Structure and Tribological Properties of Ni–Cr–Al-Based Gradient Coating Prepared by Detonation Spraying

Abstract

1. Introduction

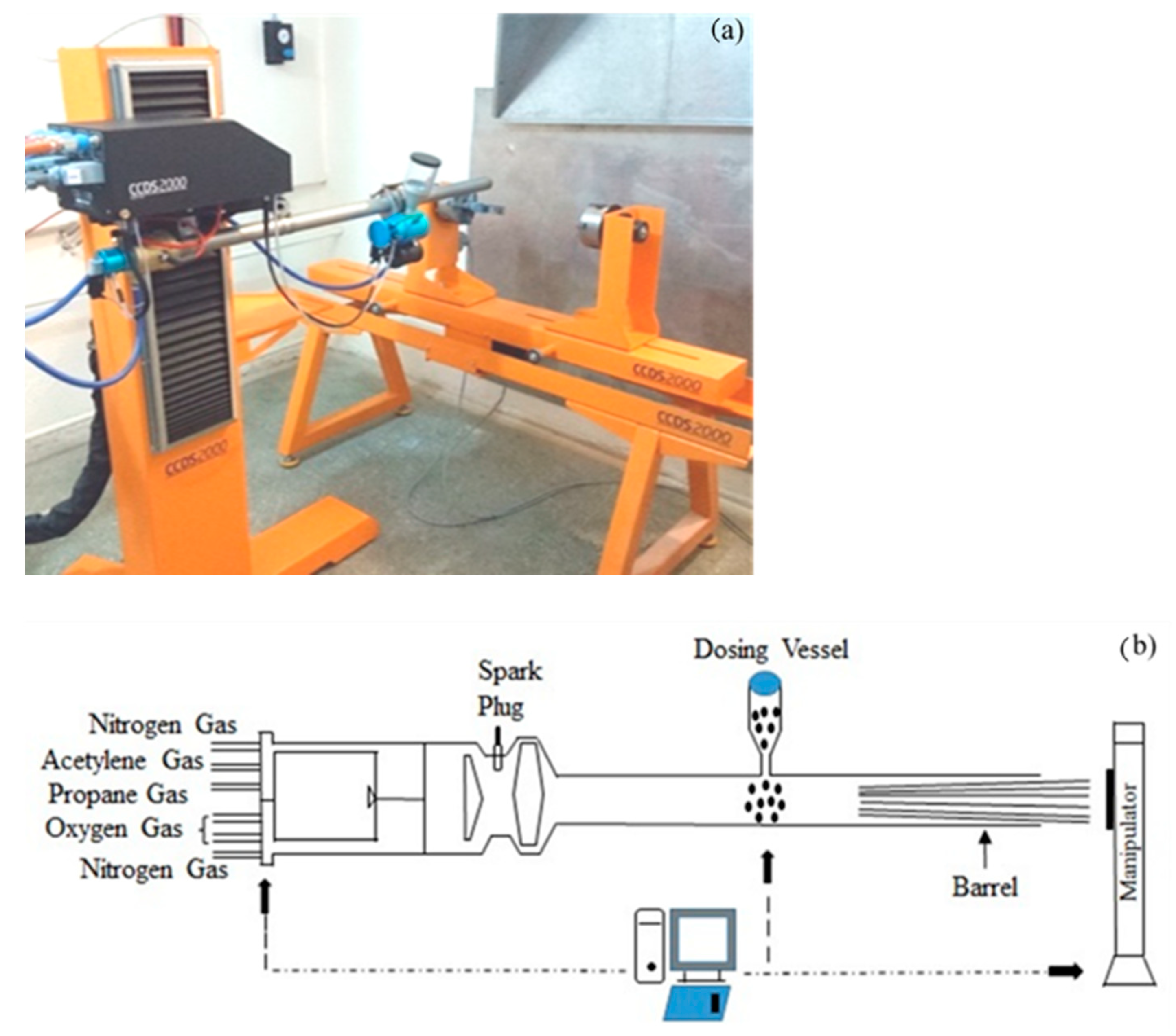

2. Materials and Methods

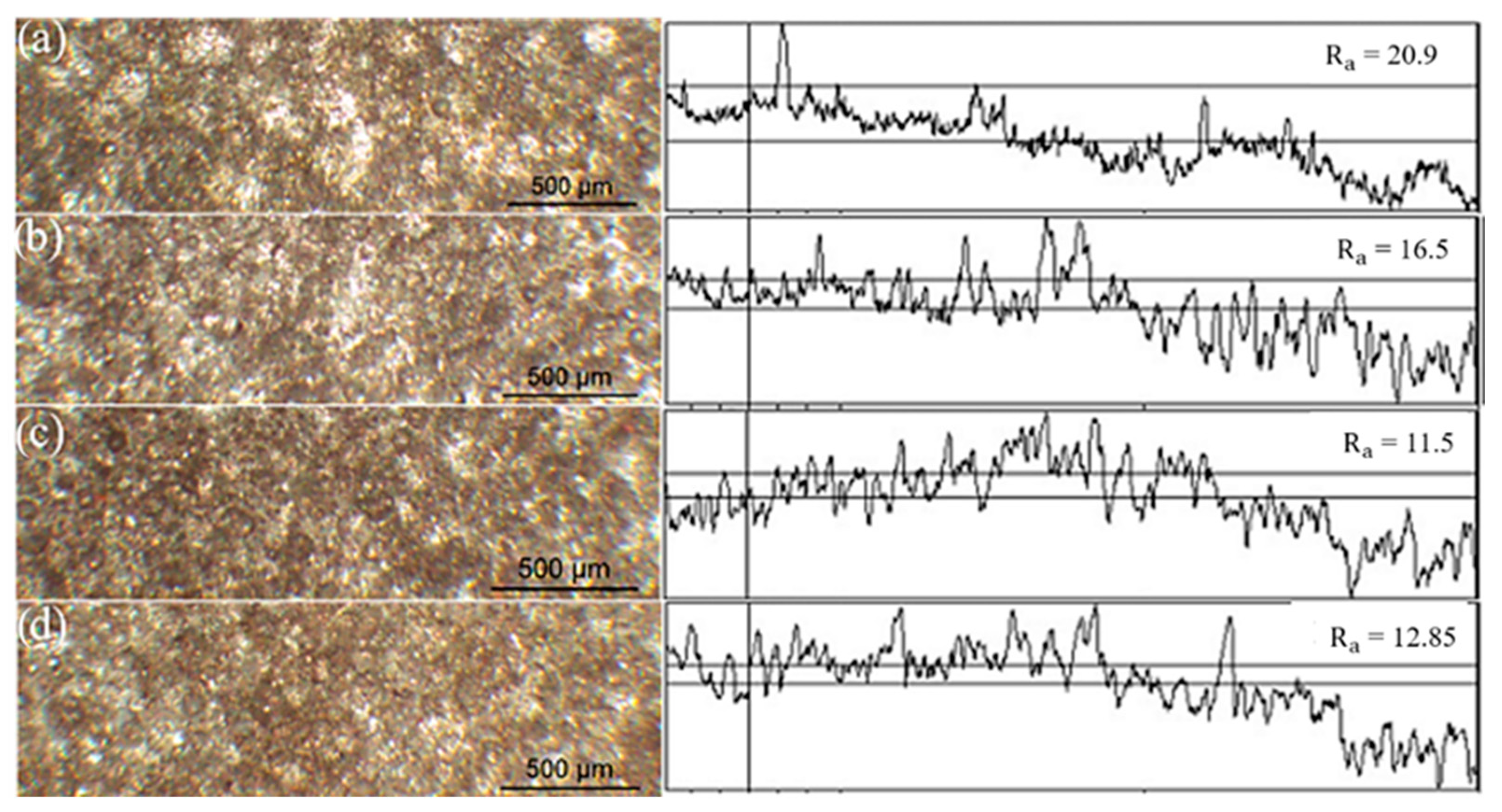

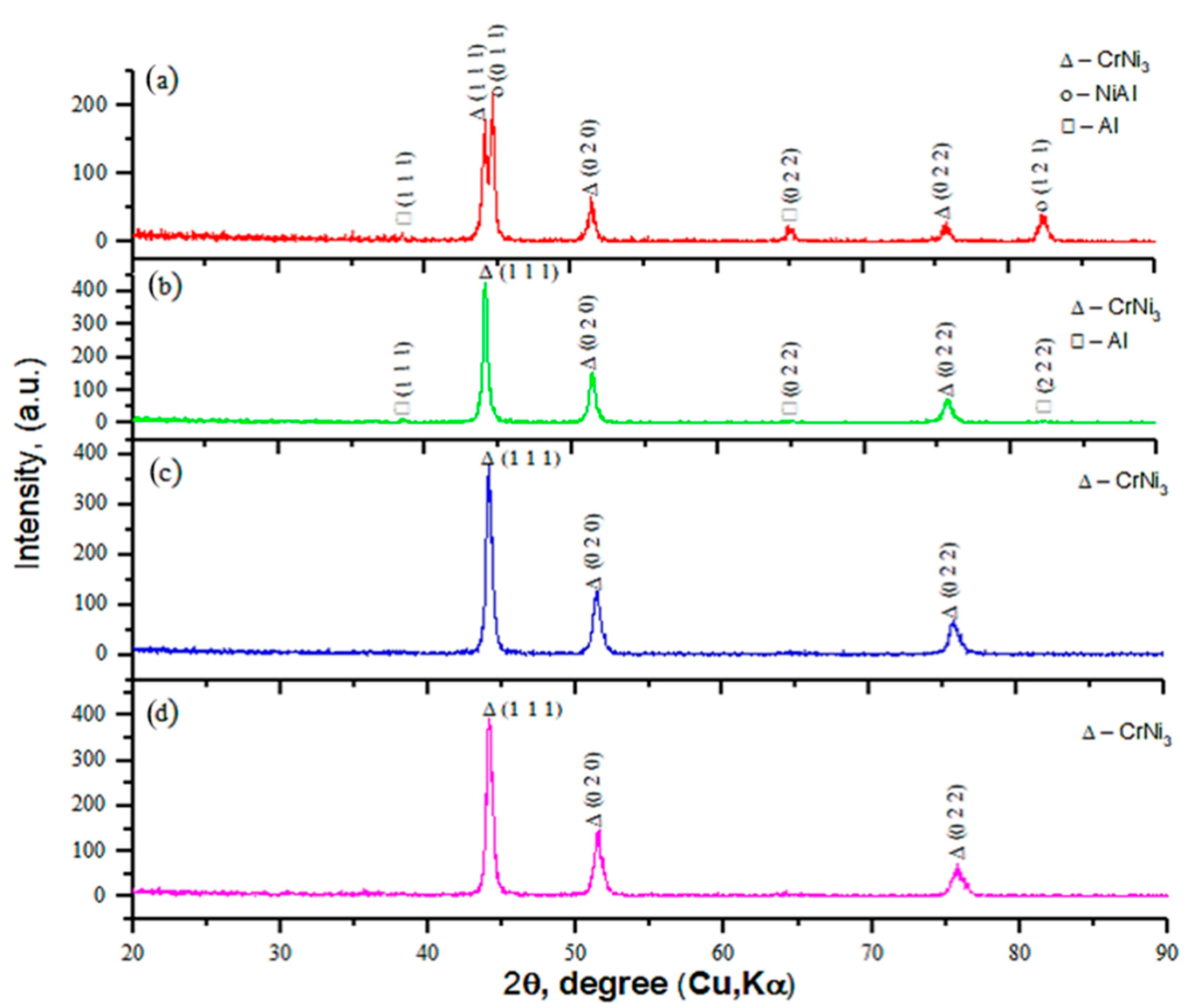

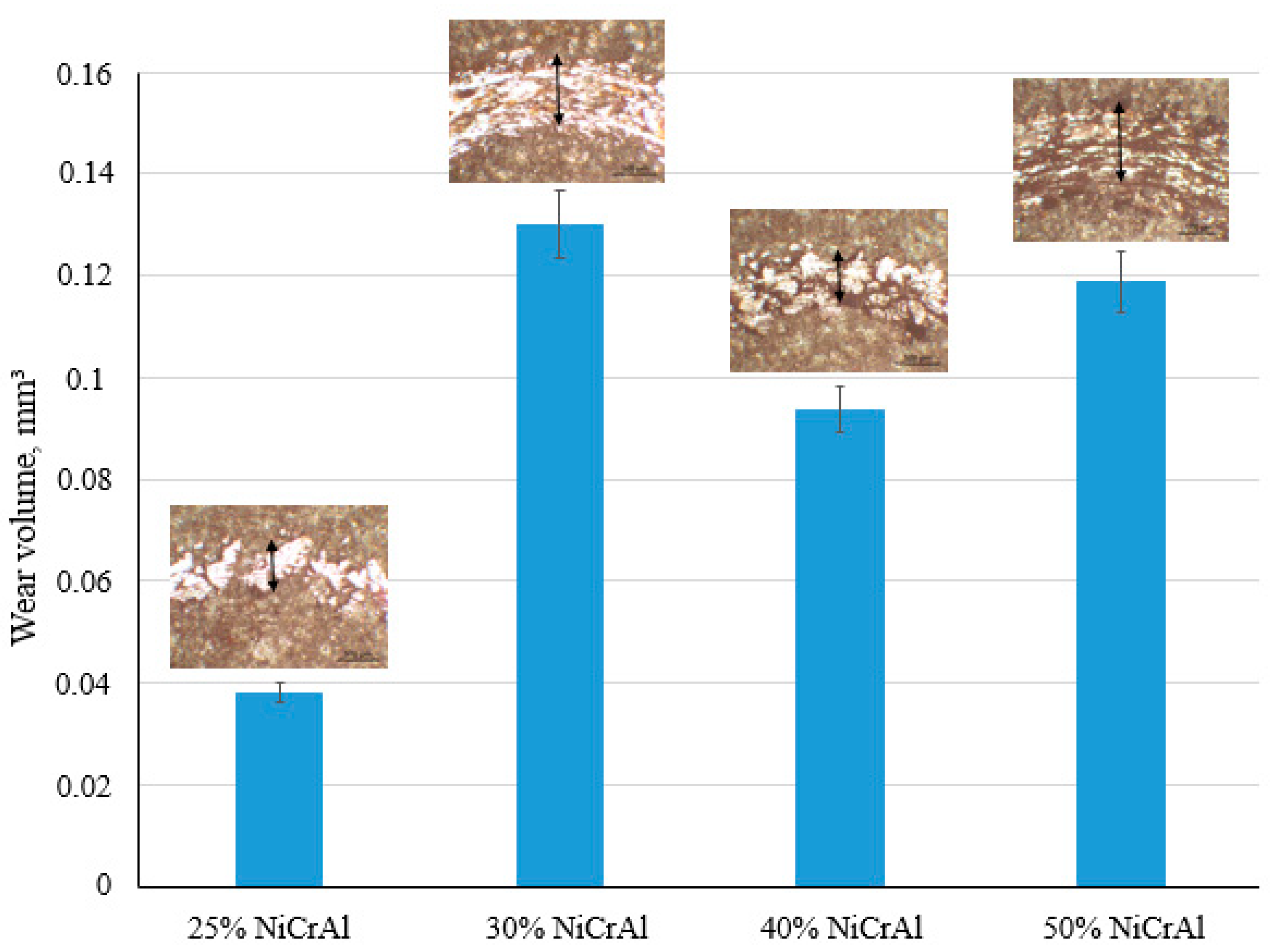

3. Results and Discussions

4. Conclusions

- The phase composition and properties of detonation coatings strongly depend on the technological spraying parameters. For spraying powder based on Ni–Cr–Al, the chemical and phase composition coatings produced strongly depend on the degree to which the barrel is filled with an O2/C2H2 gas mixture. This provides a way to control the structure and composition of the coatings and, thereby, to obtain coatings with specified properties;

- A method for producing gradient coatings based on Ni–Cr–Al using a detonation unit with only one dispenser was developed. This method employs a composite powder based on Ni–Cr–Al. Changing the technological spraying parameters provides control over the characteristics of the gradient coatings produced;

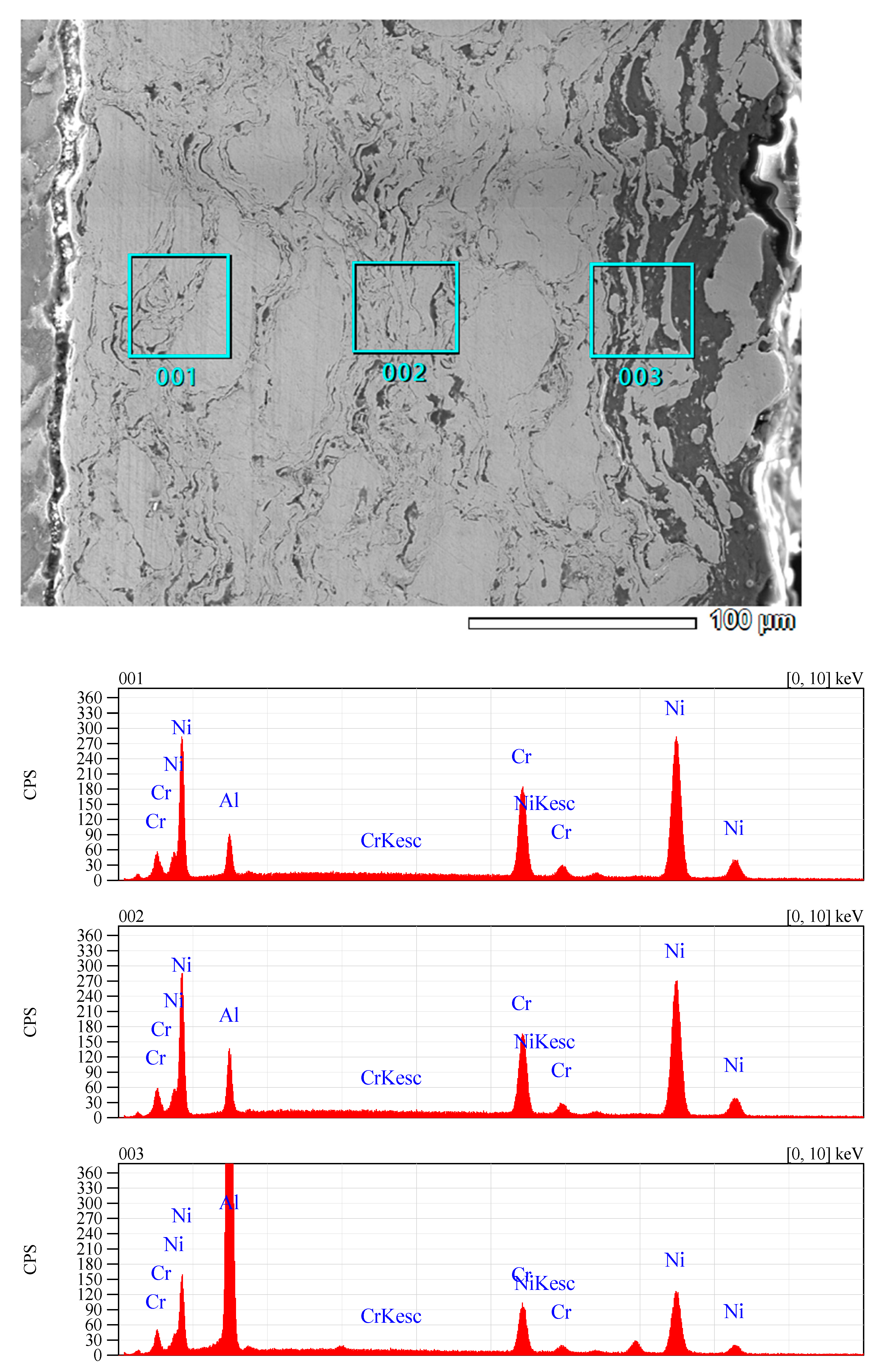

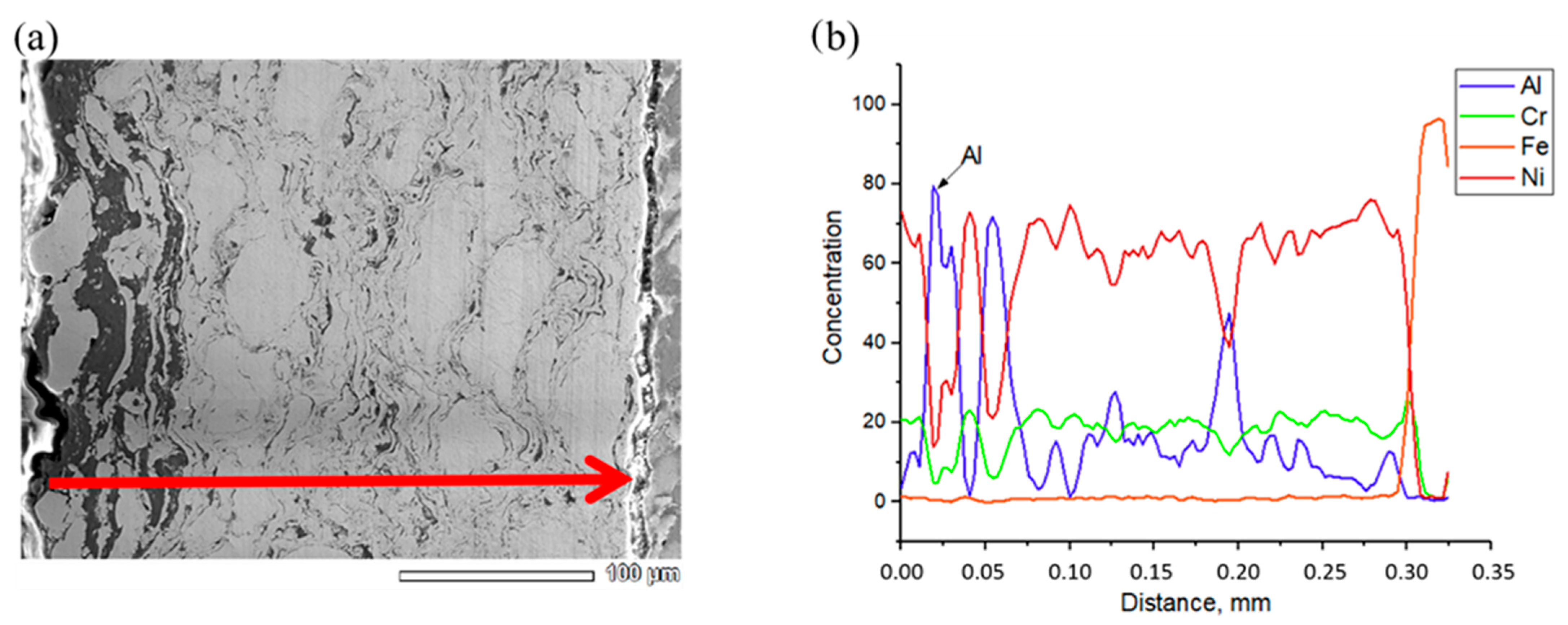

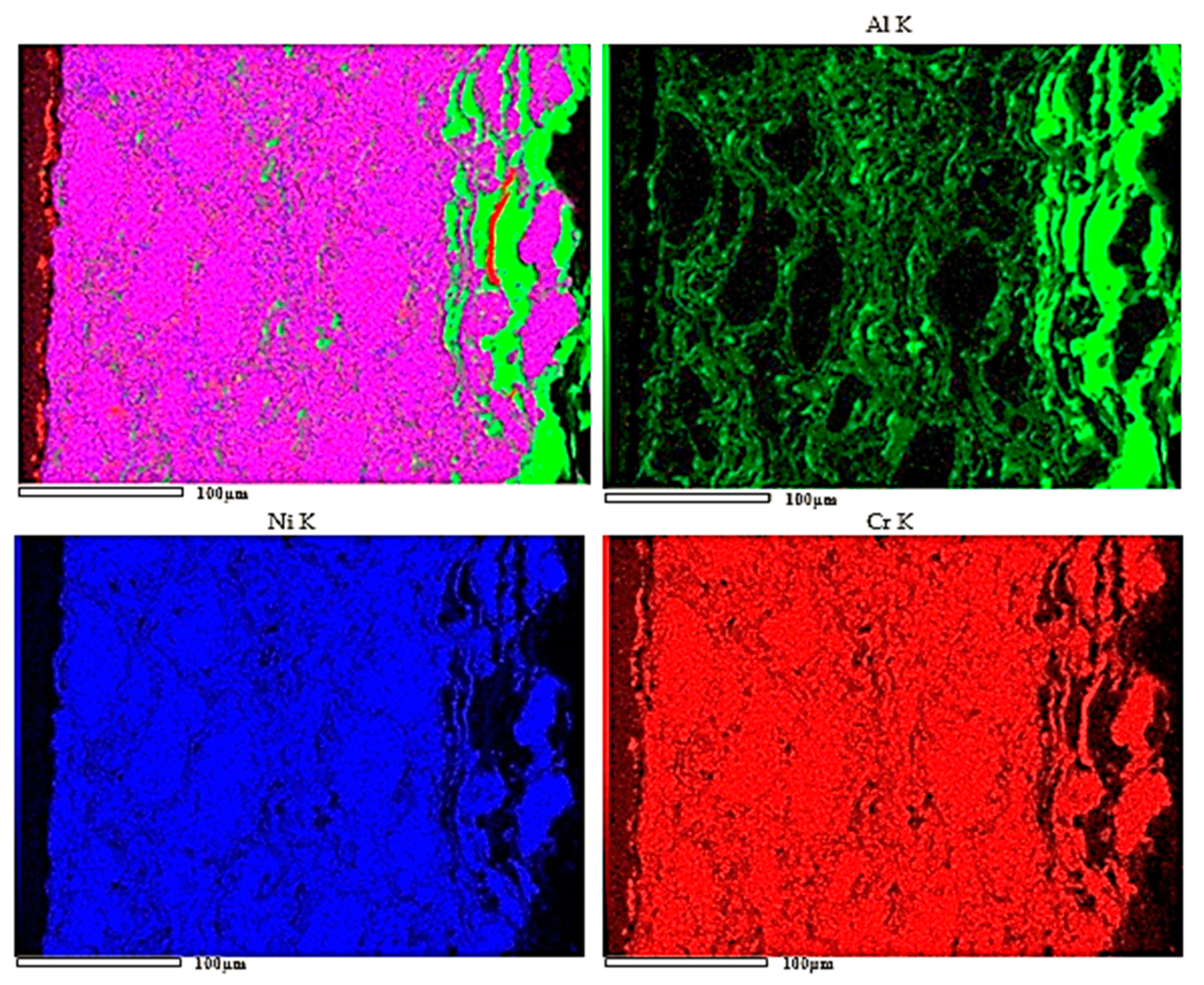

- A study of the elemental composition by the EDS method showed that the gradient coatings based on Ni–Cr–Al have a gradient structure in which the concentration of aluminum increases gradually from the substrate to the coating surface;

- Structure analyses results showed that when the barrel filling volume decreases from 50% to 25%, the phase composition of the coating changes as follows: NiCr → NiCr → NiCr, Al → NiCr, Al, NiAl. The Ni–Cr–Al gradient coating thereby obtained presents of phases NiCr with a surface of Al and NiAl that has a high hardness and wear resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nakano, T.; Kousaka, H.; Tanaka, I.; Shibasawa, H.; Kitazume, K.; Hashitomi, H. The friction property of a-C:H:Si deposited by high-speed coating with microwave sheath-voltage combination plasma method. J. Surf. Finish. Soc. Jpn. 2018, 69, 29–33. [Google Scholar] [CrossRef]

- Vignesh, S.; Shanmugam, K.; Balasubramanian, V.; Sridha, K. Identifying the optimal HVOF spray parameters to attain minimum porosity and maximum hardness in iron based amorphous metallic coatings. Def. Technol. 2017, 13, 101–110. [Google Scholar] [CrossRef]

- Ulianitsky, V.Y.; Batraev, I.S.; Shtertser, A.A.; Dudina, D.V.; Bulina, N.V.; Smurov, I. Detonation spraying behaviour of refractory metals: Case studies for Moand Ta-based powders. Adv. Powder Technol. 2018, 29, 1859–1864. [Google Scholar] [CrossRef]

- Niu, S.; Zhou, K.; Xu, L.; Deng, C.; Liu, M.; Mao, J. A comparative study of La0.6Sr0.4Co0.2Fe0.8O3—δ oxygen transport membranes deposited on porous metal supports prepared by supersonic air-gas plasma spraying (SAPS) and low-pressure plasma spraying-physical vapor deposition (PS-PVD). Surf. Coat. Technol. 2016, 307, 963–970. [Google Scholar] [CrossRef]

- Student, M.M.; Pokhmurs’ka, H.V.; Zadorozhna, K.R. Structure and wear resistance of VC–FeCr and VC–FeCrCo coatings obtained by supersonic flame spraying. Mater. Sci. 2018, 54, 22–29. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, H.; Chen, Y.; Zhao, X.; Guo, F.; Xiao, P. Effect of microstructure of a NiCoCrAlY coating fabricated by high-velocity air fuel on the isothermal oxidation. Corros. Sci. 2019, 159, 108126. [Google Scholar] [CrossRef]

- Kuroda, S.; Kawakita, J.; Watanabe, M.; Kim, K.H.; Molak, R.; Katanoda, H. Current statues and future prospects of warm spray technology. In Future Development of Thermal Spray Coatings; Woodhead Publishing: Cambridge, UK, 2015; pp. 163–206. [Google Scholar]

- Kilic, M.; Ozkan, D.; Gok, M.S.; Karaoglanli, A.C. Room- and high temperature wear resistance of MCrAlY coatings deposited by detonation gun (D-gun) and supersonic plasma spraying (SSPS) techniques. Coatings 2020, 10, 1107. [Google Scholar] [CrossRef]

- Rakhadilov, B.K.; Buitkenov, D.B.; Tuyakbaev, B.T.; Sagdoldina, Z.B.; Kenesbekov, A.B. Structure and properties of detonation coatings based on titanium carbosilicide. Key Eng. Mater. 2019, 821, 301–306. [Google Scholar]

- Ulianitsky, V.Y.; Shtertser, A.A.; Batraev, I.S.; Rybin, D.K. Fabrication of layered ceramic-metal composites by detonation spraying. Ceram. Int. 2020, 46, 27903–27908. [Google Scholar] [CrossRef]

- Rakhadilov, B.K.; Buitkenov, D.B.; Wieleba, W.; Kylyshkanov, M.K.; Yerbolatuly, D. Impact of the detonation gas spraying mode on the phase composition and adhesional strength of Ti-Si-C coatings. Eurasian Phys. Tech. J. 2020, 17, 59–64. [Google Scholar] [CrossRef]

- Rakhadilov, B.K.; Baizhan, D.R.; Sagdoldina, Z.B.; Buitkenov, D.B.; Maulet, M. Phase composition and structure of composite Ti/HA coatings synthesized by detonation spraying. AIP Conf. Proc. 2020, 2297, 020022. Available online: https://aip.scitation.org/doi/abs/10.1063/5.0029754 (accessed on 10 December 2020).

- Zhen, H.; Peng, X. Oxidation-resistant CoCrAl coatings fabricated by electrodeposition in combination with electrophoretic deposition. Surf. Coat. Technol. 2018, 352, 541–548. [Google Scholar] [CrossRef]

- Shmorgun, V.G.; Bogdanov, A.I.; Taube, A.O.; Gurevich, L.M. Formation of the diffusion barrier at the interface of Cr20Ni80 alloy–Ni-Cr-Al coating. Mat. Sci. Eng 2018, 450, 5–11. [Google Scholar] [CrossRef]

- Cheruvu, N.S.; Wei, R.; Shingledecker, J.; Gandy, D.W. Evaluation of nanocrystalline MCrAl coatings for power plants. In Proceedings of the 6th International Conference, Santa Fe, NM, USA, 31 August–3 September 2010. [Google Scholar]

- Zhang, P.; Peng, R.L.; Li, X.-H.; Johansson, S. Investigation of element effect on high-temperature oxidation of HVOF NiCoCrAlX coatings. Coatings 2018, 8, 129. [Google Scholar] [CrossRef]

- Chadami, F.; Sabour Rough Aghdam, A.; Chadami, S. Microstructural characteristics and oxidation behavior of the modified MCrAlX coatings: A critical review. Vacuum 2021, 185, 109980. [Google Scholar]

- Lin, L.; Hu, S.; Hu, Y.; Xu, G.; Jiao, H.; Weng, C. Experimental study on the detonation process of a pulse detonation engine with ionized seeds. Def. Technol. 2020, 16, 178–187. [Google Scholar] [CrossRef]

- Latka, L.; Pawlowski, L.; Winnicki, M.; Sokolowski, P.; Malachowska, A.; Kozerski, S. Review of functionally graded thermal sprayed coatings. Appl. Sci. 2020, 10, 5153. [Google Scholar] [CrossRef]

- Naebe, M.; Shirvanimoghaddam, K. Functionally graded materials: A review of fabrication and properties. Appl. Mater. Today 2016, 5, 223–245. [Google Scholar] [CrossRef]

- Ulianitsky, V.Y.; Dudina, D.V.; Shtertser, A.; Smurov, I. Computer-controlled detonation spraying: Flexible control of the coating chemistry and microstructure. Metals 2019, 12, 1244. [Google Scholar] [CrossRef]

- Maulet, M.; Rakhadilov, B.K.; Sagdoldina, Z.B.; Kassymov, A.B.; Kakimzhanov, D.N. Influence of the detonation-spraying mode on the phase composition and properties of Ni-Cr coatings. Eurasian J. Phys. Funct. Mater. 2020, 4, 184–189. [Google Scholar] [CrossRef]

- Maulet, M.; Rakhadilov, B.; Stepanova, O.; Sagdoldina, Z.; Kassymov, A.; Kakimzhanov, D. Structure, hardness and wear resistance of the Ni-Cr-Al detonation coating. In Proceedings of the 2020 IEEE 10th International Conference on “Nanomaterials: Applications & Properties” (NAP-2020), Varna, Bulgaria, 28–30 August 2020. [Google Scholar]

- GOST 2789-73 Surface roughness. Parameters and Characteristics; Russian GOST: Moscow, Russia, 1975.

- GOST 9450-76 Measurements Microhardness by Diamond Instruments Indentation; Russian GOST: Moscow, Russia, 1976.

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- ASTM E2546-07 Standard Pracice for Instrumental Indentation Testing; ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM G133-95, Standard Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear; ASTM International: West Conshohocken, PA, USA, 1995.

- ASTM G99-05, Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus; ASTM International: West Conshohocken, PA, USA, 2005.

- Sagdoldina, Z.; Rakhadilov, B.; Skakov, M.; Stepanova, O. Structural evolution of ceramic coatings by mechanical alloying. Mater. Test. 2019, 61, 304–308. [Google Scholar] [CrossRef]

- Rogachev, A.S.; Shkodich, N.F.; Vadchenko, S.G.; Baras, F.; Kovalev, D.Y.; Rouvimov, S.; Nepapushev, A.A.; Mukasyan, A.S. Influence of the high energy ball milling on structure and reactivity of the Ni + Al powder mixture. J. Alloy. Compd. 2013, 577, 600–605. [Google Scholar] [CrossRef]

- Miracle, D.B.; Darolia, R. NiAl and its alloys. Intermet. Compd. 1995, 2, 55–74. [Google Scholar]

- Potekaev, A.I.; Chaplygina, A.A.; Chaplygina, P.A.; Starostenkov, M.D.; Kulagina, V.V.; Klopotov, A.A.; Grinkevich, L.S. The influence of grain size on low-stability pre-transitional structural-phase states of NiAl intermetallide. Russ. Phys. J. 2019, 62, 519–526. [Google Scholar] [CrossRef]

| C | Si | Mn | Ni | S | P | Cr | Mo | V | Cu |

|---|---|---|---|---|---|---|---|---|---|

| 0.1–0.15 | 0.17–0.37 | 0.4–0.7 | to 0.3 | to 0.025 | to 0.03 | 0.9–1.2 | 0.25–0.35 | 0.15–0.3 | to 0.2 |

| № | O2/C2H2 | Barrel Filling Volume,% | Spray Distance, mm | Number of Shots |

|---|---|---|---|---|

| 1 | 1856 | 25 | 250 | 40 |

| 2 | 1856 | 30 | 250 | 40 |

| 3 | 1856 | 40 | 250 | 40 |

| 4 | 1856 | 50 | 250 | 40 |

| 5 | 1856 | 25–50 | 250 | 40 |

| Element | Al, Mass% | Cr, Mass% | Ni, Mass% | Total, Mass% |

|---|---|---|---|---|

| Spectrum 001 | 10.88 | 21.82 | 67.30 | 100.00 |

| Spectrum 002 | 16.28 | 19.23 | 64.49 | 100.00 |

| Spectrum 003 | 74.09 | 7.54 | 18.37 | 100.00 |

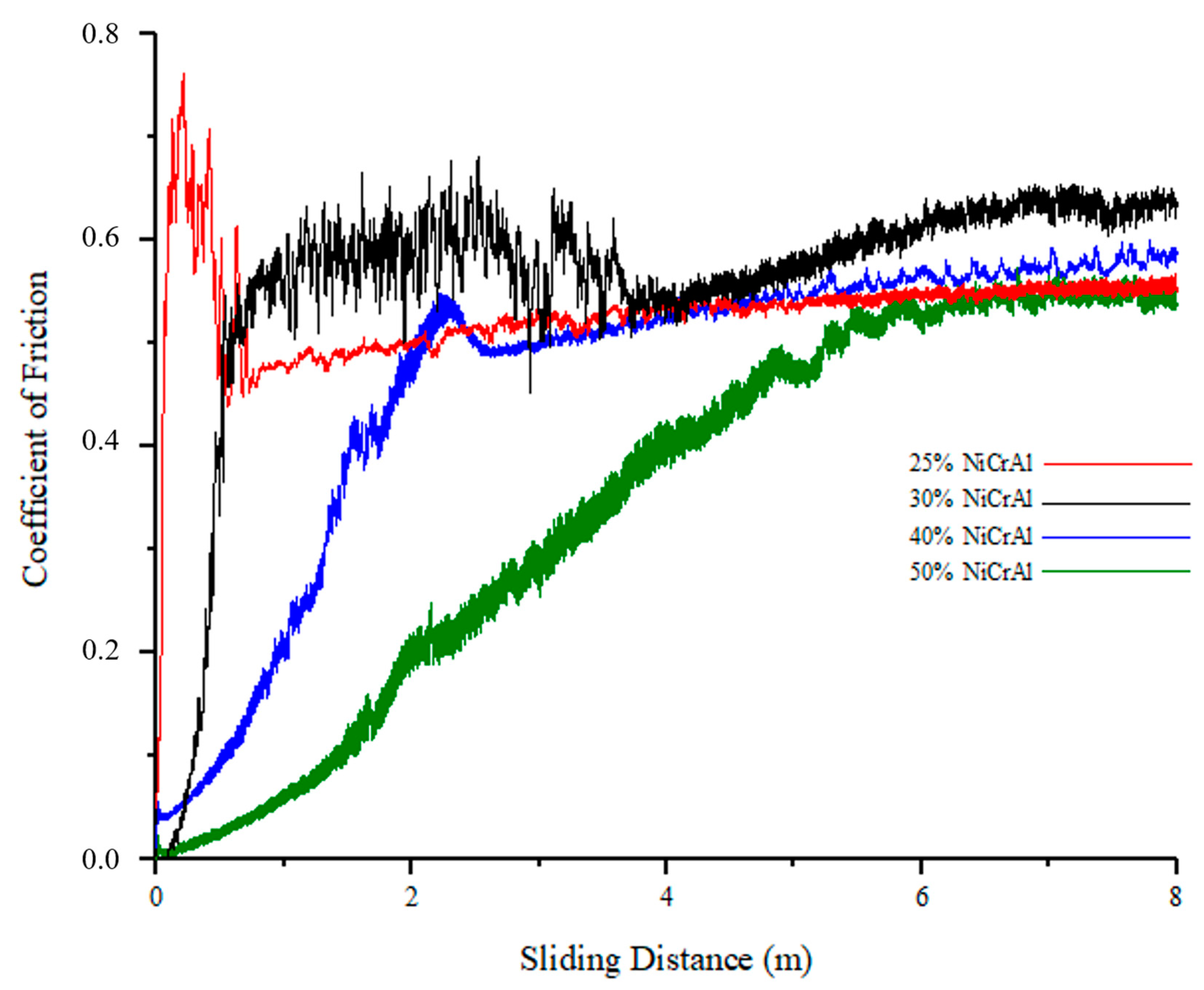

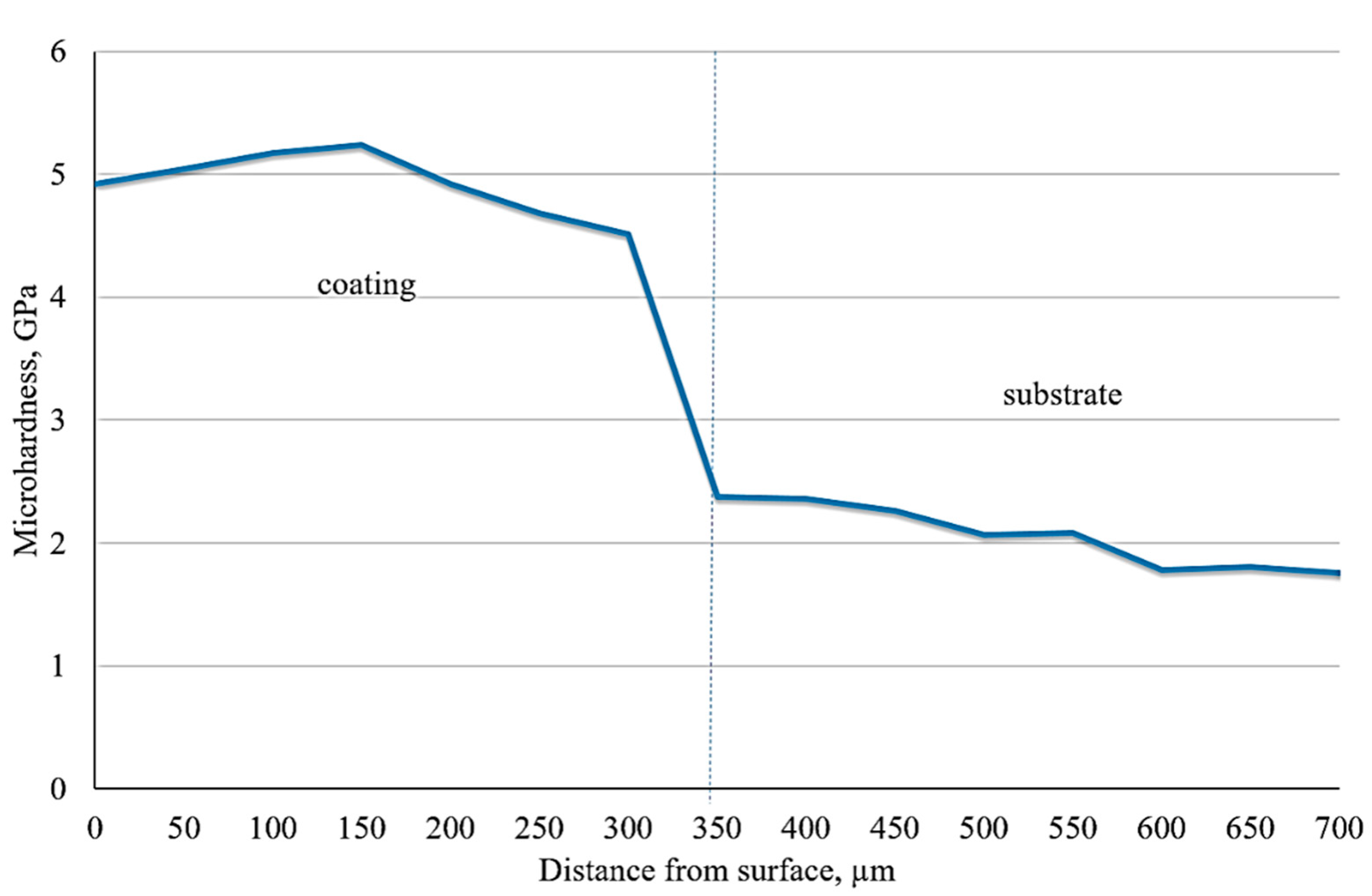

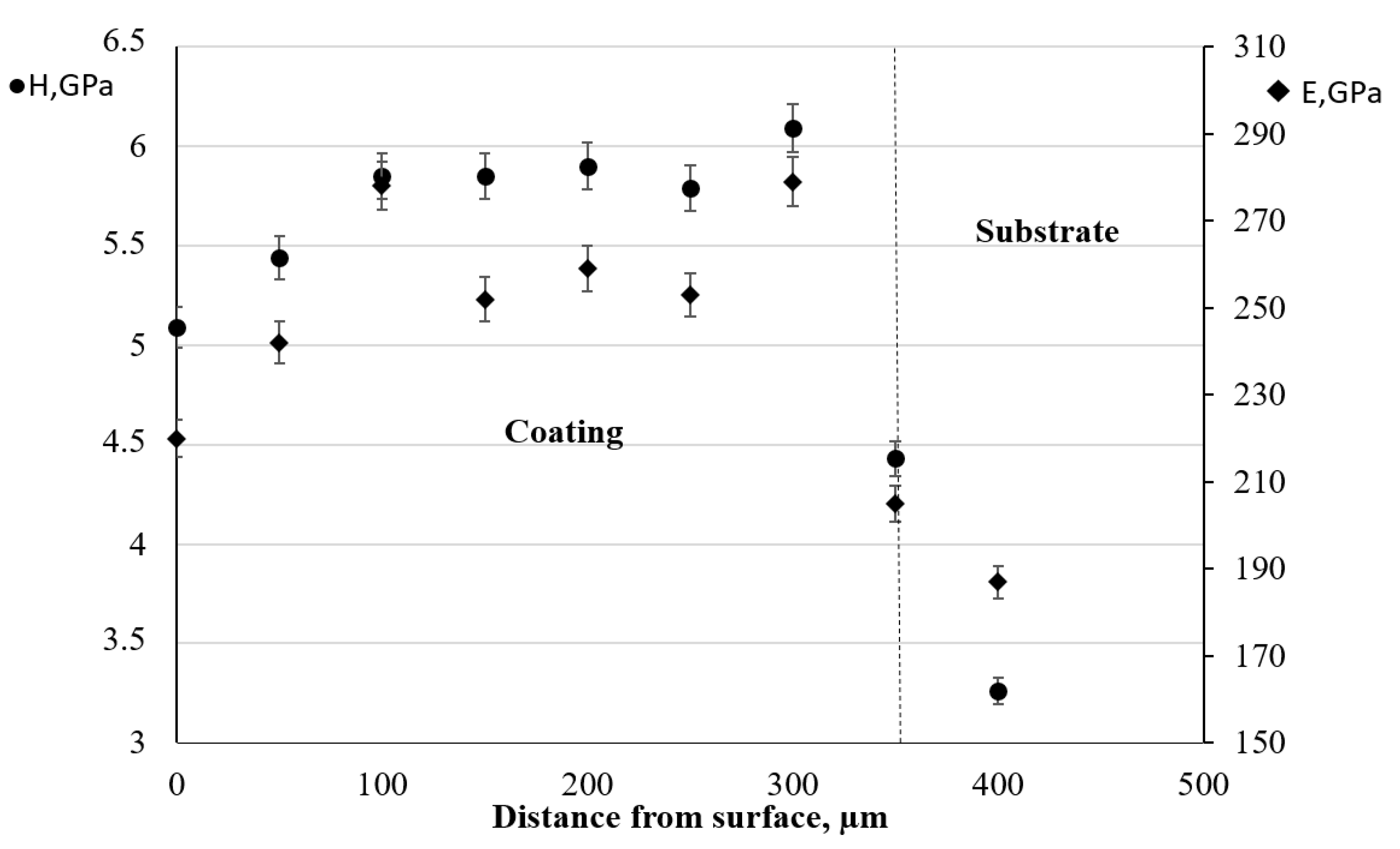

| Name. | Phase Composition | Micro Hardness, GPa | Nano Hardness, GPa | Young′s Modulus, GPa | Friction Coefficient | Wear Volume, mm3 |

|---|---|---|---|---|---|---|

| Substrate | α-Fe | 1.80–2.50 | 3.0–3.50 | 170–190 | 0.4–0.45 | 0.08 |

| Ni–Cr–Al | NiCr, Al, NiAl | 4.50–5.23 | 5.10–6.20 | 200–280 | 0.5–0.6 | 0.0378 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rakhadilov, B.; Maulet, M.; Abilev, M.; Sagdoldina, Z.; Kozhanova, R. Structure and Tribological Properties of Ni–Cr–Al-Based Gradient Coating Prepared by Detonation Spraying. Coatings 2021, 11, 218. https://doi.org/10.3390/coatings11020218

Rakhadilov B, Maulet M, Abilev M, Sagdoldina Z, Kozhanova R. Structure and Tribological Properties of Ni–Cr–Al-Based Gradient Coating Prepared by Detonation Spraying. Coatings. 2021; 11(2):218. https://doi.org/10.3390/coatings11020218

Chicago/Turabian StyleRakhadilov, Bauyrzhan, Meruyert Maulet, Madi Abilev, Zhuldyz Sagdoldina, and Rauan Kozhanova. 2021. "Structure and Tribological Properties of Ni–Cr–Al-Based Gradient Coating Prepared by Detonation Spraying" Coatings 11, no. 2: 218. https://doi.org/10.3390/coatings11020218

APA StyleRakhadilov, B., Maulet, M., Abilev, M., Sagdoldina, Z., & Kozhanova, R. (2021). Structure and Tribological Properties of Ni–Cr–Al-Based Gradient Coating Prepared by Detonation Spraying. Coatings, 11(2), 218. https://doi.org/10.3390/coatings11020218