Atomic Manipulation of 2D Materials by Scanning Tunneling Microscopy: Advances in Graphene and Transition Metal Dichalcogenides

Abstract

1. Introduction

2. STM Manipulation

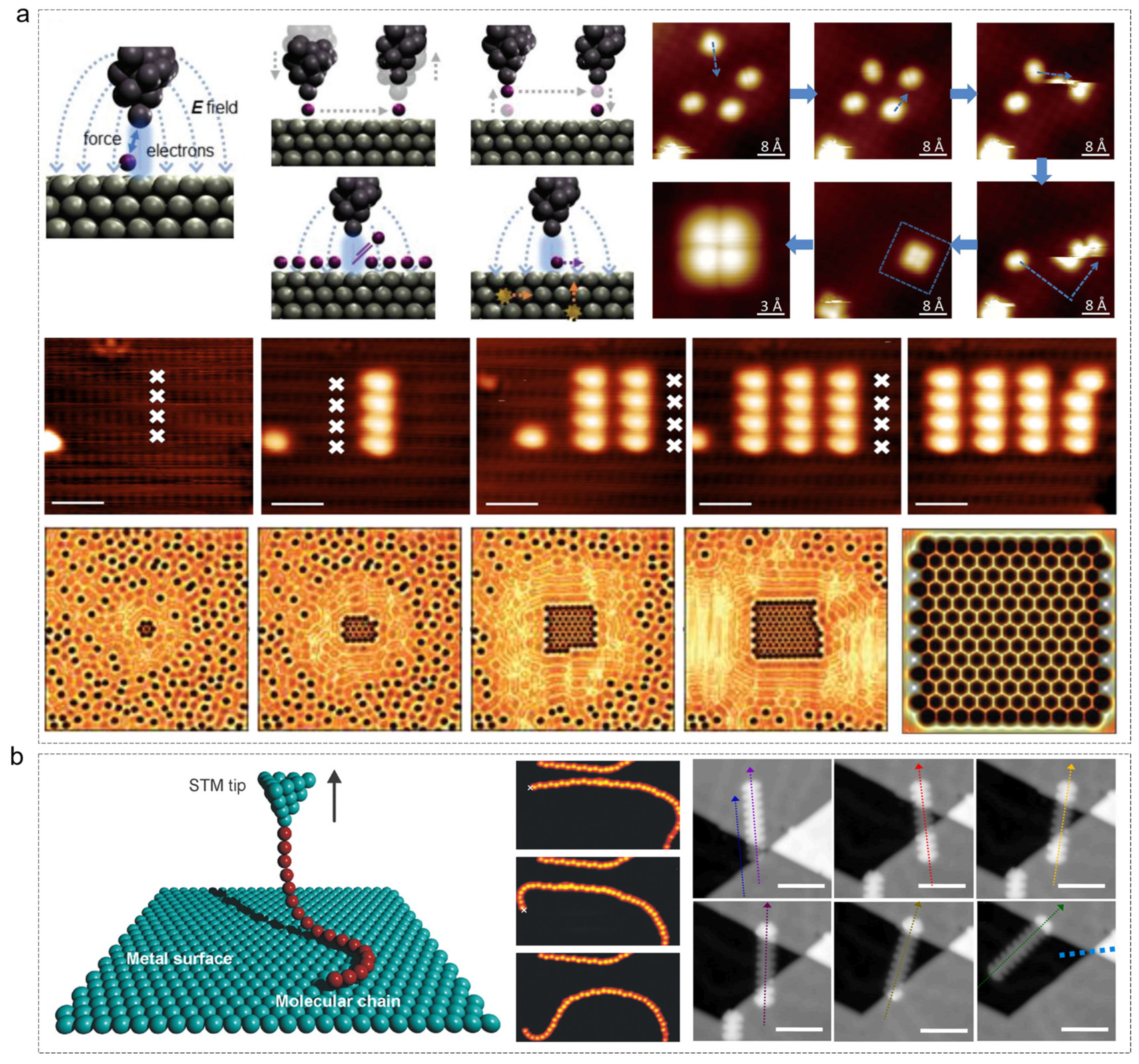

2.1. STM Manipulation in Zero-Dimensional and One-Dimensional Materials

2.2. STM Manipulation Methods in Two-Dimensional Materials

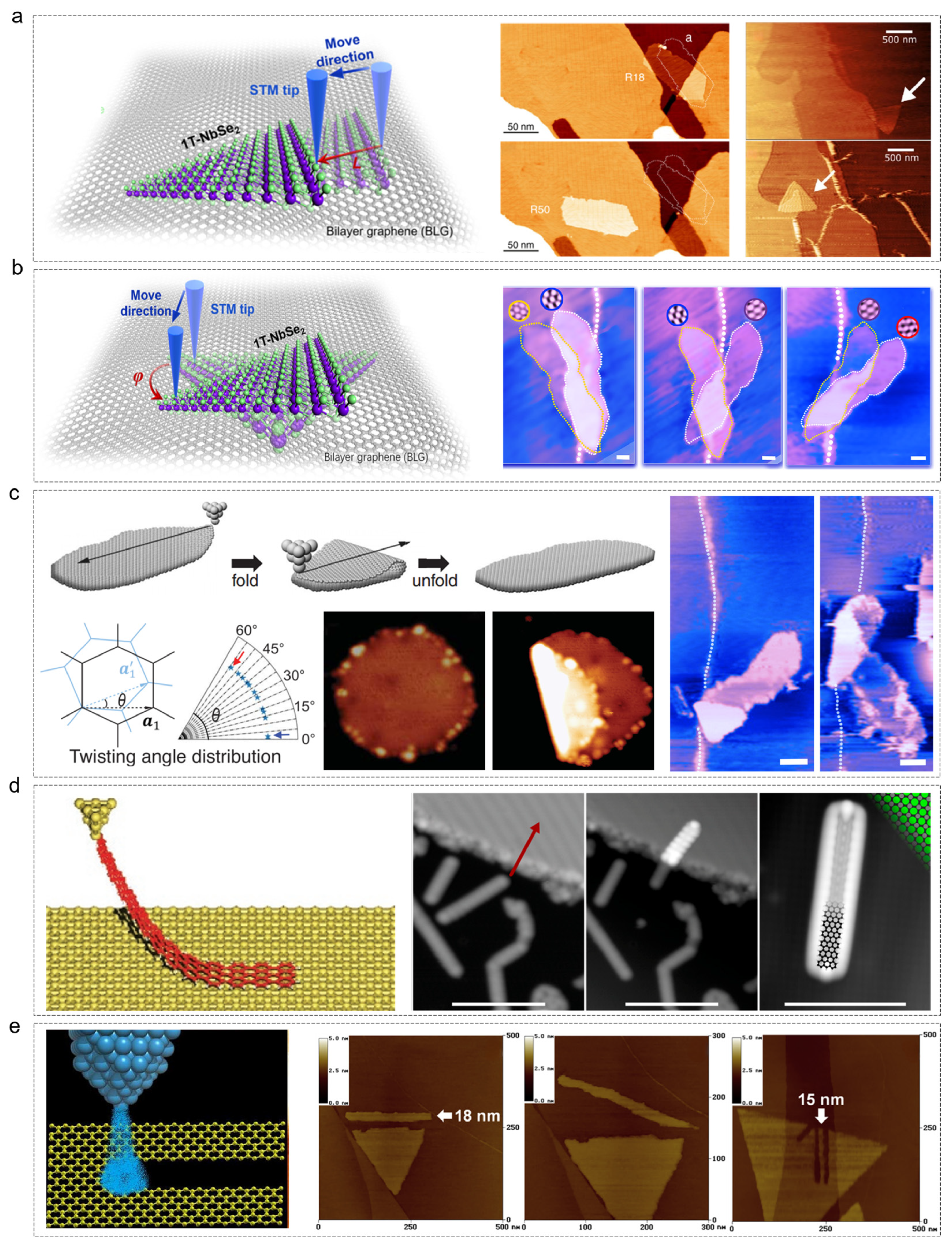

2.2.1. Translation and Rotation

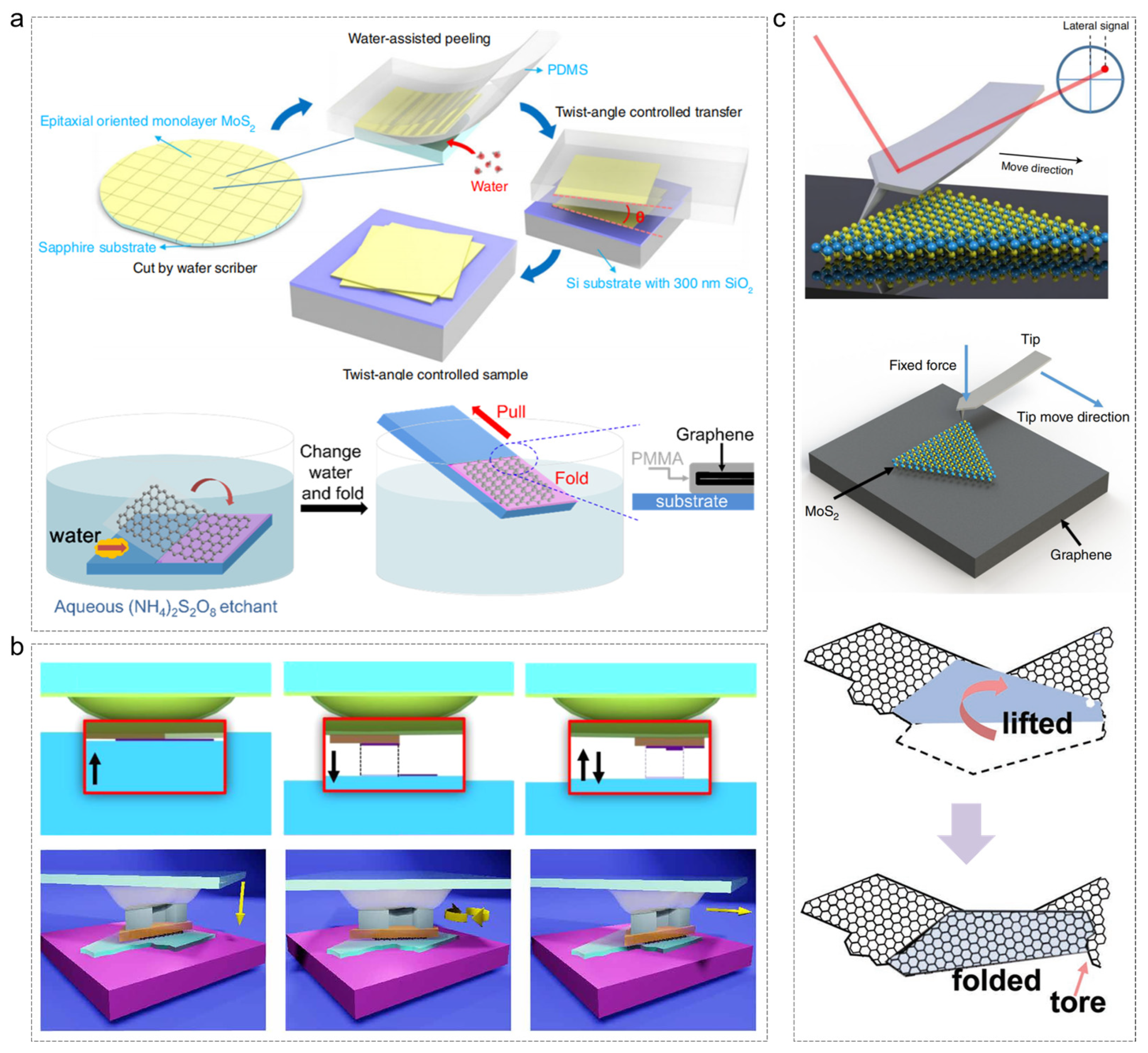

2.2.2. Folding (Origami)

2.2.3. Picking and Transfer

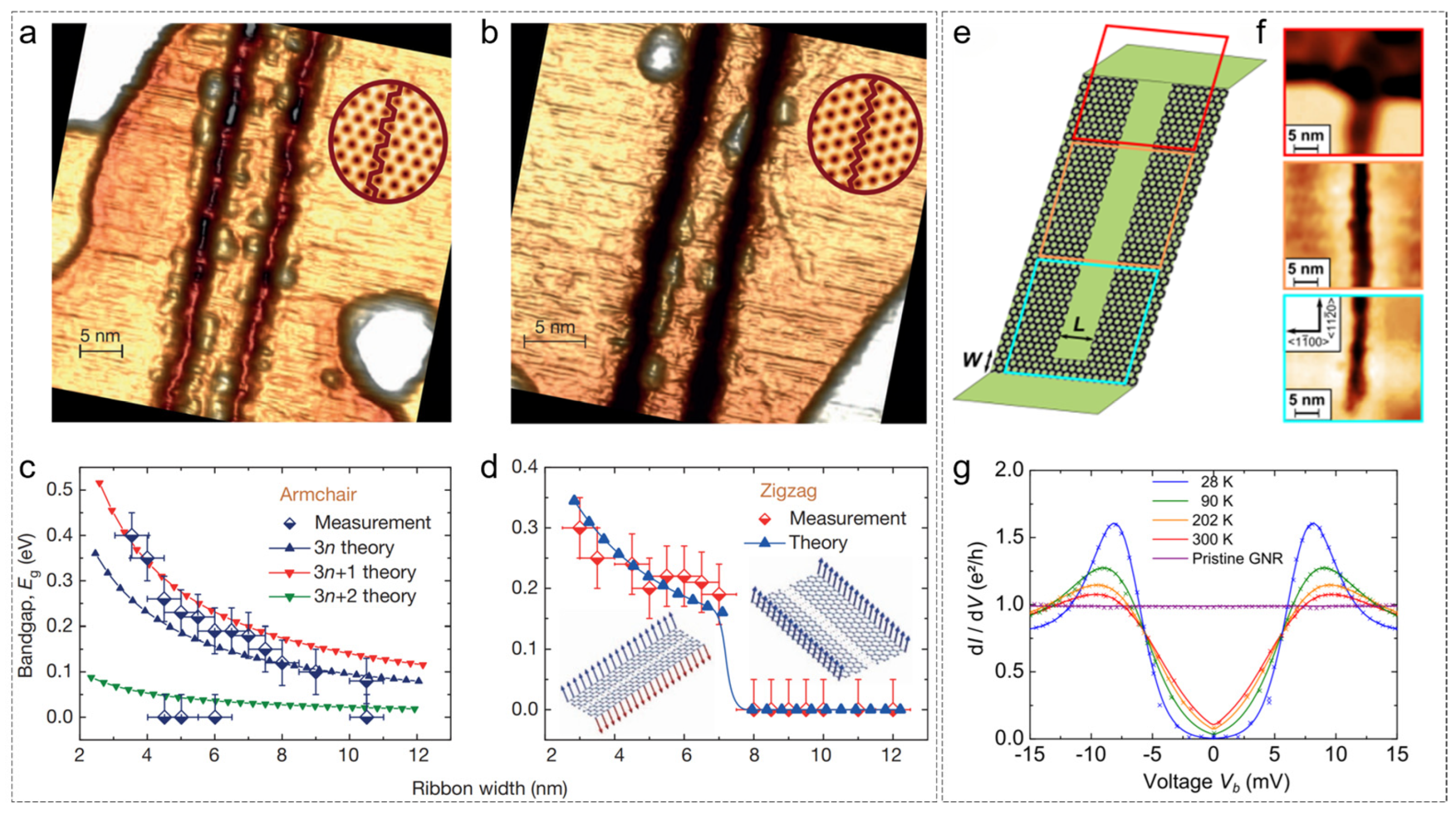

2.2.4. Cutting and Etching

3. STM Manipulation Application

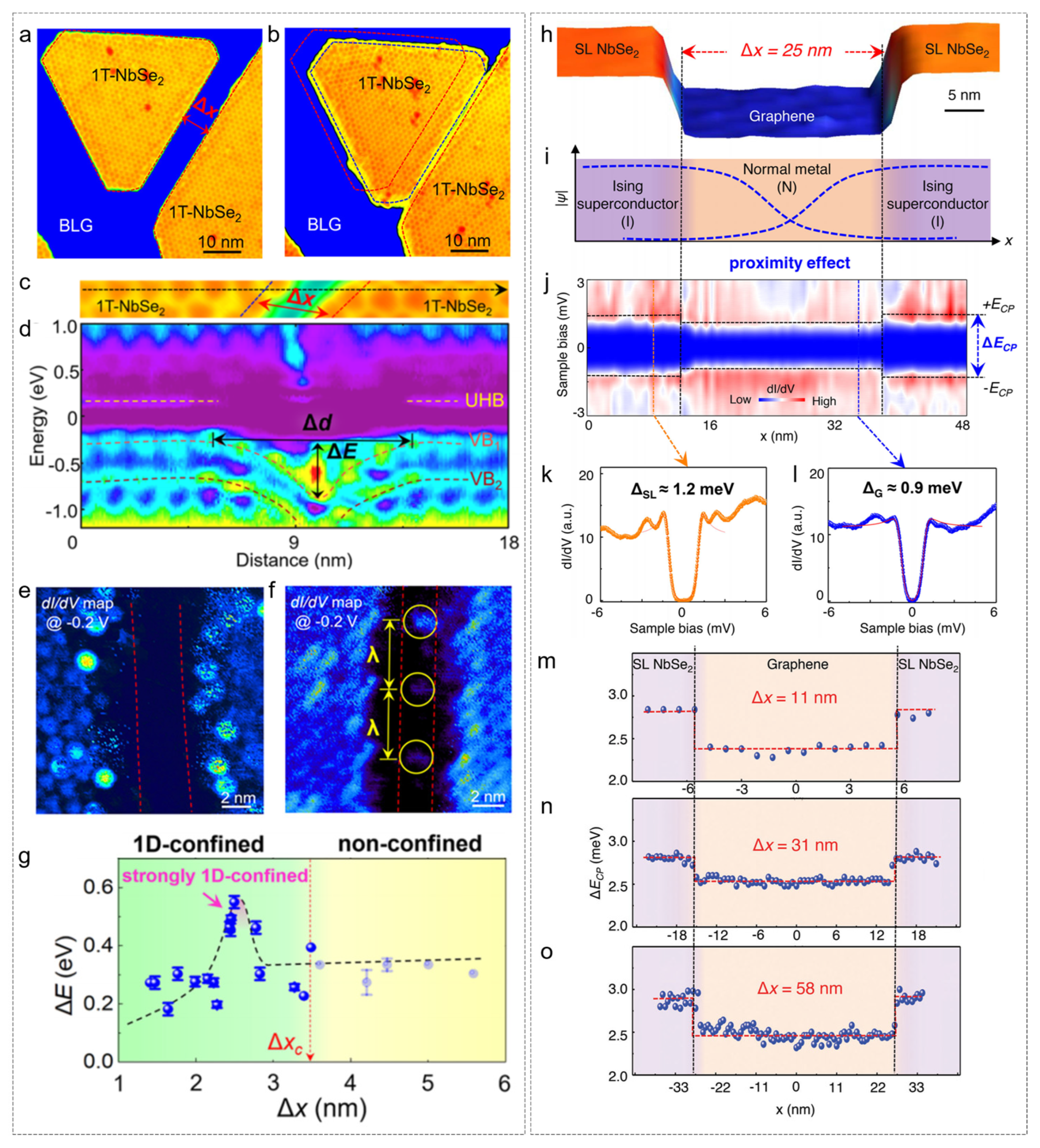

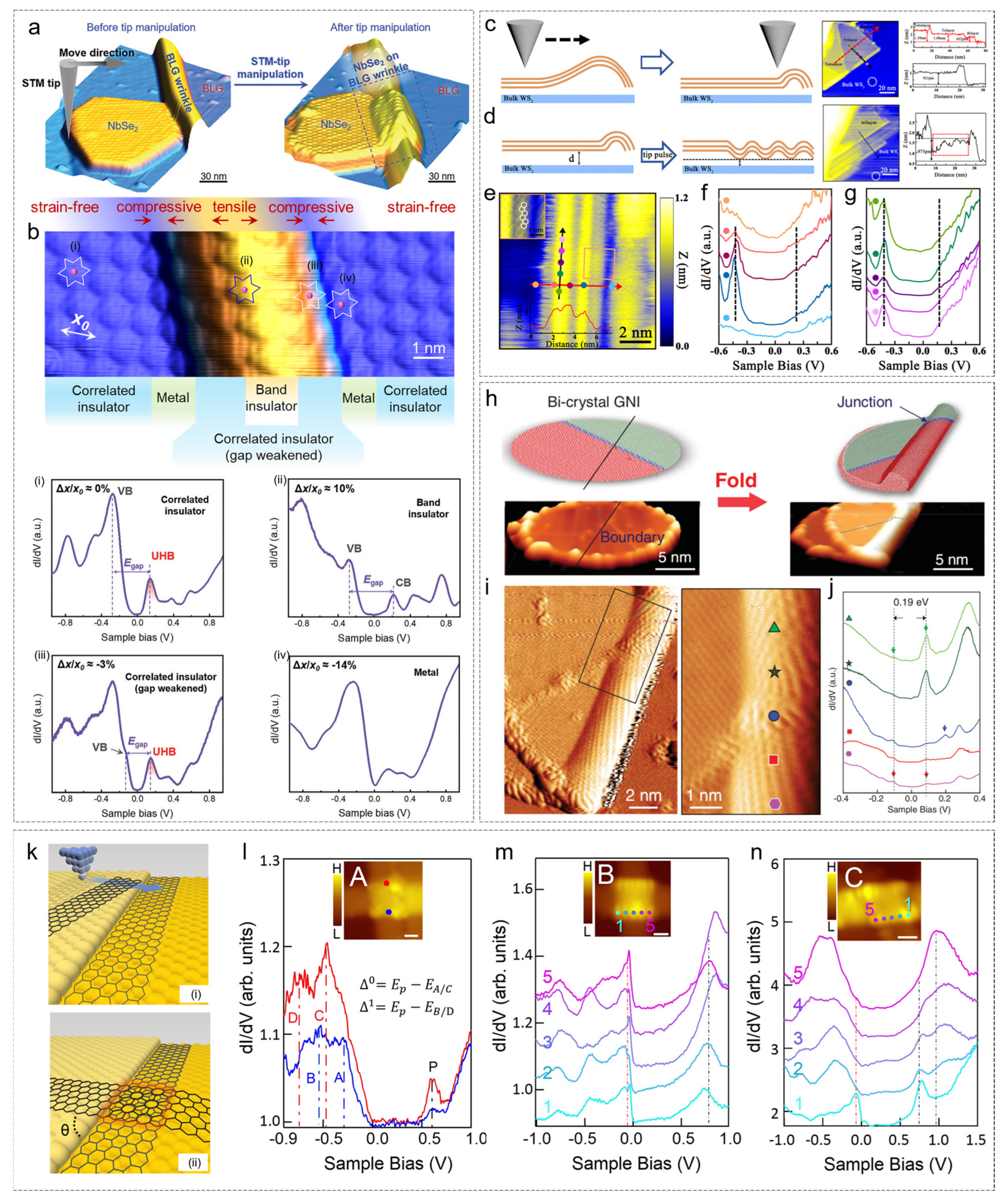

3.1. Distance Regulation Between Islands

3.2. Strain Regulation

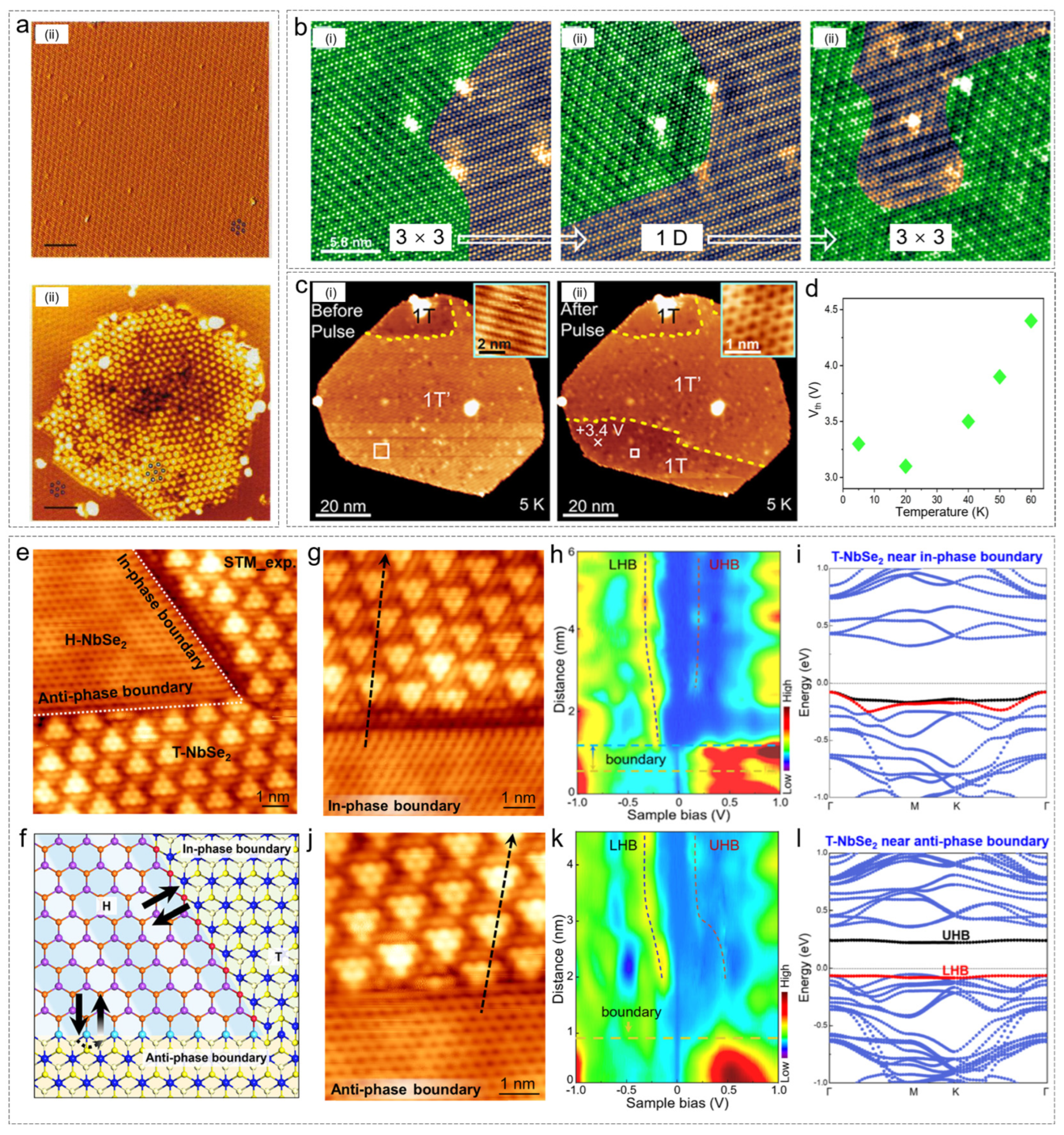

3.3. Phase Transformation Induced by STM

3.4. Atomic-Scale Etching and Nanostructure Customization

4. Summary and Perspectives

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Tan, C.; Cao, X.; Wu, X.-J.; He, Q.; Yang, J.; Zhang, X.; Chen, J.; Zhao, W.; Han, S.; Nam, G.-H.; et al. Recent Advances in Ultrathin Two-Dimensional Nanomaterials. Chem. Rev. 2017, 117, 6225–6331. [Google Scholar]

- Zhang, H. Ultrathin Two-Dimensional Nanomaterials. ACS Nano 2015, 9, 9451–9469. [Google Scholar] [CrossRef]

- Lin, C.-Y.; Wu, J.-Y.; Chiu, Y.-H.; Chang, C.-P.; Lin, M.-F. Stacking-dependent magnetoelectronic properties in multilayer graphene. Phys. Rev. B 2014, 90, 205434. [Google Scholar] [CrossRef]

- Shinjo, K.; Hirano, M. Dynamics of friction: Superlubric state. Surf. Sci. 1993, 283, 473–478. [Google Scholar] [CrossRef]

- Cao, Y.; Fatemi, V.; Fang, S.; Watanabe, K.; Taniguchi, T.; Kaxiras, E.; Jarillo-Herrero, P. Unconventional superconductivity in magic-angle graphene superlattices. Nature 2018, 556, 43–50. [Google Scholar] [CrossRef]

- Zhao, C.; Tan, C.; Lien, D.-H.; Song, X.; Amani, M.; Hettick, M.; Nyein, H.Y.Y.; Yuan, Z.; Li, L.; Scott, M.C.; et al. Evaporated tellurium thin films for p-type field-effect transistors and circuits. Nat. Nanotechnol. 2020, 15, 53–58. [Google Scholar] [CrossRef]

- Koman, V.B.; Liu, P.; Kozawa, D.; Liu, A.T.; Cottrill, A.L.; Son, Y.; Lebron, J.A.; Strano, M.S. Colloidal nanoelectronic state machines based on 2D materials for aerosolizable electronics. Nat. Nanotechnol. 2018, 13, 819–827. [Google Scholar] [CrossRef]

- Zhu, W.; Low, T.; Wang, H.; Ye, P.; Duan, X. Nanoscale electronic devices based on transition metal dichalcogenides. 2D Mater. 2019, 6, 032004. [Google Scholar] [CrossRef]

- Amani, M.; Tan, C.; Zhang, G.; Zhao, C.; Bullock, J.; Song, X.; Kim, H.; Shrestha, V.R.; Gao, Y.; Crozier, K.B.; et al. Solution-Synthesized High-Mobility Tellurium Nanoflakes for Short-Wave Infrared Photodetectors. ACS Nano 2018, 12, 7253–7263. [Google Scholar] [CrossRef]

- Mak, K.F.; Shan, J. Photonics and optoelectronics of 2D semiconductor transition metal dichalcogenides. Nat. Photonics 2016, 10, 216–226. [Google Scholar] [CrossRef]

- Huo, C.; Cai, B.; Yuan, Z.; Ma, B.; Zeng, H. Two-Dimensional Metal Halide Perovskites: Theory, Synthesis, and Optoelectronics. Small Methods 2017, 1, 1600018. [Google Scholar] [CrossRef]

- Cheng, Z.; Cao, R.; Wei, K.; Yao, Y.; Liu, X.; Kang, J.; Dong, J.; Shi, Z.; Zhang, H.; Zhang, X. 2D Materials Enabled Next-Generation Integrated Optoelectronics: From Fabrication to Applications. Adv. Sci. 2021, 8, 2003834. [Google Scholar] [CrossRef]

- Liao, M.; Nicolini, P.; Du, L.; Yuan, J.; Wang, S.; Yu, H.; Tang, J.; Cheng, P.; Watanabe, K.; Taniguchi, T.; et al. UItra-low friction and edge-pinning effect in large-lattice-mismatch van der Waals heterostructures. Nat. Mater. 2022, 21, 47–53. [Google Scholar] [CrossRef]

- Sinclair, R.C.; Suter, J.L.; Coveney, P.V. Graphene–graphene interactions: Friction, superlubricity, and exfoliation. Adv. Mater. 2018, 30, 1705791. [Google Scholar] [CrossRef]

- Feng, X.; Kwon, S.; Park, J.Y.; Salmeron, M. Superlubric Sliding of Graphene Nanoflakes on Graphene. ACS Nano 2013, 7, 1718–1724. [Google Scholar] [CrossRef]

- Zheng, X.; Gao, L.; Yao, Q.; Li, Q.; Zhang, M.; Xie, X.; Qiao, S.; Wang, G.; Ma, T.; Di, Z. Robust ultra-low-friction state of graphene via moiré superlattice confinement. Nat. Commun. 2016, 7, 13204. [Google Scholar] [CrossRef]

- Li, S.; Li, Q.; Carpick, R.W.; Gumbsch, P.; Liu, X.Z.; Ding, X.; Sun, J.; Li, J. The evolving quality of frictional contact with graphene. Nature 2016, 539, 541–545. [Google Scholar] [CrossRef]

- Choi, J.S.; Kim, J.-S.; Byun, I.-S.; Lee, D.H.; Lee, M.J.; Park, B.H.; Lee, C.; Yoon, D.; Cheong, H.; Lee, K.H. Friction anisotropy–driven domain imaging on exfoliated monolayer graphene. Science 2011, 333, 607–610. [Google Scholar] [CrossRef]

- Thomson, A.; Chatterjee, S.; Sachdev, S.; Scheurer, M.S. Triangular antiferromagnetism on the honeycomb lattice of twisted bilayer graphene. Phys. Rev. B 2018, 98, 075109. [Google Scholar] [CrossRef]

- Geim, A.K.; Grigorieva, I.V. Van der Waals heterostructures. Nature 2013, 499, 419–425. [Google Scholar] [CrossRef]

- Liao, M.; Wei, Z.; Du, L.; Wang, Q.; Tang, J.; Yu, H.; Wu, F.; Zhao, J.; Xu, X.; Han, B.; et al. Precise control of the interlayer twist angle in large scale MoS2 homostructures. Nat. Commun. 2020, 11, 2153. [Google Scholar] [CrossRef]

- Wang, B.; Huang, M.; Kim, N.Y.; Cunning, B.V.; Huang, Y.; Qu, D.; Chen, X.; Jin, S.; Biswal, M.; Zhang, X.; et al. Controlled Folding of Single Crystal Graphene. Nano Lett. 2017, 17, 1467–1473. [Google Scholar] [CrossRef]

- Kim, K.; Yankowitz, M.; Fallahazad, B.; Kang, S.; Movva, H.C.P.; Huang, S.; Larentis, S.; Corbet, C.M.; Taniguchi, T.; Watanabe, K.; et al. van der Waals Heterostructures with High Accuracy Rotational Alignment. Nano Lett. 2016, 16, 1989–1995. [Google Scholar] [CrossRef]

- Yang, Y.; Li, J.; Yin, J.; Xu, S.; Mullan, C.; Taniguchi, T.; Watanabe, K.; Geim, A.K.; Novoselov, K.S.; Mishchenko, A. In situ manipulation of van der Waals heterostructures for twistronics. Sci. Adv. 2020, 6, eabd3655. [Google Scholar] [CrossRef]

- Zhang, Q.; Hou, Y.; Zhang, T.; Xu, Z.; Huang, Z.; Yuan, P.; Jia, L.; Yang, H.; Huang, Y.; Ji, W.; et al. Visualizing Spatial Evolution of Electron-Correlated Interface in Two-Dimensional Heterostructures. ACS Nano 2021, 15, 16589–16596. [Google Scholar] [CrossRef]

- Liao, M.; Wu, Z.-W.; Du, L.; Zhang, T.; Wei, Z.; Zhu, J.; Yu, H.; Tang, J.; Gu, L.; Xing, Y.; et al. Twist angle-dependent conductivities across MoS2/graphene heterojunctions. Nat. Commun. 2018, 9, 4068. [Google Scholar] [CrossRef]

- Chang, J.S.; Kim, S.; Sung, H.-J.; Yeon, J.; Chang, K.J.; Li, X.; Kim, S. Graphene Nanoribbons with Atomically Sharp Edges Produced by AFM Induced Self-Folding. Small 2018, 14, 1803386. [Google Scholar] [CrossRef]

- Wang, D.; Chen, G.; Li, C.; Cheng, M.; Yang, W.; Wu, S.; Xie, G.; Zhang, J.; Zhao, J.; Lu, X.; et al. Thermally Induced Graphene Rotation on Hexagonal Boron Nitride. Phys. Rev. Lett. 2016, 116, 126101. [Google Scholar] [CrossRef]

- Chen, P.Y.; Zhang, X.Q.; Lai, Y.Y.; Lin, E.C.; Chen, C.A.; Guan, S.Y.; Chen, J.J.; Yang, Z.H.; Tseng, Y.W.; Gwo, S. Tunable moiré superlattice of artificially twisted monolayers. Adv. Mater. 2019, 31, 1901077. [Google Scholar] [CrossRef]

- Cao, Y.; Fatemi, V.; Demir, A.; Fang, S.; Tomarken, S.L.; Luo, J.Y.; Sanchez-Yamagishi, J.D.; Watanabe, K.; Taniguchi, T.; Kaxiras, E.; et al. Correlated insulator behaviour at half-filling in magic-angle graphene superlattices. Nature 2018, 556, 80–84. [Google Scholar] [CrossRef]

- Bian, K.; Gerber, C.; Heinrich, A.J.; Müller, D.J.; Scheuring, S.; Jiang, Y. Scanning probe microscopy. Nat. Rev. Methods Primers 2021, 1, 36. [Google Scholar] [CrossRef]

- Binnig, G.; Rohrer, H.; Gerber, C.; Weibel, E.J.P.R.L. Surface studies by scanning tunneling microscopy. Phys. Rev. Lett. 1982, 49, 57. [Google Scholar] [CrossRef]

- Huang, Y.; Sutter, E.; Shi, N.N.; Zheng, J.B.; Yang, T.Z.; Englund, D.; Gao, H.J.; Sutter, P. Reliable Exfoliation of Large-Area High-Quality Flakes of Graphene and Other Two-Dimensional Materials. ACS Nano 2015, 9, 10612–10620. [Google Scholar] [CrossRef]

- Barron, A.R.; Khan, M.R. Caorbon nanotubes: Opportunities and challenges. Adv. Mater. Process 2008, 166, 41–43. [Google Scholar]

- Puente Santiago, A.R.; Fernandez-Delgado, O.; Gomez, A.; Ahsan, M.A.; Echegoyen, L. Fullerenes as Key Components for Low-Dimensional (Photo)electrocatalytic Nanohybrid Materials. Angew. Chem. Int. Ed. 2021, 60, 122–141. [Google Scholar] [CrossRef]

- Zheng, X.T.; Ananthanarayanan, A.; Luo, K.Q.; Chen, P. Glowing Graphene Quantum Dots and Carbon Dots: Properties, Syntheses, and Biological Applications. Small 2015, 11, 1620–1636. [Google Scholar] [CrossRef]

- Ko, W.; Ma, C.; Nguyen, G.D.; Kolmer, M.; Li, A.-P. Atomic-Scale Manipulation and In Situ Characterization with Scanning Tunneling Microscopy. Adv. Funct. Mater. 2019, 29, 1903770. [Google Scholar] [CrossRef]

- Moller, M.; Jarvis, S.P.; Guerinet, L.; Sharp, P.; Woolley, R.; Rahe, P.; Moriarty, P. Automated extraction of single H atoms with STM: Tip state dependency. Nanotechnology 2017, 28, 075302. [Google Scholar] [CrossRef]

- Gomes, K.K.; Mar, W.; Ko, W.; Guinea, F.; Manoharan, H.C. Designer Dirac fermions and topological phases in molecular graphene. Nature 2012, 483, 306–310. [Google Scholar] [CrossRef]

- Guo, J.; Meng, X.; Chen, J.; Peng, J.; Sheng, J.; Li, X.-Z.; Xu, L.; Shi, J.-R.; Wang, E.; Jiang, Y. Real-space imaging of interfacial water with submolecular resolution. Nat. Mater. 2014, 13, 184–189. [Google Scholar] [CrossRef]

- Lafferentz, L.; Ample, F.; Yu, H.; Hecht, S.; Joachim, C.; Grill, L. Conductance of a Single Conjugated Polymer as a Continuous Function of Its Length. Science 2009, 323, 1193–1197. [Google Scholar] [CrossRef]

- Thupakula, U.; Bouju, X.; Castro-Esteban, J.; Dujardin, E.; Pena, D.; Joachim, C. Planar bridging an atomically precise surface trench with a single molecular wire on an Au(111) surface. Chem. Phys. Lett. 2022, 806, 140029. [Google Scholar] [CrossRef]

- Eigler, D.M.; Schweizer, E.K. Positioning single atoms with a scanning tunnelling microscope. Nature 1990, 344, 524–526. [Google Scholar] [CrossRef]

- Bartels, L.; Meyer, G.; Rieder, K.H. Basic steps involved in the lateral manipulation of single CO molecules and rows of CO molecules. Chem. Phys. Lett. 1997, 273, 371–375. [Google Scholar] [CrossRef]

- Wang, Y.; Wong, D.; Shytov, A.V.; Brar, V.W.; Choi, S.; Wu, Q.; Tsai, H.-Z.; Regan, W.; Zettl, A.; Kawakami, R.K.; et al. Observing Atomic Collapse Resonances in Artificial Nuclei on Graphene. Science 2013, 340, 734–737. [Google Scholar] [CrossRef]

- Hla, S.W.; Meyer, G.; Rieder, K.H.J.C. Inducing single-molecule chemical reactions with a UHV-STM: A new dimension for nano-science and technology. Phys. Rev. Lett. 2001, 2, 361–366. [Google Scholar] [CrossRef]

- Nilius, N.; Wallis, T.M.; Ho, W. Development of one-dimensional band structure in artificial gold chains. Science 2002, 297, 1853–1856. [Google Scholar] [CrossRef]

- Hirjibehedin, C.F.; Lutz, C.P.; Heinrich, A.J. Spin coupling in engineered atomic structures. Science 2006, 312, 1021–1024. [Google Scholar] [CrossRef]

- Crommie, M.F.; Lutz, C.P.; Eigler, D.M. Confinement of electrons to quantum corrals on a metal-surface. Science 1993, 262, 218–220. [Google Scholar] [CrossRef]

- Hla, S.-W.; Bartels, L.; Meyer, G.; Rieder, K.-H. Inducing All Steps of a Chemical Reaction with the Scanning Tunneling Microscope Tip: Towards Single Molecule Engineering. Phys. Rev. Lett. 2000, 85, 2777–2780. [Google Scholar] [CrossRef]

- Ma, C.; Liang, L.; Xiao, Z.; Puretzky, A.A.; Hong, K.; Lu, W.; Meunier, V.; Bernholc, J.; Li, A.-P. Seamless Staircase Electrical Contact to Semiconducting Graphene Nanoribbons. Nano Lett. 2017, 17, 6241–6247. [Google Scholar] [CrossRef]

- Friedrich, N.; Brandimarte, P.; Li, J.; Saito, S.; Yamaguchi, S.; Pozo, I.; Peña, D.; Frederiksen, T.; Garcia-Lekue, A.; Sánchez-Portal, D.; et al. Magnetism of Topological Boundary States Induced by Boron Substitution in Graphene Nanoribbons. Phys. Rev. Lett. 2020, 125, 146801. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, Y.; Hou, Y.; Xu, R.; Jia, L.; Huang, Z.; Hao, X.; Zhou, J.; Zhang, T.; Liu, L.; et al. Nanoscale Control of One-Dimensional Confined States in Strongly Correlated Homojunctions. Nano Lett. 2022, 22, 1190–1197. [Google Scholar] [CrossRef]

- Leicht, P.; Zielke, L.; Bouvron, S.; Moroni, R.; Voloshina, E.; Hammerschmidt, L.; Dedkov, Y.S.; Fonin, M. In Situ Fabrication of Quasi-Free-Standing Epitaxial Graphene Nanoflakes On Gold. ACS Nano 2014, 8, 3735–3742. [Google Scholar] [CrossRef]

- Büch, H.; Rossi, A.; Forti, S.; Convertino, D.; Tozzini, V.; Coletti, C. Superlubricity of epitaxial monolayer WS2 on graphene. Nano Res. 2018, 11, 5946–5956. [Google Scholar] [CrossRef]

- Liu, Y.-W.; Hao, C.-Y.; He, L. Tailoring the Energy Landscape of Graphene Nanostructures on Graphene and Manipulating Them Using Tilt Grain Boundaries. Phys. Rev. Appl. 2022, 17, 034013. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, X.-L.; Zhang, Y.-Y.; Wang, D.; Bao, D.-L.; Que, Y.; Xiao, W.; Du, S.; Ouyang, M.; Pantelides, S.T.; et al. Atomically precise, custom-design origami graphene nanostructures. Science 2019, 365, 1036–1040. [Google Scholar] [CrossRef]

- Li, L.X.; Liu, R.P.; Chen, Z.W.; Wang, Q.; Ma, M.Z.; Jing, Q.; Li, G.; Tian, Y. Tearing, folding and deformation of a carbon-carbon sp2-bonded network. Carbon 2006, 44, 1544–1547. [Google Scholar] [CrossRef]

- Roy, H.V.; Kallinger, C.; Marsen, B.; Sattler, K. Manipulation of graphitic sheets using a tunneling microscope. J. Appl. Phys. 1998, 83, 4695–4699. [Google Scholar] [CrossRef]

- Jacobse, P.H.; Mangnus, M.J.J.; Zevenhuizen, S.J.M.; Swart, I. Mapping the Conductance of Electronically Decoupled Graphene Nanoribbons. ACS Nano 2018, 12, 7048–7056. [Google Scholar] [CrossRef]

- Koch, M.; Ample, F.; Joachim, C.; Grill, L. Voltage-dependent conductance of a single graphene nanoribbon. Nat. Nanotechnol. 2012, 7, 713–717. [Google Scholar] [CrossRef]

- Wang, S.; Talirz, L.; Pignedoli, C.A.; Feng, X.; Müllen, K.; Fasel, R.; Ruffieux, P. Giant edge state splitting at atomically precise graphene zigzag edges. Nat. Commun. 2016, 7, 11507. [Google Scholar] [CrossRef]

- Koós, A.A.; Vancsó, P.; Magda, G.Z.; Osváth, Z.; Kertész, K.; Dobrik, G.; Hwang, C.; Tapasztó, L.; Biró, L.P. STM study of the MoS2 flakes grown on graphite: A model system for atomically clean 2D heterostructure interfaces. Carbon 2016, 105, 408–415. [Google Scholar] [CrossRef]

- Magda, G.Z.; Jin, X.; Hagymási, I.; Vancsó, P.; Osváth, Z.; Nemes-Incze, P.; Hwang, C.; Biró, L.P.; Tapasztó, L. Room-temperature magnetic order on zigzag edges of narrow graphene nanoribbons. Nature 2014, 514, 608–611. [Google Scholar] [CrossRef]

- Dienwiebel, M.; Verhoeven, G.S.; Pradeep, N.; Frenken, J.W.M.; Heimberg, J.A.; Zandbergen, H.W. Superlubricity of Graphite. Phys. Rev. Lett. 2004, 92, 126101. [Google Scholar] [CrossRef]

- Zheng, Q.; Jiang, B.; Liu, S.; Weng, Y.; Lu, L.; Xue, Q.; Zhu, J.; Jiang, Q.; Wang, S.; Peng, L. Self-Retracting Motion of Graphite Microflakes. Phys. Rev. Lett. 2008, 100, 067205. [Google Scholar] [CrossRef]

- Ru, G.; Qi, W.; Tang, K.; Wei, Y.; Xue, T. Interlayer friction and superlubricity in bilayer graphene and MoS2/MoSe2 van der Waals heterostructures. Tribol. Int. 2020, 151, 106483. [Google Scholar] [CrossRef]

- Gao, F.; Li, D.; Barreteau, C.; Brandbyge, M. Proposal for All-Electrical Spin Manipulation and Detection for a Single Molecule on Boron-Substituted Graphene. Phys. Rev. Lett. 2022, 129, 027201. [Google Scholar] [CrossRef]

- Li, J.; Sanz, S.; Corso, M.; Choi, D.J.; Peña, D.; Frederiksen, T.; Pascual, J.I. Single spin localization and manipulation in graphene open-shell nanostructures. Nat. Commun. 2019, 10, 200. [Google Scholar] [CrossRef]

- Stühler, R.; Reis, F.; Müller, T.; Helbig, T.; Schwemmer, T.; Thomale, R.; Schäfer, J.; Claessen, R. Tomonaga–Luttinger liquid in the edge channels of a quantum spin Hall insulator. Nat. Phys. 2020, 16, 47–51. [Google Scholar] [CrossRef]

- Xia, Y.; Wang, B.; Zhang, J.; Jin, Y.; Tian, H.; Ho, W.; Xu, H.; Jin, C.; Xie, M. Quantum confined Tomonaga–Luttinger liquid in Mo6Se6 nanowires converted from an epitaxial MoSe2 monolayer. Nano Lett. 2020, 20, 2094–2099. [Google Scholar] [CrossRef]

- Zheng, C.; Zhang, Q.; Weber, B.; Ilatikhameneh, H.; Chen, F.; Sahasrabudhe, H.; Rahman, R.; Li, S.; Chen, Z.; Hellerstedt, J. Direct observation of 2D electrostatics and ohmic contacts in template-grown graphene/WS2 heterostructures. ACS Nano 2017, 11, 2785–2793. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Huang, Z.-P.; Jia, L.-G.; Liu, L.-W.; Yang, H.-X.; Zhang, T.; He, L.; Zhou, J.-D.; Huang, Y.; et al. Visualization of Macroscopic Ising Superconducting State in Superconductor-Graphene Junctions. Adv. Quantum Technol. 2023, 6, 2300087. [Google Scholar] [CrossRef]

- Hou, B.; Zhang, Y.; Zhang, T.; Wu, J.; Zhang, Q.; Han, X.; Huang, Z.; Chen, Y.; Ji, H.; Wang, T.; et al. Multiple electronic phases coexisting under inhomogeneous strains in the correlated insulator. Adv. Sci. 2023, 10, 2300789. [Google Scholar] [CrossRef]

- Guan, W.; Li, K.; Xiao, Y.; Li, S.-Y.; Pan, A. Structural and electronic property engineering in graphene nanowrinkles via scanning tunneling microscopy. Phys. Rev. B 2022, 106, 205417. [Google Scholar] [CrossRef]

- Chen, H.; Bao, D.-L.; Wang, D.; Que, Y.; Xiao, W.; Zhang, Y.-Y.; Sun, J.; Du, S.; Gao, H.-J. Fabrication and manipulation of nanosized graphene homojunction with atomically-controlled boundaries. Nano Res. 2020, 13, 3286–3291. [Google Scholar] [CrossRef]

- Wang, D.; Bao, D.-L.; Zheng, Q.; Wang, C.-T.; Wang, S.; Fan, P.; Mishra, S.; Tao, L.; Xiao, Y.; Huang, L.; et al. Twisted bilayer zigzag-graphene nanoribbon junctions with tunable edge states. Nat. Commun. 2023, 14, 1018. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, J.; Huang, J.L.; Kim, P.; Lieber, C.M. Creation of nanocrystals through a solid-solid phase transition induced by an STM tip. Science 1996, 274, 757–760. [Google Scholar] [CrossRef]

- Bischoff, F.; Auwärter, W.; Barth, J.V.; Schiffrin, A.; Fuhrer, M.; Weber, B. Nanoscale Phase Engineering of Niobium Diselenide. Chem. Mater. 2017, 29, 9907–9914. [Google Scholar] [CrossRef]

- Song, X.; Liu, L.; Chen, Y.; Yang, H.; Huang, Z.; Hou, B.; Hou, Y.; Han, X.; Yang, H.; Zhang, Q.; et al. Atomic-scale visualization of chiral charge density wave superlattices and their reversible switching. Nat. Commun. 2022, 13, 1843. [Google Scholar] [CrossRef]

- He, Z.; Poudel, S.P.; Stolz, S.; Wang, T.; Rossi, A.; Wang, F.; Mo, S.-K.; Weber-Bargioni, A.; Qiu, Z.Q.; Barraza-Lopez, S.; et al. Synthesis and Polymorph Manipulation of FeSe2 Monolayers. Nano Lett. 2024, 24, 8535–8541. [Google Scholar] [CrossRef]

- Ren, Y.-N.; Zhang, M.-H.; Zhou, X.-F.; Zheng, Q.; Ren, H.-Y.; He, L. In situ creation and tailoring of interfacial quantum dots in graphene/transition metal dichalcogenide heterostructures. Phys. Rev. B 2024, 110, 125416. [Google Scholar] [CrossRef]

- Chen, Y.; Dai, Y.-X.; Zhang, Y.; Zhang, C.; Zhou, L.; Jia, L.; Wang, W.; Han, X.; Yang, H.X.; Liu, L.; et al. Nanoscale Polymorph Engineering of Metal-Correlated Insulator Junctions in Monolayer NbSe2. ACS Nano 2025, 19, 14808–14816. [Google Scholar] [CrossRef]

- Ringger, M.; Hidber, H.R.; Schlögl, R.; Oelhafen, P.; Güntherodt, H.J. Nanometer lithography with the scanning tunneling microscope. Appl. Phys. Lett. 1985, 46, 832–834. [Google Scholar] [CrossRef]

- Wiesendanger, R.; Eng, L.; Hidber, H.R.; Oelhafen, P.; Rosenthaler, L.; Staufer, U.; Güntherodt, H.J. Local tunneling barrier height images obtained with the scanning tunneling microscope. Surf. Sci. 1987, 189, 24–28. [Google Scholar] [CrossRef]

- Tománek, D.; Louie, S.G.; Mamin, H.J.; Abraham, D.W.; Thomson, R.E.; Ganz, E.; Clarke, J. Theory and observation of highly asymmetric atomic structure in scanning-tunneling-microscopy images of graphite. Phys. Rev. B 1987, 35, 7790–7793. [Google Scholar] [CrossRef]

- Dagata, J.A.; Schneir, J.; Harary, H.H.; Evans, C.J.; Postek, M.T.; Bennett, J. Modification of hydrogen-passivated silicon by a scanning tunneling microscope operating in air. Appl. Phys. Lett. 1990, 56, 2001–2003. [Google Scholar] [CrossRef]

- Li, N.L.N.; Yoshinobu, T.Y.T.; Iwasaki, H.I.H. Low energy electron beam stimulated surface reaction: Selective etching of SiO2/Si using scanning tunneling microscope. Jpn. J. Appl. Phys. 1998, 37, L995. [Google Scholar]

- Baringhaus, J.; Settnes, M.; Aprojanz, J.; Power, S.R.; Jauho, A.P.; Tegenkamp, C. Electron Interference in Ballistic Graphene Nanoconstrictions. Phys. Rev. Lett. 2016, 116, 186602. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Zhan, L.; Zhang, T.; Li, Y.; Fan, H.; Cao, X.; Zhou, Z.; Yu, Q.; Grazioli, C.; Yang, H.; et al. Atomic Manipulation of 2D Materials by Scanning Tunneling Microscopy: Advances in Graphene and Transition Metal Dichalcogenides. Nanomaterials 2025, 15, 888. https://doi.org/10.3390/nano15120888

Wang T, Zhan L, Zhang T, Li Y, Fan H, Cao X, Zhou Z, Yu Q, Grazioli C, Yang H, et al. Atomic Manipulation of 2D Materials by Scanning Tunneling Microscopy: Advances in Graphene and Transition Metal Dichalcogenides. Nanomaterials. 2025; 15(12):888. https://doi.org/10.3390/nano15120888

Chicago/Turabian StyleWang, Tingting, Lingtao Zhan, Teng Zhang, Yan Li, Haolong Fan, Xiongbai Cao, Zhenru Zhou, Qinze Yu, Cesare Grazioli, Huixia Yang, and et al. 2025. "Atomic Manipulation of 2D Materials by Scanning Tunneling Microscopy: Advances in Graphene and Transition Metal Dichalcogenides" Nanomaterials 15, no. 12: 888. https://doi.org/10.3390/nano15120888

APA StyleWang, T., Zhan, L., Zhang, T., Li, Y., Fan, H., Cao, X., Zhou, Z., Yu, Q., Grazioli, C., Yang, H., Zhang, Q., & Wang, Y. (2025). Atomic Manipulation of 2D Materials by Scanning Tunneling Microscopy: Advances in Graphene and Transition Metal Dichalcogenides. Nanomaterials, 15(12), 888. https://doi.org/10.3390/nano15120888