Synergistic LPCVD and PECVD Growth of β-Ga2O3 Thin Films for High-Sensitivity and Low-Dose Direct X-Ray Detection

Abstract

1. Introduction

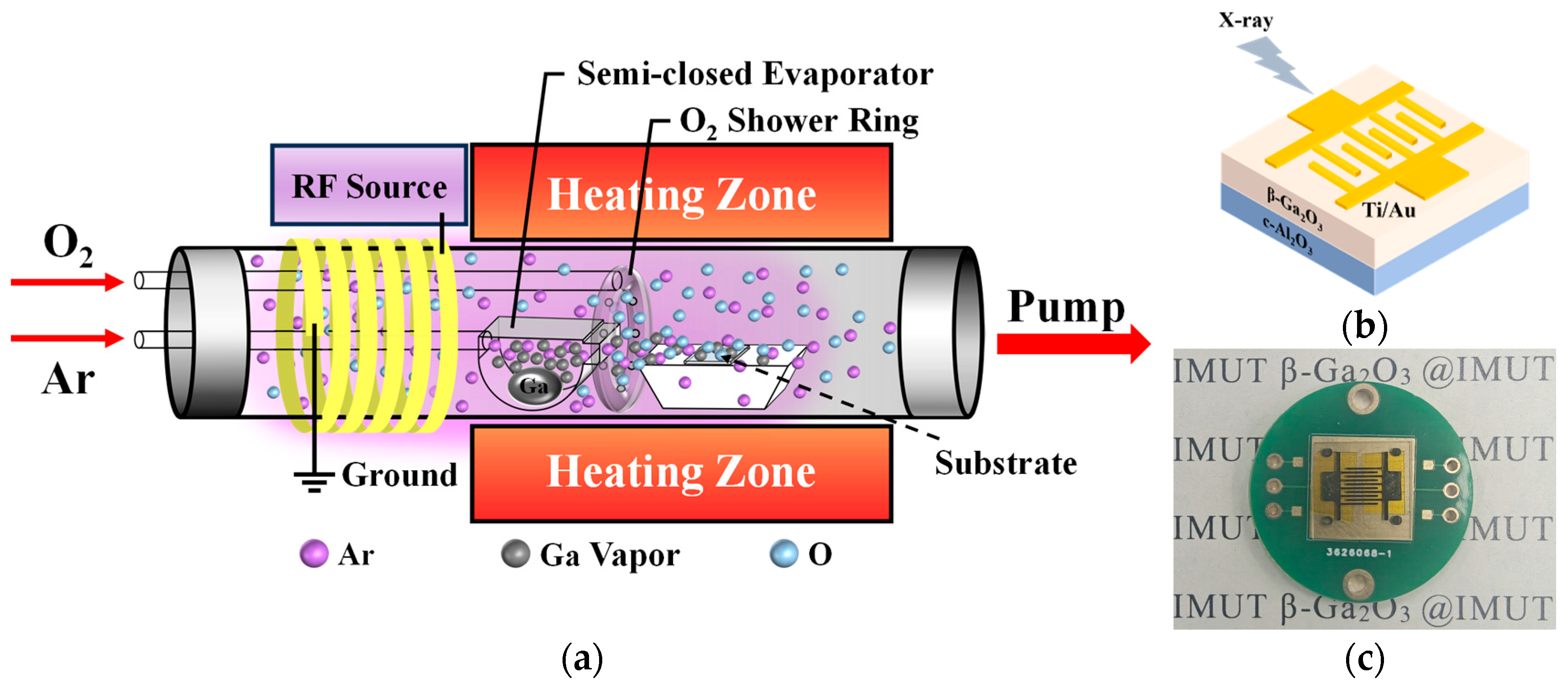

2. Materials and Methods

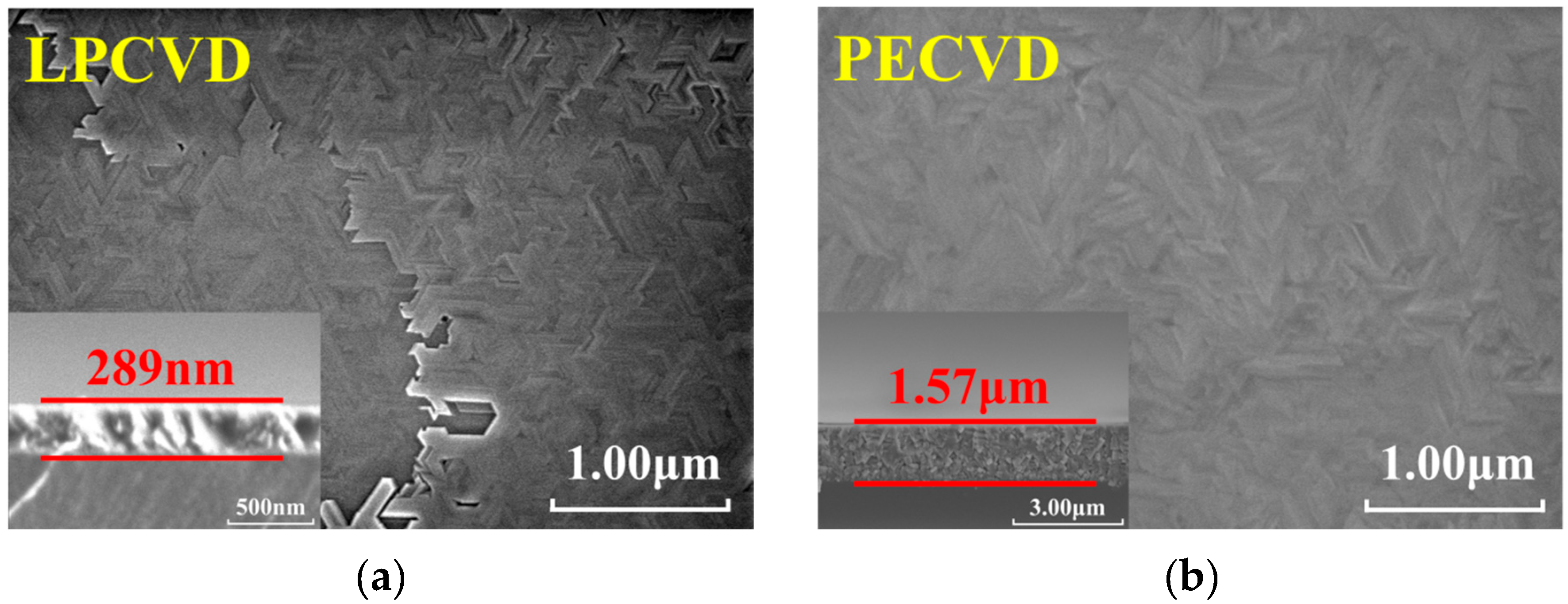

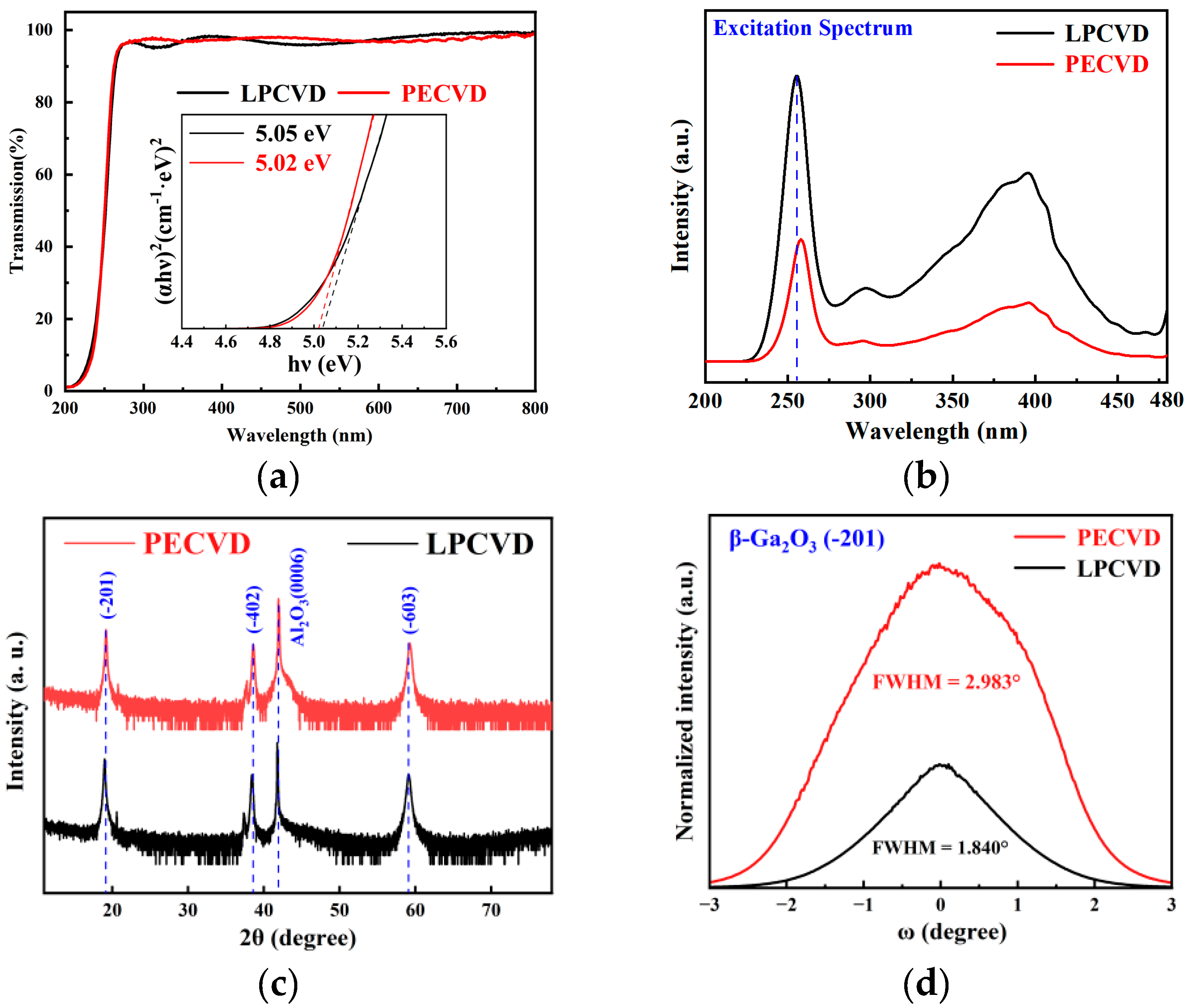

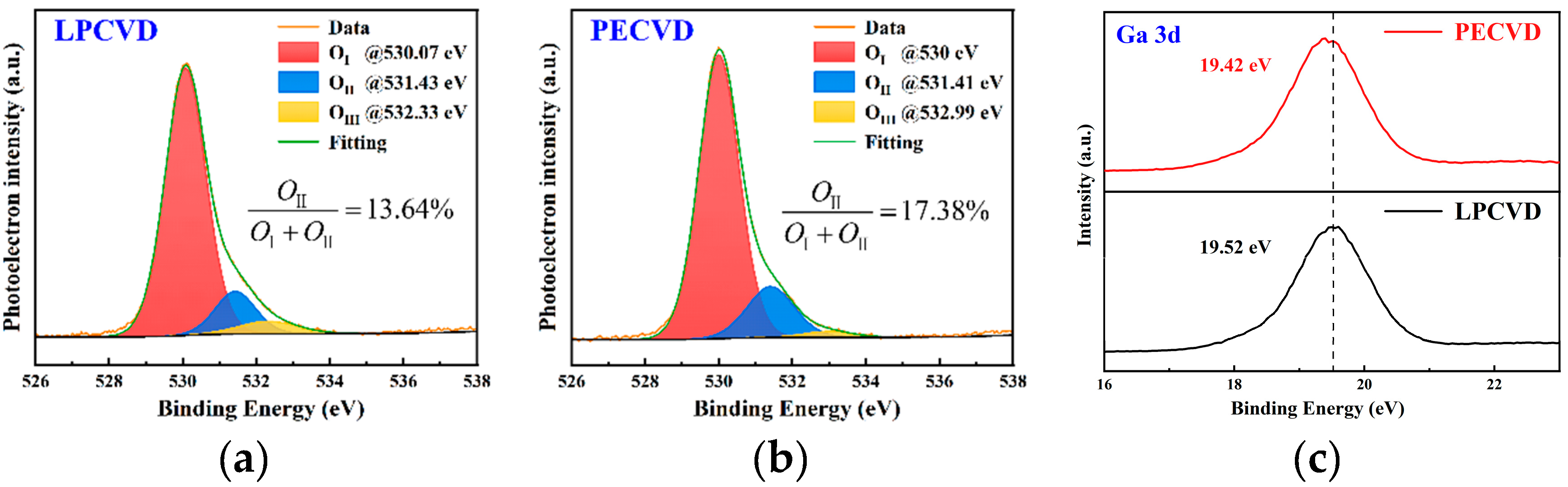

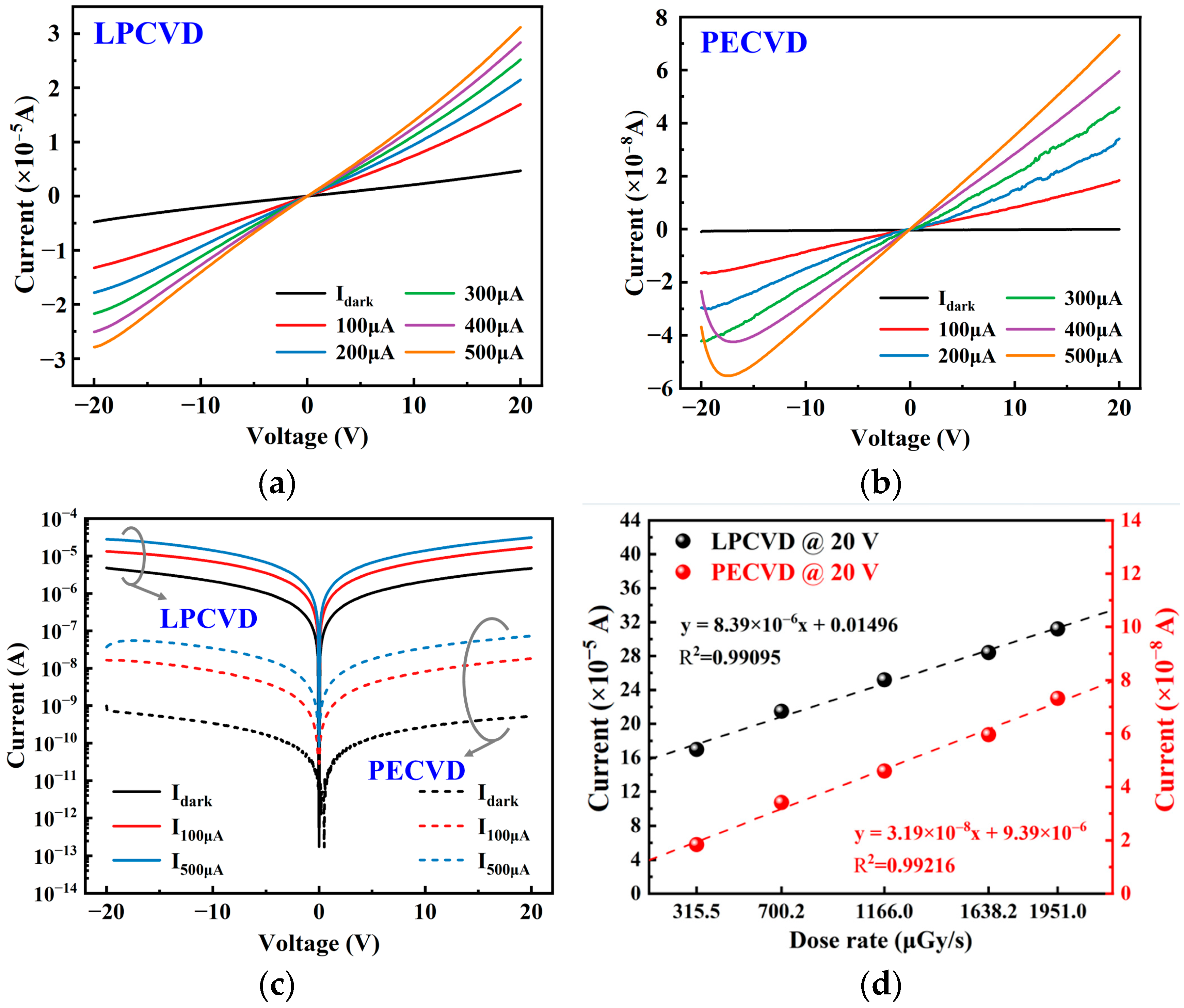

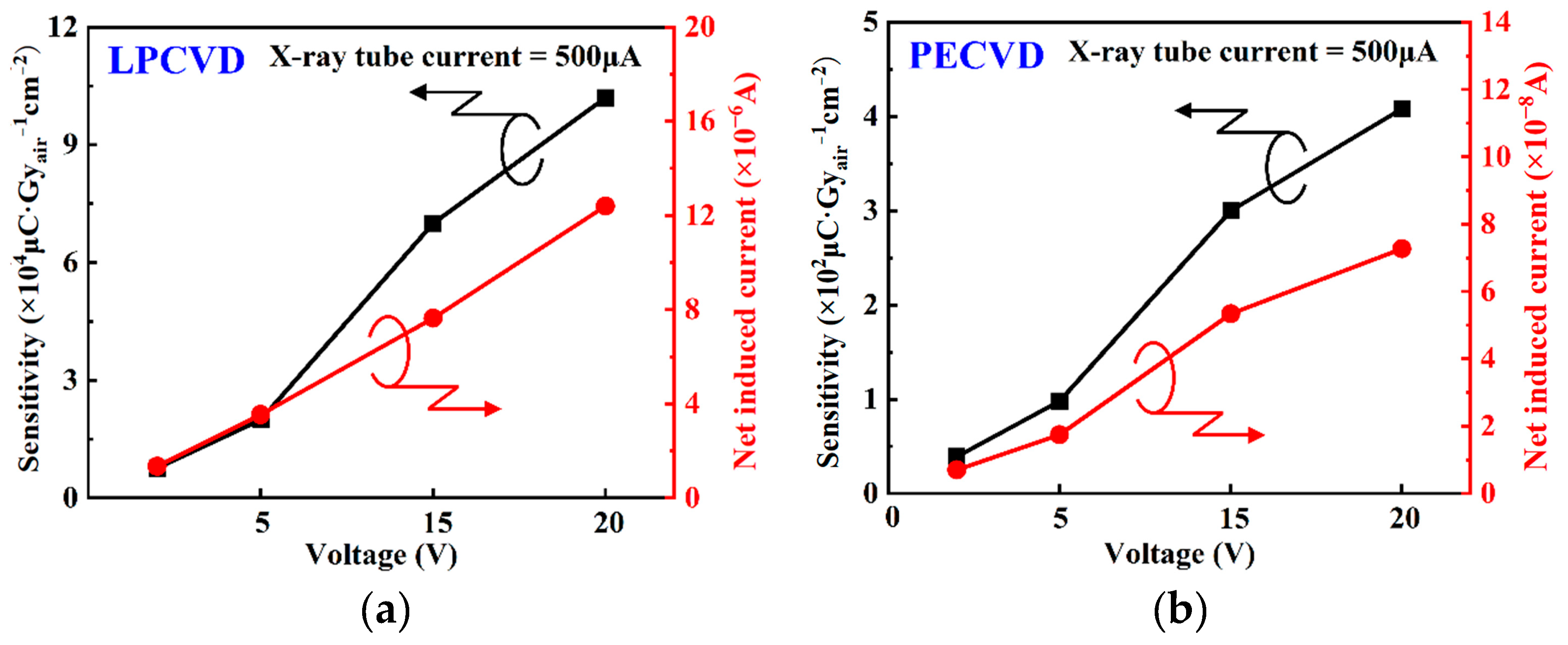

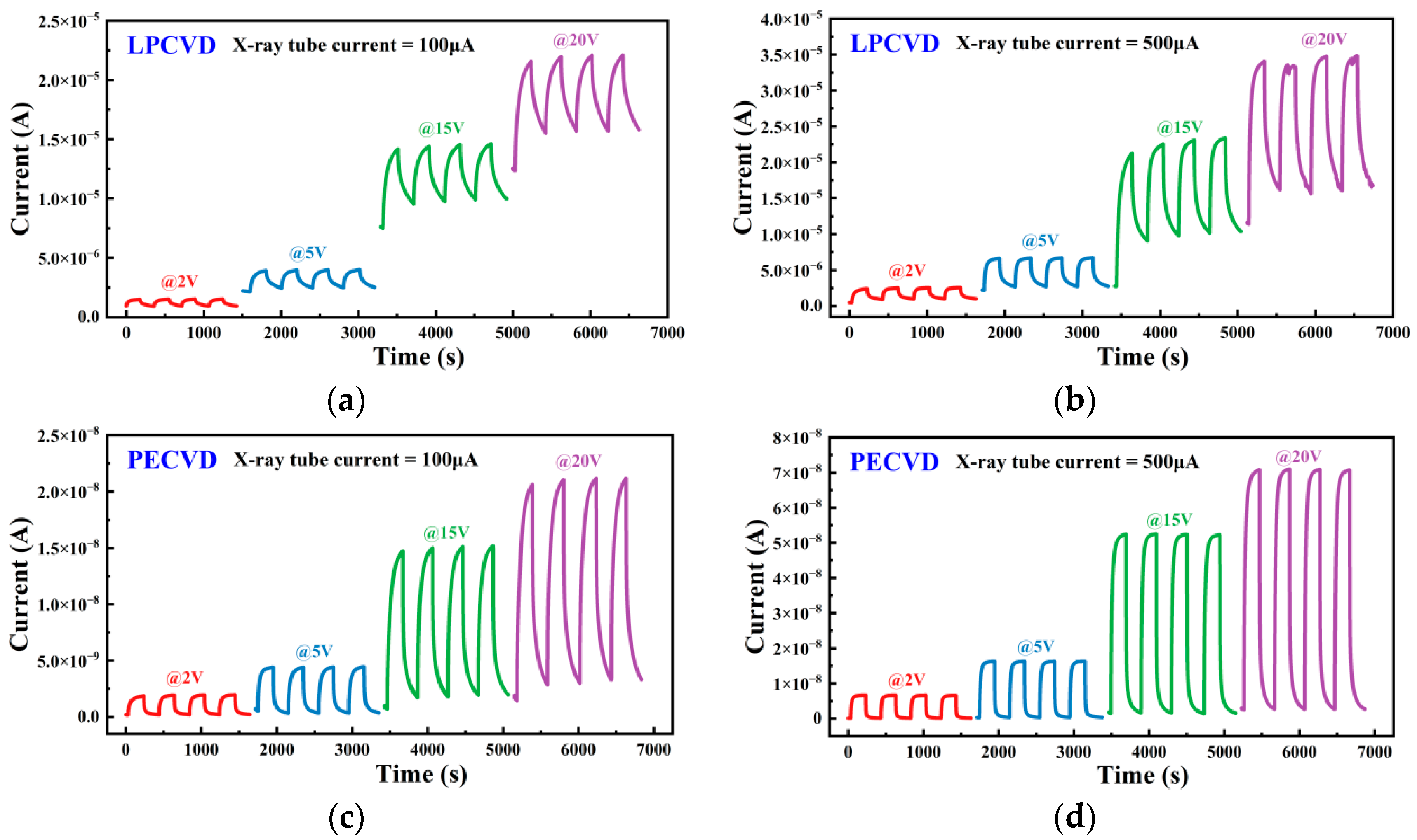

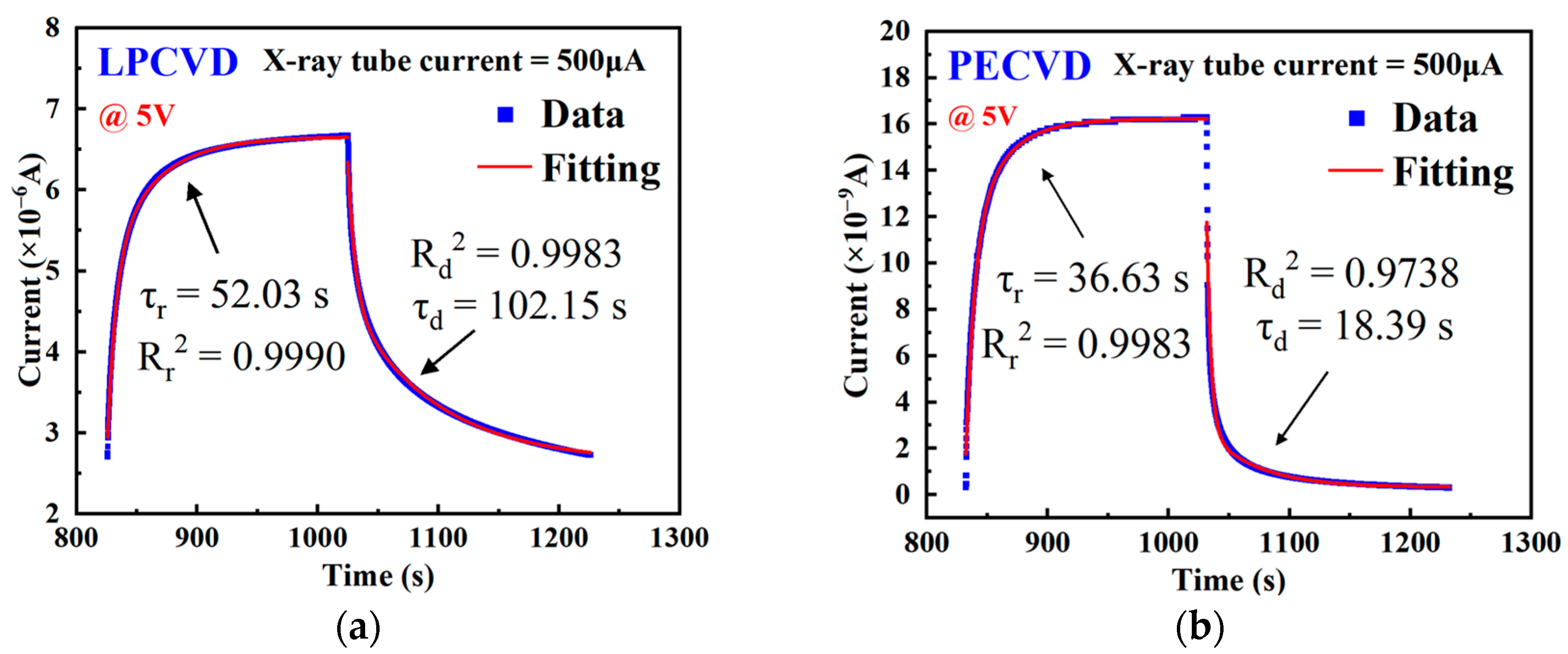

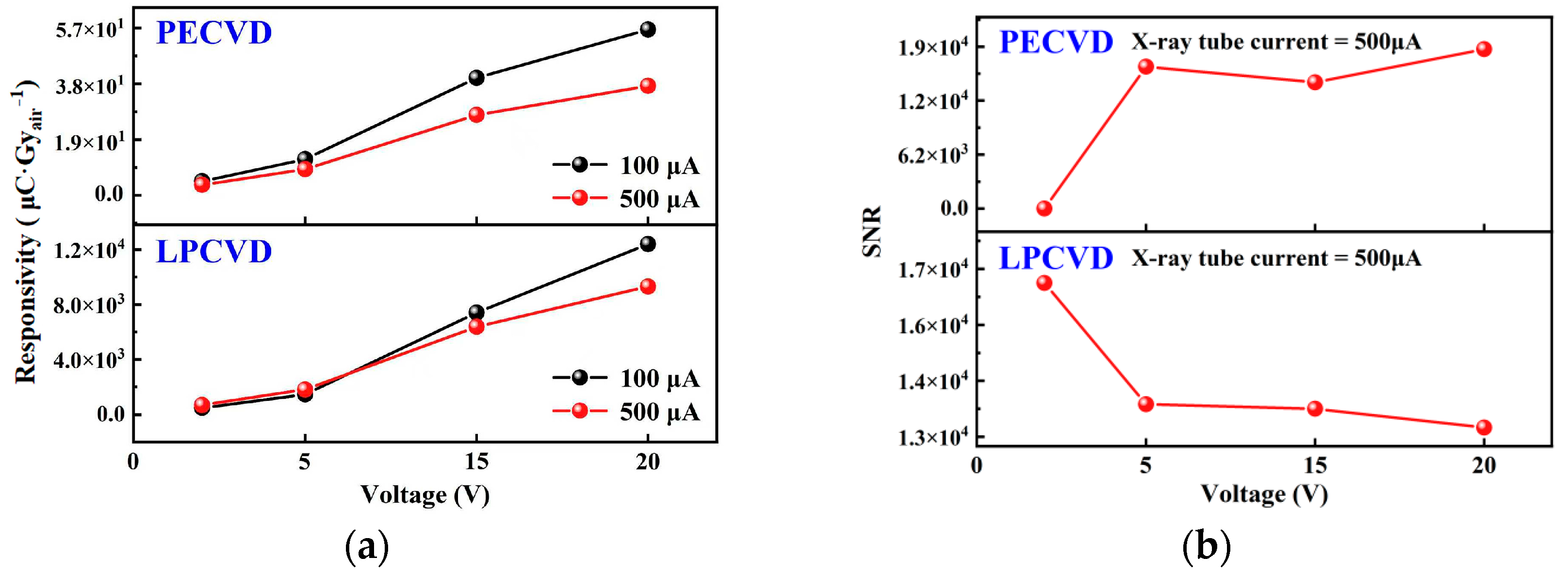

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, Y.C.; Kim, K.H.; Son, D.-Y.; Jeong, D.-N.; Seo, J.-Y.; Choi, Y.S.; Han, I.T.; Lee, S.Y.; Park, N.-G. Printable Organometallic Perovskite Enables Large-Area, Low-Dose X-Ray Imaging. Nature 2017, 550, 87–91. [Google Scholar] [CrossRef]

- Suchikova, Y.; Nazarovets, S.; Popov, A.I. Ga2O3 Solar-Blind Photodetectors: From Civilian Applications to Missile Detection and Research Agenda. Opt. Mater. 2024, 157, 116397. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, Z.; Zhan, R.; She, J.; Deng, S.; Xu, N.; Chen, J. Fast-Response X-Ray Detector Based on Nanocrystalline Ga2O3 Thin Film Prepared at Room Temperature. Appl. Surf. Sci. 2021, 554, 149619. [Google Scholar] [CrossRef]

- Ouyang, X.; Zhang, S.; Bai, T.; Chen, Z.; Deng, Y.; Zhou, L.; Song, X.; Chen, H.; Lai, Y.; Lu, X.; et al. Performance Degradation of Ga2O3-Based X-Ray Detector Under Gamma-Ray Irradiation. Micromachines 2025, 16, 339. [Google Scholar] [CrossRef]

- Langpoklakpam, C.; Rana, S.; Hsieh, C.; Singh, J.P.; Lee, P.; Horng, R.; Tu, C.; Kuo, H. State-of-the-Art Solar Blind and X-Ray Photodetectors Based on Gallium Oxide. Adv. Photonics Res. 2025, 2500008. [Google Scholar] [CrossRef]

- Matt, G.J.; Levchuk, I.; Knüttel, J.; Dallmann, J.; Osvet, A.; Sytnyk, M.; Tang, X.; Elia, J.; Hock, R.; Heiss, W.; et al. Sensitive Direct Converting X-Ray Detectors Utilizing Crystalline CsPbBr3 Perovskite Films Fabricated via Scalable Melt Processing. Adv. Mater. Interfaces 2020, 7, 1901575. [Google Scholar] [CrossRef]

- Ye, F.; Lin, H.; Wu, H.; Zhu, L.; Huang, Z.; Ouyang, D.; Niu, G.; Choy, W.C.H. High-Quality Cuboid CH3NH3PbI3 Single Crystals for High Performance X-Ray and Photon Detectors. Adv. Funct. Mater. 2019, 29, 1806984. [Google Scholar] [CrossRef]

- Li, Y.; Wang, X.; Liang, J.; Zhang, L.; Zhang, J. Recent Progress in Direct X-Ray Detectors Based on Metal Oxide Wide Bandgap Semiconductors: A Review. IEEE Sens. J. 2024, 24, 38569–38583. [Google Scholar] [CrossRef]

- Venkata Prasad, C.; Labed, M.; Alam Shamim Shaikh, M.T.; Min, J.Y.; Vu Nguyen, T.H.; Song, W.; Kim, K.J.; Rim, Y.S. Ga2O3-Based X-Ray Detector and Scintillators: A Review. Mater. Today Phys. 2023, 35, 101095. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, X.; Li, Y.; Cheng, Q.; Onwudiwe, D.C.; Bae, B.S.; Ertuğrul, M.; Zhu, Y.; Lei, W.; Xu, X. Substance Discrimination Imaging Derived from Switchable Soft and Hard X-ray Sensing in Direct X-ray Detector. InfoMat 2025, 7, e12632. [Google Scholar] [CrossRef]

- Hang, S. Research on X-Ray Irradiation Detection Based on Amorphous Gallium Oxide. Master’s Thesis, University of Electronic Science and Technology of China, Chengdu, China, 2023. [Google Scholar]

- Geng, X.; Chen, Y.; Li, Y.; Ren, J.; Dun, G.; Qin, K.; Lin, Z.; Peng, J.; Tian, H.; Yang, Y.; et al. Lead-Free Halide Perovskites for Direct X-Ray Detectors. Adv. Sci. 2023, 10, 2300256. [Google Scholar] [CrossRef]

- Xu, X.; Qian, W.; Xiao, S.; Wang, J.; Zheng, S.; Yang, S. Halide Perovskites: A Dark Horse for Direct X-ray Imaging. EcoMat 2020, 2, e12064. [Google Scholar] [CrossRef]

- Wronski, M.M.; Rowlands, J.A. Direct-conversion Flat-panel Imager with Avalanche Gain: Feasibility Investigation for HARP-AMFPI. Med. Phys. 2008, 35, 5207–5218. [Google Scholar] [CrossRef] [PubMed]

- Kasap, S.; Frey, J.B.; Belev, G.; Tousignant, O.; Mani, H.; Greenspan, J.; Laperriere, L.; Bubon, O.; Reznik, A.; DeCrescenzo, G.; et al. Amorphous and Polycrystalline Photoconductors for Direct Conversion Flat Panel X-Ray Image Sensors. Sensors 2011, 11, 5112–5157. [Google Scholar] [CrossRef] [PubMed]

- Basiricò, L.; Ciavatti, A.; Fraboni, B. Solution-Grown Organic and Perovskite X-Ray Detectors: A New Paradigm for the Direct Detection of Ionizing Radiation. Adv. Mater. Technol. 2021, 6, 2000475. [Google Scholar] [CrossRef]

- Chaudhari, R.; RaviKant, C. A Review on BiI3 Perovskites and Composites for Direct X-Ray Detection. Sens. Actuators Phys. 2022, 346, 113863. [Google Scholar] [CrossRef]

- Shikhaliev, P.M. Tilted Angle CZT Detector for Photon Counting/Energy Weighting X-Ray and CT Imaging. Phys. Med. Biol. 2006, 51, 4267–4287. [Google Scholar] [CrossRef]

- Negre, J.P.; Rubbelynck, C. Application of Fast CVD Diamond Photoconductor Detectors to MeV X-Ray Metrology for the AIRIX Flash Radiographic Facility. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2000, 451, 638–650. [Google Scholar] [CrossRef]

- Li, Q.; Beilicke, M.; Lee, K.; Garson Iii, A.; Guo, Q.; Martin, J.; Yin, Y.; Dowkontt, P.; De Geronimo, G.; Jung, I. Study of Thick CZT Detectors for X-Ray and Gamma-Ray Astronomy. Astropart. Phys. 2011, 34, 769–777. [Google Scholar] [CrossRef]

- Kasap, S.O. X-Ray Sensitivity of Photoconductors: Application to Stabilized a-Se. J. Phys. Appl. Phys. 2000, 33, 2853–2865. [Google Scholar] [CrossRef]

- Lee, S.C.; Jeon, H.B.; Kang, K.H.; Kim, B.B.; Park, H. Study of Silicon Photodiode Performance for X-Ray Detector in Cargo System. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2018, 912, 350–353. [Google Scholar] [CrossRef]

- Pearton, S.J.; Yang, J.; Cary, P.H.; Ren, F.; Kim, J.; Tadjer, M.J.; Mastro, M.A. A Review of Ga2O3 Materials, Processing, and Devices. Appl. Phys. Rev. 2018, 5, 011301. [Google Scholar] [CrossRef]

- Kim, J.; Pearton, S.J.; Fares, C.; Yang, J.; Ren, F.; Kim, S.; Polyakov, A.Y. Radiation Damage Effects in Ga2O3 Materials and Devices. J. Mater. Chem. C 2019, 7, 10–24. [Google Scholar] [CrossRef]

- Li, Z.; Tang, H.; Xu, J.; Liu, B. Research Progress of Ultra-Wide Band Gap Semiconductor Ga2O3-Based X-Ray Detectors. J. Synth. Cryst. 2022, 51, 523–537, 570. [Google Scholar] [CrossRef]

- Zhang, H.; Niu, D.; Yang, J.; Zhang, X.; Zhu, J.; Li, W. β-Ga2O3 Thin Films via an Inorganic Sol–Gel Spin Coating: Preparation and Characterization. Nanomaterials 2025, 15, 277. [Google Scholar] [CrossRef]

- Liu, J.; Deng, H.; Zhao, X.; Wu, C.; Zhang, H.; Lang, F. Investigation of the Nano and Micromechanical Performance of β-Ga2O3 Epitaxial Films on Sapphire Using Nanoindentation. Vacuum 2024, 227, 113413. [Google Scholar] [CrossRef]

- Vashishtha, P.; Jain, S.K.; Prajapat, P.; Verma, A.K.; Aggarwal, N.; Murdoch, B.J.; Walia, S.; Gupta, G. A Self-Driven Bidirectional Photocurrent Photodetector for Optically Controlled Logic Gates Utilizes a GaN-Nanowall Network. ACS Appl. Opt. Mater. 2024, 2, 1353–1359. [Google Scholar] [CrossRef]

- Lu, X.; Zhou, L.; Chen, L.; Ouyang, X.; Liu, B.; Xu, J.; Tang, H. Schottky X-Ray Detectors Based on a Bulk β-Ga2O3 Substrate. Appl. Phys. Lett. 2018, 112, 103502. [Google Scholar] [CrossRef]

- Hany, I.; Yang, G.; Chung, C.-C. Fast X-Ray Detectors Based on Bulk β-Ga2O3 (Fe). J. Mater. Sci. 2020, 55, 9461–9469. [Google Scholar] [CrossRef]

- Chen, J.; Tang, H.; Liu, B.; Zhu, Z.; Gu, M.; Zhang, Z.; Xu, Q.; Xu, J.; Zhou, L.; Chen, L.; et al. High-Performance X-Ray Detector Based on Single-Crystal β-Ga2O3:Mg. ACS Appl. Mater. Interfaces 2021, 13, 2879–2886. [Google Scholar] [CrossRef]

- Li, Z.; Chen, J.; Tang, H.; Zhu, Z.; Gu, M.; Xu, J.; Chen, L.; Ouyang, X.; Liu, B. Band Gap Engineering in β-Ga2O3 for a High-Performance X-Ray Detector. ACS Appl. Electron. Mater. 2021, 3, 4630–4639. [Google Scholar] [CrossRef]

- Zhong, T.; Yu, s.; Zhao, X.; Ding, M.; Liang, F.; Fang, S.; Zhang, Z.; Hou, X.; Sun, H.; Xu, G.; et al. High-performance Solar-blind and X-ray Detector Based on Ultra-thin Gallium Oxide Film Grown by MOCVD (Invited). Acta Photonica Sin. 2021, 50, 213–224. [Google Scholar]

- Chen, Y.; Niu, S.; Li, Y.; Dou, W.; Yang, X.; Shan, C.; Shen, G. Flexible Single Microwire X-Ray Detector with Ultrahigh Sensitivity for Portable Radiation Detection System. Adv. Mater. 2024, 36, 2404656. [Google Scholar] [CrossRef]

- Liang, H.; Tang, X.; Shao, H.; Zhu, R.; Deng, S.; Zhan, X.; Zhu, T.; Wang, J.; Zhang, J.; Zhang, G.; et al. Retina-Inspired X-Ray Optoelectronic Synapse Using Amorphous Ga2O3 Thin Film. Adv. Sci. 2024, 11, 2410761. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Ma, Y.; Sun, J.; Wang, S.; Jia, Y.; He, Y.; Lu, X.; Lin, D.; Zhu, Q.; et al. Highly Reliable and Sensitive Solar-Blind Ultraviolet and X-Ray Detector Based on ALD Deposited Amorphous Ga2O3. IEEE Electron Device Lett. 2024, 45, 1879–1882. [Google Scholar] [CrossRef]

- Kim, M.; Kim, S.; Park, J.; Cho, H.G.; Gihm, S.H.; Jeon, D.; Hwang, W.S. Heteroepitaxial α-Ga2O3 Thin Film-Based X-Ray Detector with Metal–Semiconductor–Metal Structure. Phys. Status Solidi RRL—Rapid Res. Lett. 2025, 19, 2400193. [Google Scholar] [CrossRef]

- Gan, Z.; Li, C.; Hou, X.; Yu, S.; Bai, S.; Peng, Z.; Han, K.; Zou, Y.; Wang, Z.; Zhao, X.; et al. Sensitive Direct Converting Thin Film X-Ray Detector Utilizing β-Ga2O3 Fabricated via MOCVD. Appl. Phys. Lett. 2024, 125, 191102. [Google Scholar] [CrossRef]

- Zhang, H.; Niu, D.; Zhao, X.; Du, Z.; Cui, X. Solid-State Source Plasma Enhanced Chemical Vapor Deposition Equipment and Method CN. Patent Application No. 202411489122.1, 24 October 2024. [Google Scholar]

- Kramer, B. Electronic Structure and Optical Properties of Amorphous Germanium and Silicon. Phys. Status Solidi B 1971, 47, 501–510. [Google Scholar] [CrossRef]

- Kumarbekov, K.K.; Kakimov, A.B.; Karipbayev, Z.T.; Kassymzhanov, M.T.; Brik, M.G.; Ma, C.; Piasecki, M.; Suchikova, Y.; Kemere, M.; Konuhova, M. Temperature-Dependent Luminescence of Europium-Doped Ga2O3 Ceramics. Opt. Mater. X 2025, 25, 100392. [Google Scholar] [CrossRef]

- Xu, Y.; Cheng, Y.; Li, Z.; Chen, D.; Xu, S.; Feng, Q.; Zhu, W.; Zhang, Y.; Zhang, J.; Zhang, C.; et al. Ultrahigh-Performance Solar-Blind Photodetectors Based on High Quality Heteroepitaxial Single Crystalline β-Ga2O3 Film Grown by Vacuumfree, Low-Cost Mist Chemical Vapor Deposition. Adv. Mater. Technol. 2021, 6, 2001296. [Google Scholar] [CrossRef]

- Kaur, D.; Dahiya, R.; Shivani; Kumar, M. Origin of Near-Failure in Au Contacts to Polycrystalline β-Ga2O3 at High Temperatures Using Interfacial Studies. Appl. Phys. Lett. 2024, 124, 151601. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, L.; Lu, X.; Chen, L.; Chen, Z.; Zou, X.; Wang, G.; Yang, B.; Ouyang, X. Pulsed X-Ray Detector Based on an Unintentionally-Doped High Resistivity ε-Ga2O3 Film. IEEE Photonics Technol. Lett. 2023, 35, 89–92. [Google Scholar] [CrossRef]

- Vo, T.H.; Kim, S.; Kim, M.; Cho, H.G.; Gihm, S.H.; Park, J.-H.; Jeon, D.-W.; Hwang, W.S. Charge Neutral Point Shift of a 700 Nm-Thick α-Ga2O3 Thin-Film Detector under Soft X-Ray Irradiation. ACS Appl. Electron. Mater. 2024, 6, 5973–5978. [Google Scholar] [CrossRef]

- Yu, S.; Liu, Y.; Hou, X.; Ding, M.; Zou, Y.; Guan, Y.; Wu, Z.; Zhao, X.; Hu, Q.; Xu, G.; et al. Stable Ga2O3 Soft X-Ray Detector with Ultrahigh Responsivity. Appl. Phys. Lett. 2024, 124, 181111. [Google Scholar] [CrossRef]

- Ahn, S.; Song, I.; Jeon, S.; Jeon, Y.W.; Kim, Y.; Kim, C.; Ryu, B.; Lee, J.; Nathan, A.; Lee, S.; et al. Metal Oxide Thin Film Phototransistor for Remote Touch Interactive Displays. Adv. Mater. 2012, 24, 2631–2636. [Google Scholar] [CrossRef] [PubMed]

- Jang, J.T.; Park, J.; Ahn, B.D.; Kim, D.M.; Choi, S.-J.; Kim, H.-S.; Kim, D.H. Study on the Photoresponse of Amorphous In–Ga–Zn–O and Zinc Oxynitride Semiconductor Devices by the Extraction of Sub-Gap-State Distribution and Device Simulation. ACS Appl. Mater. Interfaces 2015, 7, 15570–15577. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.; Lee, W.; Choi, S.; Jo, J.; Kim, J.; Park, S.K.; Kim, Y. Brain-Inspired Photonic Neuromorphic Devices Using Photodynamic Amorphous Oxide Semiconductors and Their Persistent Photoconductivity. Adv. Mater. 2017, 29, 1700951. [Google Scholar] [CrossRef]

- Jeon, S.; Ahn, S.-E.; Song, I.; Kim, C.J.; Chung, U.-I.; Lee, E.; Yoo, I.; Nathan, A.; Lee, S.; Ghaffarzadeh, K.; et al. Gated Three-Terminal Device Architecture to Eliminate Persistent Photoconductivity in Oxide Semiconductor Photosensor Arrays. Nat. Mater. 2012, 11, 301–305. [Google Scholar] [CrossRef]

- Yang, Y.; Fan, Z.; He, B.; Jia, Z.; Zhao, H.; Xiong, P.; Liu, Y.; Dang, W.; Wang, J.; Zheng, H.; et al. Solution-Processed Sb2−xBixS3 Thick Junctions for Stable, Low-Noise, and Sensitive X-Ray Detection. Device 2024, 2, 100518. [Google Scholar] [CrossRef]

- Peng, Z.; Hou, X.; Han, Z.; Gan, Z.; Li, C.; Wu, F.; Bai, S.; Yu, S.; Liu, Y.; Yang, K.; et al. Ga2O3 Photon-Controlled Diode for Sensitive DUV/X-Ray Detection and High-Resolution Array Imaging Application. Adv. Funct. Mater. 2024, 34, 2405277. [Google Scholar] [CrossRef]

| Item | Value | ||||

|---|---|---|---|---|---|

| X-ray tube voltage (kV) | 40 | ||||

| X-ray tube current (μA) | 100 | 200 | 300 | 400 | 500 |

| X-ray dose rate (μGy/s) | 315.5 | 700.2 | 1166.0 | 1638.2 | 1951.0 |

| Materials | Growth Method | Device Type | Thickness (μm) | Snorm (μCGyair−1 cm−2 μm−1) | LoDmin (nGyair s−1) | Ref. |

|---|---|---|---|---|---|---|

| β-Ga2O3 | LPCVD | MSM | 0.289 | 3.539 × 105 @ 20 V | 57.07 | this work |

| β-Ga2O3 | PECVD | MSM | 1.5 | 272 @ 20 V | 30.13 | this work |

| MAPbI3/MAPbBr3 | Solution Method | MSM | 1060 | 8.197 @ 60 keV | / | [10] |

| Sb1.9Bi0.1S3 | Sol–gel Method | p-i-n | 4000 | 0.625 @ −20 V | 89 | [51] |

| α-Ga2O3 | ALD | MSM | 0.05 | 1.904 × 104 @ 15 V | 11.23 | [36] |

| α-Ga2O3 | HVPE | MSM | 0.7 | 19.57 @10 V | / | [37] |

| α-Ga2O3 | RF magnetron sputtering | MSM | 0.36 | 4.56 × 105 @ 10 V | / | [35] |

| β-Ga2O3 | MOCVD | MSM | 0.258 | 1.442 × 106 @ 40 V | / | [38] |

| β-Ga2O3 | MOCVD | MSM | 0.319 | 3.86 × 105 @ 50 V | / | [52] |

| β-Ga2O3 Microwire | CVD | MSM | 5.9 × 105 @ 20 V | 67.4 | [34] | |

| UID β-Ga2O3 | Guided-mode Method | Vertical Schottky diode | 400 | 0.165 @ −15 V | / | [31] |

| β-Ga2O3:Mg | Float-Zone Growth | MSM | 1000 | 0.339 @ −1000 V | <6.95 × 104 | [31] |

| β-Ga2O3:Al | Optical Floating Zone | MSM | 1000 | 0.852 @ 350 V | 9.8 × 103 | [32] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Niu, D.; Zhang, Y.; Zhao, X.; Li, X.; Zhu, J.; Zhang, H. Synergistic LPCVD and PECVD Growth of β-Ga2O3 Thin Films for High-Sensitivity and Low-Dose Direct X-Ray Detection. Nanomaterials 2025, 15, 1360. https://doi.org/10.3390/nano15171360

Yang L, Niu D, Zhang Y, Zhao X, Li X, Zhu J, Zhang H. Synergistic LPCVD and PECVD Growth of β-Ga2O3 Thin Films for High-Sensitivity and Low-Dose Direct X-Ray Detection. Nanomaterials. 2025; 15(17):1360. https://doi.org/10.3390/nano15171360

Chicago/Turabian StyleYang, Lan, Dingyuan Niu, Yong Zhang, Xueping Zhao, Xinxin Li, Jun Zhu, and Hai Zhang. 2025. "Synergistic LPCVD and PECVD Growth of β-Ga2O3 Thin Films for High-Sensitivity and Low-Dose Direct X-Ray Detection" Nanomaterials 15, no. 17: 1360. https://doi.org/10.3390/nano15171360

APA StyleYang, L., Niu, D., Zhang, Y., Zhao, X., Li, X., Zhu, J., & Zhang, H. (2025). Synergistic LPCVD and PECVD Growth of β-Ga2O3 Thin Films for High-Sensitivity and Low-Dose Direct X-Ray Detection. Nanomaterials, 15(17), 1360. https://doi.org/10.3390/nano15171360