Overview of Bioplastic Introduction and Its Applications in Product Packaging

Abstract

:1. Introduction

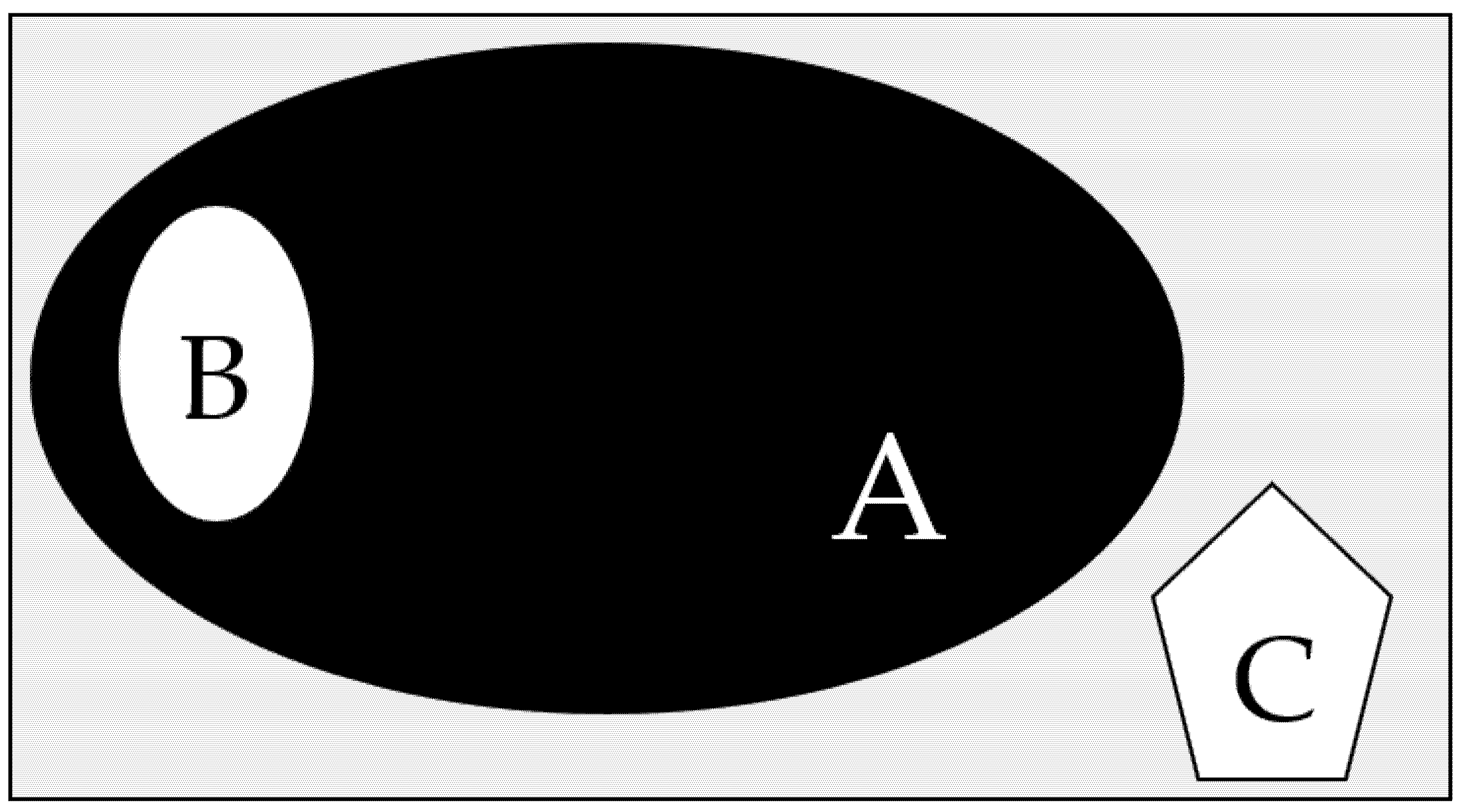

2. Description on Bioplastic—Definition, Biodegradability and Classification

| Bioplastic | Environment | Condition | Biodegradability (%) | Method | Testing Period (Days) | Ref |

|---|---|---|---|---|---|---|

| PLA | Compost | 58 °C, 60% RH | 60–70 | CO2 produced | 30 | [38] |

| Soil | 10–25 °C | 0 | CO2 produced | 120 | [41] | |

| Simulated marine environment | 25 °C | 3–4 | CO2 produced | 180 | [42] | |

| PHB | Compost | 55 °C, 70% RH | 80 | CO2 produced | 28 | [38] |

| Soil | 20 °C, 60% RH | 48.5 | CO2 produced | 280 | [38] | |

| Simulated marine environment | 25 °C | 38–45 | CO2 produced | 180 | [43] | |

| Starch-based | Compost (starch thermoplastic) | 58 °C | 73.1 | CO2 produced | 56 | [44] |

| Soil (wheat starch-derived plastic) | 20 °C, 60% RH | 14.2 | CO2 produced | 110 | [38] | |

| Marine (neat starch) | 26 °C | 100 | Weight loss | 50 | [45] | |

| Cellulose-based | Compost (cellulose acetate) | 53 °C | 100 | CO2 produced | 18 | [46] |

| Soil (bacterial and vegetable cellulose) | 25 °C | 100 | Weight loss | 180 | [47] | |

| Simulated marine environment (neat cellulose) | Room temperature | 75 | Oxygen consumed | 150 | [48] | |

| PBAT | Compost | 58 °C | 34–67 | CO2 produced | 45 | [49] |

| Soil | 10–25 °C | 6.6 | Organic carbon content | 120 | [41] | |

| Simulated marine environment | 29 °C | 1–1.4 | Biological oxygen demand | 28 | [50] | |

| PBS | Compost | 65 °C, 50–55% RH | 90 | CO2 produced | 160 | [51] |

| Soil | 20 °C, 60% RH | 1 (film), 16.8 (power) | Weight loss | 28 | [38] | |

| Simulated marine environment | 27 °C | 1 | Biological oxygen demand | 28 | [51] |

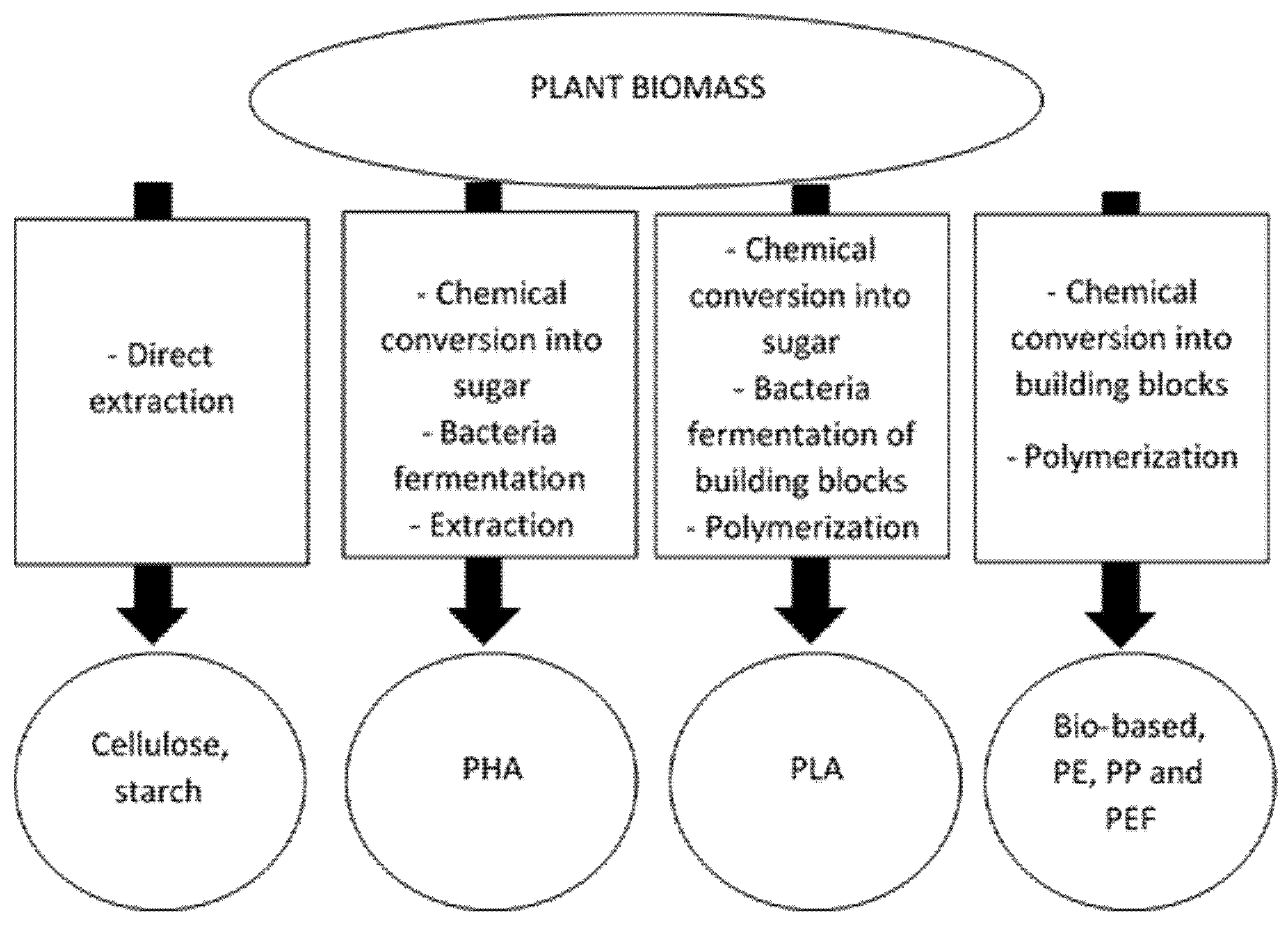

3. Types of Bioplastic

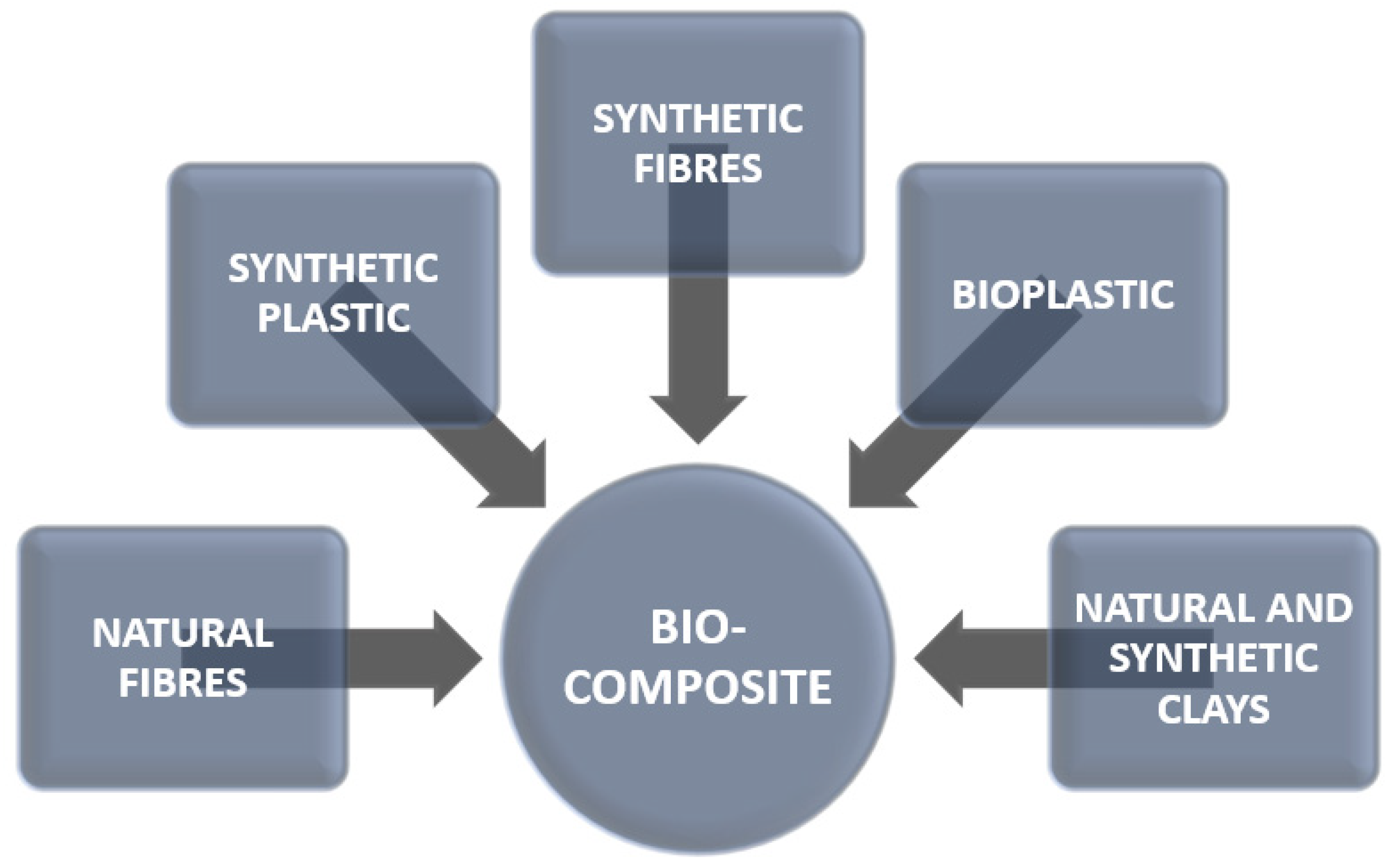

4. Bioplastic and Biocomposite

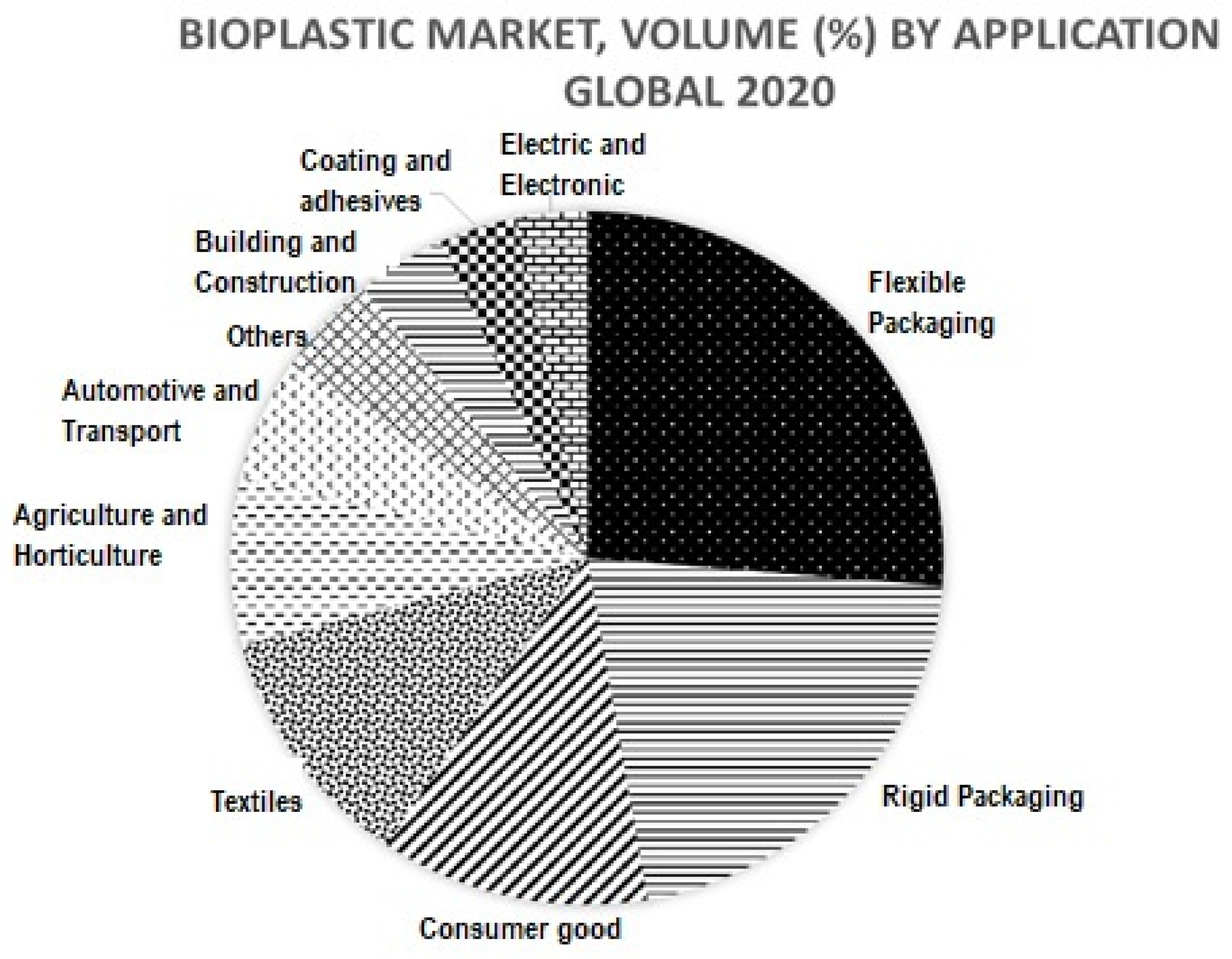

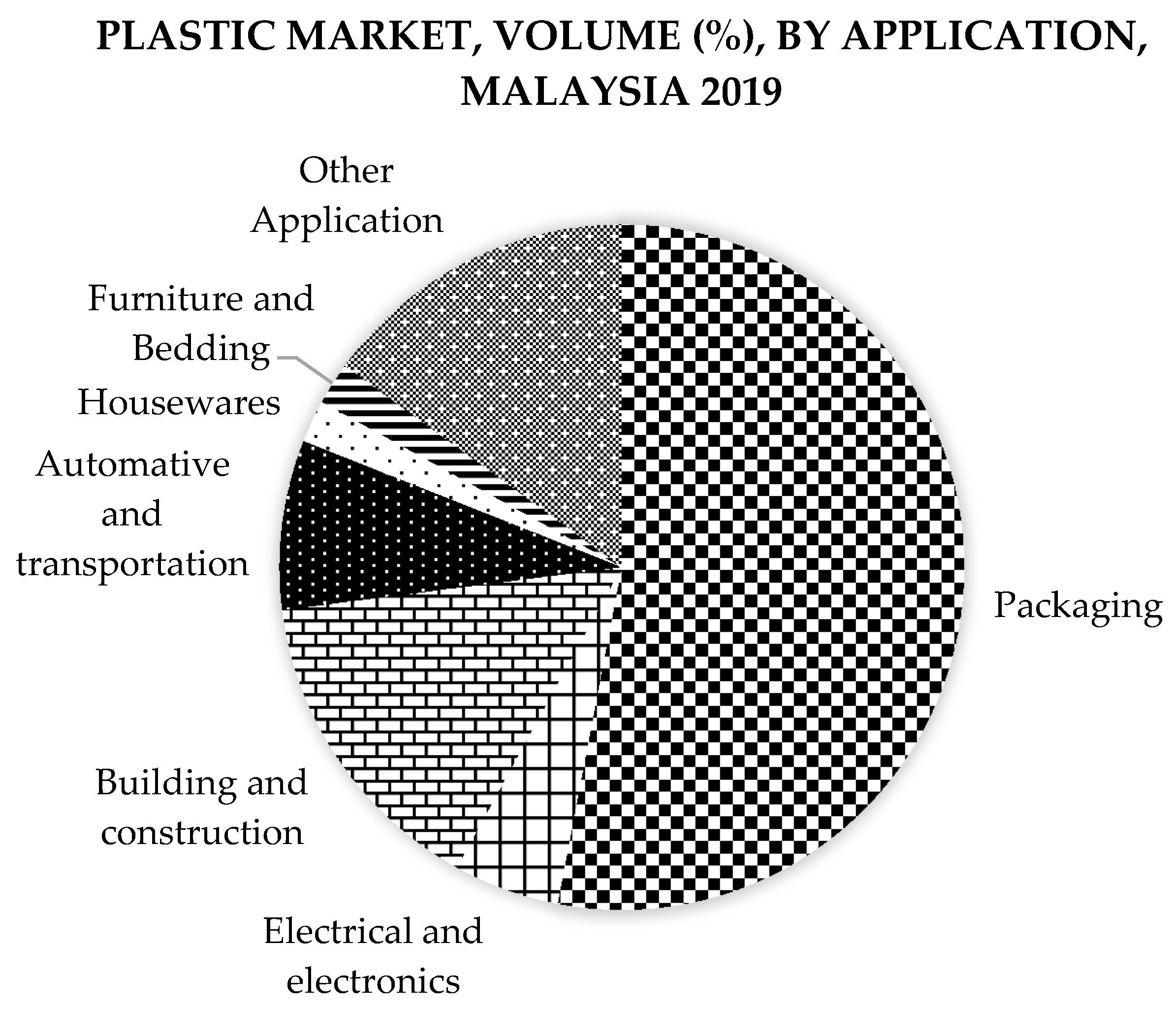

5. Bioplastic in Packaging Application—Global and Malaysian Perspectives

- (A)

- The original biodegradable sacks still used today are constructed from starch-containing resins, polyethylene, and heavy metals such as cadmium, lead, and beryllium, as well as commonly known as plastics based on petroleum.

- (B)

- A second form of starch, mixed with biodegradable polymers such as PLA or BASFEcoFlex, also known as bioplastics, has been patented. These bags comply with ASTM compostable requirements, while the standard does not comply with other bag types (types A and C).

- (C)

- To promote the breakdown of polymers, oxo-biodegradable bags use Totally Degradable Plastics Additives (TDPAt) to speed up the biodegradation process of traditional plastics, as seen in Figure 3 above.

6. Advantages and Disadvantages of Bioplastic and Its Modification in Packaging Applications

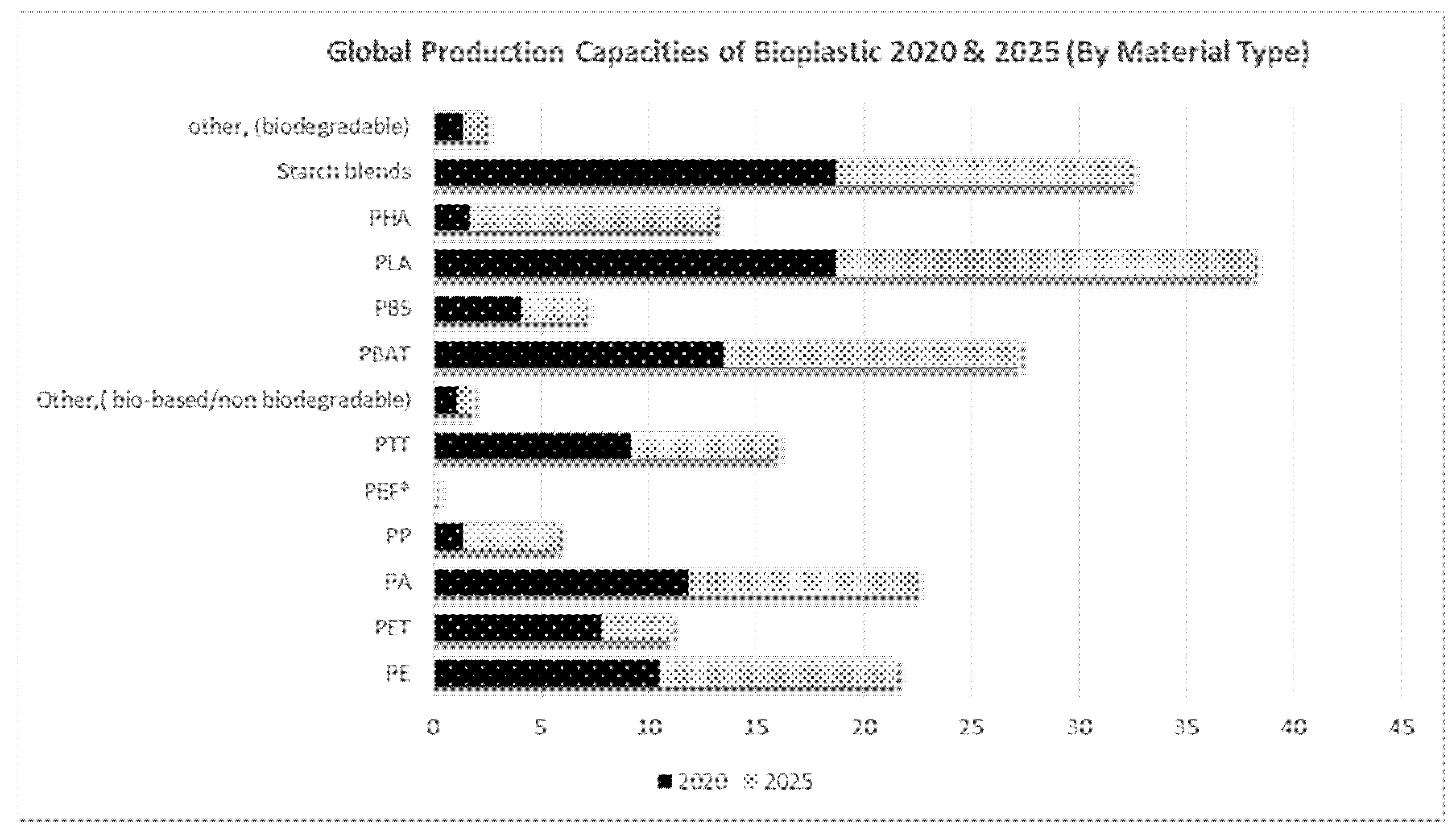

7. Bioplastic Industry Overview

8. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Science Matters: The Case of Plastics. Available online: https://www.sciencehistory.org/science-of-plastics (accessed on 11 December 2020).

- Cho, D.W.; Lee, J.S.; Jang, J.; Jung, J.W.; Park, J.H.; Pati, F. An introduction to plastics. IOP Sci. 2015, 1, 1–33. [Google Scholar]

- Lestari, R.A.S.; Kasmiyatun, M.; Dermawan, K.; Aini, A.N.; Riyati, N.; Putri, F.R. Bioplastic from Jackfruit seeds and rice. IOP Conf. Ser. Mater. Sci. Eng. 2020, 835, 012035. [Google Scholar] [CrossRef]

- Plastics Europe. Plastics—The Facts 2019. An Analysis of European Plastics Production, Demand and Waste Data. 2019. Available online: https://www.plasticseurope.org/en/resources/market-data (accessed on 30 December 2020).

- Plastics Europe. World Plastics Materials Demand 2016 by Types. Available online: https://committee.iso.org/files/live/sites/tc61/files/ThePlasticIndustryBerlinAug2016—Copy.pdf (accessed on 19 May 2021).

- Muthusamy, M.S.; Pramasivam, S. Bioplastics—An eco-friendly alternative to petrochemical plastics. Curr. World Environ. 2019, 14, 49–59. [Google Scholar] [CrossRef] [Green Version]

- Jerez, A.; Partal, P.; Mart, I.; Gallegos, C.; Guerrero, A. Rheology and processing of gluten based bioplastics. Biochem. Eng. J. 2005, 26, 131–138. [Google Scholar] [CrossRef]

- Jerez, A.; Partal, P.; Martínez, I. Protein-based bioplastics: Effect of thermo-mechanical processing. Rheol. Acta 2007, 46, 711–720. [Google Scholar] [CrossRef]

- Mohammadi, A.; Karim, A.; Mahmud, S.; Robal, M. Antimicrobial, rheological, and physicochemical properties of sago starch films filled with nanorod-rich zinc oxide. J. Food Eng. 2012, 113, 511–519. [Google Scholar] [CrossRef]

- Xie, F.; Pollet, E.; Halley, P.; Averous, L. Starch-based nano-biocomposites. Prog. Polym. Sci. 2013, 38, 1590–1628. [Google Scholar] [CrossRef] [Green Version]

- Gironi, F. Bioplastics and petroleum-based plastics: Strengths and weaknesses. Energy Sources Part A Recovery Util. Environ. Eff. 2011, 33, 1949–1959. [Google Scholar] [CrossRef]

- Jabeen, N.; Majid, I.; Nayik, G.A.; Jabeen, N.; Majid, I.; Nayik, G.A. Bioplastics and food packaging: A review. Cogent. Food Agric. 2015, 42. [Google Scholar] [CrossRef]

- Kalia, S.; Dufresne, A.; Cherian, B.M.; Kaith, B.S.; Av, L.; Njuguna, J. Cellulose-based bio- and nanocomposites: A review. Int. J. Polym. Sci. 2011, 2011, 837875. [Google Scholar] [CrossRef]

- Sanyang, M.L.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Recent developments in sugar palm (Arenga pinnata) based biocomposites and their potential industrial applications: A review. Renew Sustain. Energy Rev. 2016, 54, 533–549. [Google Scholar] [CrossRef]

- Pilla, S. Engineering applications of bioplastics and biocomposites—An overview. In Handbook of Bioplastics and Biocomposites Engineering Applications; Wiley: Hoboken, NJ, USA, 2012; pp. 1–15. [Google Scholar]

- Bashir, A.S.M.; Manusamy, Y. Recent developments in biocomposites reinforced with natural biofillers from food waste. Polym. Plast. Technol. Eng. 2015, 54, 87–99. [Google Scholar] [CrossRef]

- Suryanto, H.; Kharismawan, F.; Solichin Rahmawan, A.; Sahana, R.; Muhajir, M. Influence of nanoclay on thermal decomposition of biocomposite matrix starch/carrageenan blend influence of nanoclay on thermal decomposition of biocomposite matrix starch/carrageenan blend. In Proceedings of the The 2nd International Conference on Mechanical Engineering Research and Application (Paper Submission System), Malang, East Java, Indonesia, 7–9 October 2020. [Google Scholar]

- Harunsyah; Sariadi; Raudah. The effect of clay nanoparticles as reinforcement on mechanical properties of bioplastic base on cassava starch The effect of clay nanoparticles as reinforcement on mechanical properties of bioplastic base on cassava starch. J. Phys. Conf. Ser. 2018, 953, 012021. [Google Scholar] [CrossRef]

- Singha, A.S.; Thakur, V.K. Chemical resistance, mechanical and physical properties of biofibers-based polymer composites. Polym. Plast. Technol. Eng. 2009, 48, 736–744. [Google Scholar] [CrossRef]

- Geueke, B. Bioplastics as Food Contact Materials. Food Packag Forum. Available online: http://www.foodpackagingforum.org/fpf-2016/wp-content/uploads/2015/11/FPF_Dossier06_Bioplastics.pdf (accessed on 15 December 2020).

- Brizga, J.; Hubacek, K.; Feng, K. The unintended side effects of bioplastics: Carbon, land, and water footprints. One Earth 2020, 3, 45–53. [Google Scholar] [CrossRef]

- Wellenreuther, C.; Wolf, A. Innovative feedstocks in biodegradable bio-based plastics: A literature review. HWWI Res. Pap. 2020, 1, 194. [Google Scholar]

- Muhammad, A.; Rashidi, A.R.; Roslan, A.; Idris, S.A. Development of bio based plastic materials for packaging from soybeans waste. AIP Conf. Proc. 2017, 1885, 020230. [Google Scholar]

- Di Bartolo, A.; Infurna, G.; Dintcheva, N.T. A review of bioplastics and their adoption in the circular economy. HWWI Res. 2021, 13, 1229. [Google Scholar]

- Niaounakis, M. Definition and assessment of (bio)degradation. In Biopolymer Reuse, Recycling and Disposal; Elsevier: Amsterdam, The Netherlands, 2013; pp. 77–94. [Google Scholar]

- Tokiwa, Y.; Calabia, B.P.; Ugwu, C.U.; Aiba, S. Biodegradability of plastics bio-plastics. Int. J. Mol. Sci. 2009, 10, 3722–3742. [Google Scholar] [CrossRef]

- Lee, S.Y. Bacterial polyb ydroxyalkanoates. Biotechnol. Bioeng. 1996, 49, 1–14. [Google Scholar] [CrossRef]

- Banton, C. “What Is a Renewable Resource?” Investopedia. 2020. Available online: https://www.investopedia.com/terms/r/renewable_resource.asp (accessed on 30 January 2021).

- Borgna, I. Nanoparticles and Bioplastics: A Winning Pair for Packaging; Kosmetica World: Delhi, India, 2017; pp. 1–4. [Google Scholar]

- Tyler, B.; Gregg, W.J.C. Enzymes For Polymer Degradation. European Patent WO2019/168811A1, 6 September 2019. [Google Scholar]

- Biodegradable Plastic (Definition). Nature Plast. 2020. Available online: https://youmatter.world/en/definition/biodegradable-plastic (accessed on 5 January 2021).

- Wagner, C. 1. Types and Application. Food Packaging Forum, 2014. Available online: https://www.foodpackagingforum.org/food-packaging-health/bioplastics (accessed on 1 January 2020).

- Ammala, A.; Bateman, S.; Dean, K.; Petinakis, E.; Sangwan, P.; Wong, S. Progress in Polymer Science an Overview of Degradable and Biodegradable Polyolefins. Progress in Polymer Science; Elsevier Ltd.: Amsterdam, The Netherlands, 2011; Volume 36, pp. 1015–1049. [Google Scholar] [CrossRef]

- Amit, S.K. Eco-Labelling Scheme for Bio-Based Plastics, Packaging Products Launched. The Sundaily Newspaper, Sun Media Corporation SDN BHD. 2017, pp. 1–42. Available online: https://www.thesundaily.my/archive/2203405-KTARCH434920 (accessed on 6 January 2021).

- Ravindran, S. Biodegradable Plastics Uptake Still Discouraging in Malaysia—Bioplastics News. The Star. 2019. Available online: https://bioplasticsnews.com/2019/06/24/biodegradable-plastics-uptake-still-discouraging-in-malaysia/ (accessed on 6 January 2021).

- A Straightforward Explanation of Biodegradable vs. Compostable vs. Oxo-degradable Plastics. Green Dot Bioplastic. Available online: https://www.greendotbioplastics.com/biodegradable-vs-compostable-vs-oxo-degradable-plastics-a-straightforward-explanation (accessed on 30 December 2020).

- Zhao, X.; Cornish, K.; Vodovotz, Y. Narrowing the gap for bioplastic use in food packaging: An update. Environ. Sci. Technol. 2020, 54, 4712–4732. [Google Scholar] [CrossRef]

- Emadian, S.M.; Onay, T.T.; Demirel, B. Biodegradation of bioplastics in natural environments. Waste Manag. 2017, 59, 526–536. [Google Scholar] [CrossRef]

- van Den, O.M.; Molenveld, K.; van Der, Z.M.; Bos, H. Bio-based and biodegradable plastics—Facts and Figures. Wagening. Food Biobased Res. 2017, 67. [Google Scholar] [CrossRef] [Green Version]

- Novamont. Novamont Mater-Bi Packaging. Available online: http://uk.novamont.com/leggi_evento.php?id_event=21 (accessed on 6 January 2021).

- Fu, Y.; Wu, G.; Bian, X.; Zeng, J.; Weng, Y. Biodegradation behavior of poly(butylene adipate-co-terephthalate) (PBAT), poly(lactic acid) (PLA), and their blend in freshwater with sediment. Molecules 2020, 25, 3946. [Google Scholar] [CrossRef]

- Dilkes-ho, L.; Ashworth, P.; Laycock, B.; Pratt, S.; Lant, P. Resources, conservation & recycling Public attitudes towards bioplastics—Knowledge, perception and end-of-life management. Resour. Conserv. Recycl. 2019, 151, 104479. [Google Scholar]

- Rodriquez, M. PLA and PHA Biodegradation in the Marine Environment; California Department of Resources Recycling and Recovery: Sacramento, CA, USA, 2012. Available online: https://www2.calrecycle.ca.gov/Publications/Download/1006?opt=dln (accessed on 6 January 2021).

- Amin, A.M.M.; Saiud, S.M.; Hamid, K.H.K.; Musa, M. Biodegradation behaviour of thermoplastic starch films derived from tacca leontopetaloides starch under controlled composting condition biodegradation behaviour of thermoplastic starch films derived from tacca leontopetaloides starch under controlled comp. IOP Conf. Ser. Mater. Sci. Eng. 2018, 358, 012050. [Google Scholar] [CrossRef] [Green Version]

- Imam, S.H.; Nadathur, G.S. Degradation of starch–poly(β-Hydroxybutyrate-Co-β-Hydroxyvalerate) bioplastic in tropical coastal waters. Appl. Environ. Microbiol. 2014. [Google Scholar] [CrossRef] [Green Version]

- Puls, J.; Wilson, S.A.; Ho, D. Degradation of cellulose acetate-based materials: A review. J. Polym. Environ. 2011, 19, 152–165. [Google Scholar] [CrossRef] [Green Version]

- Schröpfer, S.B.; Bottene, M.K.; Bianchin, L.; Robinson, L.C. Biodegradation evaluation of bacterial cellulose, vegetable cellulose and poly (3-hydroxybutyrate) in soil. Polímeros 2015, 25, 154–160. [Google Scholar] [CrossRef] [Green Version]

- Tosin, M.; Weber, M.; Siotto, M.; Lott, C.; Innocenti, F.D. Laboratory test methods to determine the degradation of plastics in marine environmental conditions. Front. Microbiol. 2012, 3, 1–9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kijchavengkul, T.; Auras, R.; Rubino, M.; Selke, S. Biodegradation and hydrolysis rate of aliphatic aromatic polyester Biodegradation and hydrolysis rate of aliphatic aromatic polyester. Polym. Degrad. Stab. 2010, 95, 2641–2647. [Google Scholar] [CrossRef]

- Nakayama, A.; Yamano, N.; Kawasaki, N. Biodegradation in seawater of aliphatic polyesters. Polym. Degrad. Stab. 2019, 166, 290–299. [Google Scholar] [CrossRef]

- Sashiwa, H.; Fukuda, R.; Okura, T.; Sato, S.; Nakayama, A. Microbial degradation behavior in seawater of polyester blends containing poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBHHx). Mar. Drugs 2018, 16, 34. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kale, G.; Kijchavengkul, T.; Auras, R.; Rubino, M.; Selke, S.E.; Singh, S.P. Compostability of bioplastic packaging materials: An overview. Macromol. Biosci. 2007, 7, 255–277. [Google Scholar] [CrossRef]

- Bátori, V.; Åkesson, D.; Zamani, A.; Taherzadeh, M.J. Anaerobic degradation of bioplastics: A review. Waste Manag. 2018, 80, 406–413. [Google Scholar] [CrossRef]

- Ruggero, F.; Gori, R.; Lubello, C. Methodologies to assess biodegradation of bioplastics during aerobic composting and anaerobic digestion: A review. Waste Manag. Res. 2019, 37, 959–975. [Google Scholar] [CrossRef] [Green Version]

- European Bioplastics. Bioplastics market data 2019. Global Production Capacities of Bioplastic 2019–2024. European Bioplastic, 2019; Volume 9. Available online: https://docs.european-bioplastics.org/publications/market_data/Report_Bioplastics_Market_Data_2019.pdf (accessed on 11 December 2020).

- Siracusa, V.; Blanco, I. Bio-polyethylene (Bio-PE), Bio-polypropylene (Bio-PP) and Bio-poly(ethylene terephthalate) (Bio-PET): Recent developments in bio-based polymers analogous to petroleum-derived ones for packaging and engineering applications. Polymers 2020, 12, 1641. [Google Scholar] [CrossRef]

- Khan, B.; Niazi, M.B.K.; Samin, G.; Jahan, Z. Thermoplastic starch: A possible biodegradable food packaging material—A review. J. Food. Process. Eng. 2017, 40, e12447. [Google Scholar] [CrossRef]

- Basavarajappa, S. Applications of biocomposite materials based on natural fibers from renewable resources: A review. Sci. Eng. Compos. Mater. 2018, 23, 123–133. [Google Scholar]

- Haraguchi, K. Soft nanohybrid materials consisting of polymer–clay networks. Adv. Polym. Sci. 2014, 267, 187–248. [Google Scholar]

- Energy, G.; Jimenez, A.; Ruseckaite, R.A. Nano-biocomposites for food packaging. Environ. Chem. Lett. 2017, 15, 205–221. [Google Scholar]

- Othman, S.H.; Majid, N.A.; Tawakkal, I.S.M.A.; Basha, O.K.; Nordin, N.; Shapi’t, R.A. Tapioca starch film reinforced with microcrystalline cellulose for potential food packaging application. Food Sci. Technol. 2019, 39, 605–662. [Google Scholar] [CrossRef] [Green Version]

- Jiang, T.; Duan, Q.; Zhu, J.; Liu, H.; Yu, L. Starch-based biodegradable materials: Challenges and opportunities. Adv. Ind. Eng. Polym. Res. 2020, 3, 8–18. [Google Scholar] [CrossRef]

- Risyon, N.P.; Othman, S.H.; Basha, R.K.; Talib, R.A. Characterization of polylactic acid/halloysite nanotubes bionanocomposite films for food packaging. Food Packag. Shelf. Life 2020, 23, 100450. [Google Scholar] [CrossRef]

- Peelman, N.; Ragaert, P.; De Meulenaer, B.; Adons, D.; Peeters, R.; Cardon, L. Application of bioplastics for food packaging. Trends Food Sci. Technol. 2013, 32, 128–141. [Google Scholar] [CrossRef] [Green Version]

- Jin, M.; Zhong, Q. Structure modi fi cation of montmorillonite nanoclay by surface coating with soy protein. J. Agric. Food Chem. 2012, 60, 11965–11971. [Google Scholar] [CrossRef]

- De Silva, R.T.; Pasbakhsh, P.; Goh, K.L.; Chai, S.P.; Chen, J. Synthesis and characterisation of poly (lactic acid)/halloysite bionanocomposite films. J. Compos. Mater. 2014, 48, 3705–3717. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, Y.; Zhou, C. Nanocomposites of halloysite and polylactide. Appl. Clay. Sci. 2013, 75–76, 52–59. [Google Scholar] [CrossRef]

- Kamble, R.; Ghag, M.; Gaikawad, S.B.P. Halloysite nanotubes and applications: A review. Compos. Their. Prop. 2012, 3, 25–29. [Google Scholar]

- Süfer, Ö. Poly (lactic acid) films in food packaging systems. Food Sci. Nutr. Technol. 2017, 2, 2574–2701. [Google Scholar] [CrossRef]

- Swaroop, C.; Shukla, M. Development of blown polylactic acid-MgO nanocomposite films for food packaging. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105482. [Google Scholar] [CrossRef]

- Marra, A.; Silvestre, C.; Duraccio, D.; Cimmino, S. Polylactic acid/zinc oxide biocomposite films for food packaging application. Int. J. Biol. Macromol. 2016, 88, 254–262. [Google Scholar] [CrossRef] [PubMed]

- European Bioplastics. Bioplastics Market Development Update 2020. 2020, Volume 2020–2025. Available online: https://www.european-bioplastics.org/news/publications/#MarketData (accessed on 26 May 2021).

- Ashter, S.A. Commercial applications of bioplastics. Introd. Bioplastics. Eng. 2016, 2016, 227–249. [Google Scholar]

- Mangaraj, S.; Yadav, A.; Bal, L.M.; Dash, S.K.; Mahanti, N.K. Application of biodegradable polymers in food packaging industry: A comprehensive review. J. Packag. Technol. Res. 2019, 3, 77–96. [Google Scholar] [CrossRef]

- Lazzeri, A. Cosmetic packaging to save the environment: Future perspectives. Cosmetics 2019, 6, 26. [Google Scholar]

- Jord, M.; Stone, V.; Fernandes, T.F.; Johnston, H.J. Novel polylactic acid (PLA)-organoclay nanocomposite bio-packaging for the cosmetic industry; migration studies and in vitro assessment of the dermal toxicity of migration extracts. Polym. Degrad. Stab. 2019, 168, 108938. [Google Scholar]

- Ioelovich, M.; Figovsky, O. Nano-cellulose as promising biocarrier. Adv. Mater. Res. 2008, 50, 1286–1289. [Google Scholar] [CrossRef]

- Saha, T.; Hoque, E.; Mahbub, T. Biopolymers for Sustainable Packaging in Food, Cosmetics, and Pharmaceuticals. Advanced Processing, Properties, and Applications of Starch and Other Bio-Based Polymers; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 197–214. [Google Scholar] [CrossRef]

- Putkonen, M.; Vartiainen, J.; Shen, Y.; Kaljunen, T.; Malm, T.; Mika, V. Bio-based multilayer barrier films by extrusion, dispersion coating and atomic layer deposition. J. Appl. Polym. Sci. 2015, 42260, 1–6. [Google Scholar]

- Reichert, C.L.; Bugnicourt, E.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A.; Canesi, I. Bio-based packaging: Materials, modifications, industrial applications and sustainability. Polymers 2020, 12, 1558. [Google Scholar] [CrossRef]

- Sort, J.; Baró, M. Advances in Applications of Industrial Biomaterials; Springer: Berlin/Heidelberg, Germany, 2017; pp. 1–214. [Google Scholar]

- Lu, P.; Yang, Y.; Liu, R.; Liu, X.; Ma, J.; Wu, M. Preparation of sugarcane bagasse nanocellulose hydrogel as a colourimetric freshness indicator for intelligent food packaging. Carbohydr. Polym. 2020, 249, 116831. [Google Scholar] [CrossRef]

- Gaille, B. 25 Bioplastic Industry Statistics, Trends & Analysis. 2018. Available online: https://brandongaille.com/25-bioplastic-industry-statistics-trends-analysis/ (accessed on 6 January 2021).

- Ling, H.; Tapan, C.; Nath, K.; Chong, S.; Foo, V.; Gibbins, C. The plastic waste problem in Malaysia: Management, recycling and disposal of local and global plastic waste. SN Appl. Sci. 2021, 3, 1–15. [Google Scholar] [CrossRef]

- Mordor Intelligence. Malaysia Plastics Market–Growth, Trends, COVID-19 Impact, and Forecasts (2021–2026). 2020, pp. 1–12. Available online: https://www.mordorintelligence.com/industry-reports/malaysia-plastics-market (accessed on 6 January 2021).

- Auras, R.; Harte, B.; Selke, S. An overview of polylactides as packaging materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef]

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. Environmental impact of food packaging materials: A review of contemporary development from conventional plastics to polylactic acid based materials. Materials 2020, 13, 4994. [Google Scholar] [CrossRef]

- Bugnicourt, E.; Cinelli, P.; Lazzeri, A.; Alvarez, V. Polyhydroxyalkanoate (PHA): Review of synthesis, characteristics, processing and potential applications in packaging. Express Polym. Lett. 2014, 8, 791–808. [Google Scholar] [CrossRef] [Green Version]

- Shen, L.; Haufe, J.; Patel, M.K. Product overview and market projection of emerging bio-based plastics PRO-BIP 2009 Utrecht The Netherlands. European Polysaccharide Network of Excellence (EPNOE) and European Bioplastics. 2009. Available online: www.chem.uu.nl/nwswww.copernicus.uu.nlcommissionedbyEuropeanPolysaccharideNetworkofExcellence%0Awww.europeanbioplastics.org (accessed on 11 March 2021).

- Chen, Y.J. Bioplastics and their role in achieving global sustainability. J. Chem. Pharm. Res. 2014, 6, 226–231. Available online: www.jocpr.com (accessed on 22 November 2020).

- Rhim, J.W.; Hong, S.I.; Ha, C.S. Tensile, water vapor barrier and antimicrobial properties of PLA/nanoclay composite films. LWT Food Sci. Technol. 2009, 42, 612–617. [Google Scholar] [CrossRef]

- Cyras, V.P.; Commisso, M.S.; Mauri, A.N.; Vazquez, A. Biodegradable double-layer films based on biological resources: Polyhydroxybutyrate and cellulose. J. Appl. Polym. Sci. 2007, 106, 749–756. [Google Scholar] [CrossRef]

- Iriani, E.S.; Permana, A.W.; Yuliani, S.; Sulaiman, A.A. The effect of agricultural waste nanocellulose on the properties of bioplastic for fresh fruit packaging the effect of agricultural waste nanocellulose on the properties of bioplastic for fresh fruit packaging. Int. Conf. Agric. Postharvest Handl. Process. 2019. [Google Scholar] [CrossRef]

- Ragaert, P.; Buntinx, M.; Maes, C.; Vanheusden, C.; Peeters, R.; Wang, S. Polyhydroxyalkanoates for Food Packaging Applications. Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–9. [Google Scholar] [CrossRef]

- Fabra, M.J.; Sánchez, G.; López-Rubio, A.; Lagaron, J.M. Microbiological and ageing performance of polyhydroxyalkanoate-based multilayer structures of interest in food packaging. LWT Food Sci. Technol. 2014, 59, 760–767. [Google Scholar] [CrossRef]

- Thielen, M. Bioplastics-Basics. Applications. Markets; Polymedia Publisher GmbH: Mönchengladbach, Germany, 2012; 120p. [Google Scholar]

- Philip, S.; Keshavarz, T.; Roy, I. Polyhydroxyalkanoates: Biodegradable polymers with a range of applications. J. Chem. Technol. Biotechnol. 2007, 82, 233–247. [Google Scholar] [CrossRef]

- Arora, S. Biopolymers as packaging material in food and allied industry Value addition of makhana and its by-products View project. Int. J. Chem. Stud. 2018, 6, 2411–2418. Available online: https://www.researchgate.net/publication/342765641 (accessed on 11 March 2021).

- Webb, H.K.; Arnott, J.; Crawford, R.J.; Ivanova, E.P. Plastic degradation and its environmental implications with special reference to poly(ethylene terephthalate). Polymers 2013, 5, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Law, P. Starch-Based Biodegradable Materia. European Patent EP 2712889 A1, 2 April 2014. [Google Scholar]

- Wang, I.J.H.; Us, W.I.; Funk, S.A.; Us, W.I. Biodegradable Packaging Film. U.S. Patent US 8188185 B2, 29 May 2012. [Google Scholar]

- Tweed, E.C.; Stephens, H.M. Polylactic Acid Blown Filmand Method of Manufacturing Same. U.S. patent US 8133558 B2, 14 April 2015. [Google Scholar]

- Xu, Q. Biodegradable Packaging Materals with Enhanced Oxygen Barrier Performance. U.S. Patent US 20110135912 A1, 9 June 2011. [Google Scholar]

- Tweed, E.C.; McDaniel, J.B. Polylactic Acid Shrink Films and Methods of Casting Same. U.S. Patent US 8263197 B2, 11 September 2011. [Google Scholar]

- Tokiwa, Y.; Raku, T. Biodegradable Polylactide Resin Composition. U.S. Patent US 6987138 B2, 17 January 2006. [Google Scholar]

- Scheer, F.F. Bio based Biodegradable Polymer Compositions and Use of Same. U.S. Patent WO 2007/063361 Al, 7 June 2007. [Google Scholar]

- Tangelder, R.; Weber, K.; Van Der Meijden, J.; Plijter, J.; Van Soest, J.; Schennink, G. Bioplastics. European Patent EP 2432830 B1, 10 July 2013. [Google Scholar]

- Castillo, V.; Samuel, H. Biodegradable Films Obtained from Cassava Starch and Their Manufacture Process. U.S. Patent WO 2013/042083 Al, 16 September 2016. [Google Scholar]

- Alain, M.; Sophie, D.; Marie, G.; Marc, G.; Isabelle, A. Bioplastics. European Patent WO 2019122308 A1, 10 July 2013. [Google Scholar]

- Hu, B. Biopolymer-based lightweight materials for packaging applications. ACS Symp. Ser. 2014, 1175, 239–255. [Google Scholar]

- Pandey, J.K.; Pratheep Kumar, A.; Misra, M.; Mohanty, A.K.; Drzal, L.T.; Singh, R.P. Recent advances in biodegradable nanocomposites. J. Nanosci. Nanotechnol. 2005, 5, 497–526. [Google Scholar] [CrossRef]

- Mishra, R.K.; Ha, S.K.; Verma, K.; Tiwari, S.K. Recent progress in selected bio-nanomaterials and their engineering applications: An overview. J. Sci. Adv. Mater. Devices. 2018, 3, 263–288. [Google Scholar] [CrossRef]

- Cheng, C.; Zhou, Y.; Lin, M.; Wei, P.; Yang, S.T. Polymalic acid fermentation by Aureobasidium pullulans for malic acid production from soybean hull and soy molasses: Fermentation kinetics and economic analysis. Bioresour. Technol. 2017, 223, 166–174. [Google Scholar] [CrossRef]

- Yang, H.S.; Gardner, D.J.; Nader, J.W. Dispersion evaluation of microcrystalline cellulose/cellulose nanofibril-filled polypropylene composites using thermogravimetric analysis. J. Therm. Anal. Calorim. 2011, 103, 1007–1015. [Google Scholar] [CrossRef]

- Rešček, A.; Krehula, L.K.; Katančić, Z.; Hrnjak-Murgić, Z. Active bilayer PE/PCL films for food packaging modified with zinc oxide and casein. Croat. Chem. Acta 2015, 88, 461–473. [Google Scholar] [CrossRef]

- Agustin, M.B.; Ahmmad, B.; Alonzo, S.M.M.; Patriana, F.M. Bioplastic based on starch and cellulose nanocrystals from rice straw. J. Reinf. Plast. Compos. 2014, 33, 2205–2213. [Google Scholar] [CrossRef]

- Benhacine, F.; Ouargli, A.; Hadj-Hamou, A.S. Preparation and characterization of novel food packaging materials based on biodegradable PCL/Ag-kaolinite nanocomposites with controlled release properties. Polym. Technol. Mater. 2019, 58, 328–340. [Google Scholar] [CrossRef]

- Cabedo, L.; Feijoo, J.L.; Villanueva, M.P.; Lagarón, J.M.; Giménez, E. Optimization of biodegradable nanocomposites based on aPLA/PCL blends for food packaging applications. Macromol. Symp. 2006, 233, 191–197. [Google Scholar] [CrossRef]

- de Andrade, R.M.; da Silva Júnior, S.M.; Coutinho, S.V.C.R.; Jaques, N.G.; de Vasconcelos Pina, H.; Rodrigues, B.G. PCL/ZNO bio-friendly films as food packaging material.Thermal and morphological analysis. Rev. Mater. 2018, 23, 4. [Google Scholar] [CrossRef]

- Gesellschaft für Verpackungsmarktforschung mbH. Flexible Plastic Packaging Market in Germany and in Europe. Trends and Perspectives until 2021 by Product Categories; GVM: Mainz, Germany, 2016. [Google Scholar]

- European Bioplastics, Institute for Bioplastics and Biocomposites. Report—Bioplastic Marked Data 2017. Available online: www.european-bioplastics.org (accessed on 29 December 2020).

- Bioplastics Facts and Figures. European Bioplastics. Available online: https://docs.european-bioplastics.org/publications/EUBP_Facts_and_figures.pdf (accessed on 30 January 2021).

| Types | Bio-Based | ||

|---|---|---|---|

| Plant | Microorganism | Animal | |

| BIODEGRADABLE (bio-based plastic) | Cellulose and its derivatives (polysaccharide) | PHAs (e.g., P4HB, PHB, PHBH, PHBHx, PHBV) | Chitin (polysaccharide) |

| Lignin | PHF | Chitosan (polysaccharide) | |

| Starch and its derivates (monosaccharide) | Bacterial cellulose | Hyaluronan (polysaccharide) | |

| Alginate (polysaccharide) | Hyaluronan (polysaccharide) | Casein (protein) | |

| Lipids (triglycerides) | Xanthan (polysaccharide) | Whey (protein) | |

| Wheat, corn, pea, potato, soy, potato (protein) | Curdlan (polysaccharide) | Collagen (protein) | |

| Gums (e.g., cis-1,4-polyisoprene) | Pullulan (polysaccharide) | Albumin (protein) | |

| Carrageenan | Silk (protein) | Keratin, PFF (protein) | |

| PLA (from starch or sugarcane) | gellan | Leather (protein) | |

| - | Bio-based | ||

| NON-BIODEGRADABLE (bio-based/fossil-fuel based plastic) | PE (LDPE, HDPE), PP, PVC | ||

| PET, PPT | |||

| PU | |||

| PC | |||

| Poly(ether-ester)s | |||

| Polyamides (PA 11, PA 410, PA 610, PA 1010, PA 1012) | |||

| Polyester amides | |||

| Unsaturated polyesters | |||

| Epoxy | |||

| Phenolic resins | |||

| - | Fossil-based | ||

| BIODEGRADABLE (fossil-fuel based plastic) | Poly(alkylene dicarboxylate)s (e.g., PBA, PBS, PBSA, PBSE, PEA, PES, PESE, PESA, PPF, PPS, PTA, PTMS, PTSE, PTT) | ||

| PGA | |||

| PCL | |||

| PVOH | |||

| POE | |||

| Polyanhydrides | |||

| PPHOS | |||

| Property/Polymer | PLA | PHAs | LDPE | PET | PP | PS |

|---|---|---|---|---|---|---|

| Strength (MPa) | 37–66 | 20–40 | 10–12 | 55–79 | 15–27 | 24–60 |

| Elongation at break (%) | 0.5–9.2 | 1.4–5.5 | 300–500 | 15–165 | 100–600 | 1.6–2.5 |

| Oxygen barrier (permeation at 30 °C (×10−10 cm3(STP)·cm/cm2·S·cm Hg)) | 3.3 | 2–16.5 | 6.9 | 0.04 | 1.5 | 2.6 |

| Moisture vapour transmission rate (g-mil/10in.2/24 h) | 18–22 | 2.36 | 1.0–1.5 | 2 | 0.5 | 10 |

| Water absorbance (%) | 3.1 | 0.7 | 0.005–0.015 | 0.1–0.2 | 0.01–0.1 | 0.01–0.4 |

| Thermal properties (Glass Transition Temperature-Tg (°C)) | 55 | −9–9 | −110 | 73 | −20 | 90 |

| Transparency (Clarity) | High | High | High | Excellent | Poor | Excellent |

| Carbon dioxide barrier (permeation) | 10.2 | 3 | 28 | 0.2 | 5.3 | 10.5 |

| Chemical resistance | Poor | Poor | Good | Good | Good | Good |

| Patent No. | Topic | References |

|---|---|---|

| EP 2712889 A1 | Starch-based biodegradable material | [100] |

| US 8188185 B2 | Biodegradable packaging film made from TPS/PLA blend | [101] |

| US 8133558 B2 | Poly lactic acid blown film and method of manufacturing | [102] |

| US 20110135912 A1 | Biodegradable packaging materials with enhanced oxygen barrier performance | [103] |

| US 8263197 B2 | Poly lactic acid shrink films and methods of casting same | [104] |

| US 6987138 B2 | Biodegradable poly lactide resin composition | [105] |

| WO 2007/063361 Al | Bio-based biodegradable polymer compositions and use of same | [106] |

| EP 2 432 830 B1 | Bioplastics | [107] |

| WO 2013/042083 Al | Biodegradable films obtained from cassava starch and their manufacture process | [108] |

| WO 2019122308 A1 | Novel proteases and uses thereof | [109] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibrahim, N.I.; Shahar, F.S.; Sultan, M.T.H.; Shah, A.U.M.; Safri, S.N.A.; Mat Yazik, M.H. Overview of Bioplastic Introduction and Its Applications in Product Packaging. Coatings 2021, 11, 1423. https://doi.org/10.3390/coatings11111423

Ibrahim NI, Shahar FS, Sultan MTH, Shah AUM, Safri SNA, Mat Yazik MH. Overview of Bioplastic Introduction and Its Applications in Product Packaging. Coatings. 2021; 11(11):1423. https://doi.org/10.3390/coatings11111423

Chicago/Turabian StyleIbrahim, Nor Izaida, Farah Syazwani Shahar, Mohamed Thariq Hameed Sultan, Ain Umaira Md Shah, Syafiqah Nur Azrie Safri, and Muhamad Hasfanizam Mat Yazik. 2021. "Overview of Bioplastic Introduction and Its Applications in Product Packaging" Coatings 11, no. 11: 1423. https://doi.org/10.3390/coatings11111423

APA StyleIbrahim, N. I., Shahar, F. S., Sultan, M. T. H., Shah, A. U. M., Safri, S. N. A., & Mat Yazik, M. H. (2021). Overview of Bioplastic Introduction and Its Applications in Product Packaging. Coatings, 11(11), 1423. https://doi.org/10.3390/coatings11111423