Highly Sensitive and Stretchable c-MWCNTs/PPy Embedded Multidirectional Strain Sensor Based on Double Elastic Fabric for Human Motion Detection

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

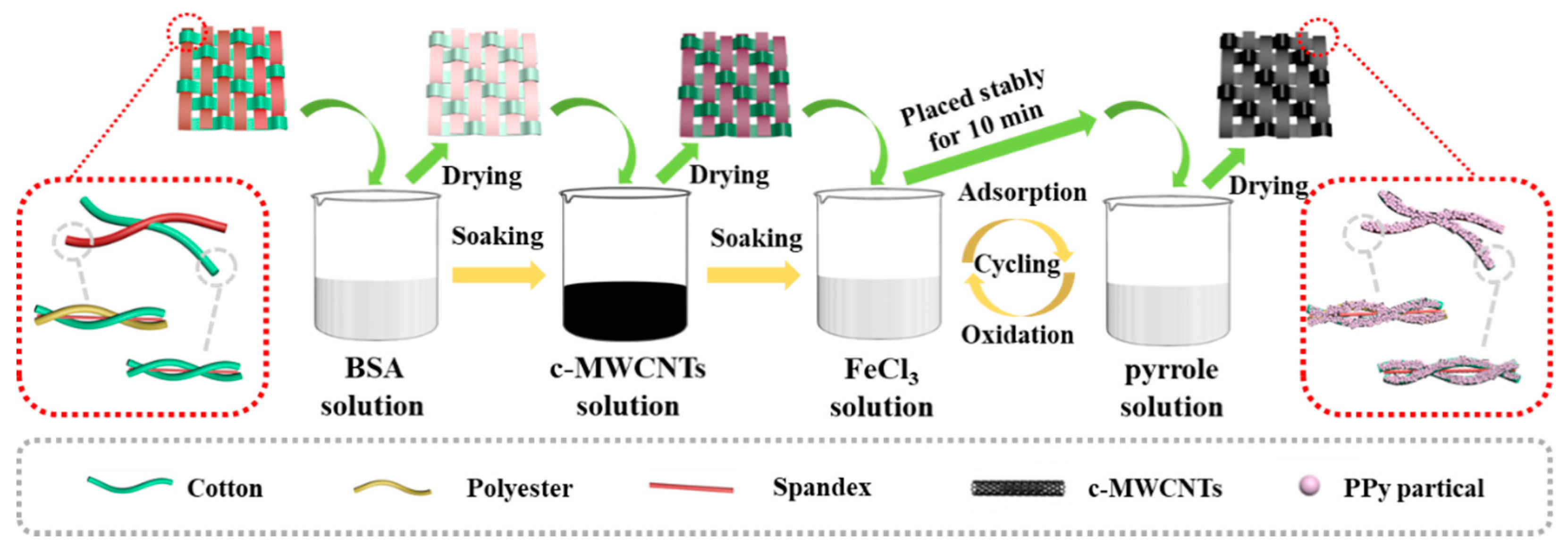

2.2. Preparation of DEF/c-MWCNTs/PPy Strain Sensors

2.3. Characterization

3. Results and Discussion

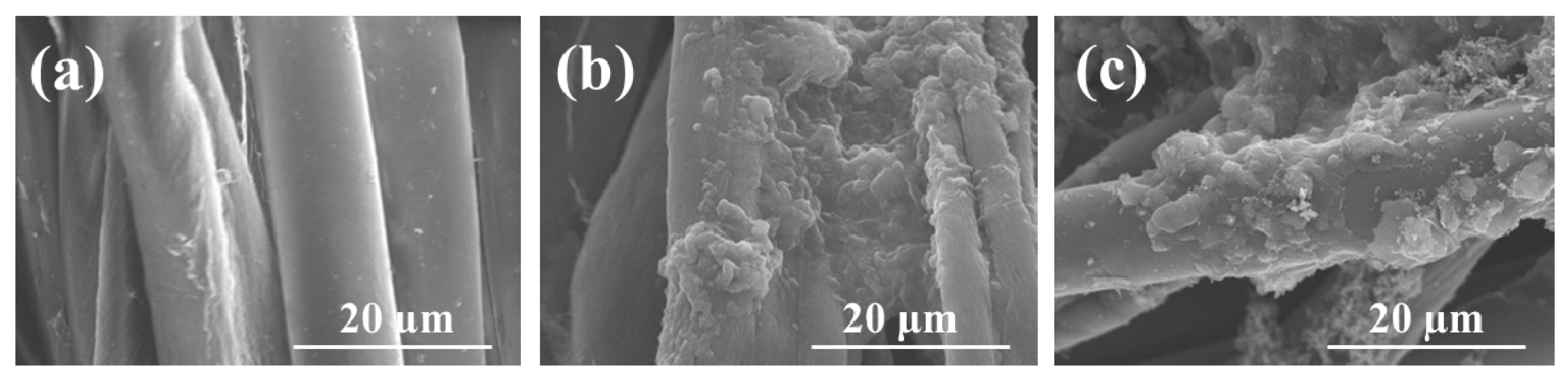

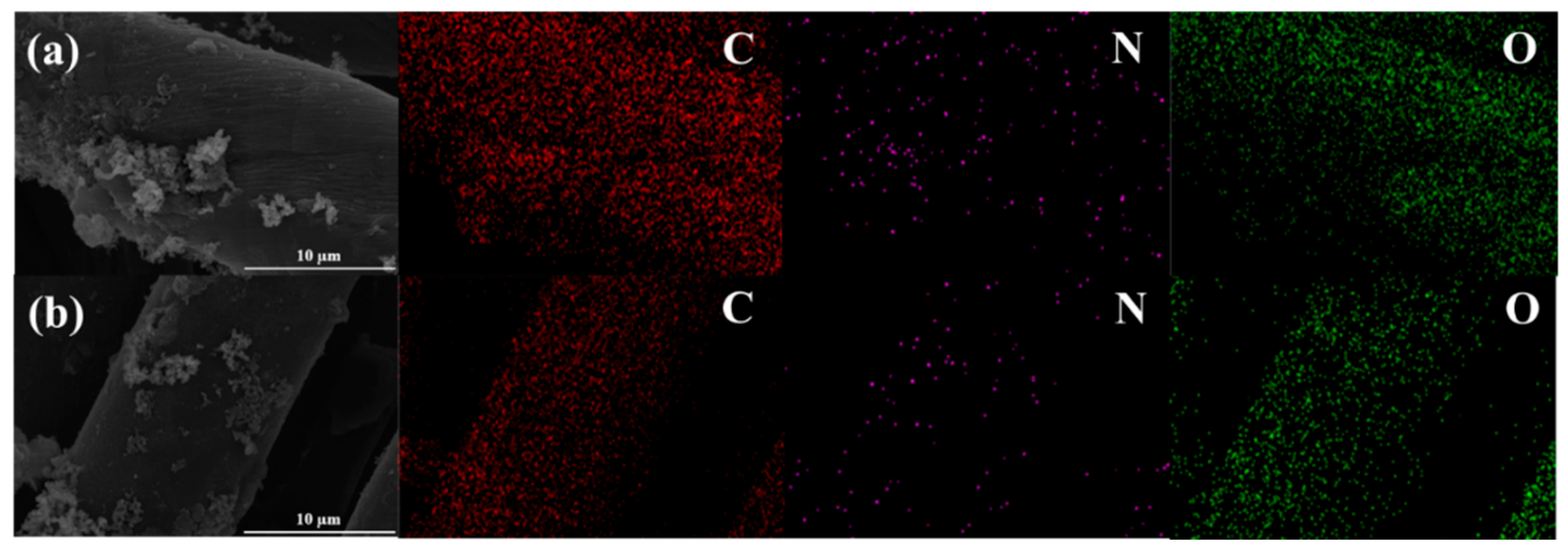

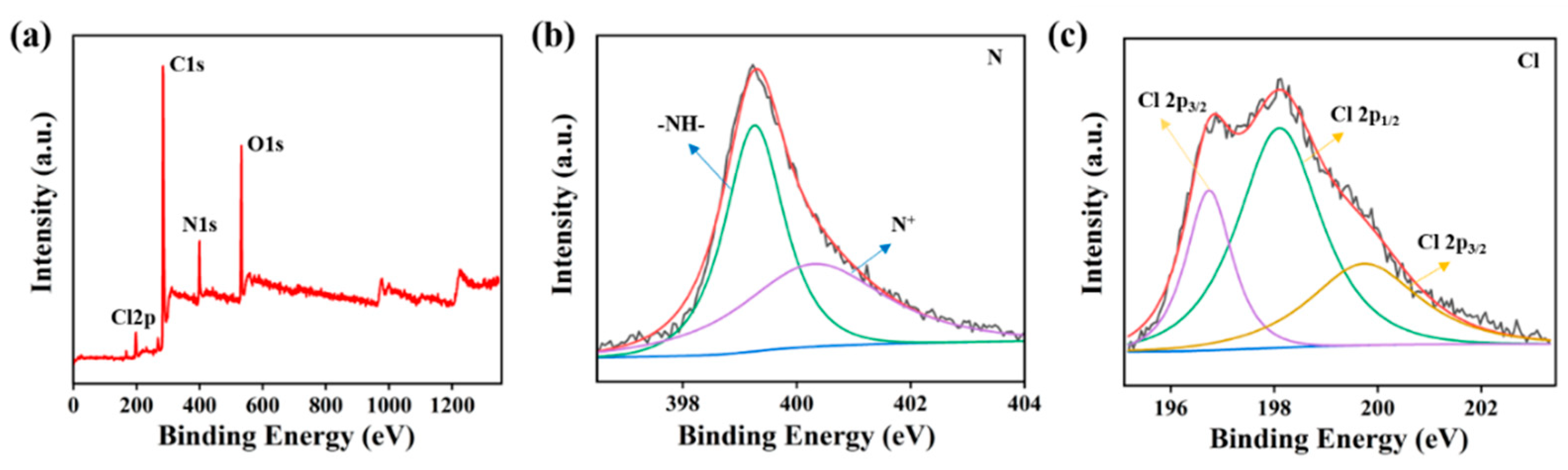

3.1. Fabrication and Characterization of DEF/c-MWCNTs/PPy Strain Sensor

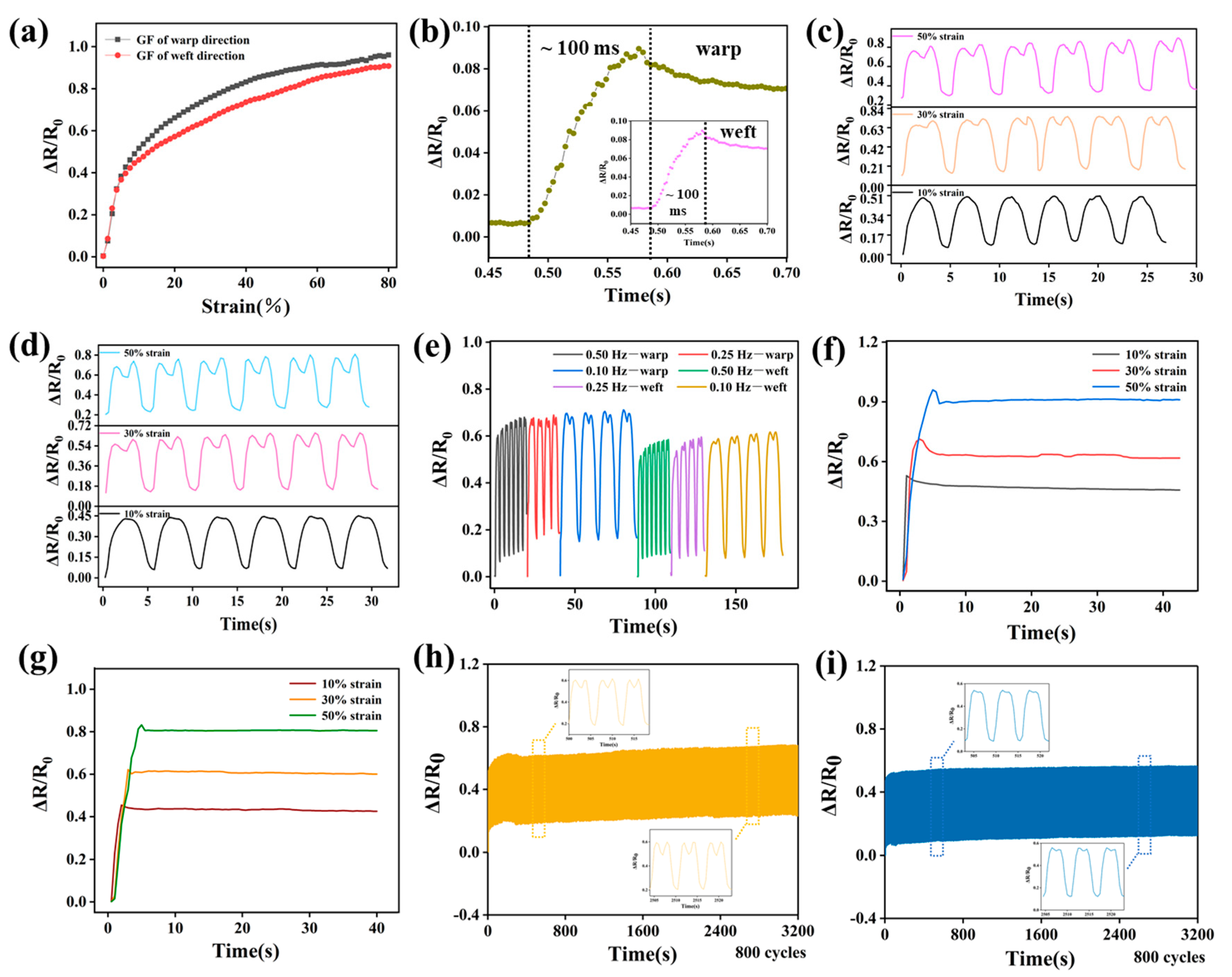

3.2. Electromechanical Performances of DEF/c-MWCNTs/PPy Strain Sensor

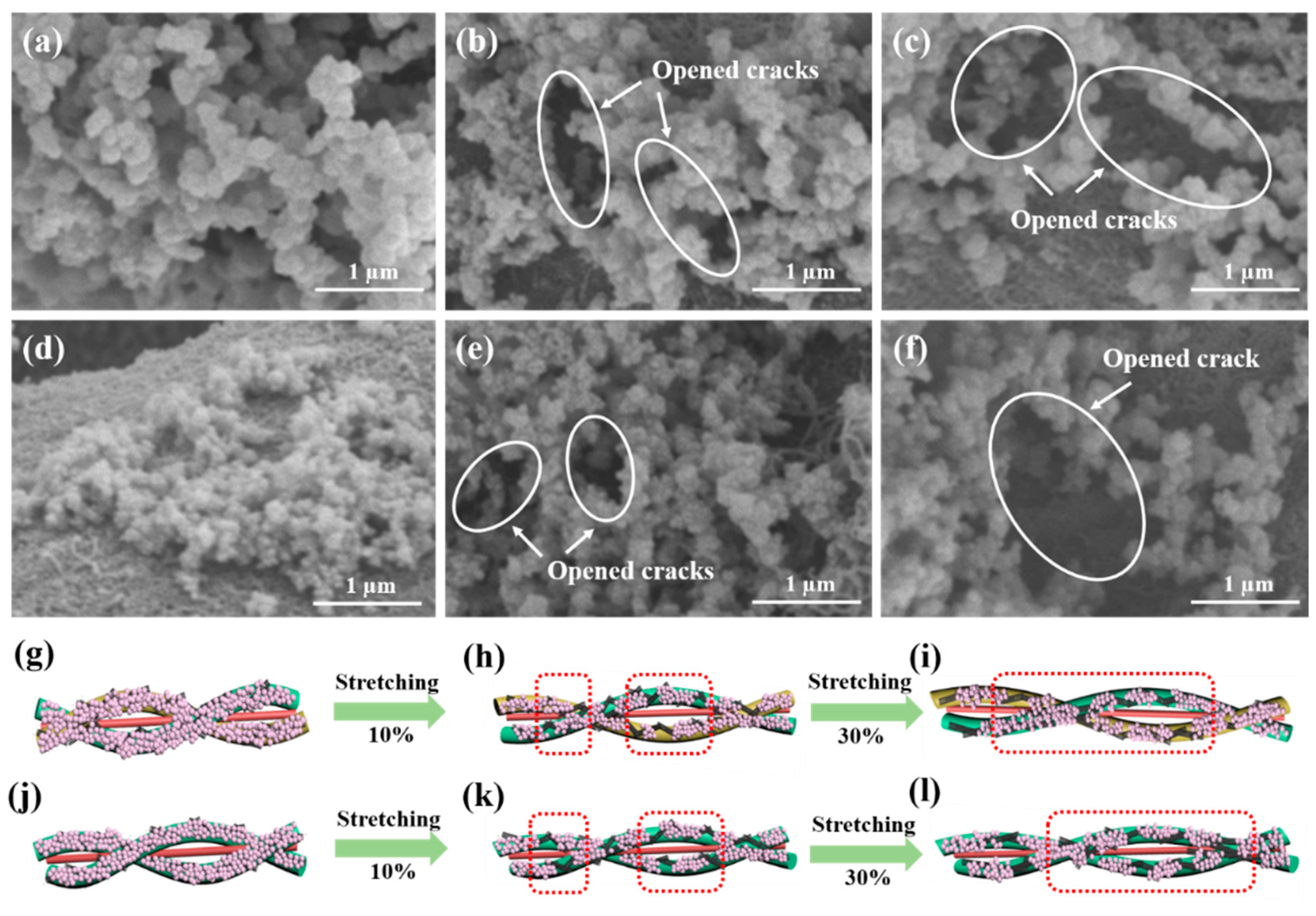

3.3. Sensing Mechanisms of DEF/c-MWCNTs/PPy Strain Sensor

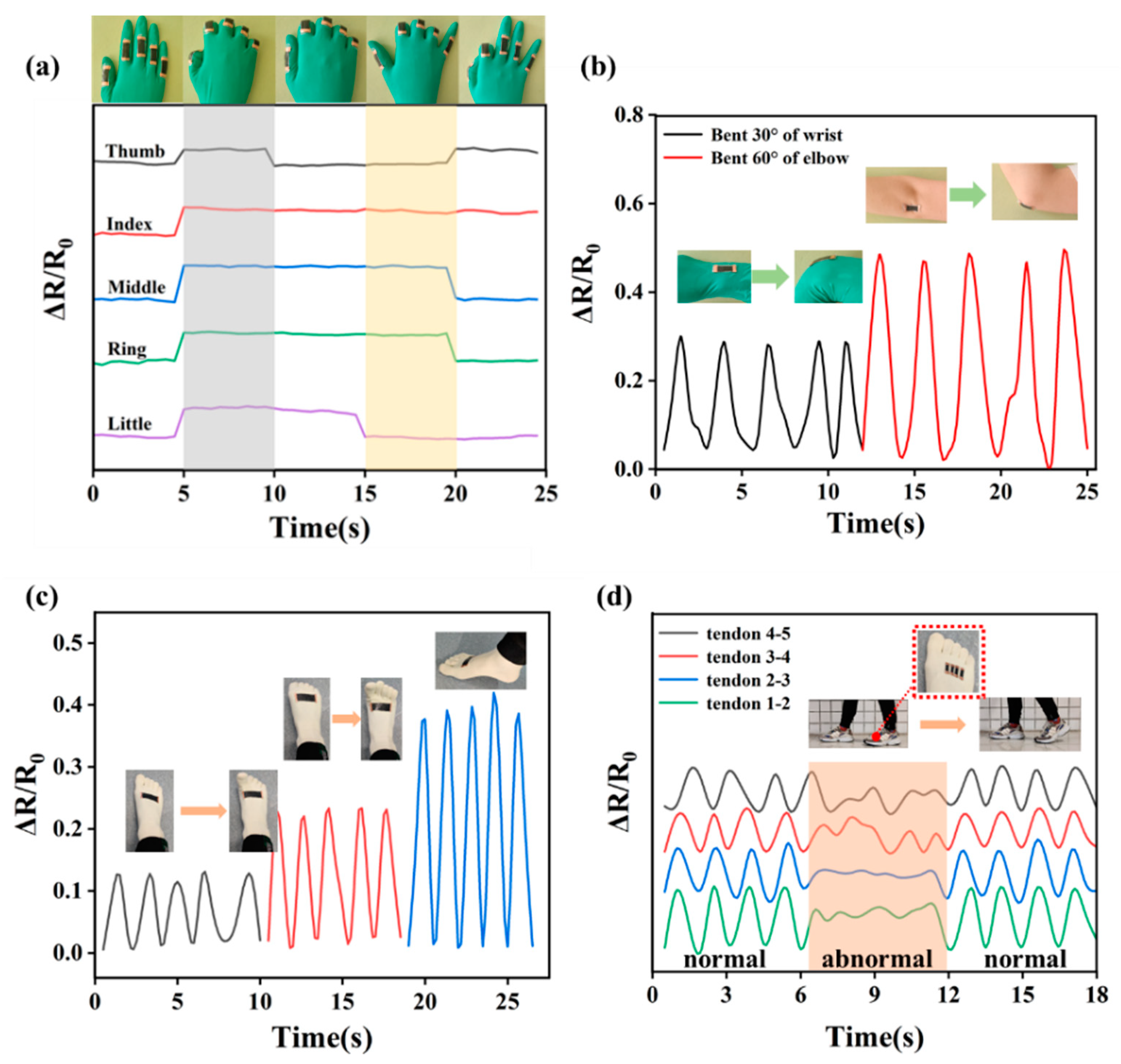

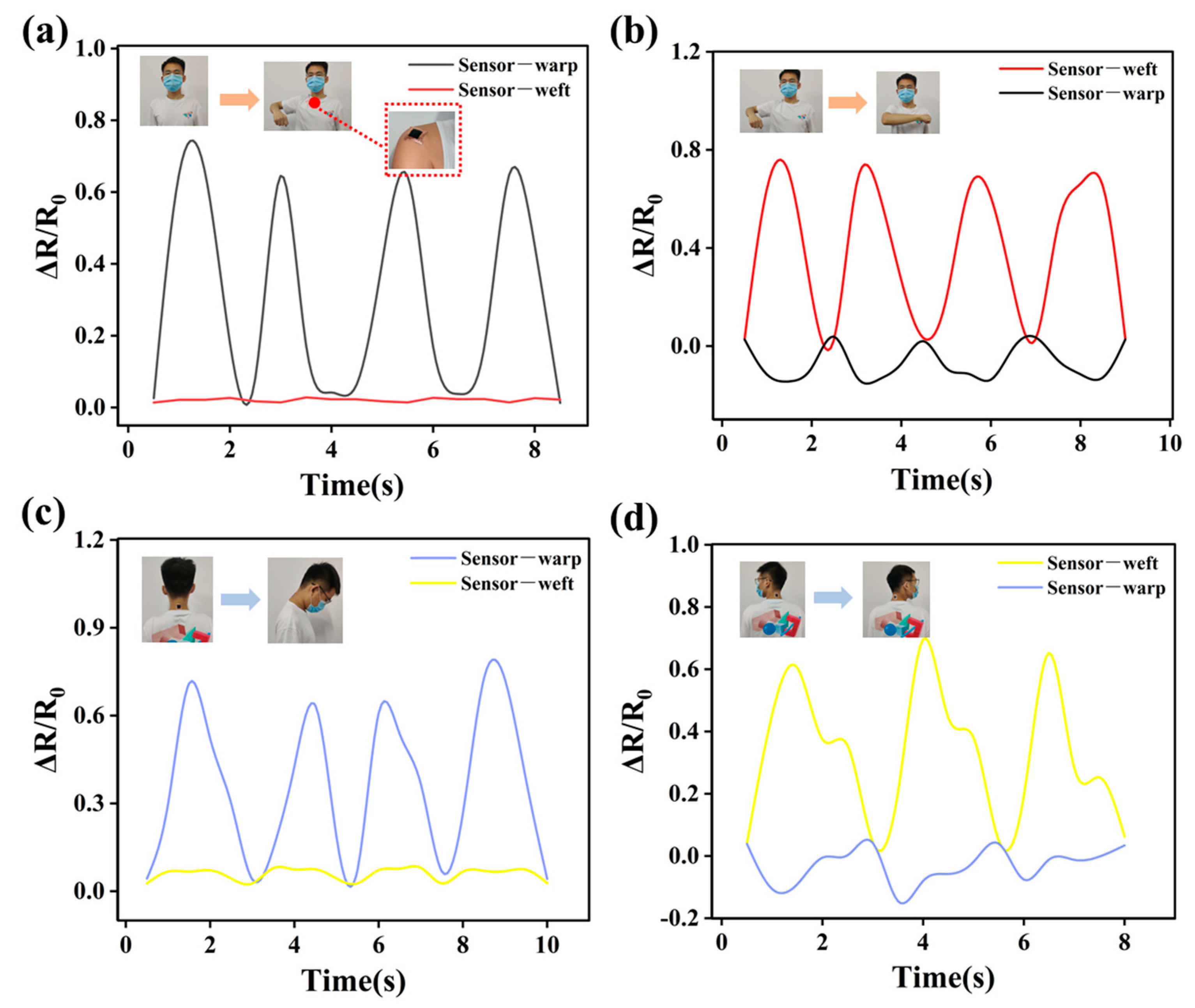

3.4. Applications of DEF/c-MWCNTs/PPy Strain Sensor for Human Motion Monitoring

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Majidi, C. Soft robotics: A perspective-current trends and prospects for the future. Soft Robot. 2014, 1, 5–11. [Google Scholar] [CrossRef]

- Jeong, S.Y.; Lee, J.U.; Hong, S.M.; Lee, C.W.; Hwang, S.H.; Cho, S.C.; Shin, B.S. Highly skin-conformal laser-induced graphene-based human motion monitoring sensor. Nanomaterials 2021, 11, 951. [Google Scholar] [CrossRef]

- Lee, S.W.; Park, J.J.; Park, B.H.; Mun, S.C.; Park, Y.T.; Liao, K.; Seo, T.S.; Hyun, W.J.; Park, O.O. Enhanced Sensitivity of Patterned Graphene Strain Sensors Used for Monitoring Subtle Human Body Motions. ACS Appl. Mater. Interfaces 2017, 9, 11176–11183. [Google Scholar] [CrossRef]

- Park, J.J.; Hyun, W.J.; Mun, S.C.; Park, Y.T.; Park, O.O. Highly stretchable and wearable graphene strain sensors with controllable sensitivity for human motion monitoring. ACS Appl. Mater. Interfaces 2015, 7, 6317–6324. [Google Scholar] [CrossRef] [PubMed]

- Ha, M.; Lim, S.; Ko, H. Wearable and flexible sensors for user-interactive health-monitoring devices. J. Mater. Chem. B 2018, 6, 4043–4064. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Ma, Z.; Sun, J.; Yan, Y.; Bu, M.; Huo, Y.; Li, Y.; Hu, N. Recent advances in natural functional biopolymers and their applications of electronic skins and flexible strain sensors. Polymers 2021, 13, 813. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Guo, W.; Qi, J.; Zhang, Y. Flexible piezoresistive strain sensor based on single Sb-doped ZnO nanobelts. Appl. Phys. Lett. 2010, 97, 223107. [Google Scholar] [CrossRef]

- Xiao, X.; Yuan, L.; Zhong, J.; Ding, T.; Liu, Y.; Cai, Z.; Rong, Y.; Han, H.; Zhou, J.; Wang, Z. High-strain sensors based on ZnO nanowire/polystyrene hybridized flexible films. Adv. Mater. 2011, 23, 5440–5444. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Chen, C.; Zhang, Y.; Chen, K.; Yang, Y.; Hu, Y.; He, J.; Wang, Z. Ultrahigh sensitive piezotronic strain sensors based on a ZnSnO3 nanowire/microwire. ACS Nano 2012, 6, 4369–4374. [Google Scholar] [CrossRef]

- Zhao, M.; Li, D.; Huang, J.; Wang, D.; Mensah, A.R.; Wei, Q. A multifunctional and highly stretchable electronic device based on silver nanowire/wrap yarn composite for a wearable strain sensor and heater. J. Mater. Chem. C 2019, 7, 13468–13476. [Google Scholar] [CrossRef]

- Huang, J.; Li, D.; Zhao, M.; Mensah, A.R.; Lv, P.; Tian, X.; Huang, F.; Ke, H.; Wei, Q. Highly sensitive and stretchable CNT-bridged AgNP strain sensor based on TPU electrospun membrane for human motion detection. Adv. Electron. Mater. 2019, 5, 1900241. [Google Scholar] [CrossRef]

- Liu, X.; Guo, R.; Li, R.; Liu, H.; Fan, Z.; Yang, Y.; Lin, Z. Effect of the processing on the resistance-strain response of multiwalled carbon nanotube/natural rubber composites for use in large deformation sensors. Nanomaterials 2021, 11, 1845. [Google Scholar] [CrossRef]

- Khalid, H.R.; Choudhry, I.; Jang, D.; Abbas, N.; Haider, M.S.; Lee, H.K. Facile synthesis of sprayed CNTs layer-embedded stretchable sensors with controllable sensitivity. Polymers 2021, 13, 311. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Yang, T.; Li, X.; Zang, X.; Zhu, M.; Wang, K.; Wu, D.; Zhu, H. Wearable and highly sensitive graphene strain sensors for human motion monitoring. Adv. Funct. Mater. 2014, 24, 4666–4670. [Google Scholar] [CrossRef]

- Fu, Y.; Li, Y.; Liu, Y.; Huang, P.; Hu, N.; Fu, S. High-performance structural flexible strain sensors based on graphene-coated glass fabric/silicone composite. ACS Appl. Mater. Interfaces 2018, 10, 35503–35509. [Google Scholar] [CrossRef]

- Suzuki, K.; Nakagawa, R.; Zhang, Q.; Miura, H. Development of highly sensitive strain sensor using area-arrayed graphene nanoribbons. Nanomaterials 2021, 11, 1701. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Cheng, X.; Leung, M.; Tsang, J.; Tao, X.; Yuen, C.W.M. A flexible strain sensor from polypyrrole-coated fabrics. Synth. Met. 2005, 155, 89–94. [Google Scholar] [CrossRef]

- Huang, Y.; Gao, L.; Zhao, Y.; Guo, X.; Liu, C.; Liu, P. Highly flexible fabric strain sensor based on graphene nanoplatelet-polyaniline nanocomposites for human gesture recognition. J. Appl. Polym. Sci. 2017, 134, 45340. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, C.; Wang, H.; Jian, M.; Hao, X.; Zhang, Y. Carbonized cotton fabric for high-performance wearable strain Sensors. Adv. Funct. Mater. 2017, 27, 1604795. [Google Scholar] [CrossRef]

- Liu, C.; Han, S.; Xu, H.; Wu, J.; Liu, C. Multifunctional highly sensitive multiscale stretchable strain sensor based on a graphene/glycerol-KCI synergistic conductive network. ACS Appl. Mater. Interfaces 2018, 10, 31716–31724. [Google Scholar] [CrossRef]

- Sang, S.; Liu, L.; Jian, A.; Duan, Q.; Ji, J.; Zhang, Q.; Zhang, W. Highly sensitive wearable strain sensor based on silver nanowires and nanoparticles. Nanotechnology 2018, 29, 255202. [Google Scholar]

- Lee, J.H.; Kim, J.; Liu, D.; Guo, F.; Shen, X.; Zheng, Q.; Jeon, S.; Kim, J.K. Highly aligned, anisotropic carbon nanofiber films for multidirectional strain sensors with exceptional selectivity. Adv. Funct. Mater. 2019, 29, 1901623. [Google Scholar] [CrossRef]

- Huang, S.; He, G.; Yang, C.; Wu, J.; Guo, C.; Hang, T.; Li, B.; Yang, C.; Liu, D.; Chen, H.; et al. Stretchable strain vector sensor based on parallelly aligned vertical graphene. ACS Appl. Mater. Interfaces 2019, 11, 1294–1302. [Google Scholar] [CrossRef]

- Zhang, F.; Ma, P.; Wang, J.; Zhang, Q.; Feng, W.; Zhu, Y.; Zheng, Q. Anisotropic conductive networks for multidimensional sensing. Mater. Horiz. 2021. Advance Article. [Google Scholar] [CrossRef]

- Chen, S.; Song, Y.; Ding, D.; Ling, Z.; Xu, F. Flexible and anisotropic strain sensor based on carbonized crepe paper with aligned cellulose fibers. Adv. Funct. Mater. 2018, 28, 1802547. [Google Scholar] [CrossRef]

- Ha, S.; Ha, S.; Jeon, M.B.; Cho, J.H.; Kim, J.M. Highly sensitive and selective multidimensional resistive strain sensors based on a stiffness-variant stretchable substrate. Nanoscale 2018, 10, 5105–5113. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.K.; Hong, S.; Cho, H.M.; Lee, J.; Suh, Y.D.; Ham, J.; Ko, S.H. Highly sensitive and stretchable multidimensional strain sensor with prestrained anisotropic metal nanowire percolation networks. Nano Lett. 2015, 15, 5240–5247. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Jing, Y.; Lee, J.H.; Liu, D.; Kim, J.; Chen, S.; Huang, K.; Shen, C.; Kim, J.K. Human skin-inspired integrated multidimensional sensors based on highly anisotropic structures. Mater. Horiz. 2020, 7, 2378–2389. [Google Scholar] [CrossRef]

- Mousavi, S.; Howard, D.; Zhang, F.; Leng, J.; Wang, C.H. Direct 3D printing of highly anisotropic, flexible, constriction resistive sensors for multidirectional proprioception in soft robots. ACS Appl. Mater. Interfaces 2020, 12, 15631–15643. [Google Scholar] [CrossRef]

- Cai, G.; Yang, M.; Xu, Z.; Liu, J.; Tang, B.; Wang, X. Flexible and wearable strain sensing fabrics. Chem. Eng. J. 2017, 325, 396–403. [Google Scholar] [CrossRef]

- Shao, F.; Bian, S.; Zhu, Q.; Guo, M.; Liu, S.; Peng, Y. Fabrication of polyaniline/graphene/polyester textile electrode materials for flexible supercapacitors with high capacitance and cycling stability. Chem. Asian. J. 2016, 11, 1906–1912. [Google Scholar] [CrossRef]

- Onggar, T.; Kruppke, I.; Cherif, C. Techniques and processes for the realization of electrically conducting textile materials from intrinsically conducting polymers and their application potential. Polymers 2020, 12, 2867. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, Y.; Zhou, Y.; Dai, K.; Zheng, G.; Zhang, B.; Liu, C.; Shen, C. High-performance wearable strain sensor based on graphene/cotton fabric with high durability and low detection limit. ACS Appl. Mater. Interfaces 2020, 12, 1474–1485. [Google Scholar] [CrossRef]

- Lee, T.; Lee, W.; Kim, S.W.; Kim, J.J.; Kim, B.S. Flexible textile strain wireless sensor functionalized with hybrid carbon nanomaterials supported zno nanowires with controlled aspect ratio. Adv. Funct. Mater. 2016, 26, 6206–6214. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, C.; Wang, Q.; Jian, M.; Zhang, Y. Sheath-core graphite/silk fiber made by dry-meyer-rod-coating for wearable strain sensors. ACS Appl. Mater. Interfaces 2016, 8, 20894–20899. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Li, X.; Gao, E.; Jian, M.; Xia, K.; Wang, Q.; Xu, Z.; Ren, T.; Zhang, Y. Carbonized silk fabric for ultrastretchable, highly sensitive, and wearable strain sensors. Adv. Mater. 2016, 28, 6640–6648. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Pan, P.; Dai, Q.; Yang, X.; Yang, Z.; Wei, J.; Liu, J.; Yuan, Q. Sensitive and wearable carbon nanotubes/carbon black strain sensors with wide linear ranges for human motion monitoring. J. Mater. Sci.-Mater. Electron. 2018, 29, 5589–5596. [Google Scholar] [CrossRef]

- Eom, J.; Heo, J.S.; Kim, M.; Lee, J.H.; Park, S.K.; Kim, Y.H. Highly sensitive textile-based strain sensors using poly(3,4-ethylenedioxythiophene):polystyrene sulfonate/silver nanowire-coated nylon threads with poly-L-lysine surface modification. RSC Adv. 2017, 7, 53373–53378. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.; Li, D.; Zhao, M.; Lv, P.; Lucia, L.; Wei, Q. Highly stretchable and bio-based sensors for sensitive strain detection of angular displacements. Cellulose 2019, 26, 3401–3413. [Google Scholar] [CrossRef]

- Guo, R.; Wang, H.; Sun, X.; Yao, S.; Chang, H.; Wang, H.; Liu, J.; Zhang, Y. Semiliquid metal enabled highly conductive wearable electronics for smart fabrics. ACS Appl. Mater. Interfaces 2019, 11, 30019–30027. [Google Scholar] [CrossRef]

- Feng, J.; Wang, X.; Lv, Z.; Qu, J.; Lu, X.; Wei, Q.; Wang, Q. Multifunctional wearable strain sensor made with an elastic interwoven fabric for patients with motor dysfunction. Adv. Mater. Technol. 2020, 5, 2000560. [Google Scholar] [CrossRef]

- Liu, J.; Fu, S.; Yuan, B.; Li, Y.; Deng, Z. Toward a universal “adhesive nanosheet” for the assembly of multiple nanoparticles based on a protein-induced reduction/decoration of graphene oxide. J. Am. Chem. Soc. 2010, 132, 7279–7281. [Google Scholar] [CrossRef] [PubMed]

- Mir, M.A.; Dar, A.A.; Amin, A.; Rather, G.M. Interaction of hydroxypropylcellulose with hexadecylbenzyldimethylammonium chloride in the absence and presence of hydrophobic salts. J. Mol. Liq. 2009, 150, 86–91. [Google Scholar] [CrossRef]

- Tan, K.; Tan, B.; Kang, E.; Neoh, K.G.; Ong, Y.K. X-ray photoelectron spectroscopic studies of conductive polypyrrole complexes chemically synthesized with FeCl3. Phys. Rev. B 1990, 42, 7563–7566. [Google Scholar] [CrossRef] [PubMed]

- Lim, V.W.L.; Kang, E.T.; Neoh, K.G.; Huang, W. In situ X-ray photoelectron spectroscopy study of evaporated magnesium on chemically synthesized polypyrrole films. J. Vac. Sci. Technol. A 2001, 19, 2680–2688. [Google Scholar] [CrossRef]

- Amjadi, M.; Kyung, K.U.; Park, I.; Sitti, M. Stretchable, skin-mountable, and wearable strain sensors and their potential applications: A review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, H.; Ke, H.; Feng, J.; Jiang, C.; Wei, Q.; Wang, Q. Highly Sensitive and Stretchable c-MWCNTs/PPy Embedded Multidirectional Strain Sensor Based on Double Elastic Fabric for Human Motion Detection. Nanomaterials 2021, 11, 2333. https://doi.org/10.3390/nano11092333

Shen H, Ke H, Feng J, Jiang C, Wei Q, Wang Q. Highly Sensitive and Stretchable c-MWCNTs/PPy Embedded Multidirectional Strain Sensor Based on Double Elastic Fabric for Human Motion Detection. Nanomaterials. 2021; 11(9):2333. https://doi.org/10.3390/nano11092333

Chicago/Turabian StyleShen, Huiying, Huizhen Ke, Jingdong Feng, Chenyu Jiang, Qufu Wei, and Qingqing Wang. 2021. "Highly Sensitive and Stretchable c-MWCNTs/PPy Embedded Multidirectional Strain Sensor Based on Double Elastic Fabric for Human Motion Detection" Nanomaterials 11, no. 9: 2333. https://doi.org/10.3390/nano11092333

APA StyleShen, H., Ke, H., Feng, J., Jiang, C., Wei, Q., & Wang, Q. (2021). Highly Sensitive and Stretchable c-MWCNTs/PPy Embedded Multidirectional Strain Sensor Based on Double Elastic Fabric for Human Motion Detection. Nanomaterials, 11(9), 2333. https://doi.org/10.3390/nano11092333