Development of Electrophoretic Deposition Prototype for Continuous Production of Carbon Nanotube-Modified Carbon Fiber Fabrics Used in High-Performance Multifunctional Composites

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Processing

2.2. Characterization

3. Results and Discussions

3.1. Dependence of Depostion Status and Deposit Yield on Concentration of CNT Suspension

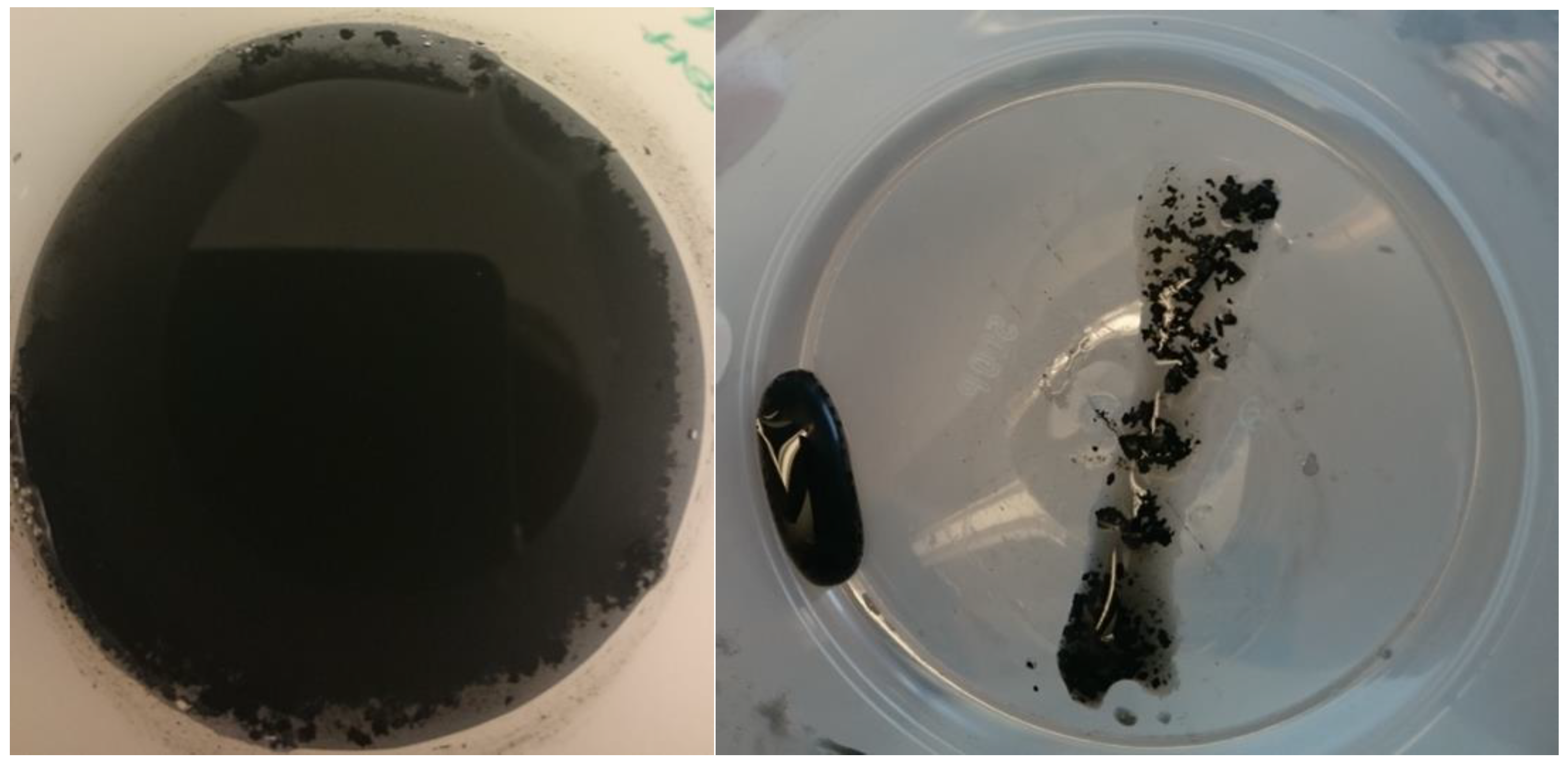

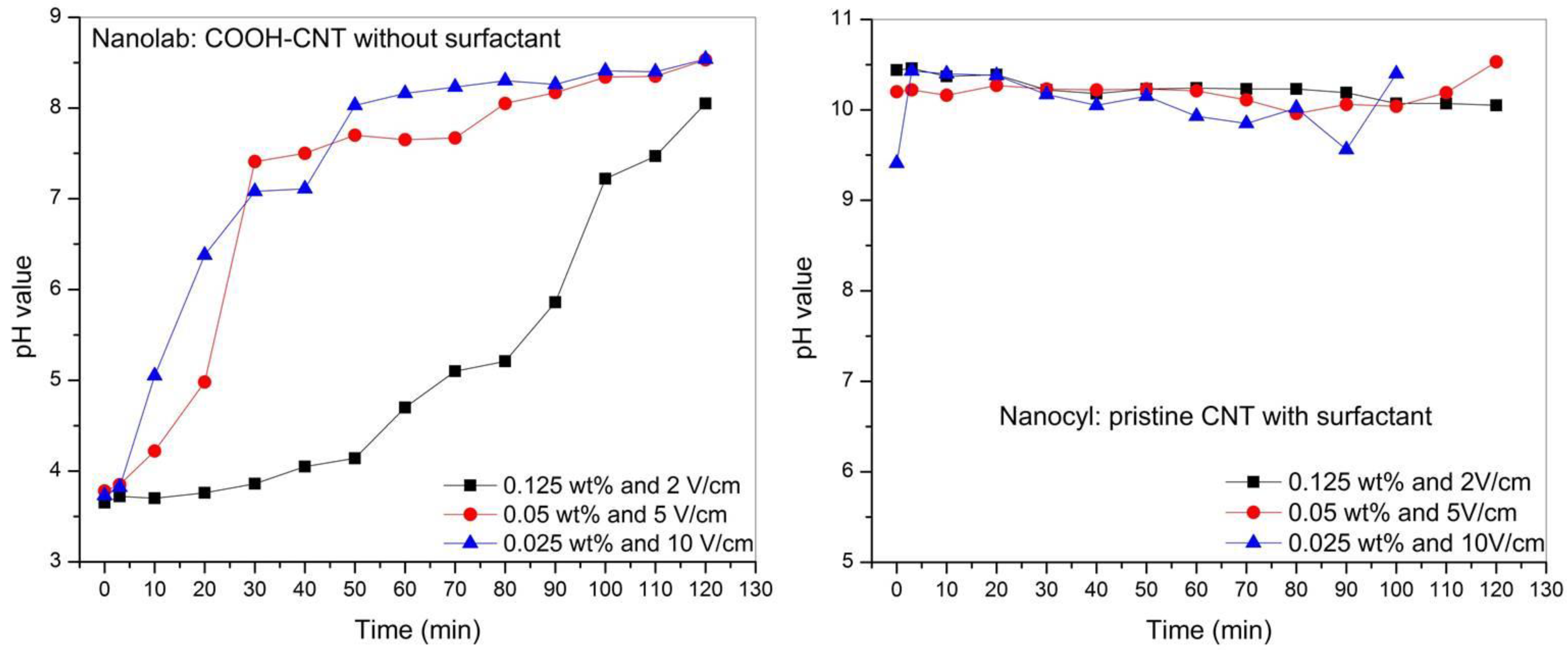

3.2. Aggregation of CNTs with Time during Continuous EPD Process

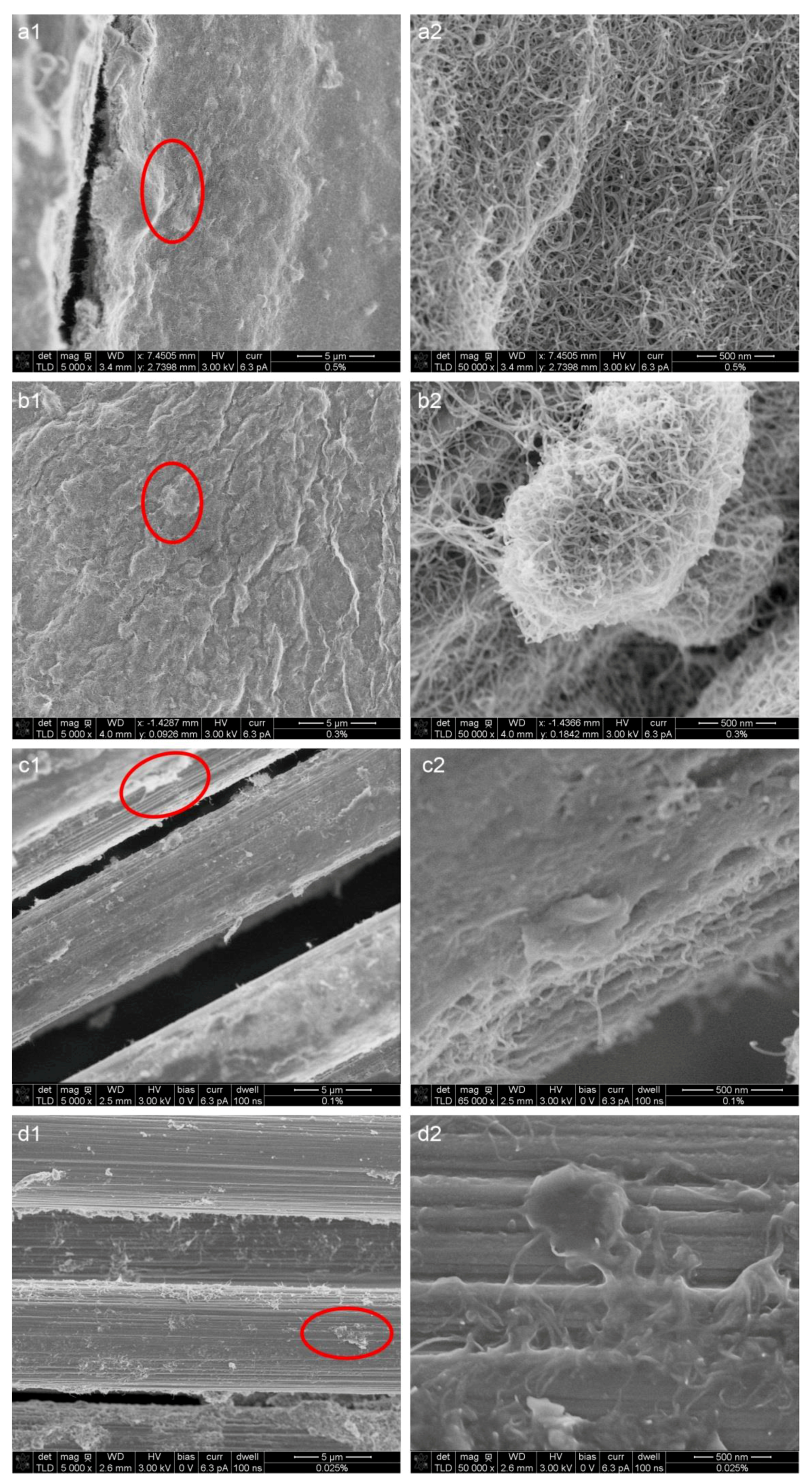

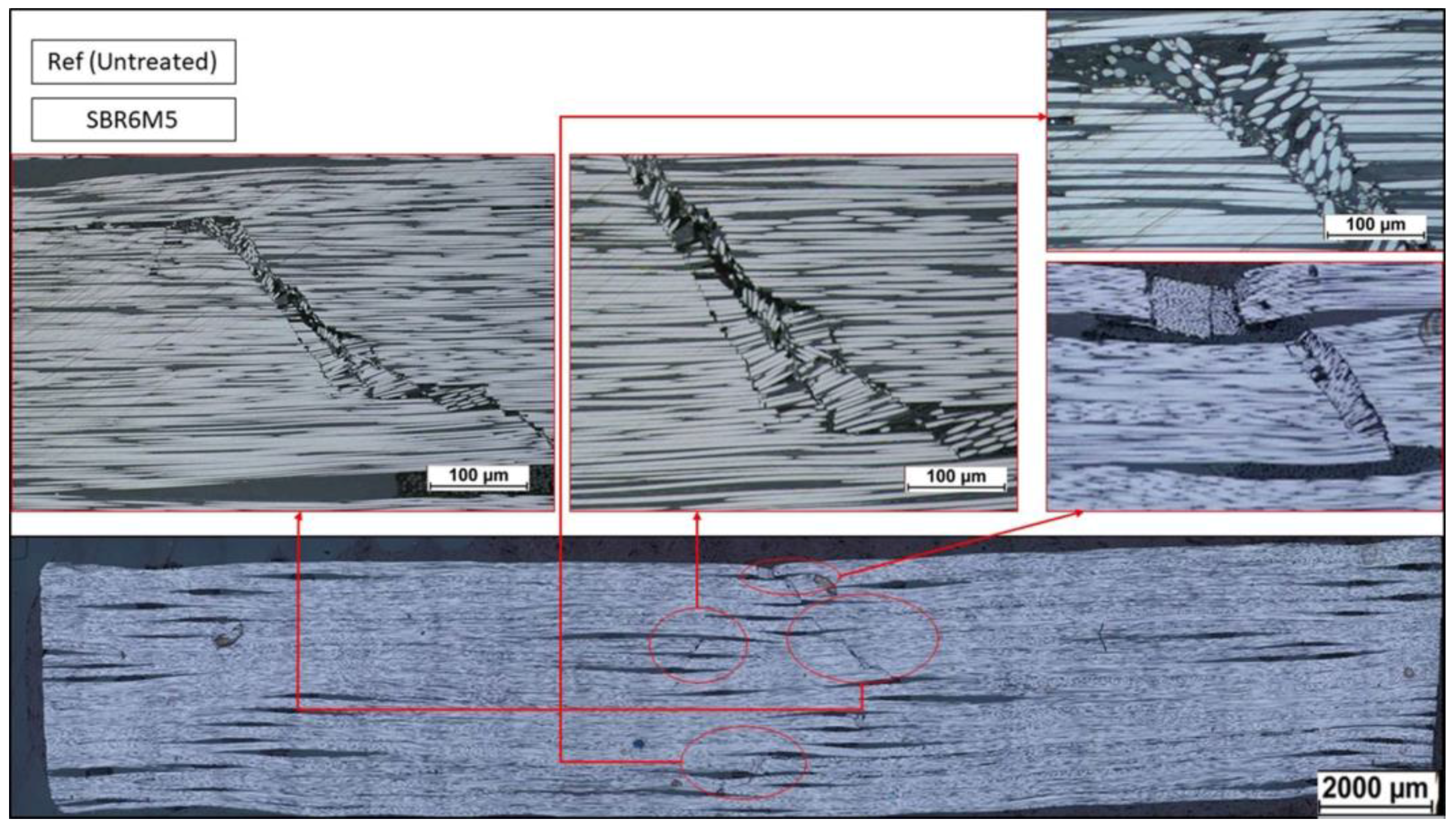

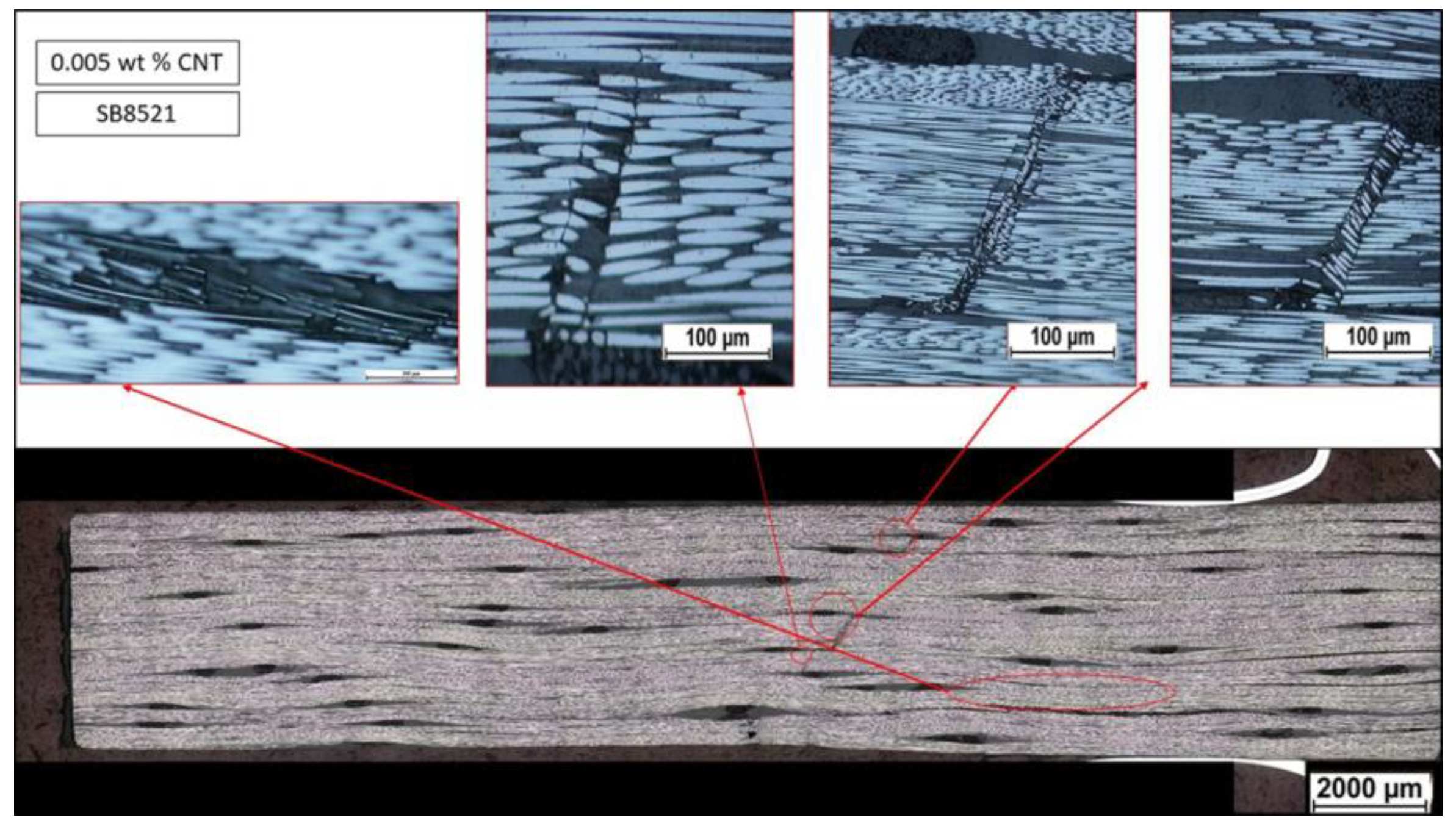

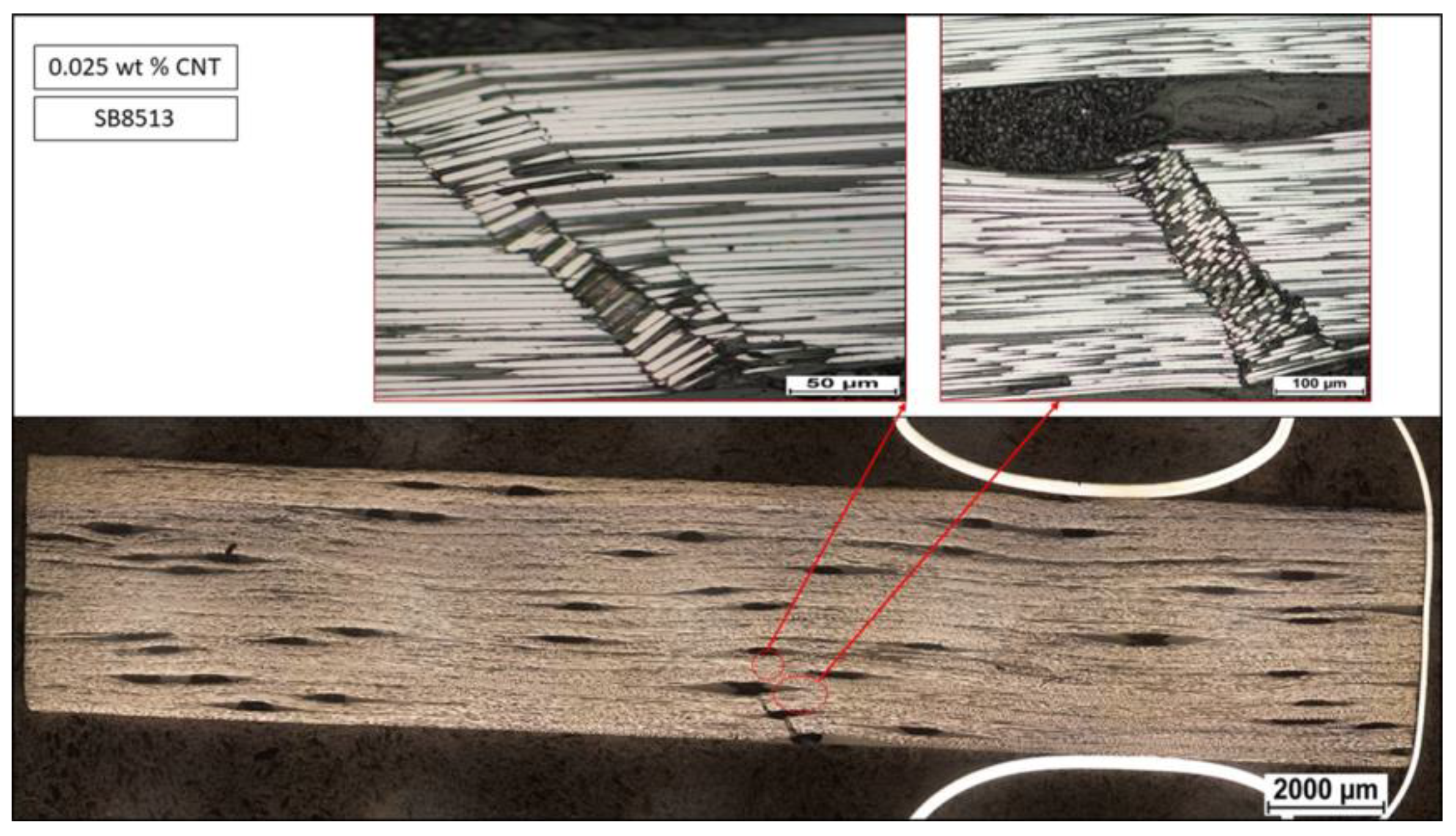

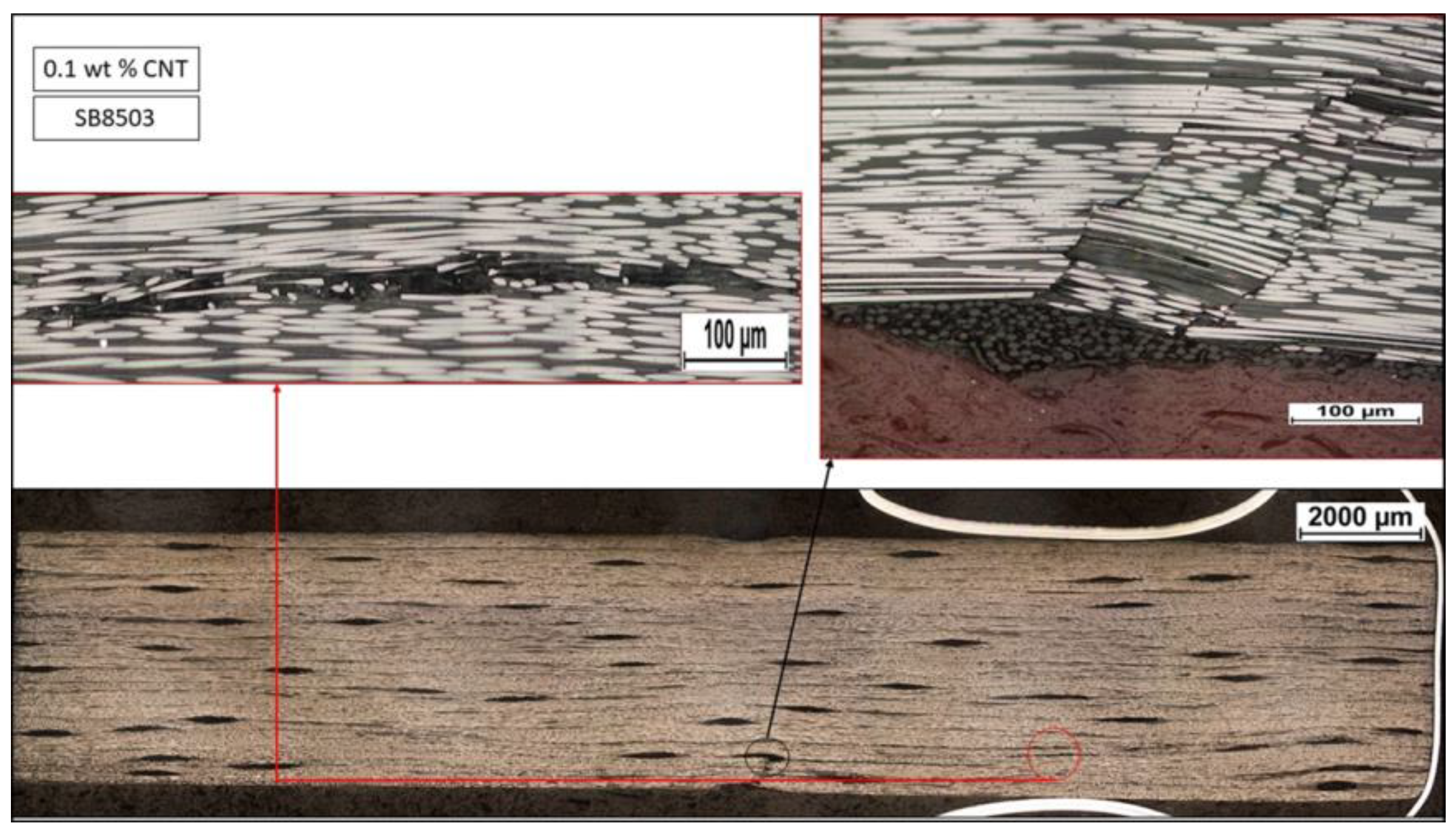

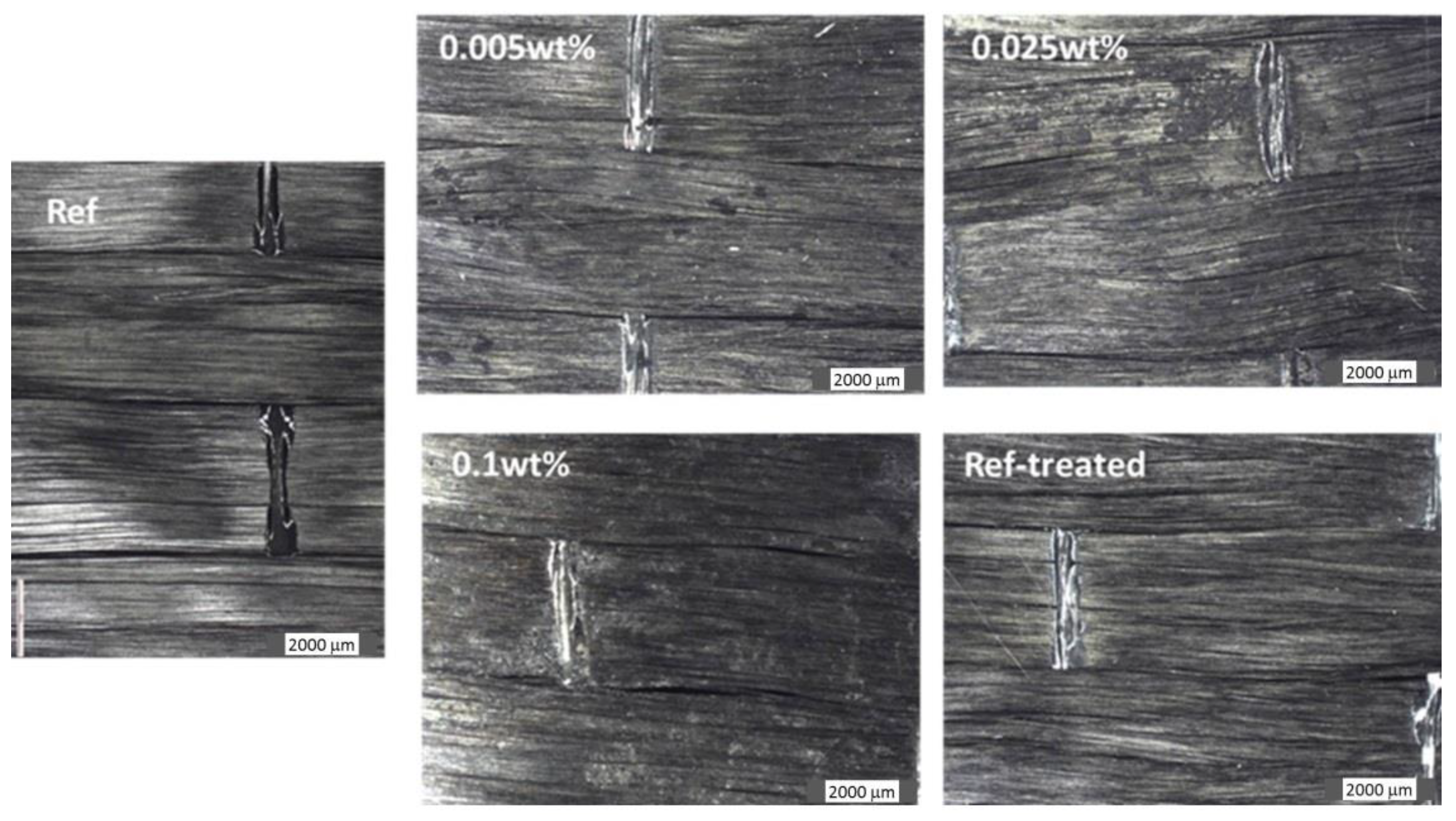

3.3. Mechanical Properties and Morphology Study

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Guadagno, L.; Raimondo, M.; Naddeo, C.; Di Bartolomeo, A.; Lafdi, K. Influence of multiwall carbon nanotubes on morphological and structural changes during UV irradiation of syndiotactic polypropylene films. J. Polym. Sci. Part B Polym. Phys. 2012, 50, 963–975. [Google Scholar] [CrossRef]

- Gorrasi, G.; Sarno, M.; Di Bartolomeo, A.; Sannino, D.; Ciambelli, P.; Vittoria, V. Incorporation of carbon nanotubes into polyethylene by high energy ball milling: morphology and physical properties. J. Polym. Sci. Part B Polym. Phys. 2007, 45, 597–606. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Lim, W.Z.; Wang, D.Z.; Ren, Z.F.; Chou, T.W. Carbon nanotube/carbon fiber hybrid multiscale composite. J. Appl. Phys. 2002, 91, 6034–6037. [Google Scholar] [CrossRef]

- Huang, K.H.; Kuo, W.S.; Ko, T.H.; Tzeng, S.S.; Yan, C.F. Processing and tensile characterization of composites of carbon nanotube-grown carbon fibers. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1299–1304. [Google Scholar] [CrossRef]

- Garcia, E.J.; Wardle, B.L.; Hart, A.J. Joining prepreg composite interfaces with aligned carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1065–1070. [Google Scholar] [CrossRef]

- Veedu, V.P.; Cao, A.Y.; Li, X.S.; Ma, K.G.; Soldano, C.; Kar, S.; Ajayan, P.M.; Ghasemi-Nejhad, M.N. Multidinctional composites using reinforced laminae with carbon-nanotube forests. Nat. Mater. 2006, 5, 457–462. [Google Scholar] [CrossRef] [PubMed]

- Bekyarova, E.; Thostenson, E.T.; Yu, A.; Kim, H.; Gao, J.; Tang, J.; Hahn, H.T.; Chou, T.W.; Itkis, M.E.; Haddon, R.C. Multiscale carbon nanotube-carbon fiber reinforcement for advanced epoxy composites. Langmuir 2007, 23, 3970–3974. [Google Scholar] [CrossRef] [PubMed]

- Van der Biest, O.O.; Vandeperre, L.J. Electrophoretic deposition of materials. Annu. Rev. Mater. Sci. 1999, 29, 327–372. [Google Scholar] [CrossRef]

- Boccaccini, A.R.; Cho, J.; Roether, J.A.; Thomas, B.J.C.; Minay, E.J.; Shaffer, M.S.P. Electrophoretic deposition of carbon nanotubes. Carbon 2006, 44, 3149–3160. [Google Scholar] [CrossRef]

- Santhanagopalan, S.; Balram, A.; Lucas, E.; Marcano, F.; Meng, D.D. High voltage electrophoretic deposition of aligned nanoforests for scalable nanomanufacturing of electrochemical energy storage devices. Key Eng. Mater. 2012, 507, 67–72. [Google Scholar] [CrossRef]

- Deng, C.; Jiang, J.; Liu, F.; Fang, L.; Wang, J.; Li, D.; Wu, J. Influence of graphene oxide coatings on carbon fiber by ultrasonically assisted electrophoretic depostion on its composite interfacial property. Surf. Coat Technol. 2015, 272, 176–181. [Google Scholar] [CrossRef]

- Deng, C.; Jiang, J.; Liu, F.; Fang, L.; Wang, J.; Li, D.; Wu, J. Effects of electrophoretically deposited graphene oxide coatings on interfacial properties of carbon fiber composite. J. Mater. Sci. 2015, 50, 5886–5892. [Google Scholar] [CrossRef]

- Liang, S.; Li, Q.; Wang, J.; He, Z.; Zhao, Y.; Kang, M. Multiscale graphene oxide-carbon fiber reinforcements for advanced polyurethane composites. Compos. Part A Appl. Sci. Manuf. 2016, 87, 1–9. [Google Scholar]

- Wang, C.; Li, J.; Sun, S.; Li, X.; Zhao, F.; Jiang, B.; Huang, Y. Electrophoretic deposition of graphene oxide on continuous carbon fibers for reinforcement of both tensile and interfacial strength. Compos. Sci. Technol. 2016, 135, 46–53. [Google Scholar] [CrossRef]

- ASTM. D7264/D7264M-15 Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM. D2344/D2344M-16 Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

| Material/Properties | Eb/GPa | σb/MPa | εb/% | FSBS/MPa |

|---|---|---|---|---|

| Composite reinforced with pristine CF fabric | 114.4 ± 1.8 | 1199.6 ± 65.2 | 1.1 ± 0.1 | 65.2 ± 2.7 |

| Composite reinforced with 0.005 wt% CNT suspension-treated CF fabric | 110.0 ± 6.4 | 923.5 ± 104.2 | 0.8 ± 0.2 | 61.5 ± 1.9 |

| Composite reinforced with 0.025 wt% CNT suspension-treated CF fabric | 97.9 ± 2.8 | 713.5 ± 46.4 | 0.7 ± 0.1 | 65.6 ± 1.3 |

| Composite reinforced with 0.1 wt% CNT suspension-treated CF fabric | 93.5 ± 1.6 | 726.3 ± 83.0 | 0.8 ± 0.1 | 55.2 ± 2.4 |

| Material/Properties | Eb/GPa | σb/MPa | εb/% | FSBS/MPa |

|---|---|---|---|---|

| Treated reference composite | 104.7 ± 1.3 | 872.1 ± 90.6 | 0.9 ± 0.1 | 60.9 ± 3.5 |

| Composite reinforced with deposited fabric using 0.025 wt% CNT suspension and no ultrasonication | 97.9 ± 2.8 | 713.5 ± 46.4 | 0.7 ± 0.1 | 65.6 ± 1.3 |

| Composite reinforced with deposited fabric using 0.025 wt% CNT suspension and with ultrasonication | 106.1 ± 2.2 | 838.5 ± 70.7 | 0.8 ± 0.1 | 65.0 ± 2.4 |

| Composite reinforced with deposited fabric using 0.005 wt% CNT suspension and no ultrasonication | 110.0 ± 6.4 | 923.5 ± 104.2 | 0.8 ± 0.2 | 61.5 ± 1.9 |

| Composite reinforced with deposited fabric using 0.005 wt% CNT suspension and with ultrasonication | 108.3 ± 3.8 | 950.2 ± 90.4 | 0.9 ± 0.2 | 62.1 ± 1.0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, G.; Nyström, B.; Sandlund, E.; Eklund, D.; Noël, M.; Westerlund, R.; Stenberg, S.; Pupure, L.; Pupurs, A.; Joffe, R. Development of Electrophoretic Deposition Prototype for Continuous Production of Carbon Nanotube-Modified Carbon Fiber Fabrics Used in High-Performance Multifunctional Composites. Fibers 2018, 6, 71. https://doi.org/10.3390/fib6040071

Gong G, Nyström B, Sandlund E, Eklund D, Noël M, Westerlund R, Stenberg S, Pupure L, Pupurs A, Joffe R. Development of Electrophoretic Deposition Prototype for Continuous Production of Carbon Nanotube-Modified Carbon Fiber Fabrics Used in High-Performance Multifunctional Composites. Fibers. 2018; 6(4):71. https://doi.org/10.3390/fib6040071

Chicago/Turabian StyleGong, Guan, Birgitha Nyström, Erik Sandlund, Daniel Eklund, Maxime Noël, Robert Westerlund, Sofia Stenberg, Liva Pupure, Andrejs Pupurs, and Roberts Joffe. 2018. "Development of Electrophoretic Deposition Prototype for Continuous Production of Carbon Nanotube-Modified Carbon Fiber Fabrics Used in High-Performance Multifunctional Composites" Fibers 6, no. 4: 71. https://doi.org/10.3390/fib6040071

APA StyleGong, G., Nyström, B., Sandlund, E., Eklund, D., Noël, M., Westerlund, R., Stenberg, S., Pupure, L., Pupurs, A., & Joffe, R. (2018). Development of Electrophoretic Deposition Prototype for Continuous Production of Carbon Nanotube-Modified Carbon Fiber Fabrics Used in High-Performance Multifunctional Composites. Fibers, 6(4), 71. https://doi.org/10.3390/fib6040071