Electric and Thermal Performance Evaluation of a Serpentine-Pipe PVT Solar Collector

Abstract

1. Introduction

- (1)

- A mathematical modeling method for serpentine-pipe photovoltaic-thermal (PVT) modules is established. Based on the modified H-W model, a heat transfer factor function is proposed.

- (2)

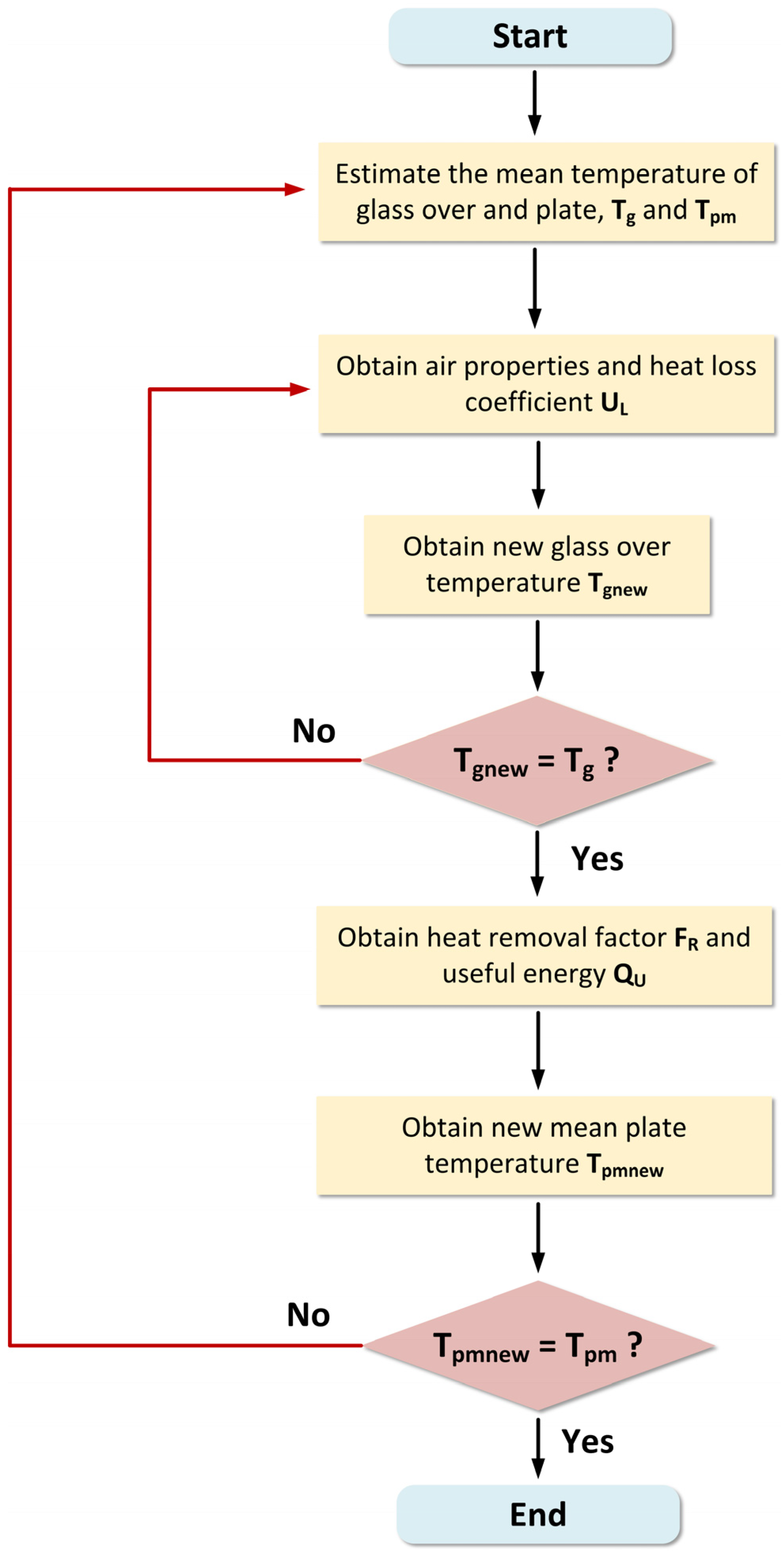

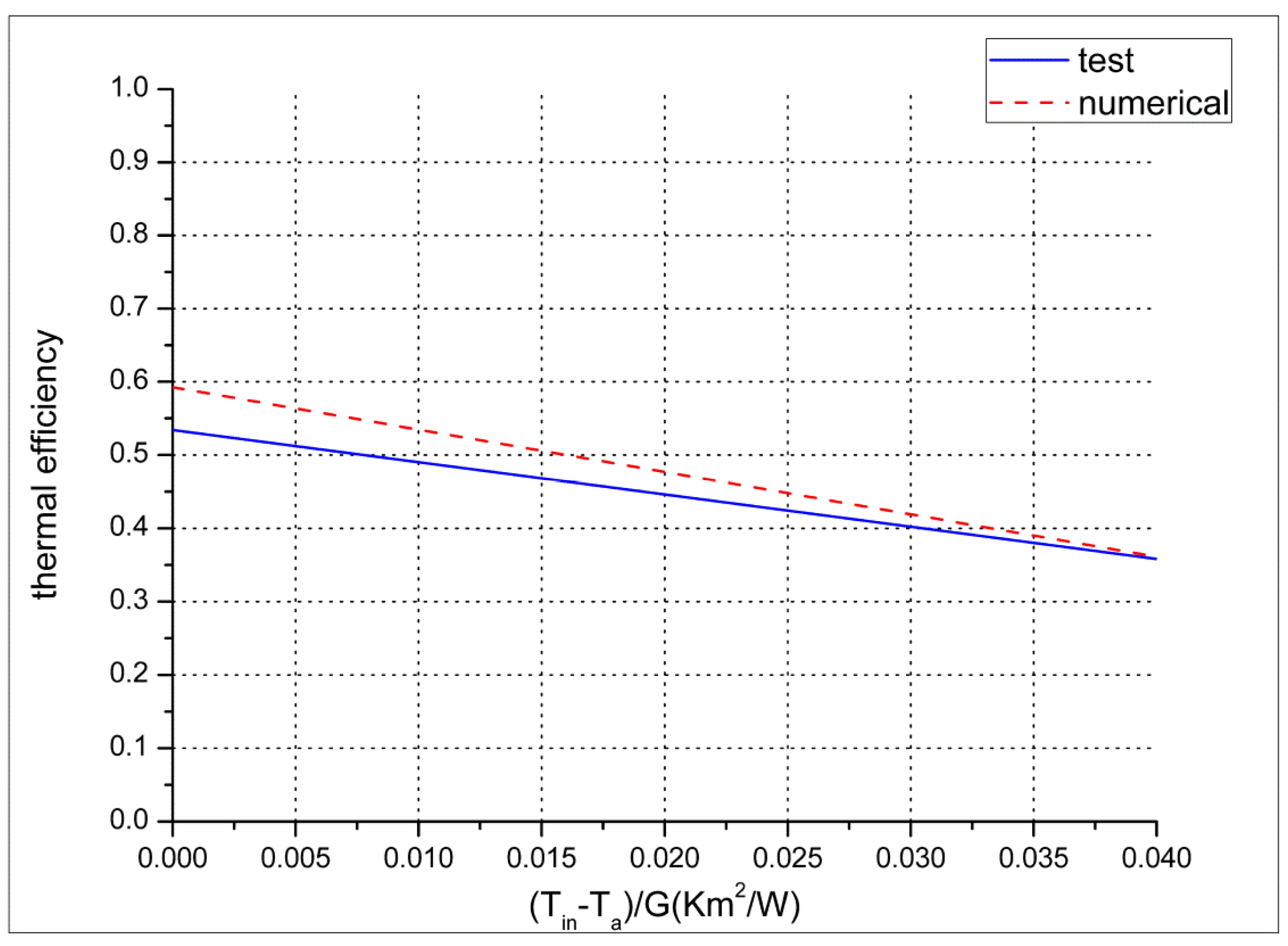

- A new double iterative strategy is proposed, which enables gradual convergent calculation of glass cover temperature and mean panel temperature. The simulation results are highly consistent with the published experimental data, effectively improving the reliability and accuracy of thermal efficiency and PCE simulation for serpentine-pipe-PVT modules.

- (3)

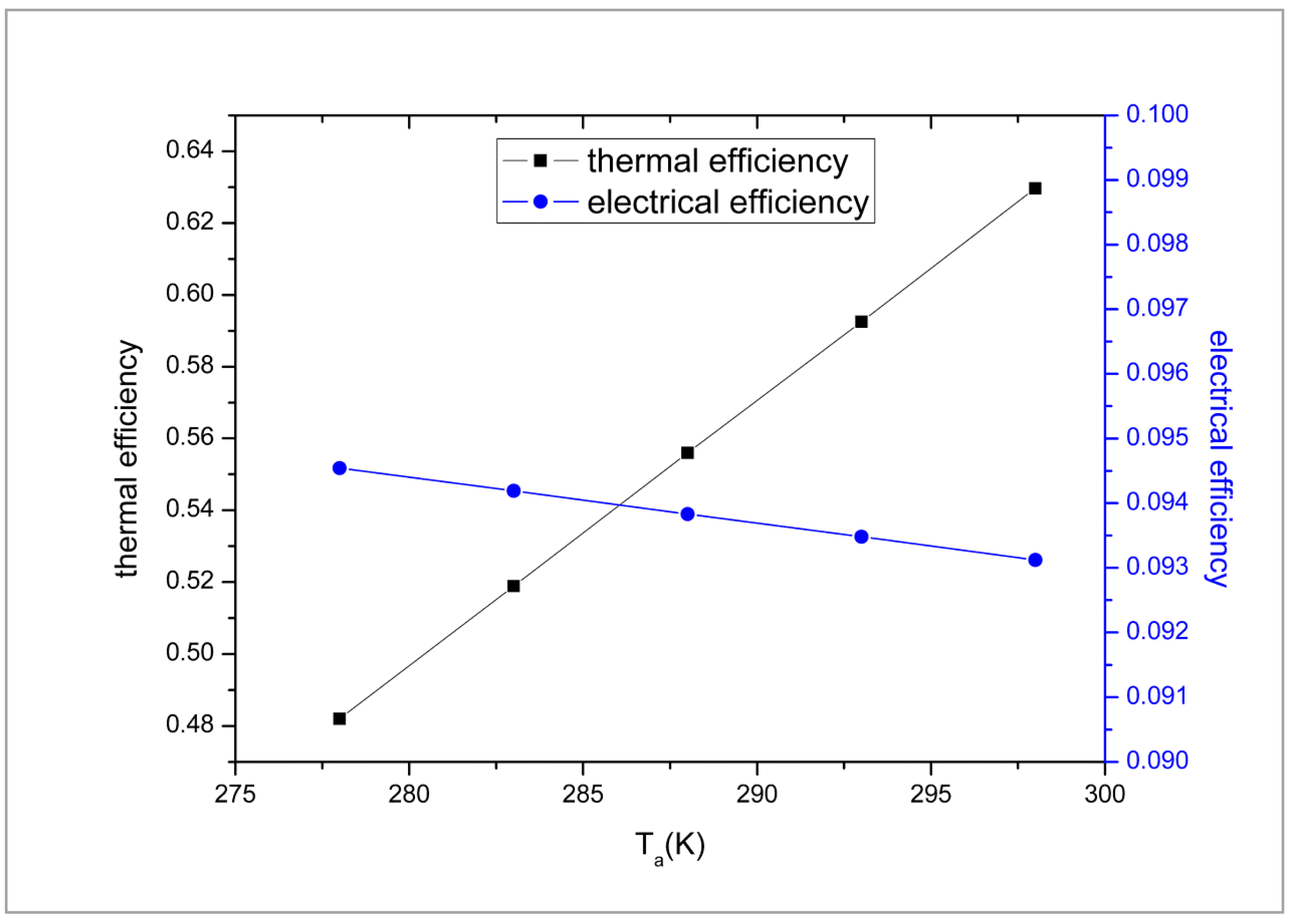

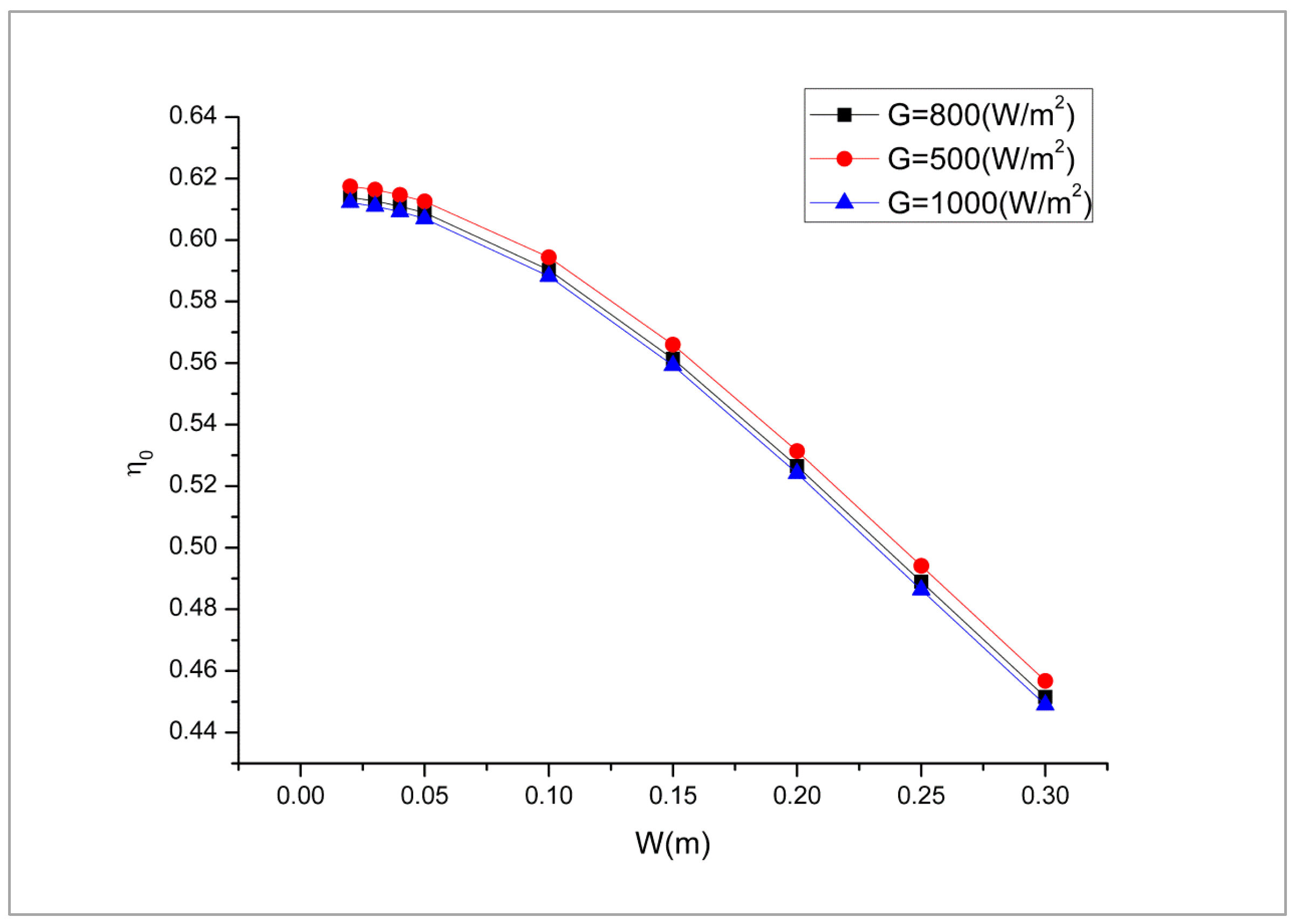

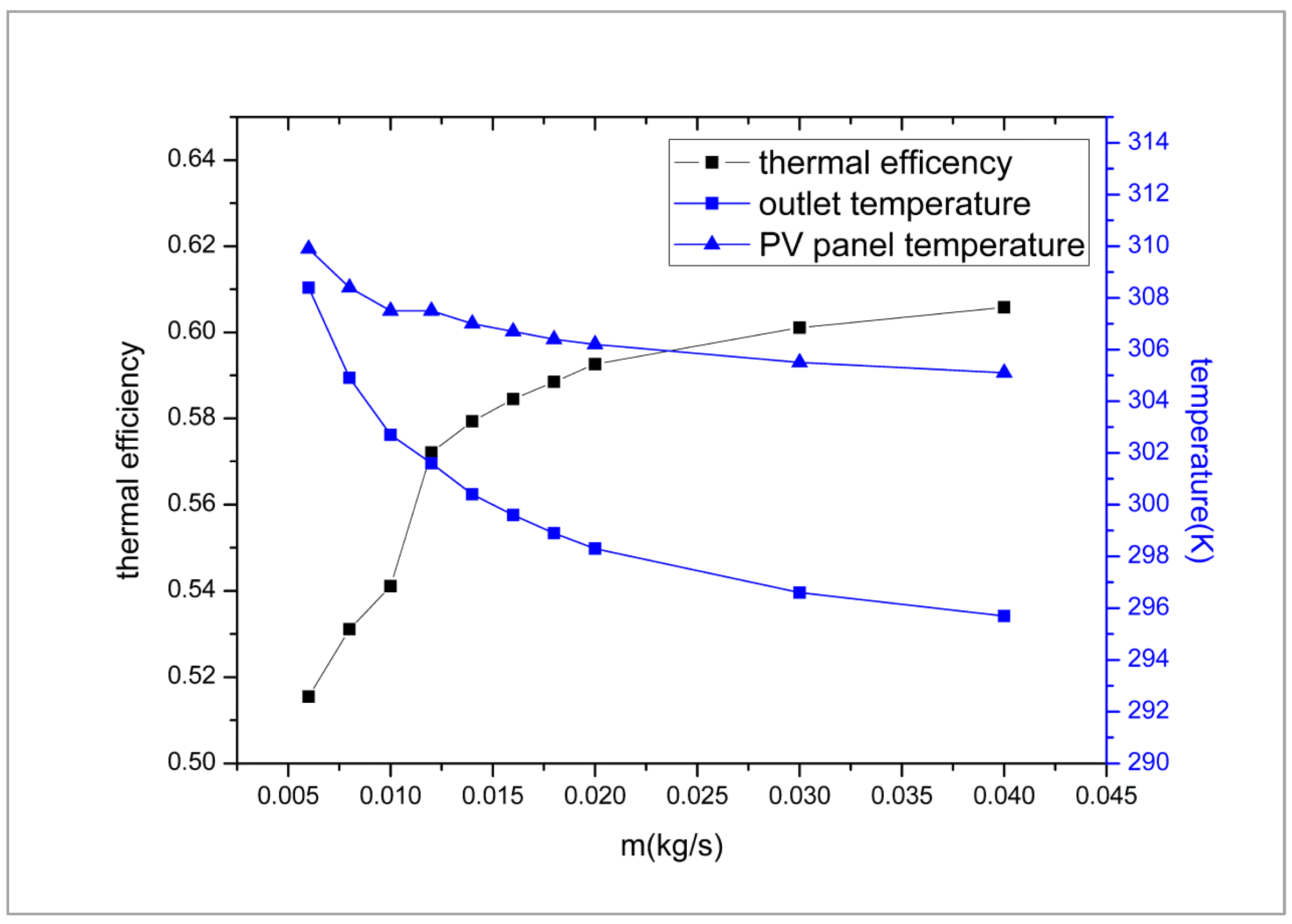

- The effects of key parameters including ambient temperature, inlet water temperature, solar irradiance, pipe spacing, mass flow rate on PVT module thermal efficiency and PCE are systematically investigated.

2. Mathematical Model

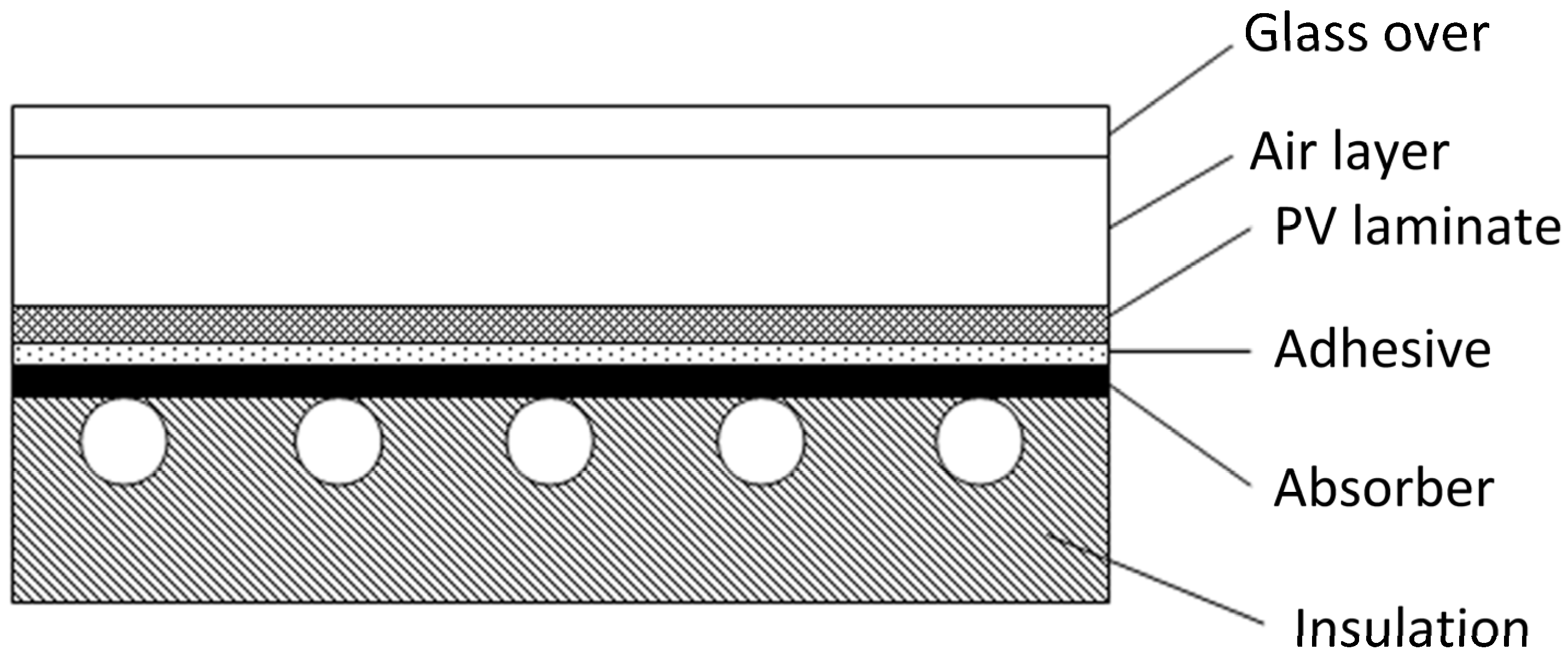

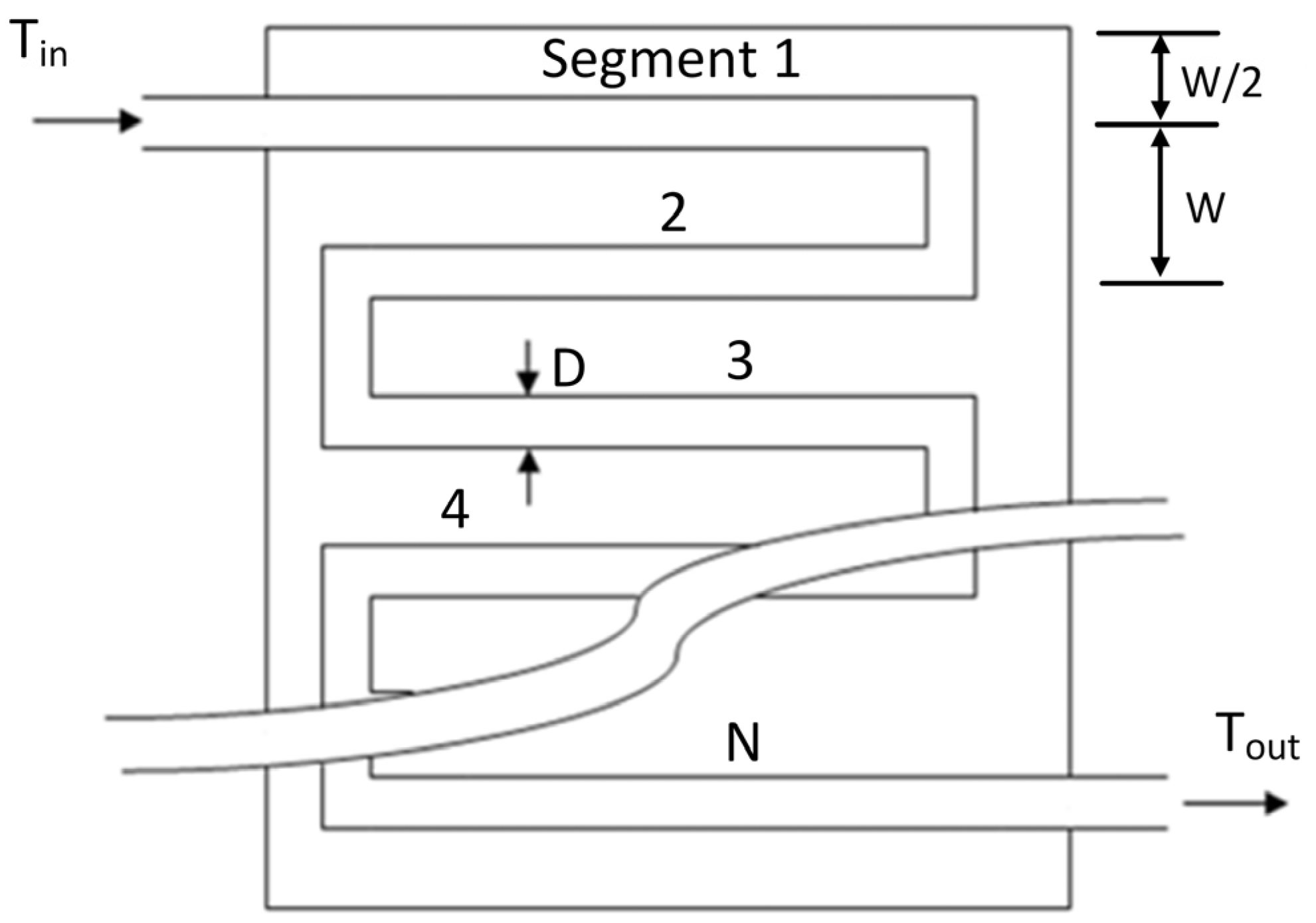

2.1. Key Parameters of Serpentine-Tube-PVT Components

2.1.1. Heat Remove Factor

2.1.2. Overall Loss Coefficient

- (1)

- (2)

- Radiation heat transfer between top cover and sky.

- (3)

- Convection heat transfer between top cover and PV laminate.

- (4)

- Radiation heat transfer between the top cover and PV laminate.

2.2. Iteration Method

3. Results and Discussion

3.1. Verification

3.2. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Nomenclature | |

| A | surface area (m2) |

| C | conductance (W·m−1·K−1) |

| D | diameter (m) |

| G | solar irradiation (W·m−2) |

| H | heat transfer coefficient (W·m−2·K−1) |

| K | thermal conductivity (W·m−1·K−1) |

| L | distance between glass and plate (mm) |

| Nu | Nusselt number |

| Ra | Rayleigh number |

| U | heat-loss coefficient (W·m−2·K−1) |

| v | wind speed (m·s−1) |

| W | tube space (m) |

| σ | the Stefan–Boltzmann constant |

| η | efficiency |

| τ | transmittance |

| Subscripts | |

| A | ambient |

| Abs | absorber |

| B | back |

| Bond | bond between absorbers and tubes |

| C | collector |

| Ca | cell and adhesive |

| G | glass cover |

| E | edge |

| Greek | |

| α | absorption factor |

| β | solar cell temperature coefficient (K−1) |

| δ | thickness (mm) |

| ε | emissivity |

| θ | tilt angle (degree) |

| ρ | density (kg·m−1) |

| In | inlet |

| P | plate |

| Ref | reference |

| S | sky |

| Rga | radiation between glass cover and ambient space |

| Cpg | convection between plate and glass cover |

| Rpg | radiation between plate and glass cover |

References

- Wei, L.T. A Simulation Study on Performance of Photovoltaic Thermal Water (PVTW) Collector Under Different Loading of Mass Flow Rate Using ANSYS Fluent. Int. J. Nanoelectr. Mater. 2021, 14, 467–478. [Google Scholar]

- Abdin, Z.U.; Rachid, A.; Korkut, T.B. Design and analysis of an innovative photovoltaic-thermal collector with embedded tank. Sol. Energy 2022, 245, 290–298. [Google Scholar] [CrossRef]

- Hassan, Q.; Viktor, P.; Al-Musawi, T.J.; Ali, B.M.; Algburi, S.; Alzoubi, H.M.; Al-Jiboory, A.K.; Sameen, A.Z.; Salman, H.M.; Jaszczur, M. The renewable energy role in the global energy Transformations. Renew. Energy Focus 2024, 48, 100545. [Google Scholar] [CrossRef]

- Deshmukh, M.K.G.; Sameeroddin, M.; Abdul, D.; Sattar, M.A. Renewable energy in the 21st century: A review. Mater. Today Proc. 2023, 80, 1756–1759. [Google Scholar] [CrossRef]

- Hashemizadeh, A.; Ju, Y.; Abadi, F.Z.B. Policy design for renewable energy development based on government support: A system dynamics model. Appl. Energy 2024, 376, 124331. [Google Scholar] [CrossRef]

- Ledmaoui, Y.; El Maghraoui, A.; El Aroussi, M.; Saadane, R.; Chebak, A.; Chehri, A. Forecasting solar energy production: A comparative study of machine learning algorithms. Energy Rep. 2023, 10, 1004–1012. [Google Scholar] [CrossRef]

- Zheng, J.; Du, J.; Wang, B.; Klemeš, J.J.; Liao, Q.; Liang, Y. A hybrid framework for forecasting power generation of multiple renewable energy sources. Renew. Sustain. Energy Rev. 2023, 172, 113046. [Google Scholar] [CrossRef]

- Stergaard, P.A.; Duic, N.; Noorollahi, Y.; Kalogirou, S. Renewable energy for sustainable development. J. Renew. Energy 2022, 199, 1145–1152. [Google Scholar] [CrossRef]

- Sueyoshi, T.; Mo, F.; Wang, D.D. Sustainable development of countries all over the world and the impact of renewable energy. J. Renew. Energy 2022, 184, 320–331. [Google Scholar] [CrossRef]

- Singh, R.; Paniyil, P.; Zhang, Z. Transformative role of power electronics: In solving climate emergency. IEEE Power Electron. Mag. 2022, 9, 39–47. [Google Scholar] [CrossRef]

- Kiehbadroudinezhad, M.; Merabet, A.; Rajabipour, A.; Cada, M.; Kiehbadroudinezhad, S.; Khanali, M.; Hosseinzadeh-Bandbafha, H. Optimization of wind/solar energy microgrid by division algorithm considering human health and environmental impacts for power-water cogeneration. Energy Convers. Manag. 2022, 252, 115064. [Google Scholar] [CrossRef]

- Ren, F.R.; Tian, Z.; Liu, J.; Shen, Y.T. Analysis of CO2 emission reduction contribution and efficiency of China’s solar photovoltaic industry: Based on Input-output perspective. Energy 2020, 199, 117493. [Google Scholar] [CrossRef]

- Gao, Y.; Chen, B.; Wu, D.; Dai, Z.; Wang, C.; Zhang, X. Comparative study of various solar power generation systems integrated with nanofluid-flat heat pipe. Appl. Energy 2022, 327, 120052. [Google Scholar] [CrossRef]

- Liu, J.; He, Y.; Ding, L.; Zhang, H.; Li, Q.; Jia, L.; Yu, J.; Lau, T.W.; Li, M.; Qin, Y.; et al. Perovskite/silicon tandem solar cells with bilayer interface passivation. Nature 2024, 635, 596–603. [Google Scholar] [CrossRef]

- Wu, H.; Ye, F.; Yang, M.; Luo, F.; Tang, X.; Tang, Q.; Qiu, H.; Huang, Z.; Wang, G.; Sun, Z.; et al. Silicon heterojunction back-contact solar cells by laser patterning. Nature 2024, 635, 604–609. [Google Scholar] [CrossRef]

- Saeidi, R.; Noorollahi, Y.; Aghaz, J.; Chang, S. FUZZY-TOPSIS method for defining optimal parameters and finding suitable sites for PV power plants. Energy 2023, 282, 128556. [Google Scholar] [CrossRef]

- Rahdan, P.; Zeyen, E.; Gallego-Castillo, C.; Victoria, M. Distributed photovoltaics provides key benefits for a highly renewable European energy system. Appl. Energy 2024, 360, 122721. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Khalili, Z. Solar photovoltaic-thermal system with novel design of tube containing eco-friendly nanofluid. Renew. Energy 2024, 222, 119862. [Google Scholar] [CrossRef]

- Zhou, J. Principles of Photovoltaic Cells, 1st ed.; Chemical Industry Press: Beijing, China, 2021. [Google Scholar]

- Martins, G.; Mendoza, O.S.H.; Amjad, M.; Bandarra Filho, E.P. Analysis of the generation potential of hybrid solar power plants. Front. Energy Res. 2023, 11, 1017943. [Google Scholar] [CrossRef]

- Elfeky, K.E.; Wang, Q. Techno-environ-economic assessment of photovoltaic and CSP with storage systems in China and Egypt under various climatic conditions. J. Renew. Energy 2023, 215, 118930. [Google Scholar] [CrossRef]

- Wolf, M. Performance analyses of combined heating and photovoltaic power systems for residences. Energy Convers. 1976, 16, 79–90. [Google Scholar] [CrossRef]

- Florschuetz, L.W. Extension of the Hottel-Whillier model to the analysis of combined photovoltaic/thermal flat plate collectors. J. Sol. Energy 1979, 22, 361–366. [Google Scholar] [CrossRef]

- Chauhan, A.; Tyagi, V.V.; Anand, S. Minimum entropy generation and its validation against Hottel Whillier model for PVT and FPC collectors. J. Sol. Energy 2019, 188, 143–157. [Google Scholar] [CrossRef]

- Guarracino, I.; Mellor, A.; Ekins-Daukes, N.J.; Markides, C.N. Dynamic coupled thermal-and-electrical modelling of sheet-and-tube hybrid photovoltaic/thermal (PVT) collectors. Appl. Therm. Eng. 2016, 101, 778–795. [Google Scholar] [CrossRef]

- Ma, T.; Li, M.; Kazemian, A. Photovoltaic thermal module and solar thermal collector connected in series to produce electricity and high-grade heat simultaneously. Appl. Energy 2020, 261, 114380. [Google Scholar] [CrossRef]

- Nahar, A.; Hasanuzzaman, M.; Rahim, N.A. Numerical and experimental investigation on the performance of a photovoltaic thermal collector with parallel plate flow channel under different operating conditions in Malaysia. J. Sol. Energy 2017, 144, 517–528. [Google Scholar] [CrossRef]

- Zarei, A.; Liravi, M.; Rabiee, M.B.; Ghodrat, M. A Novel, eco-friendly combined solar cooling and heating system, powered by hybrid Photovoltaic thermal (PVT) collector for domestic application. Energy Convers. Manag. 2020, 222, 113198. [Google Scholar] [CrossRef]

- Abdul-Ganiyu, S.; Quansah, D.A.; Ramde, E.W.; Seidu, R.; Adaramola, M.S. Study effect of flow rate on flat-plate water-based photovoltaic-thermal (PVT) system performance by analytical technique. J. Clean. Prod. 2021, 321, 128985. [Google Scholar] [CrossRef]

- De Vries, D.W. Design of a Photovoltaic/Thermal Combi-Panel. Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 1998. [Google Scholar]

- Zhou, J.; Yi, Q.; Wang, Y.; Ye, Z. Temperature distribution of photovoltaic module based on finite element simulation. J. Sol. Energy 2015, 111, 97–103. [Google Scholar] [CrossRef]

- Zhou, J.C.; Zhang, Z.; Liu, H.J.; Yi, Q. Temperature distribution and back sheet role of polycrystalline silicon photovoltaic modules. Appl. Therm. Eng. 2017, 111, 1296–1303. [Google Scholar] [CrossRef]

- Armstrong, S.; Hurley, W.G. A thermal model for photovoltaic panels under varying atmospheric conditions. Appl. Therm. Eng. 2010, 30, 1488–1495. [Google Scholar] [CrossRef]

- Abdel-Khalik, S.I. Heat removal factor for a flat-plate solar collector with a serpentine tube. J. Sol. Energy 1976, 18, 59–64. [Google Scholar] [CrossRef]

- Zhang, M.F.; Lavan, Z. Thermal performance of a serpentine absorber plate. J. Sol. Energy 1985, 34, 175–177. [Google Scholar] [CrossRef]

- Watmuff, J.H.; Charters, W.W.S.; Proctor, D. Solar and Wind Induced External Coefficients-Solar Collectors. Comples 1977, 56. [Google Scholar]

- Mitchell, J.W. Heat transfer from spheres and other animal forms. Biophys. J. 1976, 16, 561–569. [Google Scholar] [CrossRef] [PubMed]

- Hollands, K.G.T. Directional selectivity, emittance, and absorptance properties of vee corrugated specular surfaces. J. Sol. Energy 1963, 7, 108–116. [Google Scholar] [CrossRef]

- Antonanzas, J.; Del Amo, A.; Martinez-Gracia, A.; Bayod-Rujula, A.A.; Antonanzas-Torres, F. Towards the optimization of convective losses in photovoltaic–thermal panels. J. Sol. Energy 2015, 116, 323–336. [Google Scholar] [CrossRef]

- Herrando, M.; Ramos, A.; Zabalza, I.; Markides, C.N. A comprehensive assessment of alternative absorber-exchanger designs for hybrid PVT-water collectors. Appl. Energy 2019, 235, 1583–1602. [Google Scholar] [CrossRef]

- Zhou, J.; Yu, L.; Ayipaiyili, Y.; Hao, L.; Jiang, B. Comparative Analysis of Edge Soiling Resilience: Full-Cell vs. Half-Cell Photovoltaic Modules in Different Mounting Orientations. J. Eng. 2023, 2023, 5572523. [Google Scholar] [CrossRef]

- Hanifi, H.; Khan, M.Z.; Jaeckel, B.; Hagendorf, C.; Schneider, J.; Abdallah, A.; Ilse, K. Optimum PV module interconnection layout and mounting orientation to reduce inhomogeneous soiling losses in desert environments. Sol. Energy 2020, 203, 267–274. [Google Scholar] [CrossRef]

| Symbol | Value | Symbol | Value |

|---|---|---|---|

| 0.9 | 45 W/(m2·K) | ||

| 0.9 | 0.01 m | ||

| 45° | 0.008 m | ||

| 0.0045 | 0.097 | ||

| 20 mm | 0.095 m | ||

| 1.5 W/(m2·K) | 0.944 m2 | ||

| 1 W/(m2·K) | 0.02 | ||

| 1 m/s | 800 W/m2 | ||

| 390 | 0.74 | ||

| 0.2 mm | 293 K | ||

| 84 | 293 K | ||

| 0.35 mm | 298 K |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lyu, M.; Ke, H.; Zhan, J.; Zhou, J. Electric and Thermal Performance Evaluation of a Serpentine-Pipe PVT Solar Collector. Coatings 2025, 15, 1202. https://doi.org/10.3390/coatings15101202

Lyu M, Ke H, Zhan J, Zhou J. Electric and Thermal Performance Evaluation of a Serpentine-Pipe PVT Solar Collector. Coatings. 2025; 15(10):1202. https://doi.org/10.3390/coatings15101202

Chicago/Turabian StyleLyu, Miaoxian, Haoyun Ke, Jianyong Zhan, and Jicheng Zhou. 2025. "Electric and Thermal Performance Evaluation of a Serpentine-Pipe PVT Solar Collector" Coatings 15, no. 10: 1202. https://doi.org/10.3390/coatings15101202

APA StyleLyu, M., Ke, H., Zhan, J., & Zhou, J. (2025). Electric and Thermal Performance Evaluation of a Serpentine-Pipe PVT Solar Collector. Coatings, 15(10), 1202. https://doi.org/10.3390/coatings15101202