Enhanced Anticorrosion Properties through Structured Particle Design of Waterborne Epoxy-Styrene-Acrylate Composite Emulsion

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of Acrylic-Modified Epoxy Resin

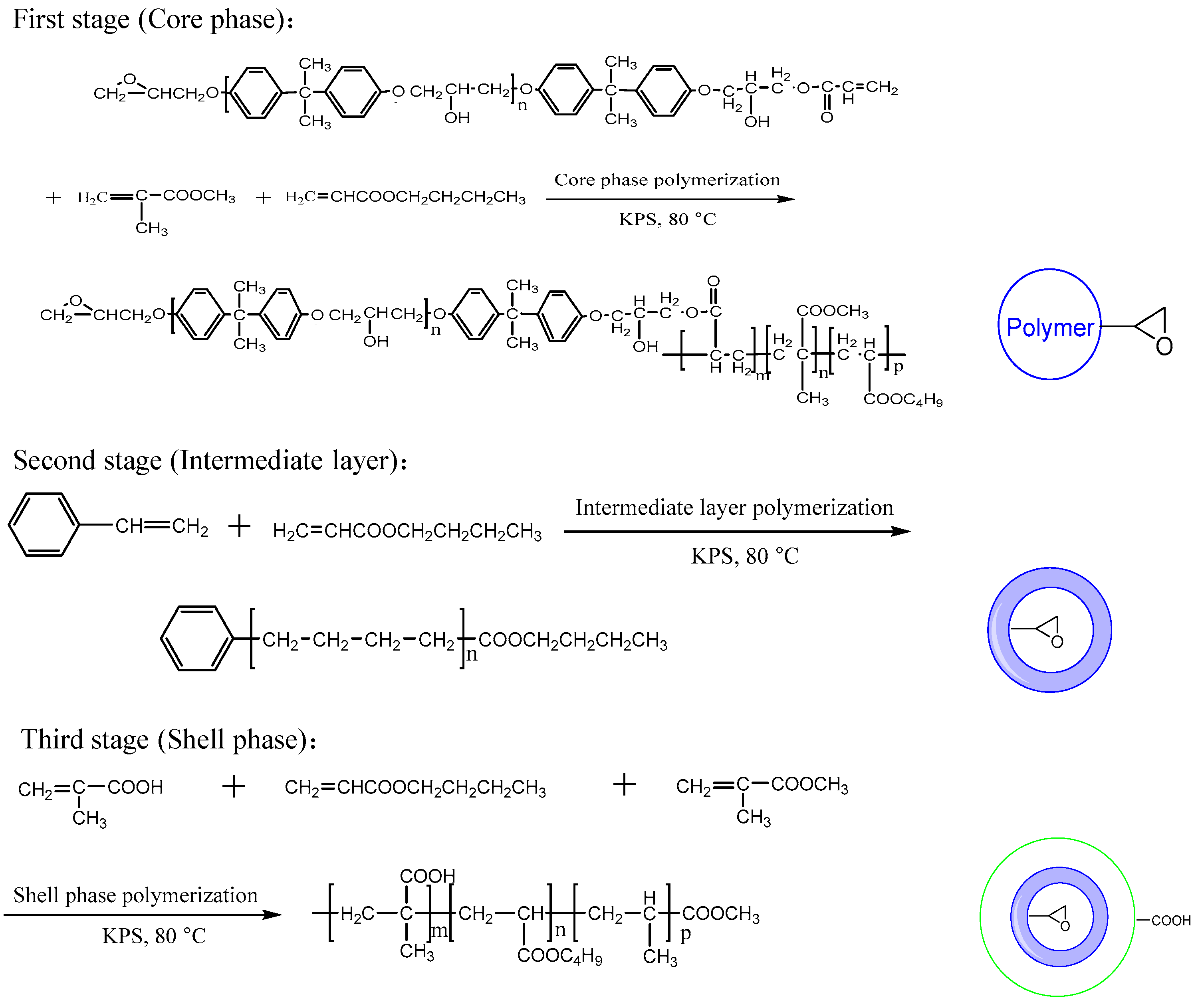

2.3. Preparation of Three-Layer Core-Shell-Structured Waterborne Epoxy-Styrene-Acrylate Composite Latex

2.4. Characterization

3. Results and Discussion

3.1. Method for the Determination of Intermediate Layer Thickness

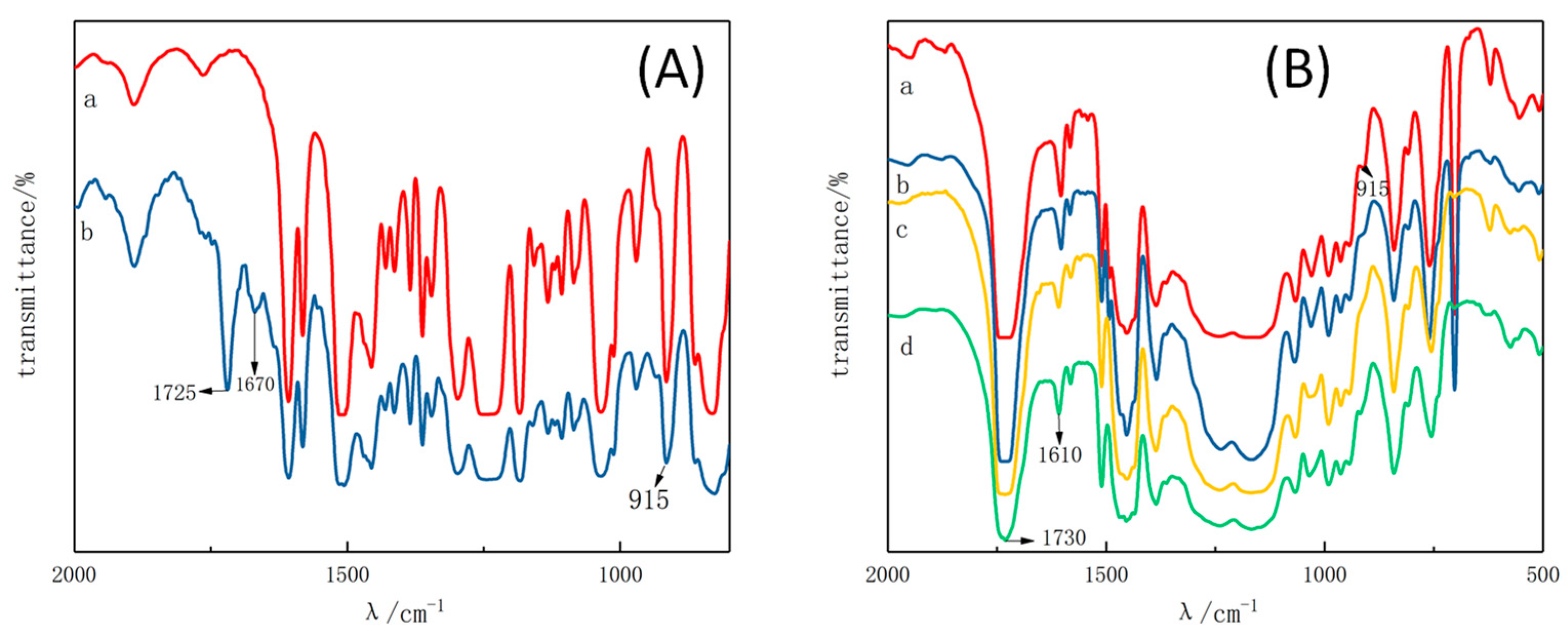

3.2. FTIR Spectroscopy

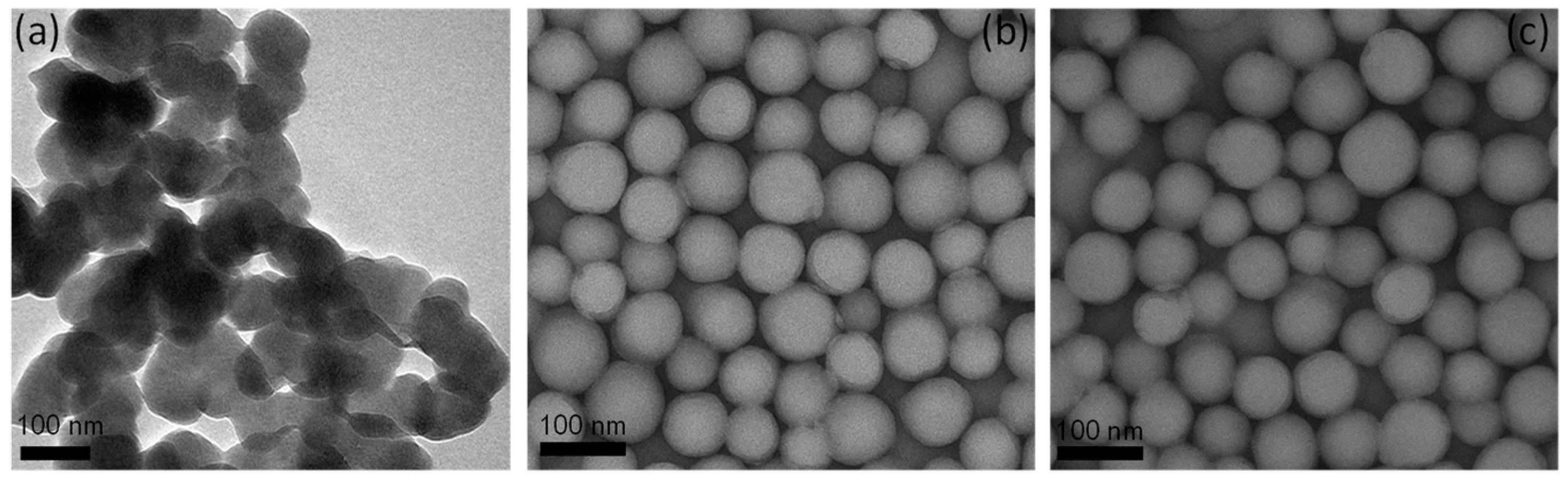

3.3. TEM Image of Three-Layer Core-Shell Emulsion

3.4. Determination of Intermediate Layer Thickness of Three-Layer Core-Shell Emulsion

3.5. Stability of Three-Layer Core-Shell Emulsion

3.6. Corrosion Resistance

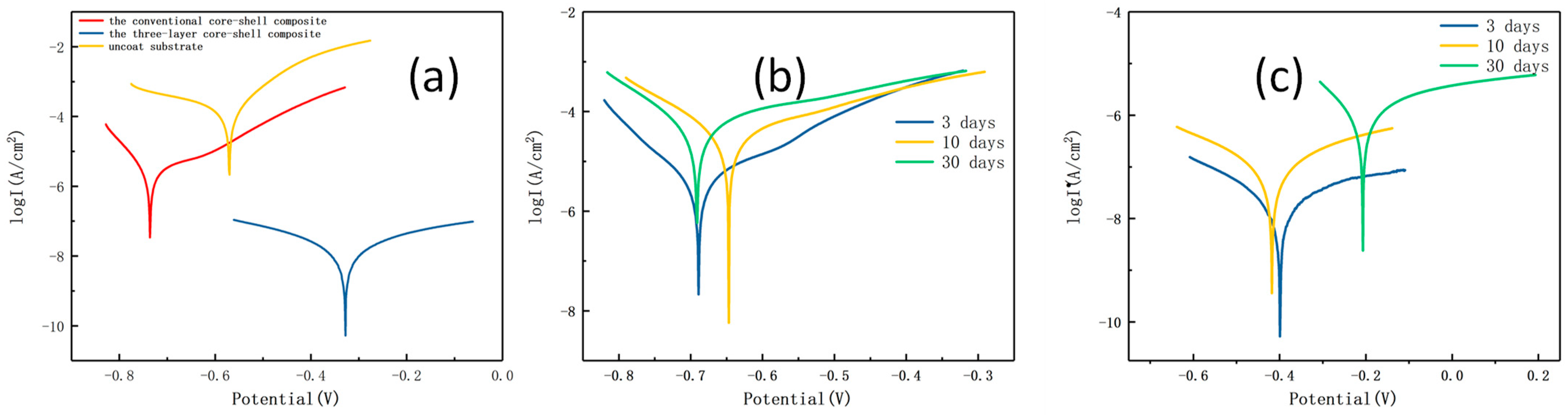

3.6.1. Potentiodynamic (PD) Polarization Study

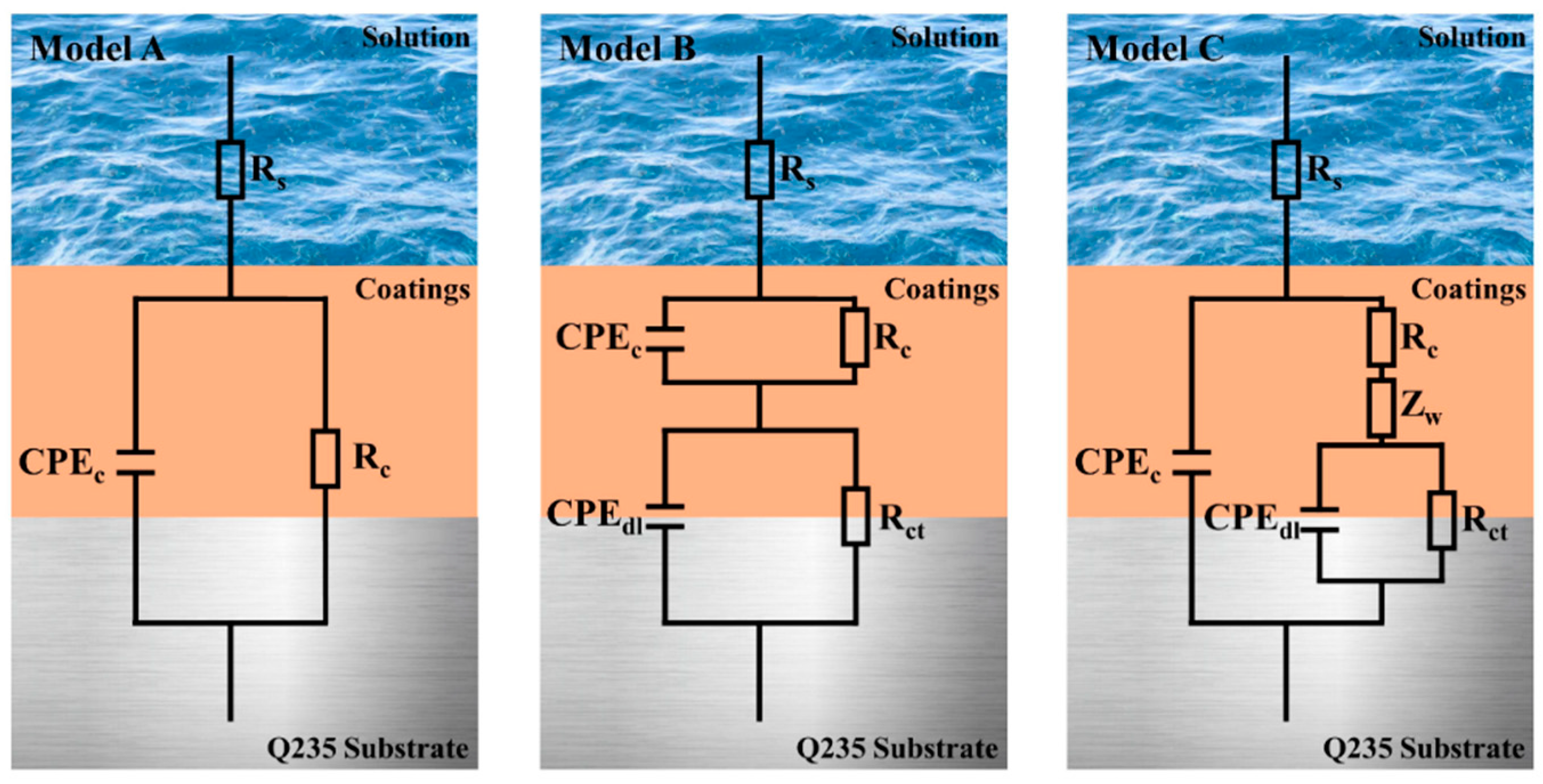

3.6.2. Electrochemical Impedance Spectroscopy (EIS) Study

3.6.3. Salt Spray Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Chen, Z.; Yu, F. Preparation of epoxy-acrylic latex based on bisphenol F epoxy resin. J. Macromol. Sci. Pure Appl. Chem. 2018, 55, 205–212. [Google Scholar] [CrossRef]

- Jiao, C.; Sun, L.; Shao, Q.; Song, J.; Hu, Q.; Naik, N.; Guo, Z. Advances in waterborne acrylic resins: Synthesis principle, modification strategies, and their applications. ACS Omega 2021, 6, 2443–2449. [Google Scholar] [CrossRef] [PubMed]

- Woo, J.T.; Toman, A. Water-based epoxy-acrylic graft copolymer. Prog. Org. Coat. 1993, 21, 371–385. [Google Scholar] [CrossRef]

- Liu, M.; Mao, X.; Zhu, H.; Lin, A.; Wang, D. Water and corrosion resistance of epoxy–acrylic–amine waterborne coatings: Effects of resin molecular weight, polar group and hydrophobic segment. Corros. Sci. 2013, 75, 106–113. [Google Scholar] [CrossRef]

- Zhang, K.; Fu, H.; Huang, H.; Chen, H. waterborne epoxy-acrylic dispersions modified by siloxane. J. Dispers. Sci. Technol. 2007, 28, 1209–1217. [Google Scholar] [CrossRef]

- Mu, R.; Dai, L.L.; Fan, S.L.; Deng, A.M. Study Epoxy resin emulsion by emulsion graft polymerization. In Advanced Materials Research; Wang, J.Z., Qi, J.G., Eds.; Parts 1–2; Trans Tech Publications Ltd.: Durnten-Zurich, Switzerland, 2011; pp. 98–101. [Google Scholar]

- Soleimani, M.; Bagheri, E.; Mosaddegh, P.; Rabiee, T.; Fakhar, A.; Sadeghi, M. Stable waterborne epoxy emulsions and the effect of silica nanoparticles on their coatings properties. Prog. Org. Coat. 2021, 156, 106250–106259. [Google Scholar] [CrossRef]

- Wang, H.S.; Yang, F.F.; Zhu, A.P.; Lu, T.; Kong, F.T.; Ji, L.J. Preparation and reticulation of styrene acrylic/epoxycomplex latex. Polym. Bull. 2014, 7, 1523–1537. [Google Scholar] [CrossRef]

- Tang, E.J.; Yao, M.M.; Du, P.Y.; Yuan, M.; Liu, S.J. Synthesis and dynamic mechanical study of core-shell structure epoxy/polyacrylate composite particle. J. Polym. Res. 2016, 23, 204–209. [Google Scholar] [CrossRef]

- Daniloska, V.; Tomovska, R.; Asua, J.M. Hybrid miniemulsion photopolymerization in a continuous tubular reactor—A way to expand the characteristics of polyurethane/acrylics. Chem. Eng. J. 2012, 184, 308–314. [Google Scholar] [CrossRef]

- Assanvo, E.F.; Baruah, S.D. Synthesis and properties of Ricinodendron heudelotii oil based hybrid alkyd–acrylate latexes via miniemulsion polymerization. Prog. Org. Coat. 2015, 86, 25–32. [Google Scholar] [CrossRef]

- Asua, J.M. Challenges for industrialization of miniemulsion polymerization. Prog. Polym. Sci. 2014, 39, 1797–1826. [Google Scholar] [CrossRef]

- Yao, M.M.; Tang, E.; Guo, C.C.; Liu, S.J.; Tian, H.S.; Hao, H. Synthesis of waterborne epoxy/polyacrylate composites via miniemulsion polymerization and corrosion resistance of coatings. Prog. Org. Coat. 2017, 113, 143–150. [Google Scholar] [CrossRef]

- Tang, E.; Bian, F.; Klein, A.; El-Aasser, M.; Liu, S.; Yuan, M.; Zhao, D. Fabrication of an epoxy graft poly(St-acrylate) composite latex and its functional properties as a steel coating. Prog. Org. Coat. 2014, 77, 1854–1860. [Google Scholar] [CrossRef]

- Duan, Y.; Huo, Y.; Duan, L. Preparation of acrylic resins modified with epoxy resins and their behaviors as binders of waterborne printing ink on plastic film. Colloids Surf. A Physicochem. Eng. Asp. 2017, 535, 225–231. [Google Scholar] [CrossRef]

- Zhang, K.; Li, L.; Chen, X.; Lu, C.; Ran, J. Controlled preparation and properties of acrylic acid epoxy-acrylate composite emulsion for self-crosslinking coatings. J. Appl. Polym. Sci. 2021, 139, e51441. [Google Scholar] [CrossRef]

- Liu, L.; Li, J.; Zhang, X.; Jin, K. The preparation of a three-layer “core-shell” structured epoxy-acrylate emulsion. RSC Adv. 2014, 4, 47184–47190. [Google Scholar] [CrossRef]

- Liu, B.; Sun, S.; Zhang, M.; Ren, L.; Zhang, H. Facile Synthesis of large scale and narrow particlesize distribution polymer particles via control particle coagulation during one-step emulsion polymerization. Colloid Surf. A. 2015, 484, 81–88. [Google Scholar] [CrossRef]

- Jana, M.; Hedvika, Z.; Stepan, P.; Roman, S.; Jiri, P.; Jaromir, S. Property study of structured self-crosslinking acrylic latex binder: Effect of molar mass and particle design. Prog. Org. Coat. 2017, 111, 258–266. [Google Scholar] [CrossRef]

- Cheaburu-Yilmaz, C.N.; Yilmaz, O.; Darie-Nita, R.N. The effect of different soft core/hard shell ratios on the coating performance of acrylic copolymer latexes. Polymers 2021, 13, 3521. [Google Scholar] [CrossRef]

- Gholami, F.; Pakzad, L.; Behzadfar, E. Morphological, interfacial and rheological properties in multilayer polymers: A review. Polymer 2020, 208, 122950. [Google Scholar] [CrossRef]

- Song, Q.; Yan, P.; Wang, H.; Zhu, X.; Xu, Y. Preparation and characterization of multi-layer core-shell polysiloxane/PSt/PMMA latex. Pigment. Resin Technol. 2012, 41, 339–343. [Google Scholar] [CrossRef]

- Foster, A.B.; Lovell, P.A.; Rabjohns, M.A. Rabjohns, Control of adhesive properties through structured particle designof water-borne pressure-sensitive adhesives. Polymer 2009, 50, 1654–1670. [Google Scholar] [CrossRef]

- Deplace, F.; Rabjohns, M.A.; Yamaguchi, T.; Foster, A.B.; Carelli, C.; Lei, C.-H.; Ouzineb, K.; Keddie, J.L.; Lovell, P.A.; Creton, C. Deformation and adhesion of a periodic soft–soft nanocomposite designed with structured polymer colloid particles. Soft Matter 2009, 5, 1440–1447. [Google Scholar] [CrossRef]

- Cui, M.; Ren, S.; Chen, J.; Liu, S.; Zhang, G.; Zhao, H.; Wang, L.; Xue, Q. Anticorrosive performance of waterborne epoxy coatings containing water-dispersible hexagonal boron nitride (h-BN) nanosheets. Appl. Surf. Sci. 2017, 397, 77–86. [Google Scholar] [CrossRef]

- Wang, N.; Zhang, Y.; Chen, J.; Zhang, J.; Fang, Q. Dopamine modified metal-organic frameworks on anti-corrosion properties of waterborne epoxy coatings. Prog. Org. Coat. 2017, 109, 126–134. [Google Scholar] [CrossRef]

- Ramezanzadeh, B.; Niroumandrad, S.; Ahmadi, A.; Mahdavian-Ahadi, M.; Moghadam, M.M. Enhancement of barrier and corrosion protection performance of an epoxy coating through wet transfer of amino functionalized grapheneoxide. Corros. Sci. 2016, 103, 283–304. [Google Scholar] [CrossRef]

- Chen, C.; Qiu, S.; Cui, M.; Qin, S.; Yan, G.; Zhao, H.; Wang, L.; Xue, Q. Achieving high performance corrosion and wear resistant epoxy coatings via incorporation of noncovalent functionalized graphene. Carbon 2017, 114, 356–366. [Google Scholar] [CrossRef]

- Yu, D.; Wen, S.; Yang, J.; Wang, J.; Chen, Y.; Luo, J.; Wu, Y. RGO modified ZnAl-LDH as epoxy nanostructure filler: A novel synthetic approach to anticorrosive waterborne coating. Surf. Coat. Technol. 2017, 326, 207–215. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Zhu, K.; Wang, H.; Fei, G. Reinforcement of phosphorylated graphene oxide on the anticorrosive properties of waterborne acrylate-epoxy resin coatings. J. Macromol. Sci. A 2018, 55, 649–657. [Google Scholar] [CrossRef]

- Yan, R.; Liu, Y.; Liu, B.; Zhang, Y.; Zhao, Q.; Sun, Z.; Hu, W.; Zhang, N. Improved performance of dual-cured organosolv lignin-based epoxy acrylate coatings. Compos. Commun. 2018, 10, 52–56. [Google Scholar] [CrossRef]

- Wang, X.; Cui, Y.; Wang, Y.; Ban, T.; Zhang, Y.; Zhang, J.; Zhu, X. Preparation and characteristics of crosslinked fluorinated acrylate modified waterborne polyurethane for metal protection coating. Prog. Org. Coat. 2021, 158, 106371. [Google Scholar] [CrossRef]

- Sun, M.; Ma, Z.; Li, A.; Zhu, G.; Zhang, Y. Anticorrosive performance of polyaniline/waterborne epoxy/poly (methylhydrosiloxane) composite coatings. Prog. Org. Coat. 2020, 139, 105462. [Google Scholar] [CrossRef]

- Tang, E.J.; Yao, M.M.; Guo, X.F.; Wang, R.H.; Liu, S.J.; Gao, H. Film formation for aqueous epoxy acrylate latex coatings. CIESC J. 2018, 69 (Suppl. S1), 143–147. [Google Scholar] [CrossRef]

- Yuan, T.; Liang, B.; Huang, J.J.; Yang, Z.H.; Shao, Q.H. Effect of shell thickness on morphology and opacity ability of hollow styrene acrylic latex particles. Mater. Rev. 2019, 33, 106–113. [Google Scholar] [CrossRef]

- Chen, X.F.; Wang, H.Y.; Zhang, K. Research progress on preparation technology of waterborne epoxy-acrylate composite emulsion. Paint. Coat. Technol. 2019, 49, 72–76. [Google Scholar] [CrossRef]

- Yi, M.; Qiu, T.; Okubo, M.; Li, X.; Guo, L. Innovative on-line near-infrared (NIR) spectroscopy to estimate content of each phase in composite polymer particles prepared by seeded emulsion polymerization. Vib. Spectrosc. 2018, 95, 23–31. [Google Scholar] [CrossRef]

- Duan, M.; Qiu, T.; Huang, C.; Xu, G.; Guo, L.; Li, X. Synthesis of poly(acrylate-styrene)/poly(acrylate-styrene) core/shell latex and TOPEM-DSC characterization. Prog. Org. Coat. 2013, 76, 216–223. [Google Scholar] [CrossRef]

- Zahedi, F.; Amraei, I.A.; Fathizade, M.A. Investigation of dynamic-mechanical properties of multilayer latexIPNs (MLIPNs) with core/shell morphology: Synthesis and characterization. Polymer 2016, 83, 162–171. [Google Scholar] [CrossRef]

- Amores, E.; Sanchez-Molina, M.; Sanchez, M. Effects of the marine atmosphere on the components of an alkaline waterelectrolysis cell for hydrogen production. Results Eng. 2021, 10, 100235. [Google Scholar] [CrossRef]

- Berce, P.; Skale, S.; Slemnik, M. Electrochemical impedance spectroscopy study of waterborne coatings film formation. Prog. Org. Coat. 2015, 82, 1–6. [Google Scholar] [CrossRef]

- Li, S.; Huang, H.; Chen, F.; He, X.; Ma, Y.; Zhang, L.; Sheng, X.; Chen, Y.; Shchukina, E.; Shchukin, D. Reinforced anticorrosion performance of waterborne epoxy coating with eco-friendly L-cysteine modified Ti3C2Tx MXene nanosheets. Prog. Org. Coat. 2021, 161, 106478. [Google Scholar] [CrossRef]

- Skale, S.; Doleček, V.; Slemnik, M. Substitution of the constant phase element by Warburg impedance for protective coatings. Corros. Sci. 2007, 49, 1045–1055. [Google Scholar] [CrossRef]

- Margarit-Mattos, I. EIS and organic coatings performance: Revisiting some key points. Electrochim. Acta 2020, 354, 136725. [Google Scholar] [CrossRef]

- Bonin, P.; Roggero, A.; Caussé, N.; Pébère, N.; Thierry, D.; Le Bozec, N. Impedance analysis of the barrier effect of coil-coated materials: Water uptake and glass transition variations. Prog. Org. Coat. 2021, 153, 106163. [Google Scholar] [CrossRef]

- Bera, S.; Rout, T.; Udayabhanu, G.; Narayan, R. Water-based & eco-friendly epoxy-silane hybrid coating for enhanced corrosion protection & adhesion on galvanized steel. Prog. Org. Coat. 2016, 101, 24–44. [Google Scholar] [CrossRef]

- Kamil, M.; Suhartono, T.; Ko, Y. Corrosion behavior of plasma electrolysis layer cross-linked with a conductive polymer coating. J. Mater. Res. Technol. 2021, 15, 4672–4682. [Google Scholar] [CrossRef]

| Raw Material | Process | |

|---|---|---|

| Backing material | NaHCO3 | Heated to 80 °C with vigorous stirring |

| DSB | ||

| H2O | ||

| KPS | ||

| Seed composition | MMA | Dripped off in 15 min, kept at 80 °C for 10 min |

| BA | ||

| Core composition | MMA | Simultaneous dropwise addition, monomer dripped off in 2 h. After adding core monomers, the addition of core initiator was stopped, and kept warm for 20 min |

| BA | ||

| Modified E-44 | ||

| Core initiators | KPS | |

| DSB | ||

| H2O | ||

| Transition monomers | St | Simultaneous dropwise addition, transition monomer and the remaining core initiator dripped off in 1 h, kept at 80 °C for 20 min |

| BA | ||

| Shell composition | MMA | Simultaneous dropwise addition, monomer and initiator dripped off in 2 h, increased to 85 °C for 30 min |

| BA | ||

| MAA | ||

| Shell initiators | KPS | |

| H2O | ||

| CO-436 | ||

| OP-10 | ||

| Parameter | Three-Layer Core-Shell | Conventional Core-Shell |

|---|---|---|

| ΔCpc0/J/(g·°C) | 0.326 | 0.414 |

| ΔCps0/ J/(g·°C) | 0.372 | 0.372 |

| ΔCpc/ J/(g·°C) | 0.056 | 0.182 |

| ΔCps/ J/(g·°C) | 0.159 | 0.123 |

| ωc | 0.172 | 0.440 |

| ωs | 0.427 | 0.330 |

| ωi | 0.401 | – |

| Rc/nm | 49.47 | 78.87 |

| Rs/nm | 15.07 | 12.96 |

| Ri/nm | 24.42 | 11.86 |

| Particle Size | Three-Layer Core-Shell | Conventional Core-Shell |

|---|---|---|

| Rc″/nm | 58.87 | 62.81 |

| Rs″/nm | 16.68 | – |

| Ri″/nm | 13.41 | – |

| R | 88.96 | 79.91 |

| Parameter | Three-Layer Core-Shell Structure | Conventional Core-Shell Structure |

|---|---|---|

| The emulsion appearance | Creamy white with distinct blue light | Creamy white with distinct blue light |

| Wet gel weight upon discharging (g/200 g) | 2.05 | 3.21 |

| Zeta/mV | −39.41 | −12.32 |

| Stability (after 6 months) | No sight of condensate | Condensate can be clearly seen |

| Sample | Time (Day) | Ecorr (V) | Icorr (μA/cm2) | βa (mV/dec) | βc (mV/dec) | Rp (kΩ·cm2) | Rcorr (mmpy) |

|---|---|---|---|---|---|---|---|

| Carbon steel | 0 | −0.570 | 184.9 | 101.30 | −293.26 | 0.18 | 3.05 × 10−1 |

| 1 | 0 | −0.736 | 2.92 | 183.02 | −71.27 | 7.72 | 4.80 × 10−3 |

| 2 | 0 | −0.328 | 1.46 × 10−2 | 196.27 | −183.18 | 2.83 × 103 | 2.40 × 10−5 |

| 1 | 3 | −0.689 | 4.25 | 252.53 | −65.18 | 5.25 | 7.00 × 10−3 |

| 2 | 3 | −0.399 | 1.99 × 10−2 | 237.30 | −167.73 | 2.15 × 103 | 3.28 × 10−5 |

| 1 | 10 | −0.647 | 42.64 | 267.95 | −122.61 | 0.86 | 7.03 × 10−2 |

| 2 | 10 | −0.418 | 8.34 × 10−2 | 20,400 | −286.88 | 5.08 × 102 | 1.38 × 10−4 |

| 1 | 30 | −0.691 | 69.83 | 280.11 | −106.52 | 0.48 | 1.15 × 10−1 |

| 2 | 30 | −0.207 | 9.98 × 10−1 | 252.59 | −121.24 | 35.7 | 1.60 × 10−3 |

| Sample | Time (Day) | CPEc | Rc (Ω·cm2) | CPEdl | Rct (Ω·cm2) | Zw | ||

|---|---|---|---|---|---|---|---|---|

| Qc (F·cm−2·sn−1) | n1 | Qdl (F·cm−2·sn−1) | n2 | |||||

| Conventional | 0 | 7.27 × 10−5 | 0.52 | 1.44 × 104 | – | – | – | – |

| 3 | 1.56 × 10−4 | 0.66 | 6.26 × 103 | 6.72 × 10−5 | 0.53 | 2.75 × 103 | – | |

| 10 | 6.99 × 10−4 | 0.66 | 5.65 × 103 | 2.71 × 10−4 | 0.28 | 1.08 × 103 | – | |

| 30 | 7.20 × 10−4 | 0.60 | 1.09 × 103 | 3.35 × 10−4 | 0.26 | 7.80 × 102 | – | |

| Three-layer | 0 | 4.08 × 10−11 | 0.96 | 8.56 × 107 | – | – | – | – |

| 3 | 2.39 × 10−10 | 0.97 | 5.94 × 106 | 4.99 × 10−8 | 0.11 | 3.30 × 107 | 1.20 × 10−7 | |

| 10 | 2.44 × 10−10 | 0.98 | 1.19 × 106 | 3.40 × 10−7 | 0.07 | 5.52 × 106 | 1.01 × 10−7 | |

| 30 | 3.98 × 10−10 | 0.95 | 1.14 × 105 | 1.15 × 10−5 | 0.46 | 2.46 × 105 | 1.09 × 10−6 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, K.; Chen, X.; Xiao, Y.; Liu, R.; Liu, J. Enhanced Anticorrosion Properties through Structured Particle Design of Waterborne Epoxy-Styrene-Acrylate Composite Emulsion. Coatings 2021, 11, 1422. https://doi.org/10.3390/coatings11111422

Zhang K, Chen X, Xiao Y, Liu R, Liu J. Enhanced Anticorrosion Properties through Structured Particle Design of Waterborne Epoxy-Styrene-Acrylate Composite Emulsion. Coatings. 2021; 11(11):1422. https://doi.org/10.3390/coatings11111422

Chicago/Turabian StyleZhang, Kai, Xifang Chen, Yuling Xiao, Rujia Liu, and Jie Liu. 2021. "Enhanced Anticorrosion Properties through Structured Particle Design of Waterborne Epoxy-Styrene-Acrylate Composite Emulsion" Coatings 11, no. 11: 1422. https://doi.org/10.3390/coatings11111422

APA StyleZhang, K., Chen, X., Xiao, Y., Liu, R., & Liu, J. (2021). Enhanced Anticorrosion Properties through Structured Particle Design of Waterborne Epoxy-Styrene-Acrylate Composite Emulsion. Coatings, 11(11), 1422. https://doi.org/10.3390/coatings11111422