Abstract

The potential for sustainable lignocellulosic agro-waste is immense, owing to the fact that it represents the most abundant organic compound on Earth. It is a valuable and desirable source for material production across numerous industries due to its abundance, renewability, and biodegradability. This paper explores the world of barley fibers, which are extracted from the straw of two different cultivars (old Rex or new Barun) and have tremendous potential for use, primarily for technical textiles. The quantity of the extracted fibers depends both on the type of barley used and on climate conditions that influence the plants’ growth, resulting in fiber yields ranging from 14.82% to 19.59%. The chemical composition of isolated fibers revealed an optimal content of cellulose and lignin in barley fibers isolated from the Rex variety. Those results were confirmed with FTIR analysis, which revealed a lower intensity of peaks associated with hemicellulose and lignin and, therefore, indicated their better removal after the chemical maceration process. In terms of fiber density, the quality of the fibers was comparable to that of cotton fibers, but they differed significantly in moisture regain (10.37–11.01%), which was higher. Furthermore, sufficient fiber tenacity (20.31–23.08 cN/tex) was obtained in a case of old-variety Rex, indicating the possibility of spinning those fibers into yarns, followed by their extended usage for apparel. Additionally, our paper reveals the possibility of fulfilling the requirements of the zero waste principle due to the fact that a high percentage of solid waste left after the fiber extraction (26.3–32.3%) was afterwards successfully used for the production of biofuels, enabling the closing of the loop in a circular economy.

1. Introduction

We live in an era in which sustainable practices are at the core of all research. Scientists are searching for new biodegradable, sustainable, and renewable sources of textile fibers and materials. For this reason, the use of natural fiber sources has significantly increased in popularity. Furthermore, there is a rising trend of environmental awareness among people who are becoming more aware of the pollution of our planet and the disturbance it has caused to the balance of our planet’s ecosystems. The manufacturing of synthetic fibers has also contributed to this imbalance, with about 60% of all fiber output worldwide being synthetic, and polyester (PET) and polyamide (PA) dominating.

Textiles made from synthetic materials have the potential to release microplastics (less than 5 mm in size) into the environment during production and cleaning processes [1]. This issue has become a hot topic, but at the same time, it is an inspiration to use natural resources in a more sustainable manner. Natural fibers have stood out among these resources as an affordable, healthy, and environmentally friendly option. The term “environmental sustainability” refers to finding a balance between human needs and nature preservation, and global concerns are oriented towards achieving this.

Due to the amount of pollution on our planet, innovative solutions are needed now more than ever before, and greener alternatives are taking place in various applications. Biowaste has now become a prominent raw material, and one such solution is biowaste from barley straw, which is considered a second-generation biomass. Barley is the fourth-largest grain crop in the world, grown in more than 100 countries, making it very interesting and widely available. In the last ten years, Europe generated over 60% of the world’s production of barley, and Asia 15%, while North and South America produced 13%, respectively. Its distribution is worldwide, and it grows in different climate conditions. Today, thanks to its biowaste, its importance as a crop may rise even more [2,3].

People have been harvesting barley for 10,000 years, making it one of the earliest domesticated crop species in the world. Initially, humans consumed wild barley, which was later developed into a cultivated crop. Wild barley (Hordeum spontaneum L.) was discovered by the German botanist Carl Koch. Like all cereals and their ancestors, the barley we have been using nowadays and wild barley share the same genes [4,5,6,7].

1.1. Barley’s Anatomy

Understanding the anatomy of plants and their different parts is essential for their cultivation and agricultural productivity [8]. Additionally, this knowledge is necessary for researchers and breeders attempting to improve barley varieties for diverse applications.

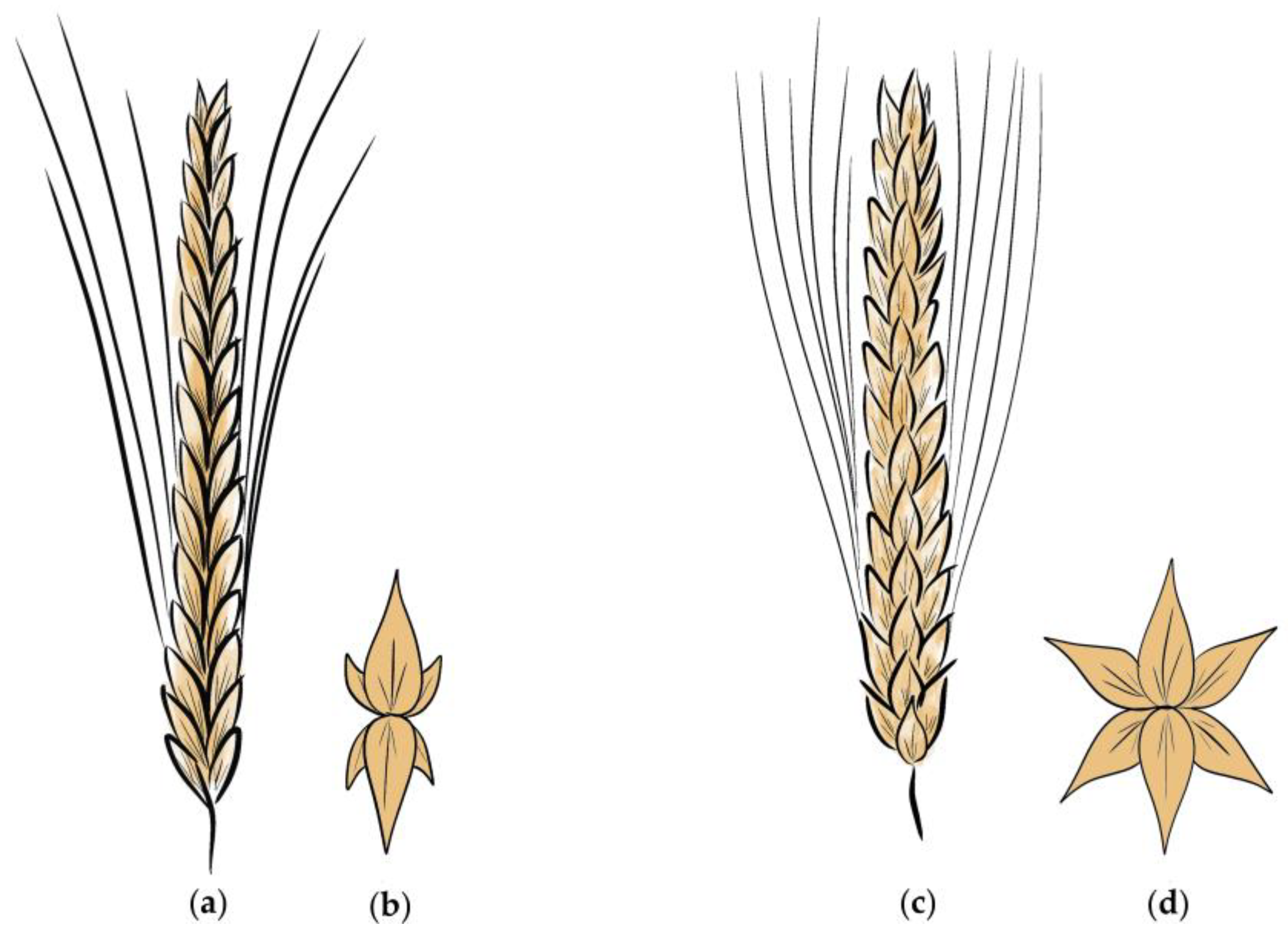

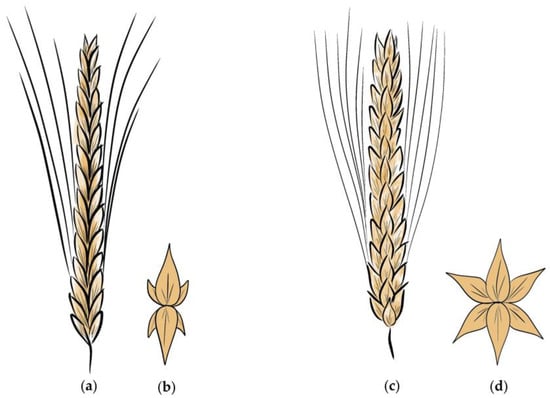

Barley (Hordeum vulgare L.) is a cereal crop that belongs to the family of Poaceae, which is economically the most important order of plants. This order contains more than 18,000 species of monocotyledons, meaning flowering plants characterized by a single seed leaf [8]. Barley differs in its grain arrangement. There are two main types of barley, based on the number and arrangement of barley kernels (seeds/grains) on the central stem (rachis): two-row barley and six-row barley (Figure 1) [8]. These two types have different characteristics, based on their plant anatomy and morphology.

Figure 1.

Two main types of barley, where: (a) Ear of two-row barley, (b) Arrangement of two-row barley grains, (c) Ear of six-row barley and (d) Arrangement of six-row barley grains.

Two-row barley grains are shorter and have a higher amount of starch content, while six-row barley grains are longer, containing less starch and more proteins. That is why the two-row barley is more desirable in the brewery industry.

1.2. Barley’s Harvesting and Usage

The most common way of harvesting barley is by using a combine that cuts the barley and separates the grain from the straw. Thanks to its nutritional value, barley is widely used for food, animal feed, and the production of beer and other alcoholic beverages.

According to Zohary and Hopf [9], all parts of the barley plant, including the straw, grain derivatives, and hull, are classified as agro-residues [10]. After the harvest, huge amounts of agro-residues (barley straw) are usually left on the fields, burnt, and left unused. This kind of disposal negatively impacts the environment and may endanger ecosystems, especially if left untreated. Such disposal of biowaste requires a more sustainable approach. Legal restrictions within the EU have made it illegal to burn agricultural waste in the field [11,12,13,14].

Since it is widely known that cereal straws are an important part of waste lignocellulosic biomass and they have a significant amount of cellulose (approx. 30–50%) their usage as a cellulose source is promising [15,16]. A more sustainable approach to reducing high amounts of agro-residue involves utilizing this source as a renewable source of lignocellulosic fibers. This kind of biomass represents a biomass of the second generation and stands out as a promising solution in our quest for a sustainable future. Additionally, it has huge potential for being a valuable raw material for various applications, such as textiles, pulp and paper production, bioplastics production, and as a source of thermal-electric power [5,17,18,19,20]. According to the literature presented in Table 1, barley straw is mainly used in its initial form of straw as reinforcements for construction materials [21,22,23,24]. Additionally, barley straw can be used as a source for biofuel production [23] or for aerogel production, which can consequently be used as a cleaner for spilled oil [25]. Barley cellulose fibers isolated from barley straw are commonly used in the composite and paper industry since the extracted fibers can be modified or combined with other materials and successfully enhance the properties of the final product [18,26,27,28,29,30,31].

Table 1.

Literature review based on barley straw usage.

Up to now, cellulose fibers have been isolated from the plant stem using different methods such as retting (Table 2), physical and/or mechanical procedures, and their combinations [36,37,38,39].

Table 2.

Retting methods for fiber isolation.

Some of the most commonly used retting methods for fiber isolation from the plant stem can be applied to cereal straw [39].

Fibers from barley straw are most often extracted via chemical retting methods, followed by physical and mechanical processes, using extreme conditions in terms of temperature, pretreatment time, chemicals, etc., and in this way, fibers of relatively short lengths are isolated. The best usage of such short fibers is in the paper industry, but longer fibers could be more efficiently applied as reinforcements in the composite industry, or even in the clothing industry if their length is sufficient for spinning into yarn [40]. In this paper, reduced alkali concentration was applied for chemical retting in order to preserve the fiber quality as much as possible. Additionally, this entire process of isolating the fibers from the barley straw and gathering solid and liquid waste during the chemical maceration process contributes to the generation of a circular economy. After the use of barley grain for food, agro-waste in the form of straw becomes a raw material for fiber production, while solid waste from fiber production, together with evaporated waste chemicals (filtrates), becomes an input raw material for solid biofuel production.

Our research investigated the potential of different two-row barley varieties (Barun and Rex) for fiber production, and the determination of fiber quality was determined from the perspective of their possible application for apparel or technical textiles.

The successful isolation of barley fibers from straw and their usage in the clothing industry or for technical textiles presents a novel and sustainable solution.

2. Materials and Methods

2.1. Barley Variety

Barun barley is one of the primary varieties of winter two-row barley from the selection program of the Osijek Agricultural Institute. It has a low, firm, and elastic stem that is resistant to lodging and a large and uniform grain. Additionally, it is tolerant of the most common diseases [41]. Rex barley is also a winter two-row cultivar, having a well-formed, round grain. It is low-growing and highly resistant to diseases [42]. The barley straw used in this study was obtained from the experimental field set up by the Osijek Agricultural Institute.

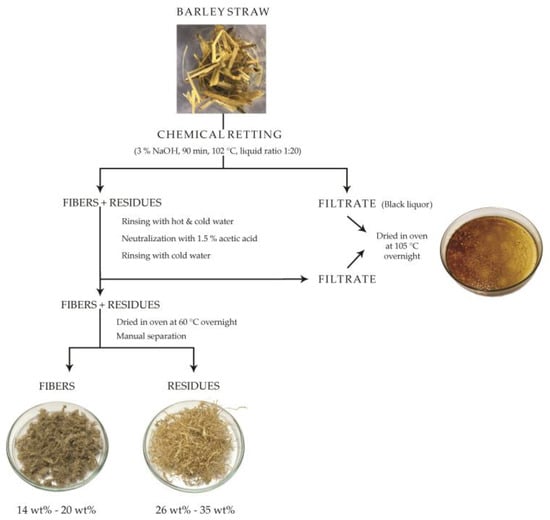

2.2. Biomass Pretreatments and Fiber Extraction

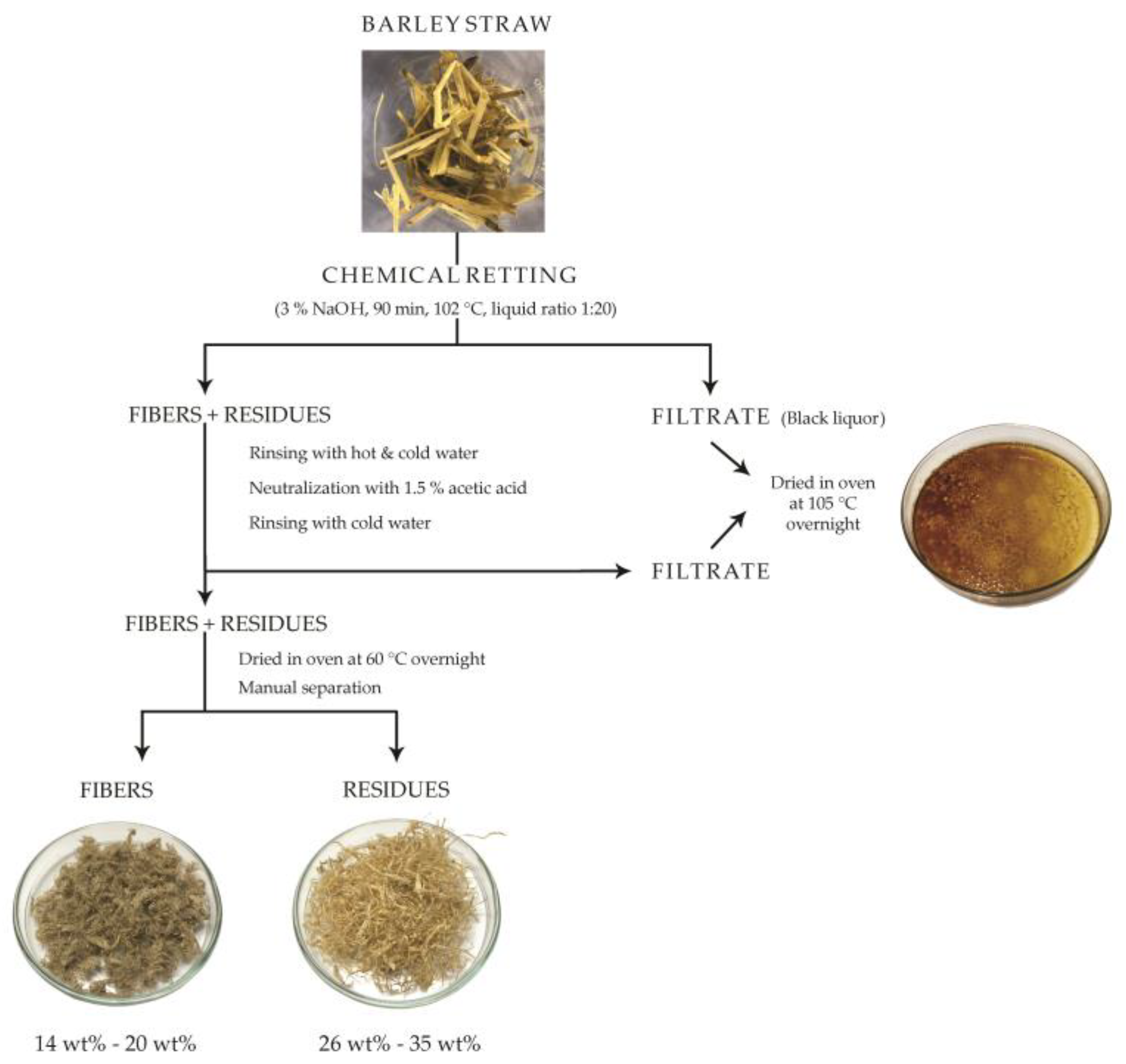

A chemical retting process was applied according to a slight modification of a method found in the literature review [43]. The barley biomass was cut into lengths of approximately 10 to 12 cm and subjected to chemical treatment in three parallel baths containing 3% sodium hydroxide (NaOH). The bath ratio was 1:20, and the processing time was 90 min. The fibers and residues were removed from the liquid and washed first with hot water and then with cold water. The next steps involved neutralization with acetic acid (CH3COOH) and washing with cold water. The liquid in which the extraction took place was filtered and separated to become black liquor. The mixture of fibers and residue was then dried overnight at 60 °C. The next step was the separation of the fibers from the residue, followed by weighing both the fibers and residue. In order to better explain the experimental processes in this paper, an experimental flow chart is presented in Figure 2.

Figure 2.

Experimental flow chart.

2.3. Fiber Testing

The following tests were performed: the determination of fiber and residue yields, tensile properties, the length of the fibers, the moisture content, the moisture regain, and density. Additionally, fiber morphology and chemical composition testing were determined on both the initial and extracted barley straw.

Fiber and residue yield percentages (Yf% and Yr%) were determined via the gravimetric method using Equations (1) and (2) [44]. All measurements were performed in triplicate.

where Yf% = fiber yield percentage, mf = the mass of barley fibers extracted from the barley straw, mi = the initial mass of the barley straw, Yr% = the residue yield percentage, and mr = the mass of barley residues after the fibers’ extraction.

The tensile properties of 50 individual fibers of each variety were examined using the Vibroskop 500 and Vibrodyn 500 devices (Lenzing Instruments, Gampern, Austria). The preload, testing speed, and gauge length values were 1500 mg, 3 mm/min, and 5 mm, respectively.

The fiber length of 100 individual fibers of each variety was determined using a measuring scale placed parallel to the straightened but unstretched fiber.

To determine the moisture content and moisture regain, the mass of the air-dried sample was first calculated. The same sample was then placed in a climate chamber and conditioned for 24 h under standard atmosphere conditions. The mass of the conditioned sample was determined, and the sample was then dried for 24 h. Finally, the mass of the absolutely dried sample was calculated. The following Equations (3) and (4) were then used to determine the moisture content and moisture regain, respectively. All measurements were performed in triplicate.

where MC% = moisture content, m1 = the mass of an air-dried sample, m2 = the mass of an absolute dried sample, MR% = the moisture regain, and m3 = the mass of a conditioned sample.

The density was measured using the gas pycnometer Ultrapyc 1200e (Anton Paar, Vernon Hills, IL, USA). The actual density of the barley fibers was determined under atmospheric conditions according to the ASTM D8171-18 standard [45]. High-purity nitrogen (N2) gas was used because of its ability to penetrate the smallest pores, allowing for the highest measurement precision. All measurements were performed in triplicate.

The morphology of the fibers was analyzed using a scanning electron microscope, Mira II LMU (Tescan, Brno, Czech Republic). Prior to SEM examination, the fibers were coated with chrome to achieve better sample conductivity.

The major chemical constituents (cellulose, hemicellulose, and lignin) of the barley straw, fibers, and residues were determined using an automatic fiber analyzer, the ANKOM Delta Fiber Analyzer (ANKOM Technology, New York, NY, USA). According to the manufacturer’s methods, the mass fractions of neutral detergent fiber (NDF), acid detergent fiber (ADF), and acid detergent lignin (ADL) were determined using F57 filter bags. Hemicellulose content was calculated by subtracting ADF from NDF and cellulose content by subtracting ADL from ADF. NDF represents the residue after digestion of the sample in the detergent solution and was mainly composed of hemicellulose, cellulose, and lignin. ADF represents the residue after digestion using sulfuric acid (H2SO4) and detergent and consists mainly of cellulose and lignin, while ADL represents lignin. All measurements were performed in triplicate.

The evaluation of the barley straw’s and fibers’ surface chemistry was performed with a Spectrum 100 FTIR spectrometer (Perkin Elmer, Buckinghamshire, UK) using the attenuated total reflection method. Five different measurements for each fiber were evaluated, and the average value was considered. All spectra were registered from 4000 cm−1 to 380 cm−1, with a resolution of 4 cm−1 and four scans.

3. Results and Discussion

The first part of the experiment involved determining the fiber and residue yields. The experiment included two series of results: one for the old-variety Barun and another for the new-variety Rex. The influence of climate conditions was investigated over a two-year period (2021 and 2022).

3.1. Biomass Pretreatment

Up to this point, the most frequently used chemical agent in the pretreatment process has been sodium hydroxide (NaOH), also known as caustic soda. It is a versatile chemical compound used in various sectors, including the textile industry, where it is one of the key agents in textile processing. Its main usage in textiles is related to the mercerization procedure, but it is frequently used for dyeing, printing, neutralization, cleaning, and alkali scouring to remove all remaining impurities from the fibers [46,47,48]. Apart from that, NaOH is often used as an active agent in the process of the chemical extraction of textile fibers from lignocellulosic biomass. It is generally known that alkaline treatment with caustic soda removes hemicellulose and lignin, simultaneously releasing cellulose fibers and improving their physico-chemical and mechanical properties [49,50,51,52].

However, the negative aspect of NaOH lies in its character, as it is a strong base and hazardous to the environment. Therefore, its concentration should be minimized [53]. In our research, its quantity was reduced to 3%. The results revealed that the application of a more environmentally friendly option still results in a high fiber yield, ranging from 14.82% to 19.59%.

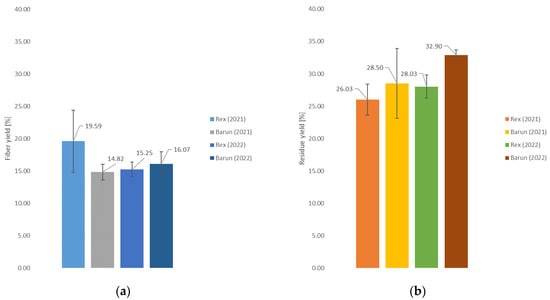

3.2. Fiber and Residue Yield

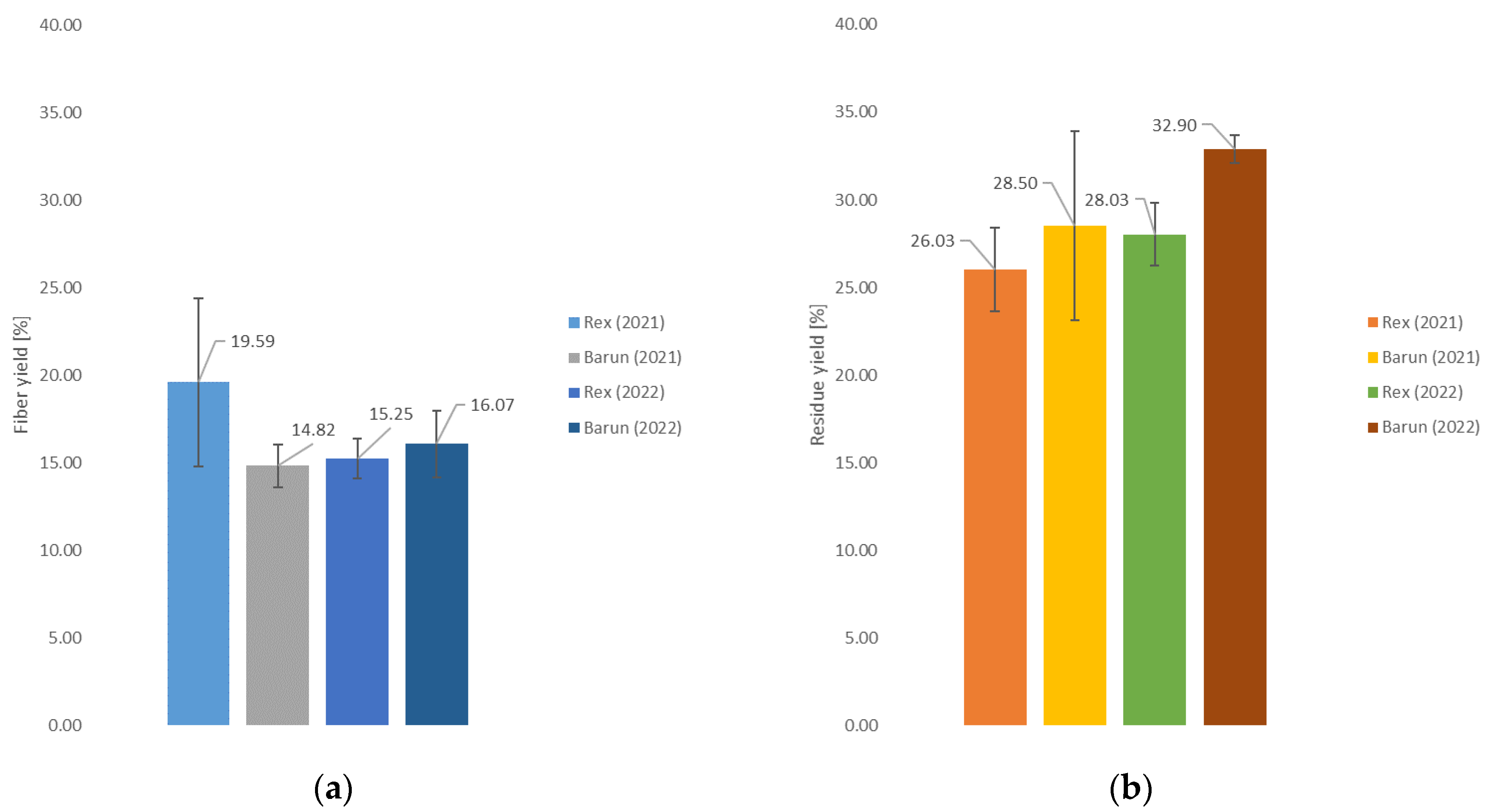

One of the goals of our project was to investigate how strongly different varieties of barley (the “old” and “new” cultivars) influence the fiber yield. The extracted fibers were intended for technical textile usage, while the remaining solid residues, ranging from 26.03% to 32.90%, were intended for biofuel production and were tested accordingly.

The results revealed that the old barley variety (Rex) harvested in 2021 had the highest fiber yield of 19.59% (Figure 3a), while its residue yield was 26.03% (Figure 3b). The lowest fiber yield of 14.82% was obtained from the new variety, Barun, collected in 2021, while its residue yield was 28.50%. An opposite trend was detected in the 2022 harvest, where the fiber yield of the Rex variety was slightly lower than that of the Barun variety (15.25% compared to 16.07%). The residue yield for the Rex variety was 28.03%, compared to the higher value of 32.90% for Barun.

Figure 3.

(a) Fiber yield and (b) residual yield of the Rex and Barun varieties (2021 and 2022).

The total amount of precipitation from sowing to harvest is presented in Table 3. It is noticeable that the amount of precipitation for the 2021 harvest was much higher, at 433.7 mm, compared to 363.1 mm for the 2022 harvest, indicating that the year 2022 was characterized by more drought [54].

Table 3.

Total amount of precipitation from October 2020 to May 2022.

Considering that the descriptive statistical analysis indicated higher variability in the fiber yield results for the 2021 Rex variety, it can be concluded, from the perspective of different barley varieties and the climatological data in the 2020–2022 period (Table 3), that the new barley variety, Barun, showed a positive trend of higher fiber and residue yields despite the negative effect of climate change, specifically the increase in drought.

3.3. Tensile Properties

The investigation of the mechanical properties of different varieties of barley fibers consisted of breaking tenacity, Young’s modulus, and elongation measurements (Table 4). It can be concluded that the fiber breaking tenacity for the varieties from 2021 was slightly higher than the fiber tenacity of varieties from 2022. The Barun variety from 2021 showed the highest fiber tenacity of 25.63 cN/tex, indicating the spinning possibility of these fibers into yarn [40]. Fibers are spinnable into yarn if their minimal tenacity is within the range of 10 cN/tex–25 cN/tex but with the indication that fibers whose strength corresponds to the lower limit of the minimum range must show a good ability to withstand deformation [40]. All the tested samples fulfilled the minimal requirements for tenacity and had sufficient resistance to deformation. Although both varieties of fibers from 2022 had lower Young’s modulus values in comparison to the 2021 varieties, they were still spinnable due to their characteristics of softness and high cohesion forces [55] and a rough surface (confirmed via SEM).

Table 4.

Tensile properties of barley fibers.

Natural fibers, though very attractive in the means of their low density and environmental compatibility, show non-uniformity in their properties. That is especially noticeable within the variability of the diameter along their length [56]. This property, together with other factors such as the retting method used for fiber isolation, pore size distribution, fiber type and variety, gauge length, strain rate, average number of tested fibers, etc., have been found to affect tensile properties, which explains the high values of statistical parameters (SD and CV) and, thus, the high variability of the results. The tensile properties of cellulose fiber representatives in each category (seed fibers, stem (bast) fibers, and leaf and fruit fibers) are presented in Table 5.

Table 5.

Tensile properties of some of the most commonly used fibers from the seed, stem, leaf, and fruit categories in comparison to the barley fibers from this study.

It was noticeable that the tensile properties of barley fibers corresponded to the lower range of given properties in the case of strength but fit very well with cotton fibers, according to the deformation parameters (Young’s modulus and elongation).

3.4. Fiber Length

As part of the project “Production of food, bio-composites, and biofuels from cereals in the circular bioeconomy KK.05.1.1.02.0016”, the possibility of isolating cellulose fibers from barley straw and their quality for usage in the production of technical textiles, specifically biocomposites and biofilters, was investigated. The chosen barley varieties, Rex and Barun, had stems growing up to 80 cm in height [59]. In the fiber extraction process, a chemical maceration procedure was carried out in an alkaline medium using a 3% sodium hydroxide solution. Although the literature often mentions the production of cellulose pulp from barley, which is then used to produce biofilters [18,26,33,60], there are almost no scientific papers on the extraction of long barley fibers, which would be even more suitable for the reinforcement of composite materials [15]. Natural fibers, used as reinforcements in composites, have been categorized by Djafari Petroudy into two groups based on their length: short fibers (1–5 mm) and long fibers (5–50 mm) [61].

One of the most important properties of fiber-reinforced composites that affects the strength of the final product is the critical fiber length, which differs based on the type of fiber [62]. If the fiber reinforcements are shorter than the critical length, the composite will not have satisfactory strength because the necessary stress transfer between the fiber and the polymer matrix will not occur. The ends of the fibers act as the points where stress concentration is the highest and where cracking occurs. Therefore, a large volume of short fibers inside the composite will cause a high concentration of free fiber ends, leading to a high possibility of cracks occurring inside the composite when it is exposed to stress forces [32]. In cases where the fiber’s length is greater than the critical length, and the strength of the composite is still not satisfactory, the reason is the entanglement of too-long fibers during processing, causing the deterioration of the mechanical properties due to the poor dispersion of fibers in the matrix [61].

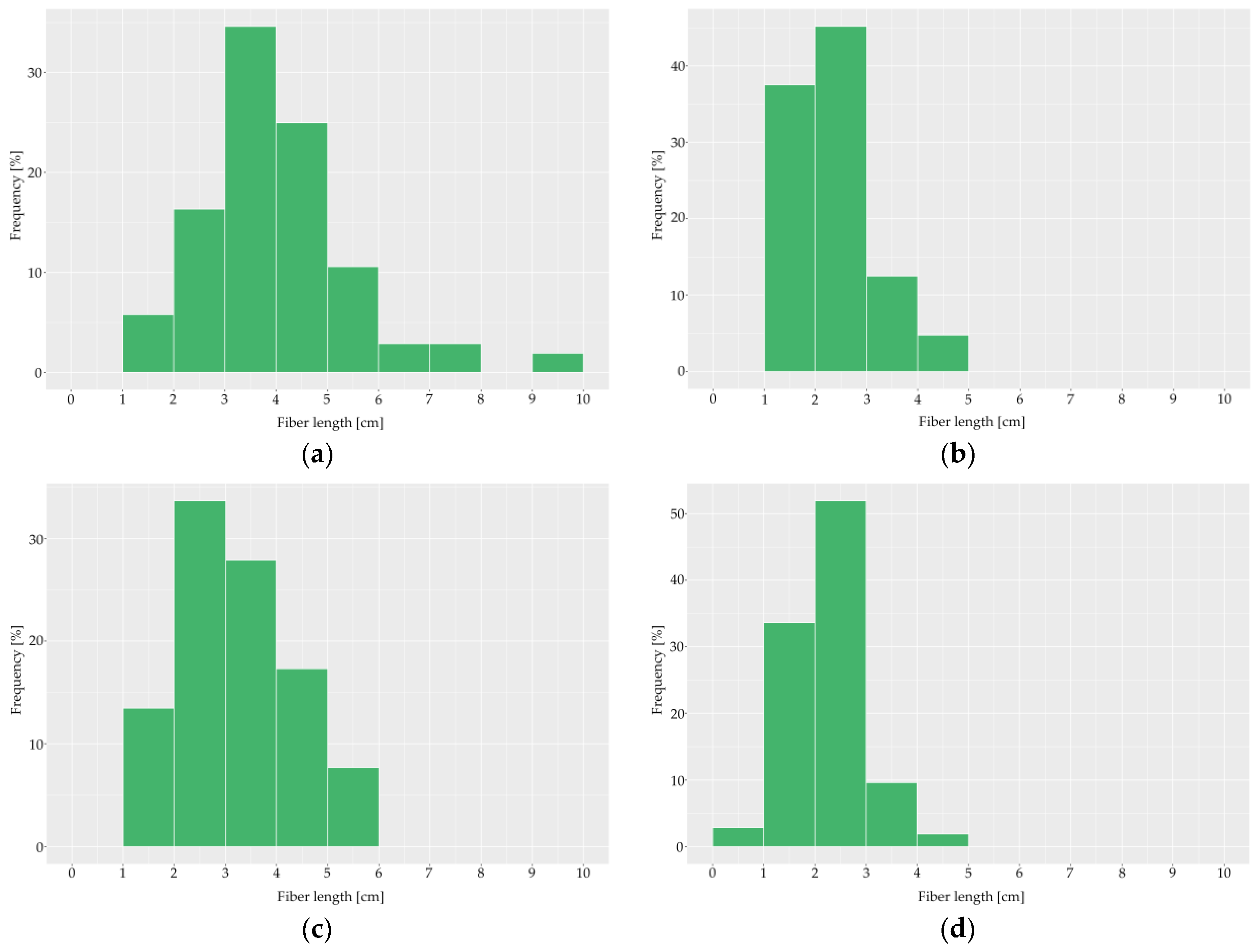

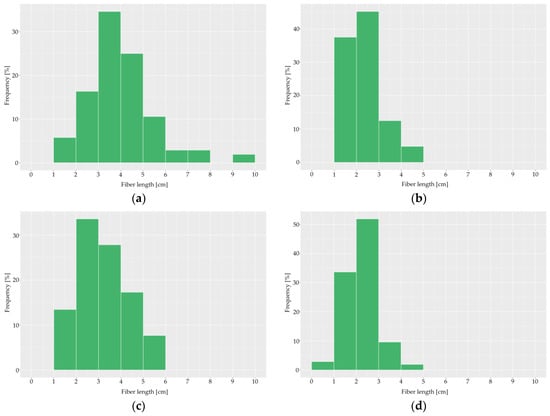

The fibers used in this research were obtained from barley straw via an alkaline maceration process with a low NaOH concentration, resulting in technical fibers (bundles of fibers consisting of elementary or ultimate fibers, as presented in SEM images below in a text). The straw was chopped to a length of 10–12 cm before the chemical maceration process, which also affected the length of the isolated fibers. The isolated fiber length is presented in Table 6, and the distribution of their lengths in Figure 4. The Rex variety harvested in 2021 showed the greatest fiber length—4.03 cm—but also the highest variability in results. According to a two-way ANOVA, there was a significant difference in the length means within the following variables: barley variety and harvesting year (Fcritical < Fstatistical and p-value < 0.05 for each variable). The length of cellulose fibers is influenced by many factors, such as a combination of the genetic factors of the plant, its anatomy and composition, environmental conditions, the growth stage, stress factors, pretreatment, and the stem processing procedures used to isolate the fibers, etc. [63]. From these results, it can be concluded that the old-variety Rex produces fibers of longer length than the new-variety Barun. Also, weather conditions during growth and the fact that 2022 was drier compared to 2021 negatively affected the length of the fibers.

Table 6.

Length of technical fibers isolated from different barley varieties collected within a 2-year period.

Figure 4.

Fiber length distribution of the varieties: (a) Rex (2021), (b) Rex (2022), (c) Barun (2021), and (d) Barun (2022).

3.5. Moisture Content and Moisture Regain

Natural fibers are hygroscopic and rich in hydroxyl groups, which has a great influence on the moisture content and water absorption of the fibers [64]. The processes of water sorption and the swelling of natural fibers are complex due to their biochemical, structural, and morphological features. In this sense, these processes are influenced by several factors, such as lumen size, microfibrillar angle, cellulose crystallinity, accessibility to hydroxyl groups, amounts of amorphous biopolymers, and their relative hydrophilic/hydrophobic character [65]. The amount of moisture in the fibers is related not only to the amount of hemicellulose and lignin but also to the proportion of non-crystalline cellulose parts in the fiber [61,66]. In summary, the hemicellulose content in natural fibers is influenced by a combination of genetic, environmental, and process factors [67]. Understanding and controlling these factors can be essential for optimizing the hemicellulose content in natural fibers so that they can be used for various industrial and commercial applications.

One of the main deficiencies in the properties of natural fibers is their high moisture content, caused by the large amount of hydroxyl and other polar functional groups found in natural fibers. The negative aspect of this property is that it can have a detrimental effect on the mechanical properties of the fiber, as well as its dimensional stability. The positive aspect is biodegradability, which is improved by increasing the water content in the fiber [61].

Table 7 presents the moisture content of isolated barley fibers. The moisture content was the lowest in 2022 for both barley varieties—Rex and Barun—at 7.12% and 6.75%, respectively. A significant difference among the mean values of moisture content was confirmed with a two-way ANOVA, where Fcritical < Fstatistical and the p-value for both variables (variety and harvesting year) was lower than 0.05. Moisture content below 10% is a positive property, as drying such fibers would consume less energy, and storage conditions would be easier to maintain [68,69].

Table 7.

Moisture content of barley fibers.

Table 8 presents the standard moisture regain of isolated barley fibers. The lowest moisture regain was observed in both varieties of barley fibers—Rex and Barun—from 2021, i.e., 10.37% and 10.41%, respectively. The new-variety Barun from 2022 showed a slightly higher moisture regain of 11.01%, but all the values of the tested barley fibers met the moisture regain characteristic for natural fibers (Table 9). A significant difference among the mean values of moisture regain was confirmed with a two-way ANOVA, where Fcritical < Fstatistical and the p-value for both variables (variety and harvesting year) was lower than 0.05.

Table 8.

Moisture regain of barley fibers.

Table 9.

Physical properties of some of the most commonly used fibers from the seed, stem, leaf, and fruit categories in comparison to the barley fibers from this study.

When considering the application of barley straw fibers as reinforcements in composite materials, it should be noted that their hygroscopic character will affect the overall mechanical properties of the composite material. Moisture penetrates the cellulose structure through the amorphous regions, leading to fiber swelling and microcracks within the composite [72]. The amount of moisture in the fibers has a negative effect on the adhesion between the hydrophobic matrix and the hydrophilic fibers, thus negatively affecting the mechanical properties of such a composite [69,72]. The lower the regain, the better the adhesion between the fibers and the polymer matrix. Additionally, the regain affects other properties of the material, such as dimensions, thermal effects, and electrical properties [73,74].

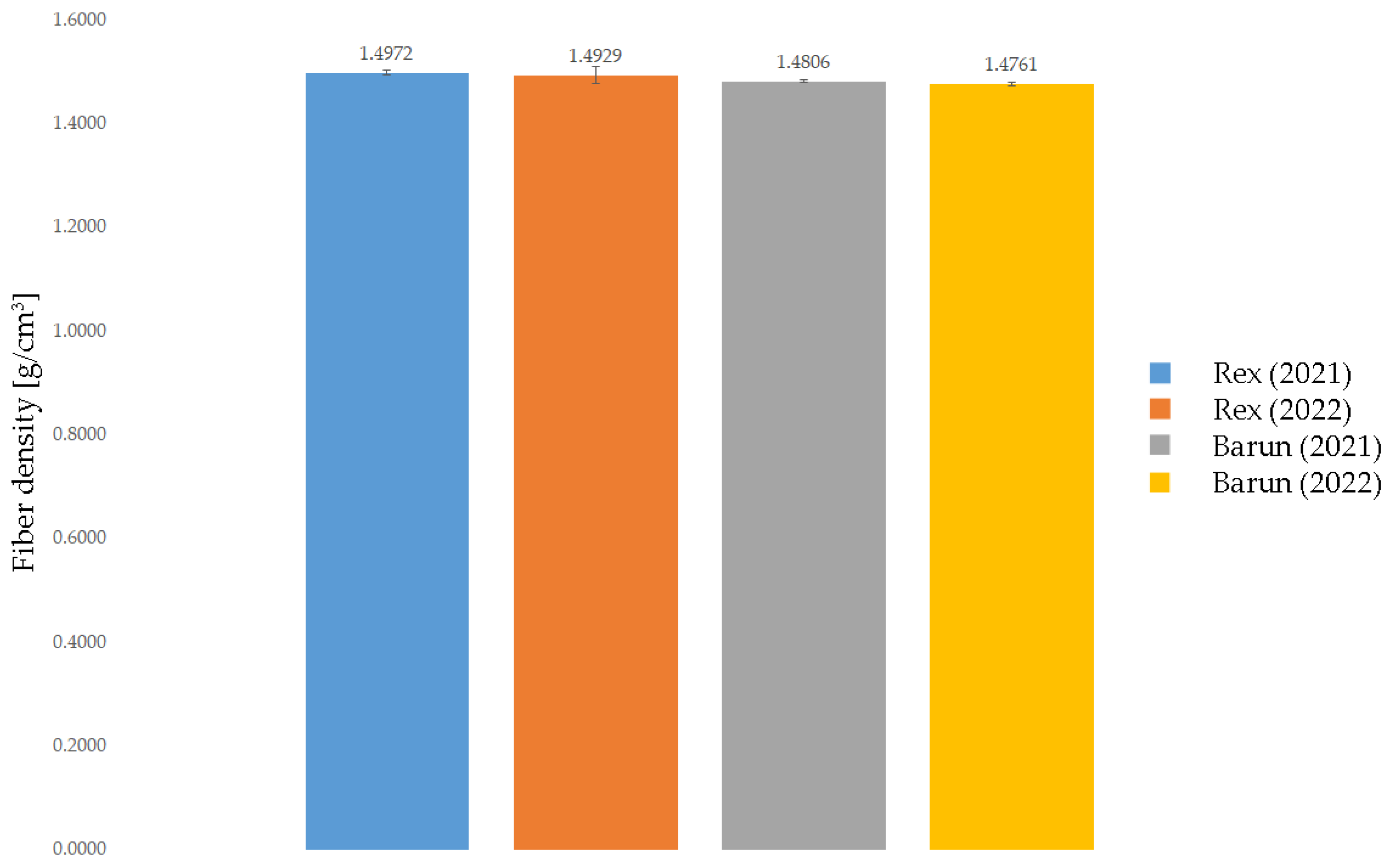

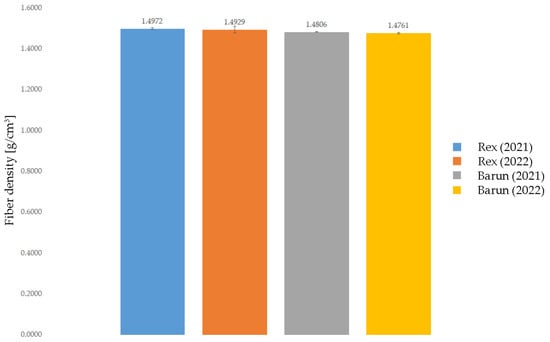

3.6. Fiber Density

Fiber density is an important property of textile fibers that affects their further application. When used as a reinforcement in composite materials, such as those used in the automotive industry, it is crucial that the product is lightweight, as its use reduces fuel consumption and expenses [75].

The mean value of fiber density was determined as a result of 45 parallel measurements per variety (Figure 5). The tested barley fibers showed density values ranging from 1.4761 g/cm3 (new-variety-from-2022 Barun) to 1.4972 g/cm3 (old-variety-from-2021 Rex). Natural fibers typically have a density range from 1.2 g/cm3 to 1.6 g/cm3 [76], so the investigated barley fibers fell within this range. Statistical analysis revealed a significant difference in the density mean values for fibers from different varieties of barley collected from two consecutive years (Fcritical = 2.656 < Fstatistical = 5.486 and p-value = 0.001 < 0.05). We could rank the tested fibers in order of lightest to heaviest as follows: Barun (2022) < Barun (2021) < Rex (2022) < Rex (2021). After the two-way ANOVA, it was concluded that there was a statistically significant difference in fiber density between the different varieties (p-value < 0.05), but fiber density did not depend on the year in which the straw was collected from which the fibers were isolated (p-value > 0.05).

Figure 5.

Density of barley fibers.

The density of fibers was inversely proportional to their volume, and the volume depended on the chemical structure of the fiber, including the content of hemicellulose, lignin, and cellulose, as well as their amorphous or crystalline nature. Therefore, it could be concluded that the old-variety Rex had a smaller volume of fibers due to fiber shrinkage caused by the better removal of hemicellulose and lignin, which was not the case with the fibers from the Barun variety (the new variety). Additionally, the alkaline treatment of barley straw and the subsequently isolated fibers with NaOH affected the filling of micropores on the surface of the fibers, resulting in a reduction in the fiber volume and an increase in its density [56,77,78,79]. Although fibers from both varieties of barley are suitable as reinforcements in composite materials, fibers from the new Barun variety would enable a slightly lower mass of the final product, resulting in better energy and economic efficiency, for example, in the automotive industry.

Table 9 presents the physical properties of fiber representatives in each category of cellulose fibers (seed fibers, stem (bast) fibers, and leaf and fruit fibers). The results revealed the correspondence of barley fibers’ characteristics to most of the stem or fruit fibers.

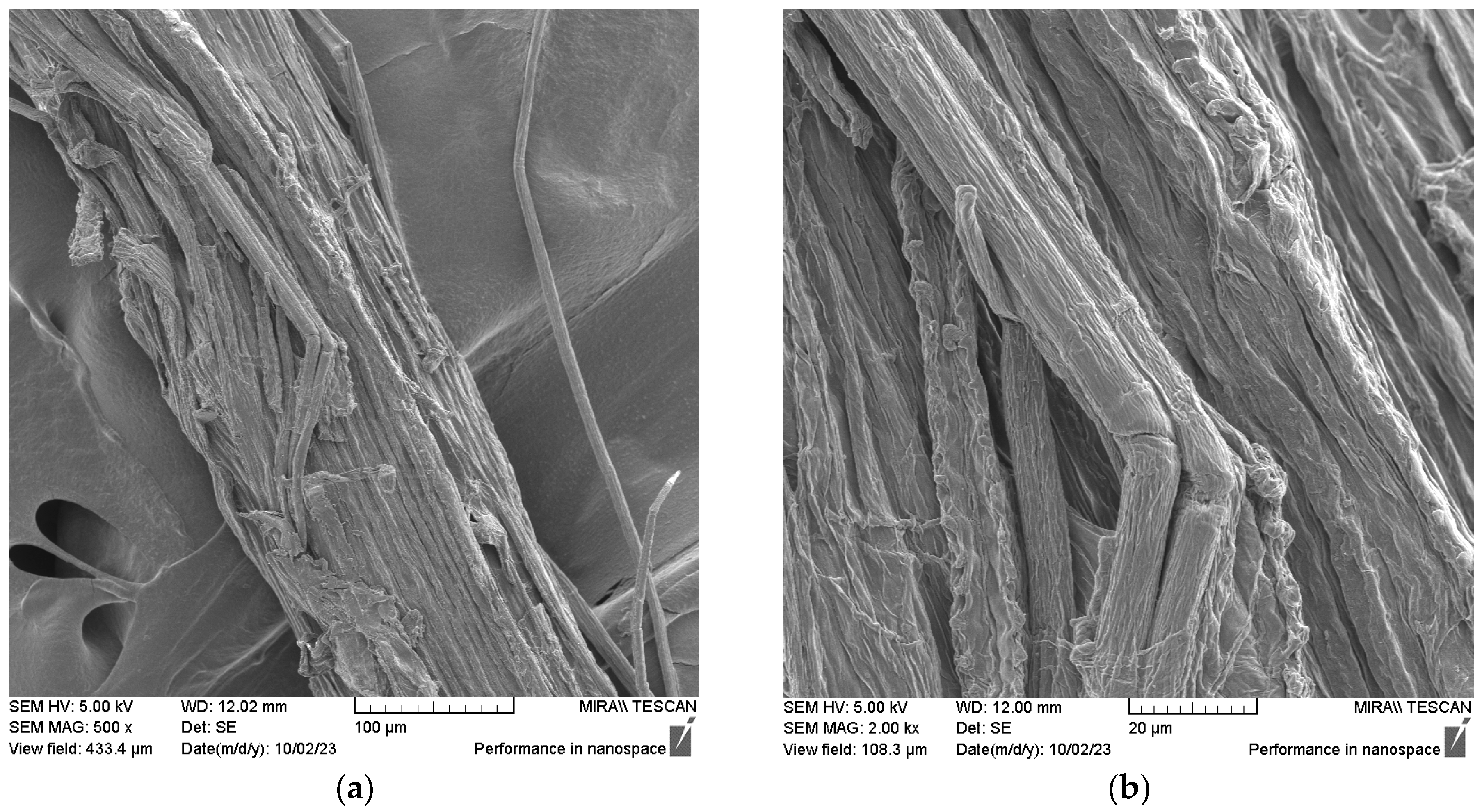

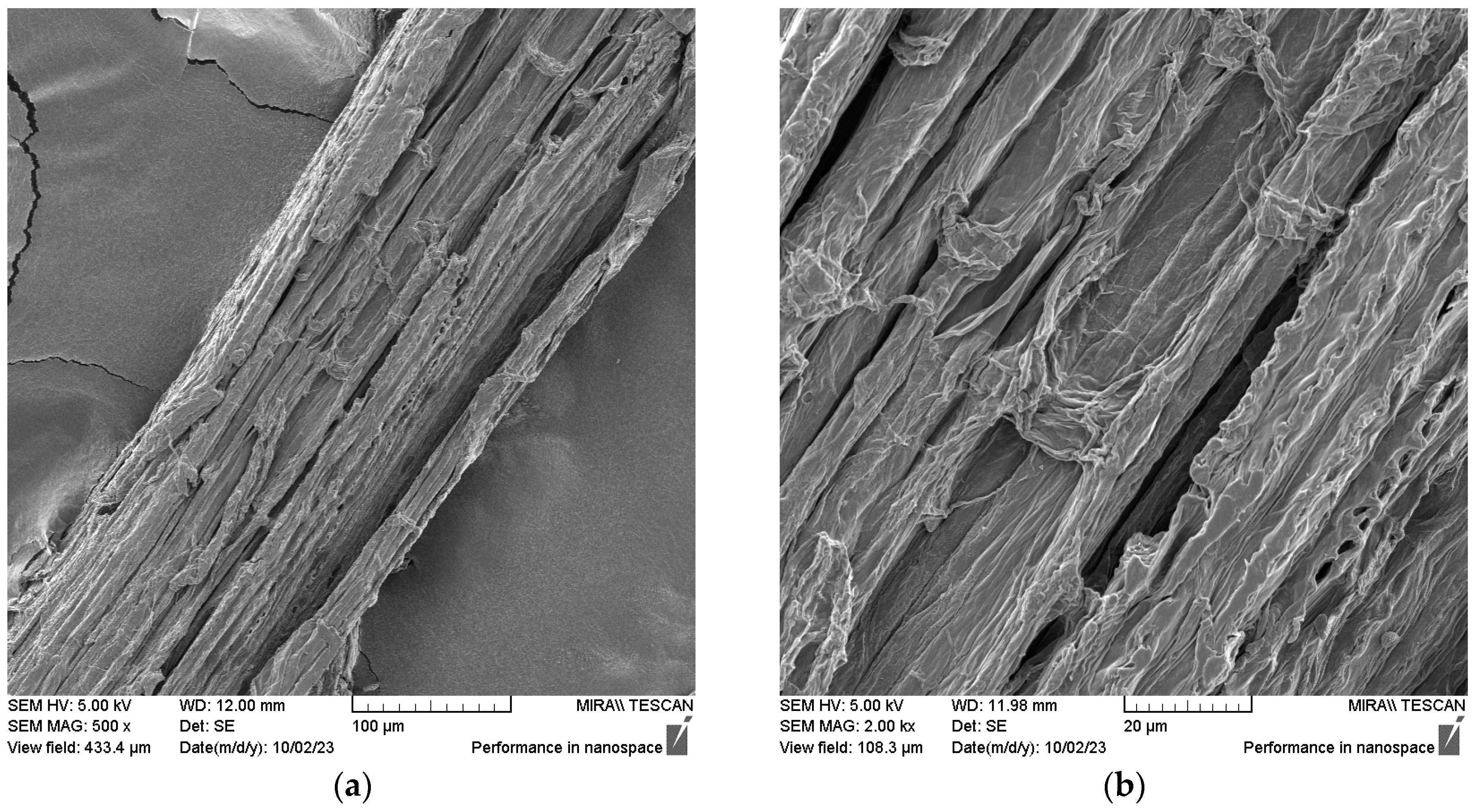

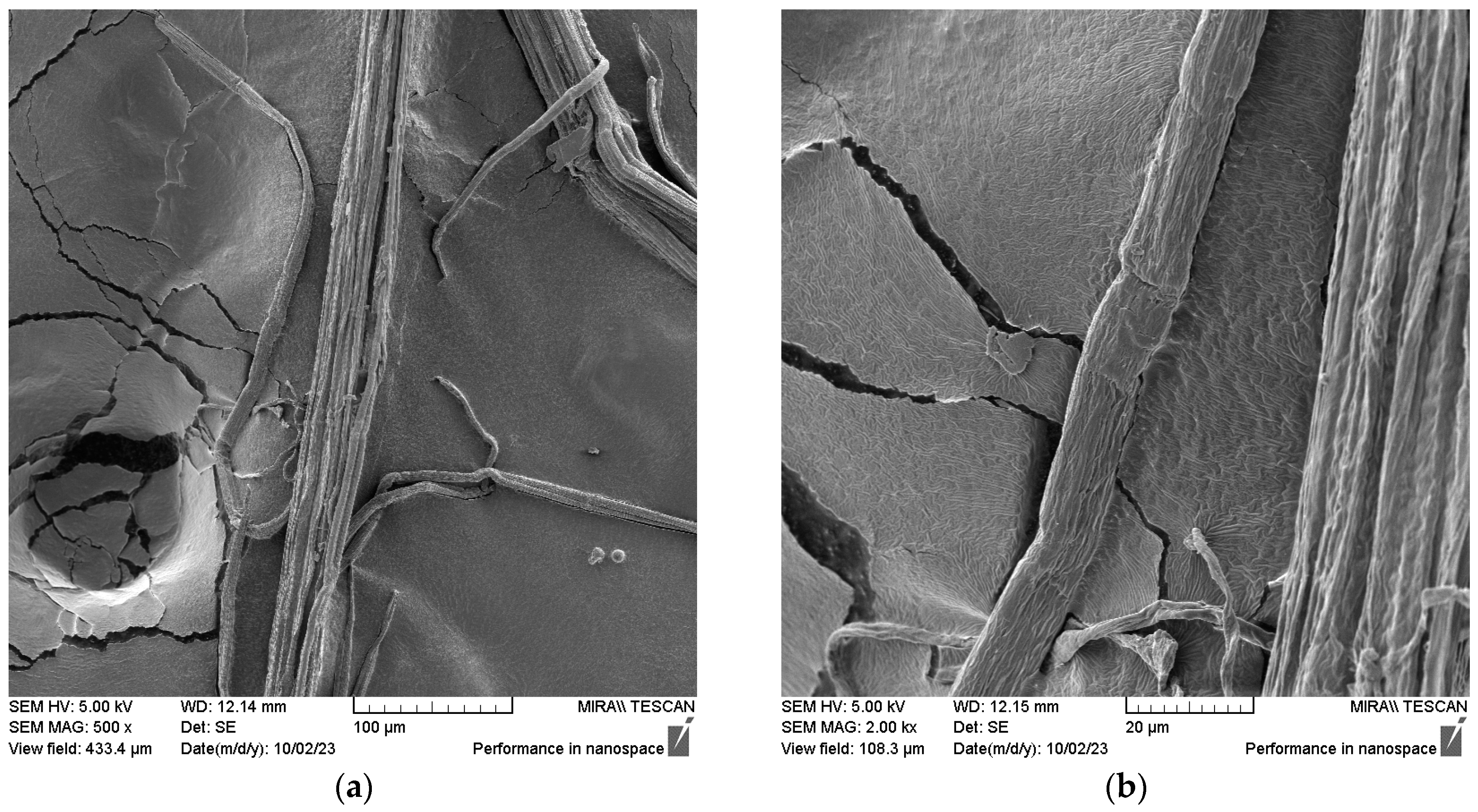

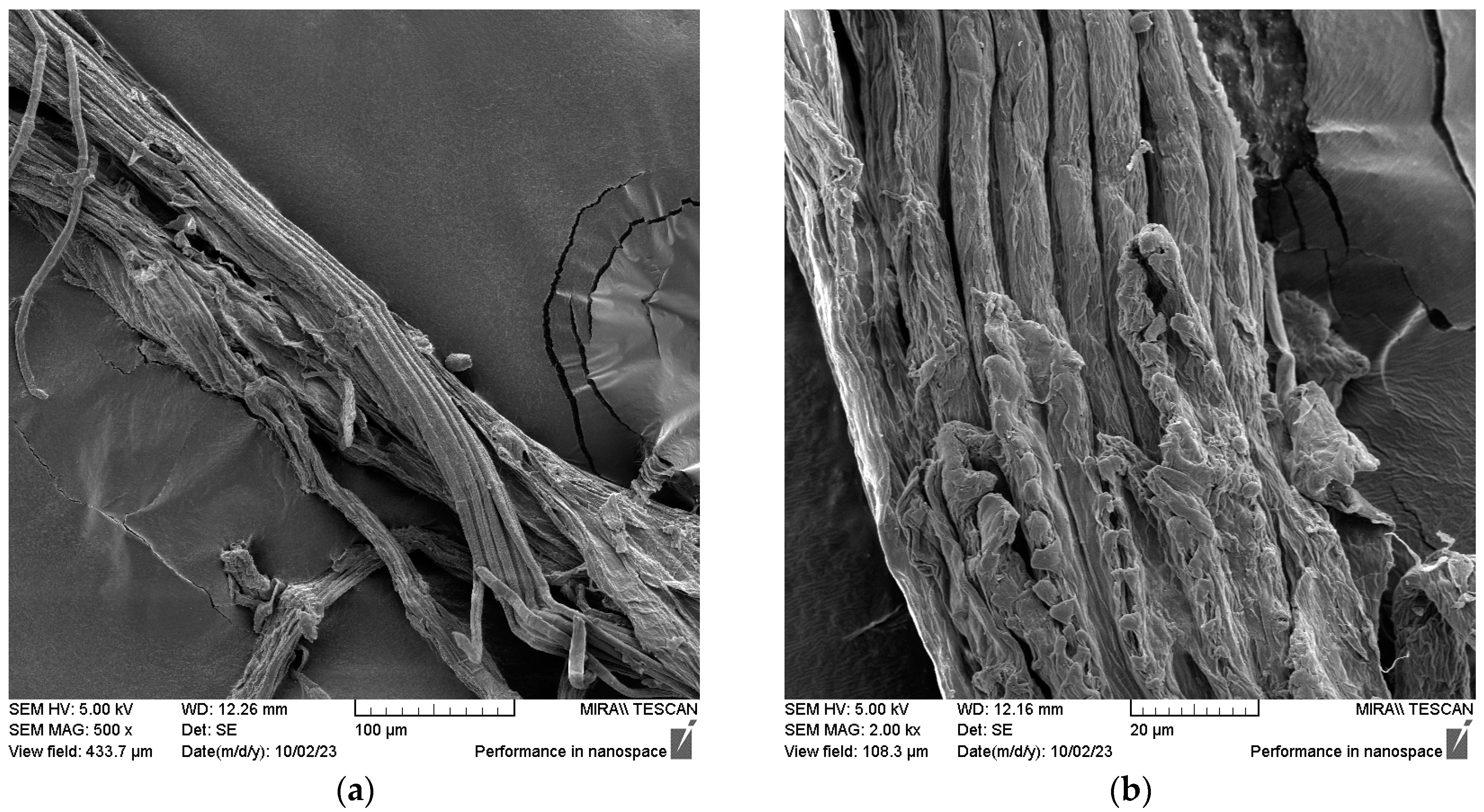

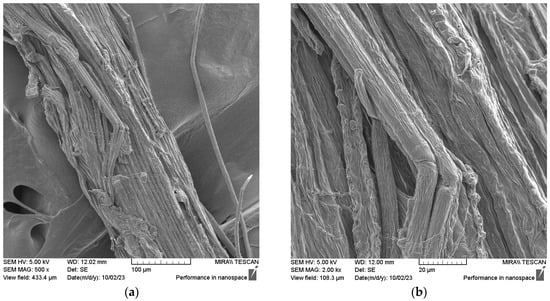

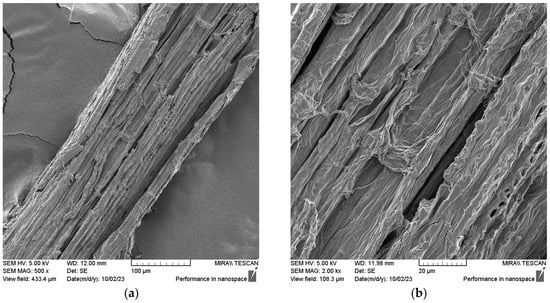

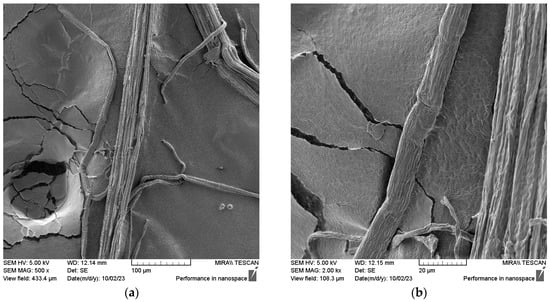

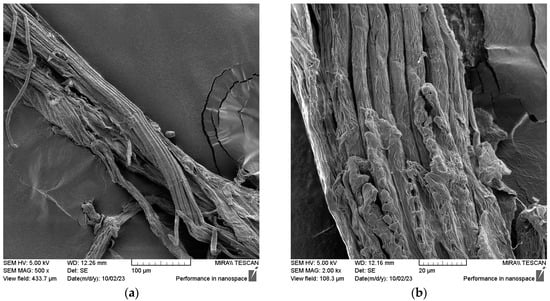

3.7. Fiber Morphology

Figure 6, Figure 7, Figure 8 and Figure 9 depict SEM micrographs of fibers that were isolated from different varieties of barley. The micrographs, captured at 500× magnification, reveal technical fibers (fiber bundles) that consist of elementary fibers (ultimate fibers), which were isolated from barley straw. It is observable that all the fibers were isolated using the same alkaline process with the use of low-concentration NaOH, which resulted in the incomplete delignification and solubilization of hemicellulose.

Figure 6.

SEM micrographs of barley fiber isolated from the straw of the REX variety from 2021: (a) technical fiber under magnification of 500× and (b) the ultimate fiber as part of the technical fiber under magnification of 2000×.

Figure 7.

SEM micrographs of barley fiber isolated from the straw of the REX variety from 2022: (a) technical fiber under magnification of 500× (b) the ultimate fiber as part of the technical fiber under magnification of 2000×.

Figure 8.

SEM micrographs of barley fiber isolated from the straw of the Barun variety from 2021: (a) technical fiber under magnification of 500× and (b) the ultimate fiber as part of the technical fiber under magnification of 2000×.

Figure 9.

SEM micrographs of barley fiber isolated from the straw of the Barun variety from 2022: (a) technical fiber under magnification of 500× and (b) the ultimate fiber as part of the technical fiber under magnification of 2000×.

Chen et al. [80] investigated the effect of different concentrations of sodium alkali on the microstructure of fibers. They concluded that the concentration of alkali lower than 5% has a relatively small effect on the microstructure of fibers.

In the case of the Barun variety from 2021, a more significant separation of the elementary fibers from the technical fibers was visible. In Figure 8b, at a magnification of 2000×, the rough surface made of cellulose microfibrils is visible, along with nodes along the elementary fibers. Such a surface with non-uniform geometrical characteristics is typical of most natural fibers isolated from plant stems [67].

The irregular surface of the fibers is a beneficial feature when such fibers are used as a reinforcement in composite materials. It can lead to a better adhesion and interlock effect between the polymer matrix and the fiber, which, in turn, affects the composite’s mechanical properties. The transfer of stress between the polymer matrix and fibers determines the effectiveness of the reinforcement [67,81].

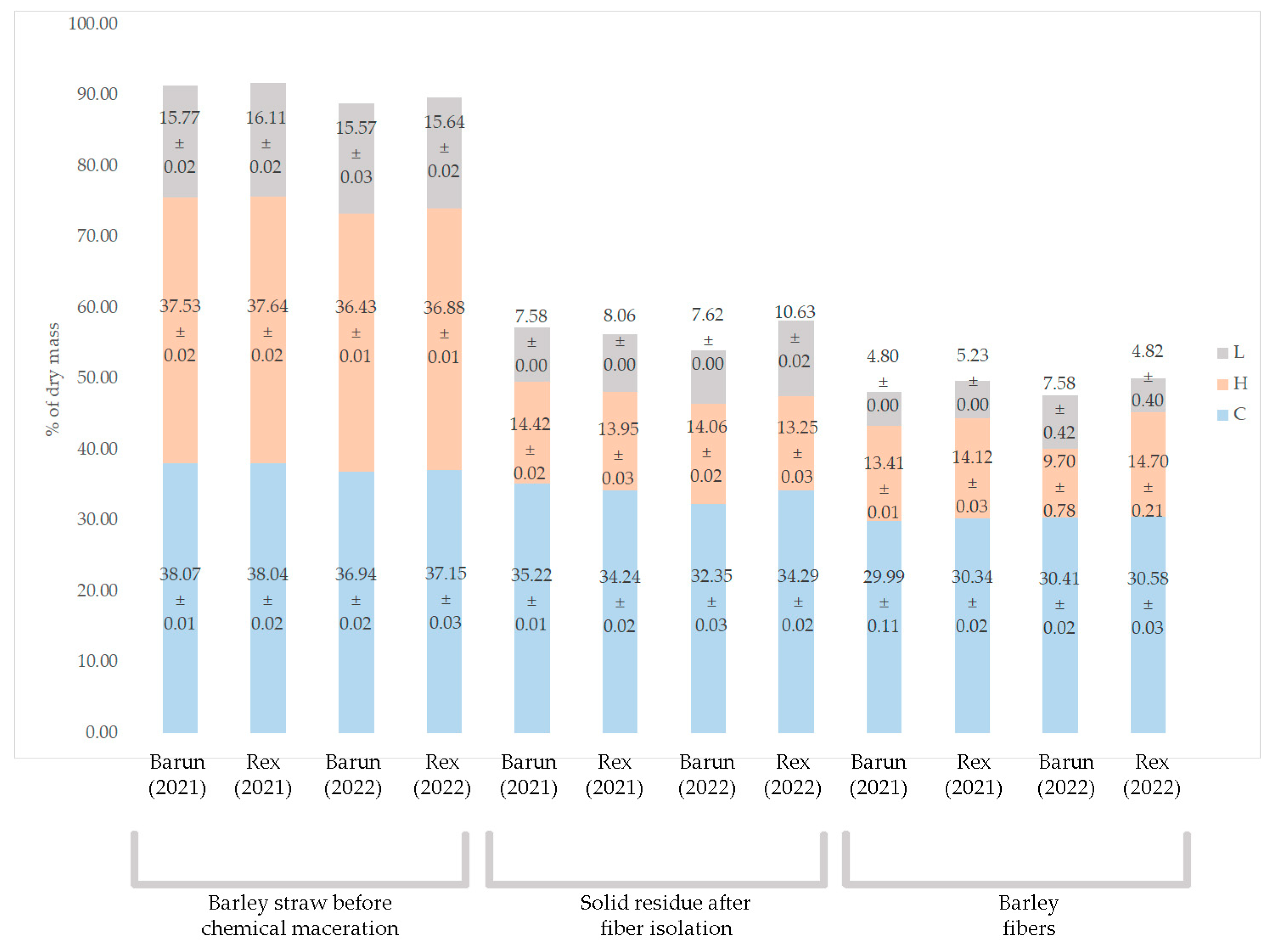

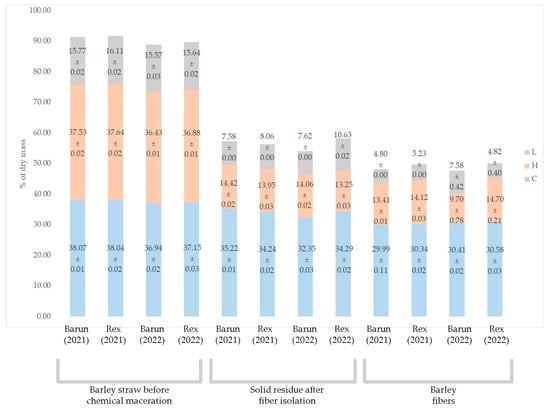

3.8. Chemical Composition

3.8.1. Cellulose, Hemicellulose, and Lignin Content

The chemical composition of barley straw before and after fiber isolation, as well as the chemical composition of the solid residue (Figure 2), are presented in Figure 10.

Figure 10.

Chemical composition of barley straw before chemical maceration, solid residue after fiber isolation, and barley fibers, where L is the lignin content (wt.%), H is the hemicellulose content (wt.%), and C is the cellulose content (wt.%).

The barley fibers isolated from the Rex variety (2022) straw showed the highest content of cellulose among all the tested fibers—30.58%—and lignin content below 5%. All the tested fibers showed very similar properties regarding cellulose, hemicellulose, and lignin content, except fibers isolated from the straw of the Barun variety (2022), which showed 58% higher lignin content compared to the lowest value.

Table 10 presents the chemical composition of some of the most commonly used fibers expressed as the content of cellulose, hemicellulose, and lignin. The barley fibers investigated in this paper showed very low cellulose content, which was also confirmed via tensile testing. Comparing the results from Table 10, the barley fibers can be categorized as bast and leaf fibers.

Table 10.

Chemical properties of some of the most commonly used fibers from the seed, stem, leaf, and fruit categories in comparison to the barley fibers from this study.

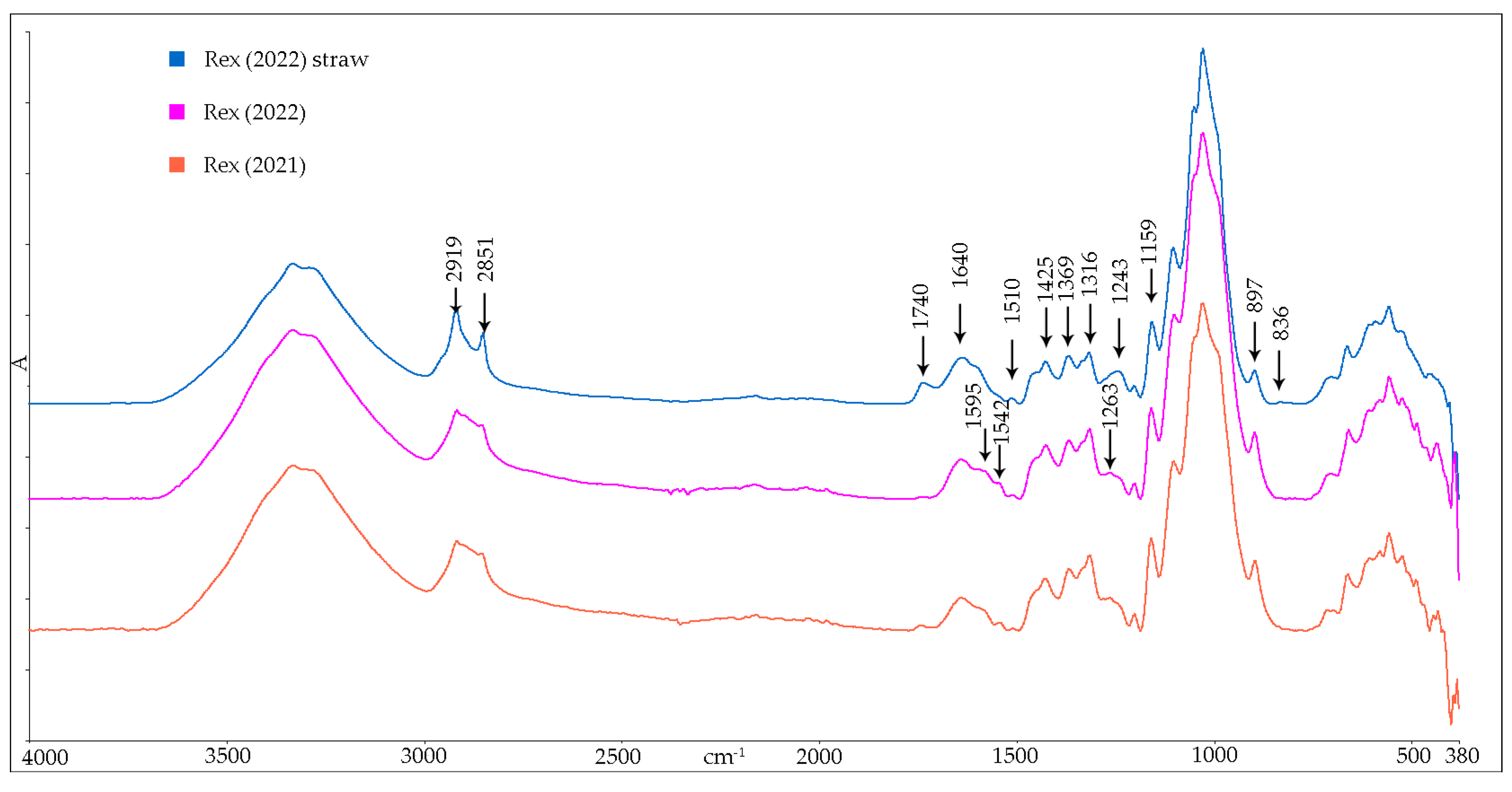

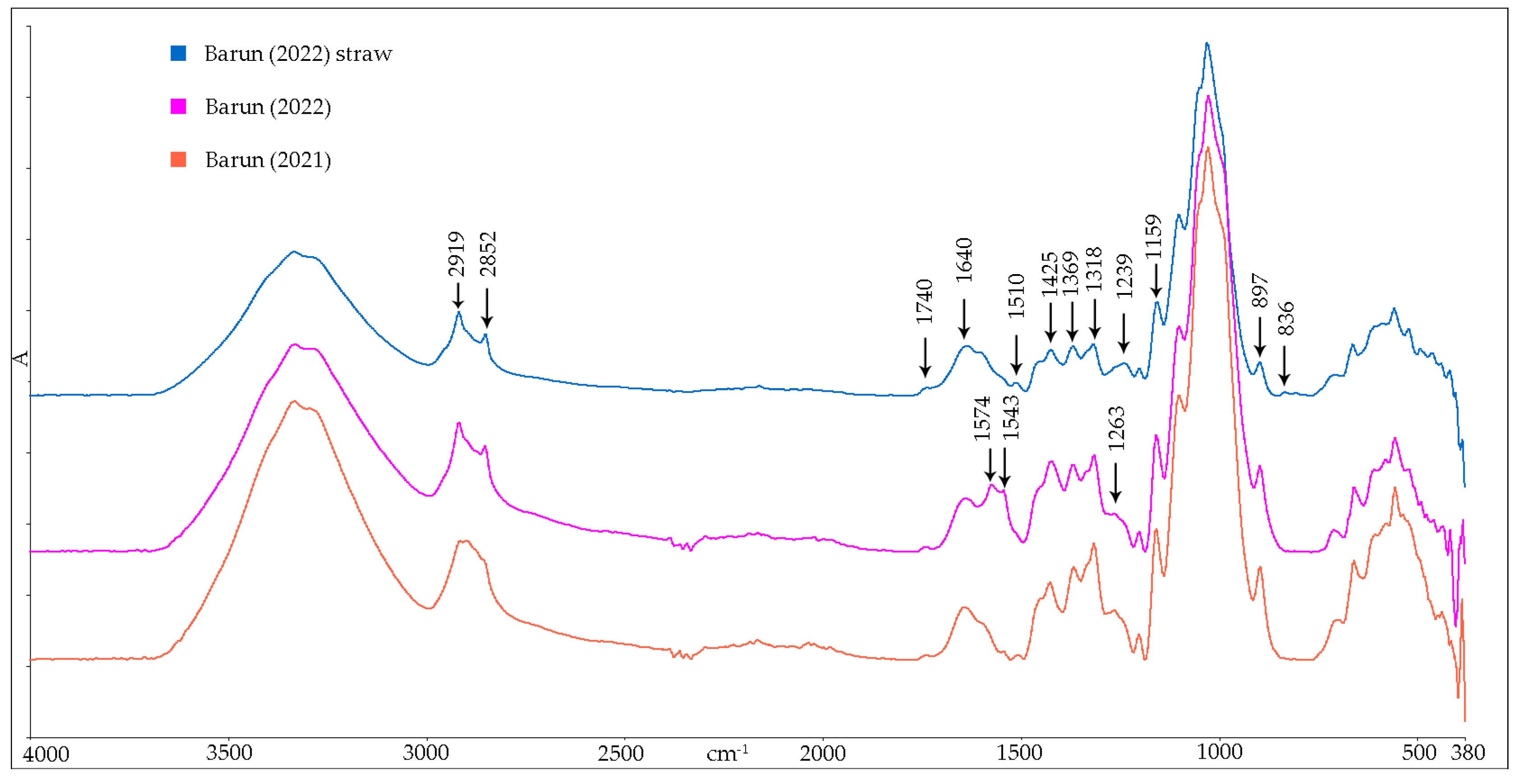

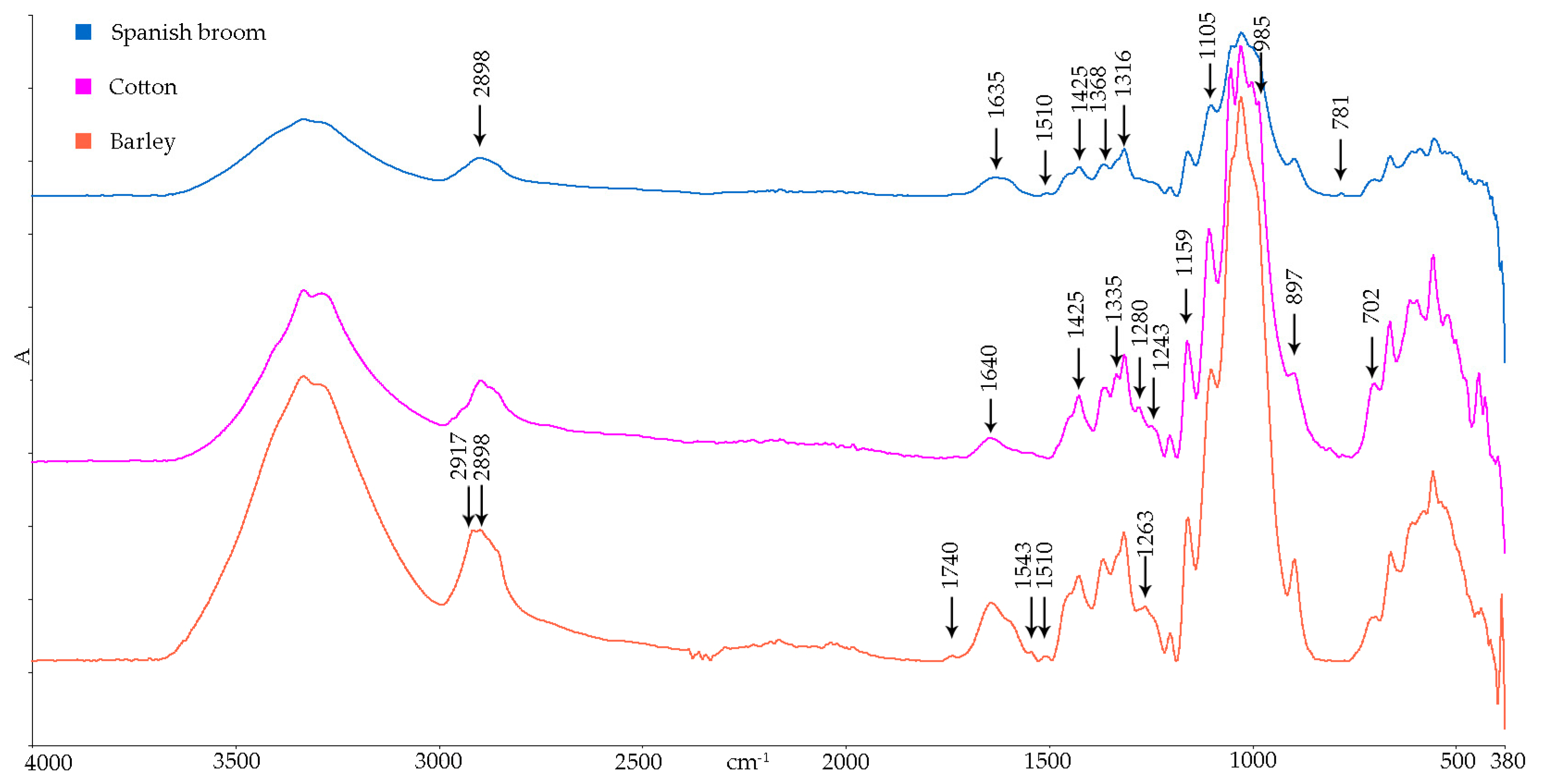

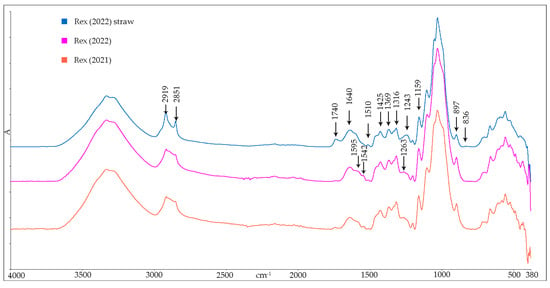

3.8.2. FTIR

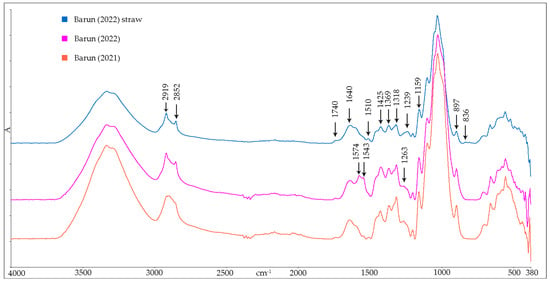

The ATR-FTIR spectra of the investigated fibers isolated from the barley varieties Rex and Barun are presented in Figure 11 and Figure 12. The effect of chemical maceration was evaluated according to characteristic peaks of lignin, cellulose, and hemicellulose (Table 11).

Figure 11.

FTIR spectra of barley fibers isolated from straw of the old Rex variety.

Figure 12.

FTIR spectra of barley fibers isolated from straw of the new Barun variety.

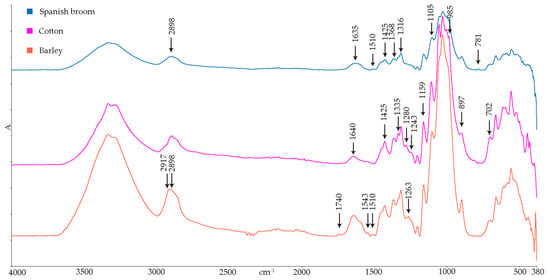

A large absorption band visible within the range of 3200–3400 cm−1 was attributed to the -OH group, while bands at 2919 cm−1 and 2850–2852 cm−1 were attributed to the -CH2 and -CH groups of cellulose, hemicellulose, pectin, fats, and waxes [55]. The barley straw of the Rex variety exhibited the highest intensity of its band at 1740 cm−1. This peak was associated with free -COOH groups of polygalacturonic acid, which is the main constituent of pectins, and therefore, the lower intensity of this peak observed within barley fibers indicates the successful removal of pectin and the positive effect of chemical maceration [82,83]. The absorption band at 1640 cm−1 corresponded to the adsorbed water and derived from hydrogen bonding in the amorphous region of the cellulose macromolecules [84]. Fibers from the Rex variety (2021) showed a lower intensity of this peak, which was due to the removal of hemicellulose after chemical maceration, thus improving the internal organization of cellulose chains in more crystalline regions and, consequently, allowing better fiber strength [55]. The barley straws and fibers from both varieties showed characteristic bands for lignin at 1574–1595 cm−1, 1542 cm−1, and 1510 cm−1. In Figure 11 and Figure 12, the lower intensity of those peaks is noticeable in the case of the barley fibers, indicating lignin removal after the chemical maceration process [85,86]. The same observations were captured for lignin bands at 1239 cm−1 and 836 cm−1. The absence of these peaks in the barley fibers in comparison to the straw indicated good efficiency of chemical maceration and confirmed the elimination of lignin. The peaks at 1239–1243 cm−1 and 1263 cm−1 correspond to syringyl (S) and guaiacyl (G) units in lignin, respectively. Therefore, it could be concluded that the fibers contained more guaiacyl moieties, which are characteristic of softwood species, while syringyl moieties were reduced after chemical maceration [87]. The absorption band at around 1420–1430 cm−1 corresponds to the cellulose crystalline structure, while the band at 897 cm−1 is associated with the amorphous structure of the cellulose [55,88]. The bands at 1369 cm−1, 1335 cm−1, 1318 cm−1, and 1204 cm−1 are associated with the stretching and bending of -CH2, -CH, -OH, and C-O-C bonds in cellulose and hemicellulose [88]. In comparison to the FTIR spectra from Figure 11 and Figure 12, the spectra from Figure 13 indicates that the fibers isolated from barley straw correspond well with the other cellulose fibers, showing the same peaks at 1159 cm−1, 1105 cm−1, 1050 cm−1, 1030 cm−1, 1000 cm−1, and 985 cm−1. These peaks are assigned to C-O-C glycosidic ether, -CO stretching vibrations of acetyl xylan, and -CO stretching vibrations of the polysaccharide components, mainly cellulose. The bands at 1050 cm−1, 1000 cm−1, and 985 cm−1 are visible only as shoulders in the barley fiber FTIR spectra, pointing to the less developed secondary cell wall of these fibers that influences the mechanical strength of barley fibers [55].

Figure 13.

FTIR spectra of barley fibers compared to Spanish broom and cotton fibers.

Table 11.

Main infrared (IR) transitions of cellulose fibers [55,85,86].

Table 11.

Main infrared (IR) transitions of cellulose fibers [55,85,86].

| Wavenumber (cm−1) | Vibration | Sources |

|---|---|---|

| 3200–3400 | OH stretching | Cellulose and hemicellulose |

| 2917–2919, 2850–2852 | C-H symmetrical stretching | Cellulose and hemicellulose |

| 1740 | C=O stretching vibration | Pectin and waxes |

| 1640 | OH bending of absorbed water | Water |

| 1574–1605 | Aromatic skeletal vibrations and C=O stretch | Lignin |

| 1543 and 1510–1515 | C=C aromatic symmetrical stretching | Lignin |

| 1456 | C-H and C-O deformations, bending or stretching vibrations in lignin and carbohydrates | Cellulose, hemicellulose, and lignin |

| 1425 | HCH and OCH in-plane bending vibration | Cellulose |

| 1368 | In-plane CH bending | Cellulose and hemicellulose |

| 1335 | C-H vibrations and O-H in-plane bending | Cellulose and hemicellulose |

| 1316–1318 | CH2 rocking vibration | Cellulose |

| 1230–1263 | C=O and S and G ring stretching | Lignin |

| 1204 | C-O-C symmetric stretching | Cellulose and hemicellulose |

| 1159 | C-O-C asymmetrical stretching | Cellulose and hemicellulose |

| 1105 | C-O-C glycosidic ether | Cellulose |

| 1051, 1030, and 1000 | C-C, C-OH, C-H ring, and side group vibrations | Cellulose and hemicellulose |

| 985 | C-O valence vibrations | Cellulose |

| 897 | COC, CCO, and CCH deformation and stretching | Cellulose |

| 836 | Out-of-plane aromatic CH | Lignin |

| 781 | Deformation vibrations of C-H bonds associated with aromatic rings | Lignin |

4. Conclusions

Despite today’s enormous potential for information flow, the media’s influence, higher rates of education, and the significant impact of social networks, people still consider textiles to be fabrics and clothes used in daily life. However, the use of textiles extends far beyond the fashion and clothing industry, with applications in various fields, including automotive and construction, maritime and aerospace, composites, nanotechnology, and biomedicine. The properties of textile products depend on the properties of their basic components, i.e., textile fibers.

This research aimed to promote the circular bioeconomy by examining the properties of textile fibers obtained from the straw of two varieties of barley. These fibers will be used to produce technical textiles, specifically biocomposite materials. The fiber extraction process was accomplished via chemical maceration under milder alkali conditions using a low concentration of NaOH to achieve more environmentally friendly conditions.

Although the Rex variety harvested in 2021 showed the best fiber yield results (23.98%), due to the significant variability in the results, it can be concluded that the new Barun variety harvested in 2022 has a positive tendency in fiber (16.07%) and residue (32.90%) yield, considering the negative effects of climate change, such as an increase in drought.

The fiber breaking tenacity for the varieties from 2021 was slightly higher compared to the varieties from 2022. Both barley varieties from 2021 showed high fiber tenacity of 25.63 cN/tex and 23.08 cN/tex, respectively, indicating the possibility of spinning such fibers into yarn.

Our results confirmed that the parameter of fiber length is influenced by the barley variety and harvest year. The longest fiber length was observed for the Rex variety from the 2021 harvest year (average length: 4.03 cm). According to the length distribution analysis, most of the investigated fibers showed the highest frequency in the range 2–3 cm, except for the Rex variety from 2021, which showed the highest frequency in the length range of 3–4 cm. Both fiber lengths had satisfactory values to be used as reinforcements in composite materials.

Moisture content and moisture regain were strongly influenced by the feedstock variety and its harvest year. The moisture content of fibers isolated from straw harvested in 2022 was low, approx. 7%, which is positive from the perspective of storage maintenance conditions and lower energy consumption. All the tested fibers showed moisture regain in the range of 10.37% to 11.01%, which is in line with conventional bast fibers. Furthermore, fibers with a low moisture regain perform better when used for reinforcement in composite material due to the better adhesion between the polymer matrix and the fiber.

The density of all the tested fibers fell within the range of 1.4761 g/cm3 to 1.4972 g/cm3, which is consistent with the densities of natural fibers. Although fibers from both varieties of barley are suitable as reinforcements in composite materials, fibers from the new Barun variety would enable a slightly lower mass of the final product and, thus, better energy and economic efficiency if used, for example, in the automotive industry.

Morphology analysis revealed non-uniform geometrical characteristics on the fiber surfaces, which are typical for most natural fibers isolated from plant stems. The roughness of the fiber surface is a positive characteristic if such fibers are used as reinforcements in composite material since its relief topography has a positive effect on adhesion between a polymer matrix and natural fibers.

The chemical composition of isolated fibers showed that the optimal content of cellulose and lignin was observed in the barley fibers isolated from the straw of the old Rex variety (2021 and 2022). They showed a higher content of cellulose in comparison to the Barun variety within the same harvesting year—30.34% and 30.58%, respectively. Those results were confirmed via FTIR analysis since the spectra of the Rex fibers showed lower intensities of peak characteristics for hemicellulose and lignin, which proved their better removal after the performed chemical pretreatment.

The results concerning fiber density confirmed low values (lower than 1.5 g/cm3), which are favorable for their usage as light reinforcements of a composite matrix designed for the automotive industry. Another possible usage of barley fibers derived from old cultivars is in the clothing industry due to the fact that the obtained fiber tenacity of 20.31–23.08 cN/tex fulfills minimal spinning requirements. This research presents only part of the very broad investigation of the possible usage of cereal biomass for the dual production of fibers and biofuels. Our results revealed the possibility of the usage of a very high percentage of solid waste left after the fiber isolation for the production of high-quality biofuels.

Author Contributions

Conceptualization, S.S. and Z.K.; methodology, Z.K.; software, Z.K.; validation, Z.K. and S.B.; formal analysis, Z.K. and S.S.; investigation, Z.K. and S.S.; resources, Z.K. and S.B.; data curation, Z.K.; writing—original draft preparation, S.S. and S.B.; writing—review and editing, Z.K. and S.B.; visualization, S.S. and Z.K.; supervision, S.B.; project administration, S.B.; funding acquisition, S.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the European Regional Development Fund via the KK.05.1.1.02.0016 project: Production of Food, Biocomposites and Biofuels from Cereals in a Circular Economy, https://projekt-klima.eu/ (accessed on 17 October 2023).

Data Availability Statement

Data are contained within the article.

Acknowledgments

This research was performed using equipment purchased for the K.K.01.1.1.02.0024 project: Modernization of Textile Science Research Centre Infrastructure (MI-TSRC). Fibers’ breaking tenacity and titer measurements were obtained using Vibroskop & Vibrodyn devices located at the premises of the University of Zagreb Faculty of Textile Technology, Department of Materials, Fibres and Textile Testing. The authors would like to thank Ksenija Višić for her contribution to the experimental part of the study regarding fibers’ extraction from barley straw, their separation from the residue, and testing of the fibers’ moisture and density, as well as Ivana Tomić, for her contribution to cellulose, hemicellulose, and lignin determinations.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Dalla Fontana, G.; Mossotti, R.; Montarsolo, A. Assessment of microplastics release from polyester fabrics: The impact of different washing conditions. Environ. Pollut. 2020, 264, 113960. [Google Scholar] [CrossRef]

- Giraldo, P.; Benavente, E.; Manzano-Agugliaro, F.; Gimenez, E. Worldwide research trends on wheat and barley: A bibliometric comparative analysis. Agronomy 2019, 9, 352. [Google Scholar] [CrossRef]

- Britannica: Poales. Available online: https://www.britannica.com/plant/Poales (accessed on 31 August 2023).

- Pourkheirandish, M.; Komatsuda, T. The importance of barley genetics and domestication in a global perspective. Ann. Bot. 2007, 100, 999–1008. [Google Scholar] [CrossRef]

- Geng, L.; Li, M.; Zhang, G.; Ye, L. Barley: A potential cereal for producing healthy and functional foods. Food Qual. Saf. 2022, 6, fyac012. [Google Scholar] [CrossRef]

- Newman, C.W.; Newman, R.K. A brief history of barley foods. Cereal Foods World 2006, 51, 4–7. [Google Scholar] [CrossRef]

- Wendler, N. Unlocking the Secondary Gene Pool of Barley for Breeding and Research. Ph.D. Dissertation, Naturwissenschaftlichen Fakultät III Agrar- und Ernährungswissenschaften, Geowissenschaften und Informatik, der Martin-Luther-Universität, Halle-Wittenberg, Germany, 25 January 2016. [Google Scholar] [CrossRef]

- Reid, D.A. Morphology and anatomy of the barley plant. In Barley, 1st ed.; Rasmusson, D.C., Ed.; American Society of Agronomy, Inc.: Madison, WI, USA; Crop Science Society of America, Inc.: Madison, WI, USA; Soil Science Society of America, Inc.: Madison, WI, USA, 1985; Volume 26, pp. 73–101. [Google Scholar] [CrossRef]

- Zohary, D.; Hopf, M. Domestication of Pulses in the Old World: Legumes were companions of wheat and barley when agriculture began in the Near East. Science 1973, 182, 887–894. [Google Scholar] [CrossRef] [PubMed]

- Mamun, A.A.; Heim, H.P.; Bledzki, A.K. The use of maize, oat, barley and rye fibres as reinforcements in composites. In Biofiber Reinforcements in Composite Materials; Faruk, O., Sain, M., Eds.; Woodhead Publishing: Cambridge, UK, 2015; pp. 454–487. [Google Scholar] [CrossRef]

- EMEP/EEA Emission Inventory Guidebook 2013. 3. F Field Burning of Agricultural Residues. Available online: https://www.eea.europa.eu/publications/emep-eea-guidebook-2013/part-b-sectoral-guidance-chapters/4-agriculture/3-f-field-burning (accessed on 20 September 2023).

- Chilakamarry, C.R.; Sakinah, A.M.; Zularisam, A.W.; Sirohi, R.; Khilji, I.A.; Ahmad, N.; Pandey, A. Advances in solid-state fermentation for bioconversion of agricultural wastes to value-added products: Opportunities and challenges. Bioresour. Technol. 2022, 343, 126065. [Google Scholar] [CrossRef] [PubMed]

- Awogbemi, O.; Von Kallon, D.V. Pretreatment techniques for agricultural waste. Case Stud. Chem. Environ. Eng. 2022, 6, 100229. [Google Scholar] [CrossRef]

- Bala, S.; Garg, D.; Sridhar, K.; Inbaraj, B.S.; Singh, R.; Kamma, S.; Tripathi, M.; Sharma, M. Transformation of agro-waste into value-added bioproducts and bioactive compounds: Micro/nano formulations and application in the agri-food-pharma sector. Bioengineering 2023, 10, 152. [Google Scholar] [CrossRef]

- Borrega, M.; Hinkka, V.; Hörhammer, H.; Kataja, K.; Kenttä, E.; Ketoja, J.A.; Palmgren, R.; Salo, M.; Sundqvist-Andberg, H.; Tanaka, A. Utilizing and Valorizing Oat and Barley Straw as an Alternative Source of Lignocellulosic Fibers. Materials 2022, 15, 7826. [Google Scholar] [CrossRef]

- Gunjan; Chopra, L.; Manikanika. Extraction of cellulose from agro-waste—A short review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. The use of wheat straw fibres as reinforcements in composites. In Biofiber Reinforcements in Composite Materials; Faruk, O., Sain, M., Eds.; Woodhead Publishing: Cambridge, UK, 2015; pp. 423–453. [Google Scholar] [CrossRef]

- Fortunati, E.; Benincasa, P.; Balestra, G.M.; Luzi, F.; Mazzaglia, A.; Del Buono, D.; Puglia, D.; Torre, L. Revalorization of barley straw and husk as precursors for cellulose nanocrystals extraction and their effect on PVA_CH nanocomposites. Ind. Crops Prod. 2016, 92, 201–217. [Google Scholar] [CrossRef]

- Cruz, R.M.; Krauter, V.; Krauter, S.; Agriopoulou, S.; Weinrich, R.; Herbes, C.; Scholten, P.; Uysal-Unalan, I.; Sogut, E.; Kopacic, S.; et al. Bioplastics for Food Packaging: Environmental Impact, trends and regulatory aspects. Foods 2022, 11, 3087. [Google Scholar] [CrossRef]

- Schildbach, R. Barley worldwide. J. Inst. Brew. 1986, 92, 11–20. [Google Scholar] [CrossRef]

- Koutous, A.; Hilali, E. Reinforcing rammed earth with plant fibers: A case study. Case Stud. Constr. Mater. 2021, 14, e00514. [Google Scholar] [CrossRef]

- Reddy, N.; Yang, Y. Biofibers from Agricultural Byproducts for Industrial Applications. Faculty Publications—Textiles, Merchandising and Fashion Design. Available online: https://digitalcommons.unl.edu/textiles_facpub/28 (accessed on 17 October 2023).

- Meyer, G.; Okudoh, V.; van Rensburg, E. A rumen based anaerobic digestion approach for lignocellulosic biomass using barley straw as feedstock. S. Afr. J. Chem. Eng. 2022, 41, 98–104. [Google Scholar] [CrossRef]

- Bouasker, M.; Belayachi, N.; Hoxha, D.; Al-Mukhtar, M. Physical characterization of natural straw fibers as aggregates for construction materials applications. Materials 2014, 7, 3034–3048. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, H.S.H.; Phan, H.H.; Huynh, H.K.P.; Nguyen, S.T.; Nguyen, V.T.T.; Phan, A.N. Understanding the effects of cellulose fibers from various pre-treated barley straw on properties of aerogels. Fuel Process. Technol. 2022, 236, 107425. [Google Scholar] [CrossRef]

- Juarez, M.; Sanchez, R.; Espinosa, E.; Dominguez-Robles, J.; Bascon-Villegas, I.; Rodriguez, A. Environmentally friendly lignocellulose nanofibres from barley straw. Cellul. Chem. Technol. 2018, 52, 589–595. [Google Scholar]

- Vargas, F.; Gonzales, Z.; Rojas, O.; Garrote, G.; Rodriguez, A. Barley straw (Hordeum vulgare) as a supplementary raw material for Eucalyptus camaldulensis and Pinus sylvestris Kraft Pulp in the Paper Industry. Bioresources 2015, 10, 3682–3693. [Google Scholar] [CrossRef]

- Puglia, D.; Luzi, F.; Lilli, M.; Sbardella, F.; Pauselli, M.; Torre, L.; Benincasa, P. Straw fibres from barley hybrid lines and their reinforcement effect in polypropylene based composites. Ind. Crops. Prod. 2020, 154, 112736. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Julian, F.; Espinach, F.X.; Mendez, J.A. Simulated Environmental Conditioning of PHB Composites Reinforced with Barley Fibers to Determine the Viability of Their Use as Plastics for the Agriculture Sector. Polymers 2023, 15, 579. [Google Scholar] [CrossRef] [PubMed]

- Luan, P.; Zhao, X.; Copenhaver, K.; Ozcan, S.; Zhu, H. Turning Natural Herbaceous Fibers into Advanced Materials for Sustainability. Adv. Fiber Mater. 2022, 4, 736–757. [Google Scholar] [CrossRef]

- Li, Y.; Wei, C.; Jiang, Y.; Cheng, R.; Zhang, Y.; Ning, C.; Dong, K.; Wang, Z.L. Continuous Preparation of Chitosan-Based Self-Powered Sensing Fibers Recycled from Wasted Materials for Smart Home Applications. Adv. Fiber Mater. 2022, 4, 1584–1594. [Google Scholar] [CrossRef]

- Serra-Parareda, F.; Julián, F.; Espinosa, E.; Rodríguez, A.; Espinach, F.X.; Vilaseca, F. Feasibility of Barley Straw Fibers as Reinforcement in Fully Biobased Polyethylene Composites: Macro and Micro Mechanics of the Flexural Strength. Molecules 2020, 25, 2242. [Google Scholar] [CrossRef] [PubMed]

- Serra-Parareda, F.; Tarrés, Q.; Delgado-Aguilar, M.; Espinach, F.X.; Mutjé, P.; Vilaseca, F. Biobased composites from biobased-polyethylene and barley thermomechanical fibers: Micromechanics of composites. Materials 2019, 12, 4182. [Google Scholar] [CrossRef]

- Sushma, M. Barley straw: A promising non-wood source for pulp and paper making. IPPTA 2001, 13, 53–59. [Google Scholar]

- Sun, J.X.; Xu, F.; Sun, X.F.; Xiao, B.; Sun, R.C. Physico-chemical and thermal characterization of cellulose from barley straw. Polym. Degrad. Stab. 2005, 88, 521–531. [Google Scholar] [CrossRef]

- Franck, R.R. Overview. In Bast and Other Plant Fibres; Franck, R.R., Ed.; Woodhead Publishing Ltd.: Cambridge, UK, 2005; pp. 1–23. [Google Scholar]

- Sisti, L.; Totaro, G.; Vannini, M.; Celli, A. Retting Process as a Pretreatment of Natural Fibers for the Development of Polymer Composites. In Lignocellulosic Composite Materials; Kalia, S., Ed.; Springer International Publishing AG: Basingstoke, UK, 2018; pp. 97–135. [Google Scholar]

- Konczewicz, W.; Zimniewska, M.; Valera, M.A. The selection of a retting method for the extraction of bast fibres as response to challenges in composite reinforcement. Text. Res. J. 2017, 88, 2104–2119. [Google Scholar] [CrossRef]

- Lee, C.H.; Khalina, A.; Lee, S.H.; Liu, M. A Comprehensive Review on Bast Fibre Retting Process for Optimal Performance in Fibre-Reinforced Polymer Composites. Advanc. Mater. Sci. Eng. 2020, 2020, 6074063. [Google Scholar] [CrossRef]

- Čunko, R.; Andrassy, M. Vlakna; Zrinski d.d.: Čakovec, Croatia, 2005; pp. 1–341. [Google Scholar]

- Agricultural Institute Osijek. Available online: https://www.poljinos.hr/en/ (accessed on 2 October 2023).

- Martinčić, J.; Kovačević, J.; Lalić, A. Rex-nova sorta ozimog dvorednog ječma. Agron. Glas. Glas. Hrvat. Agron. Društva 1991, 3, 141–147. [Google Scholar]

- Aaditaa, A.; Jahan, S. Extraction and processing of bast fibres from Ficus glomerata- A new source for non-conventional fibres. J. App. Natur. Sci. 2018, 10, 661–666. [Google Scholar] [CrossRef]

- Feleke, K.; Thothadri, G.; Beri Tufa, H.; Rajhi, A.A.; Ahmed, G.M.S. Extraction and characterization of fiber and cellulose from Ethiopian linseed straw: Determination of retting period and optimization of multi-step alkaline peroxide process. Polymers 2023, 15, 469. [Google Scholar] [CrossRef] [PubMed]

- Punia Bangar, S.; Ilyas, R.A.; Chaudhary, N.; Dhull, S.B.; Chowdhury, A.; Lorenzo, J.M. Plant-Based Natural Fibers For Food Packaging: A Green Approach To The Reinforcement of Biopolymers. J. Polym. Environ. 2023, 31, 5029–5049. [Google Scholar] [CrossRef]

- Manian, A.P.; Braun, D.E.; Široká, B.; Bechtold, T. Distinguishing liquid ammonia from sodium hydroxide mercerization in cotton textiles. Cellulose 2022, 29, 4183–4202. [Google Scholar] [CrossRef]

- Naik, S.R. Dyeing and printing of natural and synthetic fibre/fabrics by vegetable dyes. In Natural Dyes: Scope and Challenges, 1st ed.; Daniel, M., Bhattacharya, S.D., Arya, A., Vinay, M., Eds.; Scientific Publishers: Jodhpur, India, 2006; pp. 151–160. [Google Scholar]

- DSPAT TEXTILE. Available online: https://www.dspattextile.com/2022/06/scouring-processes-methods.html (accessed on 10 September 2023).

- Sari, N.H.; Wardana, I.N.G.; Irawan, Y.S.; Siswanto, E. The effect of sodium hydroxide on chemical and mechanical properties of corn husk fiber. Orient. J. Chem. 2017, 33, 3037–3042. [Google Scholar] [CrossRef]

- Kulshreshtha, A. Sustainable energy generation from municipal solid waste. In Waste-to-Energy Approaches Towards Zero Waste; Hussain, C.M., Singh, S., Goswami, L., Eds.; Elsevier: Oxford, UK, 2021; pp. 315–342. [Google Scholar] [CrossRef]

- Yew, B.S.; Muhamad, M.; Mohamed, S.B.; Wee, F.H. Effect of alkaline treatment on structural characterisation, thermal degradation and water absorption ability of coir fibre polymer composites. Sains Malays. 2019, 48, 653–659. [Google Scholar] [CrossRef]

- Gao, F.; Yang, F.; De, Y.; Tao, Y.; Ta, N.; Wang, H.; Sun, Q. Dilute alkali pretreatment and subsequent enzymatic hydrolysis of amur silvergrass for ethanol production. Bioresources 2020, 15, 4823–4834. [Google Scholar] [CrossRef]

- Right to Know, Hazardous Fact Sheet. Available online: https://nj.gov/health/eoh/rtkweb/documents/fs/1706.pdf (accessed on 10 September 2023).

- Croatian Meteorological and Hydrological Service. Available online: https://meteo.hr/klima.php?section=klima_podaci¶m=k2_1&Godina=2020 (accessed on 13 October 2023).

- Kovačević, Z. Development of Advanced Polylactide Nanobiocomposite Reinforced with Spartium junceum L. Fibres. Ph.D. Dissertation, University of Zagreb Faculty of Textile Technology, Zagreb, Croatia, 25 October 2019. [Google Scholar]

- Madueke, C.I.; Mbah, O.M.; Umunakwe, R. A review on the limitations of natural fibres and natural fibre composites with emphasis on tensile strength using coir as a case study. Polym. Bull. 2023, 80, 3489–3506. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Nasir, M.; Abdan, K. A Review on Pineapple Leaves Fibre and Its Composites. Int. J. Polym. Sci. 2015, 2015, 950567. [Google Scholar] [CrossRef]

- Vujasinović, E.; Pavunc Samaržija, M. Održivi dizajn biokompozita—Skrivena prilika za kružno gospodarstvo. In Proizvodnja Hrane, Biokompozita i Biogoriva iz Žitarica u Kružnom Gospodarstvu; Krička, T., Ed.; University of Zadar: Zadar, Croatia, 2023; pp. 193–220. [Google Scholar]

- Madić, M.; Knežević, D.; Paunović, A.; Đurović, D. Plant height and internode length as components of lodging resistance in barley. Acta Agric. Serb. 2016, 21, 99–106. [Google Scholar] [CrossRef]

- Plazonić, I.; Barbarić-Mikočević, Ž.; Španić, N. Effect of Agricultural Residue Fibers on Newsprint Strength Properties. Wood Res. 2020, 65, 437–446. [Google Scholar] [CrossRef]

- Djafari Petroudy, S.R. Physical and mechanical properties of natural fibers. In Advanced High Strength Natural Fibre Composites in Construction; Fan, M., Fu, F., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 59–83. [Google Scholar] [CrossRef]

- Madueke, C.I.; Umunakwe, R.; Mbah, O.M. A review on the factors affecting the properties of natural fibre polymer composites. Niger. J. Technol. 2022, 41, 55–64. [Google Scholar] [CrossRef]

- Bismarck, A.; Mishra, S.; Lampke, T. Plant Fibers as Reinforcement for Green Composites. In Natural Fibers, Biopolymers and Biocomposites; Mohanty, A.K., Misra, M., Drzal, L.T., Eds.; CRC Press: Boca Raton, FL, USA, 2005; pp. 37–108. [Google Scholar]

- Sweygers, N.; Depuydt, D.E.; Eyley, S.; Thielemans, W.; Mosleh, Y.; Ivens, J.; Dewil, R.; Appels, L.; Van Vuure, A.W. Prediction of the equilibrium moisture content based on the chemical composition and crystallinity of natural fibres. Ind. Crops Prod. 2022, 186, 115187. [Google Scholar] [CrossRef]

- Garat, W.; Le Moigne, N.; Corn, S.; Beaugrand, J.; Bergeret, A. Swelling of natural fibre bundles under hygro-and hydrothermal conditions: Determination of hydric expansion coefficients by automated laser scanning. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105803. [Google Scholar] [CrossRef]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Ismadi; Amin, Y.; Damayanti, R.; Lubis, M.A.R.; Wulandari, A.P.; Nurindah; Iswanto, A.H.; et al. A comprehensive review on natural fibers: Technological and socio-economical aspects. Polymers 2021, 13, 4280. [Google Scholar] [CrossRef] [PubMed]

- Sfiligoj Smole, M.; Hribernik, S.; Kurečič, M.; Krajnc, A.U.; Kreže, T.; Kleinschek, K.S. Surface Properties of Non-Conventional Cellulose Fibres; Springer Nature Switzerland AG: Cham, Switzerland, 2019; pp. 1–88. [Google Scholar] [CrossRef]

- Zuhudi, N.Z.M.; Zulkifli, A.F.; Zulkifli, M.; Yahaya, A.N.A.; Nur, N.M.; Aris, K.D.M. Void and moisture content of fiber reinforced composites. J. Adv. Res. Fluid Mech. Therm. Sci. 2021, 87, 78–93. [Google Scholar] [CrossRef]

- Al-Oqla, F.M.; Sapuan, S.M.; Ishak, M.R.; Nuraini, A.A. A novel evaluation tool for enhancing the selection of natural fibers for polymeric composites based on fiber moisture content criterion. Bioresources 2015, 10, 299–312. [Google Scholar] [CrossRef]

- Ansell, M.P.; Mwaikambo, L.Y. The structure of cooton and other plant fibres. In Handbook of Textile Fibre Structure, Natural, Regenerated, Inorganic and Specialist Fibres; Eichorn, S.J., Hearle, J.W.S., Jaffe, M., Kikutani, T., Eds.; Woodhead Publishing: Sawston, UK, 2009; pp. 62–94. [Google Scholar]

- Yuksel, I. Fiber Length Measurement by Image Processing. Ph.D. Dissertation, Graduate Faculty of North Carolina State University, Raleigh, NC, USA, 2000. [Google Scholar]

- Batara, A.G.N.; Llanos, P.S.P.; de Yro, P.A.N.; Sanglay, G.C.D.; Magdaluyo, E.R. Surface modification of abaca fibers by permanganate and alkaline treatment via factorial design. In Proceedings of the 7th International Conference on Nano and Materials Science ICNMS 2019, San Francisco, CA, USA, 4–7 January 2019; AIP Publishing 2019. Volume 2083, pp. 1–5. [Google Scholar] [CrossRef]

- Martina, T.; Wardiningsih, W.; Rianti, A.; Rudy, R.; Pradana, S.M. An investigation into the potential of water retted fiber from agricultural waste of Curcuma longa plant for textile application. Res. J. Text. Appar. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Al-Maharma, A.Y.; Al-Huniti, N. Critical review of the parameters affecting the effectiveness of moisture absorption treatments used for natural composites. J. Compos. Sci. 2019, 3, 27. [Google Scholar] [CrossRef]

- Shuvo, I.I. Fibre attributes and mapping the cultivar influence of different industrial cellulosic crops (cotton, hemp, flax, and canola) on textile properties. Bioresour. Bioprocess. 2020, 7, 51. [Google Scholar] [CrossRef]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural fibers as sustainable and renewable resource for development of eco-friendly composites: A comprehensive review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Hussain, M.; Levacher, D.; Leblanc, N.; Zmamou, H.; Djeran-Maigre, I.; Razakamanantsoa, A.; Saouti, L. Analysis of physical and mechanical characteristics of tropical natural fibers for their use in civil engineering applications. J. Nat. Fibers 2023, 20, 2164104. [Google Scholar] [CrossRef]

- Verma, D.; Goh, K.L. Effect of mercerization/alkali surface treatment of natural fibres and their utilization in polymer composites: Mechanical and morphological studies. J. Compos. Sci. 2021, 5, 175. [Google Scholar] [CrossRef]

- Valášek, P.; Müller, M.; Šleger, V.; Kolář, V.; Hromasová, M.; D’Amato, R.; Ruggiero, A. Influence of Alkali Treatment on the Microstructure and Mechanical Properties of Coir and Abaca Fibers. Materials 2021, 14, 2636. [Google Scholar] [CrossRef]

- Chen, H.; Wu, J.; Shi, J.; Zhang, W.; Wang, H. Effect of alkali treatment on microstructure and thermal stability of parenchyma cell compared with bamboo fiber. Ind. Crops Prod. 2021, 164, 113380. [Google Scholar] [CrossRef]

- Sahu, P.; Gupta, M.K. A review on the properties of natural fibres and its bio-composites: Effect of alkali treatment. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 198–217. [Google Scholar] [CrossRef]

- Makarem, M.; Lee, C.M.; Kafle, K.; Huang, S.; Chae, I.; Yang, H.; Kubicki, J.D.; Kim, S.H. Probing cellulose structures with vibrational spectroscopy. Cellulose 2019, 26, 35–79. [Google Scholar] [CrossRef]

- Cai, H.; Du, F.; Li, B.; Shi, H. A practical approach based on FTIR spectroscopy for identification of semi-synthetic and natural celluloses in microplastic investigation. Sci. Total. Environ. 2019, 669, 692–7014. [Google Scholar] [CrossRef]

- Abidi, N.; Hequet, E.; Cabrales, L.; Wilkins, T.; Wells, L.W. Evaluating Cell Wall Structure and Composition of Developing Cotton Fibers using Fourier Transform Infrared Spectroscopy and Thermogravimetric Analysis. J. Appl. Polym. Sci. 2008, 107, 476–486. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, L.; Chao, Y.; Nawawi, D.S.; Akiyama, T.; Yokoyama, T.; Matsumoto, Y. Analysis of lignin aromatic structure in wood based on the IR spectrum. J Wood. Chem. Technol. 2012, 32, 294–303. [Google Scholar] [CrossRef]

- Suciyati, S.W.; Manurung, P.; Sembiring, S.; Situmeang, R. Comparative study of Cladophora sp. Cellulose by using FTIR and XRD. J. Phys. Conf. Ser. 2021, 1751, 012075. [Google Scholar] [CrossRef]

- Fellak, S.; Rafik, M.; Haidara, H.; Boukir, A.; Lhassani, A. Study of natural degradation effect on lignocellulose fibers of archeological cedar wood: Monitoring by Fourier Transform Infrared (FTIR) spectroscopy. MATEC Web Conf. 2022, 360, 00006. [Google Scholar] [CrossRef]

- Hospodarova, V.; Singovszka, E.; Stevulova, N. Characterization of Cellulosic Fibers by FTIR Spectroscopy for their Further Implementation to Building Materials. Am. J. Anal. Chem. 2018, 9, 303–310. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).