Abstract

Despite extensive research on the effect of nitrogen flow rate on titanium nitride (TiN) coating properties, its influence on esthetic and engineering performance through microstructure control remains insufficiently explored. To simultaneously meet the requirements for surface strengthening and decorative esthetics in high-end stainless-steel crafts, TiN coatings were deposited on 304L stainless-steel substrates using multi-arc ion plating. The regulatory mechanisms and synergistic evolution laws of nitrogen flow rates (100, 200, and 300 sccm) on the microstructure, decorative properties (color and gloss), and engineering performance (adhesion strength, hardness, wear resistance, and corrosion resistance) of the coatings were investigated. At a nitrogen flow rate of 200 sccm, the coating exhibited a uniform and dense columnar crystal structure, as well as a saturated golden hue with high surface gloss. Additionally, the film–substrate adhesion, microhardness, tribological properties, and corrosion resistance reached optimal levels. In contrast, excessively low (100 sccm) or high (300 sccm) nitrogen flow rates resulted in coarse particles and blurred grain boundaries owing to uncontrolled droplet ejection or target poisoning, respectively, thereby deteriorating both appearance and engineering performance. These findings can inform the optimization of TiN coatings, enabling the design of surfaces that simultaneously meet esthetic and high-performance engineering requirements.

1. Introduction

Titanium nitride (TiN) coatings are widely used in decorative plating (e.g., hardware, watch accessories, and jewelry) and engineering protection (e.g., cutting tools, molds, and precision components) owing to their unique golden color, high hardness, wear resistance, and corrosion resistance [1,2,3,4]. Multi-arc ion plating (MAIP) has emerged as a mainstream process for preparing high-performance TiN coatings, offering advantages such as a high ionization rate, fast deposition, and strong film–substrate adhesion [5,6,7,8]. However, owing to the complex plasma physics and chemical reactions during MAIP, the coating performance depends on deposition parameters, especially the flow rate of reactive gases (e.g., nitrogen), which considerably influences coating growth kinetics, microstructure, and final properties.

Chen et al. [9] studied the tribological behavior of MAIP-deposited TiN films against GCr15 in a nitrogen environment, revealing adaptability to alternating atmospheres and lower friction coefficients under low-nitrogen conditions. The authors proposed a synergistic mechanism, providing strategies for regulating hard films in nitrogen environments. Xue et al. [10] explored the orientation and tribocorrosion behavior of MAIP-deposited ZrN coatings under different N2 partial pressures. With increasing N2 proportion, a (111)–(200) orientation transition was observed, and the corrosion resistance first increased and then decreased, highlighting the critical role of crystal texture. Sadeghi et al. [11] prepared TiN coatings on NiTi substrates via physical vapor deposition. Increased gas flow rate enhanced coating thickness, reduced porosity, and improved adhesion strength. In contrast, samples deposited at low gas flow rates exhibited higher hardness and elastic modulus, along with reduced wear width, wear rate, and friction coefficient compared with those of the substrate. Wang et al. [12] fabricated TiSiCN coatings using a hybrid technique combining MAIP and magnetron sputtering. Increasing the N2/Ar flow ratio resulted in smoother and denser surfaces, enhanced TiN (200) diffraction peak intensity, and optimal hardness and wear resistance at a 5:1 ratio. Tu et al. [13] focused on MAIP-prepared TaN/(Ta/Ti)/TiN multilayers with Ta/Ti interlayers, investigating the effect of target-to-substrate distance on their deposition rate, microstructure, mechanical, and tribological and corrosion properties, aiming to obtain high-performance protective coatings and provide theoretical support for industrial applications. Lyu et al. [14] studied the effect of selective laser melting (SLM) parameters (laser power, scanning speed, scanning space) on TiAlN/TiN multilayer coatings on 316L steel via MAIP. They observed macro-particles and pinholes on the coating surface, with coated specimens showing over fourfold higher microhardness and 2–4 times lower wear rate than uncoated ones. Laser power most strongly affected performance, with optimal properties at 170 W, 1100 mm/s, and 0.08 mm, as SLM parameters influenced coatings through substrate porosity and surface structure. Collectively, these studies demonstrate that nitrogen flow rate significantly influences the microstructure and functional properties of nitride coatings; however, systematic investigations addressing its effect on both esthetic appeal and engineering performance through microstructural control remain limited.

Although numerous studies have focused on the effect of nitrogen flow rate on TiN coating properties, systematic research on its influence on both esthetic and engineering performance through microstructure modulation remains insufficient. To address this knowledge gap, this study employs 304L stainless steel as the substrate, with nitrogen flow rate (100, 200 and 300 sccm) as the sole variable under controlled deposition parameters, aiming to establish a process-structure-property relationship for guiding the design of high-performance decorative-functional coatings. The novelty of this work lies in the systematic investigation of the synergistic evolution of microstructure, esthetic attributes, and engineering performance of TiN coatings under varying nitrogen flow rates—an aspect underexplored in existing literature. We systematically examined The influence of nitrogen flow rate on TiN coating microstructure (morphology, crystal structure, preferred orientation and chemical composition) was systematically examined, quantitatively characterized decorative properties (color and gloss), and evaluated engineering performance (adhesion, hardness, wear resistance, and corrosion resistance). The intrinsic relationships among these aspects were analyzed to provide a scientific basis and technical support for the design and manufacturing of high-end stainless-steel crafts, promoting the integration of materials science, advanced manufacturing, and artistic design.

2. Materials and Methods

The substrate material was 15 mm thick 304L stainless-steel plates (Shangdong Xinzhan Stainless Steel Co., Ltd., Zibo, China), processed into 30 mm × 30 mm specimens with chemical compositions summarized in Table 1. 304L stainless steel was chosen as the substrate due to its broad application in high-end decorative products, where a combination of corrosion resistance, surface quality, and compatibility with physical vapor deposition processes is essential. The 15 mm substrate thickness was chosen to approximate real-world industrial applications and provide adequate thermal mass to mitigate rapid temperature fluctuations during deposition, thereby promoting uniform coating growth and reducing thermal distortion. Specimens were sequentially ground with metallographic sandpaper, followed by ultrasonic cleaning in acetone and anhydrous ethanol (Shandong Yingsheng Chemical Co., Ltd., Jinan, China) to remove oil. The cleaned samples were immersed in 2% hydrochloric acid (Shanghai Maopanwei Technology Co., Ltd., Shanghai, China) to enhance surface adhesion, dried, and then loaded into a QX-650 MAIP system (Chengdu Qixing Co., Ltd., Chengdu, China) for Ar+ ion bombardment cleaning to remove residual oxides and contaminants. For TiN coating deposition, a 99.999% pure Ti target (Baoji Titanium Industry Co., Ltd., Baoji, China) was used, with the following deposition parameters: temperature, 300 °C; target current, 80 A; substrate bias, 100 V; and deposition time, 60 min. The only variable was the nitrogen flow rate (100, 200, and 300 sccm), with the argon flow rate fixed at 40 sccm. Coating samples were labeled TiN-100, TiN-200, and TiN-300. The process parameters are listed in Table 2.

Table 1.

Energy dispersive spectroscopy (EDS) results of 304L stainless-steel substrate and TiN coatings.

Table 2.

Parameters for the preparation of TiN coatings.

Surface and cross-sectional morphologies, along with elemental composition, were observed using field-emission scanning electron microscopy (SEM; SU8600, HITACHI Ltd., Tokyo, Japan) integrating energy dispersive spectroscopy (EDS; Oxford ULTIM Max100, Oxford Co., Ltd., London, UK). Phase analysis was performed using X-ray diffraction (XRD; D8-ADVANCE, BRUKER Co., Leipzig, Germany) over a scanning range of 20–80°. Optical reflection properties were measured using a UH4150 UV–visible spectrophotometer (HITACHI Ltd., Tokyo, Japan) in diffuse reflection mode, with a wavelength range of 200–800 nm and a step size of 1 nm. The surface roughness was measured at nine random locations using a DCM8 optical profilometer (LEICA Co., Ltd., Wetzlar, Germany). Film–substrate adhesion was evaluated using an ST30 micro-scratch tester (FISCHER Co., Ltd., Paderborn, Germany) with a load range of 0–100 N, a loading rate of 100 N/min, and a scratch length of 5 mm. Hardness was tested at nine random points using an HVST-1000Z digital microhardness tester (ZHONGYAN Co., Shanghai, China) with a Vickers indenter, applying a test force of 0.98 N (100 gf) with a dwell time of 15 s. Wear resistance was assessed via reciprocating friction tests using a UMT Tribolab tribometer (BRUKER Co., Leipzig, Germany) with a 4 mm steel ball as the counterbody, a reciprocating distance of 8 mm, a test duration of 30 min, and a frequency of 2 Hz. Corrosion resistance was evaluated using a CHI660E electrochemical workstation (CHENHUA Co., Shanghai, China) in a three-electrode configuration (working electrode: specimen surface, auxiliary electrode: platinum sheet, and reference electrode: saturated calomel electrode) with 3.5 wt.% NaCl solution (Guangzhou Fu Chun Biotechnology Co., Ltd., Guangzhou, China) as the electrolyte. The corroded area was circular with a diameter of 12 mm, and the test temperature was 25 °C ± 5 °C. After stabilizing the open circuit potential for 30 min, potentiodynamic polarization scans were performed over a range of −0.5 V to 1.5 V at a rate of 1 mV/s. Corrosion current density and potential were analyzed via Tafel extrapolation. Nyquist impedance tests were conducted over a frequency range of 0.01 Hz to 100 kHz.

3. Experimental Results and Analysis

3.1. Microstructure

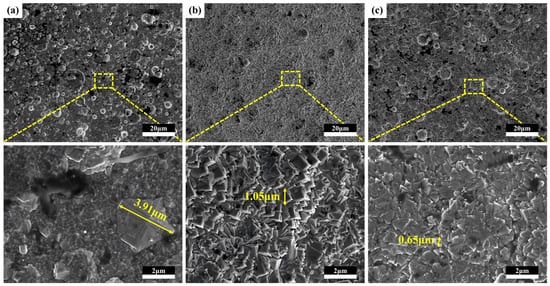

Figure 1 shows the surface SEM images of the coatings prepared under different nitrogen flow rates. At 100 sccm, the surface exhibited large, unevenly sized particles. High-magnification images revealed irregularly distributed equiaxed crystals with a maximum grain size of ~3.91 μm. At 200 sccm, the particles were significantly refined and uniformly distributed. High-magnification images showed regular and clear columnar crystals and an average grain size of ~1.05 μm. At 300 sccm, overlapping large particles appeared on the surface, with high-magnification observations revealing flower-like columnar crystal structures, fine grains, and blurred grain boundaries. EDS analysis indicated surface nitrogen contents of 22.98 wt.% (TiN-100), 25.52 wt.% (TiN-200), and 24.32 wt.% (TiN-300), confirming the regulatory effect of nitrogen flow rate on chemical composition. Low nitrogen content (100 sccm) resulted in concentrated arc energy, leading to uncontrolled droplet ejection and the formation of coarse particles from attached droplets. As the nitrogen flow rate increased to 200 sccm, more nitrogen atoms participated in the reaction, improving coating growth and crystal quality and balancing plasma ionization and arc stability [15,16]. Further increasing the nitrogen flow rate to 300 sccm induced target poisoning, triggering micro-arc clusters and plasma shielding, which promoted droplet collision and aggregation during flight, resulting in interlaced and fused grains [12,17].

Figure 1.

Scanning electron microscopy (SEM) images of the upper surface: (a) TiN-100; (b) TiN-200; (c) TiN-300.

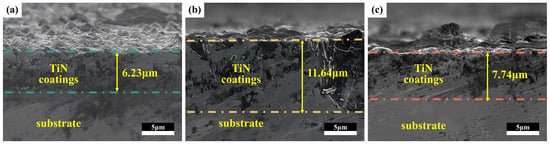

Figure 2 shows cross-sectional SEM images of the specimens, revealing clear coating–substrate interfaces and uniform thicknesses: ~6.23 μm (TiN-100), ~11.64 μm (TiN-200), and ~7.74 μm (TiN-300). With increasing nitrogen flow rate, the coating thickness increased and then decreased, peaking at 200 sccm. This trend occurred because initial increases in nitrogen flow rate ensured sufficient reaction between nitrogen atoms and Ti to form a stable TiN phase, accelerating deposition [18]. In contrast, excessive nitrogen reduced deposition rate through two mechanisms: (1) nitrogen reacted with the Ti target surface to form a TiN layer, which has a lower sputtering rate than that of pure Ti, decreasing target sputtering efficiency; (2) increased nitrogen flow rate reduced argon partial pressure at constant total flow, decreasing Ar+ bombardment on the target and further lowering sputtering rate [19]. The decrease in coating thickness at 300 sccm is accompanied by a reduction in nitrogen content (from 25.52 wt.% to 24.32 wt.%), which can be attributed to the target poisoning effect. As the nitrogen flow rate increases excessively, a thick and poorly conducting TiN layer forms on the target surface, reducing not only the sputtering rate of titanium but also the effective incorporation of nitrogen into the coating due to charge accumulation and abnormal arc events. This results in fewer nitrogen atoms being actively deposited and incorporated into the growing film, leading to a less stoichiometric coating and a thinner, structurally compromised layer. The thickness variation trend was consistent with the nitrogen content determined using EDS.

Figure 2.

SEM images of cross-sections: (a) TiN-100; (b) TiN-200; (c) TiN-300.

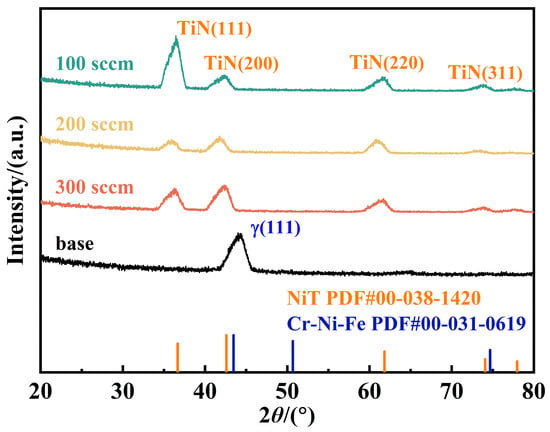

Figure 3 shows XRD patterns of the substrate and coatings. All three coatings exhibited a face-centered cubic (fcc) TiN structure (PDF#38-1420), with diffraction peaks corresponding to (111), (200), (220) and (311). At 100 sccm, the coating showed a strong (111) preferred orientation. With increasing flow rate, (111) peak intensity weakened, (200) peak intensity increased, and all peaks shifted to lower angles. The orientation transition was directly related to the nitrogen content: At low nitrogen content, strain energy dominated, promoting (111)-oriented growth; at high nitrogen content, surface energy dominated, driving (200)-oriented growth. Additionally, increased nitrogen content enhanced target nitridation, reduced deposition rate, and improved the surface diffusion of deposited atoms, further facilitating the (111) to (200) orientation transition [20,21].

Figure 3.

X-ray diffraction (XRD) results.

3.2. Chromaticity Coordinates and Surface Roughness

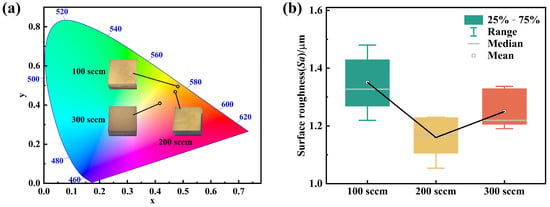

Based on the Commission Internationale de l’Éclairage (CIE) 1931 standard chromaticity system [22], under a D65 light source and 10° standard observer conditions, UV–visible diffuse reflection spectra were measured. CIE chromaticity diagrams (Figure 4a) were obtained using the Origin 2025 software Chromaticity Diagram plugin, converted to CIELAB values listed in Table 3. In the CIELAB system, L represents lightness, a represents the red–green axis (positive values indicate red bias), and b represents the yellow–blue axis (positive values indicate yellow bias). With increasing nitrogen flow rate, L decreased, a increased, and b first increased and then decreased. TiN-200 exhibited a smaller L and larger b, approaching a saturated golden color. TiN-100 displayed a pale golden hue, related to its lower nitrogen content. TiN-300 had the smallest L, largest a, and smallest b, approaching a dark red tone, likely owing to lattice distortion and the shadow effects of surface macro-particles under high nitrogen flow [23]. These results indicate that controlling nitrogen flow rate and defect states enables precise regulation of the electronic structure and optical response of coatings, providing a designable golden color spectrum for craft-related applications.

Figure 4.

Effect of N2 flow rate on (a) chromaticity coordinates; (b) surface roughness.

Table 3.

Chromaticity coordinates and CIELAB values of TiN coatings.

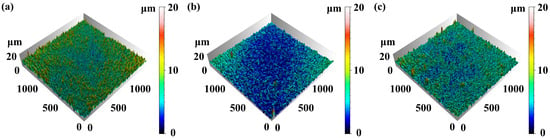

Figure 4b and Figure 5 show coating surface roughness and three-dimensional morphologies. The average surface roughness values were 1.351 ± 0.087 μm (TiN-100), 1.164 ± 0.052 μm (TiN-200), and 1.249 ± 0.034 μm (TiN-300). TiN-100 exhibited the highest roughness, attributable to uncontrolled droplet ejection caused by concentrated arc energy under low nitrogen flow. In this scenario, un-ionized droplets impacted to form micrometer-scale protrusions, leading to anisotropic light scattering and a matte, coarse texture. TiN-200 had the lowest roughness owing to optimized plasma density at 200 sccm, forming uniform columnar crystals and achieving mirror-like reflection. TiN-300 showed increased roughness as target poisoning at 300 sccm promoted droplet collision and aggregation, forming overlapping macro-particles that disrupted surface continuity [24]. Although the visual appearance in Figure 4a primarily reflects differences in color, the matte texture of TiN-100 and the high-gloss surface of TiN-200 can be attributed to their distinct surface roughness and light-scattering behaviors, as quantified in Figure 4b and further corroborated by the three-dimensional profiles in Figure 5.

Figure 5.

Three-dimensional profiles: (a) TiN-100; (b) TiN-200; (c) TiN-300.

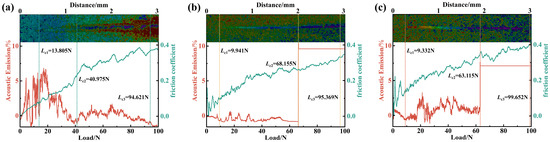

3.3. Adhesion, Microhardness and Tribological Analysis

Film-substrate adhesion was assessed using micro-scratch testing, with critical loads defined as follows: Lc1 (initial cracking), Lc2 (onset of local spallation), and Lc3 (complete failure). As illustrated in Figure 6, the TiN-200 coating demonstrated the optimal adhesion, with an Lc2 value of 68.155 ± 1.102 N, approximately 70% higher than that of TiN-100 (40.975 ± 1.324 N). For decorative-functional applications such as high-end stainless steel crafts, a critical load (Lc2) is generally considered acceptable to ensure resistance against delamination during handling, wear, and mild mechanical contact. This superior performance is attributable to the uniformly distributed columnar crystal structure formed under sufficient plasma ionization, coupled with the internal stress release mechanism enabled by the maximum coating thickness, which enhanced the interface bonding toughness. The 85 N difference between Lc1 and Lc3 confirmed excellent resistance to crack propagation, while scratches displayed only edge flaking, characteristic of ductile failure. In contrast, as observed from the acoustic emission curves in Figure 6, a sudden signal mutation occurs precisely at the Lc2 position. This abrupt change is attributed to the rapid release of strain energy caused by large-scale coating fracture and spallation events. TiN-100 exhibited insufficient toughness owing to coarse grains, leading to transverse through-cracks and significant debris spallation at the Lc2 stage, indicating brittle failure. In the case of TiN-300, target poisoning and droplet collisions resulted in the formation of flower-like columnar crystals and surface macro-particles, causing stress concentration. This reduced Lc2 to 63.115 ± 1.156 N and led to longitudinal cracks and powdery debris, corresponding to plastic buckling failure [25,26].

Figure 6.

Optical micrograph and acoustic emission after the scratch test: (a) TiN-100; (b) TiN-200; (c) TiN-300.

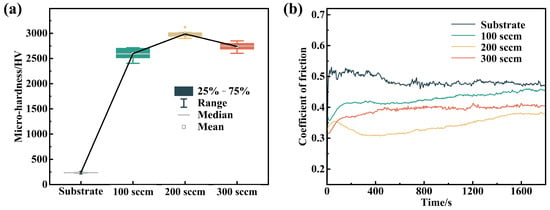

Figure 7a shows Vickers hardness values of the substrate and coatings. The substrate displayed an average hardness of 236 ± 3 HV, whereas the values for TiN-100, TiN-200, and TiN-300 coatings reached 2597 ± 6 HV, 2987 ± 8 HV, and 2738 ± 3 HV, respectively, more than 10 times higher than that of the substrate. This strengthening originated from the covalent-bond-dominated crystal structure of TiN and coating densification. Nitrogen flow rate affected hardness by regulating grain size and crystal quality: TiN-200 formed uniform columnar crystals, with effective internal stress release attributable to its maximum thickness, achieving a peak hardness of 2987 ± 7 HV, consistent with the Hall–Petch fine-grain strengthening mechanism [27].

Figure 7.

(a) Microhardness and (b) friction coefficient curves of 304L stainless-steel substrate and TiN coatings.

Figure 7b shows friction coefficient curves of the substrate and coatings. All specimens exhibited severe fluctuations in the coefficient of friction (COF) during the initial friction phase owing to increased roughness attributable to surface macro-particles and defects. With continued friction, the abrasive particles were eliminated and interfaces became smoother, stabilizing COFs. The substrate exhibited the highest average COF of 0.485 with the most significant fluctuations, while TiN-100, TiN-200, and TiN-300 had average COFs of 0.428 ± 0.023, 0.342 ± 0.012, and 0.392 ± 0.022, respectively. The average COF first decreased and then increased with nitrogen flow rate, with TiN-200 exhibiting the minimum value (0.308). This trend was attributable to the synergistic effect of high hardness and dense structure, resulting in only shallow wear marks [28].

In summary, the TiN-200 coating exhibits the optimal combination of mechanical properties including the highest adhesion strength, maximum microhardness, and the lowest average friction coefficient, which are attributed to its denser morphology, uniform columnar structure, and greatest coating thickness. These values not only exceed typical industrial requirements for decorative-functional coatings but also compare favorably with other PVD TiN coatings reported in the literature under similar deposition conditions [11,17]. The enhanced performance underscores the critical role of nitrogen flow rate in balancing microstructure and functional properties.

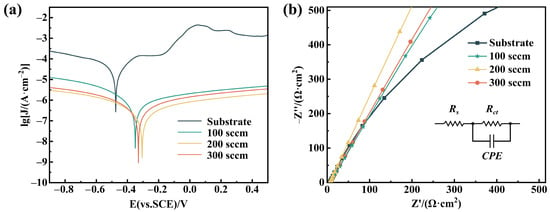

3.4. Electrochemical Properties

Figure 8a shows potentiodynamic polarization curves of the substrate and coatings. After TiN deposition, all samples exhibited a positive shift in corrosion potential (Ecorr) and significant decrease in corrosion current density (Icorr), indicating reduced corrosion tendency and corrosion rate. As outlined in Table 4, Ecorr increased and Icorr decreased with nitrogen flow rate, with optimal values observed at 200 sccm, attributable to the formation of a denser and more uniform columnar crystal surface that effectively blocked electron penetration and delayed anodic dissolution. With further increase in the nitrogen flow rate to 300 sccm, Ecorr decreased and Icorr increased owing to the disordered overlapping of surface columnar crystals, resulting in the formation of corrosion micro-channels that accelerated pitting initiation, consistent with morphological observations [29,30].

Figure 8.

(a) Tafel and (b) Nyquist plots of 304L stainless-steel substrate and TiN coatings.

Table 4.

Electrochemical parameters.

Electrochemical impedance spectra (Figure 8b) showed that all three coatings had flatter capacitive arcs with larger radii than those of the substrate across the entire frequency range, indicating superior corrosion resistance. TiN-200 had the largest capacitive arc radius, corresponding to the highest charge transfer resistance (Rct). This configuration thus displayed the highest impedance for ion transport through the film and superior microstructure compactness and dielectric properties. Nyquist plots for all specimens included a single semicircle (single time constant), indicating the absence of substrate corrosion, attributable to the passive film on the substrate surface and brief exposure to the corrosive medium. The solution resistance (Rs) varied only minimally among coatings, indicating similar ion transport environments at the interface [31,32].

4. Conclusions

The effects and mechanisms of nitrogen flow rate (100, 200, 300 and sccm) on the microstructure, decorative properties, and engineering performance of TiN coatings deposited by MAIP were systematically investigated. The following conclusions were derived:

- Nitrogen flow rate is a core parameter determining the microstructure of TiN coatings. At 200 sccm, the optimal balance between plasma ionization and arc stability is achieved, resulting in a uniform and dense structure with distinct columnar grain boundaries and a (200) preferred orientation. At 100 sccm, concentrated arc energy leads to uncontrolled droplet ejection, forming coarse equiaxed grains with high surface roughness. At 300 sccm, target poisoning and plasma shielding effects are induced, generating flower-like columnar crystals, blurred grain boundaries, and large particles, which reduce thickness and cause internal stress concentration.

- The microstructure directly determines the esthetic performance of the coating. The sample prepared at 200 sccm, with uniform and dense columnar crystals, exhibits a color closest to saturated gold (high b, appropriate L and a values) and the highest surface gloss (lowest average roughness). Nitrogen flow rate regulates the optical response and esthetics of the coating by influencing lattice integrity, defect states, and surface morphology.

- The TiN coating deposited at 200 sccm displays the best comprehensive engineering performance: The film–substrate adhesion (Lc2) reaches 68.155 N, 70% higher than that of the sample prepared at 100 sccm, attributable to the uniform columnar crystals, most effective internal stress release associated with the maximum thickness, and excellent crack propagation resistance. The microhardness is 2987 HV, significantly higher than that of other samples and the substrate, benefiting from fine-grain strengthening and dense structure. The average COF is the lowest (0.342), with only slight wear marks on the worn surface, owing to the synergistic effect of high hardness and dense structure. This coating also exhibits the highest corrosion resistance (most positive Ecorr, lowest Icorr, and largest Rct), as the uniform and dense columnar crystals effectively inhibit the penetration of corrosive media and anodic dissolution.

- Nitrogen flow rate affects the plasma state and growth kinetics, thereby modifying the microstructure (morphology, crystal structure, preferred orientation, and chemical composition), which in turn regulates the synergistic evolution of the decorative esthetics (color and gloss) and engineering performance (adhesion, hardness, wear resistance, and corrosion resistance) of the coating.

In conclusion, by optimizing the nitrogen flow rate to approximately 200 sccm, TiN coatings with a uniform and dense microstructure, an elegant saturated golden color, and high gloss, as well as high hardness, high bonding strength, excellent wear resistance, and corrosion resistance, can be prepared. This research provides a theoretical basis and practical guidance for the design and controlled preparation of high-performance TiN coatings for high-end decorative and engineering applications.

Author Contributions

Conceptualization, T.F. and H.J.; methodology, Y.W., T.F. and X.Z.; software, Y.W. and T.F.; validation, X.Z. and H.J.; formal analysis, Y.W. and X.Z.; investigation, Y.W. and T.F.; resources, Y.W., T.F., X.Z. and H.J.; data curation, Y.W. and T.F.; writing—original draft preparation, Y.W. and T.F.; writing—review and editing, X.Z. and H.J.; supervision, T.F.; project administration, Y.W. and T.F.; funding acquisition, Y.W., T.F., X.Z. and H.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Key Scientific Research Project of Institutions of Higher Education in Anhui Province (2024AH053269 and 2023AH051372); the Research Project on Scientific Innovation and Development in Anhui Province (2023CX138); and the Start Project of Huangshan University Talents (2022xkjq002).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mahajan, U.; Dhonde, M.; Sahu, K.; Ghosh, P.; Shirage, P.M. Titanium Nitride (TiN) as a Promising Alternative to Plasmonic Metals: A Comprehensive Review of Synthesis and Applications. Mater. Adv. 2024, 5, 846–895. [Google Scholar] [CrossRef]

- Atta, S.; NarendraKumar, U.; Kumar, K.V.A.N.P.S.; Yadav, D.P.; Dash, S. Recent Developments and Applications of TiN-Based Films Synthesized by Magnetron Sputtering. J. Mater. Eng. Perform. 2023, 32, 9979–10015. [Google Scholar] [CrossRef]

- Novikov, V.; Stepanov, N.; Zherebtsov, S.; Salishchev, G. Structure and Properties of High-Entropy Nitride Coatings. Metals 2022, 12, 847. [Google Scholar] [CrossRef]

- Ssennyimba, K.W.; Nkele, A.C.; Byaruhanga, P.; Waligo, D.; Ezema, F.I. Recent Advances in Titanium Nitride (TiN) Nanostructures and Thin Films for Bio-Sensing Applications. JOM 2025, 77, 4286–4300. [Google Scholar] [CrossRef]

- Zhou, J.; Fan, X.; Chen, H.; Feng, D. Effect of Multi-Arc Current on the Microstructure and Properties of TiAlSiN Coating on Zircaloy-4 Alloy. J. Mater. Res. Technol.-JMRT 2023, 25, 7101–7108. [Google Scholar] [CrossRef]

- Zhao, R.; Ren, X.; Wen, K.; Liu, H.; Huang, M.; Wang, Z.; Deng, Y. Multi-Arc Ion Plating and DC Magnetron Sputtering Integrated Technique for High-Performance Al,C-Co-Doped δ-TiN Quaternary Films. Corros. Sci. 2021, 182, 109261. [Google Scholar] [CrossRef]

- Xu, W.; Jia, B.; Liu, X.; Ji, L.; Zhou, H.; Chen, J.; Sun, C.; Li, H. Structural Evolution and Mechanical Properties of Multi-Element (TiCrZrVNb)C High Entropy Ceramics Films by Multi-Arc Ion Plating. Ceram. Int. 2022, 48, 19191–19197. [Google Scholar] [CrossRef]

- Li, J.; Liu, Z.; Zhang, Y.; Jia, B.; Xu, W.; Liu, X.; Ji, L.; Wang, A.; Sun, C.; Li, H. Effect of O2/Ar Ratio on the Microstructure and Tribological Properties of Y2O3 Films by Multi-Arc Ion Plating. Ceram. Int. 2024, 50, 43032–43043. [Google Scholar] [CrossRef]

- Chen, Q.; Li, A.; Wu, G.; Lu, Z.; Zhang, G.; Tian, G. Structure vs Chemistry: Tribological Behavior of TiN Films in the Nitrogen Atmosphere. Ceram. Int. 2020, 46, 28053–28063. [Google Scholar] [CrossRef]

- Xue, L.; Hu, X.; Xi, Y.; Qiu, L.; Pan, X.; Zhang, Y. Effect of N2 Partial Pressure on ZrN Coating Orientation and Tribocorrosion Behavior and Mechanism. Ceram. Int. 2024, 50, 24847–24863. [Google Scholar] [CrossRef]

- Botshekanan, N.; Majidian, H.; Farvizi, M. Thin TiN Coating on NiTi Substrate through PVD Method: Improvement of the Wear Resistance. Tribol.-Mater. Surf. Interfaces 2023, 17, 324–337. [Google Scholar] [CrossRef]

- Wang, J.; Wang, M.; Wang, Y.; Ma, D.; Li, H. Effect of the N2/Ar Flow Ratio on the Microstructure and Mechanical Properties of TiSiCN Coatings. Mater. Tehnol. 2021, 55, 789. [Google Scholar] [CrossRef]

- Tu, R.; Yang, M.; Yuan, Y.; Min, R.; Li, Q.; Yang, M.; Ji, B.; Zhang, S. Sandwich Structure to Enhance the Mechanical and Electrochemical Performance of TaN/(Ta/Ti)/TiN Multilayer Films Prepared by Multi-Arc Ion Plating. Coatings 2022, 12, 694. [Google Scholar] [CrossRef]

- Lyu, Y.; Wang, J.; Wan, Y.; Chen, Y. The Influence of Selective Laser Melting Process Parameters on the Property of TiAlN/TiN Multilayer Coating on the 316L Steel. Coatings 2019, 9, 377. [Google Scholar] [CrossRef]

- Gong, Z.; Chen, R.; Li, J.; Cao, P.; Geng, H. Effect of N2 Flow Rate on Structure and Corrosion Resistance of AlCrN Coatings Prepared by Multi-Arc Ion Plating. Int. J. Electrochem. Sci. 2020, 15, 1117–1127. [Google Scholar] [CrossRef]

- Xu, W.; Liao, M.; Liu, X.; Ji, L.; Ju, P.; Li, H.; Zhou, H.; Chen, J. Microstructures and Properties of (TiCrZrVAl)N High Entropy Ceramics Films by Multi-Arc Ion Plating. Ceram. Int. 2021, 47, 24752–24759. [Google Scholar] [CrossRef]

- Shan, L.; Wang, Y.; Li, J.; Chen, J. Effect of N2 Flow Rate on Microstructure and Mechanical Properties of PVD CrNx Coatings for Tribological Application in Seawater. Surf. Coat. Technol. 2014, 242, 74–82. [Google Scholar] [CrossRef]

- Zhang, L.; Shao, M.; Wang, Z.; Zhang, Z.; He, Y.; Yan, J.; Lu, J.; Qiu, J.; Li, Y. Comparison of Tribological Properties of Nitrided Ti-N Modified Layer and Deposited TiN Coatings on TA2 Pure Titanium. Tribol. Int. 2022, 174, 107712. [Google Scholar] [CrossRef]

- Wan, Q.; Ding, H.; Yousaf, M.I.; Chen, Y.M.; Liu, H.D.; Hu, L.; Yang, B. Corrosion Behaviors of TiN and Ti-Si-N (with 2.9 at.% and 5.0 at.% Si) Coatings by Electrochemical Impedance Spectroscopy. Thin Solid Film. 2016, 616, 601–607. [Google Scholar] [CrossRef]

- Duan, L.; Wu, H.; Guo, L.; Xiu, W.; Yu, X. The Effect of Phase on Microstructure and Mechanical Performance in TiAlN and TiSiN Films. Mater. Res. Express 2020, 7, 066401. [Google Scholar] [CrossRef]

- Lu, G.; Yu, L.; Ju, H.; Zuo, B.; Xu, J. Influence of Nitrogen Content on the Thermal Diffusivity of TiN Films Prepared by Magnetron Sputtering. Surf. Eng. 2020, 36, 192–198. [Google Scholar] [CrossRef]

- Wyszecki, G.W.; Stiles, W.S. Color Science: Concepts and Methods, Quantitative Data and Formulas. Am. J. Psychol. 1968, 81, 128–129. [Google Scholar] [CrossRef]

- De Arruda, A.C.S.; Mansano, R.D.; Ordonez, N.; Ruas, R.; Durrant, S.F. Ag Behavior on TiN Thin Films for Decorative Coatings. Coatings 2024, 14, 322. [Google Scholar] [CrossRef]

- Zhou, S.; Zhao, W.; Wu, Y.; Qiu, Z.; Lin, S.; Zheng, Z.; Zeng, D.C. Fabrication and Characterization of High-Performance Mo-Doped TiN Coatings. Vacuum 2021, 190, 110311. [Google Scholar] [CrossRef]

- Liu, J.; Mei, H.; Hua, J.; Wang, J.; Wang, Y.; Yi, G.; Deng, X. High-Temperature Oxidation and Wear Resistance of TiAlSiN/AlCrN Multilayer Coatings Prepared by Multi-Arc Ion Plating. Nanomaterials 2025, 15, 503. [Google Scholar] [CrossRef]

- Guan, W.; Zhu, H.; Zhu, W.; Chen, Z.; Liu, J.; Shi, X.; Wang, X. Effects of the Different Interlayer Deposition Processes on the Microstructure of Cr/tiN Coating. Mater. Res. Express 2020, 6, 126444. [Google Scholar] [CrossRef]

- Ma, H.; Miao, Q.; Zhang, G.; Liang, W.; Wang, Y.; Sun, Z.; Lin, H. The Influence of Multilayer Structure on Mechanical Behavior of TiN/TiAlSiN Multilayer Coating. Ceram. Int. 2021, 47, 12583–12591. [Google Scholar] [CrossRef]

- Yu, Y.; Li, M.; Zou, C.; Tian, C.; Xiang, Y. Effect of CrYN/TiBN Coating on Friction Performance and Corrosion Resistance of 316 Stainless Steel in Artificial Seawater. Mater. Res. Express 2023, 10, 036506. [Google Scholar] [CrossRef]

- Lei, Z.; Zhang, Q.; Zhu, X.; Ma, D.; Ma, F.; Song, Z.; Fu, Y.Q. Corrosion Performance of ZrN/ZrO 2 Multilayer Coatings Deposited on 304 Stainless Steel Using Multi-Arc Ion Plating. Appl. Surf. Sci. 2018, 431, 170–176. [Google Scholar] [CrossRef]

- Gao, Z.; Guo, Q.; Wang, Y.; Li, M.; Yang, Z. Effect of Micro-Arc Oxidation/Multi-Arc Ion Plating on the Galvanic Corrosion Behavior of TC4/AH36 Steel. J. Mater. Eng. Perform. 2025, 1–11. [Google Scholar] [CrossRef]

- Wang, L.; Wang, M.; Chen, H. Corrosion Mechanism Investigation of TiAlN/CrN Superlattice Coating by Multi-Arc Ion Plating in 3.5 Wt% NaCl Solution. Surf. Coat. Technol. 2020, 391, 125660. [Google Scholar] [CrossRef]

- Sun, X.; Zhao, Y.; Ye, C.; Li, F.; Chen, H.; Miao, Y.; Zhao, Z.; Chen, R. The Effect of AlCrN, TiN and Ni-Cr-Nb Coatings on the Wear and Corrosion Performance of 45 # Steel in 3.5% Sodium Chloride Solution. Int. J. Electrochem. Sci. 2024, 19, 100608. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).