Clindamycin-Loaded Nanosized Calcium Phosphates Powders as a Carrier of Active Substances

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Ceramic Synthesis

2.3. Determination of Calcium and Phosphorus Content

2.4. X-ray Diffraction Analysis

2.5. Fourier-Transform Infrared Spectroscopy Analysis

2.6. Specific Surface Area and Porosity Studies

2.7. Preparation of Ceramic Powders with Drug

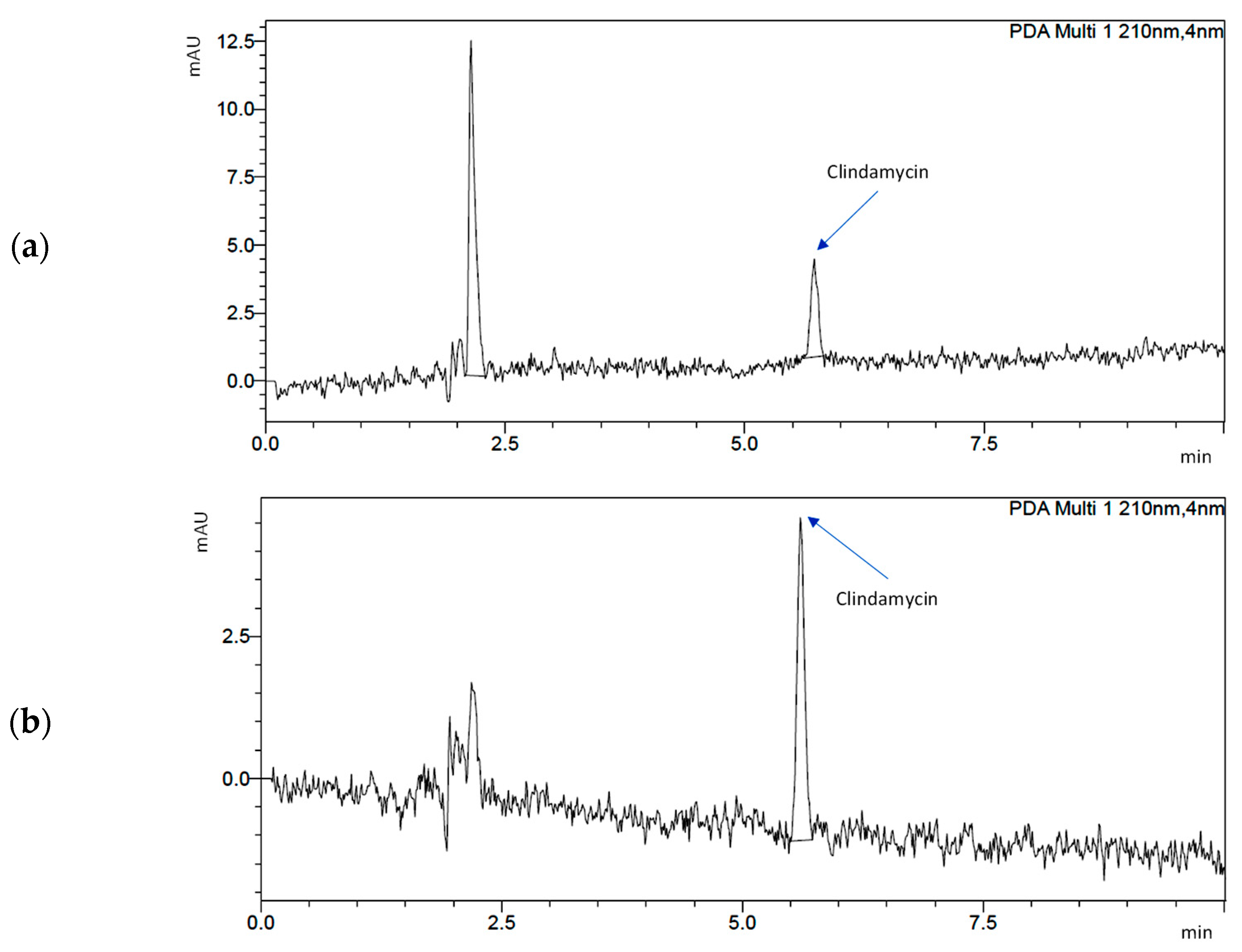

2.8. Kinetic Release Studies of Antibiotic

2.9. Morphology Analysis

2.10. Antimicrobial Activity of Clindamycin-Modified Ceramic Powders

3. Results

3.1. Determination of Calcium and Phosphorus Content

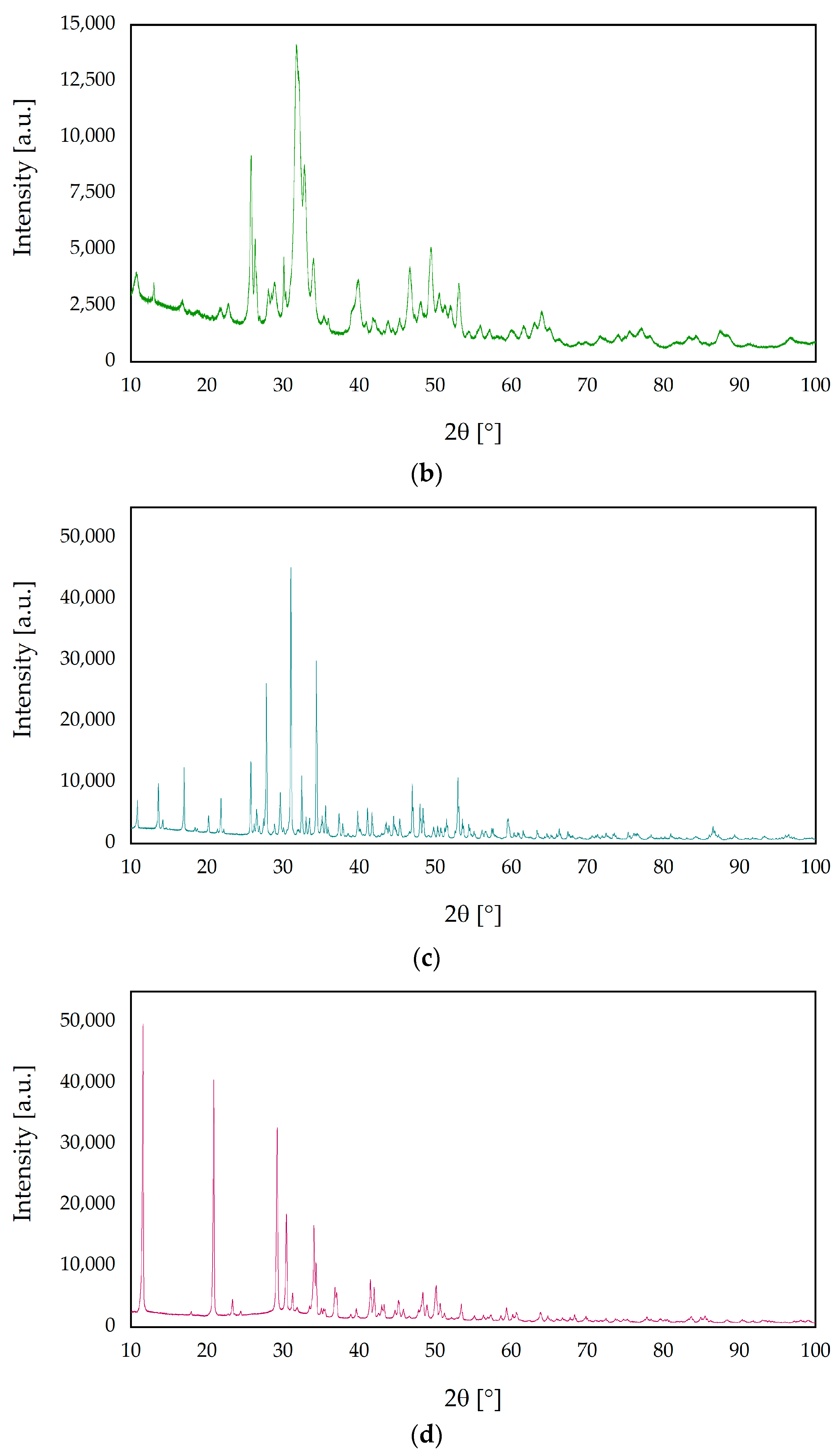

3.2. X-ray Diffraction Analysis

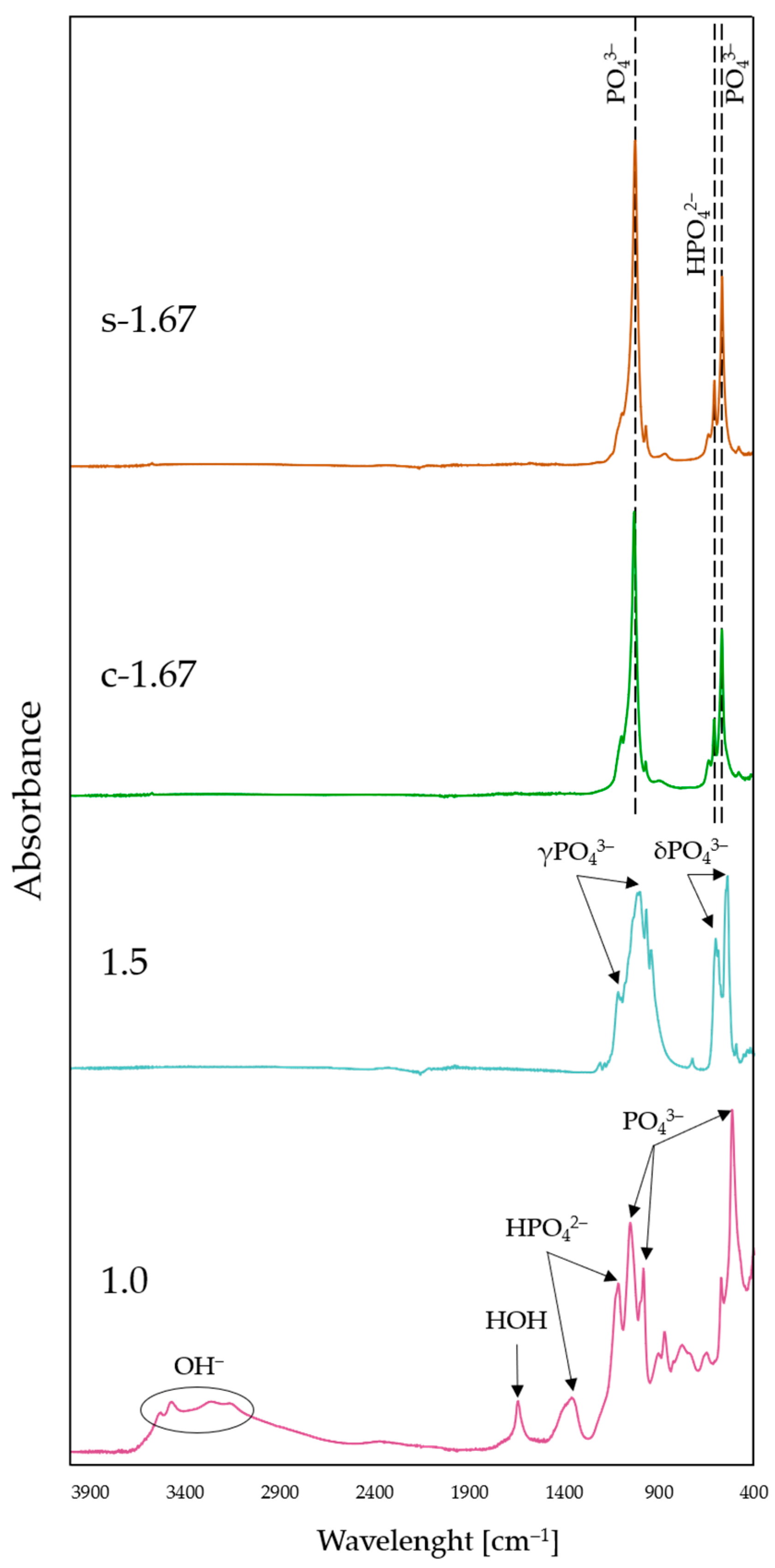

3.3. Fourier Transform Infrared Spectroscopy Analysis

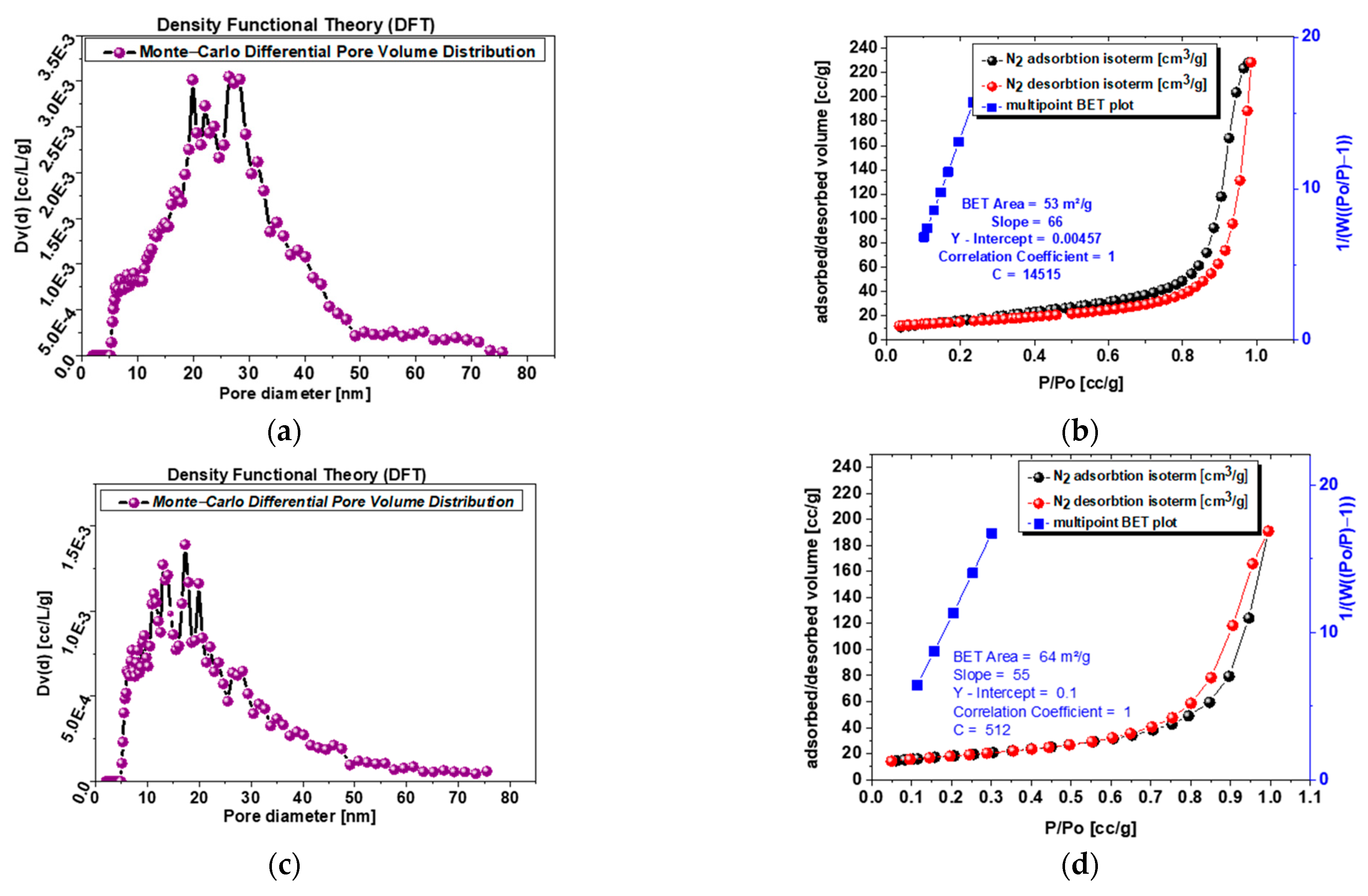

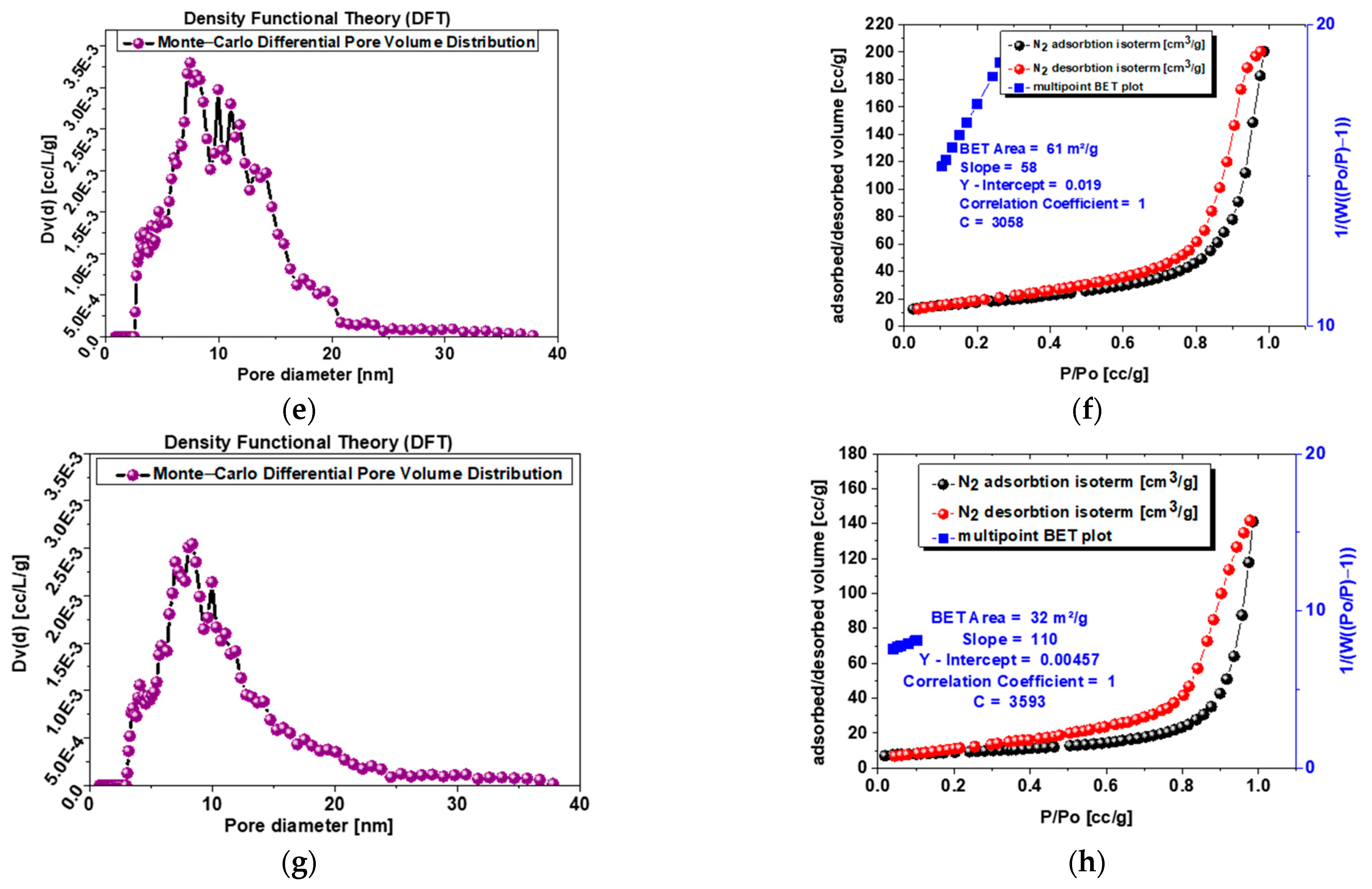

3.4. Specific Surface Area and Porosity Studies

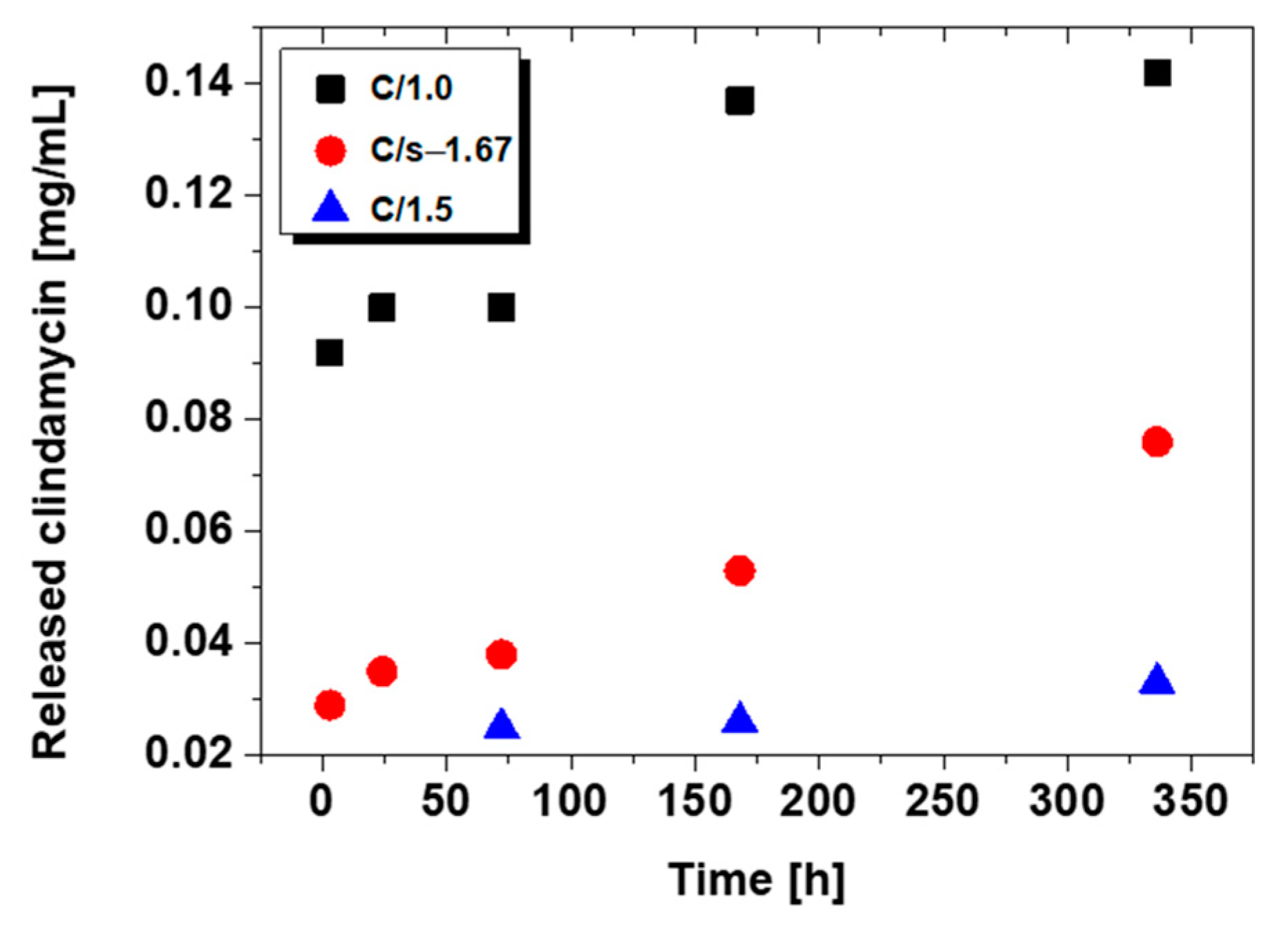

3.5. Kinetic Release Studies of Antibiotic

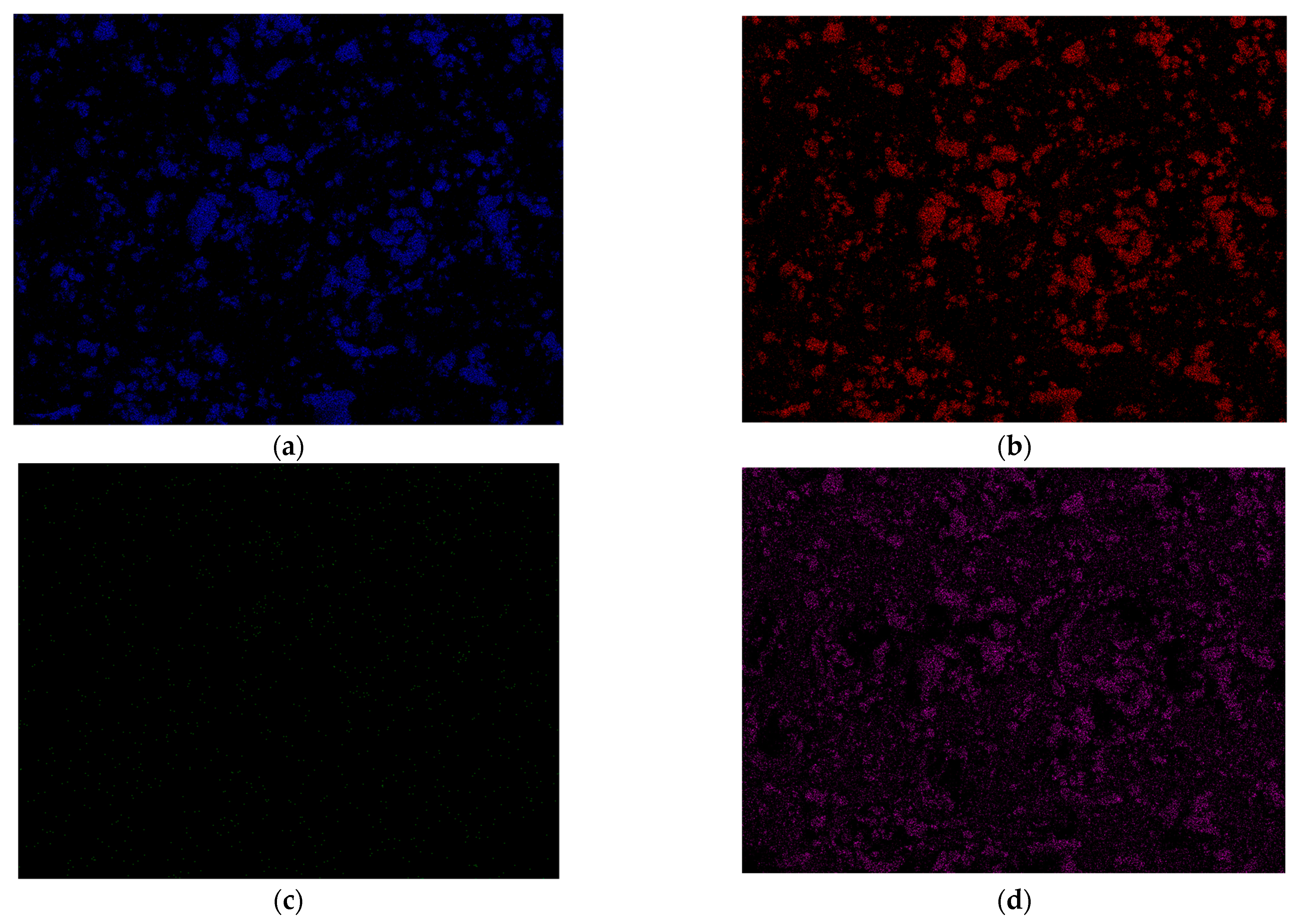

3.6. Morphology Analysis

3.7. Antimicrobial Activity of Clindamycin-Modified Ceramic Powders

4. Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zang, S.; Chang, S.; Shahzad, M.B.; Sun, X.; Jiang, X.; Yang, H. Ceramics-based Drug Delivery System: A Review and Outlook. Rev. Adv. Mater. Sci. 2019, 58, 82–97. [Google Scholar] [CrossRef]

- Trucillo, P. Drug Carriers: Classification, Administration, Release Profiles, and Industrial Approach. Processes 2021, 9, 470. [Google Scholar] [CrossRef]

- Adeyemi, O.S.; Sulaiman, F.A. Evaluation of metal nanoparticles for drug delivery systems. J. Biomed. Res. 2015, 29, 145–149. [Google Scholar] [CrossRef]

- Kong, F.Y.; Zhang, J.W.; Li, R.F.; Wang, Z.X.; Wang, W.J.; Wang, W. Unique roles of gold nanoparticles in drug delivery, targeting and imaging applications. Molecules 2017, 22, 1445. [Google Scholar] [CrossRef]

- Singh, P.; Pandit, S.; Mokkapati, V.R.S.S.; Garg, A.; Ravikumar, V.; Mijakovic, I. Gold nanoparticles in diagnostics and therapeutics for human cancer. Int. J. Mol. Sci. 2018, 19, 1979. [Google Scholar] [CrossRef] [PubMed]

- Jampilek, J.; Kralova, K. Advances in drug delivery nanosystems using graphene-based materials and carbon nanotubes. Materials 2021, 14, 1059. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, M.; Aoki, K.; Haniu, H.; Kamanaka, T.; Takizawa, T.; Sobajima, A.; Yoshida, K.; Okamoto, M.; Kato, H.; Saito, N. Applications of carbon nanotubes in bone regenerative medicine. Nanomaterials 2020, 10, 659. [Google Scholar] [CrossRef]

- Anisimov, R.A.; Gorin, D.A.; Abalymov, A.A. 3D Cell Spheroids as a Tool for Evaluating the Effectiveness of Carbon Nanotubes as a Drug Delivery and Photothermal Therapy Agents. C 2022, 8, 56. [Google Scholar] [CrossRef]

- Nair, A.; Haponiuk, J.T.; Thomas, S.; Gopi, S. Natural carbon-based quantum dots and their applications in drug delivery: A review. Biomed. Pharmacother. 2020, 132, 110834. [Google Scholar] [CrossRef]

- Iannazzo, D.; Pistone, A.; Celesti, C.; Triolo, C.; Patané, S.; Giofré, S.V.; Romeo, R.; Ziccarelli, I.; Mancuso, R.; Gabriele, B.; et al. A smart nanovector for cancer targeted drug delivery based on graphene quantum dots. Nanomaterials 2019, 9, 282. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Hashemi, S.A.; Kalashgrani, M.Y.; Omidifar, N.; Bahrani, S.; Rao, N.V.; Babapoor, A.; Gholami, A.; Chiang, W.H. Bioactive Graphene Quantum Dots Based Polymer Composite for Biomedical Applications. Polymers 2022, 14, 617. [Google Scholar] [CrossRef]

- Festas, A.J.; Ramos, A.; Davim, J.P. Medical devices biomaterials—A review. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 218–228. [Google Scholar] [CrossRef]

- Li, H.; Li, C.; Wu, L.; Wang, H.; Li, J.; Fu, M.; Wang, C.A. In-situ synthesis and properties of porous cordierite ceramics with adjustable pore structure. Ceram. Int. 2020, 46, 14808–14815. [Google Scholar] [CrossRef]

- Gbureck, U.; Vorndran, E.; Barralet, J.E. Modeling vancomycin release kinetics from microporous calcium phosphate ceramics comparing static and dynamic immersion conditions. Acta Biomater. 2008, 4, 1480–1486. [Google Scholar] [CrossRef] [PubMed]

- Zamoume, O.; Thibault, S.; Regnié, G.; Mecherri, M.O.; Fiallo, M.; Sharrock, P. Macroporous calcium phosphate ceramic implants for sustained drug delivery. Mater. Sci. Eng. C 2011, 31, 1352–1356. [Google Scholar] [CrossRef]

- Vezenkova, A.; Locs, J. Sudoku of porous, injectable calcium phosphate cements—Path to osteoinductivity. Bioact. Mater. 2022, 17, 109–124. [Google Scholar] [CrossRef]

- Mahjoory, M.; Shahgholi, M.; Karimipour, A. The Effects of Initial Temperature and Pressure on the Mechanical Properties of Reinforced Calcium Phosphate Cement with Magnesium Nanoparticles; a Molecular Dynamics Approach. SSRN Electron. J. 2022, 135, 106067. [Google Scholar] [CrossRef]

- Kołodziejska, B.; Kaflak, A.; Kolmas, J. Biologically inspired collagen/apatite composite biomaterials for potential use in bone tissue regeneration—A review. Materials 2020, 13, 1748. [Google Scholar] [CrossRef]

- Motameni, A.; Alshemary, A.Z.; Evis, Z. A review of synthesis methods, properties and use of monetite cements as filler for bone defects. Ceram. Int. 2021, 47, 13245–13256. [Google Scholar] [CrossRef]

- Braga, R.R. Calcium phosphates as ion-releasing fillers in restorative resin-based materials. Dent. Mater. 2019, 35, 3–14. [Google Scholar] [CrossRef]

- Dorozhkin, S.V. Calcium orthophosphates (CaPO4): Occurrence and properties. Prog. Biomater. 2015, 5, 9–70. [Google Scholar] [CrossRef] [PubMed]

- Matsuya, S.; Takagi, S.; Chow, L.C. Effect of mixing ratio and pH on the reaction between Ca4(PO4)2O and CaHPO4. J. Mater. Sci. Mater. Med. 2000, 1, 305–311. [Google Scholar] [CrossRef] [PubMed]

- Ślósarczyk, A. Bioceramika Hydroksyapatytowa; Biuletyn Ceramiczny nr 13 Ceramika 51; Polskie Towarzystwo Ceramiczne: Kraków, Poland, 1997. [Google Scholar]

- Harb, S.V.; Bassous, N.J.; de Souza, T.A.C.; Trentin, A.; Pulcinelli, S.H.; Santilli, C.V.; Webster, T.J.; Lobo, A.O.; Hammer, P. Hydroxyapatite and β-TCP modified PMMA-TiO2 and PMMA-ZrO2 coatings for bioactive corrosion protection of Ti6Al4V implants. Mater. Sci. Eng. C 2020, 116, 111149. [Google Scholar] [CrossRef]

- Damerau, J.M.; Bierbaum, S.; Wiedemeier, D.; Korn, P.; Smeets, R.; Jenny, G.; Nadalini, J.; Stadlinger, B. A systematic review on the effect of inorganic surface coatings in large animal models and meta-analysis on tricalcium phosphate and hydroxyapatite on periimplant bone formation. J. Biomed. Mater. Res. Part B Appl. Biomater. 2022, 110, 157–175. [Google Scholar] [CrossRef] [PubMed]

- Shalini, B.; Kumar, A.R. A comparative study of hydroxyapatite (Ca10(PO4)6(OH)2) using sol-gel and co-precipitation methods for biomedical applications. J. Indian Cham. Soc. 2019, 96, 25–28. [Google Scholar]

- De Aza, P.N.; Rodríguez, M.A.; Gehrke, S.A.; Maté-Sánchez de Val, J.E.; Calvo-Guirado, J.L. A Si-αTCP scaffold for biomedical applications: An experimental study using the rabbit tibia model. Appl. Sci. 2017, 7, 706. [Google Scholar] [CrossRef]

- Horch, H.H.; Sader, R.; Pautke, C.; Neff, A.; Deppe, H.; Kolk, A. Synthetic, pure-phase beta-tricalcium phosphate ceramic granules (Cerasorb®) for bone regeneration in the reconstructive surgery of the jaws. Int. J. Oral Maxillofac. Surg. 2006, 35, 708–713. [Google Scholar] [CrossRef]

- Sánchez-Salcedo, S.; Arcos, D.; Vallet-Regí, M. Upgrading Calcium Phosphate Scaffolds for Tissue Engineering Applications. Key Eng. Mater. 2008, 377, 19–42. [Google Scholar] [CrossRef]

- Mirkiani, S.; Mesgar, A.S.; Mohammadi, Z.; Matinfar, M. Synergetic reinforcement of brushite cements by monetite/apatite whisker-like fibers and carboxymethylcellulose. Materialia 2022, 21, 101329. [Google Scholar] [CrossRef]

- Hurle, K.; Maia, F.R.; Ribeiro, V.P.; Pina, S.; Oliveira, J.M.; Goetz-Neunhoeffer, F.; Reis, R.L. Osteogenic lithium-doped brushite cements for bone regeneration. Bioact. Mater. 2022, 16, 403–417. [Google Scholar] [CrossRef]

- Ben-Nissan, B. Advances in Calcium Phosphate Biomaterials; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Qadir, M.; Li, Y.; Wen, C. Ion-substituted calcium phosphate coatings by physical vapor deposition magnetron sputtering for biomedical applications: A review. Acta Biomaterialia 2019, 89, 14–32. [Google Scholar] [CrossRef] [PubMed]

- Tavoni, M.; Dapporto, M.; Tampieri, A.; Sprio, S. Bioactive calcium phosphate-based composites for bone regeneration. J. Compos. Sci. 2021, 5, 227. [Google Scholar] [CrossRef]

- Jeong, J.; Kim, J.H.; Shim, J.H.; Hwang, N.S.; Heo, C.Y. Bioactive calcium phosphate materials and applications in bone regeneration. Biomater. Res. 2019, 23, 4. [Google Scholar] [CrossRef]

- Frank, O.; Heim, M.; Jakob, M.; Barbero, A.; Schäfer, D.; Bendik, I.; Dick, W.; Heberer, M.; Martin, I. Real-time quantitative RT-PCR analysis of human bone marrow stromal cells during osteogenic differentiation in vitro. J. Cell. Biochem. 2002, 85, 737–746. [Google Scholar] [CrossRef] [PubMed]

- Whited, B.M.; Skrtic, D.; Love, B.J.; Goldstein, A.S. Osteoblast response to zirconia-hybridized pyrophosphate-stabilized amorphous calcium phosphate. J. Biomed. Mater. Res. Part A 2006, 76A, 596–604. [Google Scholar] [CrossRef]

- Orimo, H. The mechanism of mineralization and the role of alkaline phosphatase in health and disease. Nippon Med. Sch. 2010, 77, 4–12. [Google Scholar] [CrossRef]

- Bystrova, A.V.; Dekhtyar, Y.D.; Popov, A.I.; Coutinho, J.; Bystrov, V.S. Modified hydroxyapatite structure and properties: Modeling and synchrotron data analysis of modified hydroxyapatite structure. Ferroelectrics 2015, 475, 135–147. [Google Scholar] [CrossRef]

- Hübner, W.; Blume, A.; Pushnjakova, R.; Dekhtyar, Y.; Hein, H.J. The influence of X-ray radiation on the mineral/organic matrix interaction of bone tissue: An FT-IR microscopic investigation. Int. J. Artif. Organs 2005, 28, 66–73. [Google Scholar] [CrossRef]

- Moroi, H.; Kimura, K.; Ido, A.; Banno, H.; Jin, W.; Wachino, J.I.; Yamada, K.; Kikkawa, F.; Park, Y.J.; Arakawa, Y. Erythromycin-susceptible but clindamycin-resistant phenotype of clinical ermb-pcr-positive group b streptococci isolates with is1216e-inserted ermb. Jpn. J. Infect. Dis. 2019, 72, 420–422. [Google Scholar] [CrossRef]

- Hu, H.; Ramezanpour, M.; Hayes, A.J.; Liu, S.; Psaltis, A.J.; Wormald, P.J.; Vreugde, S. Sub-inhibitory clindamycin and azithromycin reduce s. Aureus exoprotein induced toxicity, inflammation, barrier disruption and invasion. J. Clin. Med. 2019, 8, 1617. [Google Scholar] [CrossRef]

- Ahmadi, H.; Ebrahimi, A.; Ahmadi, F. Antibiotic Therapy in Dentistry. Int. J. Dent. 2021, 2021, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Álvarez, L.A.; Van de Sijpe, G.; Desmet, S.; Metsemakers, W.J.; Spriet, I.; Allegaert, K.; Rozenski, J. Ways to Improve Insights into Clindamycin Pharmacology and Pharmacokinetics Tailored to Practice. Antibiotics 2022, 11, 701. [Google Scholar] [CrossRef]

- Słota, D.; Florkiewicz, W.; Piętak, K.; Pluta, K.; Sadlik, J.; Miernik, K.; Sobczak-Kupiec, A. Preparation of PVP and betaine biomaterials enriched with hydroxyapatite and its evaluation as a drug carrier for controlled release of clindamycin. Ceram. Int. 2022, 48, 35467–35473. [Google Scholar] [CrossRef]

- Słota, D.; Florkiewicz, W.; Piętak, K.; Szwed, A.; Włodarczyk, M.; Siwińska, M.; Rudnicka, K.; Sobczak-Kupiec, A. Preparation, Characterization, and Biocompatibility Assessment of Polymer-Ceramic Composites Loaded with Salvia officinalis Extract. Materials 2021, 14, 6000. [Google Scholar] [CrossRef] [PubMed]

- Tomala, A.M.; Słota, D.; Florkiewicz, W.; Piętak, K.; Dyląg, M.; Sobczak-Kupiec, A. Tribological Properties and Physiochemical Analysis of Polymer-Ceramic Composite Coatings for Bone Regeneration. Lubricants 2022, 10, 58. [Google Scholar] [CrossRef]

- Sawada, M.; Sridhar, K.; Kanda, Y.; Yamanaka, S. Pure hydroxyapatite synthesis originating from amorphous calcium carbonate. Sci. Rep. 2021, 11, 1–9. [Google Scholar] [CrossRef]

- Słota, D.; Florkiewicz, W.; Sobczak-Kupiec, A. Ceramic-polymer coatings on Ti-6Al-4V alloy modified with L-cysteine in biomedical applications. Mater. Today Commun. 2020, 25, 101301. [Google Scholar] [CrossRef]

- Florkiewicz, W.; Słota, D.; Placek, A.; Pluta, K.; Tyliszczak, B.; Douglas, T.E.L.; Sobczak-Kupiec, A. Synthesis and characterization of polymer-based coatings modified with bioactive ceramic and bovine serum albumin. J. Funct. Biomater. 2021, 12, 21. [Google Scholar] [CrossRef]

- Gong, X.; Liang, Z.; Yang, Y.; Liu, H.; Ji, J.; Fan, Y. A resazurin-based, nondestructive assay for monitoring cell proliferation during a scaffold-based 3D culture process. Regen. Biomater. 2020, 7, 271–281. [Google Scholar] [CrossRef]

- European Committee on Antimicrobial Susceptibility Testing. Breakpoint Tables for Interpretation of MICs and Zone Diameters, Version 13.0; European Committee on Antimicrobial Susceptibility Testing: Växjö, Sweden, 2013.

- Bilton, M.W. Nanoparticulate Hydroxyapatite and Calcium—Based CO2 Sorbents. Ph.D. Thesis, University of Leeds, Leeds, UK, 2012; pp. 201–282. [Google Scholar]

- Chang, M.C. Use of Wet Chemical Method to Prepare β Tri-Calcium Phosphates having Macro- and Nano-crystallites for Artificial Bone. J. Korean Ceram. Soc. 2016, 53, 670–675. [Google Scholar] [CrossRef]

- Nur, A.; Jumari, A.; Budiman, A.W.; Wicaksono, A.H.; Nurohmah, A.R.; Nazriati, N.; Fajaroh, F. Synthesis of nickel—Hydroxyapatite by electrochemical method. IOP Conf. Ser. Mater. Sci. Eng. 2019, 543, 012026. [Google Scholar] [CrossRef]

- Binitha, M.P.; Pradyumnan, P.P. Dielectric Property Studies of Biologically Compatible Brushite Single Crystals Used as Bone Graft Substitute. J. Biomater. Nanobiotechnol. 2013, 4, 119–122. [Google Scholar] [CrossRef]

- Mansour, S.F.; El-dek, S.I.; Ahmed, M.A.; Abd-Elwahab, S.M.; Ahmed, M.K. Effect of preparation conditions on the nanostructure of hydroxyapatite and brushite phases. Appl. Nanosci. 2016, 6, 991–1000. [Google Scholar] [CrossRef]

- Ding, X.; Li, A.; Yang, F.; Sun, K.; Sun, X. Β-Tricalcium Phosphate and Octacalcium Phosphate Composite Bioceramic Material for Bone Tissue Engineering. J. Biomater. Appl. 2020, 34, 1294–1299. [Google Scholar] [CrossRef]

- Duarte Moreira, A.P.; Soares Sader, M.; De Almeida Soares, G.D.; Leão, M.H.M.R. Strontium incorporation on microspheres of alginate/β-tricalcium phosphate as delivery matrices. Mater. Res. 2014, 17, 967–973. [Google Scholar] [CrossRef]

- Besleaga, C.; Nan, B.; Popa, A.C.; Balescu, L.M.; Nedelcu, L.; Neto, A.S.; Pasuk, I.; Leonat, L.; Popescu-Pelin, G.; Ferreira, J.M.F.; et al. Sr and Mg Doped Bi-Phasic Calcium Phosphate Macroporous Bone Graft Substitutes Fabricated by Robocasting: A Structural and Cytocompatibility Assessment. J. Funct. Biomater. 2022, 13, 123. [Google Scholar] [CrossRef] [PubMed]

- Rojas-Montoya, I.D.; Fosado-Esquivel, P.; Henao-Holguín, L.V.; Esperanza-Villegas, A.E.; Bernad-Bernad, M.J.; Gracia-Mora, J. Adsorption/desorption studies of norfloxacin on brushite nanoparticles from reverse microemulsions. Adsorption 2020, 26, 825–834. [Google Scholar] [CrossRef]

- Sayahi, M.; Santos, J.; El-Feki, H.; Charvillat, C.; Bosc, F.; Karacan, I.; Milthorpe, B.; Drouet, C. Brushite (Ca,M)HPO4, 2H2O doping with bioactive ions (M = Mg2+, Sr2+, Zn2+, Cu2+, and Ag+): A new path to functional biomaterials? Mater. Today Chem. 2020, 16, 100230. [Google Scholar] [CrossRef]

- Idowu, B.; Cama, G.; Deb, S.; Di Silvio, L. In vitro osteoinductive potential of porous monetite for bone tissue engineering. J. Tissue Eng. 2014, 5, 1–4. [Google Scholar] [CrossRef]

- Ma, M.Y.; Zhu, Y.J.; Li, L.; Cao, S.W. Nanostructured porous hollow ellipsoidal capsules of hydroxyapatite and calcium silicate: Preparation and application in drug delivery. J. Mater. Chem. 2008, 18, 2722–2727. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhang, D.; Sun, R.; Shang, S.; Wang, H.; Yang, Y.; Wang, L.; Liu, X.; Sun, T.; Chen, K. Adsorption behavior of drugs on hydroxyapatite with different morphologies: A combined experimental and molecular dynamics simulation study. Ceram. Int. 2019, 45, 19522–19527. [Google Scholar] [CrossRef]

| Calcium Phosphates in the CaO-P2O5 Arrangement | ||||

|---|---|---|---|---|

| Abbreviation | Systematic Name | Mineralogical Name | Chemical Formula | Molar Ratio Ca/P |

| CP | Calcium metaphosphate | – | Ca(PO3)2 | 0.5 |

| C2P | Calcium pyrophosphate | – | Ca2P2O7 | 1.0 |

| C3P, TCP | Tricalcium phospahte | Whitlockite | Ca3(PO4)2 | 1.5 |

| C4P, TTCP | Tetracalcium phosphate | – | Ca4(PO4)2O | 2.0 |

| Calcium Phosphates in the CaO-P2O5-H2O Arrangement | ||||

| Abbreviation | Systematic Name | Mineralogical Name | Chemical Formula | Molar Ratio Ca/P |

| MCPA | Calcium dihydrogenphosphate | – | Ca(H2PO4)2 | 0.5 |

| MCPM | Calcium dihydrogenphosphate monohydrate | – | Ca(H2PO4)2 ⋅H2O | 0.5 |

| DCPD | Dicalcium phosphate dihydrate | Brushite | CaHPO4 ⋅2 H2O | 1.0 |

| DCPA | Dicalcium phosphate anhydrous | Monethite | CaHPO4 | 1.0 |

| OCP | Octacalcium phosphate | – | Ca8H2(PO4)6 ⋅5 H2O | 1.333 |

| HA, HAp, OHAp | Pentacalcium hydroxide triphosphate | Hydroxyapatite | Ca10(PO4)6 ⋅2 H2O | 1.667 |

| Sample | Ca Content (wt. %) | P Content (wt. %) | Ca/P Molar Ratio |

|---|---|---|---|

| s-1.67 | 37.51 ± 0.65 | 17.26 ± 0.19 | 1.67 |

| c-1.67 | 37.46 ± 0.38 | 17.27 ± 0.12 | 1.67 |

| 1.5 | 36.93 ± 0.32 | 18.87 ± 0.23 | 1.51 |

| 1.0 | 37.81 ± 0.41 | 27.91 ± 0.34 | 1.04 |

| Sample | SSA [m2/g] | Porosity | ||

|---|---|---|---|---|

| Pore Size Distribution DFT [nm] | Pore Volume Macropores [cm3/g] | Pore Area Micropores Vt [m2/g] | ||

| s-1.67 | 53 | 4, 10, 11, 13 | 0.345 | 3.52 |

| c-1.67 | 64 | 11, 13, 17, 20, 22, 24, 28 | 0.27 | 0 |

| 1.5 | 61 | 8, 10, 11, 13 | 0.304 | 0 |

| 1.0 | 32 | 4, 7, 8, 10 | 0.21 | 4.94 |

| Ceramic Powder | MIC [µg/mL] |

|---|---|

| s-1.67 | >25,600 |

| C/s-1.67 | 12.5 |

| c-1.67 | >25,600 |

| C/c-1.67 | 50 |

| 1.5 | >25,600 |

| C/1.5 | 25 |

| 1.0 | >25,600 |

| C/1.0 | 12.5 |

| Clindamycin | 0.125 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Słota, D.; Piętak, K.; Florkiewicz, W.; Jampilek, J.; Tomala, A.; Urbaniak, M.M.; Tomaszewska, A.; Rudnicka, K.; Sobczak-Kupiec, A. Clindamycin-Loaded Nanosized Calcium Phosphates Powders as a Carrier of Active Substances. Nanomaterials 2023, 13, 1469. https://doi.org/10.3390/nano13091469

Słota D, Piętak K, Florkiewicz W, Jampilek J, Tomala A, Urbaniak MM, Tomaszewska A, Rudnicka K, Sobczak-Kupiec A. Clindamycin-Loaded Nanosized Calcium Phosphates Powders as a Carrier of Active Substances. Nanomaterials. 2023; 13(9):1469. https://doi.org/10.3390/nano13091469

Chicago/Turabian StyleSłota, Dagmara, Karina Piętak, Wioletta Florkiewicz, Josef Jampilek, Agnieszka Tomala, Mateusz M. Urbaniak, Agata Tomaszewska, Karolina Rudnicka, and Agnieszka Sobczak-Kupiec. 2023. "Clindamycin-Loaded Nanosized Calcium Phosphates Powders as a Carrier of Active Substances" Nanomaterials 13, no. 9: 1469. https://doi.org/10.3390/nano13091469

APA StyleSłota, D., Piętak, K., Florkiewicz, W., Jampilek, J., Tomala, A., Urbaniak, M. M., Tomaszewska, A., Rudnicka, K., & Sobczak-Kupiec, A. (2023). Clindamycin-Loaded Nanosized Calcium Phosphates Powders as a Carrier of Active Substances. Nanomaterials, 13(9), 1469. https://doi.org/10.3390/nano13091469