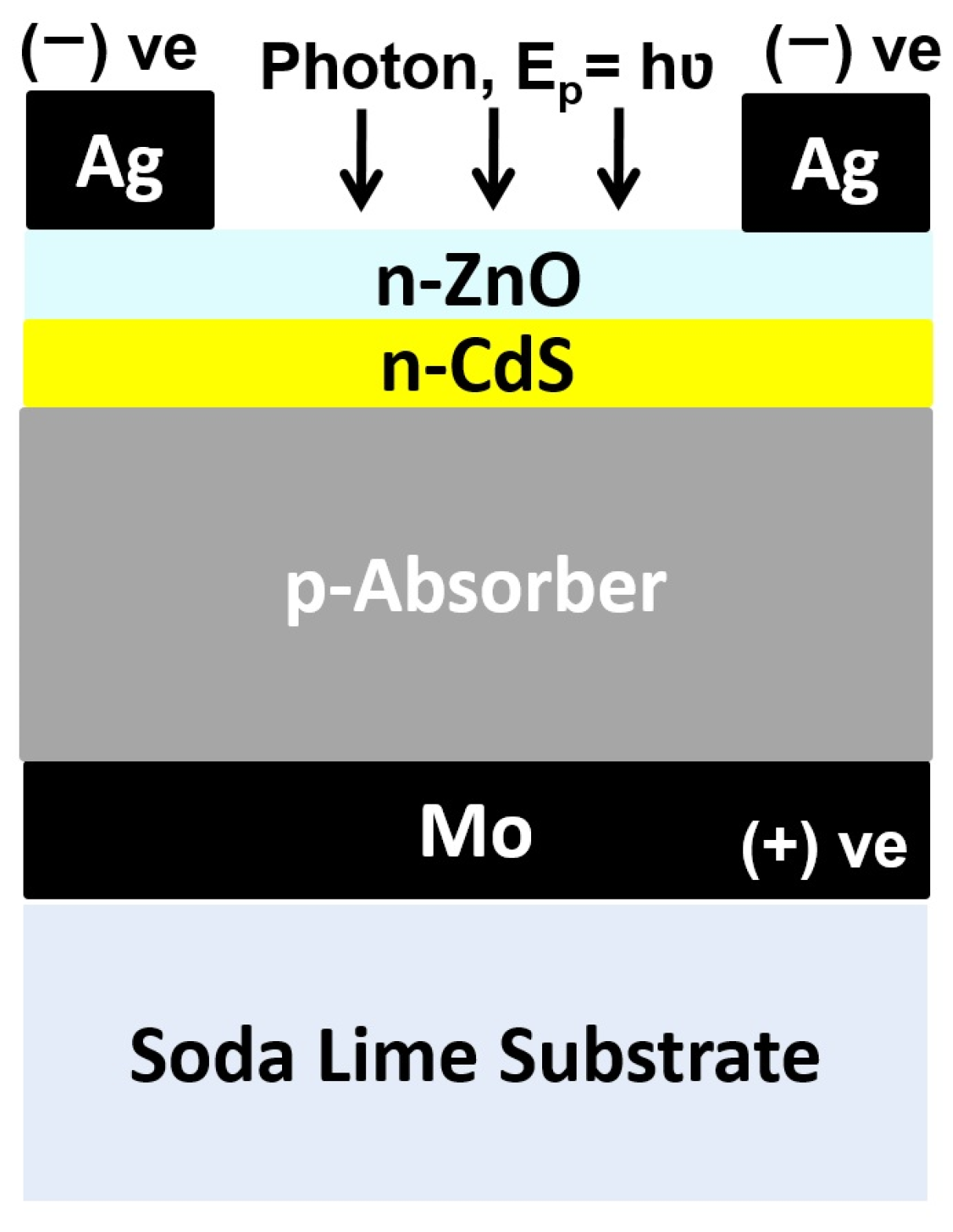

Numerical Insights into the Influence of Electrical Properties of n-CdS Buffer Layer on the Performance of SLG/Mo/p-Absorber/n-CdS/n-ZnO/Ag Configured Thin Film Photovoltaic Devices

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

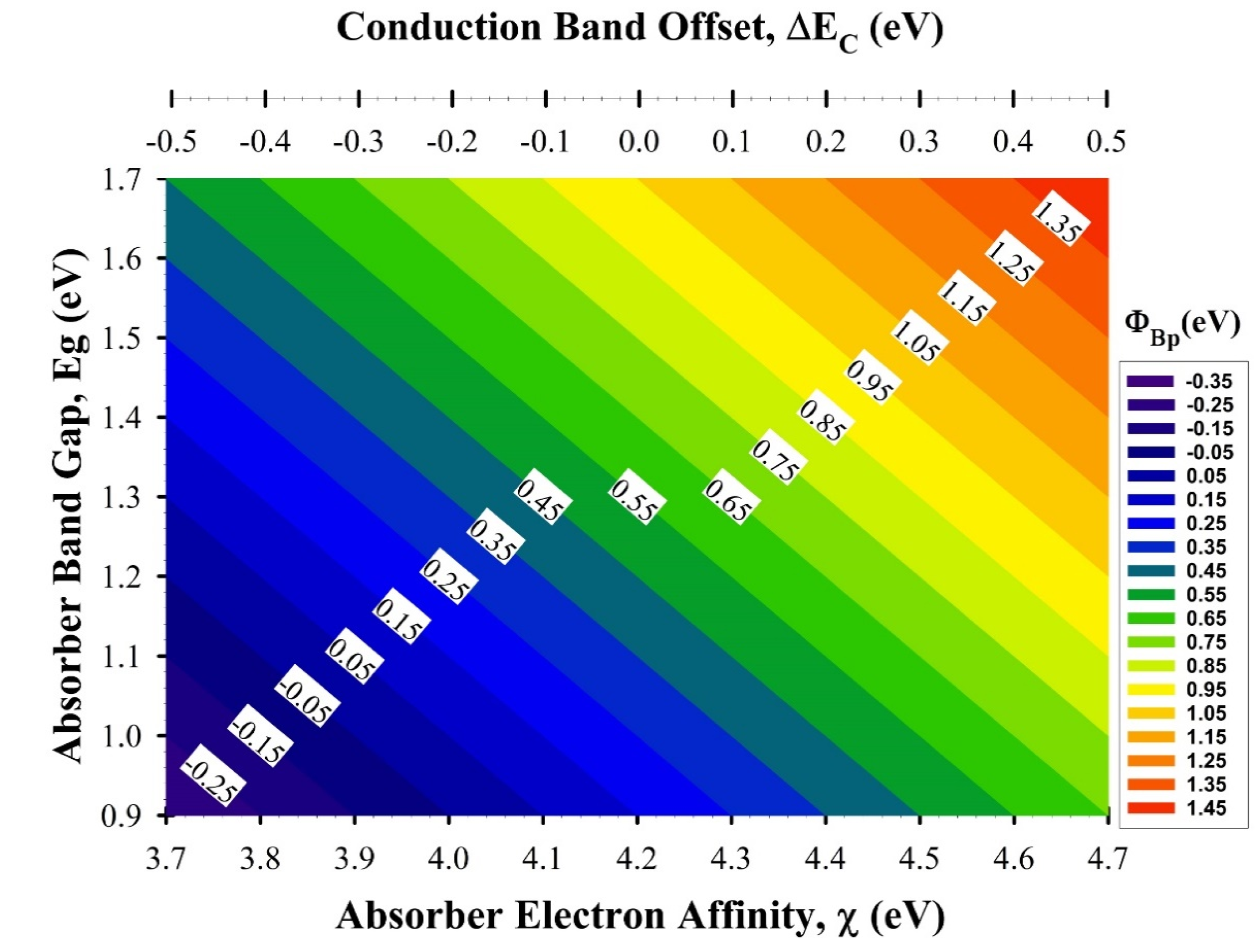

3.1. Interfacial Electronic Parameters of Mo/p-Absorber/n-CdS Heterostructure

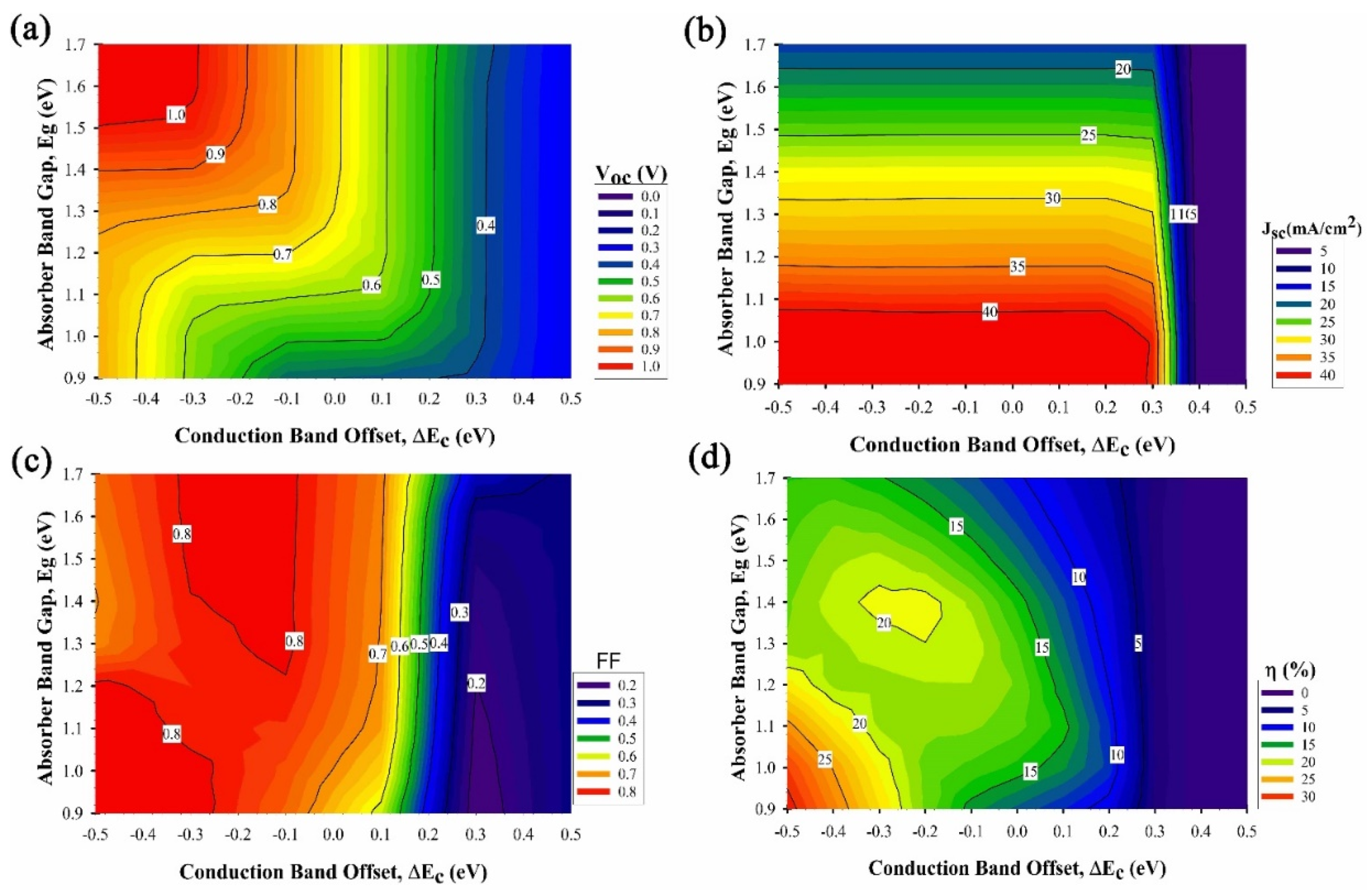

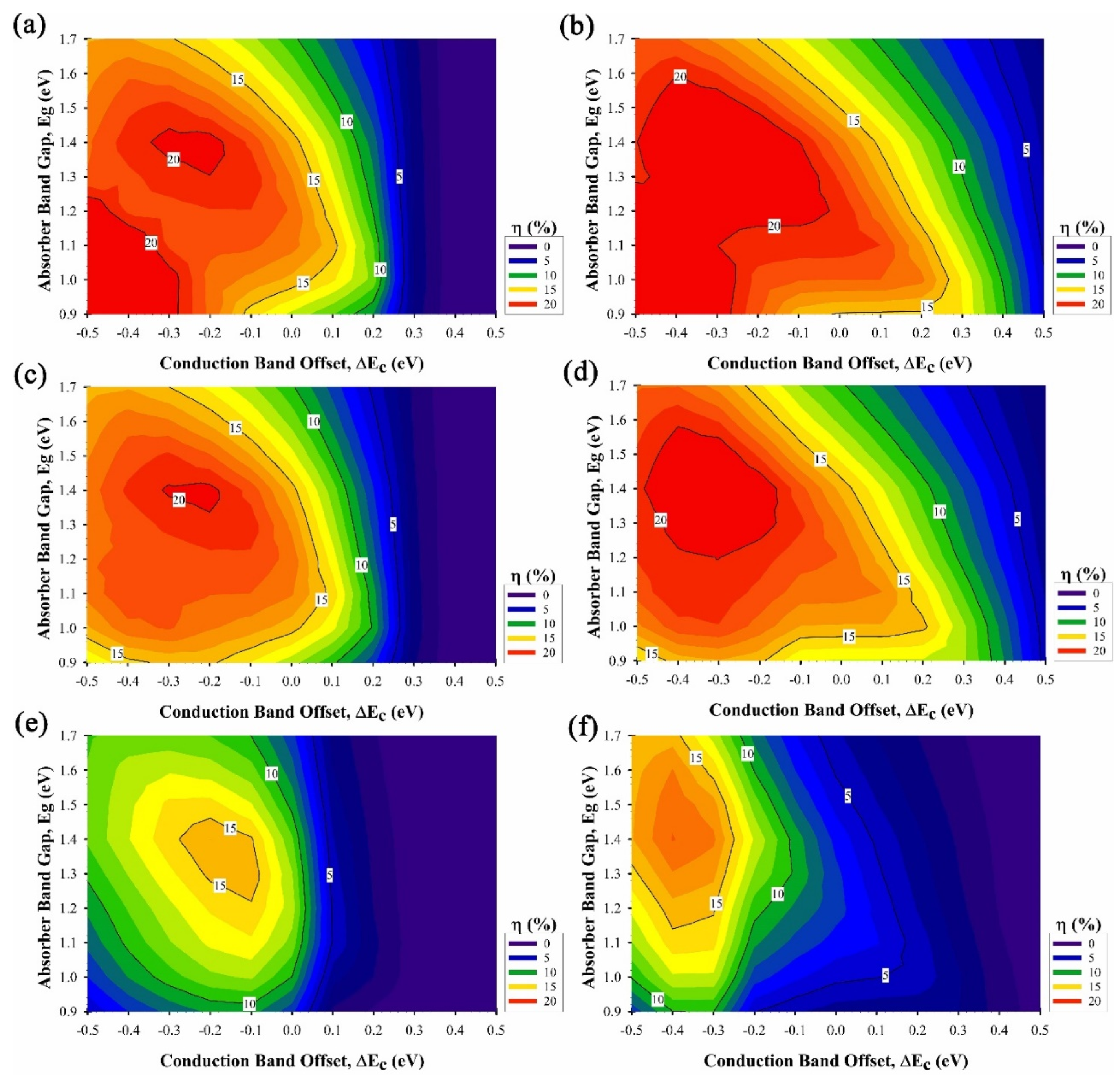

3.2. Case I: Ideal Absorber Layer (No Defect)

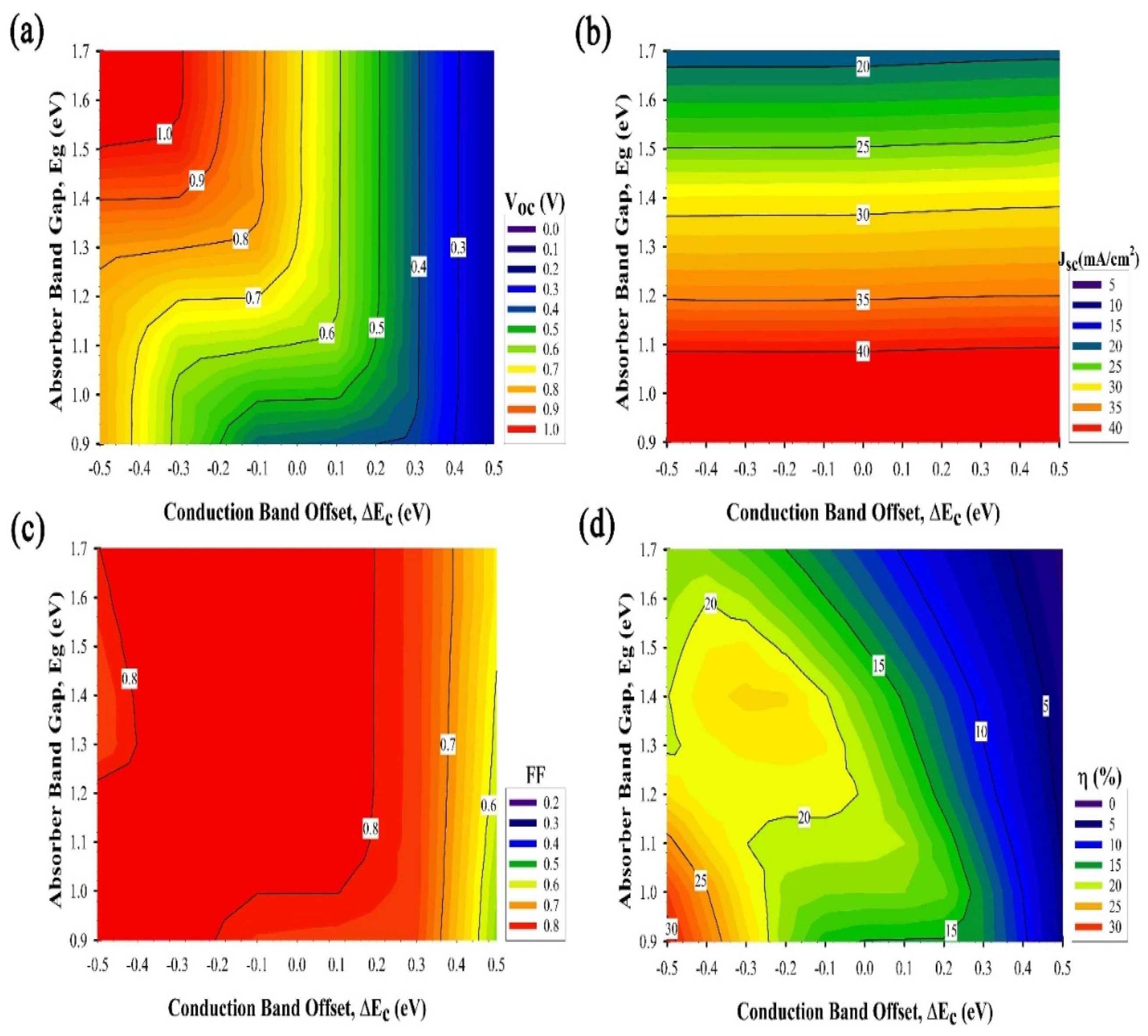

3.3. Case II: Absorber Layer with Variable Defect Density

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhuk, S.; Kushwaha, A.; Wong, T.K.S.; Masudy-Panah, S. Critical review on sputter-deposited Cu2ZnSnS4 (CZTS) based thin fi lm photovoltaic technology focusing on device architecture and absorber quality on the solar cells performance. Sol. Energy Mater. Sol. Cells 2016, 171, 239–252. [Google Scholar] [CrossRef]

- Najm, A.S.; Ludin, N.A.; Abdullah, M.F.; Almessiere, M.A.; Ahmed, N.M.; Al-Alwani, M.A.M. Areca catechu extracted natural new sensitizer for dye-sensitized solar cell: Performance evaluation. J. Mater. Sci. Mater. Electron. 2020, 31, 3564–3575. [Google Scholar] [CrossRef]

- Nayak, P.K.; Mahesh, S.; Snaith, H.J.; Cahen, D. Photovoltaic solar cell technologies: Analysing the state of the art. Nat. Rev. Mater. 2019, 4, 269–285. [Google Scholar] [CrossRef]

- Green, M.; Dunlop, E.; Hohl-Ebinger, J.; Yoshita, M.; Kopidakis, N.; Hao, X. Solar cell efficiency tables (version 57). Prog. Photovolt. Res. Appl. 2020, 27, 3–12. [Google Scholar] [CrossRef]

- Candelise, C.; Winskel, M.; Gross, R. Implications for CdTe and CIGS technologies production costs of indium and tellurium scarcity. Prog. Photovolt. Res. Appl. 2012, 20, 816–831. [Google Scholar] [CrossRef]

- Grandell, L.; Höök, M. Assessing rare metal availability challenges for solar energy technologies. Sustainability 2015, 7, 11818–11837. [Google Scholar] [CrossRef]

- Yan, C.; Huang, J.; Sun, K.; Johnston, S.; Zhang, Y.; Sun, H.; Pu, A.; He, M.; Liu, F.; Eder, K.; et al. Cu2ZnSnS4 solar cells with over 10% power conversion efficiency enabled by heterojunction heat treatment. Nat. Energy 2018, 3, 764–772. [Google Scholar] [CrossRef]

- Ferdaous, M.; Chelvanathan, P.; Shahahmadi, S.; Sapeli, M.; Sopian, K.; Amin, N. Compositional disparity in Cu2ZnSnS4 (CZTS) thin film deposited by RF-sputtering from a single quaternary compound target. Mater. Lett. 2018, 221, 201–205. [Google Scholar] [CrossRef]

- Umehara, M.; Takeda, Y.; Motohiro, T.; Sakai, T.; Awano, H.; Maekawa, R. Cu2Sn1−xGexS3(x = 0.17) thin-film solar cells with high conversion efficiency of 6.0%. Appl. Phys. Express 2013, 6, 045501. [Google Scholar] [CrossRef]

- Sabbir, E.; Chelvanathan, P.; Ahmad, S.; Bais, B.; Kiong, S.; Sopian, K. Fabrication of Cu2SnS3 thin film solar cells by sulphurization of sequentially sputtered Sn/CuSn metallic stacked precursors. Sol. Energy 2019, 177, 262–273. [Google Scholar]

- Prabukanthan, P.; Thamaraiselvi, S.; Harichandran, G. Single step electrochemical deposition of p-type undoped and Co2+Doped FeS2 thin films and performance in heterojunction solid solar cells. J. Electrochem. Soc. 2017, 164, D581–D589. [Google Scholar] [CrossRef]

- Shukla, S.; Xing, G.; Ge, H.; Prabhakar, R.R.; Mathew, S.; Su, Z.; Nalla, V.; Venkatesan, T.; Mathews, N.; Sritharan, T.; et al. Origin of photocarrier losses in iron pyrite (FeS2) nanocubes. ACS Nano 2016, 10, 4431–4440. [Google Scholar] [CrossRef] [PubMed]

- Sinsermsuksakul, P.; Sun, L.; Lee, S.W.; Park, H.H.; Kim, S.B.; Yang, C.; Gordon, R.G. Overcoming efficiency limitations of SnS-based solar cells. Mater. Views 2014, 15, 1400496. [Google Scholar] [CrossRef]

- Spalatu, N.; Hiie, J.; Kaupmees, R.; Volobujeva, O.; Krustok, J.; Acik, I.O.; Krunks, M. Postdeposition processing of SnS thin films and solar cells: Prospective strategy to obtain large, sintered, and doped SnS grains by recrystallization in the presence of a metal halide flux. ACS Appl. Mater. Interfaces 2019, 11, 17539–17554. [Google Scholar] [CrossRef]

- Mitchell, K.; Potter, R.; Ermer, J.; Wieting, R.; Eberspacher, C. High efficiency thin film tandem PV modules. In Proceedings of the 19th IEEE Hotovoltaic Specialists Conference, New Orleans, LA, USA, 4–8 May 1987; pp. 13–18. [Google Scholar]

- Holi, A.M.; Al-Zahrani, A.A.; Najm, A.S.; Chelvanathan, P.; Amin, N. PbS/CdS/ZnO nanowire arrays: Synthesis, structural, optical, electrical, and photoelectrochemical properties. Chem. Phys. Lett. 2020, 750, 137486. [Google Scholar] [CrossRef]

- Najm, A.S.; Chowdhury, M.S.; Munna, M.T.; Chelvanathan, P.; Selvanathan, V.; Aminuzzaman, M.; Techato, K.; Amin, N.; Akhtaruzzaman, M.D. Impact of cadmium salt concentration on Cds nanoparticles synthesized by chemical precipitation methot. Chalcogenide Lett. 2020, 17, 537–547. [Google Scholar]

- Voznyi, A.; Kosyak, V.; Opanasyuk, A.; Tirkusova, N.; Grase, L.; Medvids, A. Structural and electrical properties of SnS2 thin films. Mater. Chem. Phys. 2016, 173, 52–61. [Google Scholar] [CrossRef]

- Yusoff, Y.; Chelvanathan, P.; Huda, Q.; Akhtar, P.; Alam, M.M.; Al-Othman, Z.A.; Amin, N. High quality CdS thin film growth by avoiding anomalies in chemical bath deposition for large area thin film solar cell application. J. Nanosci. Nanotechnol. 2015, 15, 9240–9245. [Google Scholar] [CrossRef]

- Islam, M.; Hossain, S.; Aliyu, M.; Chelvanathan, P.; Huda, Q.; Karim, M.; Sopian, K.; Amin, N. Comparison of structural and optical properties of CdS thin films grown by CSVT, CBD and sputtering techniques. Energy Procedia 2013, 33, 203–213. [Google Scholar] [CrossRef]

- Memarian, N.; Rozati, S.M.; Concina, I.; Vomiero, A. Deposition of nanostructured CdS thin films by thermal evaporation method: Effect of substrate temperature. Materials 2017, 10, 773. [Google Scholar] [CrossRef]

- Parvez, S.; Khabir, K.M. Chemical bath deposition of CdS layer for thin film solar cell. South Asian J. Res. Eng. Sci. Technol. 2017, 2, 3. [Google Scholar]

- Zheng, X.; Li, W.; Aberle, A.G.; Venkataraj, S. Efficiency enhancement of ultra-thin Cu(In,Ga)Se2 solar cells: Optimizing the absorber bandgap profile by numerical device simulations. Curr. Appl. Phys. 2016, 16, 1334–1341. [Google Scholar] [CrossRef]

- Nakada, T.; Mizutani, M. 18% Efficiency Cd-free Cu(In,Ga)Se2 thin-film solar cells fabricated using chemical bath deposition (CBD)—ZnS buffer layers fabricated using chemical bath deposition (CBD)-ZnS buffer layers. Jpn. J. Appl. Phys. 2002, 41, 165. [Google Scholar] [CrossRef]

- Chelvanathan, P.; Yusoff, Y.; Haque, F.; Akhtaruzzaman, M.; Alam, M.; Alothman, Z.; Rashid, M.; Sopian, K.; Amin, N. Growth and characterization of RF-sputtered ZnS thin film deposited at various substrate temperatures for photovoltaic application. Appl. Surf. Sci. 2015, 334, 138–144. [Google Scholar] [CrossRef]

- Ho, W.-H.; Hsu, C.-H.; Yeh, T.-H.; Chang, Y.-H.; Wei, S.-Y.; Lin, T.-Y.; Lay, C.-H. Room-temperature chemical solution treatment for flexible ZnS(O, OH)/Cu(In,Ga)Se2 solar cell: Improvements in interface properties and. ACS Appl. Mater. Interfaces 2016, 8, 6709–6717. [Google Scholar] [CrossRef] [PubMed]

- Benzetta, A.; El, H.; Abderrezek, M.; Elamine, M. Numerical analysis of potential buffer layer for Cu2ZnSnS4 (CZTS) solar cells. Optik Stuttg. 2019, 204, 164155. [Google Scholar]

- Slonopas, A.; Ryan, H.; Foley, B.; Sun, Z.; Sun, K.; Globus, T.; Norris, P. Growth mechanisms and their effects on the opto-electrical properties of CdS thin films prepared by chemical bath deposition. Mater. Sci. Semicond. Process. 2016, 52, 24–31. [Google Scholar] [CrossRef]

- Khallaf, H.; Chai, G.; Lupan, O.; Chow, L.; Park, S.; Schulte, A. Characterization of gallium-doped CdS thin films grown by chemical bath deposition. Appl. Surf. Sci. 2009, 255, 4129–4134. [Google Scholar] [CrossRef]

- Khallaf, H.; Chai, G.; Lupan, O.; Chow, L.; Park, S. Investigation of aluminium and indium in situ doping of chemical bath deposited CdS thin films. J. Phys. D Appl. Phys. 2008, 41, 185304. [Google Scholar] [CrossRef]

- Azmi, N.; Chelvanathan, P.; Yusoff, Y.; Shahahmadi, S.; Tiong, S.; Sopian, K.; Amin, N. A comprehensive study on the effects of alternative sulphur precursor on the material properties of chemical bath deposited CdS thin films. Ceram. Int. 2020, 46, 18716–18724. [Google Scholar] [CrossRef]

- Burgelman, M.; Nollet, P.; Degrave, S. Modeling polycrystalline semiconductor solar cells. Thin Solid Films 2000, 362, 527–532. [Google Scholar] [CrossRef]

- Colombara, D.; Werner, F.; Schwarz, T.; Infante, I.C.; Fleming, Y.; Valle, N.; Spindler, C.; Vacchieri, E.; Rey, G.; Guennou, M.; et al. Sodium enhances indium-gallium interdiffusion in copper indium gallium diselenide photovoltaic absorbers. Nat. Commun. 2018, 9, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Grini, S.; Sopiha, K.V.; Ross, N.; Liu, X.; Bjørheim, T.S.; Platzer-Björkman, C.; Persson, C.; Vines, L. Strong interplay between sodium and oxygen in kesterite absorbers: Complex formation, incorporation, and tailoring depth distributions. Adv. Energy Mater. 2019, 9, 1–9. [Google Scholar] [CrossRef]

- Chantana, J.; Tai, K.; Hayashi, H.; Nishimura, T.; Kawano, Y.; Minemoto, T. Investigation of carrier recombination of Na-doped Cu2SnS3 solar cell for its improved conversion efficiency of 5.1%. Sol. Energy Mater. Sol. Cells 2020, 206, 110261. [Google Scholar] [CrossRef]

- Moon, D.G.; Rana, T.R.; Rehan, S.; Naqvi, S.D.H.; Sidique, Y.; Lee, S.M.; Ahn, S.K.; Choo, Y.S.; Ahn, S. Na-mediated stoichiometry control of FeS thin films: Suppression of nanoscale S-deficiency and improvement of photoresponse. ACS Appl. Mater. Interfaces 2019, 46, 43244–43251. [Google Scholar] [CrossRef]

- Steinmann, V.; Brandt, R.E.; Chakraborty, R.; Jaramillo, R.; Young, M.; Ofori-Okai, B.K.; Yang, C.; Polizzotti, A.; Nelson, K.A.; Gordon, R.G.; et al. The impact of sodium contamination in tin sulfide thin-film solar cells. APL Mater. 2016, 4, 026103. [Google Scholar] [CrossRef]

- Chelvanathan, P.; Zakaria, Z.; Yusoff, Y.; Akhtaruzzaman, M.; Alam, M.M. Mo thin film. Appl. Surf. Sci. 2014, 334, 129–137. [Google Scholar] [CrossRef]

- Chelvanathan, P.; Li, T.; Wei, X.; Yan, B. Effects of RF magnetron sputtering deposition process parameters on the properties of molybdenum thin fi lms. Thin Solid Films 2017, 638, 213–219. [Google Scholar] [CrossRef]

- Michaelson, H.B. The work function of the elements and its periodicity. J. Appl. Phys. 1977, 48, 4729–4733. [Google Scholar] [CrossRef]

- Pepper, M. Metal-semiconductor contacts. Phys. Technol. 1974, 5, 223. [Google Scholar] [CrossRef]

- Colinge, J.-P.; Colinge, C.A. Physics of Semiconductor Devices; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Scheer, R.; Schock, H.-W. Thin Film Heterostructures; Wiley: Hoboken, NJ, USA, 2011; pp. 9–127. [Google Scholar]

- Kotipalli, R.; Poncelet, O.; Li, G. Addressing the impact of rear surface passivation mechanisms on ultra-thin Cu(In, Ga)Se2 solar cell performances using SCAPS 1-D model Addressing the impact of rear surface passivation mechanisms on ultra-thin Cu(In, Ga)Se2 solar cell performa. Sol. Energy 2017, 157, 603–613. [Google Scholar] [CrossRef]

- Limam, N.; Belghachi, A. Analysis of CIGS and CdTe solar cell concentrators. J. Ovonic Res. 2017, 13, 129–134. [Google Scholar]

- Jhuma, F.A.; Shaily, M.Z.; Rashid, M.J. Towards high-efficiency CZTS solar cell through buffer layer optimization. Mater. Renew. Sustain. Energy 2019, 8, 6. [Google Scholar] [CrossRef]

- Cozza, D.; Ruiz, C.M.; Duche, D.; Simon, J.J.; Escoubas, L. Modeling the back contact of Cu2ZnSnSe4 solar cells. IEEE J. Photovolt. 2016, 6, 1292–1297. [Google Scholar] [CrossRef]

- Avellaneda, D.; Nair, M.T.S.; Nair, P.K. Cu2SnS3 and Cu4SnS4 thin films via chemical deposition for photovoltaic application. J. Electrochem. Soc. 2010, 157, 346–352. [Google Scholar] [CrossRef]

- MMinbashi; Ghobadi, A.; Ehsani, M.H.; Dizaji, H.R.; Memarian, N. Simulation of high efficiency SnS-based solar cells with SCAPS. Sol. Energy 2018, 176, 520–525. [Google Scholar] [CrossRef]

- Wu, L.L.; Dzade, N.Y.; Gao, L.L.; Scanlon, D.O.; Öztürk, Z.; Hollingsworth, N.; Weckhuysen, B.M.; Hensen, E.J.M.; De Leeuw, N.H.; Hofmann, J.P. Enhanced photoresponse of FeS2 Films: The role of marcasite-pyrite phase junctions. Adv. Mater. 2016, 28, 9602–9607. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Luo, T.; Chen, H.; Lou, Z.; Shen, G. Au-nanoparticles-decorated Sb2S3 nanowire-based flexible ultraviolet/visible photodetectors. J. Mater. Chem. C 2017, 5, 3330–3335. [Google Scholar] [CrossRef]

- Sze, S.M.; Kwok, K.N. Introduction Crystal Structure Energy Bands and Energy Gap Carrier Concentration at Thermal Equilibrium Carrier-Transport Phenomena Phonon, Optical, and Thermal Properties Heterojunctions and Nanostructures Basic Equations and Examples; Wiley: Hoboken, NJ, USA, 2006. [Google Scholar]

- Chelvanathan, P.; Istiaque, M.; Amin, N. Performance analysis of copper—indium—gallium—diselenide (CIGS) solar cells with various buffer layers by SCAPS. Curr. Appl. Phys. J. 2010, 10, 387–391. [Google Scholar] [CrossRef]

- Dweydari, A.W.; Mee, C.H.B. Work function measurements on (100) and (110) surfaces of silver. Phys. Status Solidi A 1975, 27, 223–230. [Google Scholar] [CrossRef]

- Streetman, B.G.; Banerjee, S.K. Solid State Electronic Device; Pearson College Div: New York, NY, USA, 2006. [Google Scholar]

- Chelvanathan, P.; Shahahmadi, S.; Ferdaous, M.; Sapeli, M.; Sopian, K.; Amin, N. Controllable formation of MoS2 via preferred crystallographic orientation modulation of DC-sputtered Mo thin film. Mater. Lett. 2018, 219, 174–177. [Google Scholar] [CrossRef]

- Kohara, N.; Nishiwaki, S.; Hashimoto, Y.; Negami, T.; Wada, T. Electrical properties of the Cu(In, Ga)Se/MoSe/Mo structure. Sol. Energy Mater. Sol. Cells 2001, 67, 209. [Google Scholar] [CrossRef]

- Hsiao, K.-J.; Liu, J.-D.; Hsieh, H.-H.; Jiang, T.-S. Electrical impact of MoSe2 on CIGS thin-film solar cells. Phys. Chem. Chem. Phys. 2013, 15, 18174–18178. [Google Scholar] [CrossRef] [PubMed]

- Abou-Ras, D.; Kostorz, G.; Bremaud, D.; Kälin, M.; Kurdesau, F.; Tiwari, A.; Döbeli, M. Formation and characterisation of MoSe2 for Cu(In,Ga)Se2 based solar cells. Thin Solid Films 2005, 481, 433–438. [Google Scholar] [CrossRef]

- Chelvanathan, P.; Hossain, M.I.; Husna, J.; Alghoul, M.; Sopian, K.; Amin, N. Effects of transition metal dichalcogenide molybdenum disulfide layer formation in copper—zinc—tin—sulfur solar cells from numerical analysis effects of transition metal dichalcogenide molybdenum disulfide layer formation in copper—zinc—TinSu. Jpn. J. Appl. Phys. 2012, 51, 10NC32. [Google Scholar] [CrossRef]

- Ferdaous, M.; Shahahmadi, S.; Chelvanathan, P.; Akhtaruzzaman; Alharbi, F.; Sopian, K.; Tiong, S.; Amin, N. Elucidating the role of interfacial MoS2 layer in Cu2ZnSnS4 thin film solar cells by numerical analysis. Sol. Energy 2019, 178, 162–172. [Google Scholar] [CrossRef]

- Northrop, D.C. Book review: Solar cells: Operating principles, technology and system applications. Int. J. Electr. Eng. Educ. 1983, 20, 177. [Google Scholar] [CrossRef]

- Minemoto, T.; Matsui, T.; Takakura, H.; Hamakawa, Y.; Negami, T.; Hashimoto, Y.; Uenoyama, T.; Kitagawa, M. Theoretical analysis of the effect of conduction band offset of window/CIS layers on performance of CIS solar cells using device simulation. Sol. Energy Mater. Sol. Cells 2001, 67, 83–88. [Google Scholar] [CrossRef]

- Gloeckler, M. Device Physics of Copper (Indium, Gallium) Selenide (2) Thin-Film Solar Cells. Ph.D. Thesis, Colorado State University, Fort Collins, CO, USA, 2004. [Google Scholar]

- Song, T.; Kanevce, A.; Sites, J.R. Emitter/absorber interface of CdTe solar cells. J. Appl. Phys. 2016, 119, 233104. [Google Scholar] [CrossRef]

- Awni, R.A.; Li, D.-B.; Song, Z.; Bista, S.S.; Razooqi, M.A.; Grice, C.R.; Chen, L.; Liyanage, G.K.; Li, C.; Phillips, A.B.; et al. Influences of buffer material and fabrication atmosphere on the electrical properties of CdTe solar cells. Prog. Photovolt. Res. Appl. 2019, 27, 1115–1123. [Google Scholar] [CrossRef]

- Zhang, X.; Yuan, Z.; Chen, S. Low electron carrier concentration near the p-n junction interface: A fundamental factor limiting short-circuit current of Cu(In,Ga)Se2 solar cells. Sol. RRL 2019, 3, 1900057. [Google Scholar] [CrossRef]

- Hayakawa, T.; Nishimura, T.; Sugiura, H.; Suyama, N.; Nakada, K.; Yamada, A. Control of donor concentration in n-type buffer layer for high-efficiency Cu(In,Ga)Se2 solar cells. IEEE J. Photovolt. 2018, 8, 1841–1846. [Google Scholar] [CrossRef]

- Pan, J.; Gloeckler, M.; Sites, J.R.; Pan, J.; Gloeckler, M.; Sites, J.R. Hole current impedance and electron current enhancement by back-contact barriers in CdTe thin film solar cells Hole current impedance and electron current enhancement by back-contact barriers in CdTe thin film solar cells. J. Appl. Phys. 2006, 100, 124505. [Google Scholar] [CrossRef]

- Roussillon, Y.; Karpo, G.V.; Svydka, D.; Drayton, J.; Compaan, A.N. Back contact and reach-through diode effects in thin-film photovoltaics Back contact and reach-through diode effects in thin-film photovoltaics. J. Appl. Phys. 2004, 96, 7283–7288. [Google Scholar] [CrossRef]

- Sze, S.M. Semiconductor Devices: Physics and Technology; Physics and Technology, Wiley Global Education: Hoboken, NY, USA, 2012. [Google Scholar]

- Li, S.S. Solar Cells and Photodetectors. In Semiconductor Physical Electronics; Springer Science and Business Media LLC.: New York, NY, USA, 2007; pp. 381–457. [Google Scholar]

- Weiss, T.P.; Bissig, B.; Feurer, T.; Carron, R.; Buecheler, S.; Tiwari, A.N. Bulk and surface recombination properties in thin film semiconductors with different surface treatments from time-resolved photoluminescence measurements. Sci. Rep. 2019, 9, 1–13. [Google Scholar] [CrossRef]

- Scheer, R.; Schock, H.-W. Design rules for heterostructure solar cells and modules. Chalcogenide Photovolt. 2011, 129–174. [Google Scholar] [CrossRef]

- Kato, T. Cu(In,Ga)(Se,S)2 solar cell research in solar frontier: Progress and current status. Jpn. J. Appl. Phys. 2017, 56, 04CA02. [Google Scholar] [CrossRef]

- Yang, R.; Wang, D.; Wan, L.; Wang, D. High-efficiency CdTe thin-film solar cell with a mono-grained CdS window layer. RSC Adv. 2014, 4, 22162–22171. [Google Scholar] [CrossRef]

- Willars-Rodríguez, F.J.; Chávez-Urbiola, I.; Ramírez-Bon, R.; Vorobiev, P.; Vorobiev, Y. Effects of aluminum doping in CdS thin films prepared by CBD and the performance on Schottky diodes TCO/CdS:Al/C. J. Alloy. Compd. 2020, 817, 152740. [Google Scholar] [CrossRef]

- Varley, J.; Lordi, V. Electrical properties of point defects in CdS and ZnS. Appl. Phys. Lett. 2013, 103, 102103. [Google Scholar] [CrossRef]

- Hur, S.G.; Kim, E.T.; Lee, J.H.; Kim, G.H.; Yoon, Z.G. Characterization of photoconductive CdS thin films prepared on glass substrates for photoconductive-sensor applications Characterization of photoconductive CdS thin films prepared on glass substrates for photoconductive-sensor applications. J. Vac. Sci. Technol. B Microelectron. Nanometer. Struct. Process. Meas. Phenom. 2008, 26, 1334–1337. [Google Scholar] [CrossRef]

- Gunawan, O.; Pae, S.R.; Bishop, D.M.; Virgus, Y.; Noh, J.H.; Jeon, N.J.; Lee, Y.S.; Shao, X.; Todorov, T.; Mitzi, D.B.; et al. Carrier-resolved photo-Hall effect. Nat. Cell Biol. 2019, 575, 151–155. [Google Scholar] [CrossRef] [PubMed]

| Interface Parameters | Front | - | Back |

|---|---|---|---|

| Metal work function (eV) | 4.47 (Ag) | - | 4.95 (Mo) |

| Majority carrier barrier height Φb (eV) | Φbn = 0 | - | Φbp = Eg-Absorber − Φbn |

| Electron surface recombination Velocity, Se (cm·s−1) | 107 | - | 107 |

| Hole surface recombination Velocity, Sh (cm·s−1) | 107 | - | 107 |

| Reflectivity | 0.05 | - | 0.80 |

| Layer Parameters | n-ZnO | n-CdS | p-Absorber |

|---|---|---|---|

| Layer thickness (nm) | 50 | 50 | 2500 |

| Dielectric constant, εr | 9 | 10 | 13.6 |

| Electron mobility, µn (cm2/V.s) | 100 | ~ | 100 |

| Hole mobility, µp (cm2/V.s) | 25 | ~ | 25 |

| Acceptor concentration, NA (cm−3) | 0 | 0 | 1 × 1016 |

| Donor concentration, ND (cm−3) | 1 × 1018 | ~ | 0 |

| Band gap, Eg (eV) | 3.3 | 2.4 | 0.9–1.7 |

| Electron affinity, χ (eV) | 4.4 | 4.2 | 3.7–4.7 |

| Effective density of states in Conduction band, NC (cm−3) | 2.2 × 1018 | 2.2 × 1018 | 2.2 × 1018 |

| Effective density of states inValence band, NV (cm−3) | 1.8 × 1019 | 1.8 × 1019 | 1.8 × 1019 |

| Electron thermal velocity (cm s−1) | 1 × 107 | 1 × 107 | 1 × 107 |

| Hole thermal velocity (cm s−1) | 1 × 107 | 1 × 107 | 1 × 107 |

| Parameters | Set A | Set B | Set C | Set D |

|---|---|---|---|---|

| Donor concentration, ND (cm−3) | 1 × 1014 | 1 × 1014 | 1 × 1018 | 1 × 1018 |

| Electron mobility, µn (cm2/V·s) | 1 | 100 | 1 | 100 |

| Hole mobility, µp (cm2/V·s) | 0.25 | 25 | 0.25 | 25 |

| Electrical resistivity (Ω·cm) | 62,415 | 624.15 | 6.2415 | 0.0624 |

| Layer Parameters | n-ZnO | n-CdS | p-Absorber |

|---|---|---|---|

| Defect Type | Neutral | Neutral | Neutral |

| Electron capture cross section (cm2) | 10−12 | 10−13 | 10−15 |

| Hole capture cross section (cm2) | 10−12 | 10−13 | 10−13 |

| Energetic distribution | Gauẞ | Gauẞ | Gauẞ |

| Reference for defect energy level Et | Above Ev | Above Ev | Above Ev |

| Energy level with respect to reference (eV) | 1.650 | 1.200 | (0.6/1.1) × Eg-Absorber |

| Characteristic energy (eV) | 0.100 | 0.100 | 0.100 |

| Total defect density, NT-total (cm−3) | 1.772 × 1016 | 1.772 × 1017 | 0–1.772 × 1017 |

| Peak defect density NT-peak (eV−1·cm−3) | 1 × 1017 | 1 × 1018 | 0–1 × 1018 |

| Absorber Material | Band Gap, Eg (eV) | Electron Affinity, χ (eV) | CBO, ΔEc (eV) | Reference for the Reported Eg and χ Values |

|---|---|---|---|---|

| CIGS | 1.15 | 4.5 | 0.3 | [44] |

| CdTe | 1.5 | 3.9 | −0.3 | [45] |

| CZTS | 1.5 | 4.5 | 0.3 | [46] |

| CZTSe | 1.05 | 4.54 | 0.34 | [47] |

| CTS | 0.95 | 4.77 | 0.57 | [48] |

| SnS | 1.1 | 3.52 | −0.68 | [49] |

| FeS2 | 0.95 | 4.71 | 0.51 | [50] |

| Sb2S3 | 1.76 | 4.7 | 0.50 | [51] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Najm, A.S.; Chelvanathan, P.; Tiong, S.K.; Ferdaous, M.T.; Shahahmadi, S.A.; Yusoff, Y.; Sopian, K.; Amin, N. Numerical Insights into the Influence of Electrical Properties of n-CdS Buffer Layer on the Performance of SLG/Mo/p-Absorber/n-CdS/n-ZnO/Ag Configured Thin Film Photovoltaic Devices. Coatings 2021, 11, 52. https://doi.org/10.3390/coatings11010052

Najm AS, Chelvanathan P, Tiong SK, Ferdaous MT, Shahahmadi SA, Yusoff Y, Sopian K, Amin N. Numerical Insights into the Influence of Electrical Properties of n-CdS Buffer Layer on the Performance of SLG/Mo/p-Absorber/n-CdS/n-ZnO/Ag Configured Thin Film Photovoltaic Devices. Coatings. 2021; 11(1):52. https://doi.org/10.3390/coatings11010052

Chicago/Turabian StyleNajm, Asmaa Soheil, Puvaneswaran Chelvanathan, Sieh Kiong Tiong, Mohammad Tanvirul Ferdaous, Seyed Ahmad Shahahmadi, Yulisa Yusoff, Kamaruzzaman Sopian, and Nowshad Amin. 2021. "Numerical Insights into the Influence of Electrical Properties of n-CdS Buffer Layer on the Performance of SLG/Mo/p-Absorber/n-CdS/n-ZnO/Ag Configured Thin Film Photovoltaic Devices" Coatings 11, no. 1: 52. https://doi.org/10.3390/coatings11010052

APA StyleNajm, A. S., Chelvanathan, P., Tiong, S. K., Ferdaous, M. T., Shahahmadi, S. A., Yusoff, Y., Sopian, K., & Amin, N. (2021). Numerical Insights into the Influence of Electrical Properties of n-CdS Buffer Layer on the Performance of SLG/Mo/p-Absorber/n-CdS/n-ZnO/Ag Configured Thin Film Photovoltaic Devices. Coatings, 11(1), 52. https://doi.org/10.3390/coatings11010052