Examination of the Hydrogen Incorporation into Radio Frequency-Sputtered Hydrogenated SiNx Thin Films

Abstract

1. Introduction

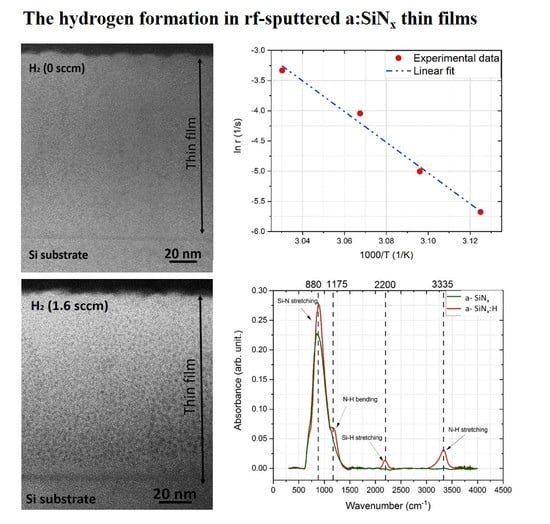

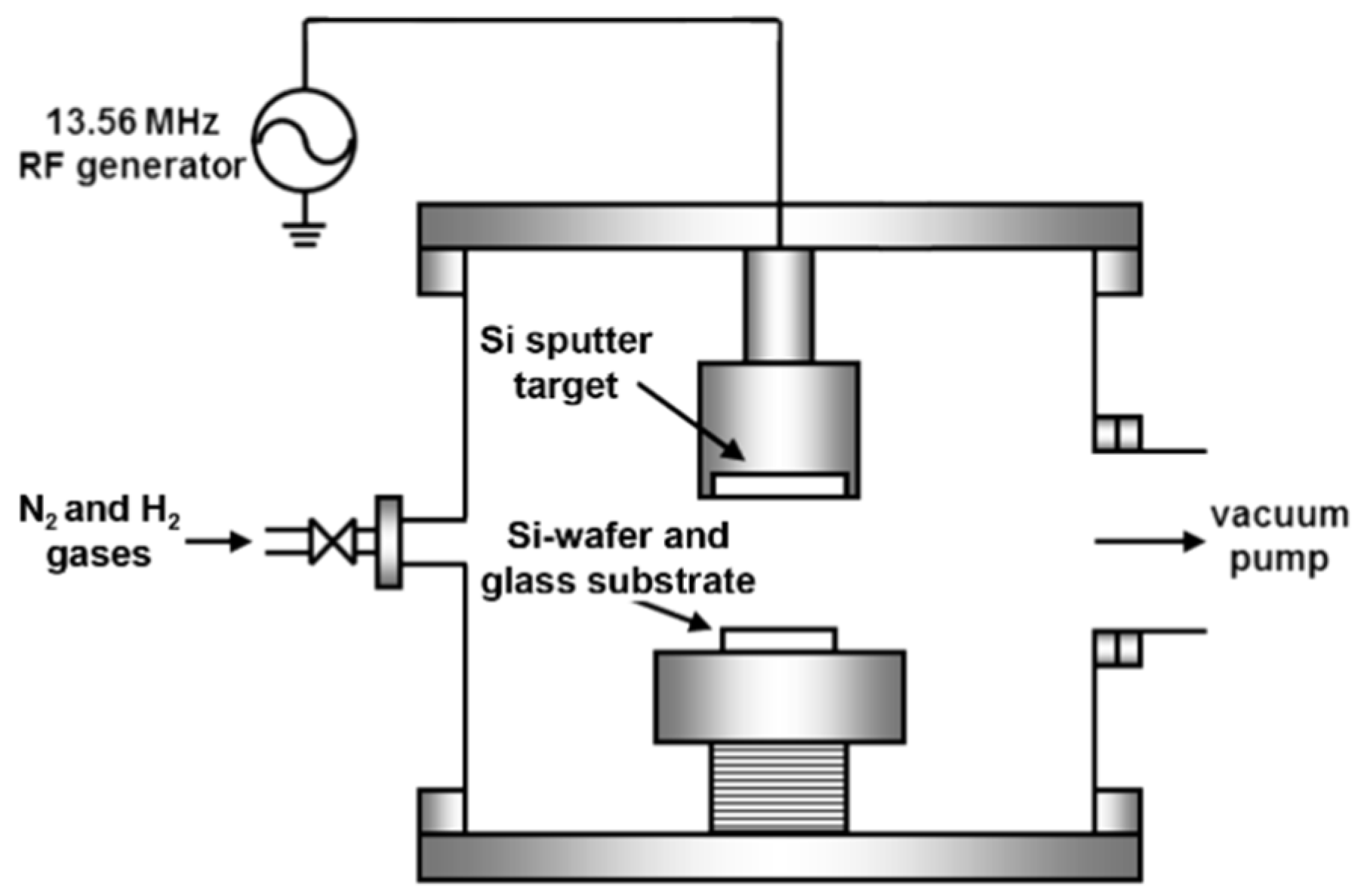

2. Experimental Section

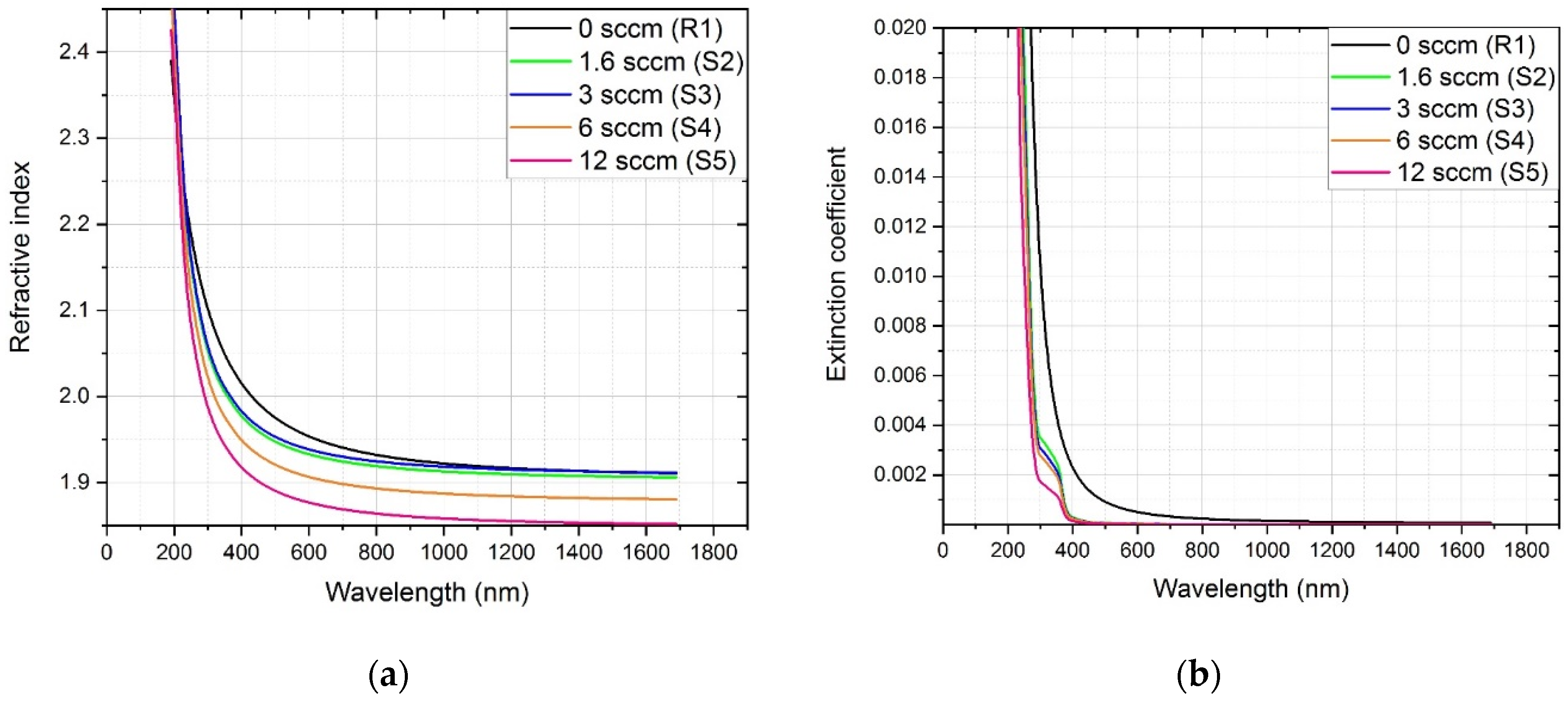

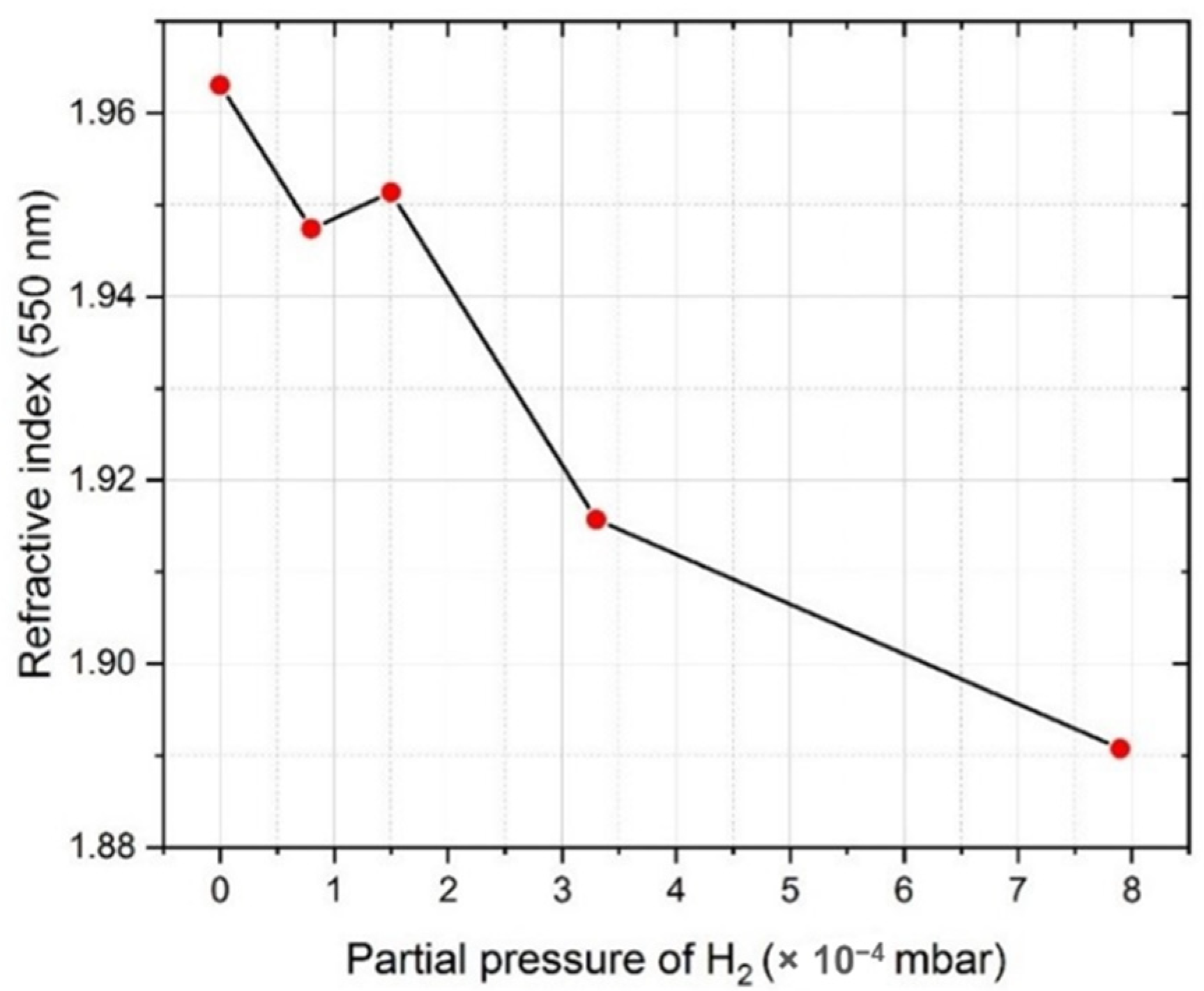

3. Results and Discussion

3.1. Optical Characterization of Thin Films

3.2. Bonding Configuration and Chemical Composition

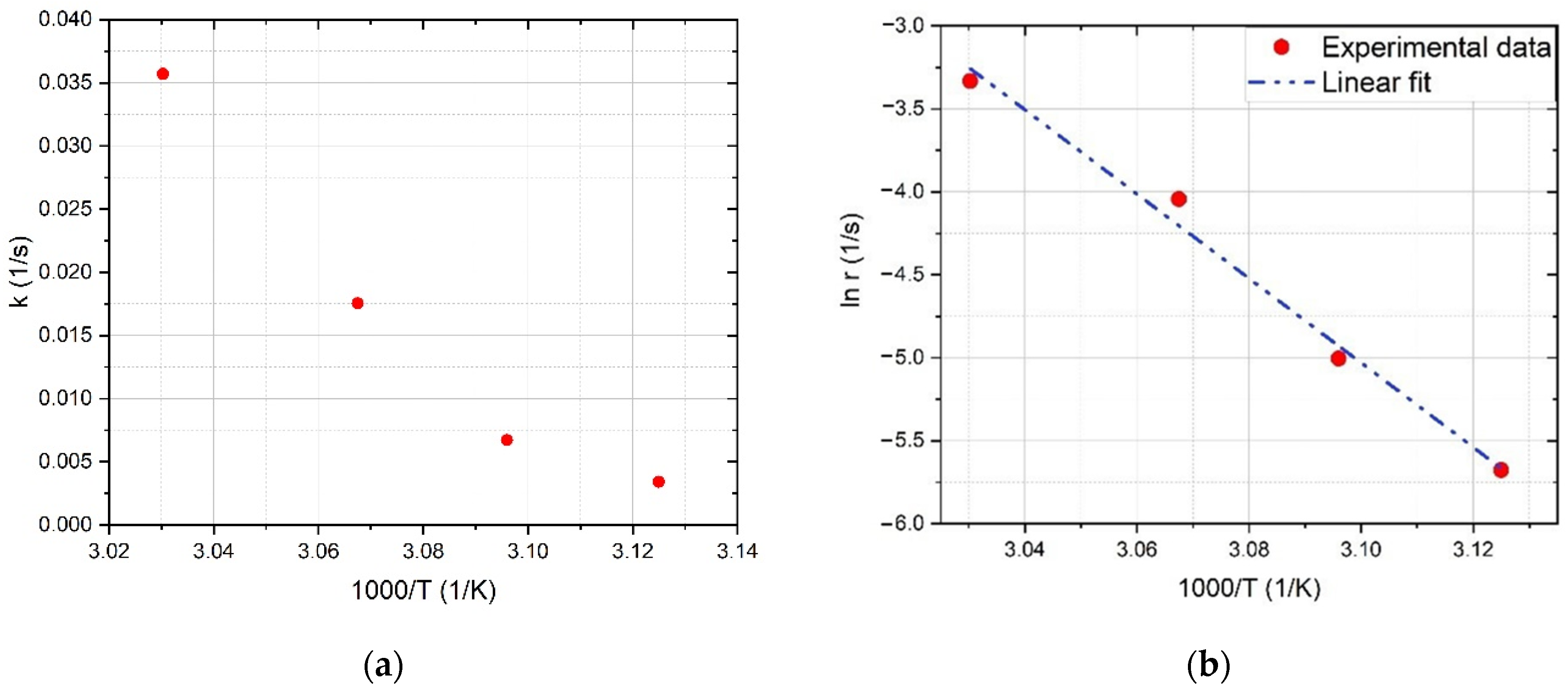

3.3. Activation Energy

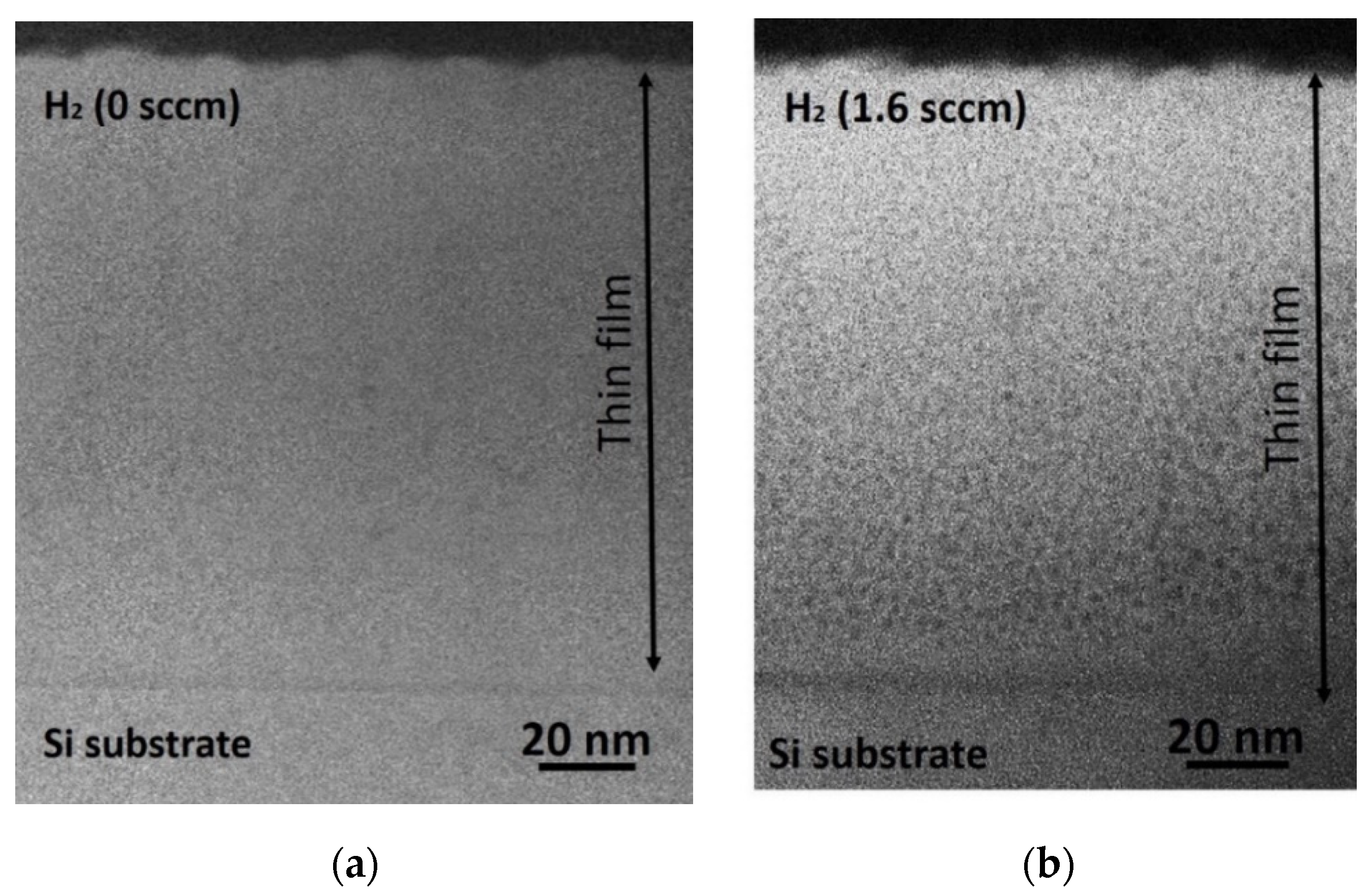

3.4. Structural and Morphological Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liao, W.; Zeng, X.; Wen, X.; Chen, X.; Wang, W. Annealing and excitation dependent photoluminescence of silicon rich silicon nitride films with silicon quantum dots. Vacuum 2015, 12, 147–151. [Google Scholar] [CrossRef]

- Kim, D.W.; Kim, D.H.; Kim, H.J.; So, H.W.; Hong, M.P. Effect of ammonia (NH3) plasma treatment on silicon nitride (SiNx) gate dielectric for organic thin film transistor with soluble organic semiconductor. Curr. Appl. Phys. 2011, 11, S67–S72. [Google Scholar] [CrossRef]

- Jin, Z.; Jung, S.; Duy, N.V.; Hwang, S.; Jang, K.; Lee, K.; Lee, J.; Hyungjun, P.; Kim, J.; Son, H.; et al. Characterization of MONOS nonvolatile memory by solid phase crystallization on glass. Surface Coat. Technol. 2008, 202, 5637–5640. [Google Scholar] [CrossRef]

- Swatowska, B.; Stapinski, T. Amorphous hydrogenated silicon-nitride films for applications in solar cells. Vacuum 2008, 82, 942–946. [Google Scholar] [CrossRef]

- Qiu, W.; Kang, Y.M.; Goddard, L.L. Quasicontinuous refractive index tailoring of SiNx and SiOxNy for broadband antireflective coatings. Appl. Phys. Lett. 2010, 96, 14116. [Google Scholar] [CrossRef]

- Duerinck, F.; Szlufcik, J. Defect passivation of industrial multicrystalline solar cells based on PECVD silicon nitride. Sol. Energy Mater. Sol. Cells 2002, 72, 231–246. [Google Scholar] [CrossRef]

- Boehme, C.; Lucovsky, G. H loss mechanism during anneal of silicon nitride: Chemical dissociation. J. Appl. Phys. 2000, 88, 6055. [Google Scholar] [CrossRef]

- Bommali, R.K.; Ghosh, S.; Khan, S.A.; Srivastava, P. Hydrogen loss and its improved retention in hydrogen plasma treated a-SiNx:H films: ERDA study with 100 MeV Ag7+ ions. Nucl. Instrum. Methods Phys. Res. B 2018, 423, 16–21. [Google Scholar] [CrossRef]

- Guler, I. Optical and structural characterization of silicon nitride thin films deposited by PECVD. Mater. Sci. Eng. B 2019, 246, 21–26. [Google Scholar] [CrossRef]

- Santos-Filho, P.; Stevens, G.; Lu, Z.; Koh, K.; Lucovsky, G. Hydrogen Release and Si-N Bond-Healing Infrared Study of Rapid Thermal Annealed Amorphous Silicon Nitride Thin Films; Cambride University Press: Cambride, UK, 1995. [Google Scholar]

- Martil, I.; del Prado, A.; San Andres, E.; Gonzalez Daz, G.; Martnez, F.L. Rapid thermally annealed plasma deposited SiNx:H thin films: Application to metal-insulator-semiconductor structures with Si, In0.53 Ga0.47 As, and InP. J. Appl. Phys. 2003, 94, 2642. [Google Scholar] [CrossRef]

- Martinez, F.L.; Ruiz-Merino, R.; del Prado, A.; San Andres, E.; Martil, I.; Gonzalez-Diaz, G.; Jeynes, C.; Barradas, N.P.; Wang, L.; Reehal, H.S. Bonding structure and hydrogen content in silicon nitride thin films deposited by electron cyclotron resonance plasma method. Thin Solid Film. 2004, 459, 203–207. [Google Scholar] [CrossRef]

- Verlaan, V.; van der Werf, C.H.M.; Houweling, Z.S.; Romijn, I.G.; Weeber, A.W.; Dekkers, H.F.W.; Goldbach, H.D.; Schropp, R.E.I. Multi-crystalline Si solar cells with very fast deposited (180 nm/min) passivating hot-wire CVD silicon nitride as antireflection coating. Prog. Photovolt. Res. Appl. 2007, 15, 563–573. [Google Scholar] [CrossRef]

- Kessels, W.M.M.; Hong, J.; van Assche, F.J.H.; Moschner, J.D.; Lauinger, T.; Soppe, W.J.; Weeber, A.W.; Schram, D.C.; van de Sanden, M.C.M. High-rate deposition of a-SiNx:H for photovoltaic application y the expanding thermal plasma. J. Vac. Sci. Technol. A 2002, 20, 1704. [Google Scholar] [CrossRef]

- Signore, M.A.; Sytchkova, A.; Dimaio, D.; Cappello, A.; Rizzo, A. Deposition of silicon nitride thin films by RF magnetron sputtering: A material and growth process study. Opt. Mater. 2012, 34, 632–638. [Google Scholar] [CrossRef]

- Mokeddem, K.; Aoucher, M.; Smail, T. Hydrogenated amorphous silicon nitride deposited by DC magnetron sputtering. Superlattices Microstruct. 2006, 40, 598–602. [Google Scholar] [CrossRef]

- Banerjee, R.; Bandyopadhyay, A.K.; Rath, A.K.; Batablyal, A.K.; Barua, A.K. Properties of hydrogenated amorphous Si-N films prepared by r.f. magnetron sputtering with emphasis on the non stochiometric region. Thin Solid Film. 1990, 192, 295–307. [Google Scholar] [CrossRef]

- Tiron, V.; Velicu, I.; Pana, I.; Cristea, D.; Rusu, B.G.; Dinca, P.; Porosnicu, C.; Grigore, E.; Munteanu, D.; Tascu, S. HiPIMS deposition of silicon nitride for solar cell application. Surf. Coat. Technol. 2018, 344, 197–203. [Google Scholar] [CrossRef]

- Boulesbaa, M. Optical and Physico-chemical Properties of Hydrogenated Silicon Nitride Thin Films—Effect of the Thermal Annealing. Spectrosc. Lett. 2016, 50, 5–12. [Google Scholar] [CrossRef]

- de Brito Mota, F.; Justo, J.F.; Fazzio, A. Hydrogen role on the properties of amorphous silicon nitride. J. Appl. Phys. 1999, 86, 1843–1847. [Google Scholar] [CrossRef]

- Tao, S.X.; Theulings, A.M.M.G.; Prodanovic, V.; Smedley, J.; van der Graaf, H. Optical Properties of Silicon-Rich Silicon Nitride (SixNyHz) from First Principles. Computation 2015, 3, 657–669. [Google Scholar] [CrossRef]

- Serényi, M.; Csík, A.; Hámori, A.; Kalas, B.; Lukács, I.; Zolnai, Z.S.; Frigeri, C. Diffusion and reaction kinetics governing surface blistering in radio frequency sputtered hydrogenated a-SixGe1−x (0 < x < 1) thin films. Thin Solid Film. 2019, 679, 58–63. [Google Scholar]

- Jellison, G.E.; Modine, F.A.; Doshi, P.; Rohatgi, A. Spectroscopic ellipsometry characterization of thin-film silicon nitride. Thin Solid Film. 1998, 313–314, 193–197. [Google Scholar] [CrossRef]

- Lanford, W.A.; Rand, M.J. The hydrogen content of plamsa-deposited silicon nitride. J. Appl. Phys. 1978, 49, 2473. [Google Scholar] [CrossRef]

- Parsons, N.; Souk, J.H.; Batey, J. Low hydrogen content stoichiometric silicon nitride films deposited by plamaenhanced chemical vapor deposition. J. Appl. Phys. 1991, 70, 1553–1560. [Google Scholar] [CrossRef]

- Rostaing, J.C.; Cros, Y.; Gujrathi, S.C.; Poulain, S. Quantitative infrared characterization of plasma enhanced CVD silicon oxynitride films. J. Non-Cryst. Solids 1987, 97–98, 1051–1054. [Google Scholar] [CrossRef]

- Dekkers, H.F.W.; Carnel, L.; Beaucarne, G.; Beyer, W. Diffusion mechanism of hydrogen through PECVD SiNx:H for a fast defect passivation of mc-Si solar cells. In Proceedings of the 20th European Photovoltaic Solar Energy Conference, Barcelona, Spain, 6–10 June 2005. [Google Scholar]

- Menzinger, M.; Wolfgang, R. The Meaning and Use of the Arrhenius Activation Energy. Angew. Chem. 1969, 8, 438–444. [Google Scholar] [CrossRef]

- Lábár, J.L. Electron Diffraction Based Analysis of Phase Fractions and Texture in Nanocrystalline Thin Films, Part I: Principles. Microsc. Microanal. 2008, 14, 287–295. [Google Scholar] [CrossRef]

- Lábár, J.L. Electron Diffraction Based Analysis of Phase Fractions and Texture in Nanocrystalline Thin Films, Part II: Implementation. Microsc. Microanal. 2009, 15, 20–29. [Google Scholar] [CrossRef]

- Lábár, J.L. Electron Diffraction Based Analysis of Phase Fractions and Texture in Nanocrystalline Thin Films, Part III: Application Examples. Microsc. Microanal. 2012, 18, 406–420. [Google Scholar] [CrossRef]

- Flewitt, A.J.; Dyson, A.P.; Robertson, J.; Milne, W.I. Low temperature growth of silicon nitride by electron cyclotron resonance plasma enhanced chemical vapour deposition. Thin Solid Film. 2001, 383, 172–177. [Google Scholar] [CrossRef]

- Jafari, S.; Hirsch, J.; Lausch, Z.; John, M.; Bernhard, N.; Meyer, S. Composition Limited Hydrogen Effusion Rate of a-SiNx:H Passivation Stack. Aip Conf. Proc. 2019, 2147, 050004. [Google Scholar]

- Fitzner, M.; Abelson, J.R.; Kanicki, J. Investigation of hydrogen and nitrogen thermal stability in PECVD a-SiNx:H. MRS Online Proc. Libr. Arch. 2011, 258, 362–368. [Google Scholar] [CrossRef]

- Martnez, F.L.; del Prado, A.; Martil, I.; Gonzalez-Daz, G.; Selle, B.; Sieber, I. Thermally induced changes in the optical properties of SiNx:H films deposited by the electron cyclotron resonance plasma method. J. Appl. Phys. 1999, 86, 2055. [Google Scholar] [CrossRef]

| Nr. | Thin Film | pH2 (10−4 mbar) | pH2 % of Total Pressure (%) | Sputtering Time (min) | Flow (sccm) | Substrate |

|---|---|---|---|---|---|---|

| R1 | a-SiNx | 0 | 0 | 30 | 0 * | SSP |

| R2 | a-SiNx | 0 | 0 | 80 | 0 * | SSP, DSP glass |

| S1 | a-SiNx:H | 0.5 | 0.2 | 30 | 0.9 | SSP |

| S2 | a-SiNx:H | 0.8 | 0.32 | 30 | 1.6 | SSP |

| S3 | a-SiNx:H | 1.5 | 0.6 | 30 | 3 | SSP |

| S4 | a-SiNx:H | 3.3 | 1.32 | 30 | 6 | SSP |

| S5 | a-SiNx:H | 7.9 | 3.16 | 30 | 12 | SSP |

| S6 | a-SiNx:H | 3.3 | 1.32 | 80 | 12 | SSP, DSP glass |

| Bond | (Y–H)s (cm−1) | (Y–H)f (cm−1) | AY–H | σY–H (10−18 cm−2) | CY–H (1020 cm−3) |

|---|---|---|---|---|---|

| N–H | 3026 | 3502 | 0.066 | 5.3 | 3.49 |

| Si–H | 1994 | 2299 | 0.016 | 7.4 | 0.61 |

| H2 Flow (sccm) | Atomic Layer Density (1022 at/cm3) | Silicon (Si) | Nitrogen (N) | Hydrogen (H) | |||

|---|---|---|---|---|---|---|---|

| at.% | (1022 at/cm3) | at.% | (1022 at/cm3) | at.% | (1022 at/cm3) | ||

| 0 * | 6.8 | 43.2 | 3.1 | 50 | 3.59 | 6.8 | 0.46 |

| 0.9 | 6.25 | 40.4 | 2.48 | 52 | 3.19 | 7.6 | 0.47 |

| 1.6 | 6.6 | 43.3 | 2.73 | 45.3 | 2.85 | 11.4 | 0.75 |

| 3 | 4.9 | 35.2 | 1.72 | 52.4 | 2.57 | 12.4 | 0.61 |

| 12 | 6 | 33.1 | 1.99 | 57 | 3.42 | 9.9 | 0.59 |

| Temperature (K) | Onset Time (s) |

|---|---|

| 320 | 292 |

| 323 | 149 |

| 326 | 57 |

| 330 | 28 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hegedüs, N.; Lovics, R.; Serényi, M.; Zolnai, Z.; Petrik, P.; Mihály, J.; Fogarassy, Z.; Balázsi, C.; Balázsi, K. Examination of the Hydrogen Incorporation into Radio Frequency-Sputtered Hydrogenated SiNx Thin Films. Coatings 2021, 11, 54. https://doi.org/10.3390/coatings11010054

Hegedüs N, Lovics R, Serényi M, Zolnai Z, Petrik P, Mihály J, Fogarassy Z, Balázsi C, Balázsi K. Examination of the Hydrogen Incorporation into Radio Frequency-Sputtered Hydrogenated SiNx Thin Films. Coatings. 2021; 11(1):54. https://doi.org/10.3390/coatings11010054

Chicago/Turabian StyleHegedüs, Nikolett, Riku Lovics, Miklós Serényi, Zsolt Zolnai, Péter Petrik, Judit Mihály, Zsolt Fogarassy, Csaba Balázsi, and Katalin Balázsi. 2021. "Examination of the Hydrogen Incorporation into Radio Frequency-Sputtered Hydrogenated SiNx Thin Films" Coatings 11, no. 1: 54. https://doi.org/10.3390/coatings11010054

APA StyleHegedüs, N., Lovics, R., Serényi, M., Zolnai, Z., Petrik, P., Mihály, J., Fogarassy, Z., Balázsi, C., & Balázsi, K. (2021). Examination of the Hydrogen Incorporation into Radio Frequency-Sputtered Hydrogenated SiNx Thin Films. Coatings, 11(1), 54. https://doi.org/10.3390/coatings11010054