A Review of the Surface Modifications for Corrosion Mitigation of Steels in Lead and LBE

Abstract

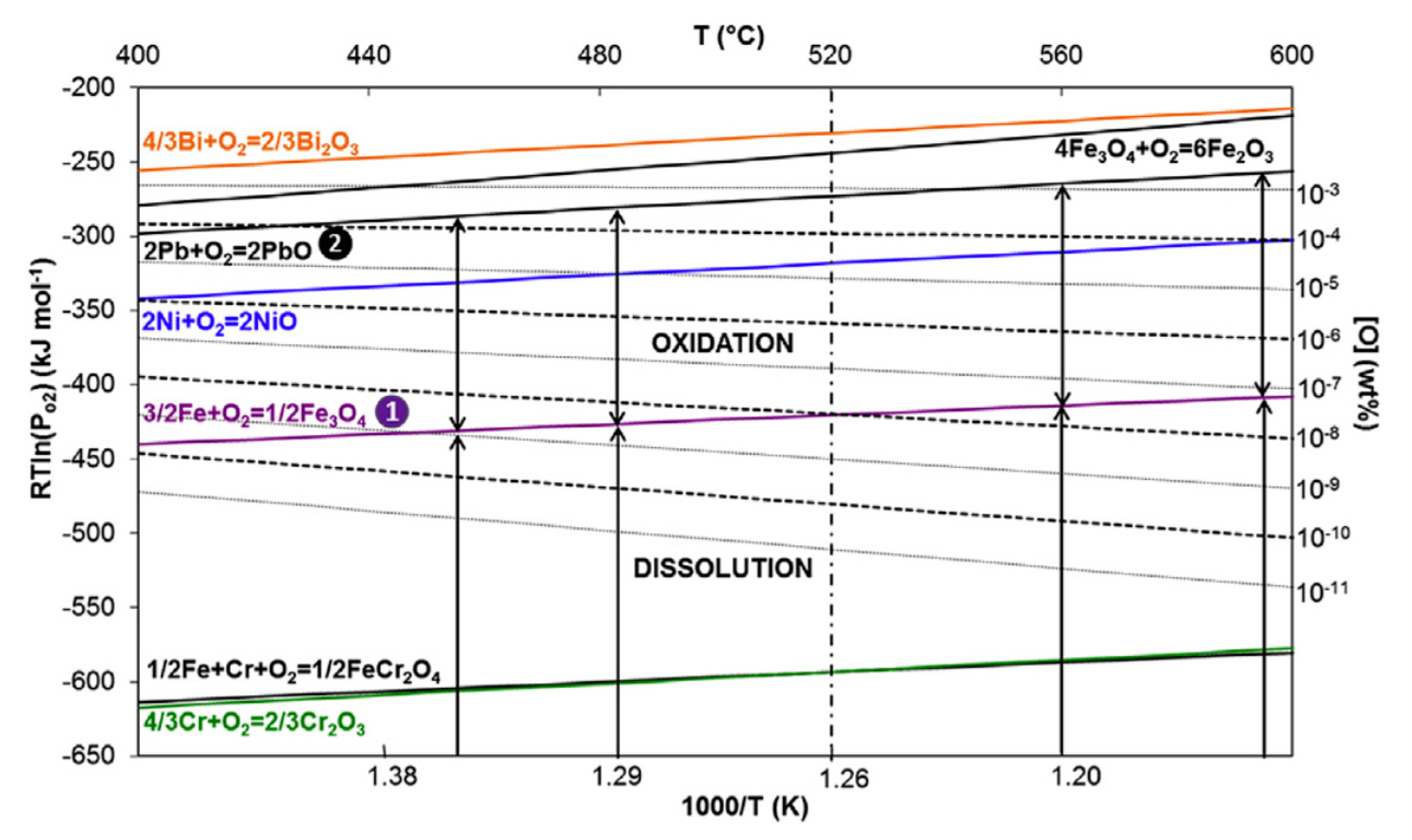

1. Introduction

2. Technical Options

- The deposition of an external coating on the steel matrix.

- An “auto—formation” of an external layer whose composition depends on the chemical composition of the steel matrix and the reaction with the liquid metal.

3. Coatings Formed by Deposition of Foreign Chemical Elements at the External Surface

3.1. Aluminized Coatings by Pack Cementation

3.2. Iron Aluminide, Iron Boride, and an Iron Solid Solution Enriched in Chromium and Covered by Carbide by Pack Cementation

3.3. Al2O3 Composite Coatings by Pulsed Laser Deposition

3.4. Al2O3 Composite Coatings by Sol–Gel Composite Coating Technique

3.5. Al2O3–TiO2 Coating by Thermal Spraying Technology and Laser In-Situ Reaction Method

3.6. AlTiN Coatings by Cathodic Arc Ion Plating

3.7. Al–Fe Coating by Physical Vapor Deposition and Unbalanced Magnetron Sputtering

3.8. FeAlTi Coating by Laser Melting Process

3.9. FeCrAl Coating by Low Pressure Plasma Spray Process Followed by GESA Pulse Power Process

3.10. TiC Coating by Arc Ion Plating

3.11. Nanostructured Surface Layer by Surface Mechanical Rolling Treatment

4. Coatings Formed Following Control of the Chemical Composition of the Bulk of the Material

4.1. Silicon Enriched Materials

4.2. Aluminum Enriched Materials

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kalantar-Zadeh, K.; Tang, J.; Daeneke, T.; O’Mullane, A.P.; Stewart, L.A.; Liu, J.; Majidi, C.; Ruoff, R.S.; Weiss, P.S.; Dickey, M.D. Emergence of liquid metals in nanotechnology. ACS Nano 2019, 13, 7388–7395. [Google Scholar] [CrossRef]

- Mansur, L.K. Materials research and development for the spallation neutron source mercury target. J. Nucl. Mater. 2003, 318, 14–25. [Google Scholar] [CrossRef]

- Takada, H.; Haga, K.; Teshigawara, M.; Aso, T.; Meigo, S.-I.; Kogawa, H.; Naoe, T.; Wakui, T.; Ooi, M.; Harada, M.; et al. Materials and life science experimental facility at the Japan Proton Accelerator Research Complex I: Pulsed spallation neutron source. Quantum Beam Sci. 2017, 1, 8. [Google Scholar] [CrossRef]

- Frazer, D.; Stergar, E.; Cionea, C.; Hosemann, P. Liquid metal as a heat transport fluid for thermal solar power applications. Energy Procedia 2014, 49, 627–636. [Google Scholar] [CrossRef]

- Lorenzin, N.; Abánades, A. A review on the application of liquid metals as heat transfer fluid in concentrated solar power technologies. Int. J. Hydrogen Energy 2016, 41, 6990–6995. [Google Scholar] [CrossRef]

- Popovic, M.P.; Bolind, A.M.; Cionea, C.; Hosemann, P. Liquid lead–bismuth eutectic as a coolant in generation IV nuclear reactors and in high temperature solar concentrator applications: Characteristics, challenges, issues. Contemp. Mater. 2015, 6, 20–34. [Google Scholar] [CrossRef]

- Sakamoto, Y.; Garnier, J.C.; Rouaul, J.; Grandy, C.; Fanning, T.; Hill, R.; Chikazawa, Y.; Kotake, S. Selection of sodium coolant for fast reactors in the US, France and Japan. Nucl. Eng. Des. 2013, 254, 194–217. [Google Scholar] [CrossRef]

- Horiike, H.; Konishi, S.; Kondo, H.; Yamaguchi, A. Liquid metal cooling issues for fusion and fission. Fusion Eng. Des. 2008, 83, 943–947. [Google Scholar] [CrossRef]

- Latge, C.; Wohlmuther, M.; Dai, Y.; Gavillet, D.; Gessi, A.; Guertin, A.; Hammer, B.; Heinitz, S.; Henry, J.; Konstantinovic, M.; et al. MEGAPIE: The world’s first high-power liquid metal spallation neutron source. In Thorium Energy for the World; Revol, J.P., Bourquin, M., Kadi, Y., Lillestol, E., de Mestral, J.C., Samec, K., Eds.; Springer: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Toshinsky, G.I.; Dedul, A.V.; Komlev, O.G.; Kondaurov, A.V.; Petrochenko, V.V. Lead–bismuth and lead as coolants for fast reactors. World J. Nucl. Sci. Technol. 2020, 10, 65–75. [Google Scholar] [CrossRef]

- Ballinger, R.G.; Lim, J. An overview of corrosion issues for the design and operation of high-temperature lead and lead–bismuth eutectic cooled reactors systems. Nucl. Technol. 2004, 147, 418–435. [Google Scholar] [CrossRef]

- Sobolev, V. Thermophysical properties of lead and lead–bismuth eutectic. J. Nucl. Mater. 2007, 362, 235–247. [Google Scholar] [CrossRef]

- Takahashi, M.; Sa, R.; Pramutadi, A.; Yamaki-Irisawa, E. Overview of recent studies related to lead-alloy-cooled fast reactors. Nucl. Sci. Eng. 2012, 1448, 39–49. [Google Scholar] [CrossRef]

- Zhang, J. Lead–bismuth eutectic (LBE): A coolant candidate for Gen. IV, advanced nuclear reactor concepts. Adv. Eng. Mater. 2014, 16, 349–356. [Google Scholar] [CrossRef]

- Courouau, J.-L.; Feron, D. Corrosion of structural materials by liquid metals used fusion, fission and spallation. In Proceedings of the 1st IAEA Workshop on Challenges for Coolants in Fast Spectrum System, Vienne, Austria, 5–7 July 2017. [Google Scholar]

- Cheng, J.; Zhu, S.; Tan, H.; Yu, Y.; Yang, J.; Liu, W. Lead–bismuth liquid metal: Lubrication behaviors. Wear 2019, 403–431, 94–99. [Google Scholar] [CrossRef]

- Fazio, C.; Balbaud, F. Corrosion phenomena induced by liquid metals in Generation IV reactors. In Structural Materials for Generation IV Nuclear Reactors; Yvon, P., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; Chapter 2; pp. 23–74. [Google Scholar] [CrossRef]

- Balbaud-Celerier, F.; Deloffre, P.; Terlain, A.; Rusanov, A. Corrosion of metallic materials in flowing liquid lead–bismuth. J. Phys. IV Fr. 2002, 12, 177–190. [Google Scholar] [CrossRef]

- Tian, S.J. Growth and exfoliation behavior of the oxide scale on 316L and T91 in flowing liquid lead–bismuth eutectic at 480 °C. Oxid. Met. 2020, 93, 183–194. [Google Scholar] [CrossRef]

- Tsisar, V.; Schroer, C.; Wedemeyer, O.; Skrypnik, A.; Konys, J. Corrosion behavior of austenitic steels 1.4970, 316L and 1.4571 in flowing LBE at 450 and 550 °C with 10−7 mass% dissolved oxygen. J. Nucl. Mater. 2014, 454, 332–342. [Google Scholar] [CrossRef]

- Roy, M.; Martinelli, L.; Ginestar, K.; Favergeon, J.; Moulin, G. Dissolution and oxidation behaviour of various austenitic steels and Ni rich alloys in lead–bismuth eutectic at 520 °C. J. Nucl. Mater. 2016, 468, 153–163. [Google Scholar] [CrossRef]

- Martinelli, L.; Courouau, J.-L.; Balbaud-Célérier, F. Oxidation of steels in liquid lead bismuth: Oxygen control to achieve efficient corrosion protection. Nucl. Eng. Des. 2011, 241, 1288–1294. [Google Scholar] [CrossRef]

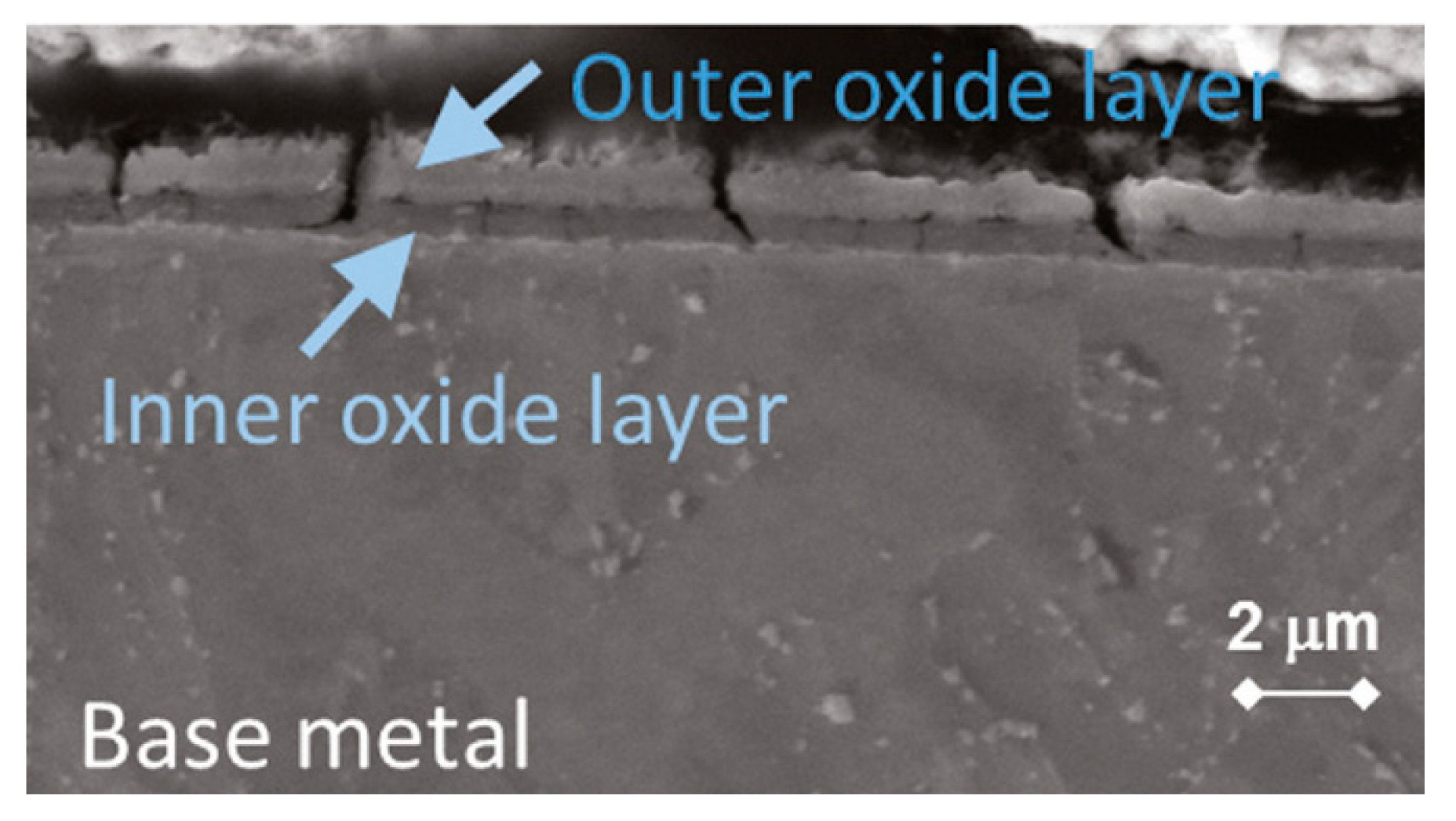

- Ye, Z.; Wang, P.; Dong, H.; Li, D.; Zhang, Y.; Li, Y. Oxidation mechanism of T91 steel in liquid lead–bismuth eutectic: With consideration of internal oxidation. Nat. Sci. Rep. 2016, 6, 35268. [Google Scholar] [CrossRef]

- Duchoň, J.; Halodová, P.; Lorinčínk, J.; Di Gabriele, F.; Hojná, A. Characterization of oxides by advanced techniques. Acta Metall. Slovaca 2018, 24, 13–19. [Google Scholar] [CrossRef]

- Tsisar, V.; Gavrilov, S.; Schroer, C.; Stergar, E. Long-term corrosion performance of T91 ferritic/martensitic steel at 400 °C in flowing Pb–Bi eutectic with 2 × 10−7 mass% dissolved oxygen. Corros. Sci. 2020, 174, 108852. [Google Scholar] [CrossRef]

- Barbier, F.; Rusanov, A. Corrosion behavior of steels in flowing lead–bismuth. J. Nucl. Mater. 2001, 296, 231–236. [Google Scholar] [CrossRef]

- Kurata, Y.; Futakawa, M. Excellent corrosion resistance of 18Cr–20Ni–5Si steel in liquid Pb–Bi. J. Nucl. Mater. 2004, 325, 217–222. [Google Scholar] [CrossRef]

- Hojná, A.; Halodová, P.; Chocholoušek, M.; Špirit, Z.; Rozumová, L. Environmentally assisted cracking of T91 ferritic-martensitic steel in heavy liquid metals. Corros. Rev. 2019, 38. [Google Scholar] [CrossRef]

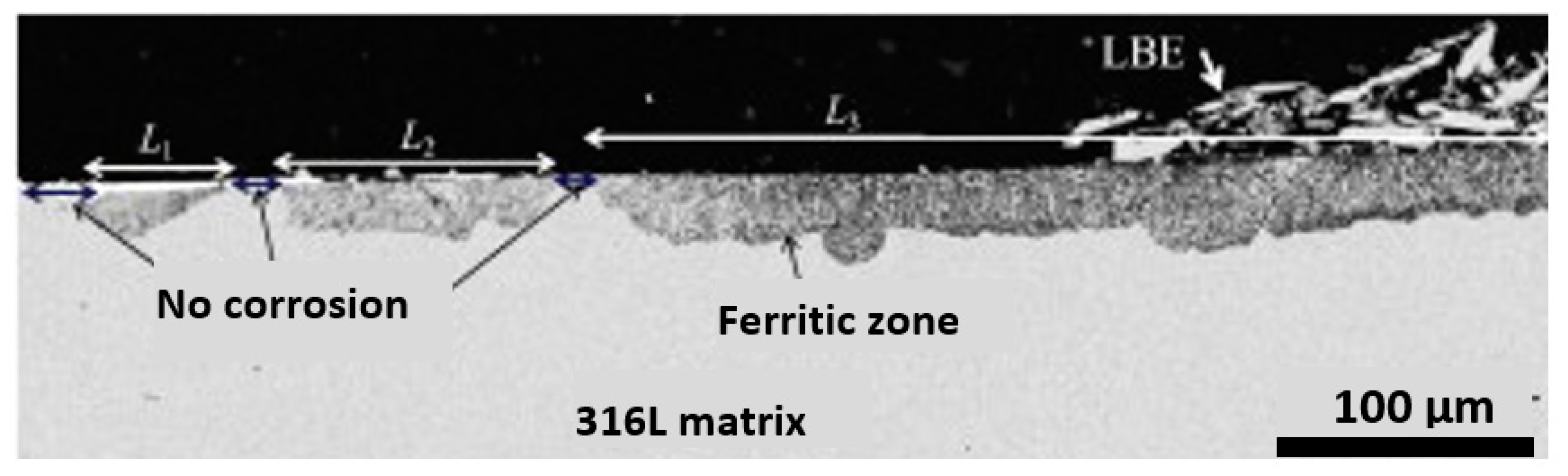

- Yamaki, E.; Ginestar, K.; Martinelli, L. Dissolution mechanism of 316L in lead–bismuth eutectic at 500 °C. Corros. Sci. 2011, 53, 3075–3085. [Google Scholar] [CrossRef]

- Klok, O.; Lambrinou, K.; Gavrilov, S.; Lim, J.; De Graeve, I. Effect of LBE oxygen concentration on the onset of dissolution corrosion in 316L austenitic stainless steel at 450 °C. J. Nucl. Eng. Radiat. Sci. 2018, 4, 031019. [Google Scholar] [CrossRef]

- Kurata, Y. Corrosion behavior of cold-worked austenitic stainless steels in liquid lead–bismuth eutectic. J. Nucl. Mater. 2014, 448, 239–249. [Google Scholar] [CrossRef]

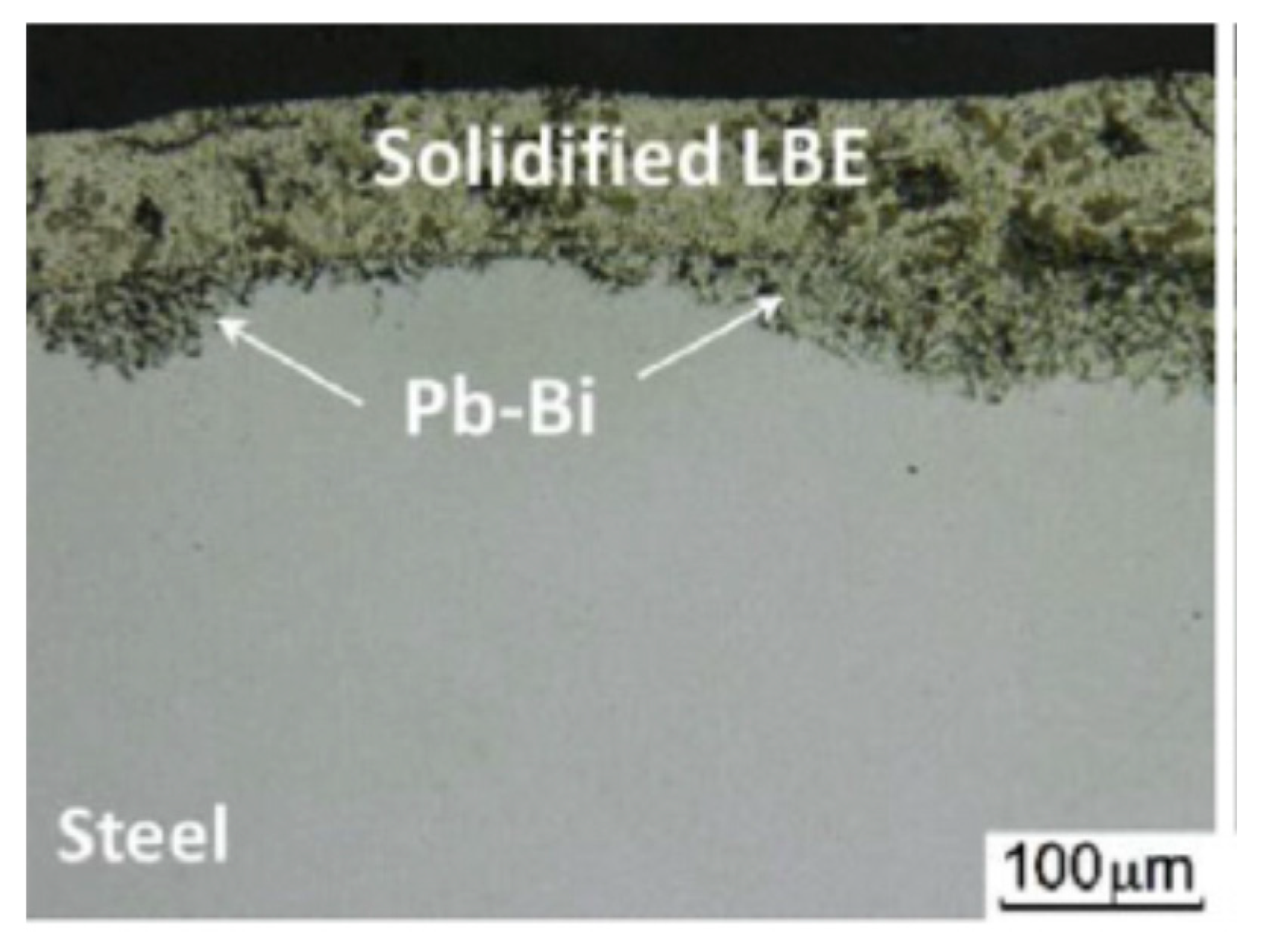

- Lambrinou, K.; Charalampopoulou, E.; Van der Donck, T.; Delville, R.; Schryvers, D. Dissolution corrosion of 316L austenitic stainless steels in contact with static liquid lead–bismuth eutectic (LBE) at 500 °C. J. Nucl. Mater. 2017, 490, 9–27. [Google Scholar] [CrossRef]

- Yurechko, M.; Schroer, C.; Skrypnik, A.; Wedemeyer, O.; Tsisar, V.; Konys, J. Steel T91 subjected to static stress in lead–bismuth eutectic at 450–550 °C and low oxygen concentration. J. Nucl. Mater. 2018, 512, 423–439. [Google Scholar] [CrossRef]

- Martinelli, L.; Ginestar, K.; Botton, V.; Delisle, C.; Balbaud-Célérier, F. Corrosion of T91 and pure iron in flowing and static Pb–Bi alloy between 450 °C and 540 °C: Experiments, modelling and mechanism. Corros. Sci. 2020, 176, 108897. [Google Scholar] [CrossRef]

- Kalkhof, D.; Grosse, M. Influence of PbBi environment on the low-cycle fatigue behavior of SNS target container materials. J. Nucl. Mater. 2003, 318, 143–150. [Google Scholar] [CrossRef]

- Vogt, J.-B.; Proriol Serre, I. Fatigue behaviour of a martensitic and an austenitic steel in heavy liquid metals. Proc. Eng. 2013, 55, 812–818. [Google Scholar] [CrossRef]

- Serre, I.; Vogt, J.-B. Heat treatment effect of T91 martensitic steel on liquid metal embrittlement. J. Nucl. Mater. 2008, 376, 330–335. [Google Scholar] [CrossRef]

- Long, B.; Tong, Z.; Gröschel, F.; Dai, Y. Liquid Pb–Bi embrittlement effects on the T91 steel after different heat treatments. J. Nucl. Mater. 2008, 377, 219–224. [Google Scholar] [CrossRef]

- Gong, X.; Marmy, P.; Qin, L.; Verlinden, B.; Wevers, M.; Seefeldt, M. Effect of liquid metal embrittlement on low cycle fatigue properties and fatigue crack propagation behaviour of a modified 9Cr–1Mo ferritic–martensitic steel in an oxygen-controlled lead–bismuth eutectic environment at 350 °C. MSE A 2014, 618, 406–415. [Google Scholar] [CrossRef]

- Gong, X.; Marmy, P.; Qin, L.; Verlinden, B.; Wevers, M.; Seefeldt, M. Temperature dependence of liquid metal embrittlement susceptibility of a modified 9Cr–1Mo steel under low cycle fatigue in lead–bismuth eutectic at 160–450 °C. J. Nucl. Mater. 2016, 468, 289–298. [Google Scholar] [CrossRef]

- Vogt, J.-B.; Bouquerel, J.; Carle, C.; Proriol-Serre, I. Stability of fatigue cracks at 350 °C in air and in liquid metal in T91 martensitic steel. Int. J. Fatigue 2020, 130, 105265. [Google Scholar] [CrossRef]

- Jianu, A.; Müller, G.; Weisenburger, A.; Heinzel, A.; Fazio, C.; Markov, V.G.; Kashtanov, A.D. Creep-to-rupture tests of T91 steel in flowing Pb–Bi eutectic melt at 550 °C. J. Nucl. Mater. 2009, 394, 102–108. [Google Scholar] [CrossRef]

- Strafella, A.; Coglitore, A.; Fabbri, P.; Salernitano, E. 15-15Ti(Si) austenitic steel: Creep behaviour in hostile environment. Frattura ed Integrità Strutturale 2017, 42, 352–365. [Google Scholar] [CrossRef]

- Gong, X.; Yang, Z.; Deng, Y.; Xiao, J.; Wang, H.; Yu, Z.; Yin, Y. Creep failure of a solution-annealed 15-15Ti steel exposed to stagnant lead–bismuth eutectic at 550 and 600 °C. MSE A 2020, 798, 140230. [Google Scholar] [CrossRef]

- Weisenburger, A.; Schroer, C.; Jianu, A.; Heinzel, A.; Konys, J.; Steiner, H.; Muller, G.; Fazio, C.; Gessi, A.; Babayan, S.; et al. Long term corrosion on T91 and AISI1 316L steel in flowing lead alloy and corrosion protection barrier development: Experiments and models. J. Nucl. Mater. 2011, 415, 260–269. [Google Scholar] [CrossRef]

- Tian, S.J.; Jiang, Z.Z.; Luo, L. Oxidation behavior of T91 steel in flowing oxygen-containing lead–bismuth eutectic at 500 °C. Mater. Corros. 2016, 67, 1274–1285. [Google Scholar] [CrossRef]

- Deloffre, P.; Balbaud-Célérier, F.; Terlain, A. Corrosion behaviour of aluminized martensitic and austenitic steels in liquid Pb–Bi. J. Nucl. Mater. 2004, 335, 180–184. [Google Scholar] [CrossRef]

- Ledoux, X.; Vilasi, M.; Mathieu, S.; Panteix, J.P.; Del-Gallo, P.; Wagner, M. Development of chromium and aluminum coatings on superalloys by pack-cementation technique. Adv. Mater. Res. 2011, 278, 491–496. [Google Scholar] [CrossRef]

- Proriol Serre, I.; Diop, I.; David, N.; Vilasi, M.; Vogt, J.-B. Mechanical behavior of coated T91 steel in contact with lead–bismuth liquid alloy at 300 °C. Surf. Coat. Technol. 2011, 205, 4521–4527. [Google Scholar] [CrossRef]

- Vogt, J.-B.; Proriol-Serre, I.; Martinelli, L.; David, N.; Vilasi, M. Fatigue resistance in liquid lead–bismuth eutectic alloy of T91 steel. In Proceedings of the ICAPP 2011: Performance and Flexibility—The Power of Innovation, Nice, France, 2–5 May 2011. Paper 11328. [Google Scholar]

- García Ferré, F.; Bertarelli, E.; Chiodoni, A.; Carnelli, D.; Gastaldi, D.; Vena, P.; Beghi, M.G.; Di Fonzo, F. The mechanical properties of a nanocrystalline Al2O3/a-Al2O3 composite coating measured by nanoindentation and Brillouin spectroscopy. Acta Mater. 2013, 61, 2662–2670. [Google Scholar] [CrossRef]

- García Ferré, F.; Ormellese, M.; Di Fonzo, F.; Beghi, M.G. Advanced Al2O3 coatings for high temperature operation of steels in heavy liquid metals: A preliminary study. Corros. Sci. 2013, 77, 375–378. [Google Scholar] [CrossRef]

- Dou, P.; Kasada, R. Preliminary study on nano- and micro-composite sol-gel based alumina coatings on structural components of lead–bismuth eutectic cooled fast breeder reactors. J. Nucl. Mater. 2011, 409, 177–182. [Google Scholar] [CrossRef]

- Chen, Y.; Hu, L.; Qiu, C.; Huang, Q. Characterization of multiphase ceramic coatings fabricated via laser in situ reaction technology. Surf. Eng. 2018, 34, 301–308. [Google Scholar] [CrossRef]

- Chen, Y.; Hu, L.; Qiu, C.; He, B.; Zhou, J.; Zhao, J.; Li, Y. Influence of LBE Temperatures on the microstructure and properties of crystalline and amorphous multiphase ceramic coatings. Coatings 2019, 9, 543. [Google Scholar] [CrossRef]

- Wu, Z.Y.; Zhao, X.; Liu, Y.; Cai, Y.; Li, J.Y.; Chen, H.; Wan, Q.; Yang, D.; Tan, J.; Liu, H.D.; et al. Lead–bismuth eutectic (LBE) corrosion behavior of AlTiN coatings at 550 and 600 °C. J. Nucl. Mater. 2020, 539, 152280. [Google Scholar] [CrossRef]

- Rivai, A.K.; Takahashi, M. Corrosion investigations of Al–Fe-coated steels, high Cr steels, refractory metals and ceramics in lead alloys at 700 °C. J. Nucl. Mater. 2010, 398, 146–152. [Google Scholar] [CrossRef]

- Rivai, A.K.; Takahashi, M. Corrosion characteristics of materials in Pb–Bi under transient temperature conditions. J. Nucl. Mater. 2010, 398, 139–145. [Google Scholar] [CrossRef]

- Yamaki, E.; Takahashi, M. Corrosion resistance of Fe–Al-alloy-coated ferritic/martensitic steel under bending stress in high-temperature lead–bismuth eutectic. J. Nucl. Sci. Technol. 2011, 48, 797–804. [Google Scholar] [CrossRef]

- Yamaki-Irisawa, E.; Numata, S.; Takahashi, M. Corrosion behavior of heat-treated Fe–Al coated steel in lead–bismuth eutectic under loading. Prog. Nucl. Energy 2011, 53, 1066–1072. [Google Scholar] [CrossRef]

- Kurata, Y.; Yokota, H.; Suzuki, T. Development of aluminum-alloy coating on type 316SS for nuclear systems using liquid lead–bismuth. J. Nucl. Mater. 2012, 424, 237–246. [Google Scholar] [CrossRef]

- Müller, G.; Schumacher, G.; Zimmermann, F. Investigation on oxygen controlled liquid lead corrosion of surface treated steels. J. Nucl. Mater. 2000, 278, 85–95. [Google Scholar] [CrossRef]

- Weisenburger, A.; Heinzel, A.; Müller, G.; Muscher, H.; Rousanov, A. T91 cladding tubes with and without modified FeCrAlY coatings exposed in LBE at different flow, stress and temperature conditions. J. Nucl. Mater. 2008, 376, 274–281. [Google Scholar] [CrossRef]

- Weisenburger, A.; Müller, G.; Heinzel, A.; Jianu, A.; Muscher, H.; Kieser, M. Corrosion, Al containing corrosion barriers and mechanical properties of steels foreseen as structural materials in liquid lead alloy cooled nuclear systems. NED 2011, 241, 1329–1334. [Google Scholar] [CrossRef]

- Fetzer, R.; Weisenburger, A.; Jianu, A.; Müller, G. Oxide scale formation of modified FeCrAl coatings exposed to liquid lead. Corros. Sci. 2012, 55, 213–218. [Google Scholar] [CrossRef]

- Weisenburger, A.; Heinzel, A.; Fazio, C.; Müller, G.; Markow, V.G.; Kastanov, A.D. Low cycle fatigue tests of surface modified T91 steel in 10−6 wt.% oxygen containing Pb45Bi55 at 550 °C. J. Nucl. Mater. 2008, 377, 261–267. [Google Scholar] [CrossRef]

- Weisenburger, A.; Jianu, A.; An, W.; Fetzer, R.; Del Giacco, M.; Heinzel, A. Creep, creep-rupture tests of Al-surface-alloyed T91 steel in liquid lead bismuth at 500 and 550 °C. J. Nucl. Mater. 2012, 431, 77–84. [Google Scholar] [CrossRef]

- Shi, Q.; Yan, W.; Sha, W.; Wang, W.; Shan, Y.-Y.; Yang, K. Corrosion resistance of self-growing TiC coating on SIMP steel in LBE at 600 °C. Mater. Corros. 2016, 67, 1204–1212. [Google Scholar] [CrossRef]

- Lu, Y.H.; Wang, Z.B.; Song, Y.Y.; Rong, L.J. Effects of pre-formed nanostructured surface layer on oxidation behaviour of 9Cr2WVTa steel in air and liquid Pb–Bi eutectic alloy. Corros. Sci. 2016, 102, 301–309. [Google Scholar] [CrossRef]

- Kondo, M.; Takahashi, M. Corrosion resistance of Si- and Al-rich steels in flowing lead–bismuth. J. Nucl. Mater. 2006, 356, 203–212. [Google Scholar] [CrossRef]

- Short, M.P.; Ballinger, R.G.; Hänninen, H.E. Corrosion resistance of alloys F91 and Fe–12Cr–2Si in lead–bismuth eutectic up to 715 °C. J. Nucl. Mater. 2013, 434, 259–281. [Google Scholar] [CrossRef]

- Kurata, Y.; Futakawa, M.; Saito, S. Corrosion experiments and materials developed for the Japanese HLM systems. J. Nucl. Mater. 2011, 424, 254–259. [Google Scholar] [CrossRef]

- Van Den Bosch, J.; Hosemann, P.; Almazouzi, A.; Maloy, S.A. Liquid metal embrittlement of silicon enriched steel for nuclear applications. J. Nucl. Mater. 2010, 398, 116–121. [Google Scholar] [CrossRef]

- Van Den Bosch, J.; Coen, G.; Hosemann, P.; Maloy, S.A. On the LME susceptibility of Si enriched steels. J. Nucl. Mater. 2012, 429, 105–112. [Google Scholar] [CrossRef]

- Lim, J.; Nam, H.O.; Hwang, I.; Soon, K.; Ji, H. Study of early corrosion behaviors of FeCrAl alloys in liquid lead–bismuth eutectic environments. J. Nucl. Mater. 2010, 407, 205–210. [Google Scholar] [CrossRef]

- Lim, J.; Hwang, I.; Kim, J. Design of alumina forming FeCrAl steels for lead or lead–bismuth cooled fast reactors. J. Nucl. Mater. 2013, 441, 650–660. [Google Scholar] [CrossRef]

- Baker, B.W.; Brewer, L.N. Evaluation of liquid metal embrittlement susceptibility of oxide. J. Nucl. Mater. 2014, 453, 239–246. [Google Scholar] [CrossRef]

- Dömstedt, P.; Lundberg, M.; Szakalos, P. Corrosion studies of low-alloyed FeCrAl steels in liquid lead at 750 °C. Oxid. Met. 2019, 91, 511–524. [Google Scholar] [CrossRef]

- Gong, X.; Chen, J.; Hu, F.; Xiang, C.; Yu, Z.; Xiao, J.; Wang, H.; Gong, H.; Wang, H.; Liu, C.; et al. Liquid metal embrittlement of an Fe10Cr4Al ferritic alloy exposed to oxygen-depleted and -saturated lead–bismuth eutectic at 350 °C. Corros. Sci. 2020, 165, 108364. [Google Scholar] [CrossRef]

- Ejenstam, E.; Szakálos, P. Long term corrosion resistance of alumina forming austenitic stainless steels in liquid lead. J. Nucl. Mater. 2015, 461, 164–170. [Google Scholar] [CrossRef]

- Shi, H.; Jianu, A.; Weisenburger, A.; Tang, C.; Heinzel, A.; Fetzer, R.; Lang, F.; Stieglitz, R.; Müller, G. Corrosion resistance and microstructural stability of austenitic Fe–Cr–Al–Ni model alloys exposed to oxygen-containing molten lead. J. Nucl. Mater. 2019, 524, 177–190. [Google Scholar] [CrossRef]

- Chen, L.; Wang, M.; Tsisar, V.; Schroer, C.; Zhou, Z. Investigation of microstructure and liquid lead corrosion behavior of a Fe–18Ni–16Cr–4Al base alumina-forming austenitic stainless steel. Mater. Res. Express 2020, 7, 026533. [Google Scholar] [CrossRef]

- Wang, H.; Yu, H.; Kondo, S.; Okubo, N.; Kasada, R. Corrosion behaviour of Al-added high Mn austenitic steels in molten lead. Corros. Sci. 2020, 175, 108864. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vogt, J.-B.; Proriol Serre, I. A Review of the Surface Modifications for Corrosion Mitigation of Steels in Lead and LBE. Coatings 2021, 11, 53. https://doi.org/10.3390/coatings11010053

Vogt J-B, Proriol Serre I. A Review of the Surface Modifications for Corrosion Mitigation of Steels in Lead and LBE. Coatings. 2021; 11(1):53. https://doi.org/10.3390/coatings11010053

Chicago/Turabian StyleVogt, Jean-Bernard, and Ingrid Proriol Serre. 2021. "A Review of the Surface Modifications for Corrosion Mitigation of Steels in Lead and LBE" Coatings 11, no. 1: 53. https://doi.org/10.3390/coatings11010053

APA StyleVogt, J.-B., & Proriol Serre, I. (2021). A Review of the Surface Modifications for Corrosion Mitigation of Steels in Lead and LBE. Coatings, 11(1), 53. https://doi.org/10.3390/coatings11010053