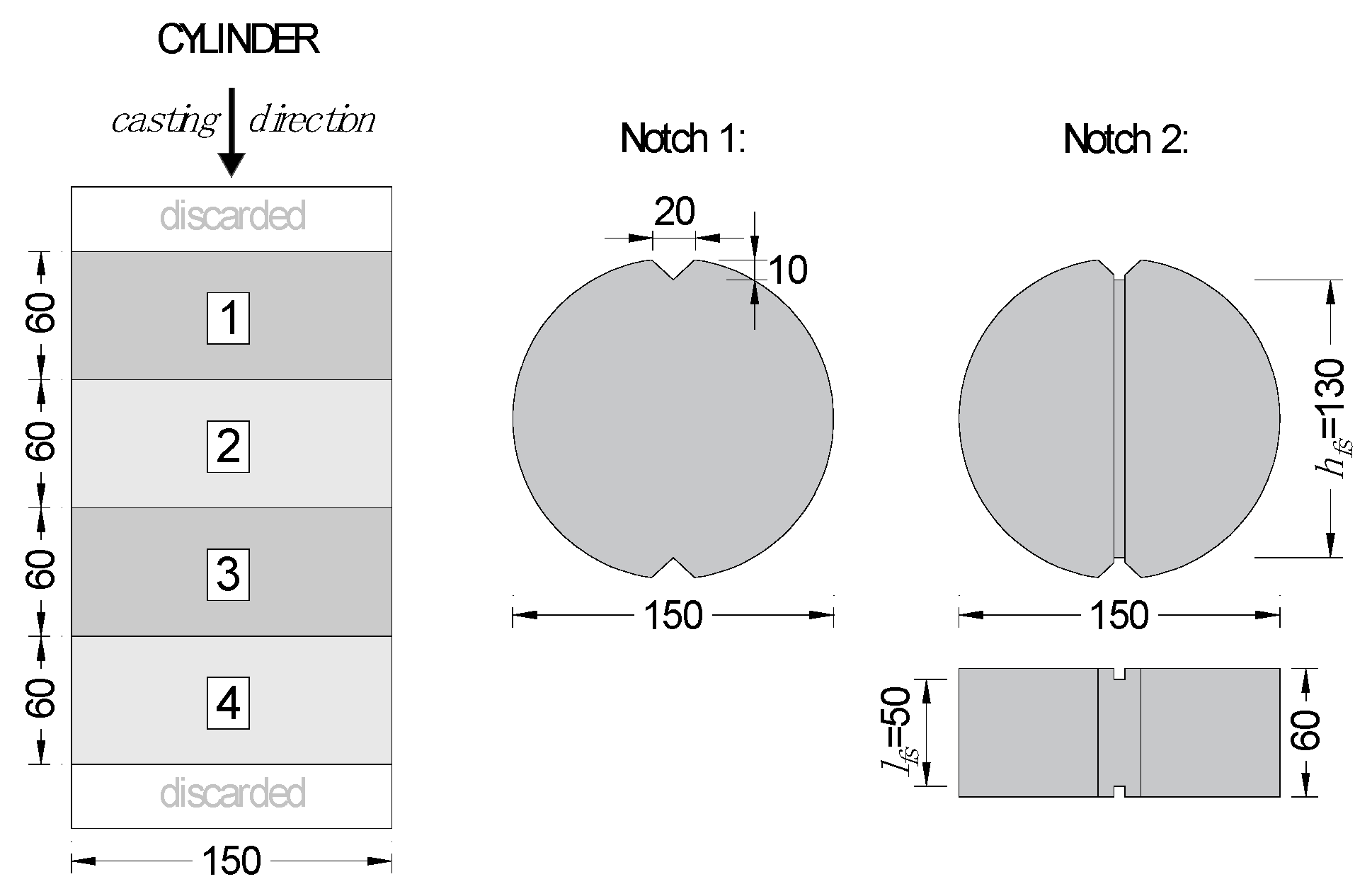

2.2.1. Specimen Preparation and Exposure Conditions

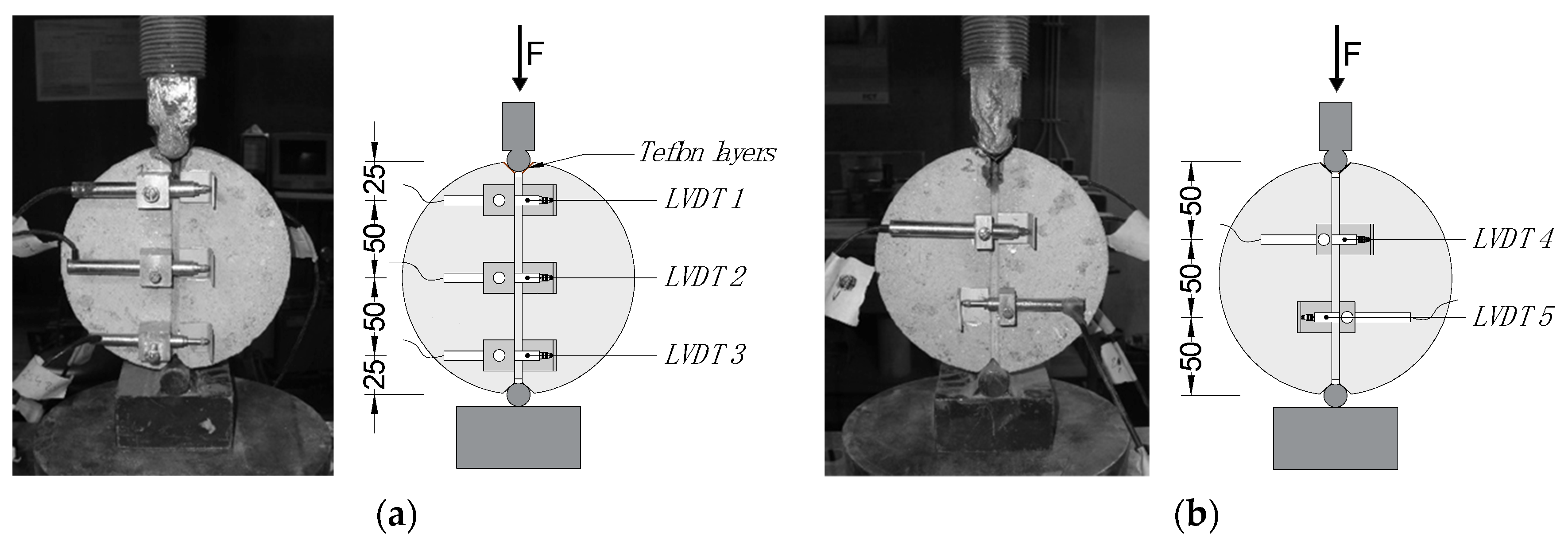

2.2.2. Splitting Tensile Test

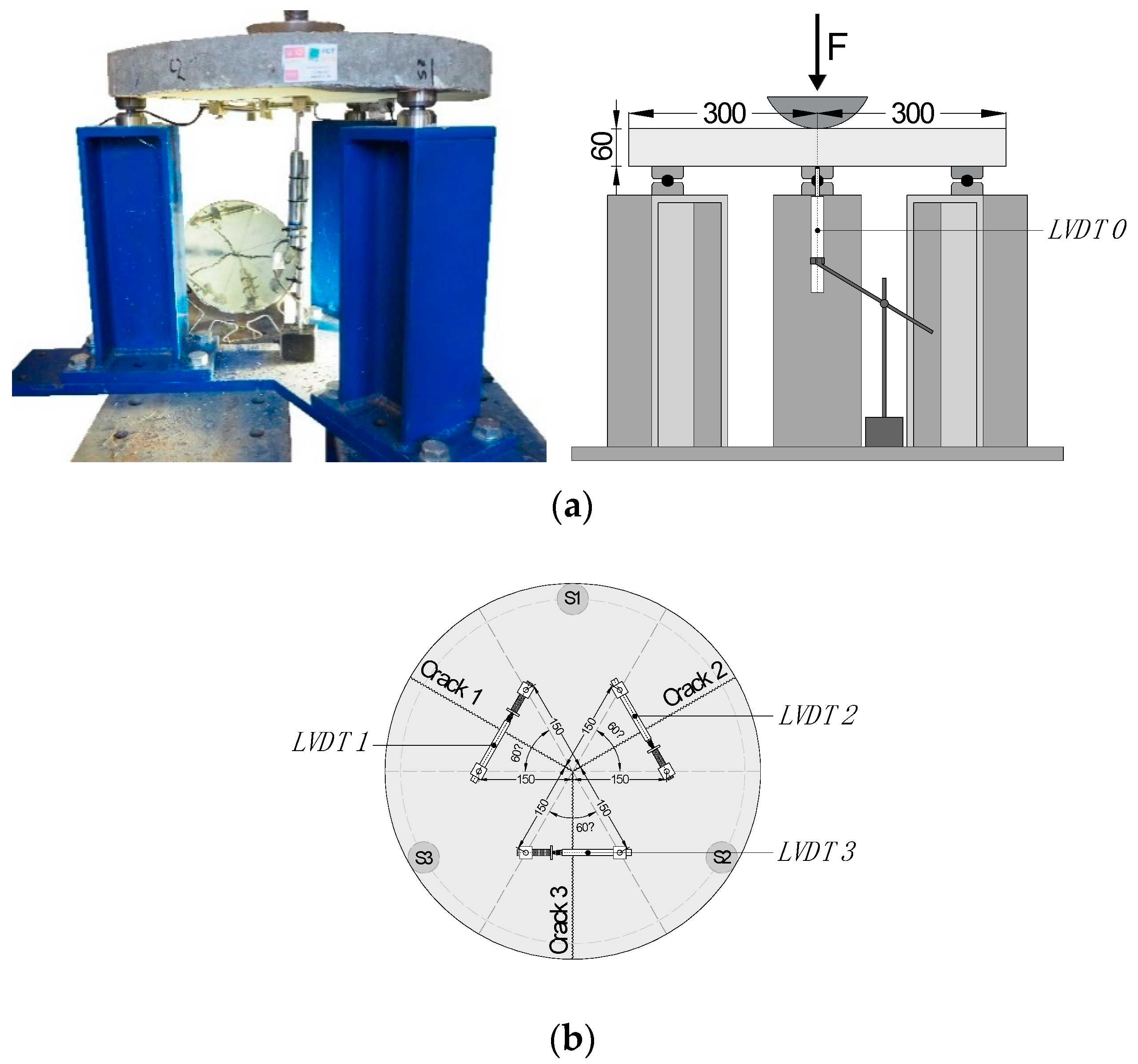

2.2.3. Round Panel Test (RPT)

2.2.4. Fiber Distribution and Orientation

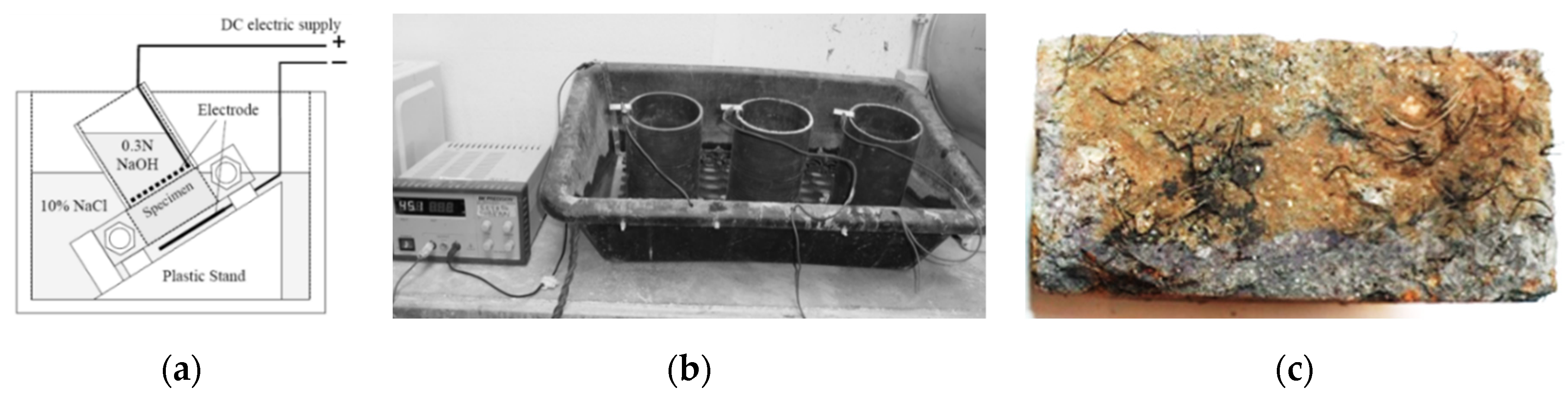

2.2.5. Non-Steady-State Rapid Chloride Migration Test

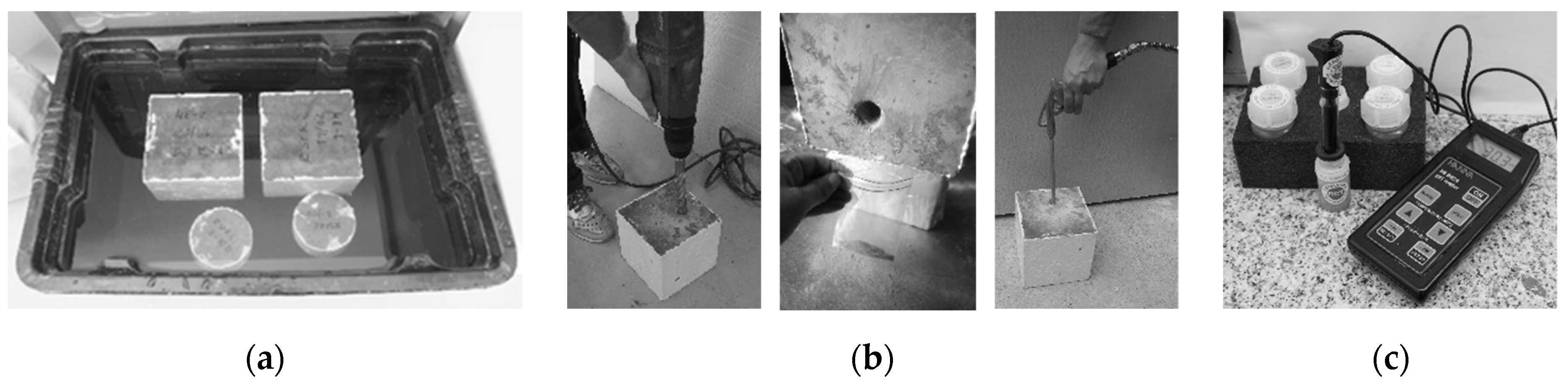

2.2.6. Immersion Test in NaCl Solution

3. Results and Discussions

3.1. Long-Term Effects of Chloride Attack on the Post-Cracking Behavior of RSFRC

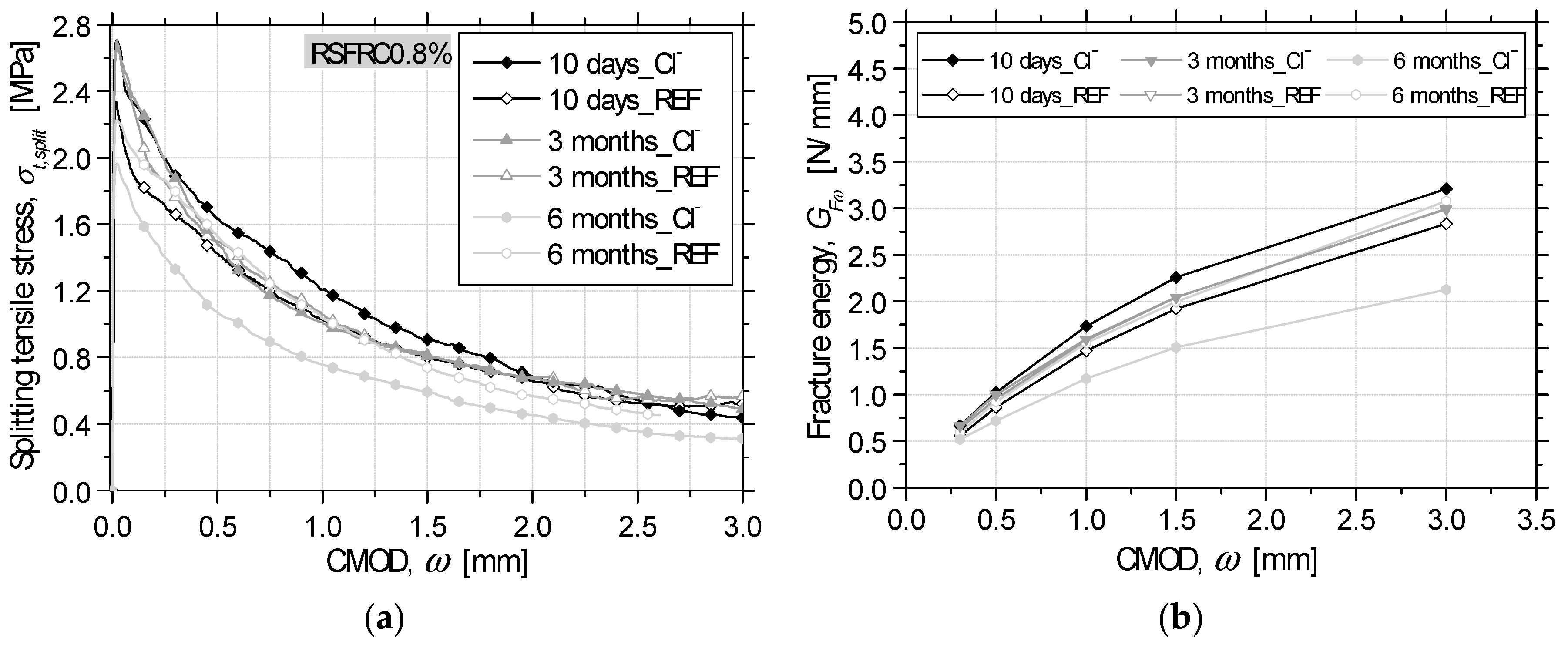

3.1.1. Splitting Tensile Tests

3.1.2. Fiber Distribution/Orientation Profiles

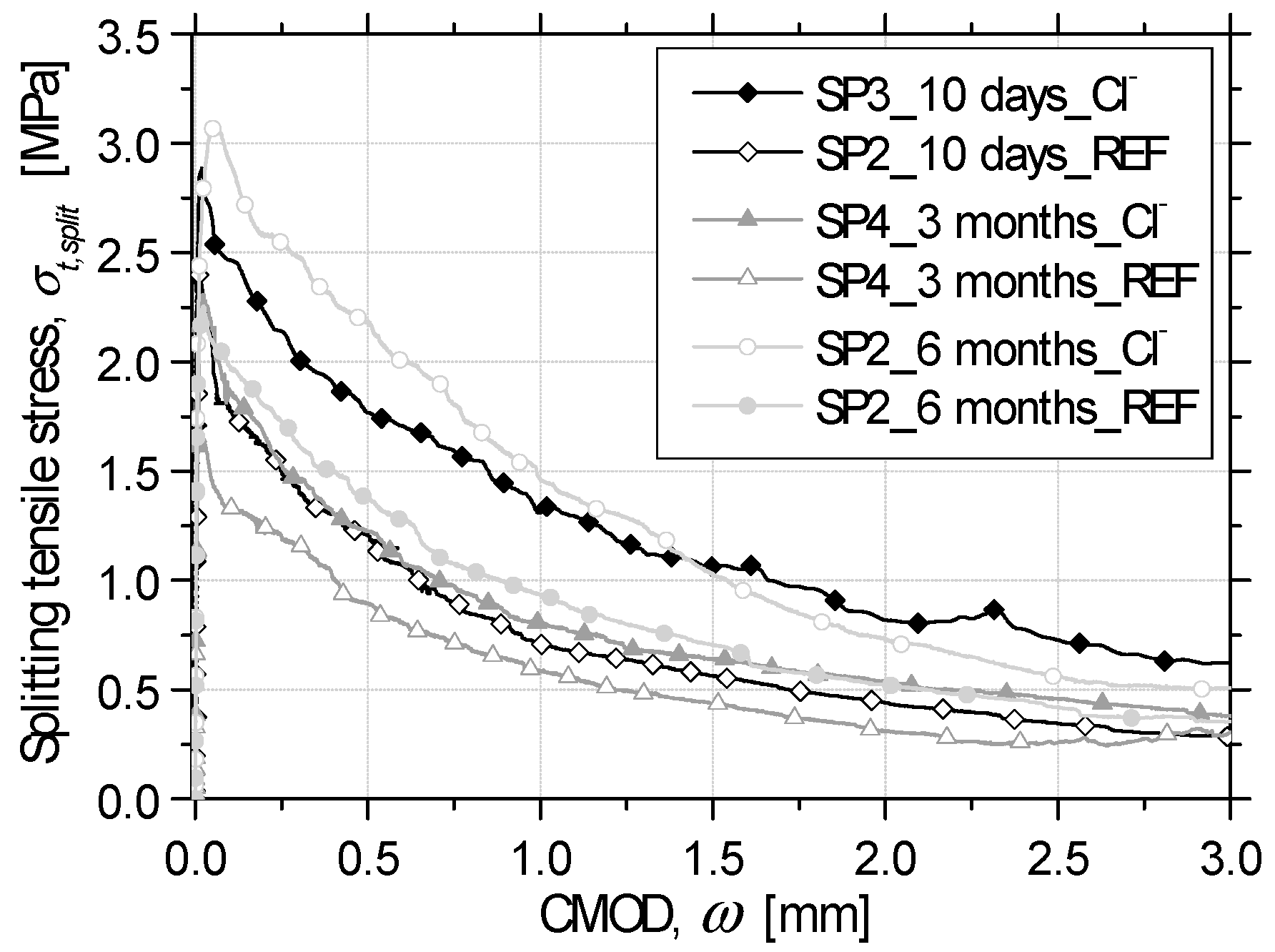

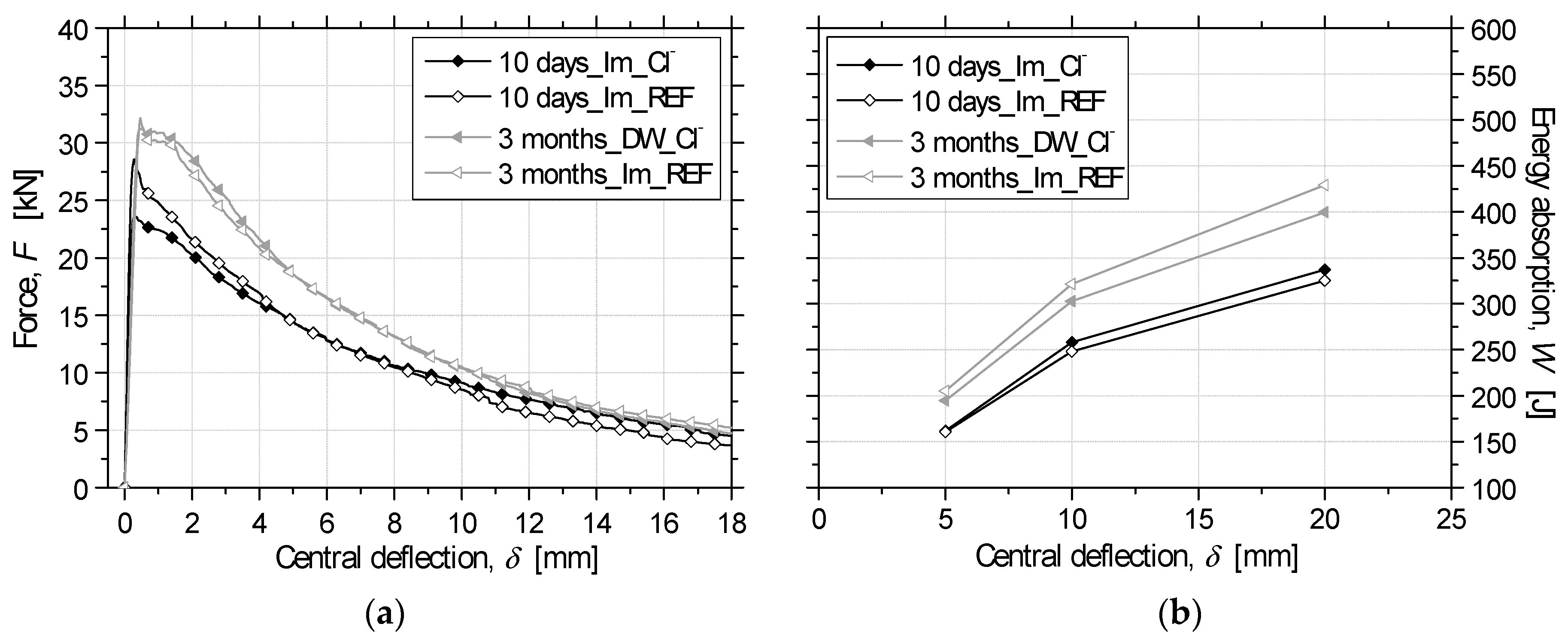

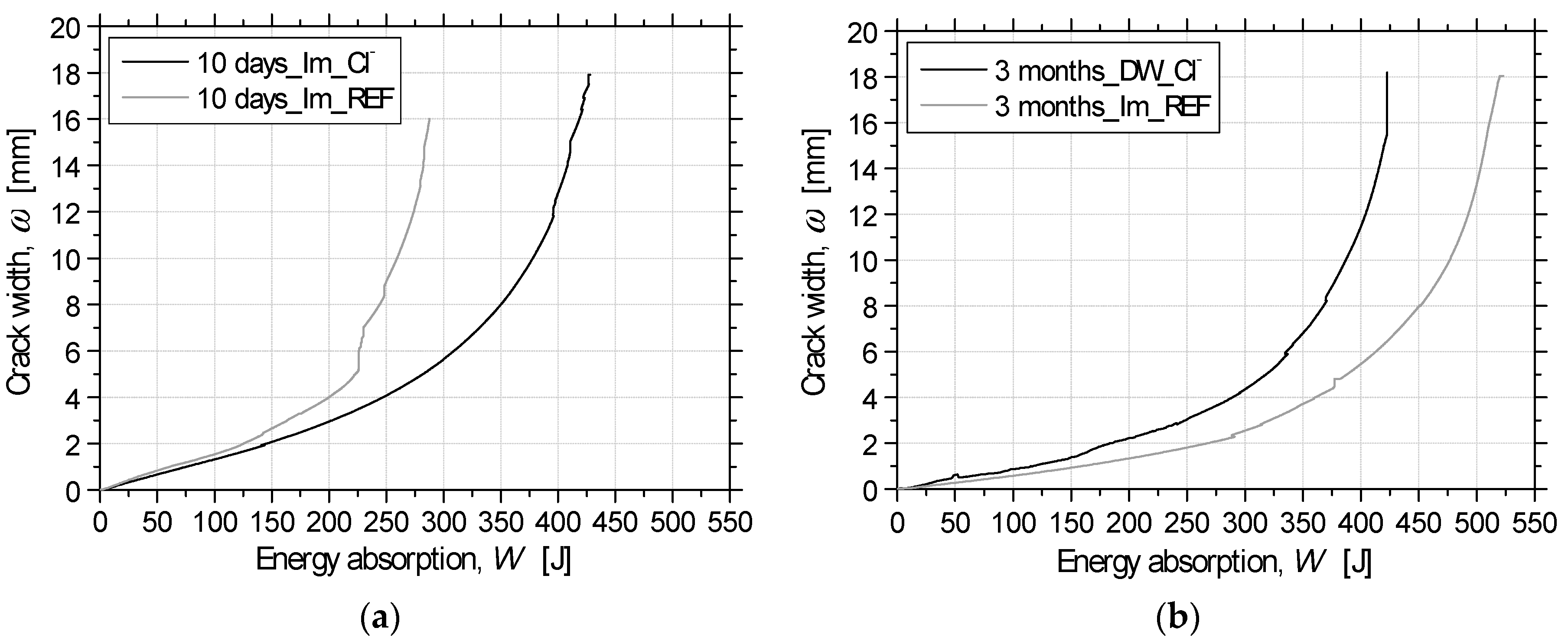

3.1.3. Round Panel Tests

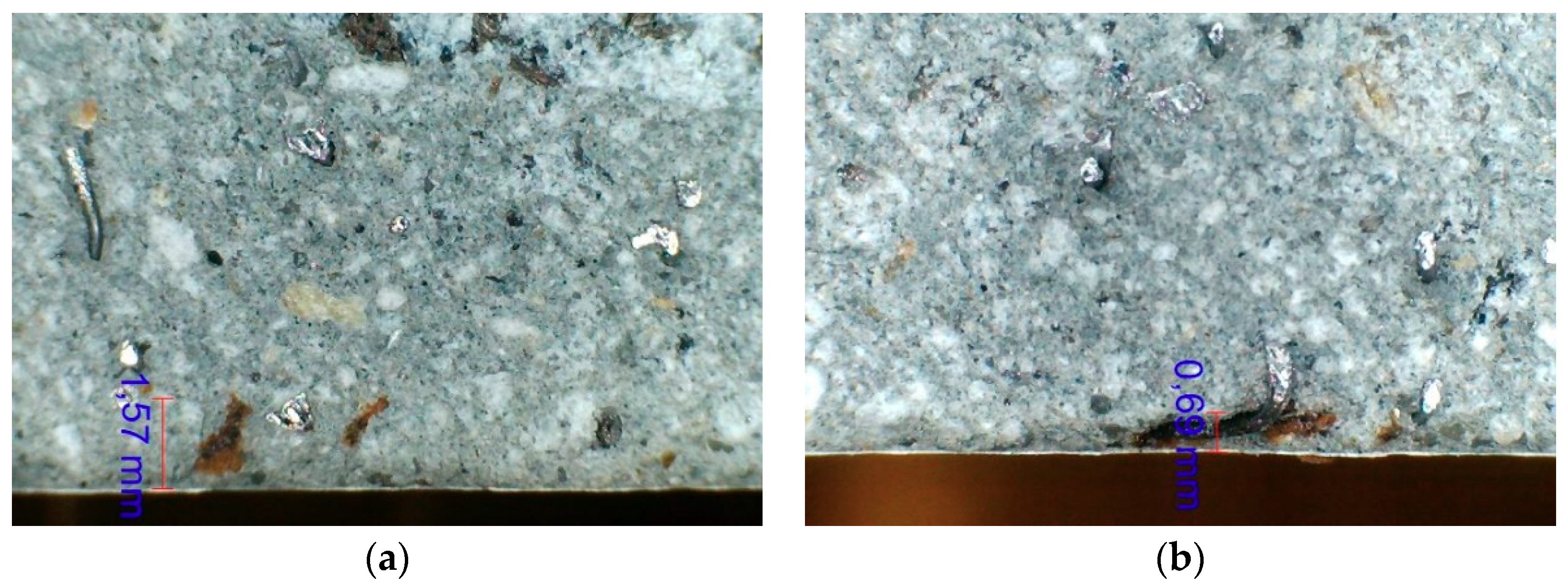

3.1.4. Fiber Distribution/Orientation Profiles

3.2. Durability Indicators of RSFRC under Chloride Exposure

Non-Steady-State Rapid Chloride Migration

3.3. Resistance to Chloride Penetration by Immersion

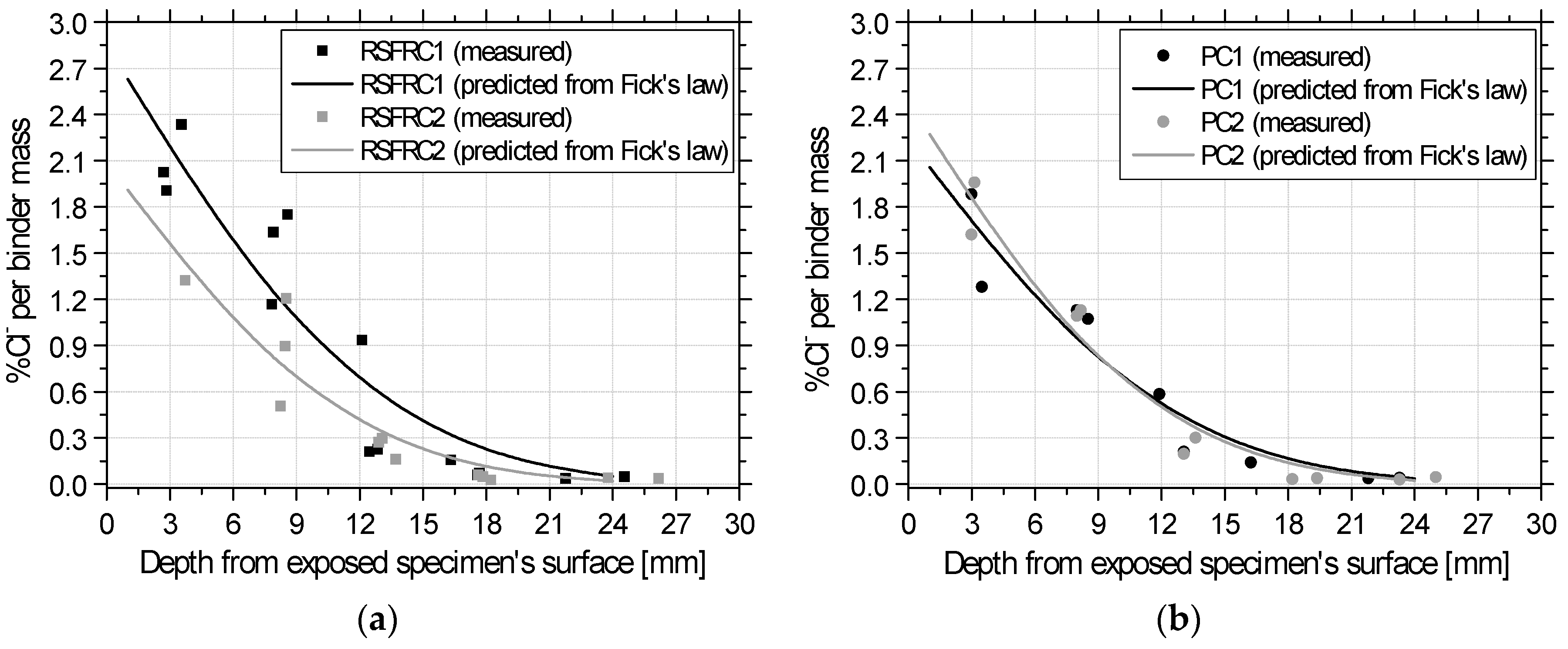

3.3.1. Chloride Profiles

3.3.2. Chloride Diffusion and Aging Coefficient by Colorimetric Method

3.3.3. Critical Chloride Concentration for Fiber Corrosion Initiation in the RSFRC Round Panels

- (1)

- Knowing the average colorimetric chloride penetration depth measured in the panels (9.5 mm, as mentioned in Section 3.1.2), the chloride diffusion coefficient, , was determined according to Equation (6) with and ; from those, a value of was obtained.

- (2)

- (3)

- The surface chloride content, , was determined by the Fick’s 2nd law (Equation (5)), considering the value of 0.7% of binder mass for in RSFRC cubic specimens (Section 3.3.2). The value estimated for was 2.157% of binder mass.

- (4)

- The critical chloride content corresponding to the beginning of fiber corrosion, , was determined by the Fick’s 2nd law, considering the parameters and obtained in steps 2) and 3), respectively. The average depth of corroded fibers was measured with a USB microscope in a cut surface of the panels after performing RPTs. The value obtained for was 2.05% of binder mass, corresponding to an average depth of corroded fibers of 0.62 mm. A typical critical chloride content in the range of 0.4–1.0 wt.% of cement is reported in the literature for conventional reinforced concrete [10], although it has been found that this may vary as much as 0.17–2.5 wt.% of cement [57]. However, the critical chloride content has been found to be much higher in SFRC [58,59], which is in line with the critical chloride content estimated from this study.

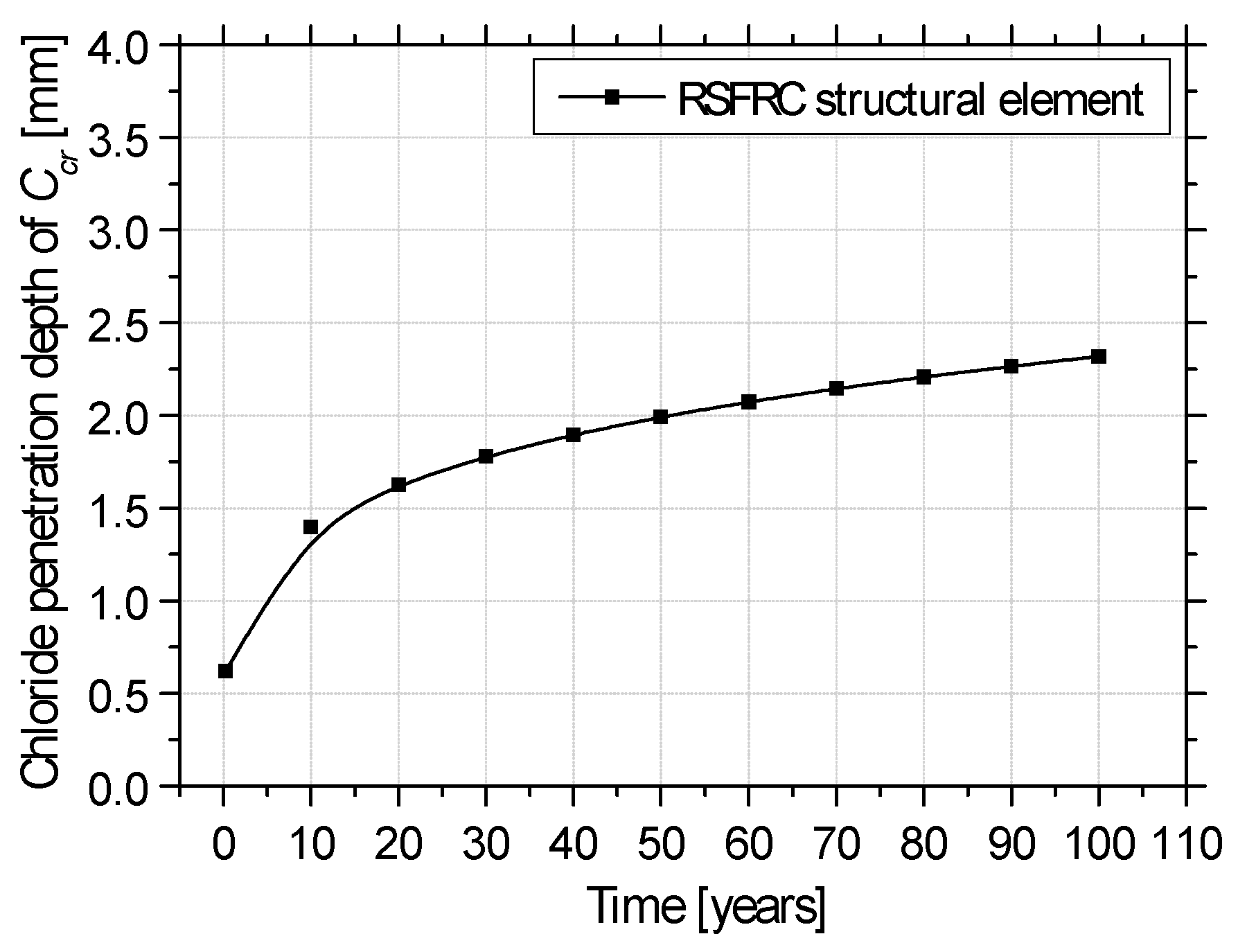

3.3.4. Chloride Penetration Prediction of RSFRC under Chloride Attack

4. Conclusions

- (1)

- For the exposure periods adopted of chloride immersion in 3.5 wt.% NaCl solution, no significant signs of corrosion were detected in the RSF on the fracture surfaces of RSFRC specimens. However, corrosion spots were observed at exposed surfaces of all specimens.

- (2)

- The curves obtained for the RSFRC0.8% specimens and the corresponding fiber distribution analysis at crack surfaces revealed for the influence of chloride attack on the post-cracking behavior of RSFRC a negligible effect after 10 days of immersion, a beneficial effect after 3 months of immersion, and a detrimental effect after 6 months of immersion.

- (3)

- The responses registered in the RSFRC1% panels and its corresponding fiber distribution analysis at crack surfaces revealed a negligible effect of the chloride attack on the post-cracking behavior of RSFRC after 10 days of immersion and 3 months of dry-wet cycles in chloride solution.

- (4)

- A significant number of fibers ruptured during the execution of tests; no significant differences were detected in terms of the fiber orientation factor between DEWST specimens and round panel tests.

- (5)

- The chloride migration test under non-steady state may not be feasible for RSFRC, since the presence of steel fibers seems to have a significant influence in the test methodology, mainly by inducing severe corrosion in RSF. The determination of the chloride diffusion for RSFRC is more prudent by natural immersion test in salt solution.

- (6)

- The presence of RSF had a negligible effect on the penetration of chloride ions into concrete. The chloride content obtained for the chloride penetration depth was 0.70% and 0.80% per binder mass for, respectively, RSFRC1% and PC cubes previously subjected to 3 months of chloride immersion. The critical content of chlorides corresponding to the beginning of fiber corrosion, obtained in RSFRC1% panels subjected to 3 months of dry-wet in chloride solution, was 2.05% by binder mass. According to the literature, these results are in agreement with the measured concentration of chlorides reported at the color change boundary in OPC concrete and with the critical chloride content reported by some authors for steel fiber reinforced concrete.

- (7)

- A chloride penetration depth of about 2.3 mm was predicted into a RSFRC structural element after exposed to dry-wet cycles in a 3.5 wt.% NaCl solution for 100 years.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microestructure, Properties and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Bogas, J.; Gomes, A. Non-steady-state accelerated chloride penetration resistance of structural lightweight aggregate concrete. Cement Concrete Compos. 2015, 60, 111–122. [Google Scholar] [CrossRef]

- Bertolini, L.; Elsener, B.; Pedeferri, P.; Polder, R.P. Corrosion of Steel in Concrete—Prevention, Diagnosis, Repair, 1st ed.; Wiley-VCH: Weinheim, Germany, 2004; pp. 21–36. [Google Scholar]

- Singh, A.P.; Singhal, D. Permeability of steel fibre reinforced concrete influence of fibre parameters. Procedia Eng. 2011, 14, 2823–2829. [Google Scholar] [CrossRef]

- Marcos-Meson, V.; Michel, A.; Solgaard, A.; Fischer, G.; Edvardsen, C.; Skovhus, T.L. Corrosion resistance of steel fibre reinforced concrete—A literature review. Cement Concrete Res. 2018, 103, 1–20. [Google Scholar] [CrossRef]

- Teruzzi, T.; Cadoni, E.; Frigeri, G.; Cangiano, S.; Plizzari, G. Durability aspects of steel fibre reinforced concrete. In Proceedings of the BEFIB’2004—6th International RILEM Symposium on Fibre-Reinforced Concretes (FRC), Varenna, Italy, 20–22 September 2004; pp. 625–634. [Google Scholar]

- Roque, R.; Kim, N.; Kim, B.; Lopp, G. Durability of Fiber-Reinforced Concrete in Florida Environments; Final Report September 2004–June 2009, UF Project No. 00050493; Dept. of Civil and Coastal Engineering, University of Florida: Gainesville, FL, USA, 2009; 25p. [Google Scholar]

- Frazão, C.; Camões, A.; Barros, J.; Gonçalves, D. Durability of steel fiber reinforced self-compacting concrete. Constr. Build. Mater. 2015, 80, 155–166. [Google Scholar] [CrossRef]

- Chen, G.; Hadi, M.N.S.; Gao, D.; Zhao, L. Experimental study on the properties of corroded steel fibres. Constr. Build. Mater. 2015, 79, 165–172. [Google Scholar] [CrossRef]

- Angst, U.; Elsener, B.; Larsen, C.K.; Vennesland, Ø. Critical chloride content in reinforced concrete—A review. Cement Concrete Res. 2009, 39, 1122–1138. [Google Scholar] [CrossRef]

- Berrocal, C.G.; Lundgren, K.; Löfgren, I. Corrosion of steel bars embedded in fibre reinforced concrete under chloride attack: State of the art. Cement Concrete Res. 2016, 80, 69–85. [Google Scholar] [CrossRef]

- Hwang, J.P.; Jung, M.S.; Kim, M.; Ann, K.Y. Corrosion risk of steel fibre in concrete. Constr. Build. Mater. 2015, 101, 239–245. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, W.; Guo, L.; Gu, C.; Zong, J. Modeling chloride diffusion coefficient of steel fiber reinforced concrete under bending load. Adv. Civ. Eng. 2018, 2018, 3789214. [Google Scholar] [CrossRef]

- Balouch, S.U.; Forth, J.P.; Granju, J.-L. Surface corrosion of steel fibre reinforced concrete. Cement Concrete Res. 2010, 40, 410–414. [Google Scholar] [CrossRef]

- Pillai, R.G.; Annapareddy, A. Service life prediction models for chloride-laden concrete structures: A review and nomographs. Int. J. 3R’s 2013, 4, 563–580. [Google Scholar]

- Safehian, M.; Ramezanianpour, A.A. Prediction of RC structure service life from field long term chloride diffusion. Comput. Concrete 2015, 15, 589–606. [Google Scholar] [CrossRef]

- Maage, M.; Helland, S.; Poulsen, E.; Vennesland, Ø.; Carlsen, J.E. Service life prediction of existing concrete structures exposed to marine environment. ACI Mater. J. 1996, 93, 602–608. [Google Scholar]

- Khan, M.U.; Ahmad, S.; Al-Gahtani, H.J. Chloride-induced corrosion of steel in concrete: An overview on chloride diffusion and prediction of corrosion initiation time. Int. J. Corros. 2017, 2017, 5819202. [Google Scholar] [CrossRef]

- Pilakoutas, K.; Neocleous, K.; Tlemat, H. Reuse of tyre steel fibres as concrete reinforcement. Proc. ICE Eng. Sustain. 2004, 157, 131–138. [Google Scholar] [CrossRef]

- Aiello, M.A.; Leuzzi, F.; Centonze, G.; Maffezzoli, A. Use of steel fibers recovered from waste tyres as reinforcement in concrete: Pull-out behaviour, compressive and flexural strength. Waste Manag. 2009, 29, 1960–1970. [Google Scholar] [CrossRef]

- Graeff, A.; Pilakoutas, K.; Lynsdale, C.; Neocleous, K.; Peres, M. Fatigue resistance and cracking mechanism of concrete pavements reinforced with recycled steel fibres recovered from post-consumer tyres. Eng. Struct. 2012, 45, 385–395. [Google Scholar] [CrossRef]

- Micelli, F.; Leone, M.; Centonze, G.; Aiello, M. Go green: Using waste and recycling materials. In Infrastructure Corrosion and Durability—A Sustainability Study; Lu, Y., Ed.; OMICS Group eBooks: Foster City, CA, USA, 2014; pp. 1–68. [Google Scholar]

- Zamanzadeh, Z.; Lourenço, L.; Barros, J. Recycled steel fibre reinforced concrete failing in bending and in shear. Constr. Build. Mater. 2015, 85, 195–207. [Google Scholar] [CrossRef]

- Lourenço, L.; Zamanzadeh, Z.; Barros, J.A.O.; Razazadeh, M. Shear strengthening of RC beams with thin panels of mortar reinforced with recycled steel fibres. J. Clean. Prod. 2018, 194, 112–126. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Scrap tire steel fiber as a substitute for commercial steel fiber in cement mortar: Engineering properties and cost-benefit analyses. Resour. Conserv. Recycl. 2018, 134, 248–256. [Google Scholar] [CrossRef]

- Centonze, G.; Leone, M.; Aiello, M.A. Steel fibers from waste tires as reinforcement in concrete: A mechanical characterization. Constr. Build. Mater. 2012, 36, 46–57. [Google Scholar] [CrossRef]

- Tlemat, H.; Pilakoutas, K.; Neocleous, K. Stress-strain characteristic of SFRC using recycled fibres. Mater. Struct. 2006, 39, 365–377. [Google Scholar] [CrossRef]

- Neocleous, K.; Tlemat, H.; Pilakoutas, K. Design issues for concrete reinforced with steel fibers, including fibers recovered from used tires. ASCE J. Mater. Civ. Eng. 2006, 18, 677–685. [Google Scholar] [CrossRef]

- Vandewalle, L.; Dupont, D. Bending Test and Interpretation. Test and design methods for steel fibre reinforced concrete—Background and experiences. In Proceedings of the RILEM TC 162-TDF Workshop, Bochum, Germany, 20–21 March 2003; RILEM Publications, S.A.R.L., Schnütgen, B., Vandevalle, L., Eds.; [Google Scholar]

- Abrishambaf, A. Creep Behaviour of Cracked Steel Fibre Reinforced Self-Compacting Concrete Laminar Structures. Ph.D. Thesis, Department of Civil Engineering, School of Engineering of the University of Minho, Guimarães, Portugal, 2015. [Google Scholar]

- Salehian, H.; Barros, J.A.O.; Taheri, M. Evaluation of the influence of post-cracking response of steel fibre reinforced concrete (SFRC) on load carrying capacity of SFRC panels. Constr. Build. Mater. 2014, 73, 289–304. [Google Scholar] [CrossRef]

- Solgaard, A.O.S.; Küter, A.; Edvardsen, C.; Stang, H.; Geiker, M. Durability aspects of steel fibre reinforced concrete in civil infrastructure. In Proceedings of the 2nd International Symposium on Service Life Design for Infrastructure, Delft, The Netherlands, 4–6 October 2010. [Google Scholar]

- Barros, J.; Pereira, E.; Santos, S. Lightweight panels of steel fibre reinforced self-compacting concrete. J. Mater. Civ. Eng. 2007, 19, 295–304. [Google Scholar] [CrossRef]

- Soltanzadeh, F.; Barros, J.A.O.; Santos, R.F.C. High performance fiber reinforced concrete for the shear reinforcement: Experimental and numerical research. Constr. Build. Mater. 2015, 77, 94–109. [Google Scholar] [CrossRef]

- di Prisco, M.; Ferrara, L.; Lamperti, M.G.L. Double edge wedge splitting (DEWS): An indirect tension test to identify post-cracking behaviour of fiber reinforced cementitious composites. Mater. Struct. 2013, 46, 1893–1918. [Google Scholar] [CrossRef]

- ASTM C1550-08. Standard Test Method for Flexural Toughness of Fiber Reinforced Concrete (Using Centrally Loaded Round Panel); ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Minelli, F.; Plizzari, G.A. Fiber reinforced concrete characterization through round panel test—Part I: Experimental study. In Proceedings of the Fracture Mechanics of Concrete and Concrete Structures (FraMCOS-7)—High Performance, Fiber Reinforced Concrete, Special Loadings and Structural Applications, Jeju, Korea, 23–28 May 2010; Korea Concrete Institute, Oh, B.H., Chol, C.O., Lan, C., Eds.; [Google Scholar]

- Lameiras, R.; Barros, J.A.O.; Azenha, M. Influence of casting condition on the anisotropy of the fracture properties of Steel Fibre Reinforced Self-Compacting Concrete (SFRSCC). Cement Concrete Compos. 2015, 59, 60–76. [Google Scholar] [CrossRef]

- Abrishambaf, A.; Cunha, V.M.C.F.; Barros, J.A.O. The influence of fibre orientation on the post-cracking tensile behaviour of steel fibre reinforced self-compacting concrete. Fract. Struct. Integr. 2015, 31, 38–53. [Google Scholar] [CrossRef]

- Abrishambaf, A.; Barros, J.A.O.; Cunha, V.M.C.F. Tensile stress-crack width law for steel fibre reinforced self-compacting concrete obtained from indirect (splitting) tensile tests. Cement Concrete Compos. 2015, 57, 153–165. [Google Scholar] [CrossRef]

- Cunha, V.M.C.F. Steel Fibre Reinforced Self-Compacting Concrete (from Micro-Mechanics to Composite Behaviour). Ph.D. Thesis, Department of Civil Engineering, School of Engineering of the University of Minho, Guimarães, Portugal, 2010. [Google Scholar]

- Eberhardt, C.; Clarke, A. Fibre-orientation measurement in short-glass-fibre composites. Part I: Automated, high-angular-resolution measurement by confocal microscopy. Compos. Sci. Technol. 2001, 61, 1389–1400. [Google Scholar] [CrossRef]

- Soroushian, P.; Lee, C.D. Distribution and orientation of fibers in steel fiber reinforced concrete. ACI Mater. J. 1990, 87, 433–439. [Google Scholar]

- NT BUILD 492. Concrete, Mortar, and Cement-Based Repair Materials: Chloride Migration Coefficient from Non-Steady-State Migration Experiments; NORDTEST: Espoo, Finland, 1999. [Google Scholar]

- ASTM C1556-03. Standard Test Method for Determining the Apparent Chloride Diffusion Coefficient of Cementitious Mixtures by Bulk Diffusion; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- NT BUILD 443. Concrete, Hardened: Accelerated Chloride Penetration; NORDTEST: Espoo, Finland, 1995. [Google Scholar]

- Frederiksen, J.M.; Mejlbro, L.; Nilsson, L.-O. Fick’s 2nd Law—Complete Solutions for Chloride Ingress into Concrete—with Focus on Time Dependent Diffusivity and Boundary Condition; Report TVBM-3146; Lund University, Institute of Technology, Division of Building Materials: Lund, Sweden, 2008; 110p. [Google Scholar]

- Yang, C.-C.; Liang, C.-H. A modified colorimetric method to determine the chloride profile from the ponding test. J. Chin. Inst. Eng. 2014, 37, 419–427. [Google Scholar] [CrossRef]

- Tang, L. Electrically accelerated methods for determining chloride diffusivity in concrete-current development. Mag. Concrete Res. 1996, 48, 173–179. [Google Scholar] [CrossRef]

- Lay, S.; Liebl, S.; Hilbig, H.; Schieβl, P. New method to measure the rapid chloride migration coefficient of chloride-contaminated concrete. Cement Concrete Res. 2004, 34, 421–427. [Google Scholar] [CrossRef]

- Bogas, J. Characterization of structural concretes with lightweight expanded clay aggregates. Ph.D. Thesis, Department of Civil Engineering, Technical University of Lisbon, Lisbon, Portugal, 2011. (In Portuguese). [Google Scholar]

- Poulsen, E.; Mejlbro, L. Diffusion of Chloride in Concrete: Theory and Application (Modern Concrete Technology), 1st ed.; Taylor & Francis: London, UK; New York, NY, USA, 2006. [Google Scholar]

- Tang, L.; Sørensen, H.E. Precision of the Nodic test methods for measuring chloride transport diffusion/migration coefficients. Mater. Struct. 2001, 34, 479–485. [Google Scholar] [CrossRef]

- Yuan, Q.; De Schutter, G.; Shi, C.; Audenaert, K. The relationship between chloride diffusion and migration coefficients in concrete. In Proceedings of the 1st International Conference on Microstructure Related Durability of Cementitious Composites, Nanjing, China, 13–15 October 2008; pp. 553–563. [Google Scholar]

- Otsuki, N.; Nagataki, S.; Nakashita, K. Evaluation of AgNO3 solution spray method for measurement of chloride penetration into hardened cementitious matrix materials. ACI Mater. J. 1992, 89, 587–592. [Google Scholar] [CrossRef]

- Chiang, C.T.; Yang, C.C. Relation between the diffusion characteristic of concrete from salt ponding test and accelerated chloride migration test. Mater. Chem. Phys. 2007, 106, 240–246. [Google Scholar] [CrossRef]

- Alonso, C.; Andrade, C.; Castellote, M.; Castro, P. Chloride threshold values to depassivate reinforcing bars embedded in a standardized OPC mortar. Cement Concrete Res. 2000, 30, 1047–1055. [Google Scholar] [CrossRef]

- Berrocal, C.; Lundgren, K.; Löfgren, I. Influence of steel fibres on corrosion of reinforcement in concrete in chloride environments: A review. In Proceedings of the International Conference: FC2013-Fiber Concrete 2013, Prague, Czech Republic, 12–13 September 2013. [Google Scholar]

- Janotka, I.; Krajcí, L.; Komlos, K.; Frtalová, D. Chloride corrosion of steel fibre reinforcement in cement mortar. Int. J. Cement Compos. Lightweight Concrete 1989, 11, 221–228. [Google Scholar] [CrossRef]

- Song, L.; Sun, W.; Gao, J. Time dependent chloride diffusion coefficient in concrete. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2013, 28, 314–319. [Google Scholar] [CrossRef]

| Properties | RSF |

|---|---|

| Length, (mm) | 20 |

| Diameter, (mm) | 0.25 |

| Aspect ratio, | 110 |

| Tensile strength (MPa) | 2648 |

| Concrete Mixture | CEM (kg) | FA (kg) | LF (kg) | W (L) | SP1 (L) | SP2 (L) | FS (kg) | CS (kg) | CG (kg) | RSF (kg) | W/C (-) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RSFRC0.8% | 380.5 | - | 353 | 140 | 7.8 | - | 237 | 710 | 590 | 60 | 0.37 |

| RSFRC1% | 400 | 200 | - | 173 | - | 7.2 | 148 | 735 | 597 | 76 | 0.43 |

| Test Series | Specimen (Figure 2) | |||

|---|---|---|---|---|

| 10 days_Cl− | 3 | 9.36 (74% 1) | 0.623 | 0.574 |

| 10 days_REF | 2 | 6.42 (76% 1) | 0.619 | 0.394 |

| 3 months_Cl− | 4 | 5.95 (74% 1) | 0.560 | 0.365 |

| 3 months_REF | 4 | 8.08 (82% 1) | 0.562 | 0.496 |

| 6 months_Cl− | 2 | 6.17 (68% 1) | 0.613 | 0.378 |

| 6 months_REF | 2 | 7.04 (69% 1) | 0.602 | 0.4326 |

| Average | 7.17 (74% 1) 18.39 | 0.596 4.76 | 0.440 18.40 | |

| CoV (%) | ||||

| Test Series | Crack (Figure 4b) | Panel Thickness (mm) | |||

|---|---|---|---|---|---|

| 10 days_Im_Cl− | 1 | 63.41 | 10.82 (76% 1) | 0.625 | 0.531 |

| 10 days_Im_REF | 1 | 67.65 | 7.69 (74% 1) | 0.629 | 0.377 |

| 3 months_DW_Cl− | 2 | 64.64 | 9.33 (77% 1) | 0.619 | 0.458 |

| 3 months_Im_REF | 2 | 66.42 | 8.73 (81% 1) | 0.628 | 0.429 |

| Average | 65.53 | 9.14 (77% 1) 14.30 | 0.625 0.72 | 0.449 14.32 | |

| CoV (%) | 2.86 | ||||

| Test Series | ||||

|---|---|---|---|---|

| 10 days_Im_Cl− | 150.94 | 248.89 | 353.18 | 424.40 |

| 10 days_Im_REF | 139.12 | 216.53 | 271.36 | - |

| 3 months_DW_Cl− | 178.78 | 286.80 | 379.42 | 432.00 |

| 3 months_Im_REF | 218.13 | 344.21 | 452.90 | 515.34 |

| RSFRC1% | PC | |

|---|---|---|

| () | 14.94 | 11.74 |

| CoV (%) | 13.60 | 22.74 |

| Concrete | ||

|---|---|---|

| RSFRC1% | 2.472 | 6.02 |

| PC | 2.361 | 5.92 |

| Test series | Cylindrical Specimens | Cubic Specimens | |

|---|---|---|---|

| RSFRC_10 days | 8.31 | 0.56 | - |

| RSFRC_3 months | 2.42 | 3.26 | |

| PC_10 days | 7.34 | 0.49 | - |

| PC_3 months | 2.48 | 2.49 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frazão, C.M.V.; Barros, J.A.O.; Bogas, J.A. Durability of Recycled Steel Fiber Reinforced Concrete in Chloride Environment. Fibers 2019, 7, 111. https://doi.org/10.3390/fib7120111

Frazão CMV, Barros JAO, Bogas JA. Durability of Recycled Steel Fiber Reinforced Concrete in Chloride Environment. Fibers. 2019; 7(12):111. https://doi.org/10.3390/fib7120111

Chicago/Turabian StyleFrazão, Cristina M. V., Joaquim A. O. Barros, and J. Alexandre Bogas. 2019. "Durability of Recycled Steel Fiber Reinforced Concrete in Chloride Environment" Fibers 7, no. 12: 111. https://doi.org/10.3390/fib7120111

APA StyleFrazão, C. M. V., Barros, J. A. O., & Bogas, J. A. (2019). Durability of Recycled Steel Fiber Reinforced Concrete in Chloride Environment. Fibers, 7(12), 111. https://doi.org/10.3390/fib7120111