Actuator Materials: Review on Recent Advances and Future Outlook for Smart Textiles

Abstract

:1. Introduction

2. Overview of Different Actuation Mechanisms

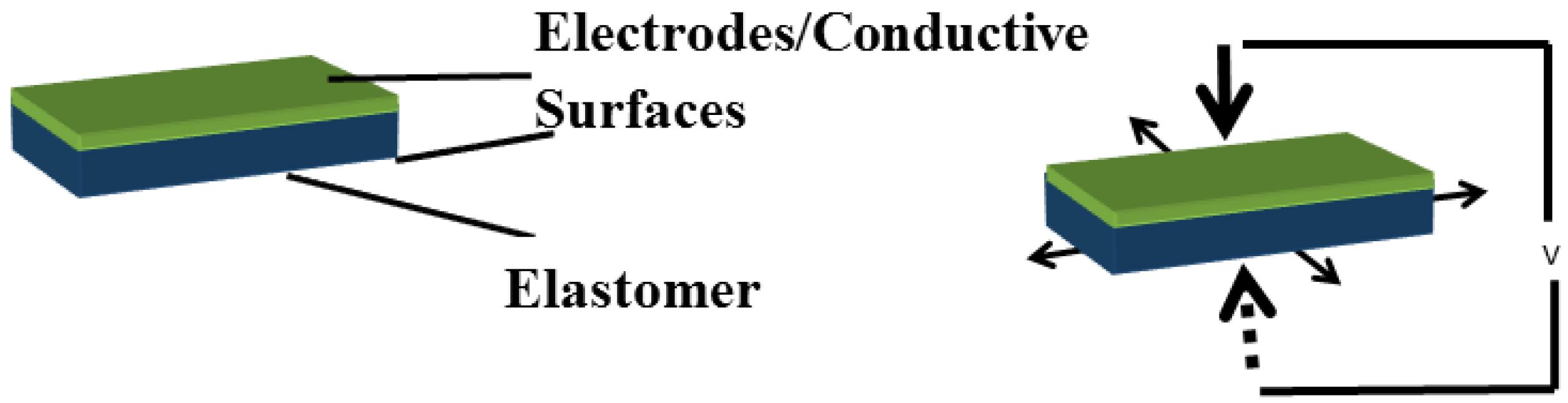

2.1. Electric Field Actuation.

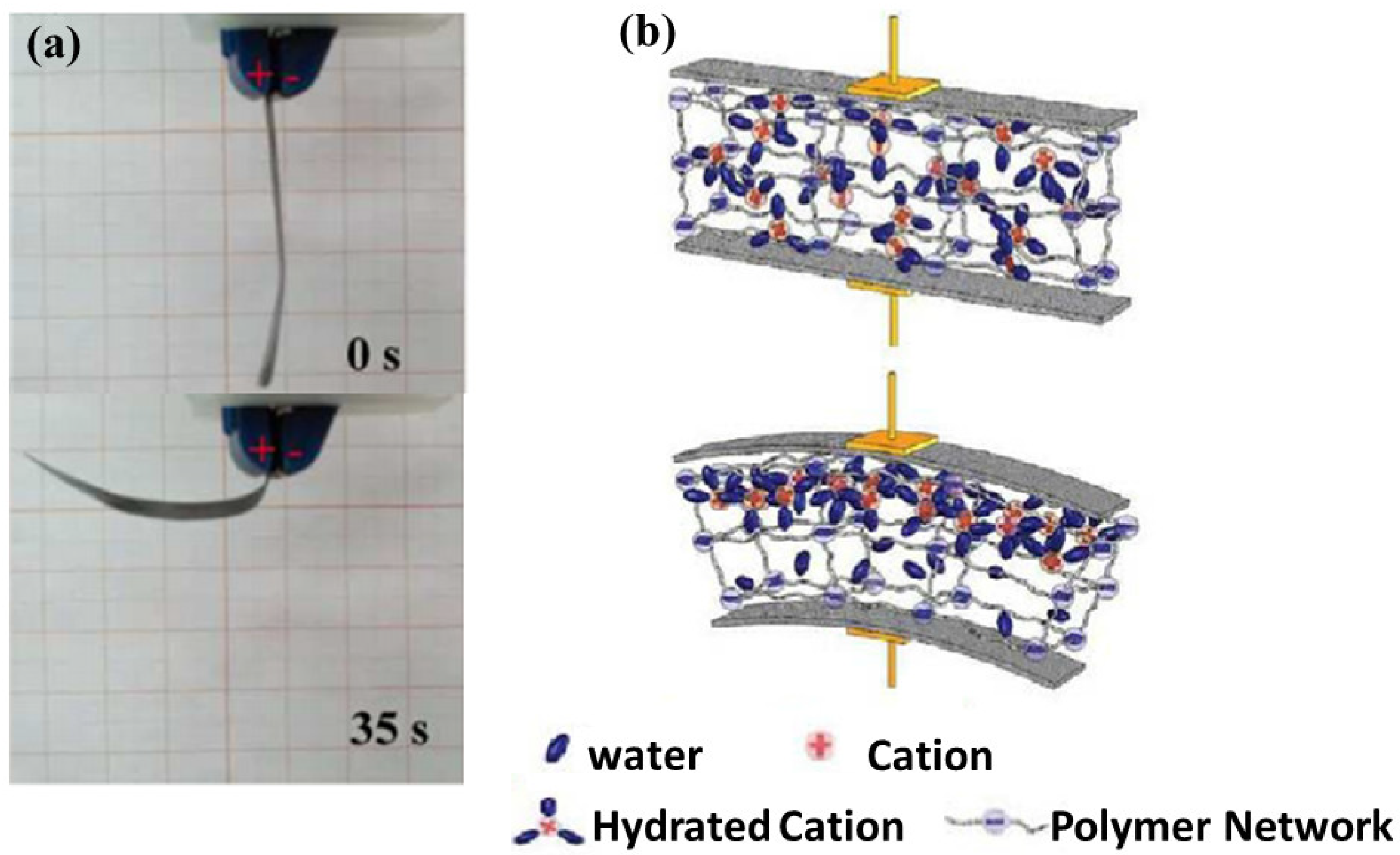

2.2. Ion Based Actuation

2.3. Pneumatic Actuation

2.4. Thermal Actuation

2.5. Other Actuation Mechanisms

3. Polymer Actuators in Smart Textiles

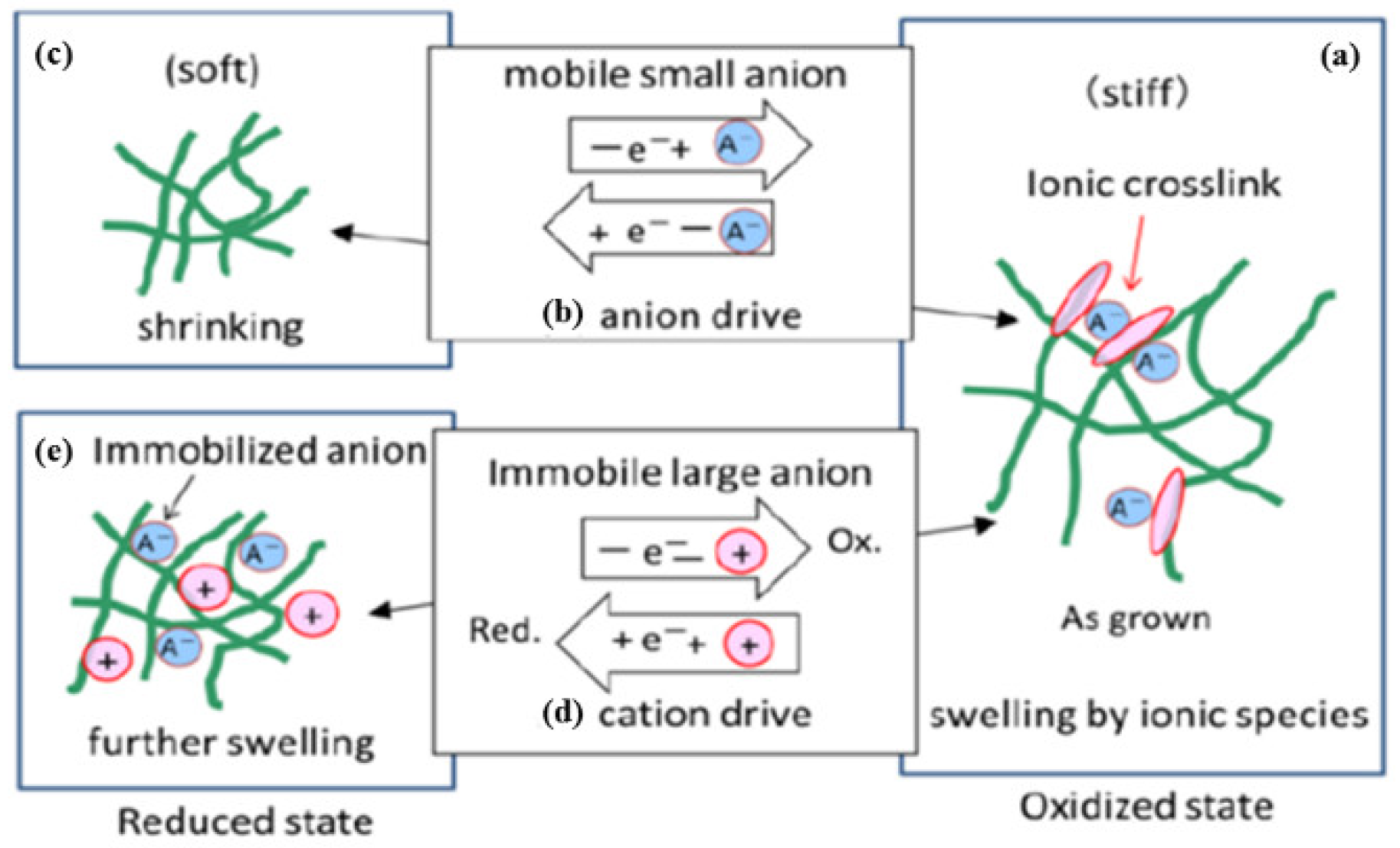

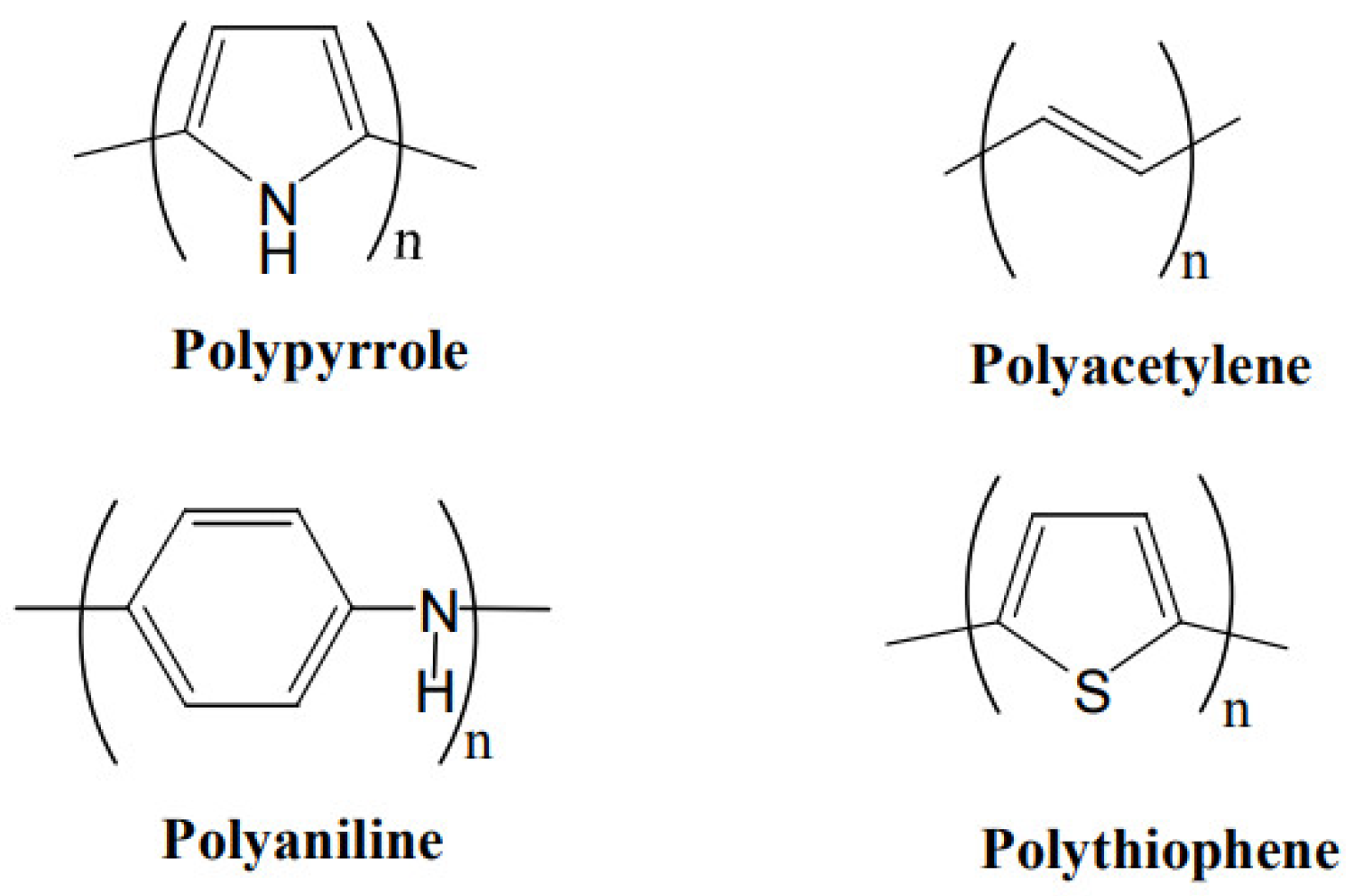

3.1. Conducting Polymers Actuators

3.1.1. Actuating Mechanism

3.1.2. Fabrication and Properties

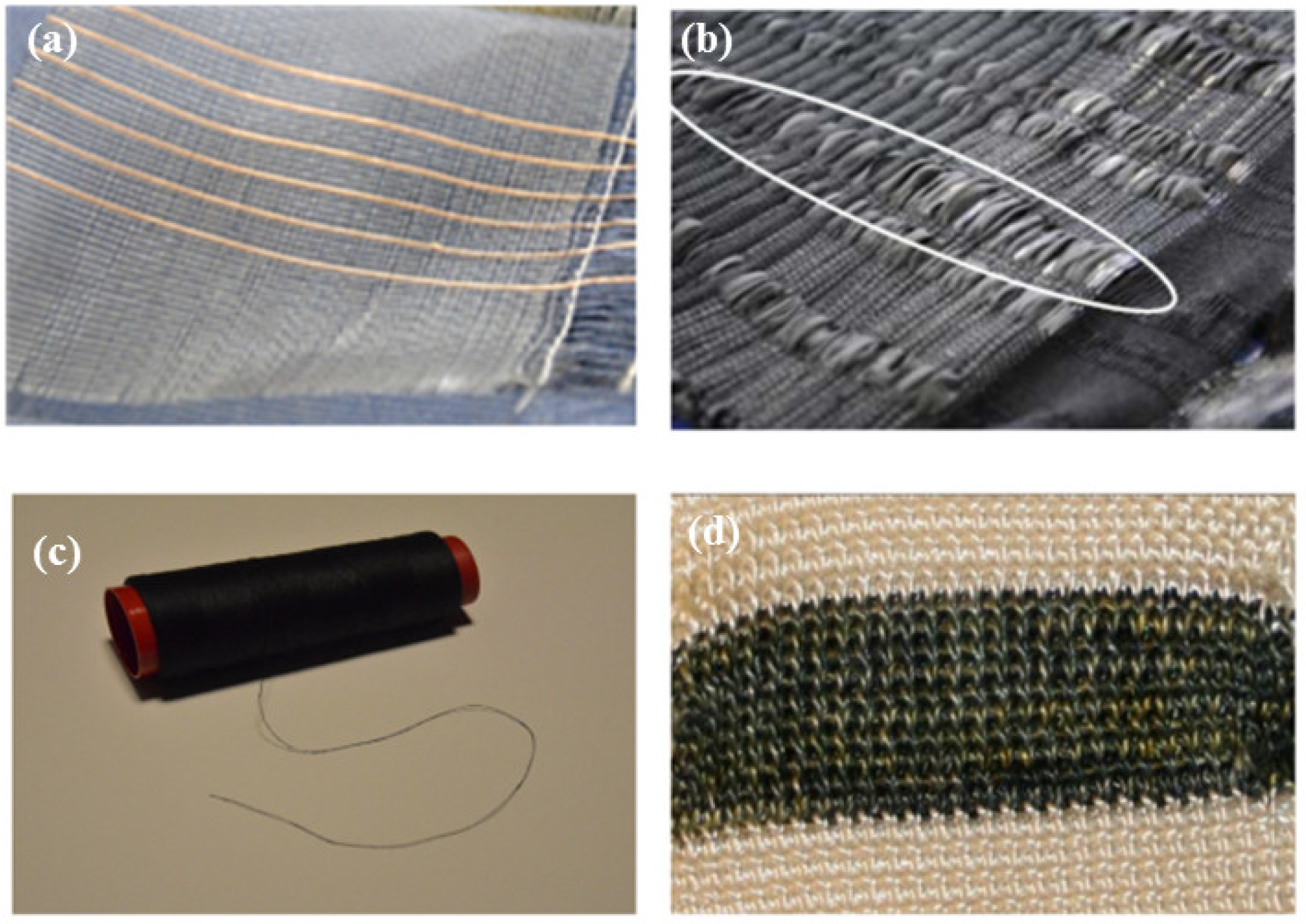

3.1.3. Conducting Polymer Based Actuating Textiles

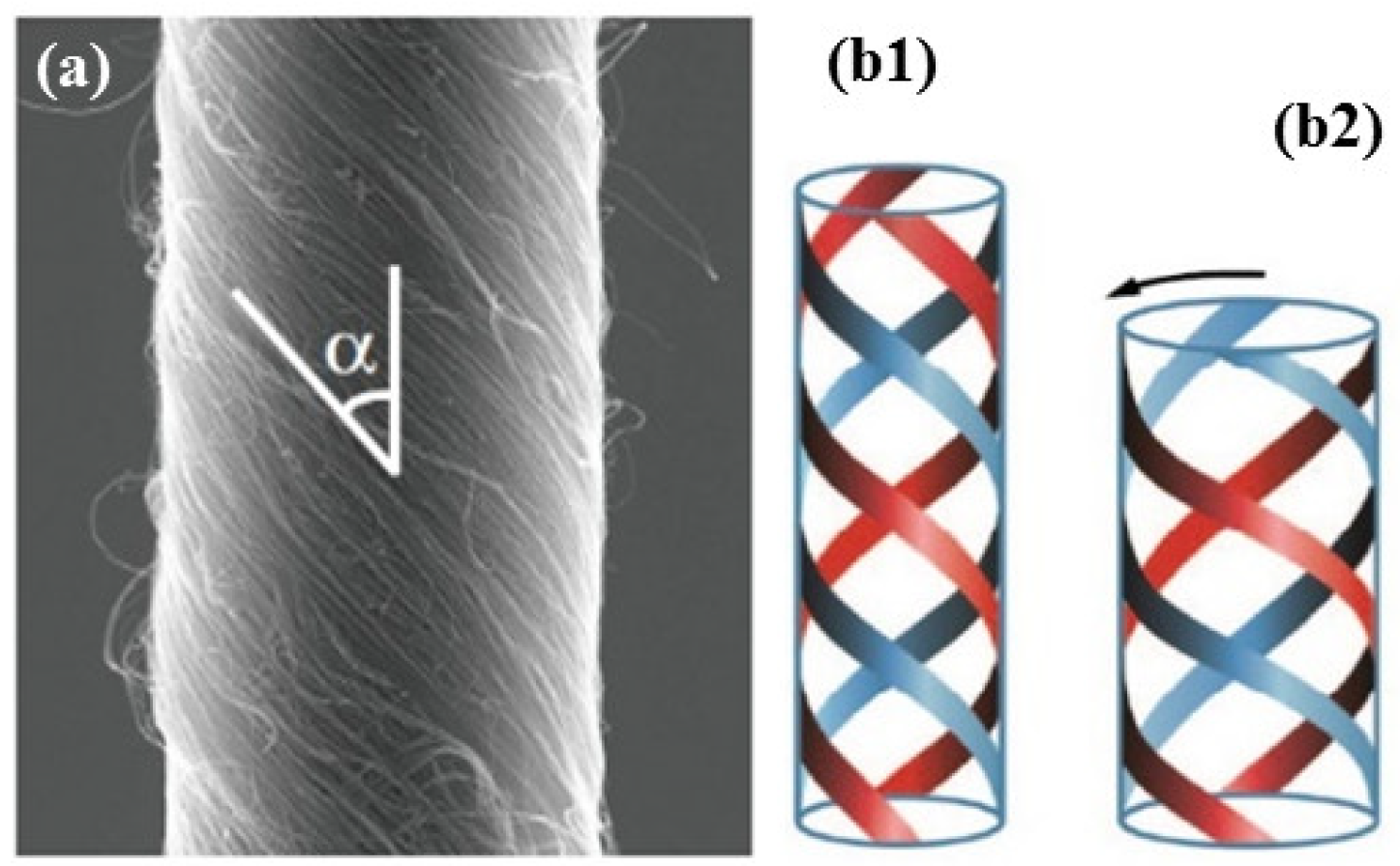

3.2. Carbon Nanotube Actuators

3.2.1. Actuating Mechanism

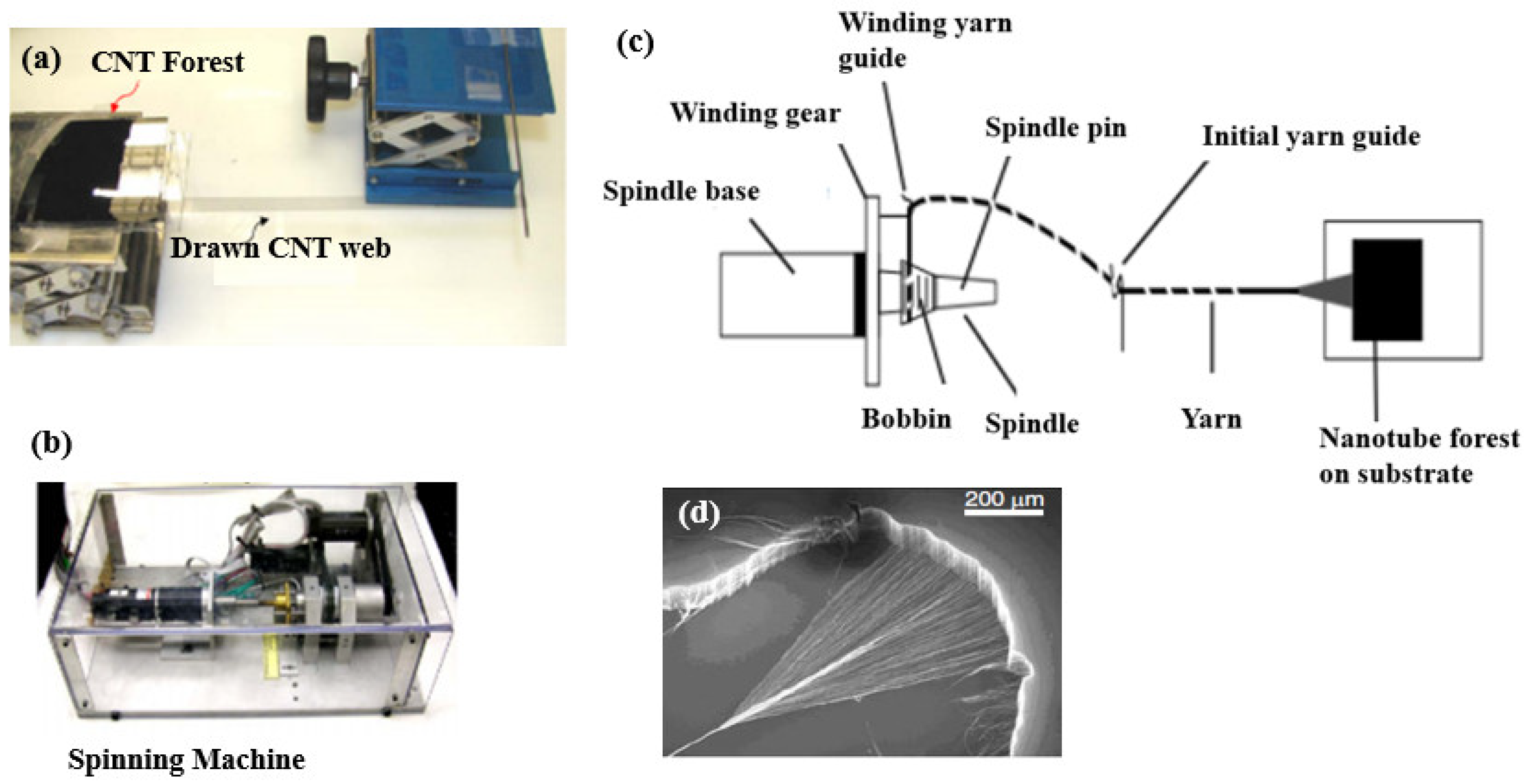

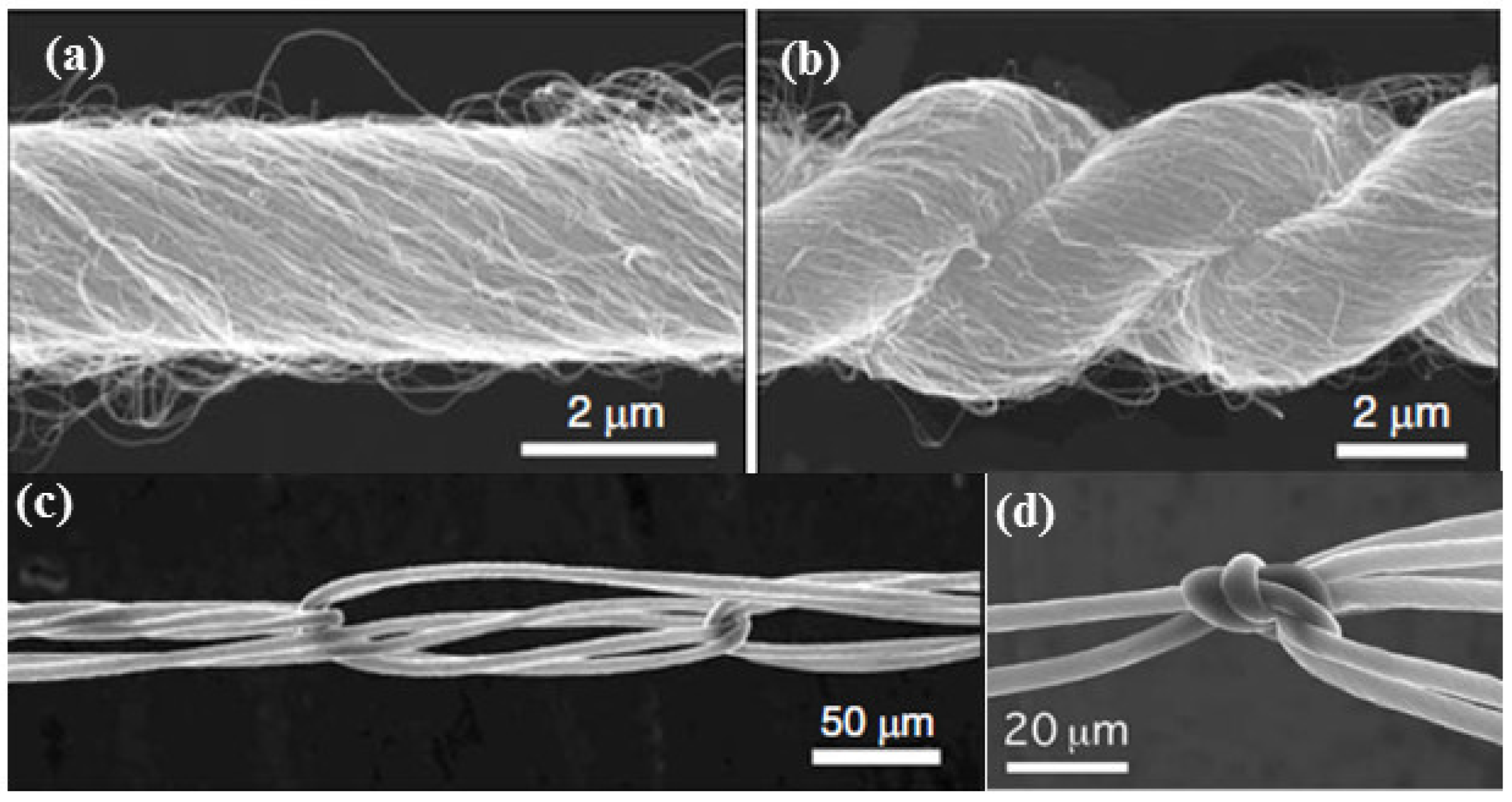

3.2.2. Fabrication and Properties

3.2.3. CNT Based Actuating Textile

3.3. Shape Memory Alloy (SMA) Actuators

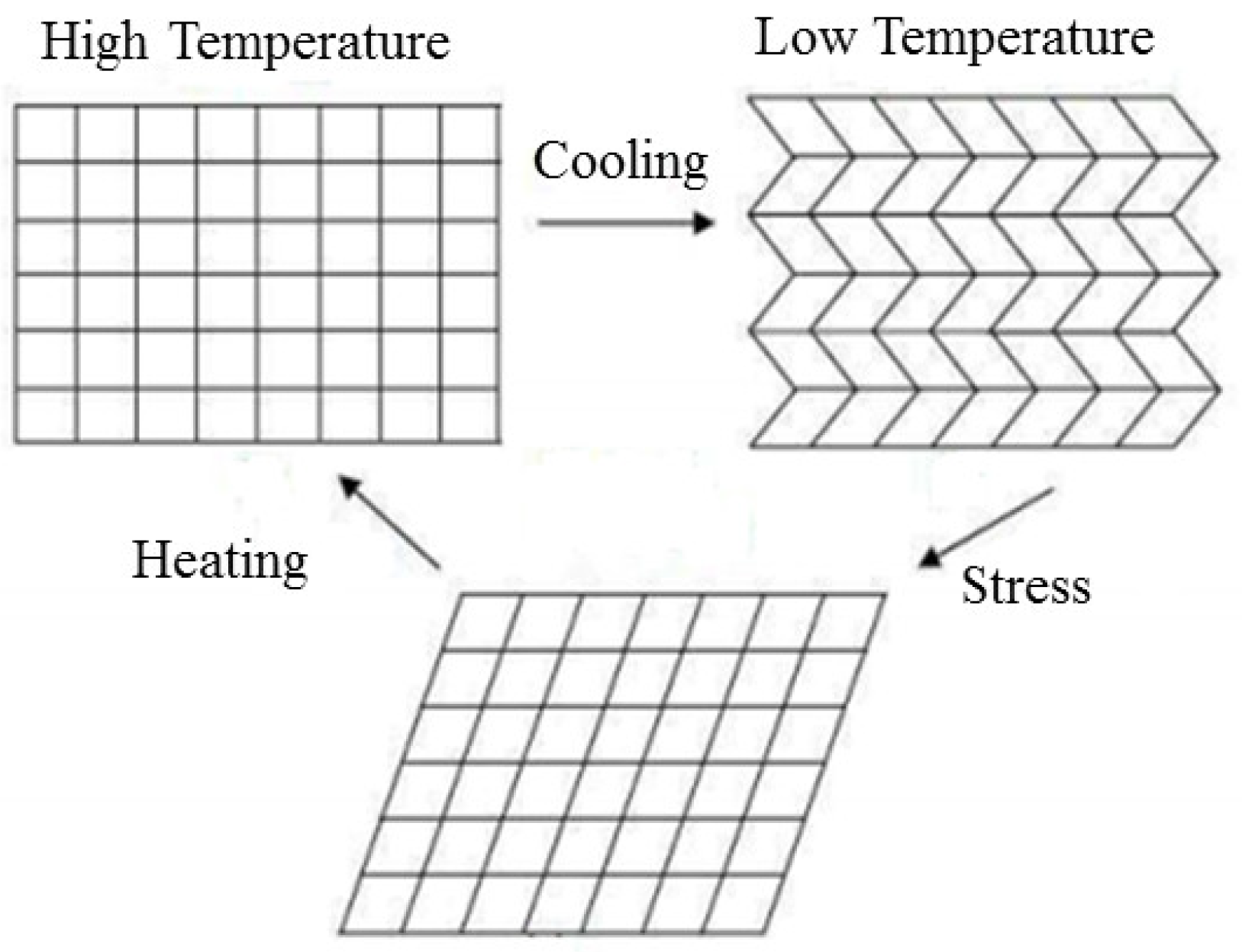

3.3.1. Actuating Mechanism

3.3.2. Fabrication and Properties

3.3.3. SMA based Actuating Textiles

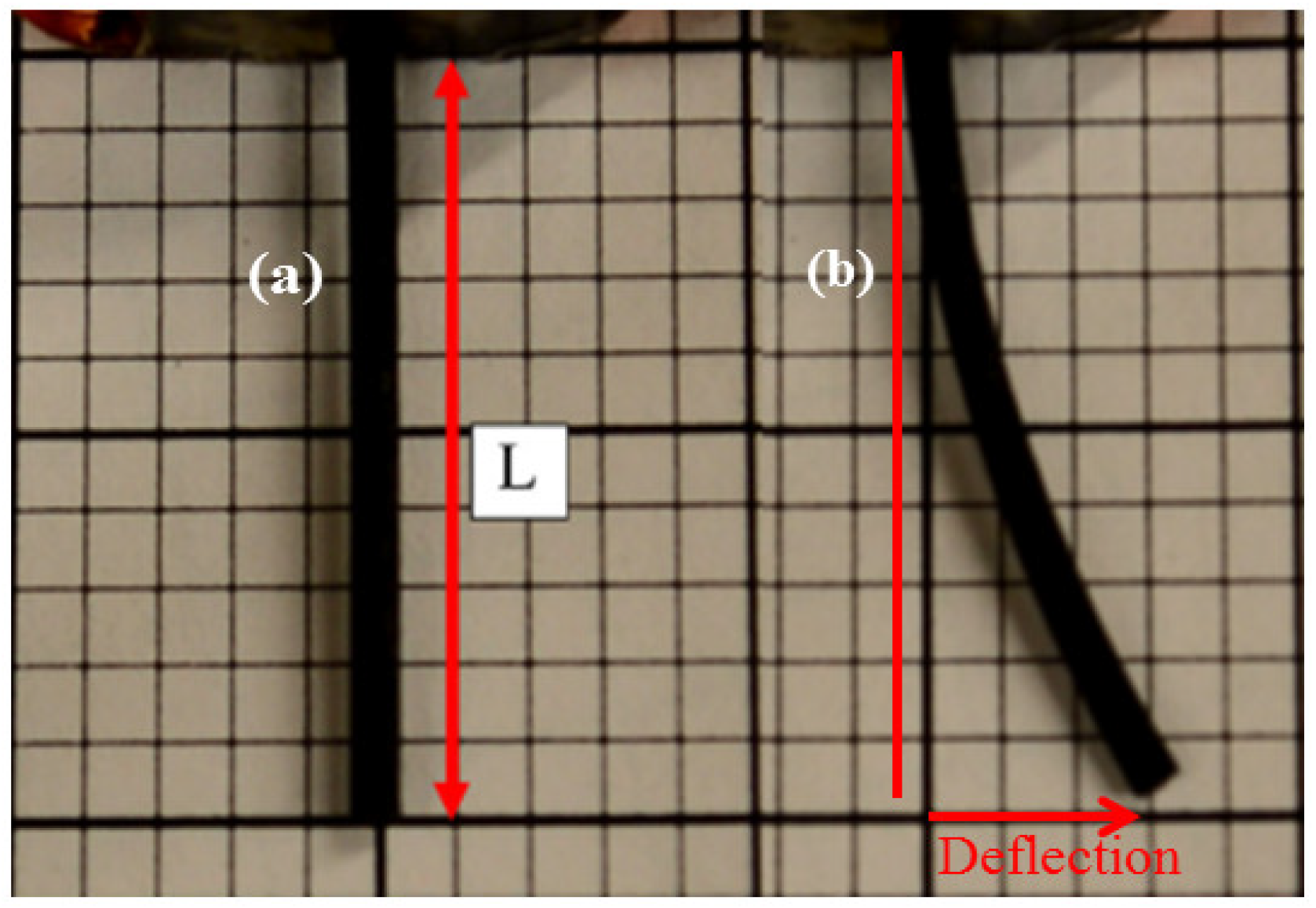

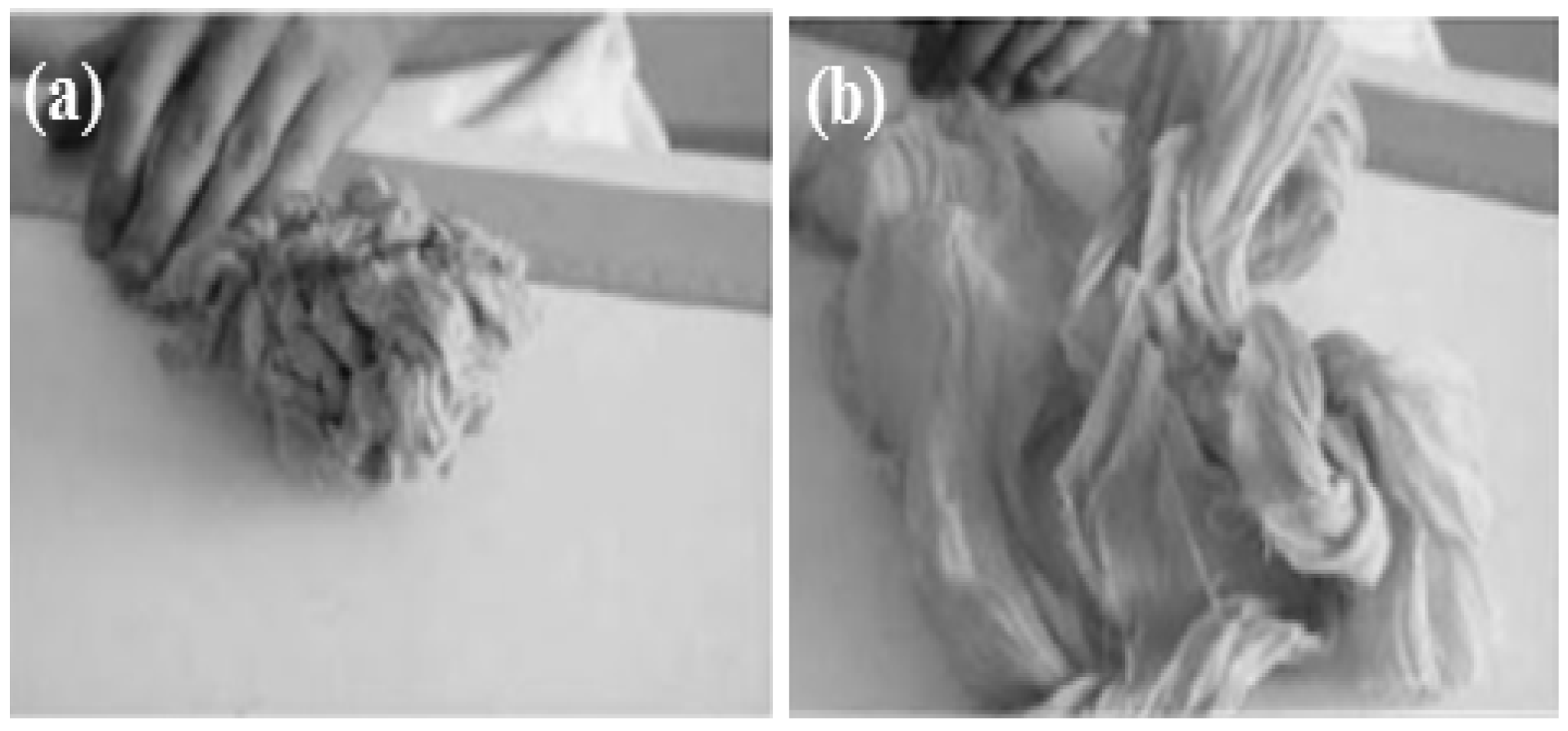

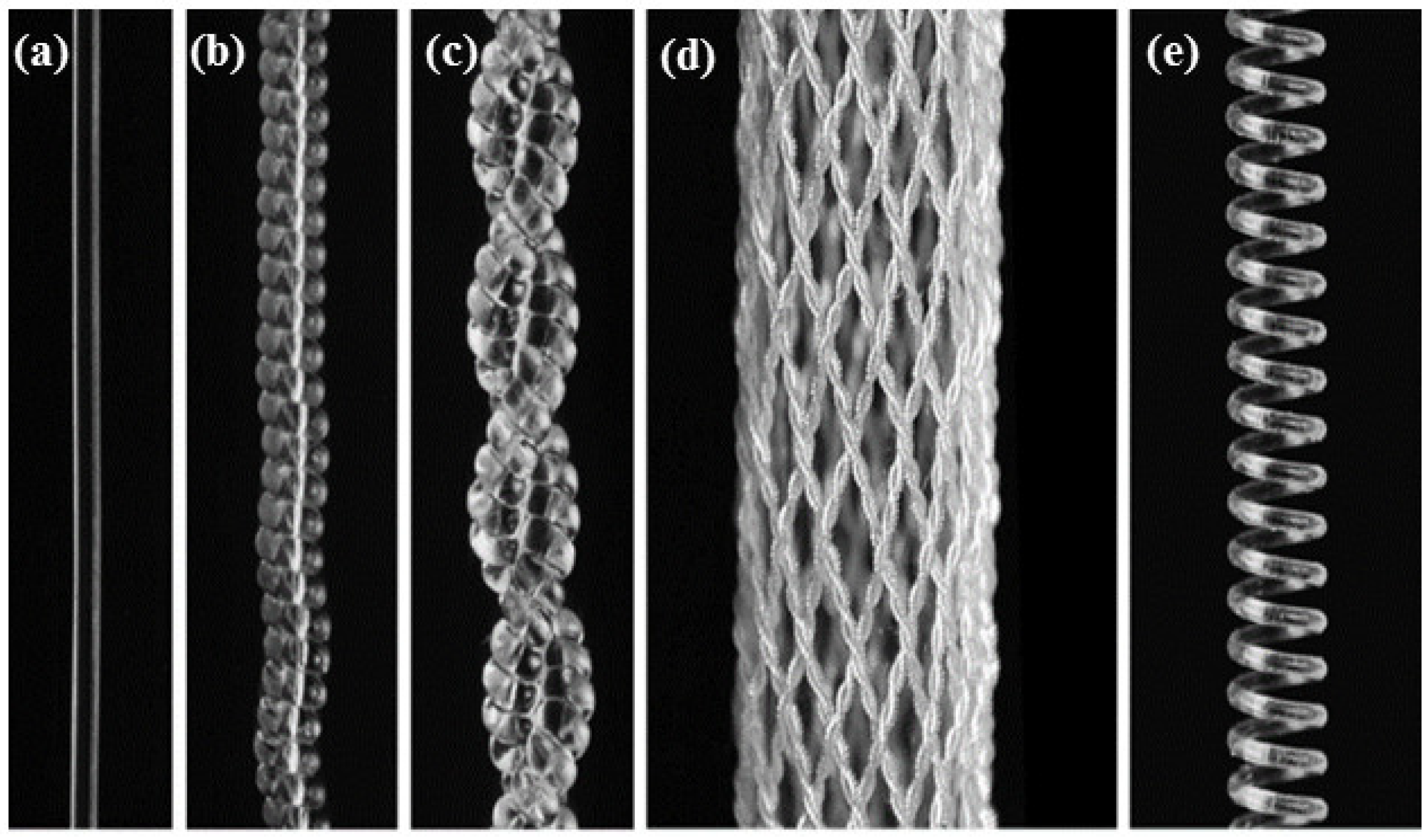

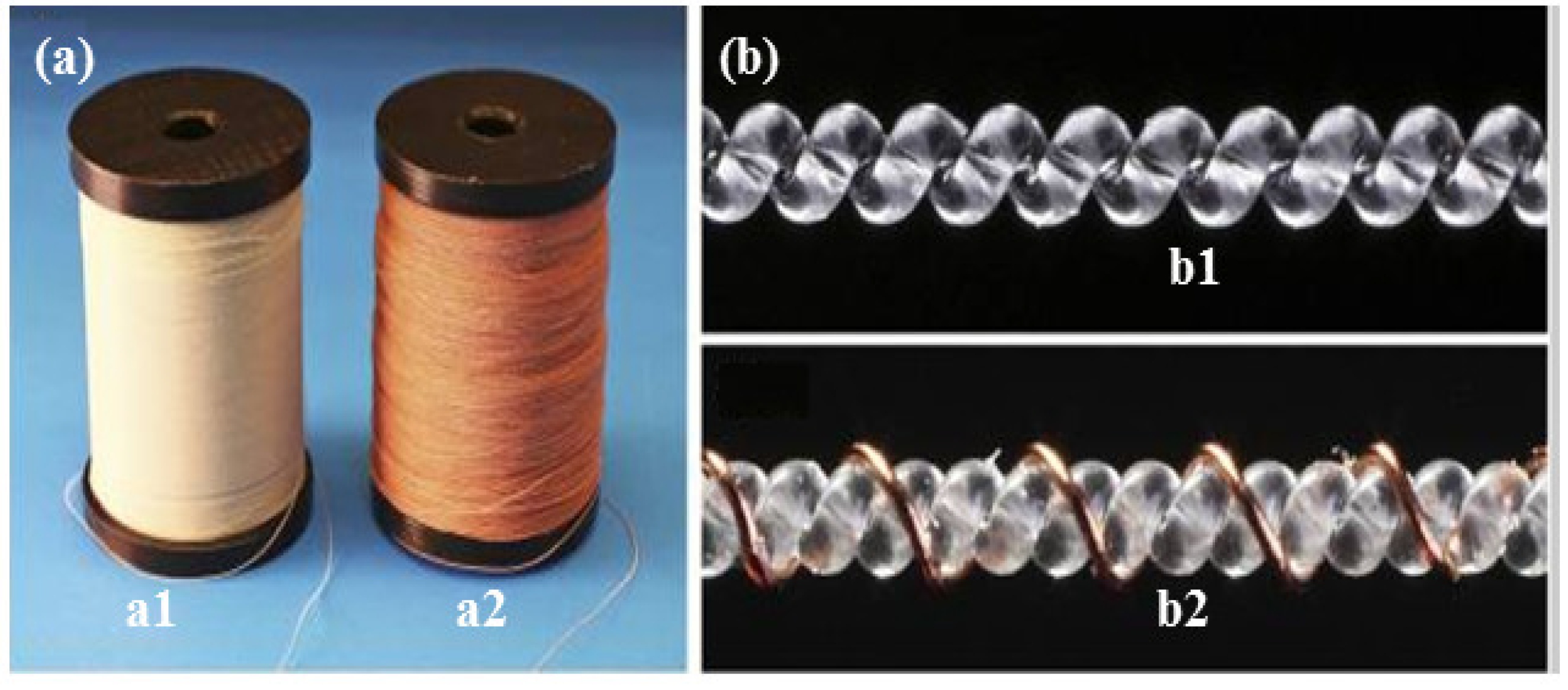

3.4. Twisted and Coiled Synthetic Fibre Actuators

3.4.1. Actuating Mechanism

3.4.2. Fabrication and Properties

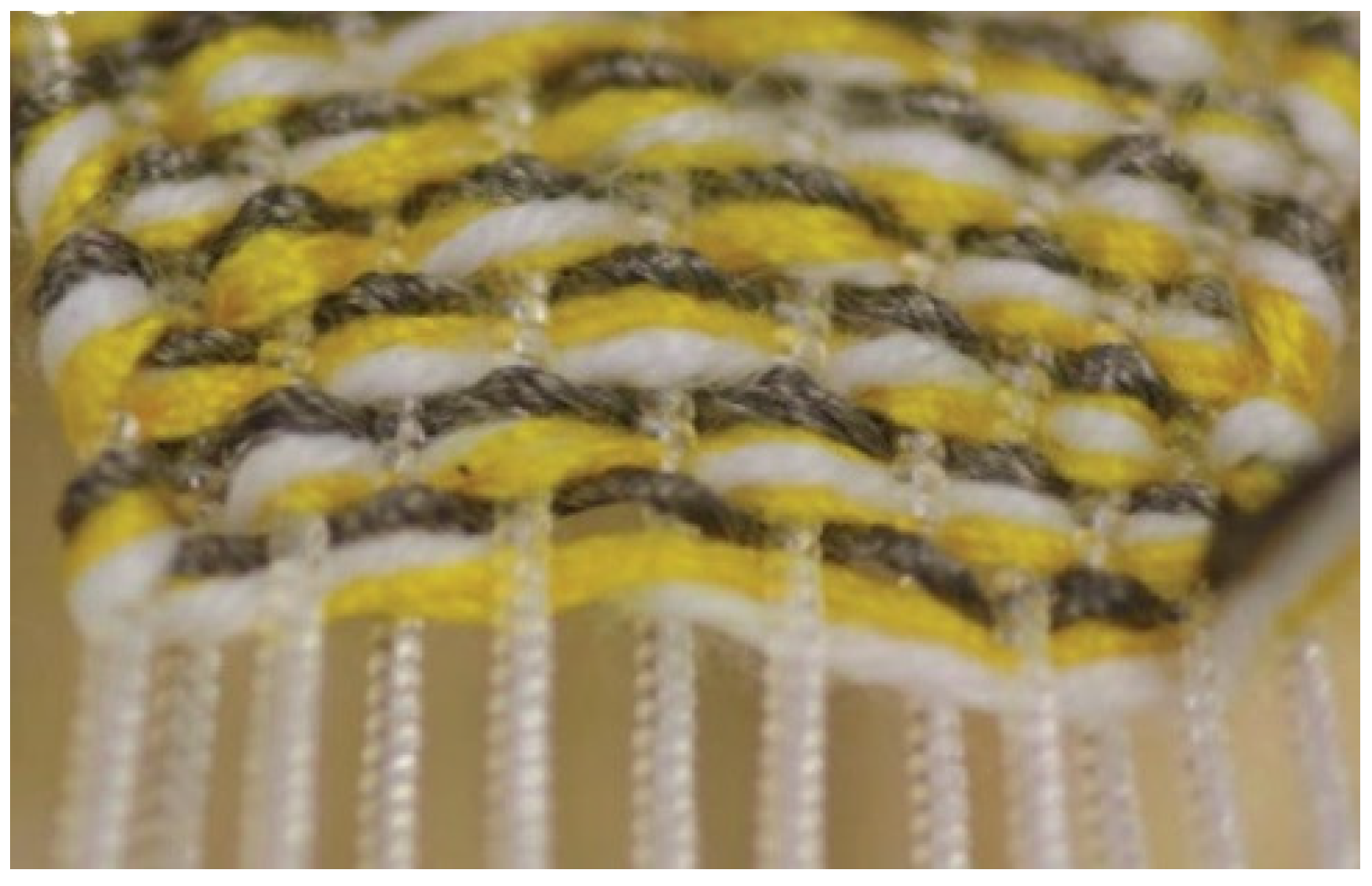

3.4.3. Twisted Polymer based Actuating Textiles

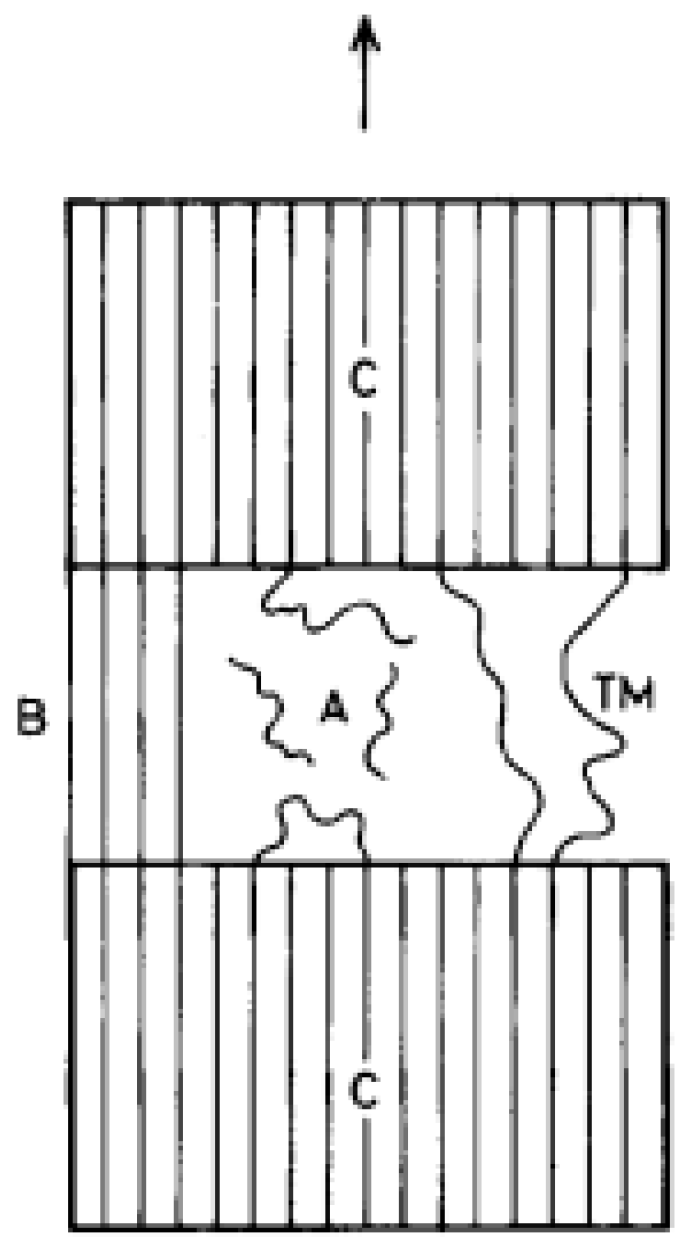

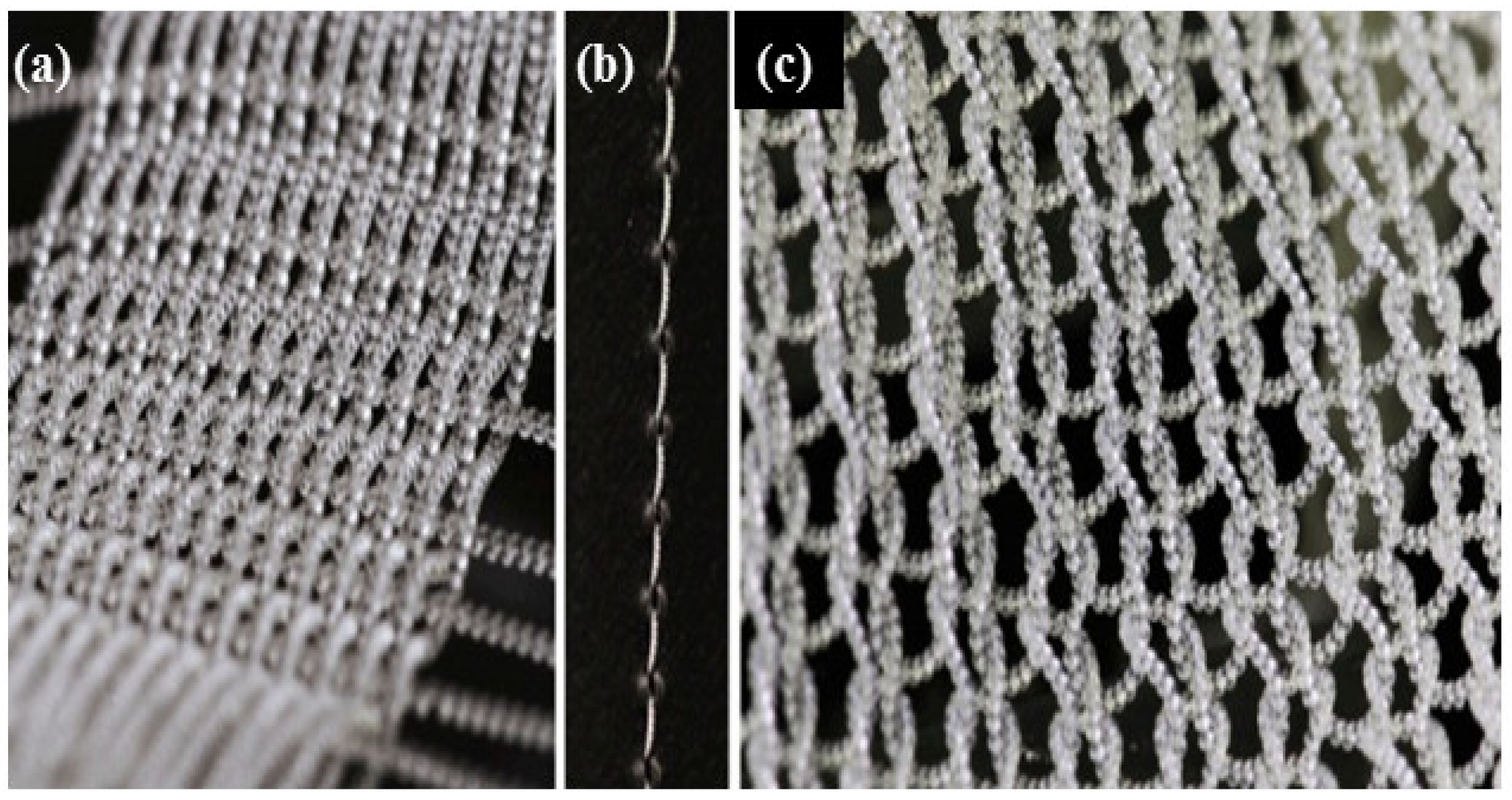

3.5. Knitted CNT/Spandex Yarn as Smart Textiles

4. Overview in Different Actuation Mechanism for Smart Textiles

5. Future Outlook

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Syduzzaman, M.; Patwary, S.U.; Farhana, K.; Ahmed, S. Smart Textiles and Nano-Technology: A General Overview. J. Text. Sci. Eng. 2015, 5, 181. [Google Scholar] [CrossRef]

- Van Langenhove, L.; Hertleer, C. Smart clothing: A new life. Int. J. Cloth. Sci. Technol. 2004, 16, 63–72. [Google Scholar] [CrossRef]

- Foroughi, J.; Spinks, G.M.; Wallace, G.G. Conducting Polymer Fibers. In Handbook of Smart Textiles; Tao, X., Ed.; Springer: Singapore, 2015; pp. 31–62. [Google Scholar]

- Park, S. Smart Textiles: Wearable Electronic Systems. MRS Bull. 2003, 28, 585–591. [Google Scholar] [CrossRef]

- Sahin, O.; Kayacan, O.; Bulgun, E.Y. Smart textiles for soldier of the future. Def. Sci. J. 2005, 55, 195–205. [Google Scholar] [CrossRef]

- Ramdayal; Balasubramanian, K. Advancement in Textile Technology for Defence Application. Def. Sci. J. 2013, 63, 331–339. [Google Scholar]

- Krishnan, M.; Kannan, G. Polygon Shaped 3G Mobile Band Antennas for High Tech Military Uniforms. Adv. Electromagn. 2016, 5, 7–13. [Google Scholar] [CrossRef]

- Zhang, X.; Tao, X. Smart textiles: Passive smart. Text. Asia 2001, 32, 45–49. [Google Scholar]

- Zhang, X.; Tao, X. Smart textiles: Very smart. Text. Asia 2001, 35–37. [Google Scholar]

- Zhang, X.; Tao, X. Smart textiles: Active smart. Text. Asia 2001, 49–52. [Google Scholar]

- Stoppa, M.; Chiolerio, A. Wearable Electronics and Smart Textiles: A Critical Review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef]

- Stoychev, G.V.; Ionov, L. Actuating Fibers: Design and Applications. ACS Appl. Mater. Interfaces 2016, 8, 24281–24294. [Google Scholar] [CrossRef] [PubMed]

- Foroughi, J.; Spinks, G.M.; Aziz, S.; Mirabedini, A.; Jeiranikhameneh, A.; Wallace, G.G.; Kozlov, M.E.; Baughman, R.H. Knitted Carbon-Nanotube-Sheath/Spandex-Core Elastomeric Yarns for Artificial Muscles and Strain Sensing. ACS Nano 2016, 10, 9129–9135. [Google Scholar] [CrossRef] [PubMed]

- Foroughi, J.; Spinks, G.M.; Wallace, G.G. High strain electromechanical actuators based on electrodeposited polypyrrole doped with di-(2-ethylhexyl)sulfosuccinate. Sens. Actuators B Chem. 2011, 155, 278–284. [Google Scholar] [CrossRef]

- Foroughi, J.; Spinks, G.M.; Wallace, G.G. A reactive wet spinning approach to polypyrrole fibres. J. Mater. Chem. 2011, 21, 6421–6426. [Google Scholar] [CrossRef]

- Foroughi, J.; Spinks, G.M.; Wallace, G.G.; Oh, J.; Kozlov, M.E.; Fang, S.; Mirfakhrai, T.; Madden, J.D.W.; Shin, M.K.; Kim, S.J.; et al. Torsional Carbon Nanotube Artificial Muscles. Science 2011, 334, 494–497. [Google Scholar] [CrossRef] [PubMed]

- Haines, C.S.; Lima, M.D.; Li, N.; Spinks, G.M.; Foroughi, J.; Madden, J.D.W.; Kim, S.H.; Fang, S.; Jung de Andrade, M.; Göktepe, F.; et al. Artificial Muscles from Fishing Line and Sewing Thread. Science 2014, 343, 868–872. [Google Scholar] [CrossRef] [PubMed]

- Lima, M.D.; Li, N.; de Andrade, M.J.; Fang, S.; Oh, J.; Spinks, G.M.; Kozlov, M.E.; Haines, C.S.; Suh, D.; Foroughi, J.; et al. Electrically, Chemically, and Photonically Powered Torsional and Tensile Actuation of Hybrid Carbon Nanotube Yarn Muscles. Science 2012, 338, 928–932. [Google Scholar] [CrossRef] [PubMed]

- Haines, C.S. New twist on artificial muscles. Proc. Natl. Acad. Sci. USA 2016, 113, 11709–11716. [Google Scholar] [CrossRef] [PubMed]

- Tondu, B. Artificial muscles for humanoid robots. In Humanoid Robots, Human-Like Machines; InTech: London, UK, 2007. [Google Scholar]

- Huber, J.E.; Fleck, N.A.; Ashby, M.F. The selection of mechanical actuators based on performance indices. Proc. R. Soc. Lond. A: Math. Phys. Eng. Sci. 1997, 453, 2185–2205. [Google Scholar] [CrossRef]

- Bar-Cohen, Y. Current and future developments in artificial muscles using electroactive polymers. Expert Rev. Med. Devices 2005, 2, 731–740. [Google Scholar] [CrossRef]

- Vincenzini, P.; Bar-Cohen, Y.; Carpi, F.; Vincenzini, P. Actuators Using Electroactive Polymers: Actuators Using Electroactive Polymers: Cimtec 2008; Trans Tech Publications, Limited: Durnten, Switzerland, 2008. [Google Scholar]

- Kornbluh, R.D.; Pelrine, R.; Pei, Q.; Oh, S.; Joseph, J. Ultrahigh strain response of field-actuated elastomeric polymers. In Proceedings of the SPIE’s 7th Annual International Symposium on Smart Structures and Materials, Beach, CA, USA, 6–9 March 2000; p. 14. [Google Scholar]

- Mirfakhrai, T.; Madden, J.D.W.; Baughman, R.H. Polymer artificial muscles. Mater. Today 2007, 10, 30–38. [Google Scholar] [CrossRef]

- Madden, J.D.; Vandesteeg, N.A.; Anquetil, P.A.; Madden, P.G.; Takshi, A.; Pytel, R.Z.; Lafontaine, S.R.; Wieringa, P.A.; Hunter, I.W. Technology: Physical principles and naval prospects. IEEE J. Ocean. Eng. 2004, 29, 706–728. [Google Scholar] [CrossRef]

- Wallmersperger, T.; Kröplin, B.; Gülch, R. Electroactive Polymer (EAP) Actuators as Artificial Muscles-Reality, Potential, and Challenges; Modelling and Analysis of Chemistry and Electromechanics; Spie Press: Bellingham, WA, USA, 2004; Volume PM 136. [Google Scholar]

- Kim, K.J. Biomimetic Robotic Artificial Muscles. [Electronic Resource]; World Scientific: Singapore; Hackensack, NJ, USA, 2013. [Google Scholar]

- Tang, Y.; Xue, Z.; Xie, X.; Zhou, X. Ionic polymer–metal composite actuator based on sulfonated poly (ether ether ketone) with different degrees of sulfonation. Sens. Actuators A Phys. 2016, 238, 167–176. [Google Scholar] [CrossRef]

- Park, I.-S.; Jung, K.; Kim, D.; Kim, S.-M.; Kim, K.J. Physical principles of ionic polymer–metal composites as electroactive actuators and sensors. MRS Bull. 2008, 33, 190–195. [Google Scholar] [CrossRef]

- Nemat-Nasser, S.; Wu, Y. Comparative experimental study of ionic polymer–metal composites with different backbone ionomers and in various cation forms. J. Appl. Phys. 2003, 93, 5255–5267. [Google Scholar] [CrossRef]

- Shahinpoor, M.; Kim, K.J. Ionic polymer-metal composites: I. Fundamentals. Smart Mater. Struct. 2001, 10, 819–833. [Google Scholar] [CrossRef]

- Laksanacharoen, S. Artificial Muscle Construction Using Natural Rubber Latex in Thailand. In Proceedings of the 3rd Thailand and Material Science and Technology Conference, Bangkok, Thailand, 10–11 August 2004; pp. 1–3. [Google Scholar]

- Agerholm, M. The “artificial muscle” of mckibben. Lancet 1961, 277, 660–661. [Google Scholar] [CrossRef]

- Sangian, D. New Types of McKibben Artificial Muscles. Ph.D. Thesis, School of Mechanical, Materials and Mechatronic Engineering, University of Wollongong, Wollongong, Australia, 2016. [Google Scholar]

- Kelasidi, E.; Andrikopoulos, G.; Nikolakopoulos, G.; Manesis, S. A survey on pneumatic muscle actuators modeling. In Proceedings of the 2011 IEEE International Symposium on Industrial Electronics (ISIE), Gdansk, Poland, 27–30 June 2011; pp. 1263–1269. [Google Scholar]

- Baughman, R.H. Carbon nanotube actuators. Science 1999, 284, 1340–1344. [Google Scholar] [CrossRef] [PubMed]

- Mirfakhrai, T.; Jiyoung, O.; Kozlov, M.; Fok, E.C.W.; Mei, Z.; Shaoli, F.; Baughman, R.H.; Madden, J.D.W. Electrochemical actuation of carbon nanotube yarns. Smart Mater. Struct. 2007, 16. [Google Scholar] [CrossRef]

- Lange, N.; Wippermann, F.; Leitel, R.; Bruchmann, C.; Beckert, E.; Eberhardt, R.; Tünnermann, A. First results on electrostatic polymer actuators based on uv replication. In Proceedings of the Micromachining and Microfabrication Process Technology XVI: SPIE Photonics West, San Francisco, CA, USA, 22–27 January 2011; p. 792609. [Google Scholar]

- Johnstone, R.W.; Parameswaran, M. Electrostatic Actuators. In An Introduction to Surface-Micromachining; Springer: Boston, MA, USA, 2004; pp. 135–152. [Google Scholar]

- Jones, B.E.; McKenzie, J.S. A review of optical actuators and the impact of micromachining. Sens. Actuators A Phys. 1993, 37–38, 202–207. [Google Scholar] [CrossRef]

- Howe, D. Magnetic actuators. Sens. Actuators A Phys. 2000, 81, 268–274. [Google Scholar] [CrossRef]

- Tiwari, R.; Meller, M.A.; Wajcs, K.B.; Moses, C.; Reveles, I.; Garcia, E. Hydraulic artificial muscles. J. Intell. Mater. Syst. Struct. 2012, 23, 301–312. [Google Scholar] [CrossRef]

- Solano, B.; Laloy, J.; Rotinat-Libersa, C. Compact and lightweight hydraulic actuation system for high performance millimeter scale robotic applications: Modeling and experiments. In Proceedings of the ASME 2010 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Philadelphia, PA, USA, 28 September–1 October 2010; pp. 405–411. [Google Scholar]

- Tondu, B.; Emirkhanian, R.; Mathé, S.; Ricard, A. A pH-activated using the McKibben-type braided structure. Sens. Actuators A Phys. 2009, 150, 124–130. [Google Scholar] [CrossRef]

- Schreyer, H.B.; Gebhart, N.; Kim, K.J.; Shahinpoor, M. Electrical Activation of Artificial Muscles Containing Polyacrylonitrile Gel Fibers. Biomacromolecules 2000, 1, 642–647. [Google Scholar] [CrossRef]

- Maziz, A.; Concas, A.; Khaldi, A.; Stålhand, J.; Persson, N.-K.; Jager, E.W.H. Knitting and weaving artificial muscles. Sci. Adv. 2017, 3. [Google Scholar] [CrossRef] [PubMed]

- Carosio, S.; Monero, A. Smart and hybrid materials: Perspectives for their use in textile structures for better health care. Stud. Health Technol. Inform. 2004, 108, 335–343. [Google Scholar] [PubMed]

- Abel, J.; Luntz, J.; Brei, D. A two-dimensional analytical model and experimental validation of garter stitch knitted shape memory alloy actuator architecture. Smart Mater. Struct. 2012, 21, 085011. [Google Scholar] [CrossRef]

- Zhang, M.; Atkinson, K.R.; Baughman, R.H. Multifunctional Carbon Nanotube Yarns by Downsizing an Ancient Technology. Science 2004, 306, 1358–1361. [Google Scholar] [CrossRef]

- Li, D.; Paxton, W.F.; Baughman, R.H.; Huang, T.J.; Stoddart, J.F.; Weiss, P.S. Molecular, supramolecular, and macromolecular motors and artificial muscles. MRS Bull. 2009, 34, 671–681. [Google Scholar] [CrossRef]

- Mirvakili, S.M. Niobium Nanowire Yarns and their Application as Artificial Muscles. Adv. Funct. Mater. 2013, 23, 4311–4316. [Google Scholar] [CrossRef]

- Peining, C.; Yifan, X.; Sisi, H.; Xuemei, S.; Shaowu, P.; Jue, D.; Daoyong, C.; Huisheng, P. Hierarchically arranged helical fibre actuators driven by solvents and vapours. Nat. Nanotechnol. 2015, 10, 1077–1083. [Google Scholar] [CrossRef]

- Harun, M.H.; Saion, E.; Kassim, A.; Yahya, N.; Mahmud, E. Conjugated conducting polymers: A brief overview. UCSI Acad. J. J. Adv. Sci. Arts 2007, 2, 63–68. [Google Scholar]

- Kaneto, K. Research Trends of Soft Actuators based on Electroactive Polymers and Conducting Polymers. J. Phys. Conf. Ser. 2016, 704, 012004. [Google Scholar] [CrossRef]

- Foroughi, J. Development of Novel Nanostructured Conducting Polypyrrole Fibres; Intelligent Polymer Research Institute, Faculty of Engineering: Wollongong, Australia, 2009. [Google Scholar]

- Madden, J. Creep and cycle life in polypyrrole actuators. Sens. Actuators A Phys. 2007, 133, 210–217. [Google Scholar] [CrossRef]

- Kim, J. Synthesis, characterization and actuation behavior of polyaniline-coated electroactive paper actuators. Polym. Int. 2007, 56, 1530–1536. [Google Scholar] [CrossRef]

- Xie, J. Fabrication and characterization of solid state conducting polymer actuators. Proc. SPIE 2004, 5385, 406–412. [Google Scholar] [CrossRef]

- De Rossi, D.; Mazzoldi, A. Linear Fully Dry Polymer Actuators; Place of Publication: Newport Beach, CA, USA, 1999; pp. 35–44. [Google Scholar]

- Takashima, W. The electrochemical actuator using electrochemically-deposited poly-aniline film. Synth. Met. 1995, 71, 2265–2266. [Google Scholar] [CrossRef]

- Simaite, A. Towards inkjet printable conducting polymer artificial muscles. Sens. Actuators B Chem. 2016, 229, 425–433. [Google Scholar] [CrossRef]

- Okuzaki, H. Ionic liquid/polyurethane/PEDOT:PSS composites for electro-active polymer actuators. Sens. Actuators B Chem. 2014, 194, 59–63. [Google Scholar] [CrossRef]

- Wang, G. Actuator and Generator Based on Moisture-Responsive PEDOT: PSS/PVDF composite film. Sens. Actuators B Chem. 2018, 255, 1415–1421. [Google Scholar] [CrossRef]

- Naficy, S. Evaluation of encapsulating coatings on the performance of polypyrrole actuators. Smart Mater. Struct. 2013, 22, 075005. [Google Scholar] [CrossRef]

- Fengel, C.V.; Bradshaw, N.P.; Severt, S.Y.; Murphy, A.R.; Leger, J.M. Biocompatible silk-conducting polymer composite trilayer actuators. Smart Mater. Struct. 2017, 26, 055004. [Google Scholar] [CrossRef]

- Khaldi, A.; Maziz, A.; Alici, G.; Spinks, G.M.; Jager, E.W.H. Bottom-up microfabrication process for individually controlled conjugated polymer actuators. Sens. Actuators B Chem. 2016, 230, 818–824. [Google Scholar] [CrossRef]

- Burriss, E.T.; Alici, G.; Spinks, G.M.; McGovern, S. Modelling and Performance Enhancement of a Linear Actuation Mechanism Using Conducting Polymers. Inf. Control Autom. Rob. 2011, 85, 63–78. [Google Scholar]

- Spinks, G.; Binbin, X.; Campbell, T.; Whitten, P.; Mottaghitalab, V.; Samani, M.B.; Wallace, G.G. In pursuit of high-force/high-stroke conducting polymer actuators. In Proceedings of the Volume 5759, Smart Structures and Materials 2005: Electroactive Polymer Actuators and Devices (EAPAD), San Diego, CA, USA, 6 May 2005; pp. 314–321. [Google Scholar]

- Baughman, R.H. Conducting polymer artificial muscles. Synth. Met. 1996, 78, 339–353. [Google Scholar] [CrossRef]

- Madden, J.D.; Madden, P.G.; Anquetil, P.A.; Hunter, I.W. Load and time dependence of displacement in a conducting polymer actuator. Mat. Res. Soc. Symp. Proc. 2002, 698, 137–144. [Google Scholar]

- Anquetil, P.A.; Rinderknecht, D.; Vandesteeg, N.A.; Madden, J.D.; Hunter, I.W. Large strain actuation in polypyrrole actuators. In Proceedings of the Smart Structures and Materials 2004: Electroactive Polymer Actuators and Devices (EAPAD), San Diego, CA, USA, 27 July 2004; pp. 380–387. [Google Scholar]

- Madden, J.D. Encapsulated polypyrrole actuators. Synth. Met. 1999, 105, 61–64. [Google Scholar] [CrossRef]

- Farajollahi, M.; Woehling, V.; Plesse, C.; Nguyen, G.T.M.; Vidal, F.; Sassani, F.; Yang, V.X.D.; Madden, J.D.W. Self-contained tubular bending actuator driven by conducting polymers. Sens. Actuators A Phys. 2016, 249, 45–56. [Google Scholar] [CrossRef]

- Lee, J.A.; Li, N.; Haines, C.S.; Kim, K.J.; Lepró, X.; Ovalle-Robles, R.; Kim, S.J.; Baughman, R.H. Electrochemically Powered, Energy-Conserving Carbon Nanotube Artificial Muscles. Adv. Mater. 2017, 29, 1700870. [Google Scholar] [CrossRef]

- Lee, J.A.; Kim, Y.T.; Spinks, G.M.; Suh, D.; Lepró, X.; Lima, M.D.; Baughman, R.H.; Kim, S.J. All-Solid-State Carbon Nanotube Torsional and Tensile Artificial Muscles. Nano Lett. 2014, 14, 2664–2669. [Google Scholar] [CrossRef]

- Chu, H.-Y. Microsystems. “CNT-Polymer” Composite-Film as a Material for Microactuators. In Proceedings of the IEEE Transducers 2007 International Solid-State Sensors, Actuators and Microsystems Conference, Lyon, France, 10–14 June 2007; pp. 1549–1552. [Google Scholar]

- Dang, D.X.; Truong, T.K.; Lim, S.C.; Suh, D. Multi-dimensional actuation measurement method for tensile actuation of paraffin-infiltrated multi-wall carbon nanotube yarns. Rev. Sci. Instrum. 2017, 88, 075001. [Google Scholar] [CrossRef]

- Chen, L.Z.; Liu, C.H.; Hu, C.H.; Fan, S.S. Electrothermal actuation based on carbon nanotube network in silicone elastomer. Appl. Phys. Lett. 2008, 92, 263104. [Google Scholar] [CrossRef]

- Srivastava, S.; Bhalla, S.; Madan, A. A review of rotary actuators based on shape memory alloys. J. Intell. Mater. Syst. Struct. 2017, 28, 1863–1885. [Google Scholar] [CrossRef]

- Lan, C.-C.; Wang, J.-H.; Fan, C.-H. Optimal design of rotary manipulators using shape memory alloy wire actuated flexures. Sens. Actuators A Phys. 2009, 153, 258–266. [Google Scholar] [CrossRef]

- Andrianesis, K.; Koveos, Y.; Nikolakopoulos, G.; Tzes, A. Experimental study of a shape memory alloy actuation system for a novel prosthetic hand. In Shape Memory Alloys; InTech: London, UK, 2010. [Google Scholar]

- Mohd Jani, J.; Leary, M.; Subic, A. Designing shape memory alloy linear actuators: A review. J. Intell. Mater. Syst. Struct. 2017, 28, 1699–1718. [Google Scholar] [CrossRef]

- Luo, H.; Liao, Y.; Abel, E.; Wang, Z.; Liu, X. Hysteresis behaviour and modeling of SMA actuators. In Shape Memory Alloys; InTech: London, UK, 2010. [Google Scholar]

- Stegmaier, T.; Mavely, J.; Schneider, P. CHAPTER 6: High-Performance and High-Functional Fibres and Textiles. In Textiles in Sports; Elsevier: Amsterdam, The Netherlands; pp. 89–119.

- Choy, C.L.; Chen, F.C.; Young, K. Negative thermal expansion in oriented crystalline polymers. J. Polym. Sci. Polym. Phys. Ed. 1981, 19, 335–352. [Google Scholar] [CrossRef]

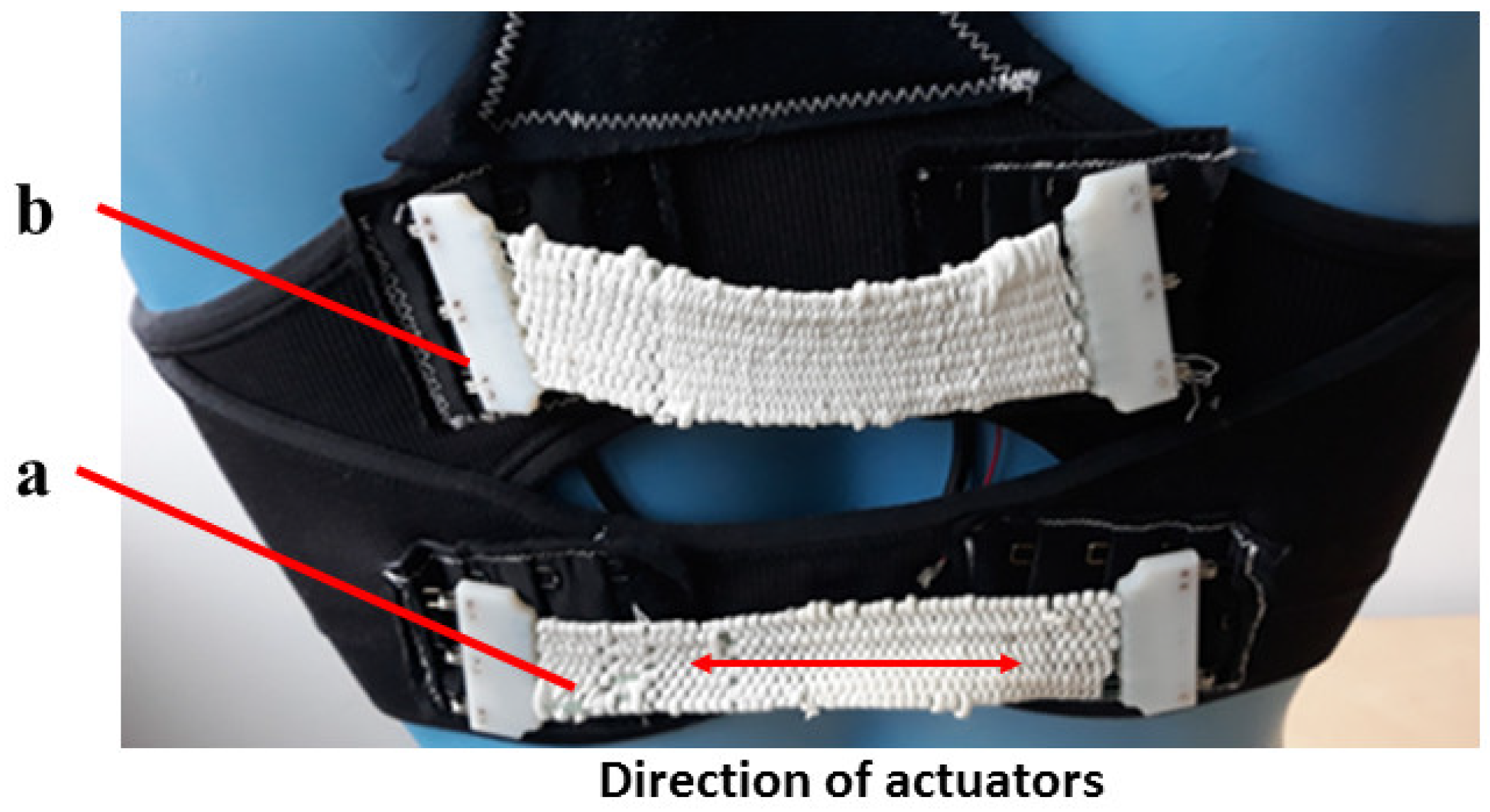

- Steele, J.R.; Gho, S.A.; Campbell, T.E.; Richards, C.J.; Beirne, S.; Spinks, G.M.; Wallace, G.G. The Bionic Bra: Using electromaterials to sense and modify breast support to enhance active living. J. Rehabil. Assist. Technol. Eng. 2018, 5. [Google Scholar] [CrossRef]

- Sárosi, J.; Csikós, S.; Asztalos, I.; Gyeviki, J.; Véha, A. Accurate Positioning of Spring Returned Pneumatic Using Sliding-mode Control. In Proceedings of the 1st Regional Conference—Mechatronics in Practice and Education MECH (CONF 2011), Subotica, Serbia, 8–10 December 2011. [Google Scholar]

- Klute, G.K.; Czerniecki, J.M.; Hannaford, B. Artificial muscles: Actuators for biorobotic systems. Int. J. Robot. Res. 2002, 21, 295–309. [Google Scholar] [CrossRef]

- Janickis, V.; Ancutienė, I. Modification of polyester textile by conductive copper sulfide layers. Poliesterinio Audinio Modifikavimas Elektrai Laidžiais Vario Sulfidų Sluoksniais 2009, 20, 136–140. [Google Scholar]

- Bashir, T.; Ali, M.; Persson, N.-K.; Ramamoorthy, S.K.; Skrifvars, M. Stretch sensing properties of conductive knitted structures of PEDOT-coated viscose and polyester yarns. Text. Res. J. 2014, 84, 323–334. [Google Scholar] [CrossRef]

- Maity, S.; Chatterjee, A.; Singh, B.; Pal Singh, A. Polypyrrole based electro-conductive textiles for heat generation. J. Text. Inst. 2014, 105, 887–893. [Google Scholar] [CrossRef]

- Lin, T.; Wang, L.; Wang, X.; Kaynak, A. Polymerising pyrrole on polyester textiles and controlling the conductivity through coating thickness. Thin Solid Films 2005, 479, 77–82. [Google Scholar] [CrossRef]

- Zhang, B.; Xue, T.; Meng, J.; Li, H. Study on property of PANI/PET composite conductive fabric. J. Text. Inst. 2014, 106, 253–259. [Google Scholar] [CrossRef]

- Molina, J.; Zille, A.; Fernández, J.; Souto, A.P.; Bonastre, J.; Cases, F. Conducting fabrics of polyester coated with polypyrrole and doped with graphene oxide. Synth. Met. 2015, 204, 110–121. [Google Scholar] [CrossRef]

- Bhattacharya, R.; Pieterson, L.V.; Os, K.V. Improving conduction and mechanical reliability of woven metal interconnects. IEEE Trans. Compon. Packag. Manuf. Technol. 2012, 2, 165–168. [Google Scholar] [CrossRef]

- Bashir, T.; Skrifvars, M.; Persson, N.K. Surface modification of conductive PEDOT coated textile yarns with silicone resin. Mater. Technol. 2011, 26, 135–139. [Google Scholar] [CrossRef]

- Xuyuan, T.; Koncar, V.; Tzu-Hao, H.; Chien-Lung, S.; Ya-Chi, K.; Gwo-Tsuen, J. How to Make Reliable, Washable, and Wearable Textronic Devices. Sensors 2017, 17, 1–16. [Google Scholar] [CrossRef]

- Mondal, S. Phase change materials for smart textiles—An overview. Appl. Therm. Eng. 2008, 28, 1536–1550. [Google Scholar] [CrossRef]

- Saito, Y.; Suzuki, Y.; Daitoku, K.; Minakawa, M.; Fukuda, I.; Goto, T. Cardiac supporting device using artificial rubber muscle: Preliminary study to active dynamic cardiomyoplasty. J. Artif. Organs 2015, 18, 377–381. [Google Scholar] [CrossRef]

- Sherif, H.M.F. The artificial ventricle: A conceptual design for a novel mechanical circulatory support system. Minim. Invasive Ther. Allied Technol. 2009, 18, 178–180. [Google Scholar] [CrossRef]

- Ruhparwar, A.; Piontek, P.; Ungerer, M.; Ghodsizad, A.; Partovi, S.; Foroughi, J.; Szabo, G.; Farag, M.; Karck, M.; Spinks, G.M.; et al. Electrically Contractile Polymers Augment Right Ventricular Output in the Heart. Artif. Organs 2014, 38, 1034–1039. [Google Scholar] [CrossRef]

| Actuating Mechanism | Actuator Type | Strain | Stress (Mpa) | Work Capacity | Advantages | Disadvantages | References |

|---|---|---|---|---|---|---|---|

| Electric Field Actuation | Dielectric elastomeric actuators | 10–380% | 7.7 | 150 kJ/m3 | Simple in mechanism and construction | High voltages | - |

| Large strains | Cost and consumes volume | - | |||||

| High efficiencies (30%) | - | [22,23] | |||||

| High bandwidths | - | ||||||

| Low current | |||||||

| Low cost | |||||||

| Electrostrictive polymers | 7% | 45 | 320 kJ/m3 | High work density | High voltages cycle life is unclear | [26,27] | |

| High Stress | |||||||

| Ion based Actuation | Conducting polymer | 12% | 34 | 100 kJ/m3 | Low Voltage | Need encapsulation Low Efficiencies | [25,70,72] |

| High Stress | - | ||||||

| High work density | - | ||||||

| Ionic Polymer Metal Composites | 3.30% | 30 | 5.5 kJ/m3 | Low Voltage | Need encapsulation | [25,26,31,32] | |

| Pneumatic Actuation | Mckibben | 25–30% | - | - | Fast | Difficulty to control | - |

| High strain | Bulky operating method | [35] | |||||

| Thermal Actuation | Shape Memory Alloys | 8% | 200 | 1000 kJ/m3 | High stress Low Voltage High work density | Difficult to control Large currents Low efficiencies | [26,84] |

| Twisted Synthetic Fibers | 49% | - | 2.48 kJ/kg | High Strain | Limited Operating temperatures (250 °C) | [17] | |

| High work output per kg Inexpensive | |||||||

| Light weight | |||||||

| Flexible | - | ||||||

| Electrochemical | Carbon Nanotubes Yarns | 16% | 2 | 2 kJ/m3 | High Stress | Expensive | - |

| Low Voltage | - | [26,75] | |||||

| High temperature range | - | ||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kongahage, D.; Foroughi, J. Actuator Materials: Review on Recent Advances and Future Outlook for Smart Textiles. Fibers 2019, 7, 21. https://doi.org/10.3390/fib7030021

Kongahage D, Foroughi J. Actuator Materials: Review on Recent Advances and Future Outlook for Smart Textiles. Fibers. 2019; 7(3):21. https://doi.org/10.3390/fib7030021

Chicago/Turabian StyleKongahage, Dharshika, and Javad Foroughi. 2019. "Actuator Materials: Review on Recent Advances and Future Outlook for Smart Textiles" Fibers 7, no. 3: 21. https://doi.org/10.3390/fib7030021

APA StyleKongahage, D., & Foroughi, J. (2019). Actuator Materials: Review on Recent Advances and Future Outlook for Smart Textiles. Fibers, 7(3), 21. https://doi.org/10.3390/fib7030021