Abstract

Globally escalating electricity demand necessitates substantial power grid capacity expansion. Current transmission line capacity enhancement technologies are seriously constrained by factors including limited accuracy of computational models, elevated line losses, requirements for new line construction, and substantial capital investment. Capacity-uprating conductors, recognized for their superior current-carrying performance and cost-effective retrofitting, represent one of the most viable solutions for transmission augmentation. However, their large-scale deployment remains impeded by increased line losses and high costs. This review systematically analyses critical constraints on transmission line ampacity through computational modeling and elucidates conductor heat dissipation pathways. Based on this foundation, we synthesize recent advancements in capacity-uprating conductors across three key dimensions: structural optimization, material engineering, and passive radiative cooling technologies. We concurrently evaluate their applications in power transmission projects and explore promising future development directions. This review aims to provide a theoretical foundation, guiding next-generation capacity enhancement solutions for grid modernization.

1. Introduction

With the development of the economy, population growth, and increased electrification, total electricity consumption across society has risen year by year, placing higher demands on the transmission capacity of the power grid [1,2]. Over the past few years, the development of renewable energy sources such as wind and solar power has alleviated the pressure on power generation to some extent [3]. However, since these sources are typically located far from power consumption centers and are constrained by the efficiency of power generation and power transmission, an efficient transmission network is required to transport the electricity they generate over long distances to power consumption centers. Additionally, electricity demand exhibits distinct seasonal patterns, with the increased usage of cooling devices in summer and heating equipment in winter leading to a significant rise in residential electricity consumption [4]. This necessitates existing transmission lines to have a greater current-carrying capacity [5]. Enhancing the capacity of transmission line proves instrumental in meeting power demand during such contingencies while reducing the risk of safety incidents [6,7]. Consequently, enhancing the capacity of transmission line is an imperative strategy to ensure the safety and stable operation of the grid.

The ampacity of transmission conductors is one of the key parameters for evaluating the capacity of transmission lines. Commonly used transmission line conductor is Aluminum Conductor Steel-Reinforced (ACSR) conductor, with the steel core providing strength and support for the conductor and the aluminum wire serving as the main current carrier [8]. When the ampacity of transmission lines increases, the joule heat generated by the current increases, causing the temperature of the conductors to increase. This leads to linear expansion of the conductors, which in turn increases the sag of the conductors and reduces the safety distance between the conductors and the ground, posing serious safety hazards [8,9]. In recent decades, the scientific community has exhibited an increasing interest in research on transmission line capacity expansion technology. Transmission line capacity expansion technology refers to technical solutions that enhance the transmission efficiency (ampacity) of existing power lines, thereby addressing the imbalance between growing electricity demand and insufficient line transmission capacity.

Existing capacity expansion technologies are primarily categorized into dynamic line rating (DLR) and static line rating (SLR). DLR involves real-time monitoring of conductor conditions (e.g., conductor temperature, tension) and environmental parameters (e.g., ambient temperature, wind speed) to calculate the maximum permissible ampacity. This approach fully utilizes the latent capacity of power lines, thereby enhancing their actual transmission capacity [10,11]. However, the DLR remains constrained by multiple factors, including limitations in online temperature monitoring technologies, and the accuracy and computational efficiency of calculation models.

Static line rating (SLR) technology currently represents the most widely adopted approach for power transmission capacity expansion. Voltage Level Elevation, particularly through ultra-high voltage (UHV) transmission [12], series compensation technology [13], flexible ac transmission systems (FACTS) [14], compact transmission technology [15], multi-circuit transmission on same tower [16], large cross-section conductors [17], temperature-enhanced capacity technology [18], capacity-expansion conductors etc., all the technologies mentioned above are static capacity expansion technologies. The initial six technologies necessitate the construction of new power lines or the upgrading of supporting transmission and distribution facilities, which entails substantial capital investment. Moreover, in regions characterized by high electricity demand, land resources are frequently limited, and acquiring approval from the relevant authorities can be arduous, thereby impeding effective implementation. During the preliminary design stage of transmission lines, operational temperature limits generally incorporate significant safety margins to account for extreme operating conditions, thereby providing inherent capacity enhancement potential. Thus, the temperature-enhanced capacity approach is a method of increasing line ampacity by appropriately elevating the permissible operating temperature of existing conductors. However, an increase in the operating temperature of the conductor will cause an increase in sag, thereby reducing the safety distance between the conductor and the ground. In extreme cases, this may result in safety accidents and is only suitable for specific areas.

Capacity-uprating conductors refer to overhead conductors that achieve either a ≥15% increase in ampacity or a ≥20% reduction in sag while maintaining the same external diameter and safety constraints (sag/temperature), through material innovations or structural optimizations. Capacity-uprating conductors can achieve long-term operating temperatures and maximum ampacity more than twice those of conventional conductors, significantly improving power grid transmission capacity and efficiency. Furthermore, for the photovoltaic power generation system the variability of photovoltaic power generation induced by environmental fluctuations necessitates a shift from static to dynamic rating systems for transmission line capacity assessment. Such variability introduces additional challenges, including cyclic load fatigue and protection coordination. Capacity-uprating conductors, characterized by their high-temperature resistance and low sag properties, offer a technical solution to these challenges. By operating in synergy with dynamic rating systems, they can provide a secure and efficient solution for large-scale photovoltaic power transmission. However, issues such as transmission losses, cost, and environmental adaptability of capacity-uprating conductors remain significant factors limiting their widespread replacement of ACSR conductors. Furthermore, some types of capacity-uprating conductors require replacement of supporting towers and associated hardware. Consequently, these conductors still face challenges in completely replacing conventional ACSR conductors in practical grid applications.

In summary, while existing power line capacity expansion technologies have demonstrated effectiveness in enhancing transmission line ampacity, their widespread implementation remains constrained by various technical and economic factors, preventing comprehensive grid upgrades. The current transmission infrastructure struggles to meet escalating electricity demands, making grid capacity expansion an inevitable developmental imperative. This review focuses on capacity-uprating technologies for overhead AC transmission lines, systematically examines the thermal generation mechanisms and heat dissipation pathways in overhead transmission conductors, elucidates the technical principles underlying capacity-uprating conductors, summarizes the state-of-the-art in conductor technology development, and outlines future research directions for transmission line capacity expansion. The primary objective is to move beyond a mere catalog of technologies and to provide a critical framework that guides the development of viable, high-performance capacity-uprating conductors, thereby directly contributing to the strategic goal of sustainable grid modernization.

2. Calculation of Ampacity for Transmission Lines

2.1. Dynamic Thermal Ratings for Transmission Lines

The method was first proposed in 1977 by Davis et al., who introduced an approach for calculating transmission line ampacity under real-time varying environmental conditions [19]. In 1991, Pacific Gas & Electric Company (PG&E) in the United States implemented a dynamic line rating system based on ambient temperature measurements. Experimental results demonstrated that this system increased the conductor ampacity by 34% compared to the originally set static thermal rating [20]. Limited by the accuracy of computational models and the precision of environmental monitoring systems, this approach, while failing to achieve large-scale implementation, provided a novel perspective for power line capacity expansion. With the continuous advancement of science and technology, the measurement accuracy of key parameters such as conductor temperature, solar radiation intensity, wind speed, and wind direction angle has been significantly improved [21]. Researchers worldwide have conducted in-depth studies on Dynamic Line Rating (DLR) technology and achieved substantial progress. However, the existing computational models face a fundamental trade-off between calculation accuracy and processing speed, which remains one of the primary technical bottlenecks limiting the widespread application of this technology. Li et al. [22] proposed an innovative assessment framework based on the second-order reliability method (SORM) that maintains accuracy comparable to Monte Carlo simulations while reducing computation time to within 40 s. Research demonstrates that under typical normal system operation and partial line fault conditions, the application of this technology can increase transmission line ampacity by 39.1% (1011A) and 51.0% (1098A), respectively, compared to static line ratings (727A), thereby significantly enhancing transmission efficiency. As a temperature and micro-meteorological monitoring-based approach, dynamic line rating technology can safely improve the load capacity of transmission lines and has achieved limited-scale implementation [23]. In conclusion, Dynamic Line Rating (DLR) represents a technology with substantial potential and practical utility. However, DLR technology still faces several critical limitations that hinder its large-scale implementation:

- (1)

- Sensor accuracy and computational model reliability, monitoring errors in environmental parameters (e.g., temperature, wind speed) may lead to ampacity calculation deviations. Meanwhile, the accuracy of computational models fundamentally determines the technology’s effectiveness and operational safety [24,25,26].

- (2)

- Radial temperature gradient in conductors, for transmission lines with large spans, the radial temperature difference across conductors can reach 4–10 °C. This may cause localized overheating, posing significant safety risks [24,27,28].

- (3)

- High initial costs and technical complexity, the implementation requires substantial capital investment and sophisticated operational expertise [22,26,29].

- (4)

- Variations in cooling conditions along the line result in the maximum current-carrying capacity being limited by the segment with the most unfavorable cooling performance. The inability to achieve full-segment monitoring poses a significant constraint for long-distance transmission lines [22,30,31].

2.2. Calculation of Steady-State Ampacity for Transmission Lines

The ampacity of conductors is intrinsically related to their maximum permissible operating temperature. For instance, a conductor with a cross-sectional area of 400 mm2 experiences approximately a 50 A increase in ampacity for every 10 °C rise in operating temperature [32]. However, for overhead transmission lines, the current-carrying capacity is primarily constrained by two critical mechanical factors at elevated temperatures: the conductor’s mechanical strength and the required ground clearance. Both factors are fundamentally governed by conductor sag, which is defined as the maximum vertical distance between the conductor and the straight line connecting its suspension points [33,34,35,36]. The conductor tension is determined by the thermal expansion coefficient, temperature, cross-sectional area, and elastic modulus. As temperature rises, conductor tension decreases, leading to increased sag [37]. For the most widely used ACSR (Aluminum Conductor Steel-Reinforced), the high thermal expansion coefficient of the aluminum strands causes the conductor to expand even at moderate temperatures. This results in reduced tension and increased sag, limiting the applicability of ACSR under higher temperature conditions [38]. Therefore, based on the calculation equations established by IEEE, IEC, and CIGRE, countries have defined the maximum operating temperatures for ACSR is typically set at 60–80 °C [38].

According to the international standard IEC and the IEEE Standard [32], the maximum steady-state current under known ambient temperatures and specified conductor operating temperatures is defined as the conductor’s ampacity. Currently, the ampacity of transmission lines under steady-state conditions is calculated primarily based on the conductor’s heat balance equation, as given in Equation (1):

Pj + Psol = Prad + Pcon

Among these terms, Pj is the heat generated by the Joule effect, with units of W/m, Prad denotes radiative heat dissipation, Pcon is convective heat dissipation, and Psol signifies solar heat gain, all measured in W/m2. Under thermal equilibrium, the heat generation rate within the conductor equals its dissipation rate. Heat generation primarily stems from Joule heating (Pj) and solar heat gain (Psol), while heat dissipation occurs through radiative (Prad) and convective (Pcon) losses. Pj is given by Equation (2):

Pj = RT · I2

RT represents the AC resistance per unit length of the conductor at temperature T, with units of Ω/m, while I denotes the ampacity with units of A.

Imax = [(Prad + Pcon − Psol)/RT]]1/2

Equation (3) shows that reducing conductor resistance (RT) and solar radiation absorption (Psol) while increasing radiative heat dissipation (Prad) and convective heat loss (Pcon) is an effective way to increase ampacity. The calculation of the heat loss (Prad) from the surface of an overhead transmission aluminum stranded wire to the surrounding space is performed using the following formula:

Prad = S · π· D · ke (Tc4 − T04)

In Equation (4), S represents the Stefan–Boltzmann constant with units of W·m−2·K−4, D is the conductor diameter in meters (m), while Tc and Tair correspond to the conductor temperature and ambient temperature, respectively, both measured in Kelvin (K). ke is the emissivity coefficient relative to a black body (i.e., the emissivity). The radiative heat loss (Prad) is primarily determined by four key factors: conductor diameter, surface emissivity, conductor temperature (Tc), and ambient temperature (Tair). Under identical operating temperatures, increasing either the conductor diameter or surface emissivity coefficient (ke) significantly enhances the radiative heat dissipation capacity of the conductor. The solar radiation heat absorption (Psol) is calculated by the following equation:

Psol = γ · D · Si

Here, γ represents the conductor’s absorption coefficient, and Si denotes the solar irradiance intensity (W/m2). The solar irradiance intensity depends on the conductor’s geographical location, time of day, and increases with altitude. Consequently, the conductor diameter and absorptivity constitute fundamental parameters governing solar radiation heat absorption, with typical conductor absorptivity ranging between 0.2 and 0.9 [39]. Although the material composition and geometric shape of the conductor do not change during operation, the outer layer aluminum wire becomes darker with increasing service life, leading to an increase in solar radiation reflectance and emissivity, which severely affects the heat dissipation capacity of the aluminum conductor surface.

It is evident that, at the rated operating temperature, convective heat loss is predominantly influenced by external wind speed and wire diameter. Convective heat loss (Pcon) can be calculated using the following formulae:

Pcon = λ · Nu · π · (Tc − Tair)

Nu = 0.65Re0.2 + 0.23Re0.61

Re = 1644 × 109v · D · [T1 + 0.5(T2 − T1)]−1.78

Among these, λ is the thermal conductivity of the air film in contact with the conductor surface. Nu is the Nusselt number, which can be calculated using Equations (7) and (8). Re is the Reynolds number, v is the wind speed, m/s; D is the conductor diameter, m. T1 and T2 are the ambient temperature and thermal equilibrium temperature, K. In practical engineering applications, the calculation of static line ratings (SLR) typically assumes a vertical wind speed of 0.5–0.6 m/s. Some scholars have suggested that natural convection heat loss is approximately equivalent to forced convection at a wind speed of 0.6 m/s. However, M. Maksić et al. [40] conducted an in-depth study on the natural convection heat loss of conductors. The experimental and simulation results obtained in this study indicated that the natural convection cooling power is 35% lower than that of forced convection at 0.6 m/s. This phenomenon is attributed to the conductor heating the surrounding air, causing the air to expand and decrease in density, thereby forming an upward jet with a velocity of only 0.25 m/s.

In summary, the ampacity of transmission lines is jointly determined by conductor temperature, intrinsic conductor properties (emissivity, absorptivity, resistance, etc.), and environmental factors including solar irradiation, ambient temperature, and wind speed [41,42]. Enhancing the heat dissipation performance of transmission conductors, reducing solar radiation heat absorption, and minimizing Joule heating are all effective approaches for increasing line ampacity. Therefore, in addition to uncontrollable environmental factors, enhancing the electrical conductivity, maximum operating temperature, and heat dissipation performance of transmission conductors constitute an effective approach for increasing line ampacity. The following sections will present both existing capacity-uprating conductors developed based on the theoretical framework mentioned before and emerging technologies with potential for developing new types of capacity-uprating conductors.

3. Development Status of Capacity-Uprating Conductor

The preceding section has expounded on the calculation methodologies for transmission line ampacity and its primary influencing factors. Optimizing conductor materials and enhancing structural design have been recognized as effective technical approaches for significantly increasing the capacity-uprating conductor conductors. Numerous commercial capacity-uprating conductor have been developed based on these strategies. Furthermore, radiative cooling coatings and surface treatment technologies represent promising approaches for developing capacity-uprating conductors. However, prototypes based on these strategies remain largely at the laboratory research stage and have not yet achieved commercialization.

It is noteworthy that the development of capacity-uprating conductor technology is closely intertwined with the overall evolution and demands of modern power systems. Capacity-uprating conductors primarily enhance the maximum power transfer capability of transmission lines, while Flexible AC Transmission Systems (FACTS) devices mainly optimize transient stability limits and power flow distribution. The synergy between these two approaches offers the most effective “non-wire” solution for maximizing the potential of existing AC lines. In contrast, High-Voltage Direct Current (HVDC) transmission is better suited for ultra-long-distance point-to-point power delivery. Capacity-uprating conductors, on the other hand, serve as a key technology for reinforcing regional AC grid backbone networks and upgrading existing lines. Thus, these two technologies are complementary rather than competitive. Given this context, the advancement of capacity-expanded conductor technology is crucial for the modernization and enhancement of power grids. The ensuing sections will provide a detailed examination of the current developmental status of capacity-uprating conductors from various perspectives.

3.1. Rational Material Selection for Conductors

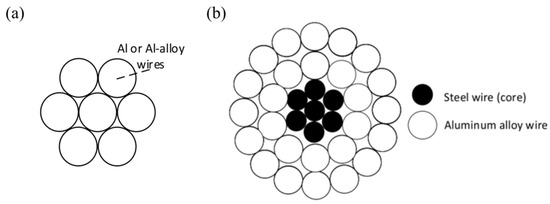

The conventional overhead transmission aluminum conductors include All-Aluminum Conductors (AAC), All-Aluminum Alloy Conductors (AAAC), and Aluminum Conductor Steel-Reinforced (ACSR), with their cross-sectional configurations illustrated in Figure 1. AAC conductor is fabricated by stranding pure aluminum wires, while AAAC conductor consists of aluminum and aluminum alloy strands. Due to the higher resistivity of aluminum alloy, AAAC exhibits greater line losses [17]. In contrast, ACSR conductor incorporates a steel core for mechanical support based on AAC’s design, demonstrating superior tensile strength while maintaining cost-effectiveness, which made it the most widely adopted conductor type during the last century [43]. Aluminum serves as a primary material for ACSR conductors, with a coefficient of thermal expansion of 23.1 × 10−6/°C. The resultant sag increase caused by thermal expansion of aluminum wires under high-temperature operation constitutes the fundamental limitation on the current-carrying capacity of ACSR conductors (see Section 2.1). Consequently, enhancing the mechanical properties of conductors under high-temperature operation has become a critical strategy for improving their current-carrying capacity [44].

Figure 1.

Cross-section of different type conductor (a) AACs and AAACs, (b) ACSR conductors—adapted from [17].

With the continuous development of power grids, the variety, and types of capacity-uprating conductors for transmission lines have increased significantly and achieved commercialization. Compared to conventional conductors, capacity-uprating conductors primarily achieve material upgrades through improvements in both conductor and core materials.

Numerous studies have demonstrated that aluminum alloys demonstrate superior suitability for transmission conductors compared to pure aluminum. Table 1 summarizes selected aluminum alloys currently employed in the fabrication of aluminum alloy conductors, including Al-Zr series [45,46,47], Al–Fe series [48,49,50], Al–Mg–Si series [51,52]. When the operating temperature of aluminum conductors increases, recrystallization occurs within aluminum grains, leading to deterioration in mechanical properties. The addition of alloying elements serves as an effective approach to enhance the mechanical performance of aluminum metals. For instance, the low diffusion rate of zirconium (Zr) atoms within the α-Al matrix endows Al3Zr nanoparticles with thermal stability at elevated temperatures [53]. However, alloying invariably compromises the electrical conductivity of aluminum while enhancing its mechanical properties [54]. The introduction of alloying atoms induces lattice distortions, grain refinement, and increased grain boundaries, which collectively impede the directional movement of electrons and intensify electron scattering, ultimately leading to degraded conductivity [55]. Consequently, researchers have focused on optimizing alloy composition and elemental concentrations to achieve a balance between mechanical strength and electrical conductivity in aluminum alloy wires. This coordinated approach has facilitated the development of various high-temperature low-sag (HTLS) transmission conductors utilizing different aluminum alloys as primary materials.

Table 1.

The mechanical and electrical properties of different series of aluminum alloys.

Conductors fabricated using these aluminum alloys exhibit significantly enhanced current-carrying capacity [56,57,58]. Due to the low thermal expansion coefficients and high tensile strengths of these conductors, which are called High Temperature Low Sag (HTLS) conductors. This concept was proposed by Douglas initially, and HTLS conductor was first used in engineering applications in the United States [44]. The ZTACIR conductor is a heat-resistant aluminum alloy wire fabricated by stranding Al-Zr alloy wires around a galvanized steel core. While maintaining an identical structural configuration to conventional ACSR conductors, the ZTACIR conductor exhibits superior maximum operating temperature tolerance due to the higher annealing temperature characteristic of the Al-Zr alloy [17]. Both the core and aluminum strands constitute critical factors determining a conductor’s current-carrying capacity under high-temperature conditions. Replacing conventional steel cores with alternative core materials exhibiting higher tensile strength represents an effective approach to further enhance ampacity while reducing thermal sag during operation. Notable examples include:

- AACSR (Aluminum Alloy Conductor Steel-Reinforced): Utilizes high-strength coated steel cores (zinc-coated or aluminum-coated) [43].

- ACCR (Aluminum Conductor Composite-Reinforced): Comprises Al-Zr alloy strands stranded around an alumina fiber-reinforced aluminum composite core [58,59].

- ZTACIR (Zirconium-Type Aluminum Conductor Invar Steel-Reinforced): features aluminum conductors stranded around an invar steel core [60].

Compared with conventional steel cores, these advanced core materials exhibit superior mechanical properties and enhanced load-bearing capacity [58]. Besides these conductors that mentioned above, heat-resistant aluminum alloy conductors [43] and composite core conductors (ACCC) [61] are both categorized as HTLS conductors.

Annealed aluminum conductors are fabricated by stranding fully annealed aluminum wires around a steel core. Annealing treatment reduces lattice defects in aluminum (e.g., dislocations, vacancies, and lattice distortions), thereby decreasing the scattering of free electrons during conduction. This reduction in electron scattering results in diminished electrical resistance and enhanced conductivity [62]. For Hard drawn 1350 H19 aluminum wires, the tensile strength ranges from 150 to 210 MPa, electrical conductivity is 62.1% IACS, and the maximum continuous operating temperature is 85 °C. In contrast, fully annealed 1350 aluminum wires exhibit reduced tensile strength (59–97 MPa) but enhanced electrical conductivity (63% IACS) and elevated maximum continuous operating temperature (350 °C). Although tensile strength is compromised, the improved electrical performance and higher permissible operating temperature collectively contribute to enhanced power transmission efficiency [63]. Table 2 summarizes the primary material composition, maximum allowable operating temperature, and electrical conductivity of selected commercially available transmission conductors. ACCC, ACCR, and ACSS conductors universally employ fully annealed aluminum strands, which provide superior electrical conductivity. This characteristic makes them suitable for high-voltage transmission lines without introducing significant additional power losses. The majority of HTLS conductors exhibit ideal performance characteristics, allowing operating temperatures of at least 150 °C and ampacity 2.5 times that of ordinary ACSR conductors. Additionally, these conductors maintain the sag of the conductor without significant change [17,64,65]. Somboon Nuchprayoon et al. [32] investigated the performance of ACSR, ACCR, ACSS, and ZTACIR conductors in 230 kV overhead transmission lines. The results demonstrate that all three HTLS conductors can effectively increase the current-carrying capacity while reducing conductor sag. Specifically, both ACCR and ZTACIR conductors achieve twice the ampacity of conventional ACSR conductors, whereas ACSS conductors provide 1.6 times the capacity of ACSR. Moreover, these HTLS conductors exhibit sag reductions exceeding 1.5 m. Additionally, the maximum allowable operating temperatures for ACCR, ACSS, and ZTACIR conductors reach 210 °C, 250 °C, and 200 °C, respectively [58]. Pooya Parvizi et al. [61] conducted an in-depth investigation into the mechanical and thermal properties of HTLS and ACSR conductors. The study revealed that the tension loss under high-temperature conditions and long-term creep strain values of HTLS conductors were significantly lower than those of conventional ACSR conductors. As demonstrated in Reference [66], several HTLS conductors exhibit lower thermal time constants compared to ACSR conductors, enabling them to reach steady-state temperatures more rapidly. Under identical current loads, HTLS conductors maintain lower operating temperatures than their ACSR counterparts. Extensive research has confirmed the superior performance of HTLS conductors over conventional ACSR conductors. The adoption of HTLS conductors in power distribution systems represents an effective and technically feasible solution for enhancing grid transmission capacity.

Table 2.

The material composition, maximum operating temperature, and electrical conductivity of different conductors.

In addition to commercially available HTLS conductors, the development of advanced aluminum alloys and conductor cores remains a research focus in the field of capacity-uprating conductors. To fabricate higher-strength aluminum alloy conductors, Aishani Sharma et al. [71] employed an innovative SolidStir® extrusion (SSE) technology to produce Al-2Cu-0.1Nb-0.15Zr (wt.%) dilute alloy conductors. These conductors achieved a yield strength of 166 MPa, tensile strength of 240 MPa, and electrical conductivity of 64% IACS, breaking the conventional strength-conductivity trade-off relationship in aluminum alloys. Chika O. Ujah et al. [72] investigated the properties of Al-Nb alloy. Compared with pure Al, this alloy demonstrated a thermal conductivity of 115.95 ± 6.9 W/(m·K), representing a 42% improvement. Additionally, the wear coefficient was reduced by 45%, while both wear volume and wear rate decreased by 20%, indicating superior wear resistance properties. In Reference [73], they additionally reported an Al-CNTs-B4C composite fabricated via a two-step stir-casting technique. This composite exhibited an electrical conductivity of 65.1% IACS and a microhardness of 725.72 MPa, representing a 94.7% enhancement compared to pure aluminum. Furthermore, S. L. Cai et al. [74] successfully developed a hierarchically structured aluminum-clad aluminum alloy conductor through composition-structure-process synergistic design. This innovative material achieved a 13% increase in yield strength while simultaneously quadrupling the uniform elongation and improving electrical conductivity by 2% IACS, thereby breaking through the performance limitations of conventional conductors.

Conductor weight constitutes a critical factor influencing the application of HTLS conductors. Compared to reinforced steel cores or Invar cores typically employed in HTLS conductors, composite cores exhibit significantly lower density, rendering them particularly advantageous for existing line retrofits. Consequently, composite cores have emerged as a research focus in the field, while simultaneously imposing more stringent performance requirements on these advanced materials. Several high-performance composite materials have recently been reported as promising candidates for developing next-generation HTLS conductors. To enhance the thermal stability of conductor cores, Chika O. Ujah et al. [75] successfully fabricated Al-CNTs-Nb composites with gradient-reinforced phases using spark plasma sintering (SPS) technology. The synergistic effect between CNTs and Nb simultaneously optimized both tribological and thermal properties. The results showed that when the content of CNTs and Nb are both 8 wt.%, the friction coefficient of the material is reduced by 79%, and the thermal conductivity is increased from 89 W/(m·K) to 128 W/(m·K), an increase of 44%, which has excellent thermal stability. Furthermore, the tensile strength of the Al-CNTs-Nb composite was recorded at 168 MPa, which is 106% higher than that of the ACCC conductor core previously reported, while its density was determined to be 2.72 g/cm3, which is more than half lighter than most conductor core materials.

The development of aluminum alloys or other alternative metals with superior electrical conductivity, corrosion resistance, and lighter weight, as well as the development of conductor cores with better mechanical properties, corrosion resistance, and thermal stability, remains the future direction for HTLS conductors. Concurrently, the mitigation of transmission losses and the cost of HTLS conductors will also promote their widespread application.

3.2. Conductor Structural Optimization

Previous studies have demonstrated that heat transfer within transmission conductors occurs primarily in the radial direction, with Joule heat generated in the aluminum layers propagating radially toward the surface [76]. The presence of numerous air gaps (thermal conductivity: 0.014 W/(m·K)) within round wires results in a temperature differential of 10–15% or higher between the conductor core and surface during operation [77,78]. During the actual operation of transmission lines, the temperature of the outer aluminum wire may be lower than that of the inner aluminum wire, which exceeds the maximum allowable operating temperature, causing a decline in mechanical performance and posing a great safety hazard [79,80]. Consequently, increasing the contact area between inner and outer aluminum strands while reducing air gaps constitutes an effective strategy for enhancing the thermal performance of transmission conductors.

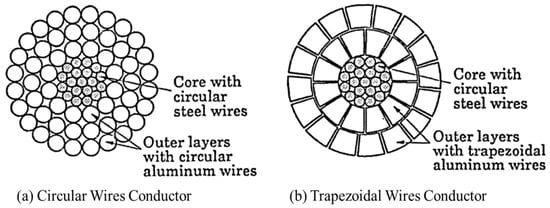

Given that HTLS conductors operate at higher permissible temperatures, they inherently exhibit greater radial temperature gradients during service. Consequently, minimizing the temperature difference between conductor core and surface is essential to ensure safe and stable conductor operation [78]. Reference [77] demonstrates that the thermal conductivity between directly contacting aluminum strands is more than twice that between aluminum strands and air. Thus, to enhance thermal conduction efficiency between aluminum strands, researchers have proposed replacing conventional round strands with trapezoidal-shaped strands (Figure 2). This geometric optimization significantly increases the contact area between adjacent strands, and effectively reduces internal voids within the conductor. Moreover, for conductors of equivalent diameter, the aluminum cross-sectional area of trapezoidal conductors exhibited a 3% increase, while the resistance at 75 °C decreased by 23.8%, thereby effectively enhancing the ampacity of the conductors [81]. The GZTACSR conductor replaces the inner layer of aluminum strands adjacent to the steel core with trapezoidal wires, while filling the gap between the steel core and aluminum strands with heat-resistant grease to reduce friction [17]. Other HTLS conductors employ trapezoidal wires (TW) to replace all aluminum strands, resulting in TW-type conductors such as ACSS/TW, ACCC/TW, and ACCR/TW. Figure 2 illustrates various models of HTLS/TW conductors. In the research of M. Tabatabai et al., TW conductors exhibit a 30% lower drag coefficient compared to conventional round conductors under high wind speeds (160 km/h), which can reduce tower maintenance costs [81]. In Reference [58], the ACCC/TW conductor achieves a maximum operating temperature of 240 °C and a current-carrying capacity of 852A at 120 °C. The use of composite cores and tighter trapezoidal aluminum wire stranding increases the aluminum content within conductors of identical diameter, thereby enhancing electrical performance [82,83].

Figure 2.

(a) Circular wires conductor; (b) trapezoidal wires conductor—adapted from [81].

Owing to variations in mechanical and electrical properties among different types of HTLS conductors, appropriate selection should be made according to specific service environments. Table 3 summarizes the core advantages, applicable voltage levels, and suitable environments for various HTLS conductor types. It should be noted that TW-type conductors are specifically designed for applications requiring higher current-carrying capacity under conditions that would otherwise be suitable for conventional round conductors. For practical engineering applications, the selection of HTLS conductors significantly impacts both the power transmission efficiency and the secure stable operation of electrical grids.

Table 3.

Core advantages, applicable voltage levels, and suitable operating environments for various types of HTLS conductors.

3.3. Radiative Cooling Coatings

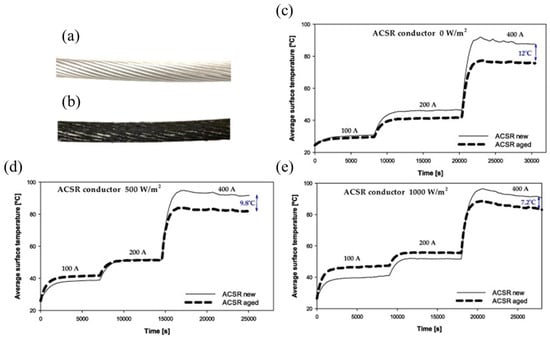

For the outer aluminum layer, heat is transferred to the surrounding environment through thermal radiation and convective heat exchange. Under windy conditions, convective heat loss depends on wind speed and direction, and may exert a more significant influence on conductor temperature than solar radiation heat absorption and radiative heat loss [89]. Emissivity (ε) is defined as the ratio of an object’s radiative power to that of a blackbody at the same temperature, ranging from 0 to 1. It serves as a critical parameter for evaluating the efficiency of radiative heat transfer. Solar absorptivity (α), the ratio of incident solar radiation to absorbed radiation by a material, is a key parameter governing solar thermal absorption. Notably, α exhibits strong correlation with ε [30]. Abboud et al. [90] explicitly demonstrated that α and ε are critical parameters for conductors operating at elevated temperatures. Jordi-Roger Riba et al. [89] conducted an in-depth investigation into the influence of surface emissivity on the current-carrying capacity of transmission lines. Their study examined the surface temperatures of ACSR conductors with different surface conditions under identical operational parameters. The macroscopic morphology of the conductors is illustrated in Figure 3a,b, wherein the aged ACSR samples were treated with an aqueous carbon black solution. As shown in Figure 3c,d, the aged ACSR conductor exhibits higher operating temperatures than the new ACSR conductor under conditions of low current and high solar irradiance. This phenomenon occurs because at low current levels, the conductor’s operating temperature remains relatively low, rendering radiative heat dissipation less significant. Meanwhile, the aged ACSR conductor demonstrates enhanced solar radiation absorption, consequently leading to elevated temperatures. Under high-current conditions, the new ACSR conductor exhibits significantly higher temperatures compared to the aged ACSR conductor. However, with increasing solar irradiance, the aged ACSR conductor demonstrates a more pronounced temperature rise. This phenomenon can be attributed to the elevated operating temperatures under high current loads. As indicated by Equation (2), radiative heat loss is proportional to both ε and (Tc4 − Tair4), resulting in more effective radiative cooling under these conditions. These findings demonstrate that both emissivity (ε) and solar absorptivity (α) significantly influence conductor operating temperature and ampacity. When the current of conductor is low, α plays the dominant role, whereas ε becomes more influential at high current.

Figure 3.

(a,b) ACSR conductor (a) New ACSR. (b) Aged ACSR. Conductor temperatures under different solar irradiation levels (c) 0 W/m2. (d) 500 W/m2. (e) 1000 W/m2, adapted from [89].

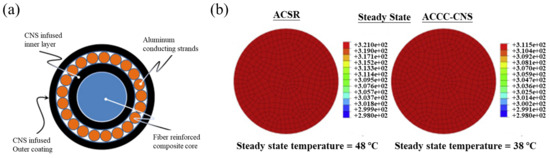

Hence, radiative heat loss represents an important factor of transmission line current-carrying capacity. However, current technical reports on enhancing transmission line ampacity through surface emissivity modification remain scarce. In contrast, the building energy-efficiency, cooling textile and other field has shown significant research interest in passive daytime radiative cooling (PDRC) technology [91,92,93,94,95]. Currently, PDRC coatings have demonstrated remarkable performance [96,97]. As reported in Reference [98], a hierarchically porous polyvinylidene fluoride (PVDF) aerogel (HPA) was developed through triple-scale synergistic design: (1) molecular-scale C-F bond vibration achieving 97.6% emissivity in the 8–13 μm atmospheric window, (2) mesoscale dual-sized pores enabling 96.7% solar reflectance. The results shows that this material achieves a temperature reduction of 12.1 °C under 1200 W/m2 solar irradiance. Reference [99] reports a passive sub-ambient daytime radiative cooling (PSDRC) coating fabricated via laser-assisted micro/nano structuring on metallic substrates. This technology achieves net radiative cooling through the synergistic effect of high solar reflectivity (0.98) and atmospheric window emissivity (0.991). The coating achieved maximum temperature reductions of 33.5 °C on top surfaces and 14.3 °C in internal air temperatures when applied to heat-dissipating metal enclosures. These results demonstrate that the PSDRC coating significantly enhances the heat dissipation capacity of the substrate, indicating its potential application in developing high-efficiency heat-dissipating transmission conductors. Extensive research has demonstrated that passive radiative cooling can significantly enhance thermal dissipation performance in materials [100,101,102]. This PDRC technology is also a potential technical strategy for producing the novel capacity-uprating conductor. S. Kumar et al. [103] developed a novel ACCC-CNS transmission conductor, as illustrated in Figure 4a. The conductor features a four-layer structure, comprising from exterior to interior: a CNS-Epoxy composite coating fabricated from carbon nanostructures and epoxy resin, an outer layer of Al-1350-H19 aluminum strands, a second CNS-Epoxy composite coating, and a unidirectional glass fiber reinforced epoxy composite core. Finite element simulation results presented in Figure 4b demonstrate that under a 400A current load, the operating temperature of the ACCC-CNS conductor reaches only 38 °C, compared to 48 °C for the ACSR conductor. Integrating the thermal conductivity and emissivity measurements—where the CNS-Epoxy composite coating exhibits a thermal conductivity of 15 W/(m·K) (facilitating internal heat transfer to the surface) and an emissivity of 0.8–0.9 (enhancing radiative heat dissipation to the ambient environment)—the authors attribute the lower operating temperature of ACCC-CNS conductors to the synergistic effect of these two properties. This study provides strategic guidance for the development of radiative cooling coatings applied to transmission conductors. Furthermore, Lee et al. [104] developed a silicone rubber coating with an emissivity approaching unity, which also demonstrates potential for enhancing power transmission efficiency during summer conditions.

Figure 4.

(a) Schematic diagram of the ACCC-CNS conductor and (b) steady-state temperature distribution across the cross-sections of both ACSR and ACCC-CNS conductors under a specified current load of 400 A, adapted from [102].

Unlike building cooling systems or heat sinks, the primary heat source in transmission conductors originates from Joule heating. Therefore, high thermal conductivity is an indispensable property for radiative cooling coatings used in the fabrication of capacity-uprating conductors. Additionally, challenges such as coating durability, scalable manufacturing and cost, compatibility with the conductor substrate, and the lack of standardized performance evaluation methods must be addressed to enable their commercialization.

3.4. Surface Modification Technology

Anodizing technology is currently one of the most used techniques for altering the emissivity and solar radiation reflectance of aluminum surfaces. Numerous researchers have conducted in-depth studies on the use of anodizing technology to modify the radiative cooling properties of aluminum and aluminum alloy surfaces. Junghoon Lee et al. [105] significantly enhanced the radiative cooling performance of aluminum alloys through an optimized anodization and sealing process. The study employed oxalic acid electrolyte (15 °C, 40 min) to fabricate a porous anodic aluminum oxide (AAO) layer featuring disordered nanopores (~280 nm diameter, 82% porosity). Subsequent blackening treatment via cobalt sulfide (CoS) deposition achieved a surface emissivity of 0.906—representing a 686% improvement over bare aluminum—while increasing the heat dissipation flux to 5088 W/m2 (156% enhancement). Experimental verification demonstrated 36.4% improvement in aluminum tube cooling efficiency, attributable to three key mechanisms: (1) nanopore-induced light scattering and enlarged effective radiation area, (2) seamless AAO-substrate integration minimizing interfacial thermal resistance, and (3) CoS deposition simultaneously optimizing emissivity and thermal conductivity.

Y. Fu et al. [106] developed a passive daytime radiative cooling material based on porous anodic aluminum oxide (AAO) membranes. The porous structure with selective radiative characteristics was fabricated through chemical anodization. This material exhibits high reflectivity (absorption < 0.06) in the solar spectrum (0.3–2.5 μm) while achieving high emissivity (>0.9) within the atmospheric window (8–13 μm). Theoretical calculations indicate that under ambient conditions of 30 °C and 70% humidity, this cooler can achieve a net cooling power of 64 W/m2, with experimental measurements demonstrating a consistent diurnal temperature reduction of 2.6 °C. The AAO membrane optimizes its optical performance by regulating the air-filling fraction (f = 0.85–0.9). Its porous structure (pore diameter 280 nm, porosity 82%) effectively reduces the dielectric constant and improves impedance matching with air. Compared to conventional multilayer film or photonic crystal approaches, this chemical fabrication method offers advantages such as low cost and scalability, providing a practical radiative cooling solution for applications such as building energy efficiency.

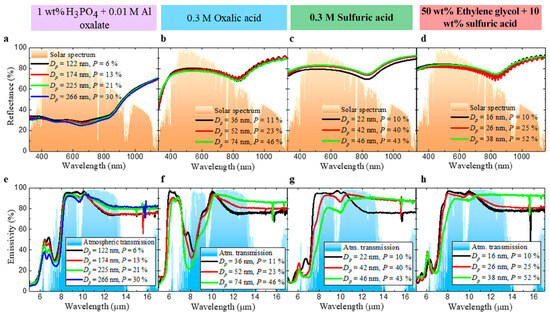

Alba Díaz-Lobo et al. [107] systematically investigated the performance optimization mechanisms of porous anodic aluminum oxide (AAO) as a passive radiative cooling material. By employing four different electrolytes (phosphoric acid, oxalic acid, sulfuric acid, and a sulfuric acid/ethylene glycol mixture), they fabricated AAO-Al samples with distinct morphologies. The emissivity and reflectivity of anodic aluminum oxide (AAO) films prepared using different electrolytes are illustrated in Figure 5. The study revealed that AAO samples prepared in a sulfuric acid electrolyte system (0.3 M, 25 V, 0 °C) with a thickness of 12 μm and porosity of 10% exhibited optimal radiative cooling performance, achieving a solar reflectance of 90% and an infrared emittance of 95% in the 7–10 μm band, which perfectly matches the atmospheric window. Field tests demonstrated that under 736 W/m2 solar irradiance, this sample achieved a temperature reduction of 8.0 °C, corresponding to a peak cooling power of 175 W/m2. Enhanced pore ordering increased the emissivity (ε) by 5%, while the characteristic infrared absorption of sulfate ions (6.7–9.6 μm) was identified as the primary reason for its superior performance compared to oxalic and phosphoric acid-based samples. Additionally, the study suggested that low porosity (10%) helps maintain chemical stability. This research provides both theoretical and practical foundations for improving the radiative cooling performance of anodized aluminum and its alloys. It also supports the application of this technology in capacity-uprating conductors for power transmission lines, thereby enhancing grid transmission efficiency.

Figure 5.

Spectral emissivity and reflectance curves of AAO prepared with different electrolytes, (a–d) emissivity, (e–g) reflectance, (a,e) phosphoric acid, (b,f) oxalic acid, (c,g) sulfuric acid and (d,h) ethylene glycol containing sulfuric acid, adapted from [107].

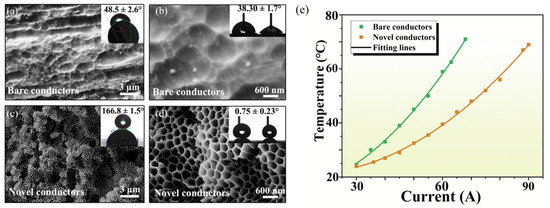

Notably, in the field of anti-icing for power transmission lines, Y. Yuan et al. [108] successfully constructed a honeycomb-like porous structure on the surface of ACSR conductors using an anodization method, developing a novel superhydrophobic anti-icing ACSR conductor as illustrated in Figure 6a. This novel conductor exhibits not only excellent superhydrophobic properties (with a contact angle reaching 166.8°) and anti-icing performance (ice adhesion strength as low as 1.75 ± 0.82 kPa), but also demonstrates higher current-carrying capacity than conventional conductors at the same temperature (Figure 6e). Furthermore, the electrical properties of the novel conductor were characterized. Resistivity tests revealed that the novel conductor has a DC resistance (RDC) of 4.4322 Ω/km and an AC resistance (RAC) of 4.4153 Ω/km, whereas the conventional conductor exhibits higher values (RDC 4.7279 Ω/km, RAC 4.7099 Ω/km). After anodization, the novel conductor exhibits even lower resistance and reduced resistive losses, demonstrating superior electrical performance. According to the literature [105,106,107,108,109], anodization technology can modify the microstructure of aluminum surfaces, thereby influencing their emissivity and reflectivity. Consequently, anodization is considered a potential technique for fabricating novel capacity-uprating conductors.

Figure 6.

Surface micro-morphology and current-dependent temperature rise profile: (a,b) bare conductor, (c,d) novel conductor, (e) temperature rises of bare and novel conductors under the applied current, adapted from [108].

In addition to the influence of porous structures on the emissivity and reflectivity of aluminum surfaces, the optical properties of aluminum can be further enhanced through methods such as incorporating nanoparticles or altering surface molecular morphology. Lee Dasol et al. [110] employed atomic vapor deposition to coat a porous anodic aluminum oxide (AAO) structure with SiO2, achieving a daytime radiative cooling material that simultaneously exhibits high solar reflectance (0.86) and atmospheric window emissivity (0.96). This resulted in a daytime temperature reduction of 6.1 °C with an average cooling flux of 65.6 W/m2.

The precise control of porous structural parameters and the underlying mechanisms by which surface modification technologies influence the solar heat absorption and radiative heat dissipation of aluminum conductors remain insufficiently studied. Furthermore, the mechanical and electrical properties of capacity-enhanced conductors manufactured using these techniques require further investigation.

4. Evaluation of Application Potential for Capacity-Uprating Conductors

With the advancement of technology, power grids worldwide are facing substantial capacity expansion demands. As one of the most promising solutions for enhancing transmission capacity and efficiency, HTLS conductors have undergone extensive evaluation of their capacity-uprating effects by numerous researchers. This section details the applications of these capacity-uprating conductors.

4.1. Potential Application Scenarios of Different Technologies

The operational conditions of overhead transmission lines exhibit significant diversity, necessitating the formulation of appropriate capacity-uprating strategies tailored to specific working environments. In regions with particularly complex environments, the combined application of multiple technologies may even be required. Table 4 systematically categorizes and correlates three major technological directions—structural optimization, materials engineering, and passive radiative cooling—with the primary industrial application scenarios they address, such as urban line upgrades, long-span crossings, coastal corrosive environments, and hot climates.

Table 4.

Selection criteria and core advantages of different capacity-uprating conductor technologies in typical application scenarios.

4.2. Application Potential for HTLS Conductors

HTLS conductors encompass various types with distinct performance characteristics, cost considerations, and application requirements. For these conductors which with comparable weight to conventional ones, capacity-uprating retrofits of existing transmission lines can be implemented through replacement of associated fittings. However, heavier HTLS conductors necessitate comprehensive infrastructure upgrades, including tower reinforcement, before deployment. Despite several decades of development history, HTLS conductors still maintain relatively limited application scales.

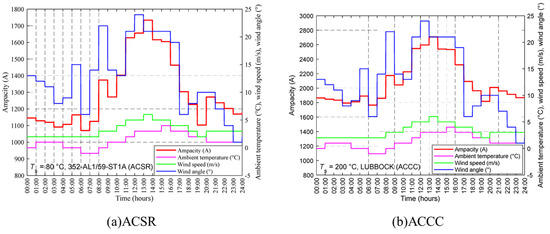

As documented in Reference [32], five distinct HTLS conductor types were implemented on 230 kV overhead transmission lines (single/double bundle, 11 km length) to evaluate their capacity-uprating effectiveness and comprehensive performance. The results demonstrate that all HTLS conductors achieved current-carrying capacities exceeding 1.5 times that of conventional ACSR conductors, with ACCR, GZTACSR and ZTACIR reaching over twice the ampacity. The ZTACIR conductor exhibited optimal overall performance, maintaining transient stability parameters (power angle 70–80°) comparable to ACSR while enabling operation at 175 °C with a 9.5% right-of-way reduction. In contrast, while ACCR achieved a 14.7% right-of-way reduction, its maximum operating temperature only reached 134 °C. S. Beryozkina et al. [62] evaluated the feasibility of replacing ACSR conductors with ACCC and ACCR conductors for constructing 110kV transmission lines in Latvia’s Kurzeme Ring network. The results indicate that ACCR demonstrates superior performance at elevated temperatures, but conductors with equivalent cross-sectional areas incur higher costs. For lines with initial temperatures around 150 °C, ACCCs reduce costs by 4.4% compared to ACCR in new line construction, while achieving 24.6% cost savings in line retrofits. F. Margita et al. [111] examined the application potential of ACCCs in Slovakia, demonstrating a maximum permissible operating temperature of 200 °C with current-carrying capacity enhancements ranging from 78% to 120%. Figure 7 presents the 24 h current-carrying capacity profiles comparing ACSR and ACCCs. Furthermore, carbon fiber composite core conductors exhibit 10% weight reduction relative to ACSR, enabling cost savings in tower retrofitting while reducing long-term operational expenditures. The composition of HTLS conductors differs from that of ACSR conductors, resulting in variations in weight per unit length. C. O. Ujah et al. [44] conducted a comparative analysis of the density among several common HTLS conductors. The results demonstrate that ACCC and ACCR conductors are lighter than ACSR, while ACSS and GTACSR conductors exhibit comparable weight to ACSR. In contrast, ZTACIR conductors are heavier than conventional ACSR conductors. Lighter conductors are more advantageous for retrofitting existing transmission lines, whereas heavier conductors require additional tower reinforcement, leading to greater capital investment. HTLS conductors provide an effective solution for enhancing power grid transmission efficiency, as demonstrated by in-depth research conducted by scholars worldwide (see Table 5). The strategic selection of appropriate HTLS conductor types based on specific service conditions and voltage levels can significantly improve grid transmission performance.

Figure 7.

The 24 h ampacity variation curves of ACSR conductors and ACCR conductors, adapted from [111].

Table 5.

Applications of various HTLS conductors across different countries and voltage levels.

5. Future Work of Capacity-Uprating Conductor

Although capacity-uprating conductor technologies (including HTLS conductors and AAO) have demonstrated their effectiveness in increasing current-carrying capacity and enhancing power grid transmission efficiency, along with achieving small-scale demonstration applications, their large-scale deployment for grid upgrades still faces numerous challenges. For current capacity-uprating conductor technologies, several critical application pain points remain to be resolved.

5.1. HTLS Conductor

The manufacturing technology of HTLS conductors still requires improvement, particularly regarding limitations in aluminum alloy processing. The incorporation of alloying elements exerts significant influences on both the mechanical properties and electrical conductivity of aluminum alloys. Xu’s research demonstrated that Fe and Si elements significantly reduce conductor conductivity, whereas V and Ti additions enhance it [115]. Furthermore, impurities may induce surface notches and serve as primary causes of treeing defects [44,116]. Consequently, the development of advanced aluminum alloys or alternative conductive materials with superior performance remains a critical research direction for the future evolution of HTLS conductors.

Given the limited deployment scale and short service duration of HTLS conductors, their long-term operational lifespan under actual working conditions cannot be reliably assessed or predicted. This necessitates establishing a comprehensive and effective lifespan evaluation system [117]. Furthermore, the applicable scope of different HTLS conductor types requires additional verification. For instance, ACCC and ACSS conductors exhibit greater sag than ACSR conductors under identical ice loading conditions, rendering them unsuitable for heavy ice accumulation areas [44].

HTLS conductors typically incur higher costs than conventional ACSR conductors. Some types of HTLS also exhibit greater weight, potentially requiring tower reinforcement or additional tower installations [62,118]. Moreover, their elevated operating temperatures necessitate replacement of associated fittings with high-temperature resistant components, further increasing implementation costs [9].

5.2. Radiative Cooling Technology

The key aspect of radiative cooling technology lies in modifying the emissivity and solar reflectance of transmission conductor surfaces through surface treatment techniques (anodization, chemical grafting, etc.). Current research on applying this technology to capacity-uprating transmission lines remains limited. Most reported radiative cooling coatings consist of organic materials with low thermal conductivity [119,120]. Unlike building cooling applications, the primary heat source in conductors originates from Joule heating induced by electric current, thus the effectiveness of radiative cooling coatings for capacity-uprating conductors requires further validation. In addition to radiative heat dissipation, thermal conduction and convective heat transfer constitute significant components of conductor thermal losses. Therefore, comprehensive thermal management strategies must account for all three heat transfer mechanisms. Moreover, the service life of coatings—encompassing durability, adhesion strength, and related properties—represents another critical factor influencing their practical application.

Regarding anodization technology, although previous studies have demonstrated its capability to regulate aluminum surface emissivity and reflectivity [105,107,109] with observable capacity-uprating effects, its application to transmission conductors still warrants in-depth investigation. Achieving precise control over the nanostructure of porous oxide layers (e.g., pore size, porosity) to maximize infrared emissivity with spectral selectivity (high infrared emission, low solar absorption) while maintaining excellent mechanical properties and adhesion strength represents a critical research challenge for applying this technology to capacity-uprating conductors. Furthermore, the operational environment of transmission conductors imposes additional functional requirements on these coatings.

In summary, the ideal heat-dissipating coating for future transmission conductors will be an intelligent material integrating highly efficient selective radiative cooling, superior weather resistance, and self-cleaning/self-healing functionalities. Such coatings should be producible through economically viable processes to enable large-scale deployment, thereby providing critical material support for building safer, more efficient, and smarter power grids.

6. Conclusions

In recent years, although capacity-uprating conductor technology has made significant progress—effectively enhancing transmission efficiency and capacity while achieving small-scale applications—traditional ACSR conductors remain the most widely used transmission conductors in power grid systems worldwide.

To improve conductor ampacity, the primary strategies for developing capacity-uprating conductors include replacing materials with superior mechanical properties at high temperatures (HTLS conductors) and modifying conductor structures (HTLS/TW conductors). With advancements in materials science—such as the development of alloys with enhanced comprehensive properties (e.g., conductivity and mechanical strength) with higher critical temperatures (Tc) and lower losses—HTLS conductors are expected to become more effective solutions for increasing transmission line ampacity. It is noteworthy that with advancements in conductor temperature monitoring and failure prediction technologies, the integration of advanced conductor technologies (providing hardware foundations) with sophisticated monitoring and prediction systems (delivering operational intelligence) represents an inevitable pathway toward maximizing utilization rates and ensuring the highest reliability of transmission lines in the future.

However, current capacity-uprating conductor technologies are constrained by capital investment limitations, making large-scale deployment across entire power grids challenging. Achieving the capacity expansion of existing transmission lines with lower financial input remains a priority for power grid operators worldwide. Passive radiative cooling technology has emerged as a promising approach for novel transmission conductors due to its energy-free operation, as well as anodization demonstrating proven capacity-uprating effects. Future research should prioritize anodized capacity-uprating conductors, as this technology may serve as the most viable transitional measure for grid-wide upgrades from ACSR to HTLS. Furthermore, the potential application of this technique to HTLS conductors for enhanced radiative cooling performance warrants systematic investigation.

This review aims to contribute to the development of modern power grid transmission systems by providing a systematic framework that bridges materials science, electrical engineering, and thermal management. Unlike incremental technical summaries, our work synthesizes disparate research threads into a coherent ‘constraint–mechanism–solution’ paradigm. We have critically evaluated advancements not in isolation, but through the lens of overcoming the primary barriers to large-scale deployment—namely, high line losses and cost. By elucidating the interplays between structural optimization, material engineering, and passive cooling, this study offers a foundational guide for the synergistic design of next-generation capacity-uprating Conductors. It is anticipated that the insights and future directions discussed will directly inform utility planning, conductor selection, and R&D strategies, facilitating a more efficient, economical, and reliable pathway for grid capacity expansion.

Author Contributions

Conceptualization, B.L. and Y.Y.; validation, R.G., Y.Y. and J.H.; formal analysis, B.L., Q.H. and R.G.; investigation, Z.F., J.H. and T.Z.; resources, B.L. and Y.Y.; data curation, X.H.; writing—original draft preparation, B.L. and Q.H.; writing—review and editing, B.L. and Y.Y.; supervision, Y.Y.; project administration, Y.Y. and X.H.; funding acquisition, B.L. and Y.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Electric Power Research Institute of Guizhou Power Grid Co., Ltd., China. Contract number 0666002024030103HX00003.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw/processed data required to reproduce these findings cannot be shared at this time due to legal or ethical reasons.

Conflicts of Interest

Authors Bo Li, Quan Hu and Ruyue Guo were employed by Institute of Electric Power Science of Guizhou Power Grid Co., Ltd. Author Jin Hu was employed by Anshun Power Supply Bureau of Guizhou Power Grid Co., Ltd. Author Zhouzhuang Fen was employed by Liupanshui Power Supply Bureau, Guizhou Power Grid Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. And the authors declare that this study received funding from Electric Power Research Institute of Guizhou Power Grid Co., Ltd. The funder was not involved in the study design, collection, analysis, interpretation of data, the writing of this article or the decision to submit it for publication.

References

- Parvizi, P.; Jalilian, M.; Dearn, K.D. Beyond traditional conductors: Aluminium conductor composite core’s role in next-generation high temperature-low sag technologies–A review. Electr. Power Syst. Res. 2025, 239, 111251. [Google Scholar] [CrossRef]

- Ujah, C.O.; Kallon, D.V.V.; Aikhuele, D.O.; Aigbodion, V.S. Advanced composite materials: A panacea for improved electricity transmission. Appl. Sci. 2022, 12, 8291. [Google Scholar] [CrossRef]

- Karimi, S.; Musilek, P.; Knight, A.M. Dynamic thermal rating of transmission lines: A review. Renew. Sustain. Energy Rev. 2018, 91, 600–612. [Google Scholar] [CrossRef]

- Sergio, M.-S.; Andrea, M. Assessment of the influence of climate change on power grid transmission capacity. Sustain. Energy Grids Netw. 2025, 42, 101695. [Google Scholar] [CrossRef]

- Shu, Y.; Chen, W. Research and application of UHV power transmission in China. High Volt. 2018, 3, 1–13. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, X.L. Extreme weather loading risk model of overhead transmission line. Adv. Mater. Res. 2012, 383, 2005–2011. [Google Scholar] [CrossRef]

- Sahin, B.; Hasenbein, J.; Kutanoglu, E. Value of considering extreme weather resilience in grid capacity expansion planning. Reliab. Eng. Syst. Saf. 2025, 259, 110892. [Google Scholar] [CrossRef]

- Kgoete, F.M.; Uyor, U.O.; Popoola, A.P.; Popoola, O. Insight on the recent materials advances for manufacturing of high-voltage transmission conductors. Int. J. Adv. Manuf. Technol. 2024, 130, 4123–4136. [Google Scholar] [CrossRef]

- Reddy, B.S.; Mitra, G. Investigations on High Temperature Low Sag (HTLS) Conductors. IEEE Trans. Power Deliv. 2020, 35, 1716–1724. [Google Scholar] [CrossRef]

- Shokri, M.S.M.; Kasran, F.A.M.; Aziz, M.H.A.; Miswan, N.S.; Noran, M.N.; Rahim, A.A. Dynamic line rating (DLR) by weather-based calculation for power grid optimization in Tenaga Nasional Berhad (TNB). In Proceedings of the 2020 IEEE 17th International Conference on Smart Communities: Improving Quality of Life Using ICT, IoT and AI (HONET), Charlotte, NC, USA, 14–16 December 2020; IEEE: New York, NY, USA. [Google Scholar]

- Xia, Z.; Xia, Y.; Xu, Z.; Wu, J. Study on the calculation model of maximum allowable time and ampacity for overload operation of overhead transmission line in a short time. In Proceedings of the 2015 5th International Conference on Electric Utility Deregulation and Restructuring and Power Technologies (DRPT), Changsha, China, 26–29 November 2015; IEEE: New York, NY, USA. [Google Scholar]

- Xing, L.; Weidong, L.; Yuan, X.; Weijiang, C.; Jiangang, B. Surface charge accumulation and pre-flashover characteristics induced by metal particles on the insulator surfaces of 1100 kV GILs under AC voltage. High Volt. 2020, 5, 134–142. [Google Scholar] [CrossRef]

- Ou, Y.; Singh, C. Improvement of total transfer capability using TCSC and SVC. In Proceedings of the 2001 Power Engineering Society Summer Meeting. Conference Proceedings (Cat. No. 01CH37262), Vancouver, BC, Canada, 15–19 July 2001; IEEE: New York, NY, USA. [Google Scholar]

- Taha, R.; Saoudi, Y.; Chrifi-Alaoui, L.; Errachdi, A. Performance enhancement of smart grid using an optimal placement of facts: Case of TCSC. Przegląd Elektrotechniczny 2024, 1, 281–287. [Google Scholar]

- Li, Q.; Li, Y.; Rowland, S.; Hu, J.; Cotton, I.; Jiang, X. Audible noise evaluation for six-phase overhead lines transformed from existing three-phase double circuit infrastructures with uprated voltages. High Volt. 2022, 7, 866–876. [Google Scholar] [CrossRef]

- Zhang, D.G.; Wang, L.H.; Liu, J.; Ren, Y.N.; Gao, F.; Shen, X.L. Research on general design and application of double-circuit t-connection tower in 110kv. J. Phys. Conf. Ser. 2020, 1634, 012169. [Google Scholar] [CrossRef]

- Riba, J.-R.; Bogarra, S.; Gómez-Pau, Á.; Moreno-Eguilaz, M. Uprating of transmission lines by means of HTLS conductors for a sustainable growth: Challenges, opportunities, and research needs. Renew. Sustain. Energy Rev. 2020, 134, 110334. [Google Scholar] [CrossRef]

- Chen, S.L.; Black, W.Z.; Loard, H.W. High-temperature ampacity model for overhead conductors. IEEE Trans. Power Deliv. 2002, 17, 1136–1141. [Google Scholar] [CrossRef]

- Davis, M.W. A new thermal rating approach: The real time thermal rating system for strategic overhead conductor transmission lines—Part I: General description and justification of the real time thermal rating system. IEEE Trans. Power Appar. Syst. 1977, 96, 803–809. [Google Scholar] [CrossRef]

- Steeley, W.; Norris, B.; Deb, A. Ambient temperature corrected dynamic transmission line ratings at two PG&E locations. IEEE Trans. Power Deliv. 2002, 6, 1234–1242. [Google Scholar]

- Swain, A.; Abdellatif, E.; Mousa, A.; Pong, P.W. Sensor technologies for transmission and distribution systems: A review of the latest developments. Energies 2022, 15, 7339. [Google Scholar] [CrossRef]

- Li, J.; Lin, J.; Han, Y.; Zhu, L.; Chang, D.; Shao, C. Overload Risk Assessment of Transmission Lines Considering Dynamic Line Rating. Energies 2025, 18, 1822. [Google Scholar] [CrossRef]

- Adapa, R.; Douglass, D.A. Dynamic thermal ratings: Monitors and calculation methods. In Proceedings of the 2005 IEEE Power Engineering Society Inaugural Conference and Exposition in Africa, Durban, South Africa, 11–15 July 2005; IEEE: New York, NY, USA. [Google Scholar]

- Wang, S.; Hu, H.; Li, L.; Wang, Y.; Ning, N. Dynamic Capacity Increasing Method For Transmission Lines. In Proceedings of the 2023 IEEE World Conference on Applied Intelligence and Computing (AIC), Sonbhadra, India, 29–30 July 2023; IEEE: New York, NY, USA. [Google Scholar]

- Dabbaghjamanesh, M.; Kavousi-Fard, A.; Mehraeen, S. Effective Scheduling of Reconfigurable Microgrids With Dynamic Thermal Line Rating. IEEE Trans. Ind. Electron. 2019, 66, 1552–1564. [Google Scholar] [CrossRef]

- Rácz, L.; Németh, B. A Novel Concept of Dynamic Line Rating Systems Based on Soft Computing Models. In Proceedings of the 2022 10th International Conference on Smart Grid (icSmartGrid), Istanbul, Turkey, 27–29 June 2022; IEEE: New York, NY, USA. [Google Scholar]

- Dupin, R.; Kariniotakis, G.; Michiorri, A. Overhead lines Dynamic Line rating based on probabilistic day-ahead forecasting and risk assessment. Int. J. Electr. Power Energy Syst. 2019, 110, 565–578. [Google Scholar] [CrossRef]

- Albizu, I.; Fernández, E.; Mazón, A.J.; Bengoechea, J. Influence of the conductor temperature error on the overhead line ampacity monitoring systems. IET Gener. Transm. Distrib. 2011, 5, 440–447. [Google Scholar] [CrossRef]

- Michiorri, A.; Nguyen, H.-M.; Alessandrini, S.; Bremnes, J.B.; Dierer, S.; Ferrero, E.; Nygaard, B.-E.; Pinson, P.; Thomaidis, N.; Uski, S. Forecasting for dynamic line rating. Renew. Sustain. Energy Rev. 2015, 52, 1713–1730. [Google Scholar] [CrossRef]

- Hou, Y.; Wang, W.; Wei, Z.; Deng, X.; Ji, Q.; Wang, T.; Ru, X. Research and application of dynamic line rating technology. Energy Rep. 2020, 6, 716–730. [Google Scholar] [CrossRef]

- Zainuddin, N.M.; Rahman, M.S.A.; Kadir, M.Z.A.A.; Ali, N.H.N.; Ali, Z.; Osman, M.; Mansor, M.; Ariffin, A.M.; Rahman, M.S.A.; Nor, S.F.M.; et al. Review of Thermal Stress and Condition Monitoring Technologies for Overhead Transmission Lines: Issues and Challenges. IEEE Access 2020, 8, 120053–120081. [Google Scholar] [CrossRef]

- Nuchprayoon, S.; Chaichana, A. Performance Comparison of Using ACSR and HTLS Conductors for Current Uprating of 230-kV Overhead Transmission Lines. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018; IEEE: New York, NY, USA. [Google Scholar]

- Kumar, P.; Singh, A.K. Optimal mechanical sag estimator for leveled span overhead transmission line conductor. Measurement 2019, 137, 691–699. [Google Scholar] [CrossRef]

- Qiao, X.; Zhu, Z.; Zhang, D.; Zhang, J.; Cheng, Y.; Wang, Y.; Zeng, W. Research on Dynamic Current Carrying Capacity Calculation Model Based on Conductor Sag Correction. IEEE Trans. Power Deliv. 2025, 40, 1656–1666. [Google Scholar] [CrossRef]

- Abboud, A.W.; Gentle, J.P.; McJunkin, T.R.; Lehmer, J.P. Using Computational Fluid Dynamics of Wind Simulations Coupled With Weather Data to Calculate Dynamic Line Ratings. IEEE Trans. Power Deliv. 2020, 35, 745–753. [Google Scholar] [CrossRef]

- Castro, P.; Lecuna, R.; Manana, M.; Martin, M.J.; del Campo, D. Infrared temperature measurement sensors of overhead power conductors. Sensors 2020, 20, 7126. [Google Scholar] [CrossRef]

- Kampik, M.; Kubek, P.; Krupanek, B.; Bogacz, R. Sag and Tension Calculations for High-Voltage Overhead Line Conductors. Energies 2024, 17, 2967. [Google Scholar] [CrossRef]

- Rashmi; Shivashankar, G.S.; Poornima. Overview of different overhead transmission line conductors. Mater. Today Proc. 2017, 4, 11318–11324. [Google Scholar] [CrossRef]

- Abas, N.H.; Kadir, M.Z.A.A.; Azis, N.; Jasnil, J.; Aziz, N.F.A.; Khurshid, Z.M. Optimizing Grid With Dynamic Line Rating of Conductors: A Comprehensive Review. IEEE Access 2024, 12, 9738–9756. [Google Scholar] [CrossRef]

- Maksić, M.; Djurica, V.; Souvent, A.; Slak, J.; Depolli, M.; Kosec, G. Cooling of overhead power lines due to the natural convection. Int. J. Electr. Power Energy Syst. 2019, 113, 333–343. [Google Scholar] [CrossRef]

- Dzobo, O.; Tazvinga, H. Impact of Weather Conditions on Line Ampacity of Overhead Transmission Lines. In Proceedings of the 2019 9th International Conference on Power and Energy Systems (ICPES), Perth, WA, Australia, 10–12 December 2019; IEEE: New York, NY, USA. [Google Scholar]

- Vejo Fernández, L.; Castro, P.B.A.; Canteli, M.M.; Pérez, A.L.; Tolosa, R.L.; Sánchez, S.B.; Ortiz, E.S. Experimental study of dynamic line rating applied to high-temperature low-sag conductors. Energies 2025, 18, 929. [Google Scholar] [CrossRef]

- Jalilian, M.; Riba, J.-R.; Parvizi, P. Aluminum conductor steel-supported conductors for the sustainable growth of power line capacity: A review and discussion. Materials 2024, 17, 4536. [Google Scholar] [CrossRef] [PubMed]

- Ujah, C.O.; Popoola, A.P.I.; Popoola, O.M. Review on materials applied in electric transmission conductors. J. Mater. Sci. 2022, 57, 1581–1598. [Google Scholar] [CrossRef]

- Hu, X.; Wang, C.; Ma, G.; He, K. Effect of Er on Microstructure, Electrical Conductivity, Mechanical Properties, and Corrosion Resistance of an Al-Zr Alloy. J. Mater. Eng. Perform. 2025, 34, 6026–6034. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, H.; Yi, D.; Wang, B.; Wang, H. Comparative study of Sc and Er addition on microstructure, mechanical properties, and electrical conductivity of Al-0.2Zr-based alloy cables. Mater. Charact. 2018, 145, 126–134. [Google Scholar] [CrossRef]

- Zhang, Y.-Z.; Jun, W. Effects of Y addition on microstructure and properties of Al-Zr alloys. Trans. Nonferrous Met. Soc. China 2014, 24, 2239–2243. [Google Scholar] [CrossRef]

- Kong, Y.; Jia, Z.; Liu, Z.; Liu, M.; Roven, H.J.; Liu, Q. Effect of Zr and Er on the microstructure, mechanical and electrical properties of Al-0.4Fe alloy. J. Alloy. Compd. 2021, 857, 157611. [Google Scholar] [CrossRef]

- Choi, Y.; Hong, S.I. Mechanical and Electrical Properties of Al–Fe–Cr and Al–Fe–Zr Alloys. Sci. Adv. Mater. 2018, 10, 480–483. [Google Scholar] [CrossRef]

- Li, S.; Jiang, H.; Li, Y.; Zhang, L.; Sun, H.; He, J.; Jiang, H.; Zhao, J. Influence of rare earth cerium on the microstructures and performances of Al-Fe alloy. Sci. China Technol. Sci. 2023, 66, 3317–3327. [Google Scholar] [CrossRef]

- Xu, H.-Y.; Jia, H.-F.; Ji, Z.-S.; Li, M.-L.; Yu, H.; Jiang, B.; Wang, Y.; Hu, M.-L. Effect of La content on microstructure, tensile properties, and electrical conductivity of cast Al-Mg-Si-xLa alloys. China Foundry 2025, 22, 385–394. [Google Scholar] [CrossRef]

- Yuan, W.; Liang, Z. Effect of Zr addition on properties of Al–Mg–Si aluminum alloy used for all aluminum alloy conductor. Mater. Des. 2011, 32, 4195–4200. [Google Scholar] [CrossRef]

- Shao, Q.; Elgallad, E.; Maltais, A.; Chen, X.G. Developing Al-Zr-Sc Alloys as High-Temperature-Resistant Conductors for Electric Overhead Line Applications. In Light Metals 2023; Springer Nature: Cham, Switzerland, 2023. [Google Scholar]

- Alvarez-Antolin, F.; Amghouz, Z.; Cofiño-Villar, A.; Gonzalez-Pociño, A.; Melero, M.G. Decrease in Electrical Resistivity below 28 nΩm by Aging in Hyperperitectic Al-Zr Alloys Treated at High Temperatures. Metals 2021, 11, 1171. [Google Scholar] [CrossRef]

- Zhang, J.; Peng, J. A review on aluminum alloy conductors influenced by alloying elements and thermomechanical treatments: Microstructure and properties. J. Mater. Res. 2023, 38, 1488–1509. [Google Scholar] [CrossRef]