Low-Damage and Self-Limiting (Al)GaN Etching Process through Atomic Layer Etching Using O2 and BCl3 Plasma

Abstract

1. Introduction

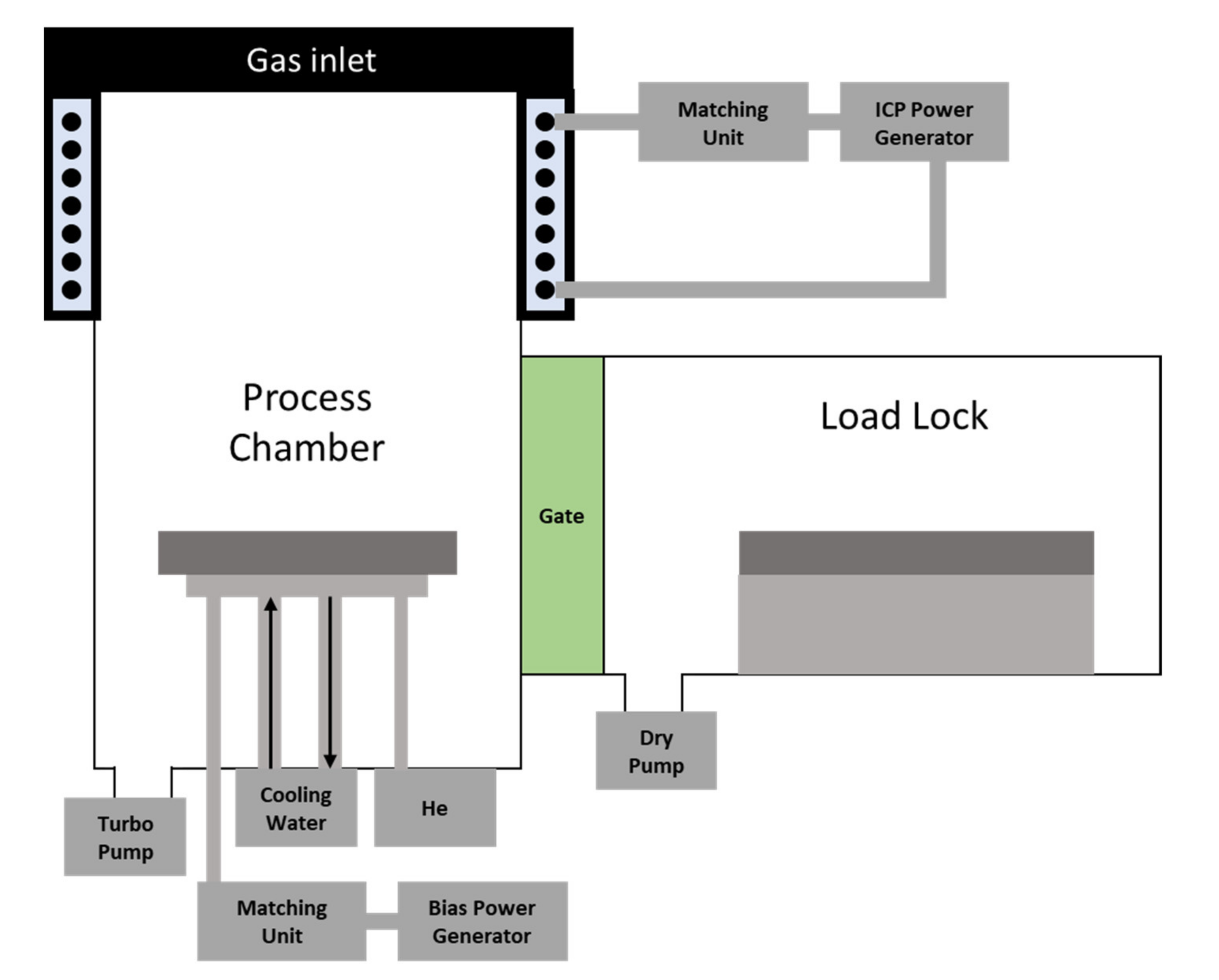

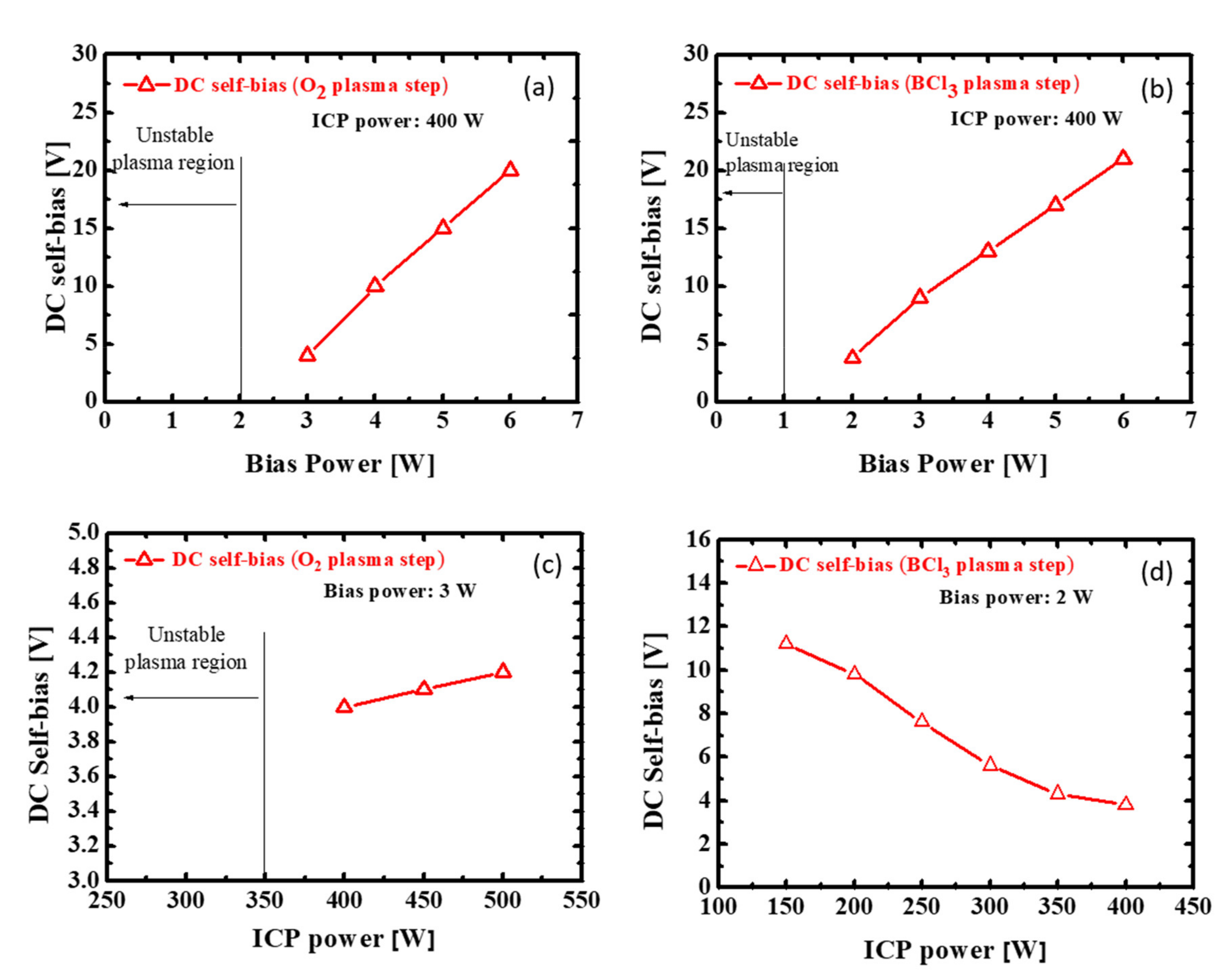

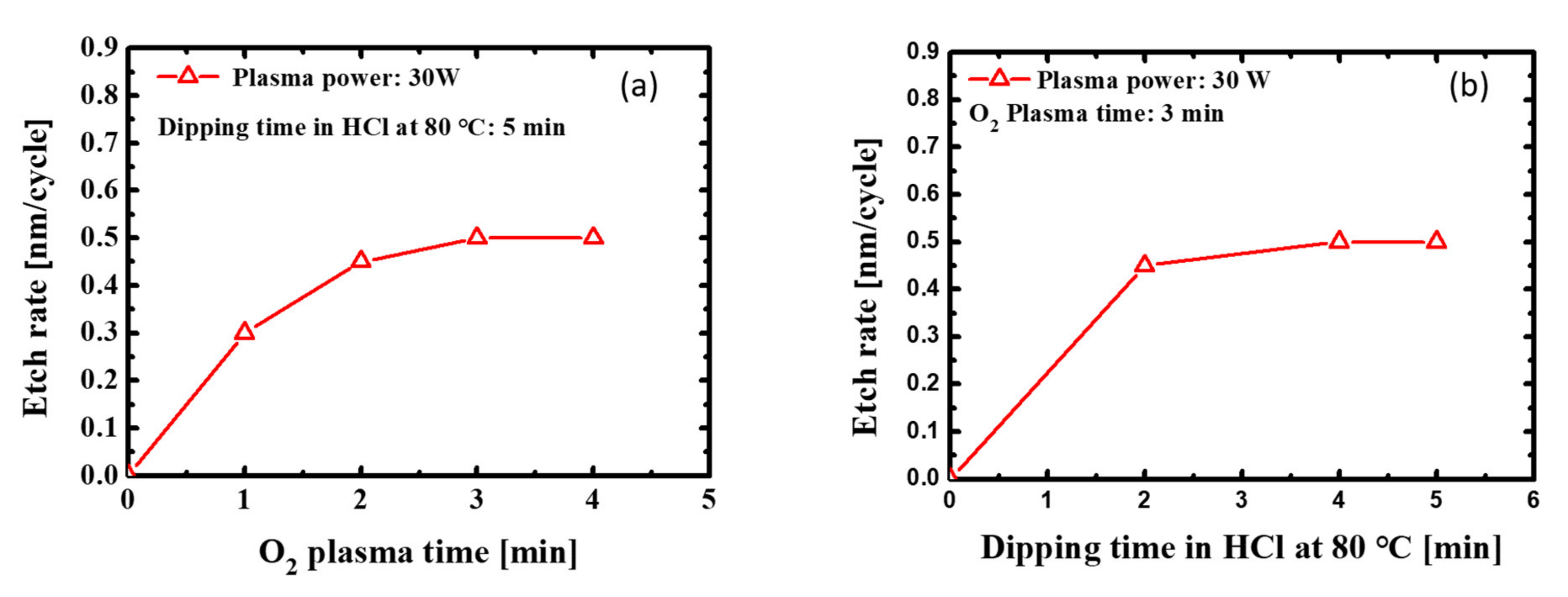

2. Experiments

2.1. ALE Process

2.2. Digital Etching Process

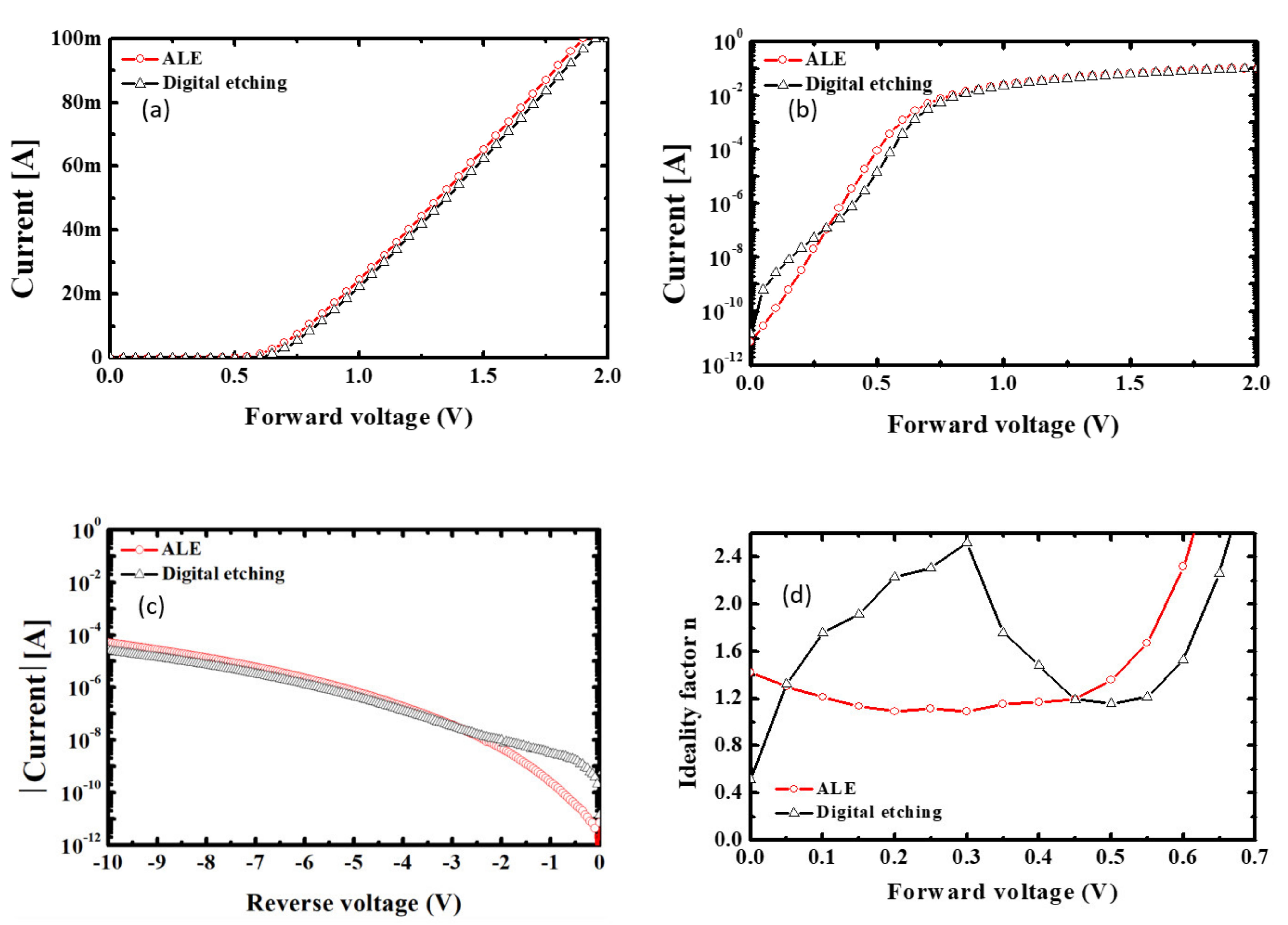

2.3. Etching Damage Evaluation

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chowdhury, S.; Stum, Z.; Li, Z.D.; Ueno, K.; Chow, T.P. Comparison of 600V Si, SiC and GaN power devices. Mater. Sci. Forum 2014, 971–974. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, C.; Zheng, X.; Ma, X.; He, Y.; Liu, K.; Li, A.; Peng, Y.; Zhang, C.; Hao, Y. Effects of recess depths on performance of AlGaN/GaN power MIS-HEMTs on the Si substrates and threshold voltage model of different recess depths for the using HfO2 gate insulator. Solid. State. Electron. 2020, 163, 107649. [Google Scholar] [CrossRef]

- Huang, S.; Jiang, Q.; Wei, K.; Liu, G.; Zhang, J.; Wang, X.; Zheng, Y.; Sun, B.; Zhao, C.; Liu, H.; et al. High-temperature low-damage gate recess technique and ozone-assisted ALD-grown Al2O3 gate dielectric for high-performance normally-off GaN MIS-HEMTs. In Proceedings of the 2014 IEEE International Electron Devices Meeting, San Francisco, CA, USA, 15–17 December 2014; pp. 17.4.1–17.4.4. [Google Scholar] [CrossRef]

- He, Y.; Gao, H.; Wang, C.; Zhao, Y.; Lu, X.; Zhang, C.; Zheng, X.; Guo, L.; Ma, X.; Hao, Y. Comparative Study Between Partially and Fully Recessed-Gate Enhancement-Mode AlGaN/GaN MIS HEMT on the Breakdown Mechanism. Phys. Status Solidi Appl. Mater. Sci. 2019, 216, 1–6. [Google Scholar] [CrossRef]

- Park, Y.; Kim, J.J.; Chang, W.; Jang, H.G.; Na, J.; Lee, H.; Jun, C.H.; Cha, H.Y.; Mun, J.K.; Ko, S.C.; et al. Low onset voltage of GaN on Si Schottky barrier diode using various recess depths. Electron. Lett. 2014, 50, 1164–1165. [Google Scholar] [CrossRef]

- Xu, R.; Chen, P.; Liu, M.; Zhou, J.; Yang, Y.; Li, Y.; Ge, C.; Peng, H. 2.5-kV AlGaN/GaN Schottky Barrier Diode on Silicon Substrate with Recessed-anode Structure. IEEE Electron Device Lett. 2021, 42, 208–211. [Google Scholar] [CrossRef]

- Hu, J.; Stoffels, S.; Lenci, S.; De Jaeger, B.; Ronchi, N.; Tallarico, A.N.; Wellekens, D.; You, S.; Bakeroot, B.; Groeseneken, G.; et al. Statistical Analysis of the Impact of Anode Recess on the Electrical Characteristics of AlGaN/GaN Schottky Diodes with Gated Edge Termination. IEEE Trans. Electron Devices 2016, 63, 3451–3458. [Google Scholar] [CrossRef]

- Chen, J.Y.; Pan, C.J.; Chi, G.C. Electrical and optical changes in the near surface of reactively ion etched n-GaN. Solid State Electron. 1999, 43, 649–652. [Google Scholar] [CrossRef]

- Shah, A.P.; Azizur Rahman, A.; Bhattacharya, A. Temperature-dependence of Cl 2/Ar ICP-RIE of polar, semipolar, and nonpolar GaN and AlN following BCl 3 /Ar breakthrough plasma. J. Vac. Sci. Technol. A 2020, 38, 013001. [Google Scholar] [CrossRef]

- Lee, C.; Lu, W.; Piner, E.; Adesida, I. DC and microwave performance of recessed-gate GaN MESFETs using ICP-RIE. Solid State Electron. 2002, 46, 743–746. [Google Scholar] [CrossRef]

- Harrison, S.E.; Voss, L.F.; Torres, A.M.; Frye, C.D.; Shao, Q.; Nikoli, R.J. Ultradeep electron cyclotron resonance plasma etching of GaN. J. Vac. Sci. Technol. A Vac. Surf. Film. 2017, 35, 061303. [Google Scholar] [CrossRef]

- Buttari, D.; Heikman, S.; Keller, S.; Mishra, U.K. Digital Etching for Highly Reproducible Low Damage Gate Recessing on AlGaN/GaN HEMTs. In Proceedings of the IEEE Lester Eastman Conference on High Performance Devices, Newark, DE, USA, 8 August 2002. [Google Scholar] [CrossRef]

- Fukumizu, H.; Sekine, M.; Hori, M.; Kanomaru, K.; Kikuchi, T. Atomic layer etching of AlGaN using Cl2 and Ar gas chemistry and UV damage evaluation. J. Vac. Sci. Technol. A 2019, 37, 021002. [Google Scholar] [CrossRef]

- Ohba, T.; Yang, W.; Tan, S.; Kanarik, K.J.; Nojiri, K. Atomic layer etching of GaN and AlGaN using directional plasma-enhanced approach. Jpn. J. Appl. Phys. 2017, 56. [Google Scholar] [CrossRef]

- Burnham, S.D.; Boutros, K.; Hashimoto, P.; Butler, C.; Wong, D.W.S.; Hu, M.; Micovic, M. Gate-recessed normally-off GaN-on-Si HEMT using a new O2- BCl3 digital etching technique. Phys. Status Solidi Curr. Top. Solid State Phys. 2010, 7, 2010–2012. [Google Scholar] [CrossRef]

- Hu, Q.; Li, S.; Li, T.; Wang, X.; Li, X.; Wu, Y. Channel engineering of normally-OFF AlGaN/GaN MOS-HEMTs by atomic layer etching and high-κDielectric. IEEE Electron Device Lett. 2018, 39, 1377–1380. [Google Scholar] [CrossRef]

- Kim, H.K.; Lin, H.; Ra, Y. Etching mechanism of a GaN/InGaN/GaN heterostructure in Cl2- and CH4-based inductively coupled plasmas. J. Vac. Sci. Technol. A Vac. Surf. Film. 2004, 22, 598. [Google Scholar] [CrossRef]

- Selvanathan, D.; Mohammed, F.M.; Bae, J.-O.; Adesida, I.; Bogart, K.H.A. Investigation of surface treatment schemes on n-type GaN and Al0.20Ga0.80N. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 2005, 23, 2538. [Google Scholar] [CrossRef]

- Sohal, R.; Dudek, P.; Hilt, O. Comparative study of NH4OH and HCl etching behaviours on AlGaN surfaces. Appl. Surf. Sci. 2010, 256, 2210–2214. [Google Scholar] [CrossRef]

- Maffeis, T.G.G.; Simmonds, M.C.; Clark, S.A.; Peiro, F.; Haines, P.; Parbrook, P.J. Influence of premetallization surface treatment on the formation of Schottky Au-nGaN contacts. J. Appl. Phys. 2002, 92, 3179–3186. [Google Scholar] [CrossRef]

- Abdalla, S.; Marzouki, F.; Al-ameer, S.; Turkestani, S. Electric Properties of n-GaN: Effect of Different Contacts on the Electronic Conduction. Int. J. Phys. 2013, 1, 41–48. [Google Scholar] [CrossRef]

- Diale, M.; Auret, F.D. Effects of chemical treatment on barrier height and ideality factors of Au/GaN Schottky diodes. Phys. B Condens. Matter 2009, 404, 4415–4418. [Google Scholar] [CrossRef]

- Kane, S.N.; Mishra, A.; Dutta, A.K. Preface: International Conference on Recent Trends in Physics (ICRTP 2016). J. Phys. Conf. Ser. 2016, 755. [Google Scholar] [CrossRef]

- Qiu, R.; Lu, H.; Chen, D.; Zhang, R.; Zheng, Y. Optimization of inductively coupled plasma deep etching of GaN and etching damage analysis. Appl. Surf. Sci. 2011, 257, 2700–2706. [Google Scholar] [CrossRef]

- Chen, Z.Z.; Qin, Z.X.; Tong, Y.Z.; Ding, X.M.; Hu, X.D.; Yu, T.J.; Yang, Z.J.; Zhang, G.Y. Etching damage and its recovery in n-GaN by reactive ion etching. Phys. B Condens. Matter 2003, 334, 188–192. [Google Scholar] [CrossRef]

- Nakano, Y.; Kawakami, R.; Niibe, M. Generation of electrical damage in n-GaN films following treatment in a CF4 plasma. Appl. Phys. Express 2017, 10, 2–5. [Google Scholar] [CrossRef]

- Niibe, M.; Maeda, Y.; Kawakami, R.; Inaoka, T.; Tominaga, K.; Mukai, T. Surface analysis of n-GaN crystal damaged by RF-plasma-etching with Ar, Kr, and Xe gases. Phys. Status Solidi Curr. Top. Solid State Phys. 2011, 8, 435–437. [Google Scholar] [CrossRef]

- Kawakami, R.; Inaoka, T.; Minamoto, S.; Kikuhara, Y. Analysis of GaN etching damage by capacitively coupled RF Ar plasma exposure. Thin Solid Film. 2008, 516, 3478–3481. [Google Scholar] [CrossRef]

- Liu, Z.; Asano, A.; Imamura, M.; Ishikawa, K.; Takeda, K.; Kondo, H.; Oda, O.; Sekine, M.; Hori, M. Thermally enhanced formation of photon-induced damage on GaN films in Cl2 plasma. Jpn. J. Appl. Phys. 2017, 56. [Google Scholar] [CrossRef]

- Aroulanda, S.; Patard, O.; Altuntas, P.; Michel, N.; Pereira, J.; Lacam, C.; Gamarra, P.; Delage, S.L.; Defrance, N.; De Jaeger, J.-C.; et al. Cl2/Ar based atomic layer etching of AlGaN layers. J. Vac. Sci. Technol. A 2019, 37, 041001. [Google Scholar] [CrossRef]

- Kauppinen, C.; Khan, S.A.; Sundqvist, J.; Suyatin, D.B.; Suihkonen, S.; Kauppinen, E.I.; Sopanen, M. Atomic layer etching of gallium nitride (0001). J. Vac. Sci. Technol. A Vac. Surf. Film. 2017, 35, 060603. [Google Scholar] [CrossRef]

- Cao, X.A.; Syed, A.A.; Piao, H. Investigation of the electronic properties of nitrogen vacancies in AlGaN. J. Appl. Phys. 2009, 105. [Google Scholar] [CrossRef]

| Parameter | O2 Plasma Step | BCl3 Plasma Step |

|---|---|---|

| ICP power (W) | 400 | 400 |

| Bias power (W) | 3 | 2 |

| DC self-bias (V) | 4 | 3.8 |

| Chamber pressure (mTorr) | 50 | 10 |

| Gas flow rate (sccm) | 50 | 10 |

| Plasma time (s) | 60 | 45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, I.-H.; Cha, H.-Y.; Seo, K.-S. Low-Damage and Self-Limiting (Al)GaN Etching Process through Atomic Layer Etching Using O2 and BCl3 Plasma. Coatings 2021, 11, 268. https://doi.org/10.3390/coatings11030268

Hwang I-H, Cha H-Y, Seo K-S. Low-Damage and Self-Limiting (Al)GaN Etching Process through Atomic Layer Etching Using O2 and BCl3 Plasma. Coatings. 2021; 11(3):268. https://doi.org/10.3390/coatings11030268

Chicago/Turabian StyleHwang, Il-Hwan, Ho-Young Cha, and Kwang-Seok Seo. 2021. "Low-Damage and Self-Limiting (Al)GaN Etching Process through Atomic Layer Etching Using O2 and BCl3 Plasma" Coatings 11, no. 3: 268. https://doi.org/10.3390/coatings11030268

APA StyleHwang, I.-H., Cha, H.-Y., & Seo, K.-S. (2021). Low-Damage and Self-Limiting (Al)GaN Etching Process through Atomic Layer Etching Using O2 and BCl3 Plasma. Coatings, 11(3), 268. https://doi.org/10.3390/coatings11030268